Physical Characteristics of Durum Wheat Dough and Pasta with Different Carrot Pomace Varieties

Abstract

1. Introduction

2. Results and Discussion

2.1. Dough Texture Properties

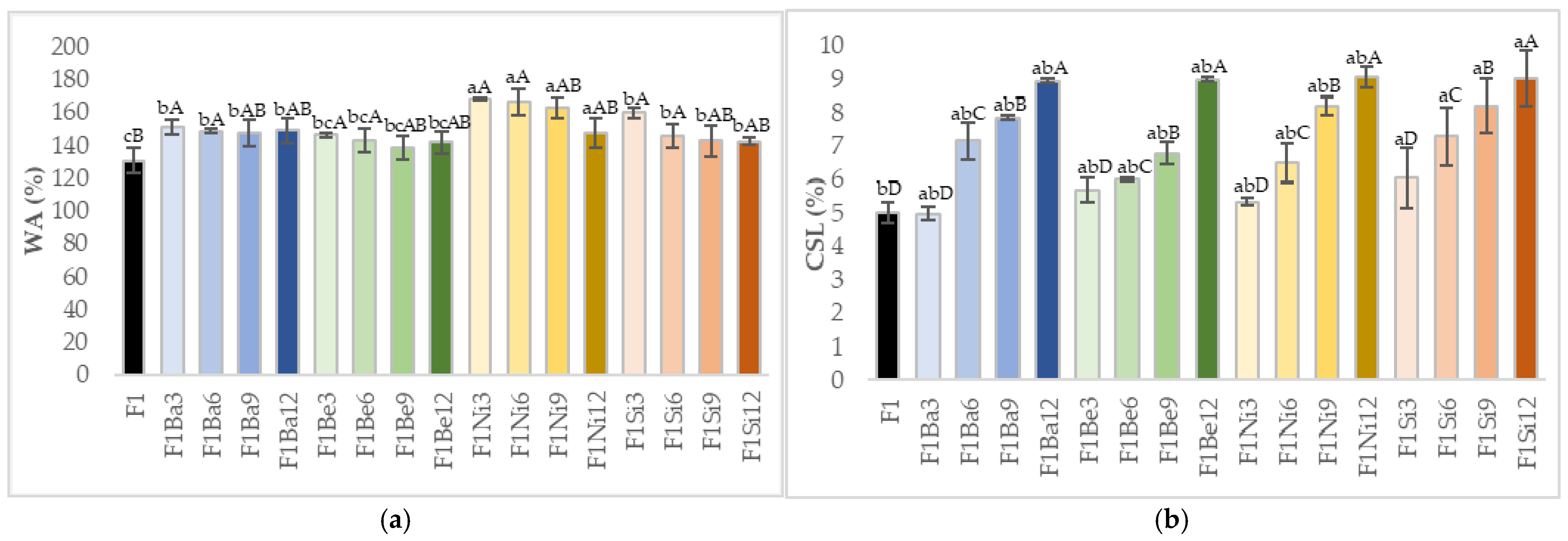

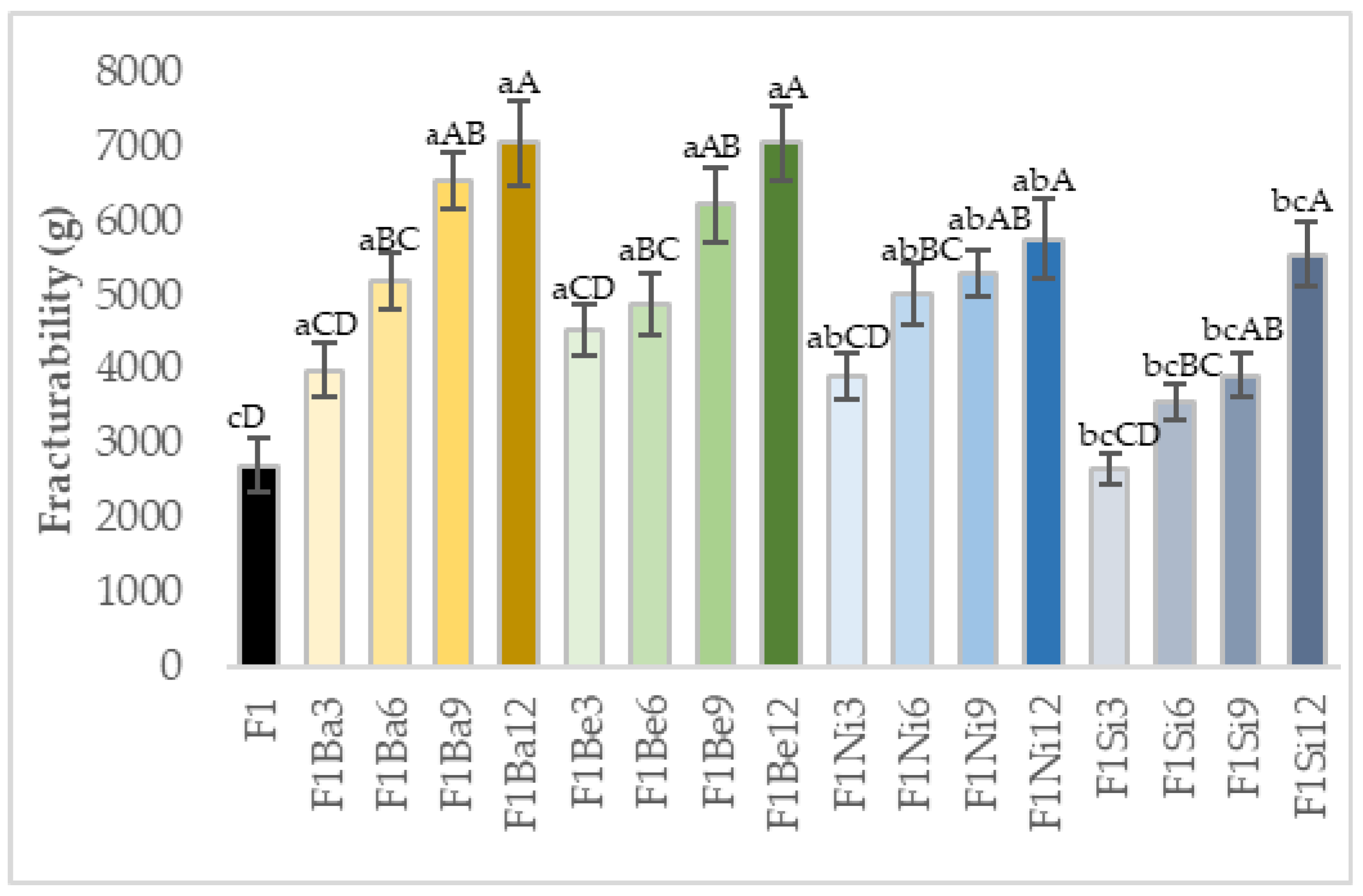

2.2. Pasta Characteristics

2.3. Correlations and Principal Component Analysis (PCA)

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Rheological Properties of Dough

4.3. Dough Texture

4.4. Pasta Fracturability

4.5. Color Properties of Pasta

4.6. Pasta Cooking Behavior

4.7. Cooked Pasta Texture

4.8. Statistical Processing of Data

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gómez, M.; Braojos, M.; Fernández, R.; Parle, F. Utilization of By-Products from the Fruit and Vegetable Processing Industry in Pasta Production. Appl. Sci. 2025, 15, 2189. [Google Scholar] [CrossRef]

- Conti, V.; Piccini, C.; Romi, M.; Salusti, P.; Cai, G.; Cantini, C. Pasta enriched with carrot and olive leaf flour retains high levels of accessible bioactives after in vitro digestion. Foods 2023, 12, 3540. [Google Scholar] [CrossRef]

- Dziki, D. Current Trends in Enrichment of Wheat Pasta: Quality, Nutritional Value and Antioxidant Properties. Processes 2021, 9, 1280. [Google Scholar] [CrossRef]

- Troncoso Recio, R.; Pérez Guerra, N.; Torrado Agrasar, A.; Tovar Rodríguez, C.A. Influence of casein hydrolysates and yeast on the rheological properties of wheat dough. Gels 2022, 8, 689. [Google Scholar] [CrossRef] [PubMed]

- Dahdah, P.; Cabizza, R.; Farbo, M.G.; Fadda, C.; Mara, A.; Hassoun, G.; Piga, A. Improving the rheological properties of dough obtained by partial substitution of wheat flour with freeze-dried olive pomace. Foods 2024, 13, 478. [Google Scholar] [CrossRef] [PubMed]

- Iuga, M.; Mironeasa, S. Potential of grape byproducts as functional ingredients in baked goods and pasta. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2473–2505. [Google Scholar] [CrossRef]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, nutritional and sensory properties of pasta fortified with agro-industrial by-products: A review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Iuga; Mironeasa, C.; Mironeasa, S. Oscillatory Rheology and Creep-Recovery Behaviour of Grape Seed-Wheat Flour Dough: Effect of Grape Seed Particle Size, Variety and Addition Level. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Food Sci. Technol. 2019, 76, 40. [Google Scholar] [CrossRef]

- Padalino, L.; Conte, A.; Lecce, L.; Likyova, D.; Sicari, V.; PELLICANÒ, T.; Poiana, M.; Del Nobile, M.A. Functional pasta with tomato by-product as a source of antioxidant compounds and dietary fibre. Czech J. Food Sci. 2017, 35, 48–56. [Google Scholar] [CrossRef]

- Umair, M.; Jabbar, S.; Nasiru, M.M.; Lu, Z.; Zhang, J.; Abid, M.; Murtaza, M.A.; Kieliszek, M.; Zhao, L. Ultrasound-assisted extraction of carotenoids from carrot pomace and their optimization through response surface methodology. Molecules 2021, 26, 6763. [Google Scholar] [CrossRef]

- Surbhi, S.; Verma, R.; Deepak, R.; Jain, H.; Yadav, K. A Review: Food, Chemical Composition and Utilization Of Carrot (Daucus carota L.) Pomace. Int. J. Chem. Stud. 2018, 6, 2921–2926. [Google Scholar]

- Luca, M.I.; Ungureanu-Iuga, M.; Mironeasa, S. Carrot Pomace Characterization for Application in Cereal-Based Products. Appl. Sci. 2022, 12, 7989. [Google Scholar] [CrossRef]

- Alam, M.S.; Gupta, K.; Khaira, H.; Javed, M. Quality of dried carrot pomace powder as affected by pretreatments and methods of drying. Agric. Eng. Int. CIGR J. 2013, 15, 236–243. [Google Scholar]

- Djordjević, M.; Djordjević, M.; Šoronja-Simović, D.; Nikolić, I.; Šereš, Z. Delving into the role of dietary fiber in gluten-free bread formulations: Integrating fundamental rheological, technological, sensory, and nutritional aspects. Polysaccharides 2021, 3, 59–82. [Google Scholar] [CrossRef]

- Peressini, D.; Sensidoni, A. Effect of soluble dietary fibre addition on rheological and breadmaking properties of wheat doughs. J. Cereal Sci. 2009, 49, 190–201. [Google Scholar] [CrossRef]

- Rosell, C.M.; Santos, E.; Collar, C. Physical characterization of fiber-enriched bread doughs by dual mixing and temperature constraint using the Mixolab Ò. Eur. Food Res. Technol. 2010, 231, 535–544. [Google Scholar] [CrossRef]

- CULEȚU, A.; MOHAN, G.; DUȚĂ, D.E. Rheological Characterization of the Dough with Added Dietary Fiber by Rheometer: A Review. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Food Sci. Technol. 2020, 77, 13–24. [Google Scholar] [CrossRef]

- Peressini, D.; Cavarape, A.; Anne, M.; Gao, J.; Stephen, C. Food Hydrocolloids Viscoelastic properties of durum wheat doughs enriched with soluble dietary fibres in relation to pasta-making performance and glycaemic response of spaghetti. Food Hydrocoll. 2020, 102, 105613. [Google Scholar] [CrossRef]

- Kultys, E.; Moczkowska-Wyrwisz, M. Effect of using carrot pomace and beetroot-apple pomace on physicochemical and sensory properties of pasta. LWT-Food Sci. Technol. 2022, 168, 113858. [Google Scholar] [CrossRef]

- Carrillo, T.G.C. Sensory Evaluation and Characterization of Supplemented Pasta with Carrot Pomace. Available online: https://food-chemistry-technology-conferences.magnusgroup.org/program/scientific-program/2023/sensory-evaluation-and-characterization-of-supplemented-pasta-with-carrot-pomace?utm_source=chatgpt.com (accessed on 16 June 2025).

- Mishra, P.; Kumar Bhatt, D. Evaluation of Nutritional and Physico-Chemical Characteristics of Dietary Fibre Enriched With Carrot Pomace Pasta. Int. J. Pharm. Sci. Res. 2018, 9, 4487. [Google Scholar] [CrossRef]

- Oncică, F.-G.; Stoica, F.; Constantin, O.E.; Turturică, M.; Aprodu, I.; Ratu, R.N.; Andronoiu, D.G.; Stănciuc, N.; Râpeanu, G. Development of value-added muffins using carrot pomace powder as a natural pigment. Ann. Univ. Dunarea Jos Galati. Fascicle VI-Food Technol. 2024, 48, 192–210. [Google Scholar] [CrossRef]

- Ahmad, M.; Ahmed, T.; Wani, W.S.M. Incorporation of carrot pomace powder in wheat flour: Effect on flour, dough and cookie characteristics. J. Food Sci. Technol. 2016, 53, 3715–3724. [Google Scholar] [CrossRef] [PubMed]

- Turksoy, S.; Özkaya, B. Pumpkin and Carrot Pomace Powders as a Source of Dietary Fiber and Their Effects on the Mixing Properties of Wheat Flour Dough and Cookie Quality. Food Sci. Technol. Res. 2011, 17, 545–553. [Google Scholar] [CrossRef]

- Kohajdová, Z.; Karovičová, J.; Jurasová, M. Influence of carrot pomace powder on the rheological characteristics of wheat flour dough and on wheat rolls quality. Acta Sci. Pol. Technol. Aliment. 2012, 11, 381–387. [Google Scholar]

- Mirsaeedghazi, H.; Emam-Djomeh, Z.; Mousavi, S.M.A. Rheometric measurement of dough rheological characteristics and factors affecting it. Int. J. Agric. Biol. 2008, 10, 112–119. [Google Scholar]

- Liu, N.; Ma, S.; Li, L.; Wang, X. Study on the effect of wheat bran dietary fiber on the rheological properties of dough. Grain Oil Sci. Technol. 2019, 2, 1–5. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Zhao, Y.; Wang, D.; Wang, W. Influence of antioxidant dietary fiber on dough properties and bread qualities: A review. J. Funct. Foods 2021, 80, 104434. [Google Scholar] [CrossRef]

- Nirmala Prasadi, V.P.; Joye, I.J. Effect of soluble dietary fibre from barley on the rheology, water mobility and baking quality of wheat flour dough. J. Cereal Sci. 2023, 112, 103715. [Google Scholar] [CrossRef]

- Gan, Z.; Galliard, T.; Ellis, P.R.; Angold, R.E.; Vaughan, J.G. Effect of the outer bran layers on the loaf volume of wheat bread. J. Cereal Sci. 1992, 15, 151–163. [Google Scholar] [CrossRef]

- Almoumen, A.; Mohamed, H.; Ayyash, M.; Yuliarti, O.; Kamleh, R.; Al-Marzouqi, A.H.; Kamal-Eldin, A. Harnessing date fruit pomace: Extraction of high fibre dietary ingredient and its impact on high fibre wheat flour dough. NFS J. 2024, 35, 100178. [Google Scholar] [CrossRef]

- Majzoobi, M.; Poor, Z.V.; Jamalian, J.; Farahnaky, A. Improvement of the quality of gluten-free sponge cake using different levels and particle sizes of carrot pomace powder. Int. J. Food Sci. Technol. 2016, 51, 1369–1377. [Google Scholar] [CrossRef]

- Reißner, A.-M.; Beer, A.; Struck, S.; Rohm, H. Pre-Hydrated Berry Pomace in Wheat Bread: An Approach Considering Requisite Water in Fiber Enrichment. Foods 2020, 9, 1600. [Google Scholar] [CrossRef] [PubMed]

- Alba, K.; Rizou, T.; Paraskevopoulou, A.; Campbell, G.M.; Kontogiorgos, V. Effects of Blackcurrant Fibre on Dough Physical Properties and Bread Quality Characteristics. Food Biophys. 2020, 15, 313–322. [Google Scholar] [CrossRef]

- Lei, M.; Huang, J.; Tian, X.; Zhou, P.; Zhu, Q.; Li, L.; Li, L.; Ma, S.; Wang, X. Effects of insoluble dietary fiber from wheat bran on noodle quality. Grain Oil Sci. Technol. 2021, 4, 1–9. [Google Scholar] [CrossRef]

- Hao, C.C.; Wang, L.J.; Li, D.; Özkan, N.; Wang, D.C.; Chen, X.D.; Mao, Z.H. Influence of alfalfa powder concentration and granularity on rheological properties of alfalfa-wheat dough. J. Food Eng. 2008, 89, 137–141. [Google Scholar] [CrossRef]

- Alvarez, M.D.; Cuesta, F.J.; Herranz, B.; Canet, W. Rheometric non-isothermal gelatinization kinetics of chickpea flour-based gluten-free muffin batters with added biopolymers. Foods 2017, 6, 3. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J.; Almusallam, A.S.; Al-Salman, F.; AbdulRahman, M.H.; Al-Salem, E. Rheological properties of water insoluble date fiber incorporated wheat flour dough. LWT-Food Sci. Technol. 2013, 51, 409–416. [Google Scholar] [CrossRef]

- Ahmed, J.; Almusallam, A.; Al-Hooti, S.N. Isolation and characterization of insoluble date (Phoenix dactylifera L.) fibers. LWT-Food Sci. Technol. 2013, 50, 414–419. [Google Scholar] [CrossRef]

- Lii, C.Y.; Tsai, M.L.; Tseng, K.H. Effect of amylose content on the rheological property of rice starch. Cereal Chem. 1996, 73, 415–420. [Google Scholar]

- Jekle, M.; Mühlberger, K.; Becker, T. Starch-gluten interactions during gelatinization and its functionality in dough like model systems. Food Hydrocoll. 2016, 54, 196–201. [Google Scholar] [CrossRef]

- Asadi, M.; Ahmadi, E.; Nourmohammadi, A. Enrichment of Sangak Bread With Carrot Pomace Powder and Its Effect on Dough Rheology, Bread Quality, and Shelf Life. Carpathian J. Food Sci. Technol. 2024, 16, 139–150. [Google Scholar] [CrossRef]

- Lu, X.; Brennan, M.A.; Serventi, L.; Brennan, C.S. Incorporation of mushroom powder into bread dough—Effects on dough rheology and bread properties. Cereal Chem. 2018, 95, 418–427. [Google Scholar] [CrossRef]

- Sivam, A.S.; Sun-waterhouse, D.; Quek, S.; Perera, C.O. Properties of Bread Dough with Added Fiber Polysaccharides and Phenolic Antioxidants: A Review. J. Food Sci. 2010, 75, R163–R174. [Google Scholar] [CrossRef]

- Nour, V.; Blejan, A.M.; Codina, G.G. Use of Bilberry and Blackcurrant Pomace Powders as Functional Ingredients in Cookies. Appl. Sci. 2025, 15, 5247. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Valorisation of Spent Grain from Malt Whisky in the Spelt Pasta Formulation: Modelling and Optimization Study. Appl. Sci. 2022, 12, 1441. [Google Scholar] [CrossRef]

- Sun-Waterhouse, D.; Jin, D.; Waterhouse, G.I.N. Effect of adding elderberry juice concentrate on the quality attributes, polyphenol contents and antioxidant activity of three fibre-enriched pastas. Food Res. Int. 2013, 54, 781–789. [Google Scholar] [CrossRef]

- Sissons, M.J. Pasta. In Encyclopaedia of Grain Science; Wrigley, C., Corke, H., Walker, C., Eds.; Academic Press: New York, NY, USA, 2004. [Google Scholar]

- Grant, L.A.; Dick, J.W.; Shelton, D.R. Effects of drying temperature, starch damage, sprouting, and additives on spaghetti quality characteristics. Cereal Chem. 1993, 70, 676–684. [Google Scholar]

- Wang, J.; Brennan, M.A.; Serventi, L.; Brennan, C.S. Impact of functional vegetable ingredients on the technical and nutritional quality of pasta. Crit. Rev. Food Sci. Nutr. 2022, 62, 6069–6080. [Google Scholar] [CrossRef]

- Tiony, M.C.; Irene, O. Quality and sensory properties of instant fried noodles made with soybean and carrot pomace flour. Afr. J. Food Sci. 2021, 15, 92–99. [Google Scholar] [CrossRef]

- Lou, W.; Zhou, H.; Li, B.; Nataliya, G. Rheological, pasting and sensory properties of biscuits supplemented with grape pomace powder. Food Sci. Technol. 2021, 42, 2061. [Google Scholar] [CrossRef]

- Prakash, P.; Prasad, K. Characterization and Optimization of Garlic-Incorporated Pasta: Physicochemical, Functional and Textural Properties. Annu. Res. Rev. Biol. 2025, 40, 16–32. [Google Scholar] [CrossRef]

- Ismail, Z.; Aziz, N. Effect of Mixing Pumpkin Puree with Wheat Flour on Physicochemical and Sensory Properties of Stick Snacks. Int. J. Tech. Vocat. Eng. Technol. 2019, 1, 25–30. [Google Scholar]

- Witrowa-Rajchert, D.; Bawoł, A.; Czapski, J.; Kidoń, M. Studies on Drying of Purple Carrot Roots. Dry. Technol. 2009, 27, 1325–1331. [Google Scholar] [CrossRef]

- Luca, M.I.; Ungureanu-iuga, M.; Mironeasa, S. Nutritional and bioactive composition of different carrot pomace varieties. Ukr. J. Food Sci. 2024, 12, 105–115. [Google Scholar] [CrossRef]

- Porto Dalla Costa, A.; Cruz Silveira Thys, R.; De Oliveira Rios, A.; Hickmann Flôres, S. Carrot Flour from Minimally Processed Residue as Substitute of β-Carotene Commercial in Dry Pasta Prepared with Common Wheat (Triticum aestivum). J. Food Qual. 2016, 39, 590–598. [Google Scholar] [CrossRef]

- Prerana, S.; Anupama, D. Influence of carrot puree incorporation on quality characteristics of instant noodles. J. Food Process Eng. 2020, 43, e13270. [Google Scholar] [CrossRef]

- Wang, Y.H.; Zhang, Y.Q.; Zhang, R.R.; Zhuang, F.Y.; Liu, H.; Xu, Z.S.; Xiong, A.S. Lycopene ε-cyclase mediated transition of α-carotene and β-carotene metabolic flow in carrot fleshy root. Plant J. 2023, 115, 986–1003. [Google Scholar] [CrossRef] [PubMed]

- Richards, J.; Lammert, A.; Madden, J.; Kang, I.; Amin, S. Physical Treatments Modified the Functionality of Carrot Pomace. Foods 2024, 13, 2084. [Google Scholar] [CrossRef]

- Piwińska, M.; Wyrwisz, J.; Kurek, M.; Wierzbicka, A. Effect of oat β-glucan fiber powder and vacuum-drying on cooking quality and physical properties of pasta. CYTA-J. Food 2016, 14, 101–108. [Google Scholar] [CrossRef]

- Xu, J.; Bock, J.E.; Stone, D. Quality and textural analysis of noodles enriched with apple pomace. J. Food Process. Preserv. 2020, 44, e14579. [Google Scholar] [CrossRef]

- Rocha Parra, A.F.; Ribotta, P.D.; Ferrero, C. Starch–Apple Pomace Mixtures: Pasting Properties and Microstructure. Food Bioprocess Technol. 2015, 8, 1854–1863. [Google Scholar] [CrossRef]

- Gałkowska, D.; Witczak, T.; Pycia, K. Quality Characteristics of Novel Pasta Enriched with Non-Extruded and Extruded Blackcurrant Pomace. Molecules 2022, 27, 8616. [Google Scholar] [CrossRef] [PubMed]

- Ungureanu-Iuga, M.; Mironeasa, S. Advance on the capitalization of grape peels by-product in common wheat pasta. Appl. Sci. 2021, 11, 11129. [Google Scholar] [CrossRef]

- Edwards, N.M.; Izydorczyk, M.S.; Dexter, J.E.; Biliaderis, C.G. Cooked pasta texture: Comparison of dynamic viscoelastic properties to instrumental assessment of firmness. Cereal Chem. 1993, 70, 122–126. [Google Scholar]

- SR EN ISO 665:2020; Oilseeds—Determination of Water and Volatile Matter Content. ASRO: Bucharest, Romania, 2020.

- SR EN ISO 659:2009; Oilseeds—Determination of Oil Content (Reference Method). ISO: Geneva, Switzerland, 2009.

- SR EN ISO 20483:2014; Cereals and Legumes. Determination of Nitrogen Content and Calculation of Crude Protein Content. Kjeldhal Method. ASRO: Bucharest, Romania, 2014.

- SR EN ISO 2171:2023; Cereals, Pulses and Derived Products—Determination of Ash Content by Ignition. ASRO: Bucharest, Romania, 2023.

- International Association for Cereal Science and Technology. ICC standards: Vienna, Austria, 1995.

- SR 90:2007; Wheat Flour. Methods of Analysis. ASRO: Bucharest, Romania, 2007.

- Bergman, C.; Gualberto, D.; Weber, C. Development of a high-temperature-dried soft wheat pasta supplemented with cowpea (Vigna unguiculata (L) Walp)-Cooking quality, color, and sensory evaluation. Cereal Chem. 1994, 71, 523–527. [Google Scholar]

- Ungureanu-Iuga, M.; Dimian, M.; Mironeasa, S. Development and quality evaluation of gluten-free pasta with grape peels and whey powders. LWT-Food Sci. Technol. 2020, 130, 109714. [Google Scholar] [CrossRef]

- Huțu, D.; Amariei, S. Effects of the sugar and fat substitution on the rheological properties of the pie dough. Ukr. Food J. 2021, 2, 592–604. [Google Scholar] [CrossRef]

- EN ISO/CIE 11664-4:2019; Colorimetry Part 4: CIE 1976 L*a*b* Colour Space. ISO: Geneva, Switzerland, 2019.

- Necula, D.; Ungureanu-Iuga, M.; Máthé, E.; Pecsenye, B.; Surdu, I.; Turcuş, V.; Ognean, L. Season and Processing Technology Impact on a Traditional Mountain Emmental Cheese. Agriculture 2024, 14, 2149. [Google Scholar] [CrossRef]

- Espinosa-Solis, V.; Zamudio-Flores, P.B.; Tirado-Gallegos, J.M.; Ramírez-Mancinas, S.; Olivas-Orozco, G.I.; Espino-Díaz, M.; Hernández-González, M.; García-Cano, V.G.; Sánchez-Ortíz, O.; Buenrostro-Figuerosa, J.J.; et al. Evaluation of Cooking Quality, Nutritional and Texture Characteristics of Pasta Added with Oat Bran and Apple Flour. Foods 2019, 8, 299. [Google Scholar] [CrossRef]

| Ingredient Added | Type of Product | Addition Level (%) | Changes Observed | References |

|---|---|---|---|---|

| Carrot pomace—unspecified variety | Pasta from semolina | 10–30 |

| Kultys et al. [19] |

| Carrot pomace—unspecified variety | Wheat pasta with eggs | 20 |

| Carrillo [20] |

| Carrot pomace—unspecified variety | Common wheat pasta | 5–25 |

| Mishra and Bhatt [21] |

| Carrot pomace—unspecified variety | Gluten free muffins | 2.5–5 |

| Oncică et al. [22] |

| Carrot pomace (Dacus carota)—unspecified variety | Cookies | 10–20 |

| Ahmad et al. [23] |

| Carrot pomace—Nanco variety | Cookies | 10–25 |

| Turksoy and Özkaya [24] |

| Carrot pomace—unspecified variety | Wheat rolls | 1–10 |

| Kohajdová et al. [25] |

| Sample | Hardness (g) | Springiness (%) | Gumminess (g) | Resilience (adim.) | Cohesiveness (adim.) |

|---|---|---|---|---|---|

| F1 | 2849.74 ± 75.71 bB | 100.11 ± 0.05 aA | 1073.73 ± 14.19 bB | 1.04 ± 0.05 aA | 0.36 ± 0.01 aA |

| F1Ba3 | 3227.33 ± 353.43 abAB | 99.82 ± 0.28 bB | 1137.72 ± 87.31 abAB | 0.97 ± 0.08 aA | 0.35 ± 0.02 aA |

| F1Ba6 | 3377.33 ± 175.68 abAB | 99.87 ± 0.05 b AB | 1232.50 ± 49.69 abAB | 1.15 ± 0.04 aA | 0.39 ± 0.02 aA |

| F1Ba9 | 4155.00 ± 100.14 abA | 99.75 ± 0.00 bB | 1521.32 ± 63.86 abA | 1.01 ± 0.06 aA | 0.37 ± 0.02 aA |

| F1Ba12 | 5080.67 ± 402.73 abB | 99.63 ± 0.02 bB | 1853.42 ± 192.39 abB | 0.96 ± 0.03 aA | 0.33 ± 0.02 aA |

| F1Be3 | 3208.08 ± 284.00 abAB | 100.14 ± 0.05 abB | 1324.19 ± 95.09 abAB | 1.12 ± 0.04 aA | 0.39 ± 0.02 aA |

| F1Be6 | 3450.00 ± 348.89 abAB | 99.75 ± 0.09 abAB | 1354.16 ± 121.41 abAB | 1.05 ± 0.04 aA | 0.34 ± 0.02 aA |

| F1Be9 | 3818.00 ± 42.93 abA | 99.72 ± 0.00 abB | 1389.49 ± 134.07 abA | 0.97 ± 0.01 aA | 0.33 ± 0.01 aA |

| F1Be12 | 4663.50 ± 194.50 abB | 99.72 ± 0.09 abB | 1745.95 ± 67.18 abB | 0.87 ± 0.07 aA | 0.31 ± 0.02 aA |

| F1Ni3 | 4077.33 ± 85.58 aAB | 99.91 ± 0.01 bB | 1327.65 ± 81.91 aAB | 1.23 ± 0.02 aA | 0.40 ± 0.02 aA |

| F1Ni6 | 4273.33 ± 113.39 aAB | 99.75 ± 0.08 bAB | 1560.05 ± 107.04 aAB | 1.11 ± 0.04 aA | 0.36 ± 0.01 aA |

| F1Ni9 | 4678.50 ± 425.50 aA | 99.73 ± 0.00 bB | 1849.72 ± 182.12 aA | 1.09 ± 0.06 aA | 0.32 ± 0.03 aA |

| F1Ni12 | 4615.33 ± 381.50 aB | 99.67 ± 0.00 bB | 1863.02 ± 18.15 aB | 0.93 ± 0.03 aA | 0.34 ± 0.01 aA |

| F1Si3 | 2832.67 ± 182.04 bAB | 99.83 ± 0.01 bB | 1133.29 ± 20.05 bAB | 1.18 ± 0.10 aA | 0.41 ± 0.02 aA |

| F1Si6 | 3288.67 ± 87.09 bAB | 99.80 ± 0.05 bAB | 1331.60 ± 67.07 bAB | 1.11 ± 0.08 aA | 0.37 ± 0.00 aA |

| F1Si9 | 4042.00 ± 107.95 bA | 99.50 ± 0.00 bB | 1485.61 ± 47.11 bA | 1.07 ± 0.04 aA | 0.36 ± 0.01 aA |

| F1Si12 | 4298.00 ± 292.18 bB | 99.50 ± 0.08 bB | 1516.23 ± 77.73 bB | 0.95 ± 0.04 aA | 0.35 ± 0.02 aA |

| Sample | L* | a* | b* | YI | WI | BI |

|---|---|---|---|---|---|---|

| F1 | 71.71 ± 0.39 aA | 0.05 ± 0.05 cD | 17.64 ± 0.17 bC | 35.15 ± 0.50 dB | 66.66 ± 0.41 aA | 27.62 ± 0.50 dB |

| F1Ba3 | 77.02 ± 0.08 aAB | 1.33 ± 0.05 abC | 25.13 ± 0.03 aA | 46.60 ± 0.10 cA | 65.93 ± 0.08 bB | 39.79 ± 0.14 cA |

| F1Ba6 | 72.20 ± 0.21 aABC | 2.09 ± 0.02 abB | 24.21 ± 0.06 aA | 47.91 ± 0.27 cA | 63.07 ± 0.20 bBC | 42.02 ± 0.29 cA |

| F1Ba9 | 69.78 ± 0.96 aBC | 2.51 ± 0.02 abAB | 21.20 ± 0.26 aB | 43.41 ± 0.06 cA | 62.99 ± 0.63 bBC | 38.09 ± 0.11 cA |

| F1Ba12 | 66.92 ± 0.12 aC | 2.57 ± 0.08 abA | 20.70 ± 0.03 aB | 44.18 ± 0.03 cA | 60.90 ± 0.09 bC | 39.04 ± 0.12 cA |

| F1Be3 | 69.17 ± 0.25 bAB | 0.56 ± 0.13 bC | 24.46 ± 0.20 aA | 50.52 ± 0.23 aA | 60.64 ± 0.07 dB | 43.07 ± 0.38 aA |

| F1Be6 | 66.34 ± 0.27 bABC | 1.84 ± 0.03 bB | 24.31 ± 0.41 aA | 52.35 ± 1.04 aA | 58.44 ± 0.43 dBC | 46.52 ± 1.14 aA |

| F1Be9 | 65.59 ± 0.48 bBC | 1.95 ± 0.05 bAB | 23.66 ± 0.03 aB | 51.54 ± 0.43 aA | 58.19 ± 0.41 dBC | 45.82 ± 0.52 aA |

| F1Be12 | 64.92 ± 0.10 bC | 2.07 ± 0.01 bA | 21.47 ± 0.01 aB | 47.25 ± 0.05 aA | 58.82 ± 0.08 dC | 41.59 ± 0.05 aA |

| F1Ni3 | 68.29 ± 0.45 bAB | 1.44 ± 0.03 abC | 23.63 ± 0.40 aA | 49.42 ± 0.65 bA | 60.43 ± 0.25 dB | 42.95 ± 0.66 bA |

| F1Ni6 | 67.47 ± 0.32 bABC | 2.18 ± 0.02 abB | 22.11 ± 0.01 aA | 46.82 ± 0.24 bA | 60.60 ± 0.27 dBC | 41.18 ± 0.26 bA |

| F1Ni9 | 65.37 ± 0.19 bBC | 2.44 ± 0.02 abAB | 21.45 ± 0.13 aB | 46.88 ± 0.36 bA | 59.19 ± 0.20 dBC | 41.63 ± 0.39 bA |

| F1Ni12 | 63.12 ± 0.08 bC | 2.52 ± 0.02 abA | 21.32 ± 0.09 aB | 48.24 ± 0.14 bA | 57.33 ± 0.03 dC | 43.21 ± 0.16 bA |

| F1Si3 | 69.30 ± 0.05 abAB | 1.89 ± 0.07 aC | 23.99 ± 0.31 aA | 49.45 ± 0.67 bA | 61.00 ± 0.22 cB | 43.46 ± 0.60 abA |

| F1Si6 | 69.18 ± 0.67 abABC | 2.31 ± 0.03 aB | 23.43 ± 0.48 aA | 48.39 ± 1.28 bA | 61.21 ± 0.71 cBC | 42.85 ± 1.29 abA |

| F1Si9 | 68.64 ± 0.24 abBC | 2.70 ± 0.05 aAB | 22.71 ± 0.21 aB | 47.26 ± 0.26 bA | 61.19 ± 0.07 cBC | 42.17 ± 0.31 abA |

| F1Si12 | 67.83 ± 0.43 abC | 2.85 ± 0.03 aA | 22.59 ± 0.11 aB | 47.58 ± 0.08 bA | 60.59 ± 0.29 cC | 42.70 ± 0.07 abA |

| Sample | Elasticity (%) | Chewiness (g) | Gumminess (g) | Cohesiveness (Adim.) | Hardness (g) | Adhesiveness (J) | Resilience (Adim.) | Stickiness (g) |

|---|---|---|---|---|---|---|---|---|

| F1 | 99.72 ± 0.21 bB | 1071.81 ± 15.38 cC | 1073.67 ± 14.13 cC | 0.36 ±0.01 aC | 2818.40 ± 239.46 bB | −90.49 ± 9.50 abA | 1.02 ± 0.06 cD | −49.99 ± 3.83 aA |

| F1Ba3 | 99.79 ± 0.08 bAB | 2688.88 ± 219.26 abA | 2693.38 ± 220.32 abA | 0.68 ± 0.02 bB | 3243.22 ± 299.16 aB | −10.51 ± 0.29 bA | 7.10 ± 0.53 abA | −74.98 ± 3.27 bA |

| F1Ba6 | 99.79 ± 0.09 bAB | 2518.87 ± 240.34 abAB | 2527.85 ± 242.78 abAB | 0.71 ± 0.04 bAB | 3361.24 ± 353.80 aAB | −84.14 ± 3.40 bA | 6.52 ± 0.61 abB | −154.37 ± 3.44 bA |

| F1Ba9 | 99.81 ± 0.06 bAB | 2402.90 ± 195.15 abAB | 2408.77 ± 196.10 abAB | 0.71 ± 0.05 bAB | 3491.71 ± 349.13 aA | −124.68 ± 4.47 bA | 6.28 ± 0.59 abBC | −208.81 ± 19.65 bA |

| F1Ba12 | 99.84 ± 0.01 bA | 2059.64 ± 134.58 abB | 2063.28 ± 133.84 abB | 0.71 ± 0.01 bA | 3788.88 ± 229.31 aA | −187.11 ± 19.21 bA | 5.94 ± 0.46 abC | −208.74 ± 23.14 bA |

| F1Be3 | 99.81 ± 0.08 abAB | 2953.62 ± 220.82 aA | 2959.00 ± 221.66 abA | 0.71 ± 0.05 aB | 3305.99 ± 317.24 aB | −136.22 ± 2.45 cA | 7.28 ± 0.66 bA | −119.92 ± 13.38 cA |

| F1Be6 | 99.85 ± 0.01 abAB | 2941.82 ± 201.87 aAB | 2949.08 ± 206.00 aAB | 0.73 ± 0.03 aAB | 3347.85 ± 383.60 aAB | −239.84 ± 9.35 cA | 6.20 ± 0.47 bB | −224.45 ± 6.00 cA |

| F1Be9 | 99.84 ± 0.01 abAB | 2658.44 ± 249.31 aAB | 2665.22 ± 249.45 aAB | 0.76 ± 0.04 aAB | 3547.67 ± 390.04 aA | −270.34 ± 24.25 cA | 5.95 ± 0.48 bBC | −330.78 ± 19.11 cA |

| F1Be12 | 99.92 ± 0.12 abA | 2041.54 ± 219.18 aB | 2045.39 ± 217.89 aB | 0.77 ± 0.02 aA | 3686.12 ± 262.54 aA | −237.00 ± 21.82 cA | 4.82 ± 0.24 bC | −345.46 ± 32.32 cA |

| F1Ni3 | 99.85 ± 0.01 aAB | 2268.82 ± 180.14 bA | 2273.12 ± 181.47 aA | 0.68 ± 0.03 abB | 2417.29 ± 189.16 bB | −23.17 ± 2.22 aA | 7.94 ± 0.54 aA | −11.20 ± 1.76 aA |

| F1Ni6 | 99.95 ± 0.08 aAB | 2034.08 ± 189.65 bAB | 2037.94 ± 190.92 bAB | 0.69 ± 0.01 abAB | 3124.16 ± 265.67 bAB | −12.15 ± 0.35 aA | 7.31 ± 0.56 aB | −56.58 ± 8.69 aA |

| F1Ni9 | 99.98 ± 0.15 aAB | 1984.24 ± 88.57 bAB | 1989.82 ± 91.49 bAB | 0.72 ± 0.05 abAB | 3318.97 ± 324.67 bA | −16.39 ± 6.52 aA | 6.83 ± 0.54 aBC | −52.08 ± 1.69 aA |

| F1Ni12 | 100.04 ± 0.24 aA | 2254.41 ± 213.28 bB | 2257.66 ± 211.07 bB | 0.74 ± 0.02 abA | 3399.38 ± 391.15 bA | −33.22 ± 6.70 aA | 6.49 ± 0.40 aC | −89.20 ± 5.67 aA |

| F1Si3 | 99.76 ± 0.09 abAB | 2379.45 ± 198.14 bA | 2385.16 ± 198.66 bA | 0.68 ± 0.04 bB | 3183.68 ± 118.07 abB | −54.13 ± 7.21 abA | 8.14 ± 0.76 aA | −142.03 ± 13.00 abA |

| F1Si6 | 99.82 ± 0.07 abAB | 2247.78 ± 234.60 bAB | 2254.05 ± 235.93 bAB | 0.70 ± 0.04 bAB | 3212.93 ± 195.00 abAB | −73.42 ± 1.12 abC | 6.89 ± 0.66 aB | −165.24 ± 18.15 ab |

| F1Si9 | 99.88 ± 0.07 abAB | 2226.47 ± 39.14 bAB | 2231.91 ± 40.63 bAB | 0.71 ± 0.02 bAB | 3317.31 ± 213.20 abA | −62.79 ± 0.73 abC | 6.68 ± 0.46 aBC | −124.25 ± 13.30 ab |

| F1Si12 | 99.92 ± 0.09 abA | 2084.92 ± 100.92 bB | 2088.93 ± 99.76 bB | 0.70 ± 0.00 bA | 3420.43 ± 119.65 abA | −29.83 ± 5.58 abC | 6.52 ± 0.34 aC | −65.96 ± 3.89 ab |

| PC1 | PC2 | PC3 | PC4 | PC5 | |

|---|---|---|---|---|---|

| Eigenvalue | 10.19 | 6.31 | 3.57 | 2.04 | 1.19 |

| Variability (%) | 39.19 | 24.28 | 13.75 | 7.84 | 4.57 |

| Cumulative % | 39.19 | 63.47 | 77.21 | 85.05 | 89.62 |

| Variable | PC1 | PC2 | PC3 | PC4 | PC5 |

|---|---|---|---|---|---|

| Dough hardness | 7.24 | 1.02 | 1.75 | 0.75 | 4.48 |

| Dough springiness | 6.04 | 0.00 | 0.87 | 3.79 | 0.19 |

| Dough gumminess | 7.47 | 0.82 | 0.86 | 3.22 | 3.06 |

| Dough resilience | 3.13 | 3.11 | 5.97 | 1.04 | 1.01 |

| Dough cohesiveness | 4.21 | 3.56 | 2.31 | 0.24 | 2.90 |

| G*10Hz | 4.70 | 1.35 | 0.87 | 6.64 | 12.46 |

| Jmax | 6.05 | 1.83 | 0.34 | 0.96 | 13.22 |

| Ti | 2.81 | 0.44 | 1.10 | 16.74 | 13.74 |

| Tg | 5.37 | 0.05 | 3.90 | 7.73 | 6.00 |

| L* | 4.88 | 0.01 | 0.00 | 21.32 | 0.42 |

| a* | 6.37 | 0.20 | 1.96 | 2.65 | 2.07 |

| b* | 0.02 | 14.01 | 0.07 | 3.22 | 1.89 |

| YI | 1.16 | 12.83 | 0.13 | 0.86 | 3.48 |

| WI | 5.02 | 2.22 | 0.03 | 14.74 | 1.62 |

| BI | 2.30 | 11.23 | 0.01 | 0.49 | 2.42 |

| WA | 0.00 | 2.93 | 14.23 | 2.01 | 11.05 |

| CSL | 7.50 | 1.07 | 0.16 | 0.34 | 0.70 |

| Pasta fracturability | 6.80 | 0.23 | 2.17 | 0.25 | 6.19 |

| Pasta elasticity | 5.93 | 0.00 | 4.73 | 4.98 | 3.48 |

| Pasta chewiness | 0.19 | 12.42 | 2.47 | 1.33 | 0.00 |

| Pasta gumminess | 0.19 | 12.42 | 2.47 | 1.34 | 0.00 |

| Pasta cohesiveness | 5.25 | 6.65 | 0.10 | 0.06 | 1.05 |

| Pasta firmness | 4.67 | 0.03 | 7.31 | 3.60 | 2.87 |

| Pasta adhesiveness | 0.69 | 0.01 | 22.15 | 1.38 | 0.29 |

| Pasta resilience | 0.44 | 11.39 | 4.65 | 0.27 | 3.24 |

| Pasta stickiness | 1.59 | 0.16 | 19.38 | 0.04 | 2.16 |

| Sample | PC1 | PC2 | PC3 | PC4 | PC5 |

|---|---|---|---|---|---|

| F1 | 33.09 | 51.97 | 1.48 | 1.88 | 3.27 |

| F1Ba3 | 6.44 | 1.61 | 0.07 | 21.63 | 0.20 |

| F1Ba6 | 0.58 | 1.56 | 0.03 | 17.29 | 0.02 |

| F1Ba9 | 0.39 | 1.18 | 0.96 | 5.58 | 25.66 |

| F1Ba12 | 6.53 | 5.14 | 1.29 | 0.36 | 30.76 |

| F1Be3 | 4.12 | 8.77 | 3.35 | 1.73 | 0.26 |

| F1Be6 | 0.20 | 6.95 | 9.99 | 1.28 | 5.95 |

| F1Be9 | 2.36 | 2.00 | 20.92 | 1.65 | 3.09 |

| F1Be12 | 9.89 | 3.58 | 11.31 | 2.44 | 0.03 |

| F1Ni3 | 3.88 | 4.19 | 16.42 | 7.40 | 0.41 |

| F1Ni6 | 0.03 | 0.00 | 11.67 | 2.27 | 1.76 |

| F1Ni9 | 5.01 | 1.08 | 13.25 | 2.04 | 1.61 |

| F1Ni12 | 8.41 | 0.47 | 2.01 | 12.73 | 0.39 |

| F1Si3 | 9.37 | 8.84 | 0.21 | 1.69 | 7.29 |

| F1Si6 | 1.49 | 1.10 | 0.06 | 0.19 | 0.52 |

| F1Si9 | 1.07 | 0.03 | 1.82 | 3.15 | 2.78 |

| F1Si12 | 7.15 | 1.52 | 5.15 | 16.69 | 16.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luca, M.I.; Ungureanu-Iuga, M.; Batariuc, A.; Mironeasa, S. Physical Characteristics of Durum Wheat Dough and Pasta with Different Carrot Pomace Varieties. Gels 2025, 11, 481. https://doi.org/10.3390/gels11070481

Luca MI, Ungureanu-Iuga M, Batariuc A, Mironeasa S. Physical Characteristics of Durum Wheat Dough and Pasta with Different Carrot Pomace Varieties. Gels. 2025; 11(7):481. https://doi.org/10.3390/gels11070481

Chicago/Turabian StyleLuca, Marian Ilie, Mădălina Ungureanu-Iuga, Ana Batariuc, and Silvia Mironeasa. 2025. "Physical Characteristics of Durum Wheat Dough and Pasta with Different Carrot Pomace Varieties" Gels 11, no. 7: 481. https://doi.org/10.3390/gels11070481

APA StyleLuca, M. I., Ungureanu-Iuga, M., Batariuc, A., & Mironeasa, S. (2025). Physical Characteristics of Durum Wheat Dough and Pasta with Different Carrot Pomace Varieties. Gels, 11(7), 481. https://doi.org/10.3390/gels11070481