Interpretable Prediction and Analysis of PVA Hydrogel Mechanical Behavior Using Machine Learning

Abstract

1. Introduction

2. Results and Discussion

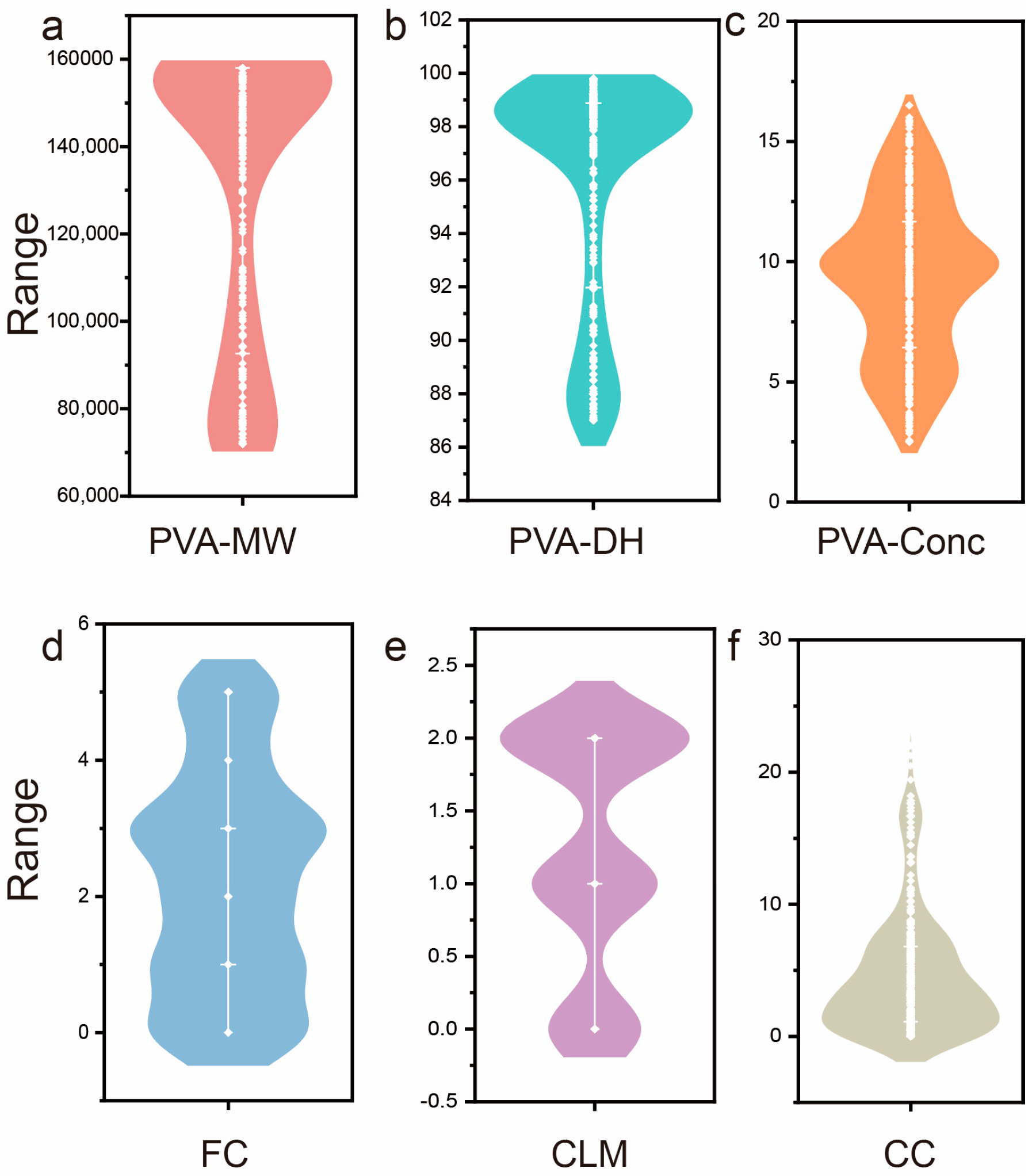

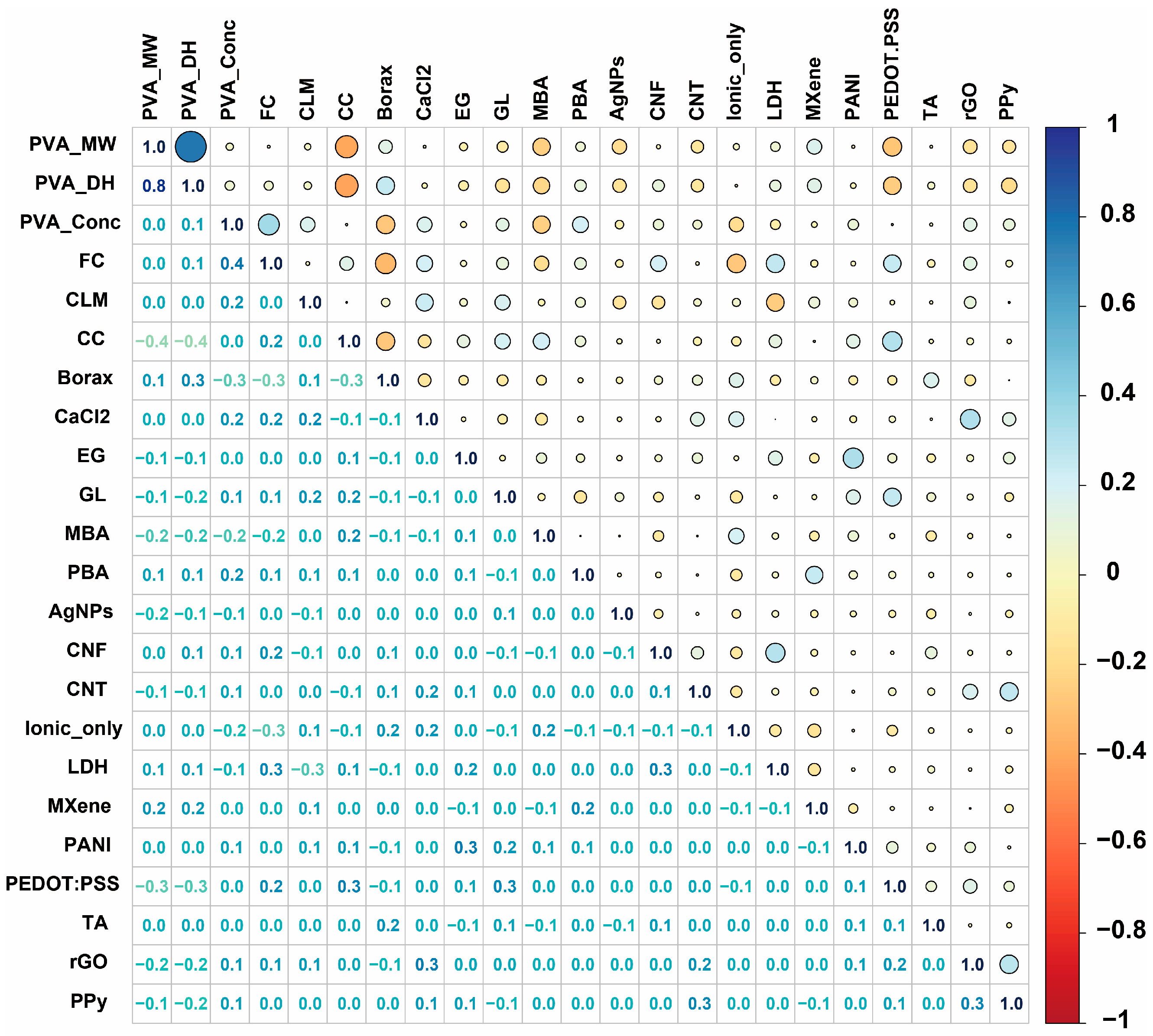

2.1. Analysis of Input Features Prior to Model Development

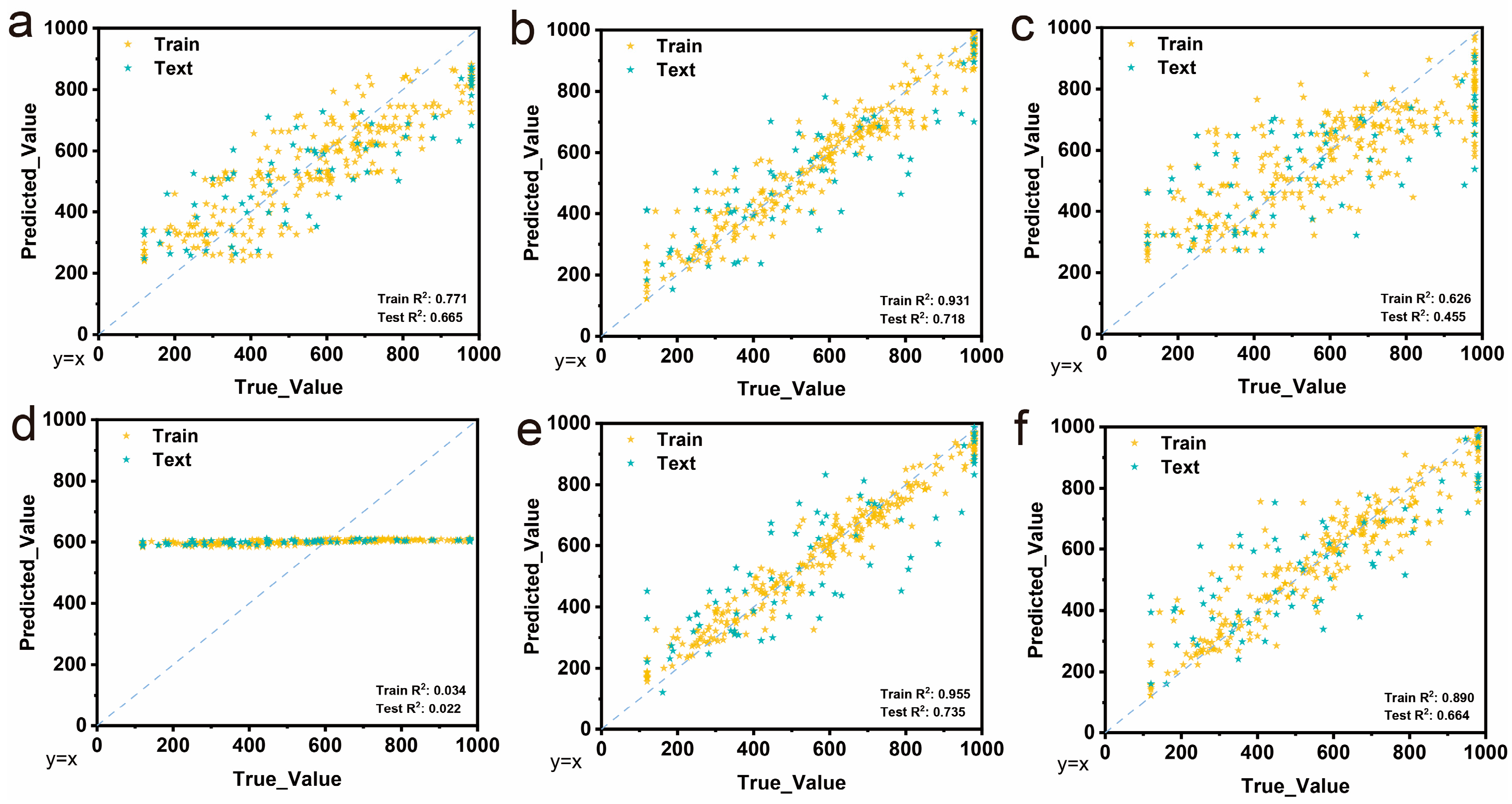

2.2. Model Development

2.3. Optimized XGBoost Model Performance and Feature Importance Analysis

2.4. Feature Importance and Interpretability Analysis

3. Conclusions

4. Materials and Methods

4.1. Data Collection and Preprocessing

4.2. Model Development and Evaluation Methodology

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yin, S.; Yao, D.R.; Song, Y.; Heng, W.; Ma, X.; Han, H.; Gao, W. Wearable and Implantable Soft Robots. Chem. Rev. 2024, 124, 11585–11636. [Google Scholar] [CrossRef]

- Li, H.; Tan, P.; Rao, Y.; Bhattacharya, S.; Wang, Z.; Kim, S.; Gangopadhyay, S.; Shi, H.; Jankovic, M.; Huh, H.; et al. E-Tattoos: Toward Functional but Imperceptible Interfacing with Human Skin. Chem. Rev. 2024, 124, 3220–3283. [Google Scholar] [CrossRef]

- Pan, X.; Pan, J.; Li, X.; Wang, Z.; Ni, Y.; Wang, Q. Tough Supramolecular Hydrogels Crafted via Lignin-Induced Self-Assembly. Adv. Mater. 2024, 36, 2406671. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Yin, F.; He, W.; Hang, T.; Li, Z.; Zheng, J.; Li, X.; Jiang, S.; Chen, Y. Anti-Freezing, Recoverable and Transparent Conductive Hydrogels Co-Reinforced by Ethylene Glycol as Flexible Sensors for Human Motion Monitoring. Int. J. Biol. Macromol. 2023, 230, 123117. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, L.; Lu, A. Highly Stretchable, Transparent Cellulose/PVA Composite Hydrogel for Multiple Sensing and Triboelectric Nanogenerators. J. Mater. Chem. A 2020, 8, 13935–13941. [Google Scholar] [CrossRef]

- Wang, H.; Lu, J.; Huang, H.; Fang, S.; Zubair, M.; Peng, Z. A Highly Elastic, Room-Temperature Repairable and Recyclable Conductive Hydrogel for Stretchable Electronics. J. Colloid Interface Sci. 2021, 588, 295–304. [Google Scholar] [CrossRef]

- Zheng, B.; Zhou, H.; Wang, Z.; Gao, Y.; Zhao, G.; Zhang, H.; Jin, X.; Liu, H.; Qin, Z.; Chen, W.; et al. Fishing Net-Inspired Mutiscale Ionic Organohydrogels with Outstanding Mechanical Robustness for Flexible Electronic Devices. Adv. Funct. Mater. 2023, 33, 2213501. [Google Scholar] [CrossRef]

- Yu, W.; Chen, J.; Gao, Q.; Guo, Y.; Zhang, S.; Pan, Y.; Nie, B.; Zhang, X.; Jiang, L.; Qiu, J.; et al. Multifunctional PVA/SA-Based Hydrogels Integrating High Stretchability, Conductivity, and Antibacterial Activity for Human-Machine Interactive Flexible Sensors. Chem. Eng. J. 2025, 519, 164695. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Z.; Alomar, T.S.; AlMasoud, N.; Liu, X.; Han, X.; Guo, N.; Weng, L.; Gao, J.; Algadi, H.; et al. Poly (Vinyl Alcohol)/Carboxylated Cellulose Nanofibers Composite Hydrogel Flexible Strain Sensors. Int. J. Biol. Macromol. 2025, 309, 142902. [Google Scholar] [CrossRef]

- Hasan, M.Z.; Xu, C.; Motaleb, K.Z.M.A.; Ahmed, M.F.; Zhuang, J.; Tan, S.; Janutėnienė, J.; Bashar, M.M.; Tu, H.; Luo, L.; et al. Extraction and Incorporation of Cellulose Microfibers from Textile Wastes into MXene-Enhanced PVA-Borax Hydrogel for Multifunctional Wearable Sensors. Int. J. Biol. Macromol. 2025, 295, 139640. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Hao, Y.; Zhao, Y.; Ding, P.; Zhai, W.; Dai, K.; Zheng, G.; Liu, C.; Shen, C. Multifunctional PVA/PNIPAM Conductive Hydrogel Sensors Enabled Human-Machine Interaction Intelligent Rehabilitation Training. Adv. Compos. Hybrid Mater. 2024, 7, 245. [Google Scholar] [CrossRef]

- Qing, X.; Liu, Z.; Vananroye, A.; Franceschini, F.; Bouropoulos, N.; Katsaounis, A.; Taurino, I.; Fardim, P. Self-Healing and Transparent Ionic Conductive PVA/Pullulan/Borax Hydrogels with Multi-Sensing Capabilities for Wearable Sensors. Int. J. Biol. Macromol. 2025, 284, 137841. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Yang, J.; Jiang, Q.; Zheng, R.; Qiu, L.; Chen, J.; You, R.; Yan, Z.; Lu, Y. AuNPs/C-CNF/PVA Hydrogel SERS Sensor for Comprehensive Detection of Antitumor Drug Separation and Enrichment. Chem. Eng. J. 2025, 516, 164282. [Google Scholar] [CrossRef]

- Huang, H.; Han, L.; Li, J.; Fu, X.; Wang, Y.; Yang, Z.; Xu, X.; Pan, L.; Xu, M. Super-Stretchable, Elastic and Recoverable Ionic Conductive Hydrogel for Wireless Wearable, Stretchable Sensor. J. Mater. Chem. A 2020, 8, 10291–10300. [Google Scholar] [CrossRef]

- Chen, S.; Dong, Y.; Ma, S.; Ren, J.; Yang, X.; Wang, Y.; Lü, S. Superstretching MXene Composite Hydrogel as a Bidirectional Stress Response Thixotropic Sensor. ACS Appl. Mater. Interfaces 2021, 13, 13629–13636. [Google Scholar] [CrossRef]

- Zhao, L.; Luo, B.; Gao, S.; Liu, Y.; Lai, C.; Zhang, D.; Guan, W.; Wang, C.; Chu, F. Stretchable, Self-Adhesive, and Conductive Hemicellulose-Based Hydrogels as Wearable Strain Sensors. Int. J. Biol. Macromol. 2024, 282, 137313. [Google Scholar] [CrossRef]

- Zhu, C.; Bamidele, E.A.; Shen, X.; Zhu, G.; Li, B. Machine Learning Aided Design and Optimization of Thermal Metamaterials. Chem. Rev. 2024, 124, 4258–4331. [Google Scholar] [CrossRef]

- Zheng, J.-J.; Li, Q.-Z.; Wang, Z.; Wang, X.; Zhao, Y.; Gao, X. Computer-Aided Nanodrug Discovery: Recent Progress and Future Prospects. Chem. Soc. Rev. 2024, 53, 9059–9132. [Google Scholar] [CrossRef]

- Xu, B.; Yang, G. Interpretability Research of Deep Learning: A Literature Survey. Inf. Fusion 2025, 115, 102721. [Google Scholar] [CrossRef]

- Yan, B.; Shi, Y.; Liu, S.; Wang, W.; Ba, Z.; Li, H.; Wang, J.; Xiao, Z.; Peng, T.; Liang, D.; et al. Development and Optimization of Lithium-Ion Sieves through Machine Learning in Complex Brine Systems. Sep. Purif. Technol. 2025, 374, 133726. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, Y.; Li, J.; Wang, B.; Li, R.; Cheng, D.; Chang, G. Self-Healing PVA/Chitosan/MXene Triple Network Hydrogel for Strain and Temperature Sensors. Int. J. Biol. Macromol. 2025, 290, 138811. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Ren, P.; Yu, S.; Cui, P.; Nielsen, C.B.; Abrahams, I.; Briscoe, J.; Lu, Y. Versatile and Recyclable Double-Network PVA/Cellulose Hydrogels for Strain Sensors and Triboelectric Nanogenerators under Harsh Conditions. Nano Energy 2024, 125, 109599. [Google Scholar] [CrossRef]

- Chen, S.; Guo, B.; Yu, J.; Yan, Z.; Liu, R.; Yu, C.; Zhao, Z.; Zhang, H.; Yao, F.; Li, J. A Polypyrrole-Dopamine/Poly(Vinyl Alcohol) Anisotropic Hydrogel for Strain Sensor and Bioelectrodes. Chem. Eng. J. 2024, 486, 150182. [Google Scholar] [CrossRef]

- Hsiao, Y.-C.; Lee, L.-C.; Lin, Y.-T.; Hong, S.-H.; Wang, K.-C.; Tung, S.-H.; Liu, C.-L. Stretchable Polyvinyl Alcohol and Sodium Alginate Double Network Ionic Hydrogels for Low-Grade Heat Harvesting with Ultrahigh Thermopower. Mater. Today Energy 2023, 37, 101383. [Google Scholar] [CrossRef]

- Li, M.; Wang, Y.; Wei, Q.; Zhang, J.; An, Y.; Chen, X.; Liu, Z.; Jiao, D. A Triple-Network PVA/Cellulose Nanofiber Composite Hydrogel with Excellent Strength, Transparency, Conductivity, and Antibacterial Properties. J. Mater. Sci. Technol. 2025, 237, 312–322. [Google Scholar] [CrossRef]

- Peng, X.; Wang, W.; Yang, W.; Chen, J.; Peng, Q.; Wang, T.; Yang, D.; Wang, J.; Zhang, H.; Zeng, H. Stretchable, Compressible, and Conductive Hydrogel for Sensitive Wearable Soft Sensors. J. Colloid Interface Sci. 2022, 618, 111–120. [Google Scholar] [CrossRef]

- Tavakoli, J.; Mirzaei, S.; Tang, Y. Cost-Effective Double-Layer Hydrogel Composites for Wound Dressing Applications. Polymers 2018, 10, 305. [Google Scholar] [CrossRef]

- Pan, X.; Wang, Q.; He, P.; Liu, K.; Ni, Y.; Chen, L.; Ouyang, X.; Huang, L.; Wang, H.; Xu, S. A Bionic Tactile Plastic Hydrogel-Based Electronic Skin Constructed by a Nerve-like Nanonetwork Combining Stretchable, Compliant, and Self-Healing Properties. Chem. Eng. J. 2020, 379, 122271. [Google Scholar] [CrossRef]

- Li, P.; Wang, H.; Ju, Z.; Jin, Z.; Ma, J.; Yang, L.; Zhao, X.; Xu, H.; Liu, Y. Ti3C2Tx MXene- and Sulfuric Acid-Treated Double-Network Hydrogel with Ultralow Conductive Filler Content for Stretchable Electromagnetic Interference Shielding. ACS Nano 2024, 18, 2906–2916. [Google Scholar] [CrossRef]

- Pan, X.; Li, X.; Wang, R.; Wang, Z.; Ni, Y.; Wang, Q. Accelerated Hydrogel Strengthening: Synergy between Mechanical Training and Lignin Intake. Nano Lett. 2025, 25, 4526–4531. [Google Scholar] [CrossRef]

- Shi, W.; Wang, Z.; Song, H.; Chang, Y.; Hou, W.; Li, Y.; Han, G. High-Sensitivity and Extreme Environment-Resistant Sensors Based on PEDOT:PSS@PVA Hydrogel Fibers for Physiological Monitoring. ACS Appl. Mater. Interfaces 2022, 14, 35114–35125. [Google Scholar] [CrossRef]

- Wang, J.; Xu, P.; Ji, X.; Li, M.; Lu, W. Feature Selection in Machine Learning for Perovskite Materials Design and Discovery. Materials 2023, 16, 3134. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.; Advincula, R.C.; Wu, H.F.; Jiang, Y. Artificial Intelligence and Machine Learning in the Design and Additive Manufacturing of Responsive Composites. MRS Commun. 2023, 13, 714–724. [Google Scholar] [CrossRef]

- Dean, J.; Scheffler, M.; Purcell, T.A.R.; Barabash, S.V.; Bhowmik, R.; Bazhirov, T. Interpretable Machine Learning for Materials Design. J. Mater. Res. 2023, 38, 4477–4496. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, W.; Iyer, A.; Apley, D.W.; Chen, W. Uncertainty-Aware Mixed-Variable Machine Learning for Materials Design. Sci. Rep. 2022, 12, 19760. [Google Scholar] [CrossRef]

- Ling, N.; Wang, Y.; Song, S.; Liu, C.; Yang, F.; Qi, X.; Li, Y.; Zhang, J.; Wang, L. Experimentally Validated Screening Strategy for Alloys as Anode in Mg-Air Battery with Multi-Target Machine Learning Predictions. Chem. Eng. J. 2024, 496, 153824. [Google Scholar] [CrossRef]

- Lai, J.-P.; Lin, Y.-L.; Lin, H.-C.; Shih, C.-Y.; Wang, Y.-P.; Pai, P.-F. Tree-Based Machine Learning Models with Optuna in Predicting Impedance Values for Circuit Analysis. Micromachines 2023, 14, 265. [Google Scholar] [CrossRef]

- Hassanali, M.; Soltanaghaei, M.; Gandomani, T.J.; Boroujeni, F.Z. Software Development Effort Estimation Using Boosting Algorithms and Automatic Tuning of Hyperparameters with Optuna. J. Softw. Evol. Process 2024, 36, e2665. [Google Scholar] [CrossRef]

- Xu, C.; Guan, S.; Dong, X.; Huang, H.; Qi, M. Ultratough and Freezing-Tolerant PVA–PAA-PANI Hybrid Hydrogel for Supercapacitors and Flexible Sensors. ACS Sustain. Chem. Eng. 2023, 11, 14886–14894. [Google Scholar] [CrossRef]

- Yuan, H.; Han, S.; Wang, S.; Yang, P.; Li, S.; Mi, H.-Y.; Liu, C.; Shen, C. Plant-Derived Adhesive Hydrogel with High Stretchability and Conductivity for Wearable Electronics. Sens. Actuators B Chem. 2023, 379, 133195. [Google Scholar] [CrossRef]

- Miao, L.; Wang, X.; Li, S.; Tu, Y.; Hu, J.; Huang, Z.; Lin, S.; Gui, X. An Ultra-Stretchable Polyvinyl Alcohol Hydrogel Based on Tannic Acid Modified Aramid Nanofibers for Use as a Strain Sensor. Polymers 2022, 14, 3532. [Google Scholar] [CrossRef] [PubMed]

- Gu, Z.; Ma, R.; Chen, X.; Lin, Z.; Yang, Y.; Tan, B.; Sun, J.; Chen, T. Polyvinyl Alcohol Modified Plant Fiber Hydrogel Pressure and Strain Dual-Model Sensors for Biomedical Signal Detection. Adv. Compos. Hybrid Mater. 2025, 8, 214. [Google Scholar] [CrossRef]

- Li, K.; Yang, X.; Dong, X.; Cao, H.; Zhuang, S.; Gu, X. Easy Regulation of Chitosan-Based Hydrogel Microstructure with Citric Acid as an Efficient Buffer. Carbohydr. Polym. 2023, 300, 120258. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, F.; Gao, X.; Yang, M.; Huang, X.; Zhang, D.; Li, X.; Zhang, Y.; Shang, Y.; Cao, A. High-Strength, Antiswelling Directional Layered PVA/MXene Hydrogel for Wearable Devices and Underwater Sensing. Adv. Sci. 2024, 11, 2405880. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Gao, Y.; Liu, L.; Ren, X.; Gao, G. Skin-Contactable and Antifreezing Strain Sensors Based on Bilayer Hydrogels. Chem. Mater. 2020, 32, 8938–8946. [Google Scholar] [CrossRef]

- Jiang, C.; Ding, X.; Xie, W.; Wu, D. Ultrastretchable Composite Organohydrogels with Dual Cross-Links Enabling Multimodal Sensing. ACS Appl. Mater. Interfaces 2022, 14, 55143–55154. [Google Scholar] [CrossRef]

- Gu, J.; Huang, J.; Chen, G.; Hou, L.; Zhang, J.; Zhang, X.; Yang, X.; Guan, L.; Jiang, X.; Liu, H. Multifunctional Poly(Vinyl Alcohol) Nanocomposite Organohydrogel for Flexible Strain and Temperature Sensor. ACS Appl. Mater. Interfaces 2020, 12, 40815–40827. [Google Scholar] [CrossRef]

- Kumar, A.; Behl, T.; Chadha, S. Synthesis of Physically Crosslinked PVA/Chitosan Loaded Silver Nanoparticles Hydrogels with Tunable Mechanical Properties and Antibacterial Effects. Int. J. Biol. Macromol. 2020, 149, 1262–1274. [Google Scholar] [CrossRef]

- Li, Q.; Zhi, X.; Xia, Y.; Han, S.; Guo, W.; Li, M.; Wang, X. Ultrastretchable High-Conductivity MXene-Based Organohydrogels for Human Health Monitoring and Machine-Learning-Assisted Recognition. ACS Appl. Mater. Interfaces 2023, 15, 19435–19446. [Google Scholar] [CrossRef]

- Gupta, B.; Bano, S.; Singh, R. High-Performance Silver Nanoparticles Embedded Conductive PVA Hydrogel for Stretchable Wearable Triboelectric Nanogenerators. J. Power Sources 2025, 632, 236271. [Google Scholar] [CrossRef]

- Lei, T.; Pan, J.; Wang, N.; Xia, Z.; Zhang, Q.; Fan, J.; Tao, L.; Shou, W.; Gao, Y. Cold-Resistant, Highly Stretchable Ionic Conductive Hydrogels for Intelligent Motion Recognition in Winter Sports. Mater. Horiz. 2024, 11, 1234–1250. [Google Scholar] [CrossRef]

- Hu, L.; Wang, Y.; Liu, Q.; Liu, M.; Yang, F.; Wang, C.; Pan, P.; Wang, L.; Chen, L.; Chen, J. Real-Time Monitoring Flexible Hydrogels Based on Dual Physically Cross-Linked Network for Promoting Wound Healing. Chin. Chem. Lett. 2023, 34, 108262. [Google Scholar] [CrossRef]

- Luo, C.; Huang, M.; Sun, X.; Wei, N.; Shi, H.; Li, H.; Lin, M.; Sun, J. Super-Strong, Nonswellable, and Biocompatible Hydrogels Inspired by Human Tendons. ACS Appl. Mater. Interfaces 2022, 14, 2638–2649. [Google Scholar] [CrossRef] [PubMed]

- Macarie, L.; Pekar, M.; Simulescu, V.; Plesu, N.; Iliescu, S.; Ilia, G.; Tara-Lunga-Mihali, M. Properties in Aqueous Solution of Homo- and Copolymers of Vinylphosphonic Acid Derivatives Obtained by UV-curing. Macromol. Res. 2017, 25, 214–221. [Google Scholar] [CrossRef]

- Guo, Y.; Jiang, Y.; Zhang, Y.; Huang, L.; Tang, K. Highly Stretchable and Adhesive Hydrogel Dressing Possessing Rapid Hemostasis and Photothermal Antibacterial Properties for Joint Wound Healing. Chem. Eng. J. 2025, 519, 164834. [Google Scholar] [CrossRef]

- Han, Y.; Liu, Y.; Liu, Y.; Jiang, D.; Wu, Z.; Jiang, B.; Yan, H.; Toktarbay, Z. High-Performance PVA-Based Hydrogels for Ultra-Sensitive and Durable Flexible Sensors. Adv. Compos. Hybrid Mater. 2025, 8, 154. [Google Scholar] [CrossRef]

- Pu, L.; Yuan, Z.; Cai, Y.; Li, X.; Xue, Z.; Niu, Y.; Li, Y.; Ma, S.; Xu, W. Multiperformance PAM/PVA/CaCO3 Hydrogel for Flexible Sensing and Information Encryption. ACS Appl. Mater. Interfaces 2024, 16, 32762–32772. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, J.; Luo, J.; Meng, J.; Cheng, L.; Qin, H. A Robust and Conductive Hydrotalcite/Nanocellulose/PVA Hydrogel Constructed Based on the Hofmeister Effect. Int. J. Biol. Macromol. 2025, 298, 139994. [Google Scholar] [CrossRef]

- Wang, T.; Xu, B.; Yu, T.; Yu, Y.; Fu, J.; Wang, Y.; Gao, X.; Xue, Z.; Li, R.; Chang, G. PVA/Chitosan-Based Multifunctional Hydrogels Constructed through Multi-Bonding Synergies and Their Application in Flexible Sensors. Carbohydr. Polym. 2025, 350, 123034. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Z.; Jiang, D.; Guo, N.; Wang, Y.; Ding, T.; Weng, L. A Highly Stretchable, Sensing Durability, Transparent, and Environmentally Stable Ion Conducting Hydrogel Strain Sensor Built by Interpenetrating Ca2+-SA and Glycerol-PVA Double Physically Cross-Linked Networks. Adv. Compos. Hybrid Mater. 2022, 5, 1712–1729. [Google Scholar] [CrossRef]

- Prameswati, A.; Nurmaulia Entifar, S.A.; Han, J.W.; Wibowo, A.F.; Kim, J.H.; Sembiring, Y.S.B.; Park, J.; Lee, J.; Lee, A.-Y.; Song, M.H.; et al. Self-Healable Conductive Hydrogels with High Stretchability and Ultralow Hysteresis for Soft Electronics. ACS Appl. Mater. Interfaces 2023, 15, 24648–24657. [Google Scholar] [CrossRef]

- Angel-Sánchez, K.D.; Treviño-Pacheco, A.V.; Perales-Martínez, I.A.; Martínez-Romero, O.; Olvera-Trejo, D.; Elías-Zúñiga, A. Antibacterial Crosslinker for Ternary PCL-Reinforced Hydrogels Based on Chitosan, Polyvinyl Alcohol, and Gelatin for Tissue Engineering. Polymers 2025, 17, 1520. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Tan, C.; He, Y.; Luo, B.; Liu, M. Chitin Nanocrystals Stabilized Liquid Metal for Highly Stretchable and Anti-Freeze Hydrogels as Flexible Strain Sensor. Carbohydr. Polym. 2024, 328, 121728. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Liu, S.; Lin, A.; Su, Z.; Liang, D. Interpretable Prediction and Analysis of PVA Hydrogel Mechanical Behavior Using Machine Learning. Gels 2025, 11, 550. https://doi.org/10.3390/gels11070550

Xu L, Liu S, Lin A, Su Z, Liang D. Interpretable Prediction and Analysis of PVA Hydrogel Mechanical Behavior Using Machine Learning. Gels. 2025; 11(7):550. https://doi.org/10.3390/gels11070550

Chicago/Turabian StyleXu, Liying, Siqi Liu, Anqi Lin, Zichuan Su, and Daxin Liang. 2025. "Interpretable Prediction and Analysis of PVA Hydrogel Mechanical Behavior Using Machine Learning" Gels 11, no. 7: 550. https://doi.org/10.3390/gels11070550

APA StyleXu, L., Liu, S., Lin, A., Su, Z., & Liang, D. (2025). Interpretable Prediction and Analysis of PVA Hydrogel Mechanical Behavior Using Machine Learning. Gels, 11(7), 550. https://doi.org/10.3390/gels11070550