Mechanical Properties of Cement-Based Gel Composites Reinforced by Plant Fiber: A Review

Abstract

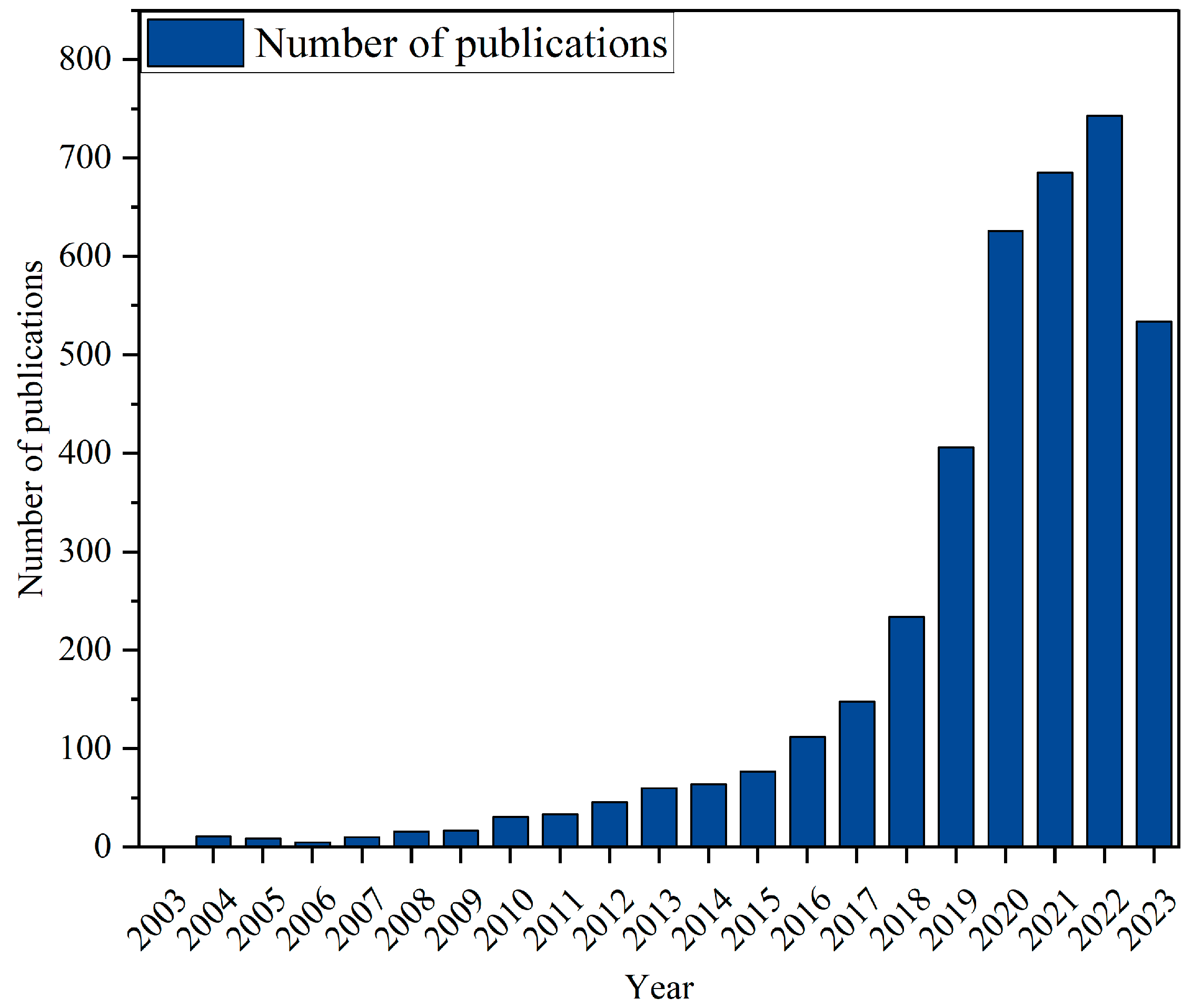

1. Introduction

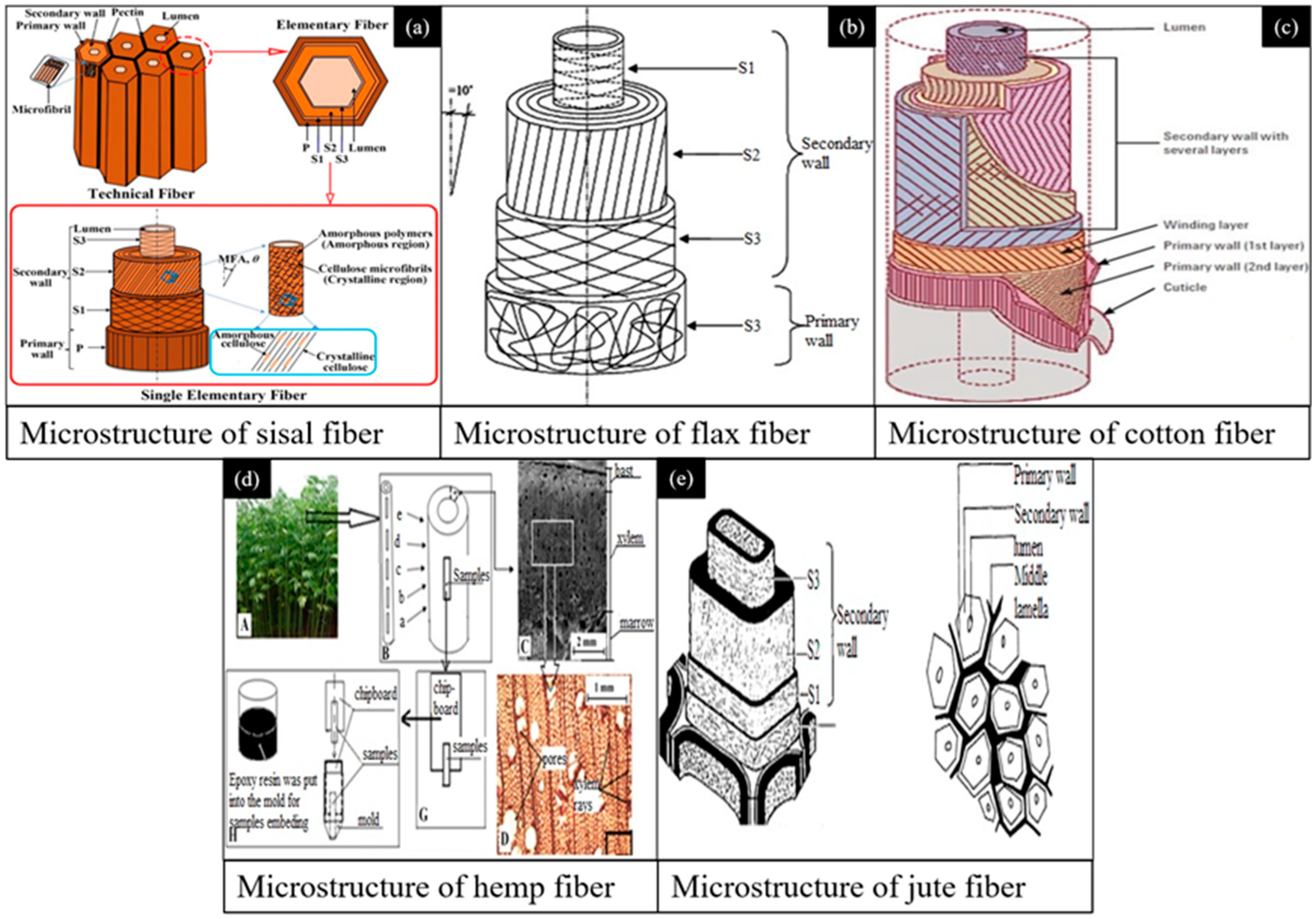

2. Characteristics of PF

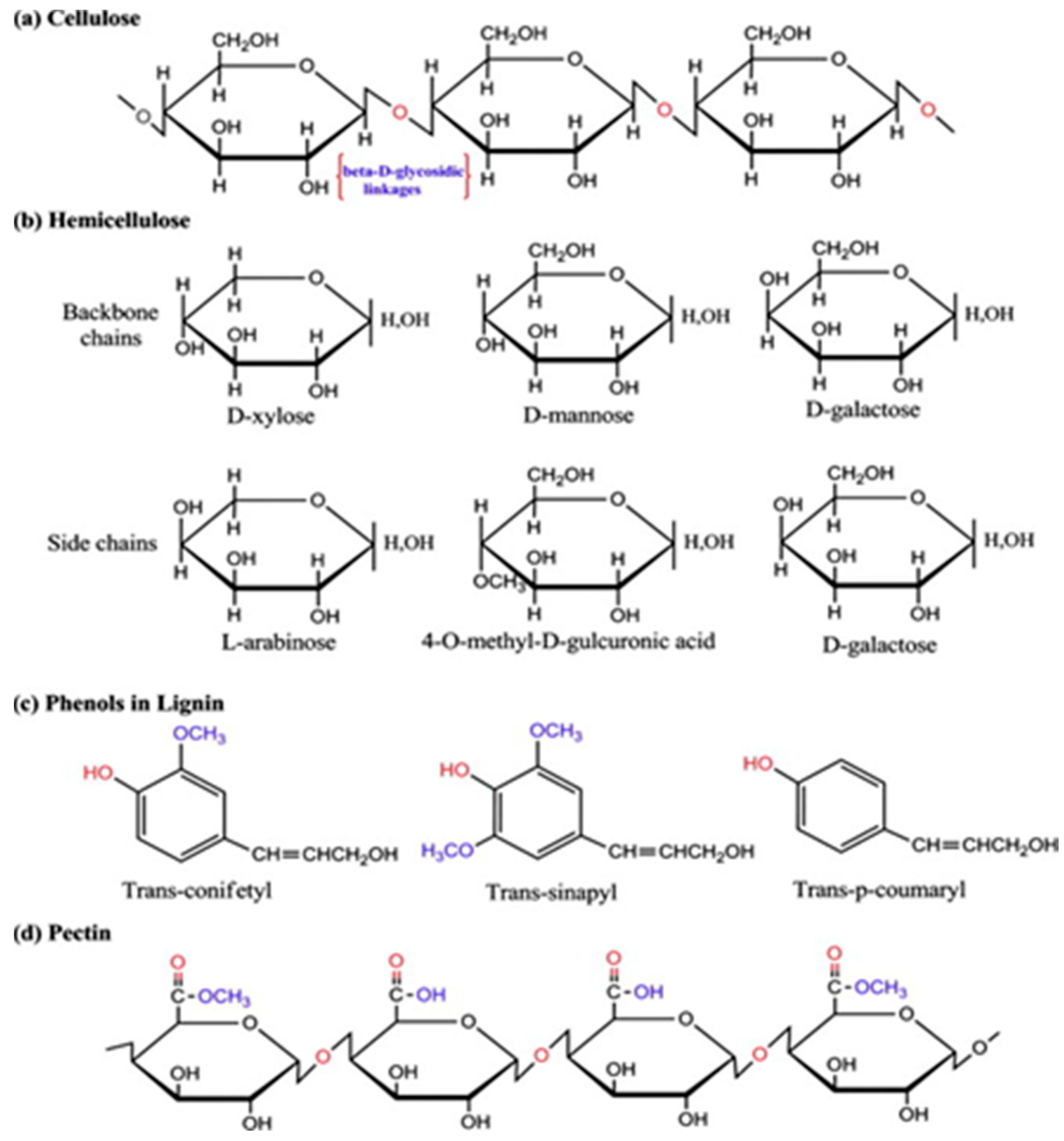

2.1. Chemical Composition of PF

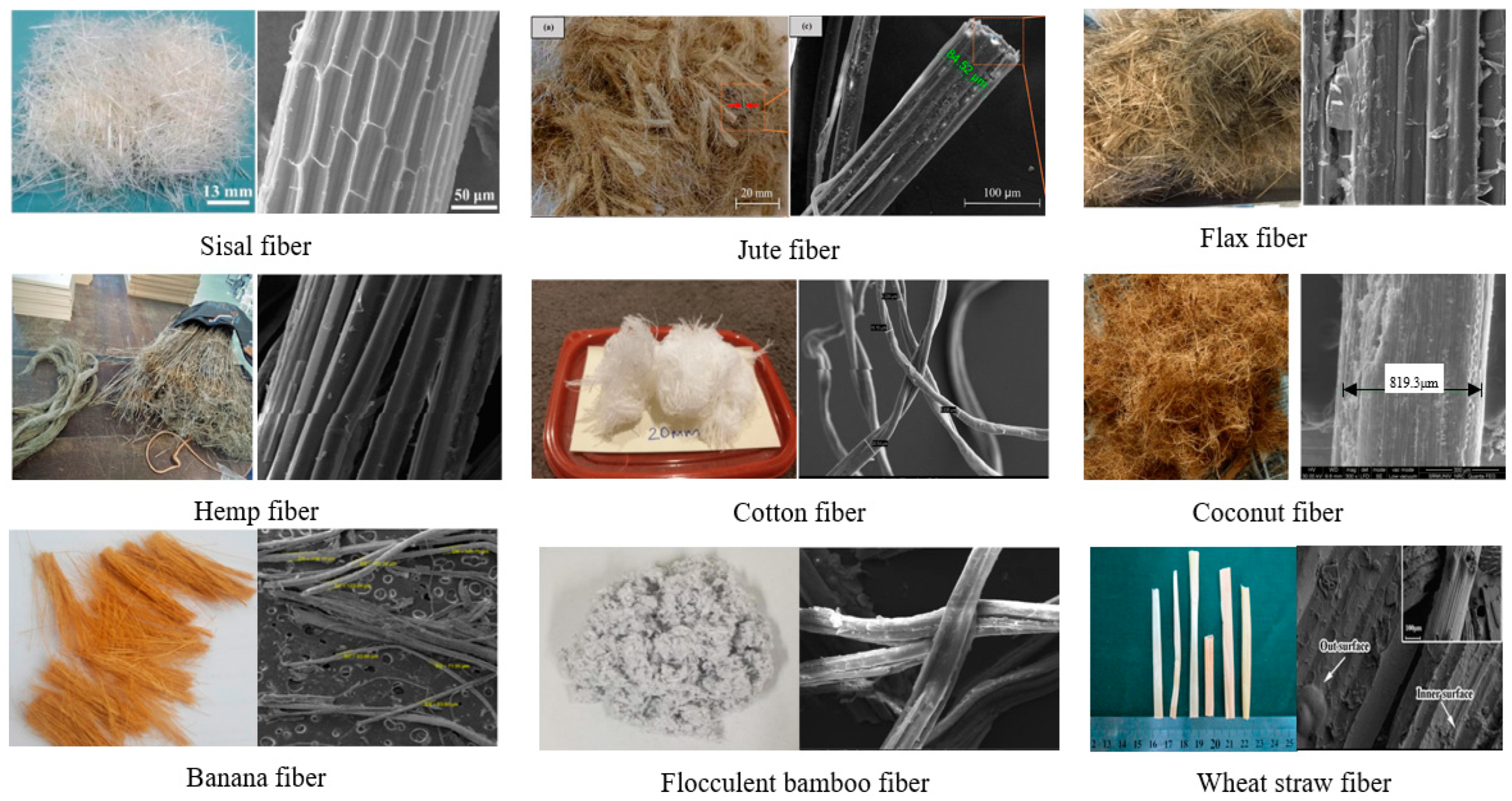

2.2. Common PFs in Construction Engineering

2.3. Physical and Mechanical Properties of PFs

3. Modification Methods

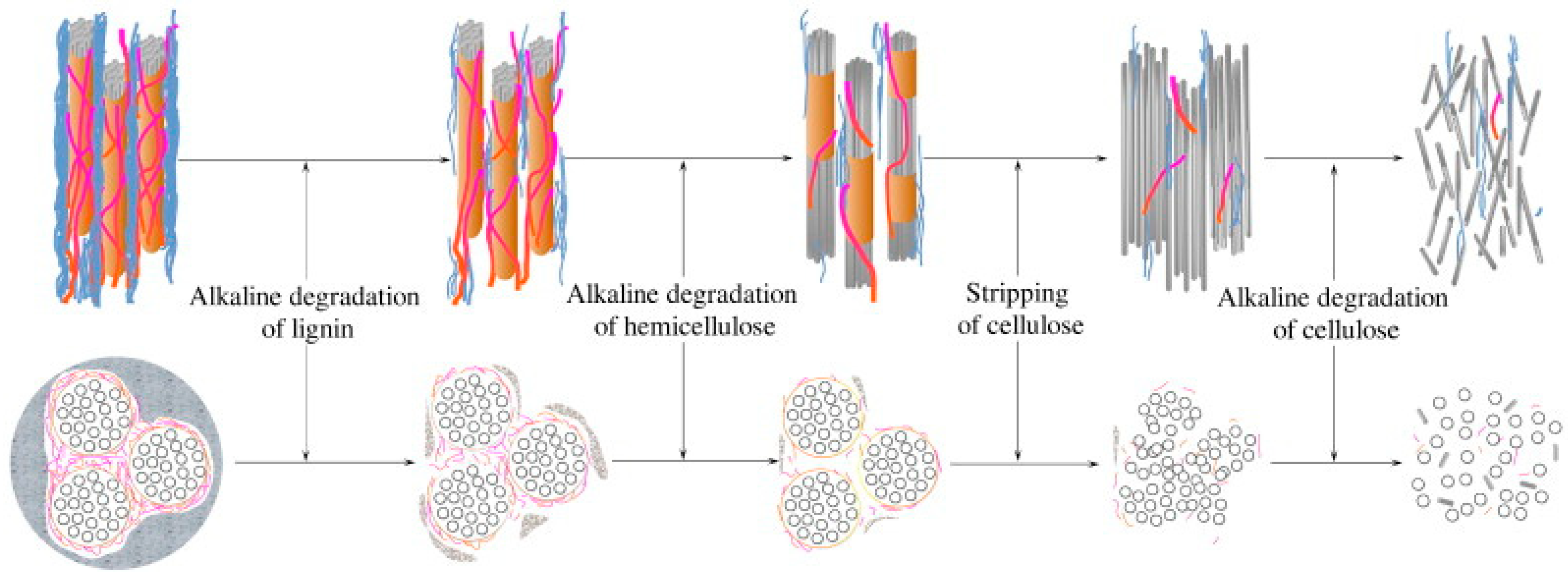

3.1. Degradation Mechanisms of PF in Cement Matrices

3.2. Cement-Based Gel Material Modification

| Modification Materials | Dosages | Fiber | Mechanical Characteristics | Durability | Ref. |

|---|---|---|---|---|---|

| FA and waste glass (WGs) | 15% FA replacement of cement; 14%, 15%, 16%, 17%, 18%, 19% and 20% WG replacement of sand | Coconut | 16% WG, compressive strength: 47.2 MPa, flexural strength: 6.2 MPa | Water absorption: 2.25, 14% WGs Penetration height: 58 mm, 20% WGs | [47] |

| Metakaolin | 15% and 30% replacement of cement | Flax | 15%, compressive strength: 35.4 MPa 15%, flexural strength: 6.5 MPa | 15%, pH: 12.26; 30%, pH: 12.20 | [100] |

| Ground-granulated blast furnace slag (GGBS) | 30% and 60% replacement of cement | Flax | 30%, compressive strength: 28.4 MPa; 30%, flexural strength: 5.6 MPa | 30%, pH: 12.26; 60%, pH: 12.17 | [100] |

| Calcium sulfa-aluminate cement (CŠA) | 100% replacement of cement | Flax | Compressive strength: 25.8 MPa Flexural strength: 5.6 MPa | pH: 10.32 | [100] |

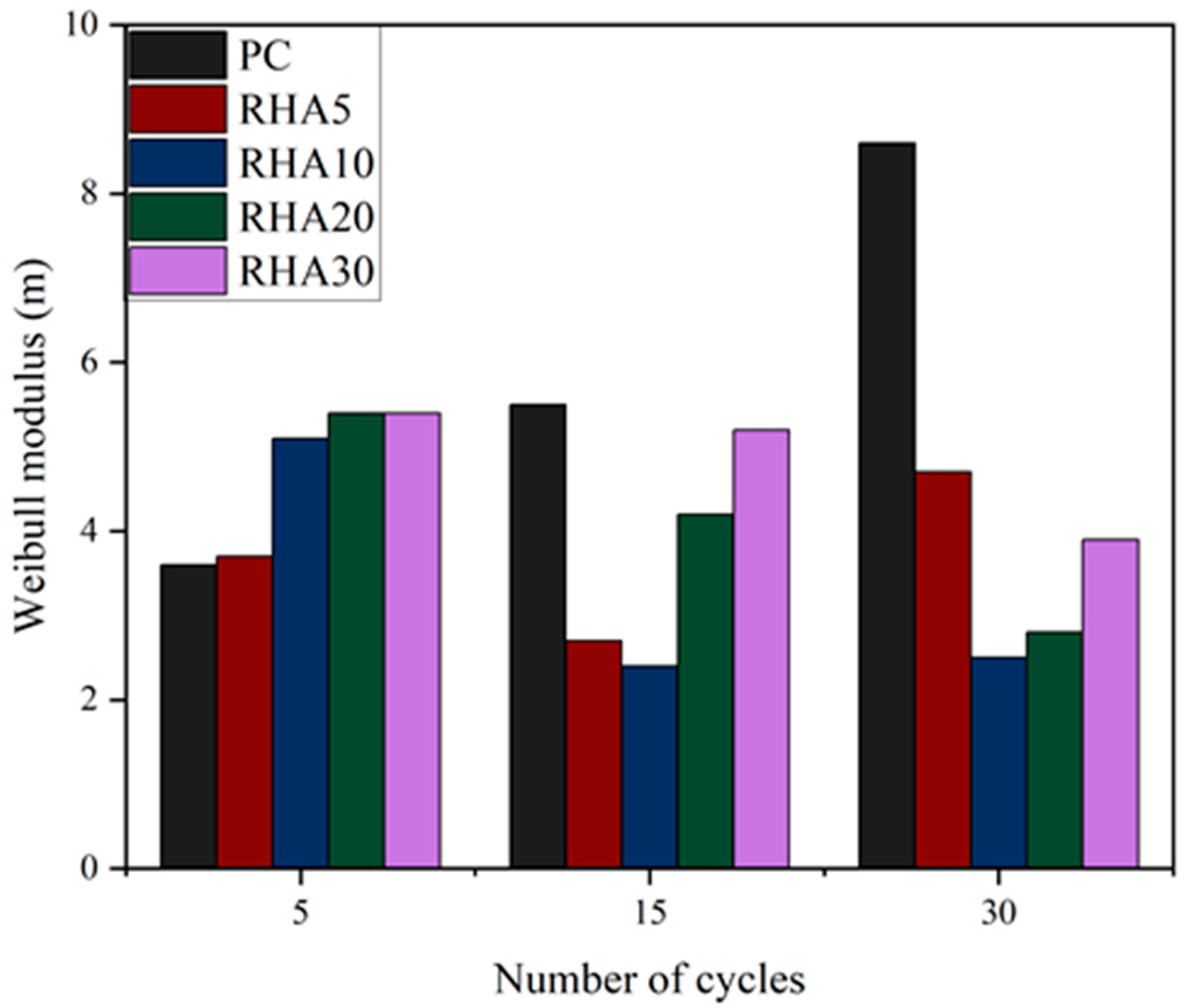

| Rice husk ash | 30% equal weight replacement cement | Sisal | - | Ultimate tensile strength: 384% ↑ (after 30 wet–dry cycles) | [101] |

| SF | 5%, 10%, 15% and 20% replacement of cement | Coconut | Compressive strength: 25% ↑ Compressive pre-crack energy absorption: 71% ↑ Flexural strength: 34% ↑ Flexural post-crack energy absorption: 105% ↑ | - | [103] |

| Alkali-activated material | 100% replacement of cement | Wheat straw | Flexural strength: 18% ↑ | Permeability: 12% ↓ | [104] |

3.3. Fiber Modification

3.3.1. Chemical Modification of PF

Alkali Treatment

Acetylation Treatment

Na2CO3 Treatment

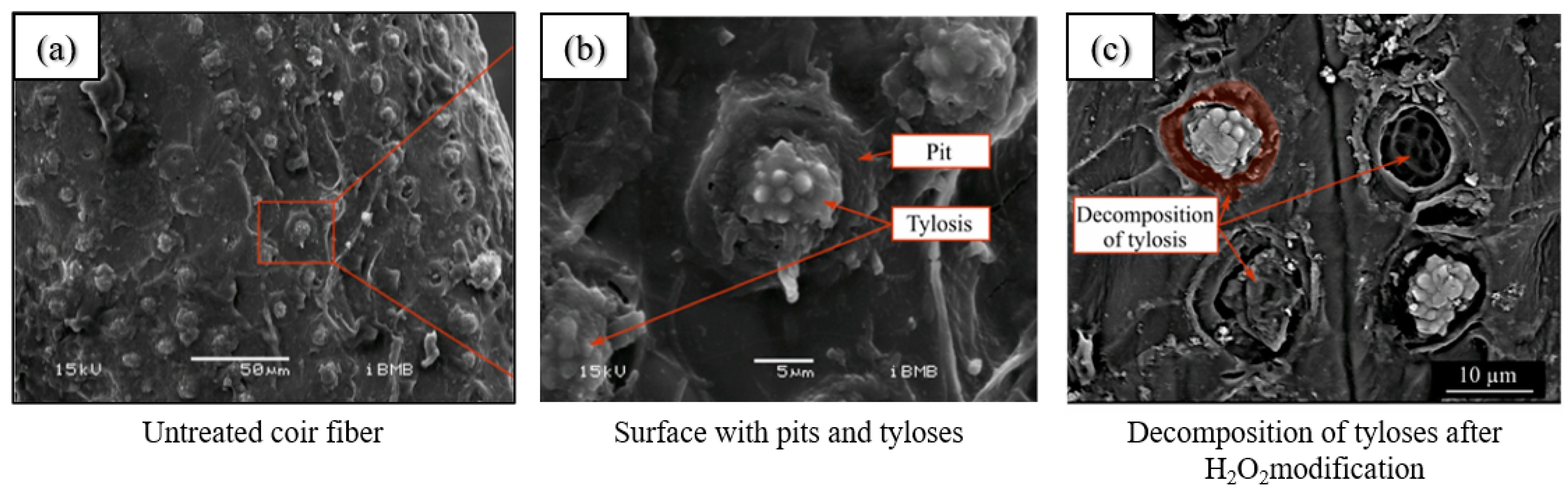

Oxide Treatment

3.3.2. Physical Modification of Plant Fiber

Thermal Treatment

3.3.3. Hybridization Methods for PF

4. Mechanical Properties of PFRCCs

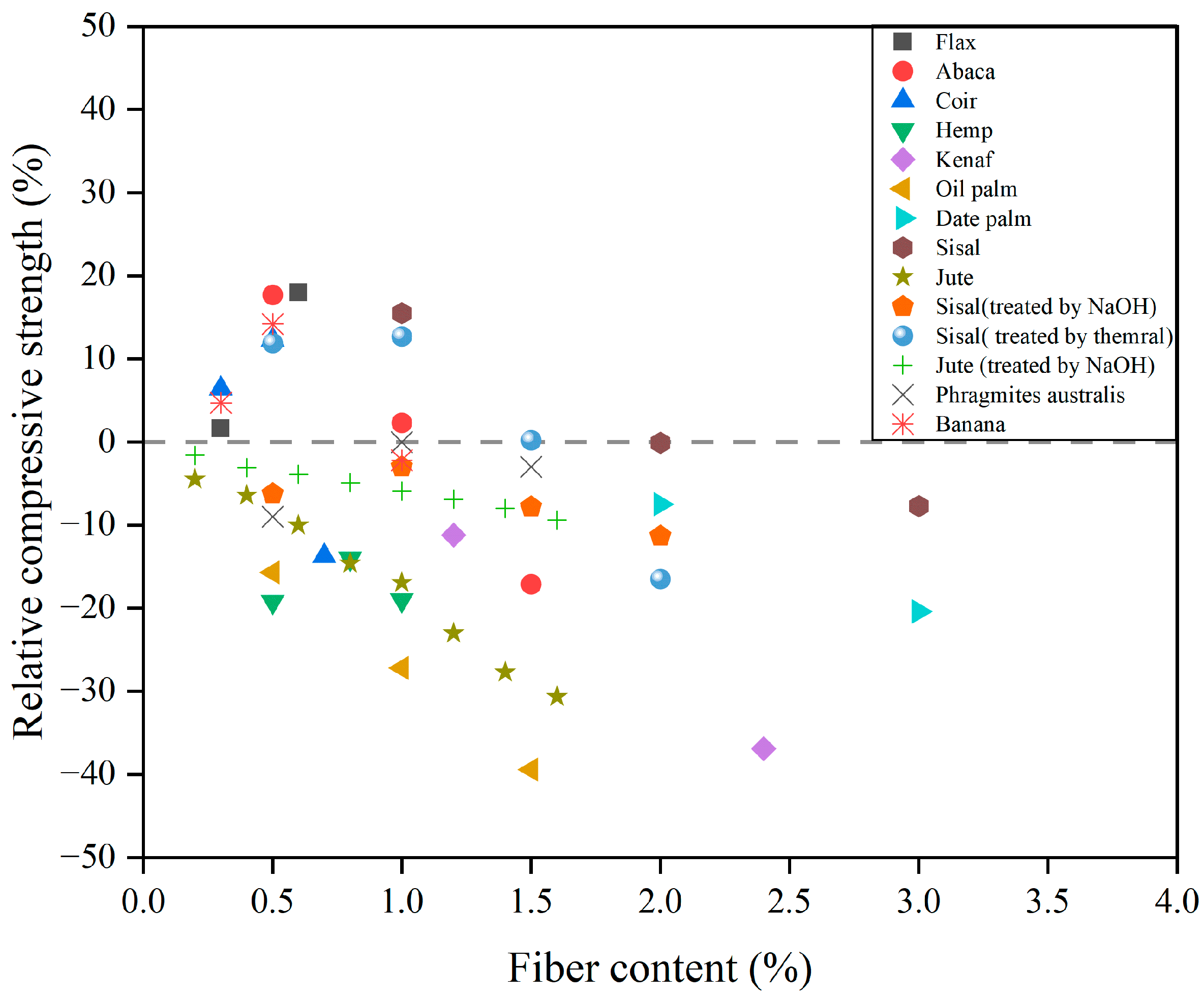

4.1. Compressive Behavior of PFRCCs

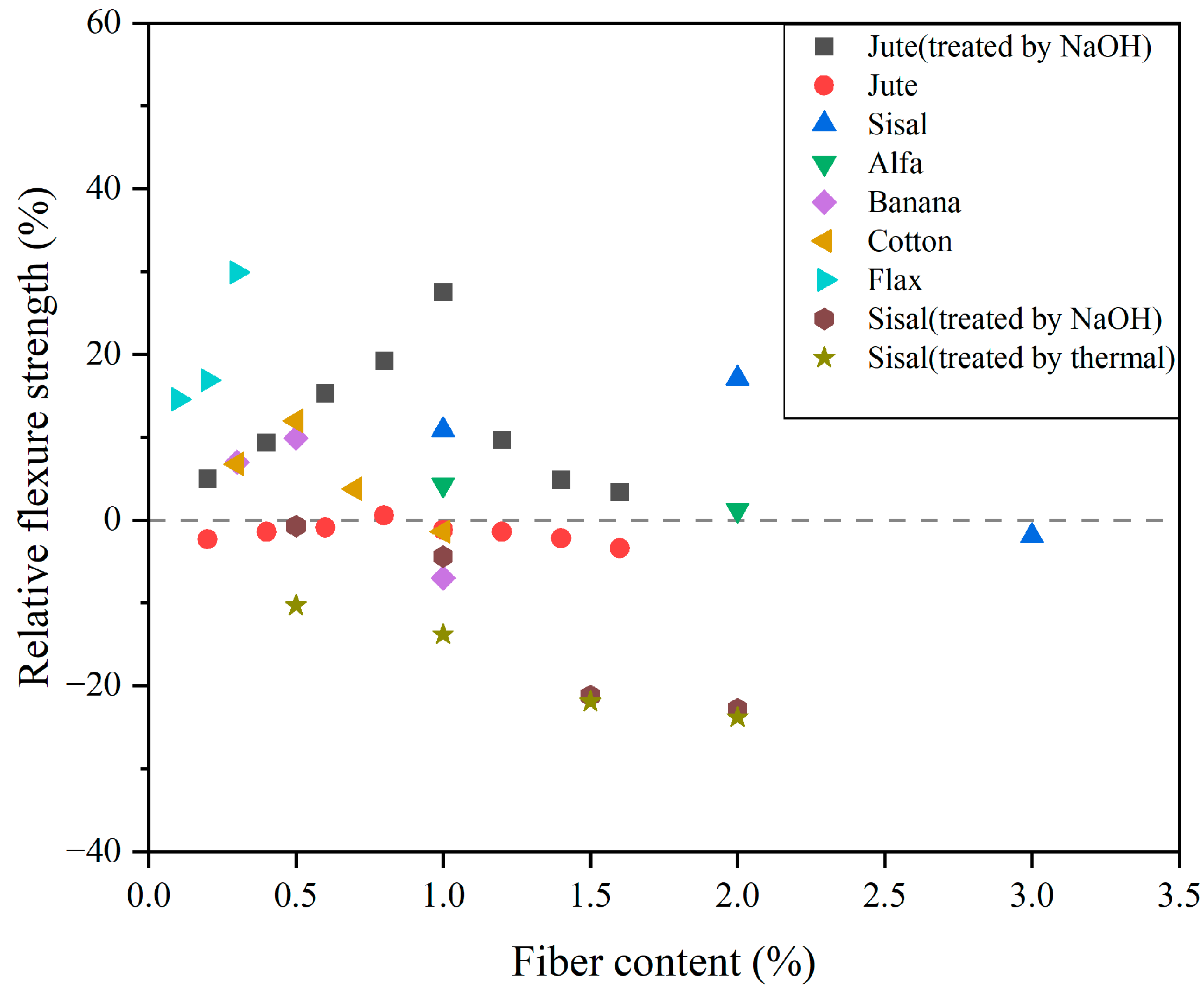

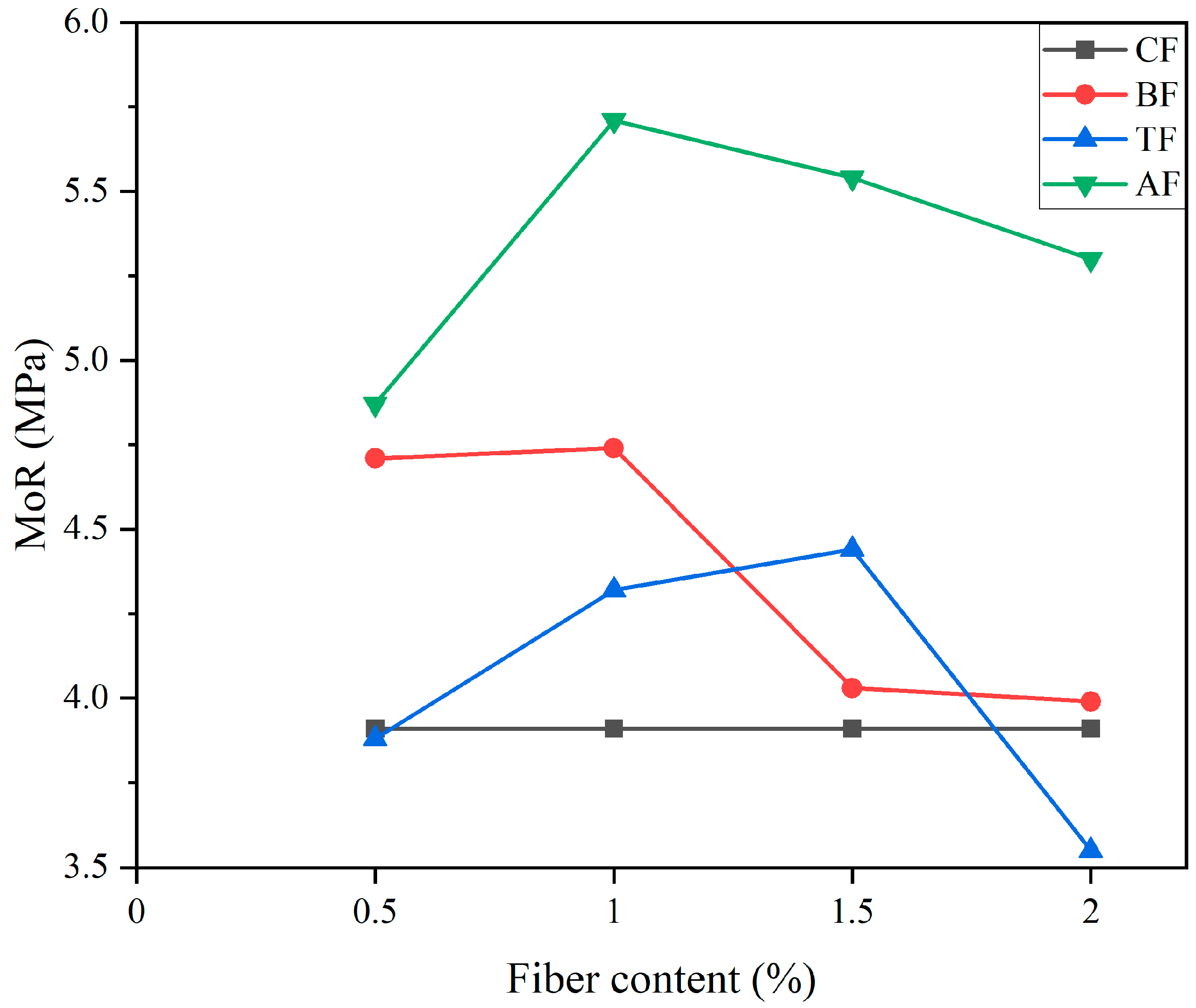

4.2. Flexural Behavior of PFRCCs

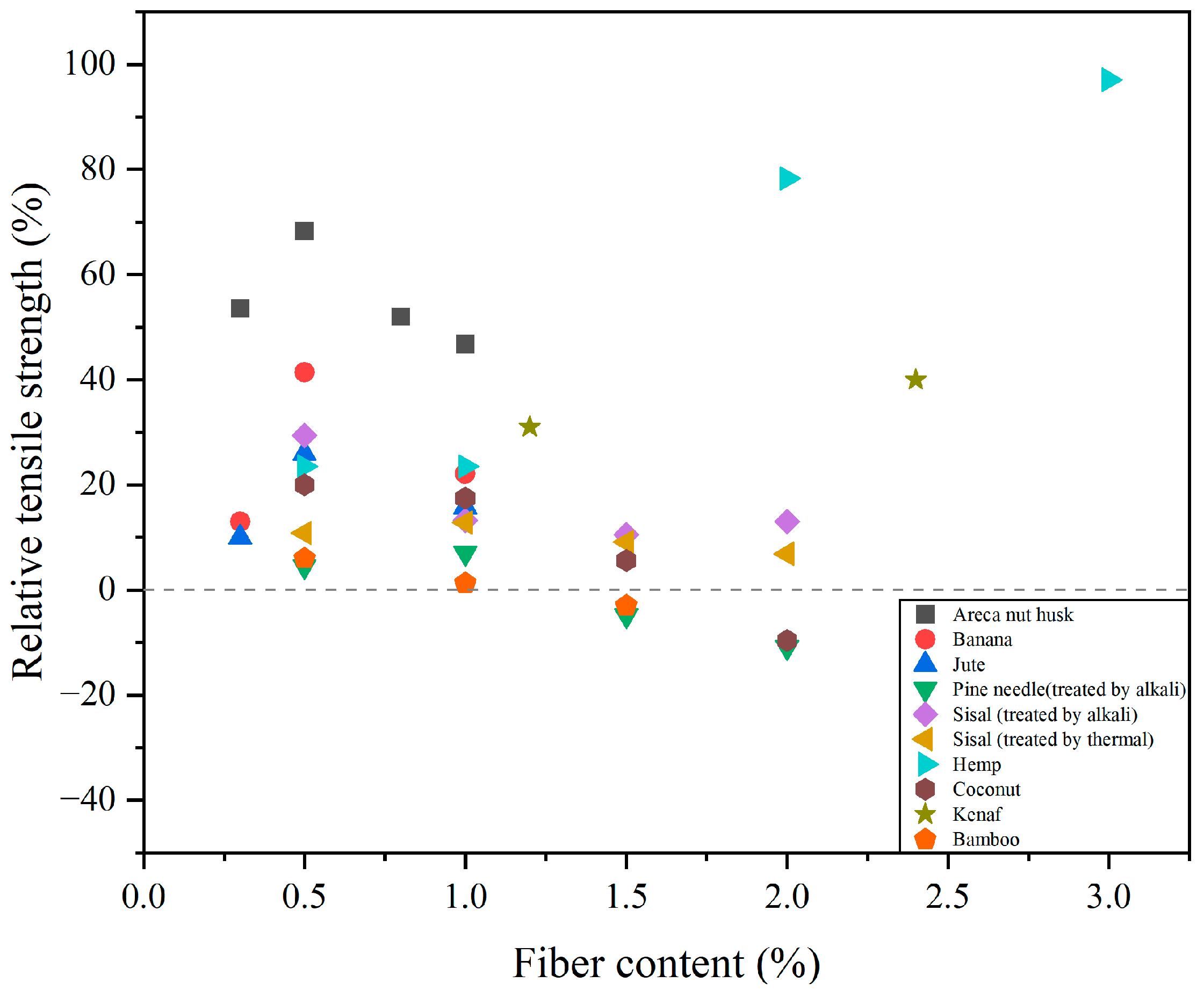

4.3. Tensile Behavior of PFRCCs

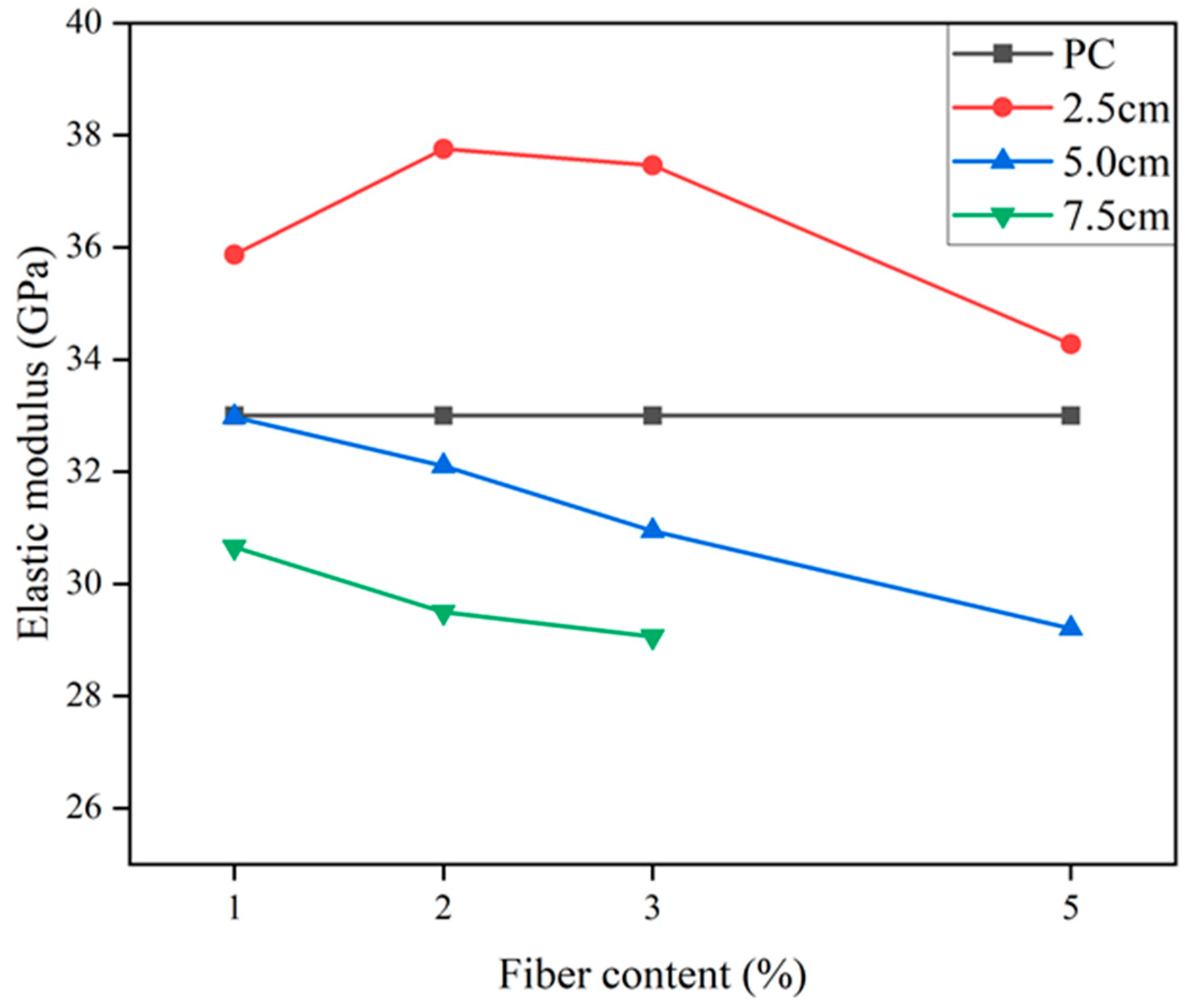

4.4. Elasticity Moduli of PFRCCs

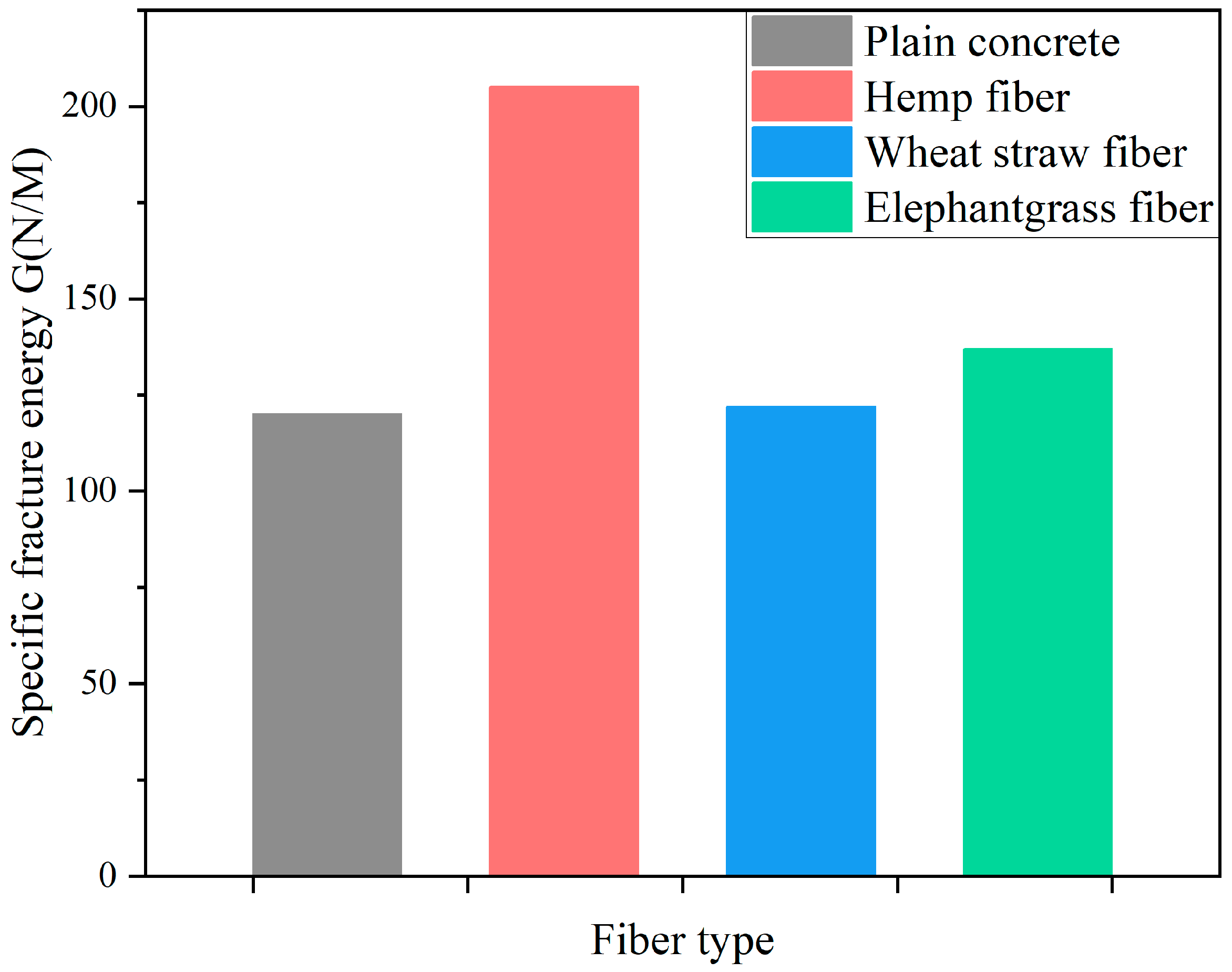

4.5. Fracture Behavior of PFRCCs

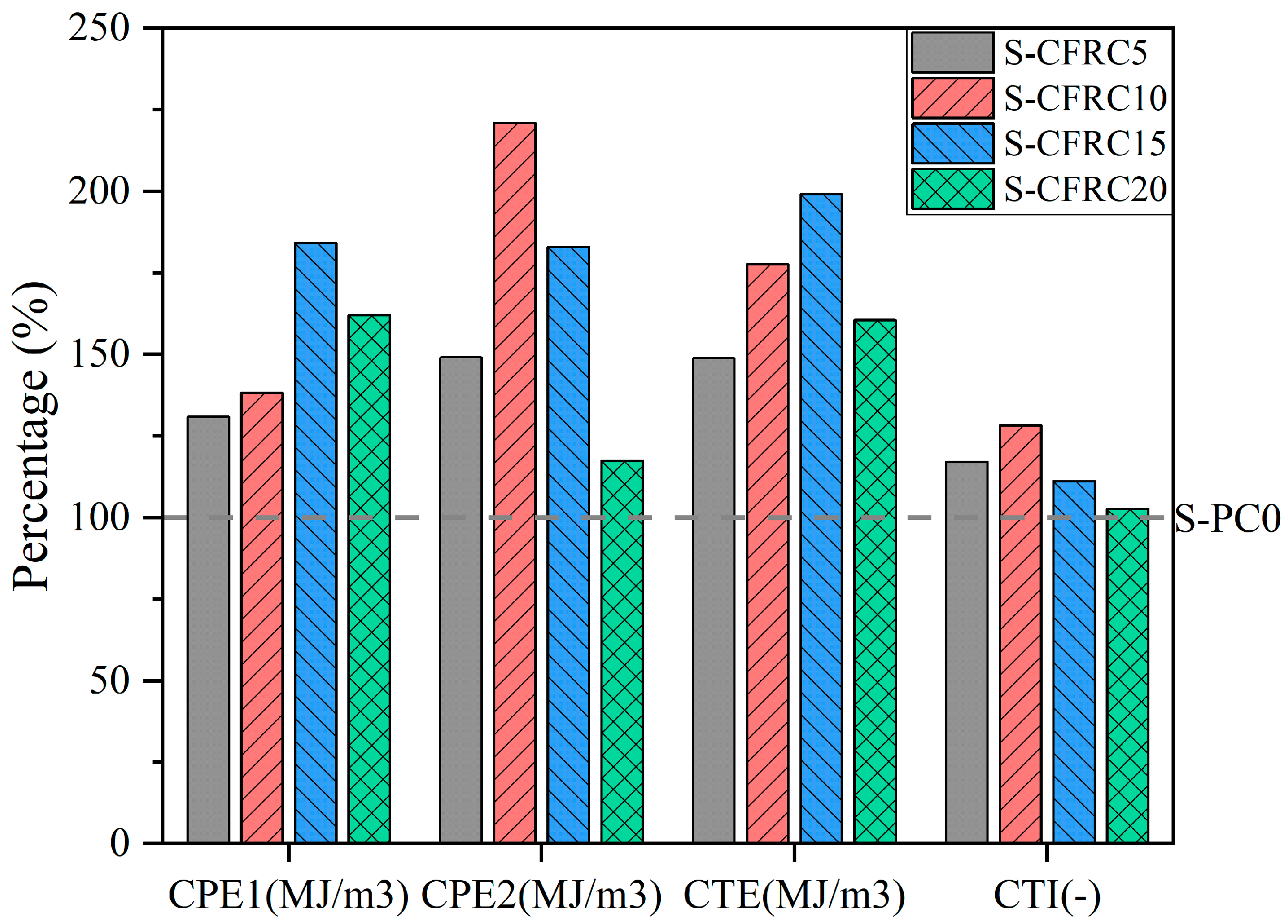

4.6. Dynamic Mechanical Properties of PFRCCs

4.7. Impact Factors of Plant Fiber in PFRCCs

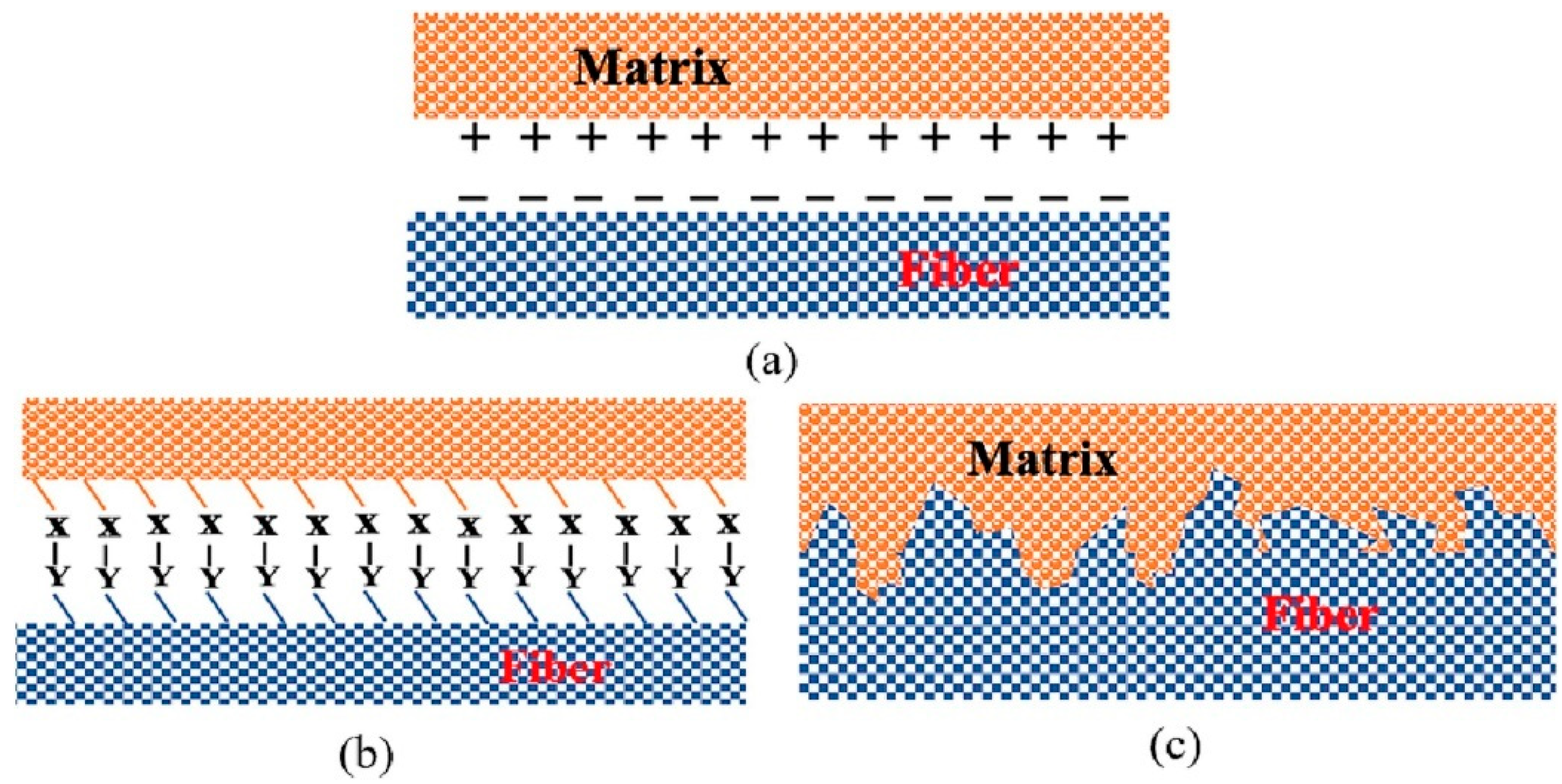

5. Interfacial Bonding Properties of PFRCCs

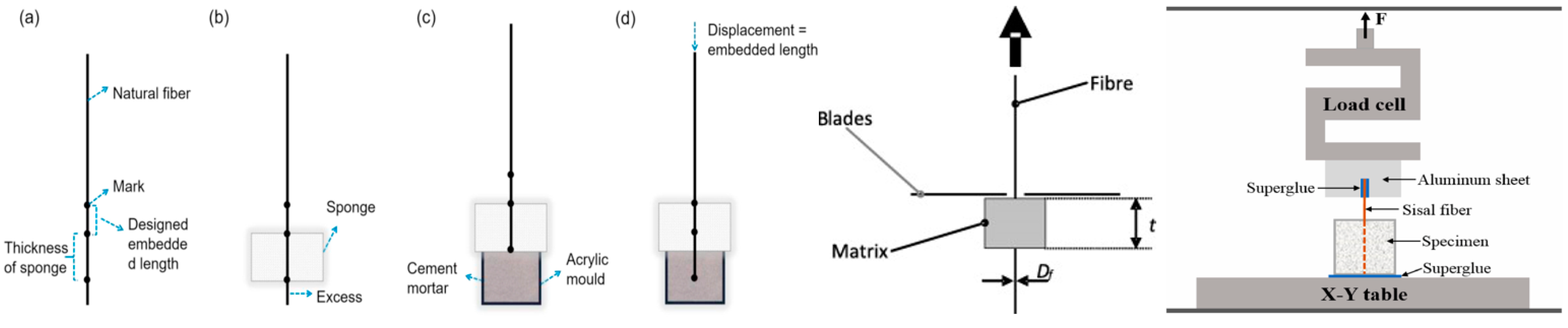

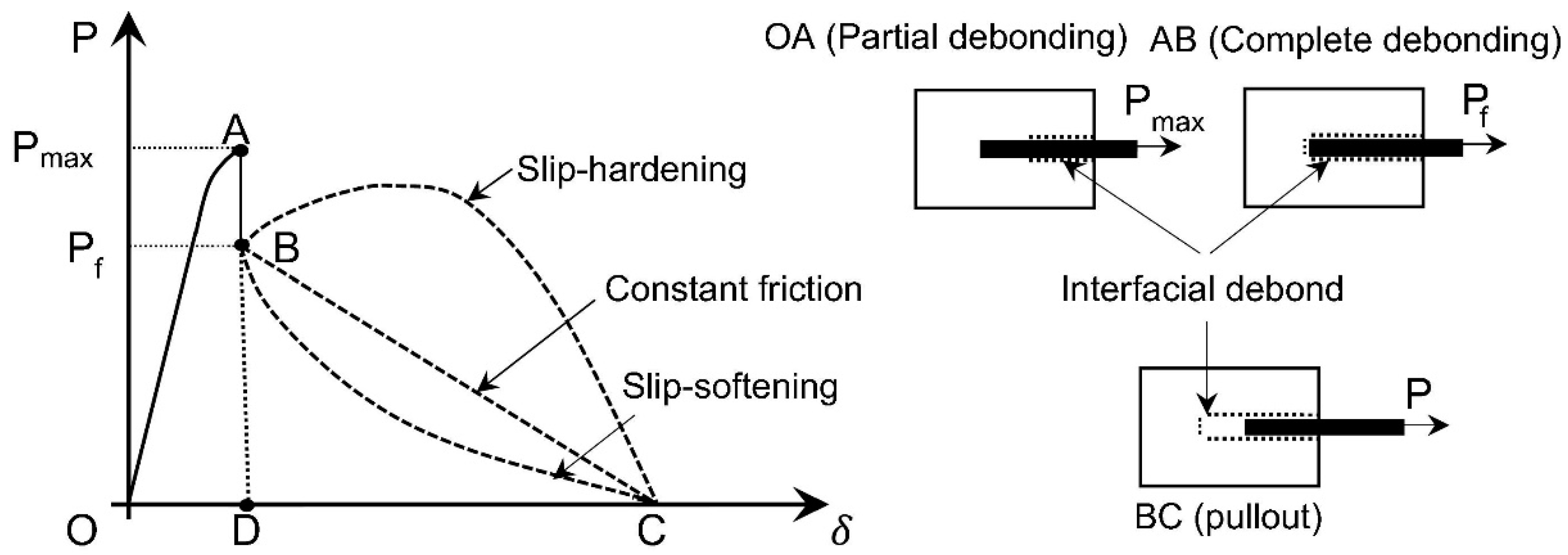

5.1. Measurement of Interface Bonding Parameters

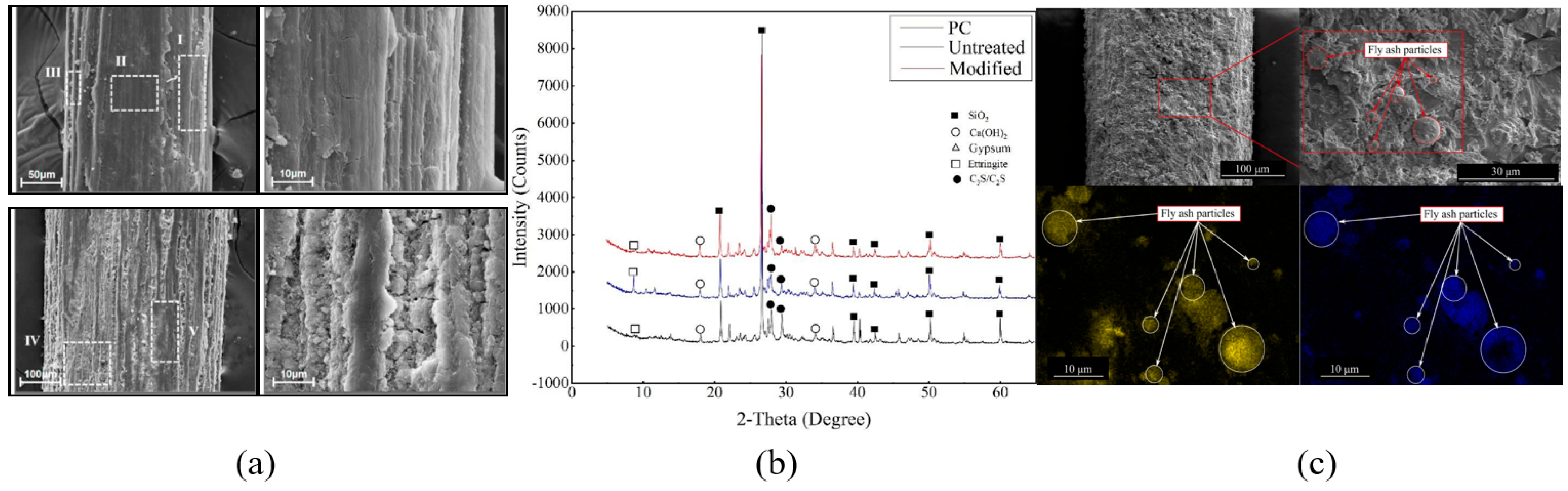

5.2. Interface Microstructure Test

5.3. Theoretical Model of Pull-Out Behavior

6. Conclusions

- (1)

- The four chemical constituents of PFs are cellulose, hemicellulose, lignin and pectin. While the hierarchical structure of PFs (cellulose, hemicellulose, lignin and pectin) provides intrinsic mechanical advantages, their hygroscopicity and alkaline degradation remain unresolved contradictions in cement matrices.

- (2)

- Modification methods include the modification of matrices and PFs. The alkalinity of a matrix can be effectively decreased by substituting different cement-based gel materials for cement, either whole or partially. However, the review uncovered a critical oversight: current studies predominantly focus on short-term mechanical gains while neglecting carbonation-accelerated fiber mineralization.

- (3)

- The appropriate amount of PF encourages hydration by removing water from the cavities and enhances mechanical properties and fracture behavior through bridging effects. It is worth noting that the compressive strength of CFRCCs is decreased by most kinds of plant fiber. It is essential to show how the ITZ affects the mechanical properties of PFRCCs.

- (4)

- Life cycle analyses indicate that current PFRCC formulations achieve only 12–18% embodied carbon reduction compared to steel fiber-reinforced cementitious composites, underscoring the urgency of developing low-pH cement-based gel composites compatible with plant fibers.

Funding

Data Availability Statement

Conflicts of Interest

References

- Salas, D.A.; Ramirez, A.D.; Rodríguez, C.R.; Petroche, D.M.; Boero, A.J.; Duque-Rivera, J. Environmental impacts, life cycle assessment and potential improvement measures for cement production: A literature review. J. Clean. Prod. 2016, 113, 114–122. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Kumar, M.S. An overview of environmental sustainability in cement and steel production. J. Clean. Prod. 2019, 231, 856–871. [Google Scholar] [CrossRef]

- Chen, W.; Hong, J.; Xu, C. Pollutants generated by cement production in China, their impacts, and the potential for environmental improvement. J. Clean. Prod. 2015, 103, 61–69. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Beaudoin, J.J.; Feldman, R.F.; Tumidajski, P.J. Pore structure of hardened portland cement pastes and its influence on properties. Adv. Cem. Based Mater. 1994, 1, 224–236. [Google Scholar] [CrossRef]

- Tian, G.; Deng, H.; Xiao, Y. Correlation analysis between microscopic pore parameters and macroscopic mechanical properties of rock-like materials from the perspective of wa-ter-cement ratio and sand-cement ratio. Materials 2022, 15, 2632. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Zhang, P.; Zheng, Y.; Wang, J. Utilization of municipal solid waste incineration fly ash with coal fly ash/metakaolin for geopolymer composites preparation. Constr. Build. Mater. 2023, 403, 133060. [Google Scholar] [CrossRef]

- Kimura, H. Deionization-induced colorless transparency in physical gels formed by clay aqueous dispersions. Appl. Clay Sci. 2024, 249, 107261. [Google Scholar] [CrossRef]

- Caruso, M.R.; Calvino, M.M.; Siler, P.; Cába, L.; Milioto, S.; Lisuzzo, L.; Lazzara, G.; Cavallaro, G. Self-Standing biohybrid xerogels incorporating nanotubular clays for sustainable removal of pollutants. Small 2025, 21, 2405215. [Google Scholar] [CrossRef]

- Ruan, H.; Chen, G.; Zhao, X.; Wang, Y.; Liao, Y.; Peng, H.; Feng, C.-L.; Xie, X.; Smalyukh, I.I. Chirality-enabled liquid crystalline physical gels with high modulus but low driving voltage. ACS Appl. Mater. Interfaces 2018, 10, 43184–43191. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Ravichandran, D.; Prem, P.R.; Kaliyavaradhan, S.K.; Ambily, P.S. Influence of fibers on fresh and hardened properties of Ultra High Performance Concrete (UHPC)—A review. J. Build. Eng. 2022, 57, 104922. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K. Effect of hybrid fibers on fresh, mechanical properties, and autogenous shrinkage of cost effective UHPC. J. Mater. Civ. Eng. 2018, 30, 04018030. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, W.; Yuan, J.; Gao, X.; Wu, Y.; Ni, W.; Feng, J. Multi-scale study on penetration performance of steel fiber reinforced ultra-high performance concrete. Constr. Build. Mater. 2024, 422, 135846. [Google Scholar] [CrossRef]

- Shabakhty, N.; Karimi, H.R.; Bakhtiary, A.Y. Statistical evaluation of fracture and mechanical performance of engineered cementitious composites (ECC), containing different percentages of glass, polypropylene, polyvinyl-alcohol fibers, and fly ash. Constr. Build. Mater. 2024, 417, 135247. [Google Scholar] [CrossRef]

- Zhou, Y.; Zou, S.; Wen, J.; Zhang, Y. Study on the damage behavior and energy dissipation characteristics of basalt fiber concrete using SHPB device. Constr. Build. Mater. 2023, 368, 130413. [Google Scholar] [CrossRef]

- Wang, F.; Xie, W.; Wan, J.; Jiang, Y.; Yu, C.; Luo, X. Experimental investigation on mechanical properties of steel-polypropylene hybrid fiber engineered cementitious composites. Constr. Build. Mater. 2024, 426, 136122. [Google Scholar] [CrossRef]

- Hwang, J.P.; Jung, M.S.; Kim, M.; Ann, K.Y. Corrosion risk of steel fibre in concrete. Constr. Build. Mater. 2015, 101, 239–245. [Google Scholar] [CrossRef]

- Silva, F.d.A.; Filho, R.D.T.; Filho, J.d.A.M.; Fairbairn, E.d.M.R. Physical and mechanical properties of durable sisal fiber–cement composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar] [CrossRef]

- Tran, N.P.; Gunasekara, C.; Law, D.W.; Houshyar, S.; Setunge, S. Microstructural characterisation of cementitious composite incorporating polymeric fibre: A comprehensive review. Constr. Build. Mater. 2022, 335, 127497. [Google Scholar] [CrossRef]

- Yang, W.; Liu, L.; Wu, W.; Zhang, K.; Xiong, X.; Li, C.; Huang, Y.; Zhang, X.; Zhou, H. A review of the mechanical properties and durability of basalt fiber recycled concrete. Constr. Build. Mater. 2024, 412, 134882. [Google Scholar] [CrossRef]

- Silva, R.M.d.C.; Zhao, J.; Liebscher, M.; Curosu, I.; Silva, F.d.A.; Mechtcherine, V. Bond behavior of polymer and mineral-impregnated carbon fiber yarns towards concrete matrices at elevated temperature levels. Cem. Concr. Compos. 2022, 133, 104685. [Google Scholar] [CrossRef]

- Zheng, D.; Song, W.; Fu, J.; Xue, G.; Li, J.; Cao, S. Research on mechanical characteristics, fractal dimension and internal structure of fiber reinforced concrete under uniaxial compression. Constr. Build. Mater. 2020, 258, 120351. [Google Scholar] [CrossRef]

- Sellami, A.; Merzoud, M.; Amziane, S. Improvement of mechanical properties of green concrete by treatment of the vegetals fibers. Constr. Build. Mater. 2013, 47, 1117–1124. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Zhao, L.; Ding, Y.; Li, S.; Song, Y.; Zhang, Y. The synergistic effect of surface coating SCA/SiO2 NPs on the degradation resistance and interfacial bond of sisal fibers in cementitious composites. Cem. Concr. Compos. 2024, 210, 105671. [Google Scholar] [CrossRef]

- Li, Z.; Guo, T.; Chen, Y.; Yang, W.; Wang, J.; Jin, L. Preparation and properties of pretreated jute fiber cement-based composites. Ind. Crops Prod. 2024, 210, 118090. [Google Scholar] [CrossRef]

- Çomak, B.; Bideci, A.; Salli Bideci, Ö. Effects of hemp fibers on characteristics of cement based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar] [CrossRef]

- Page, J.; Khadraoui, F.; Boutouil, M.; Gomina, M. Multi-physical properties of a structural concrete incorporating short flax fibers. Constr. Build. Mater. 2017, 140, 344–353. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Kasal, B. Long-term pull-out behavior of coir fiber from cementitious material with statistical and microstructural analysis. Constr. Build. Mater. 2023, 385, 131533. [Google Scholar] [CrossRef]

- Sekar, A.; Kandasamy, G. Optimization of coconut fiber in coconut shell concrete and its mechanical and bond properties. Materials 2018, 11, 1726. [Google Scholar] [CrossRef]

- Correia, V.D.C.; Santos, S.F.; Mármol, G.; Curvelo, A.A.D.S.; Savastano, H. Potential of bamboo organosolv pulp as a reinforcing element in fiber-cement materials. Constr. Build. Mater. 2014, 72, 65–71. [Google Scholar] [CrossRef]

- Raut, A.N.; Gomez, C.P. Thermal and mechanical performance of oil palm fiber reinforced mortar utilizing palm oil fly ash as a complementary binder. Constr. Build. Mater. 2016, 126, 476–483. [Google Scholar] [CrossRef]

- Wang, H.; Feng, G.; Qi, T.; Gao, X.; Wang, C.; Wang, L.; Zhang, Z. Influence of the use of corn straw fibers to connect the interfacial transition zone with the mechanical properties of cemented coal gangue backfill. Constr. Build. Mater. 2023, 367, 130334. [Google Scholar] [CrossRef]

- dos Santos, A.C.; Cardoso, F.G.; da Silva, R.J.; Gorulho, H.d.F.; Panzera, T.H. Modification of short sugarcane bagasse fibres for application in cementitious composites: A statistical approach to mechanical and physical properties. Constr. Build. Mater. 2022, 352, 129072. [Google Scholar] [CrossRef]

- Ige, O.E.; Olanrewaju, O.A.; Duffy, K.J.; Obiora, C. A review of the effectiveness of life cycle assessment for gauging environmental impacts from cement production. J. Clean. Prod. 2021, 324, 129213. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Synthesis and mechanical properties of cotton fabric reinforced geopolymer composites. Compos. Part B Eng. 2014, 60, 36–42. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Nwankwo, C.O.; Mahachi, J.; Olukanni, D.O.; Musonda, I. Natural fibres and biopolymers in FRP composites for strengthening concrete structures: A mixed review. Constr. Build. Mater. 2023, 363, 129661. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Huei Lee, Y.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-reinforced foamed concretes: A review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef] [PubMed]

- Long, W.; Wang, Y. Effect of pine needle fibre reinforcement on the mechanical properties of concrete. Constr. Build. Mater. 2021, 278, 122333. [Google Scholar] [CrossRef]

- Galicia-Aldama, E.; Mayorga, M.; Arteaga-Arcos, J.C.; Romero-Salazar, L. Rheological behaviour of cement paste added with natural fibres. Constr. Build. Mater. 2019, 198, 148–157. [Google Scholar] [CrossRef]

- Alomayri, T.; Ali, B. Effect of plant fiber type and content on the strength and durability performance of high-strength concrete. Constr. Build. Mater. 2023, 394, 132166. [Google Scholar] [CrossRef]

- Lim, J.L.G.; Raman, S.N.; Lai, F.-C.; Zain, M.F.M.; Hamid, R. Synthesis of nano cementitious additives from agricultural wastes for the production of sustainable concrete. J. Clean. Prod. 2018, 171, 1150–1160. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- Aslam, F.; Zaid, O.; Althoey, F.; Alyami, S.H.; Qaidi, S.M.A.; de Prado Gil, J.; Martínez-García, R. Evaluating the influence of fly ash and waste glass on the characteristics of coconut fibers reinforced concrete. Struct. Concr. 2023, 24, 2440–2459. [Google Scholar] [CrossRef]

- Ren, G.; Wang, J.; Wen, X.; Gao, X. Using sol-gel deposition of nanosilica to enhance interface bonding between sisal fiber and ultra-high performance concrete. Cem. Concr. Compos. 2022, 133, 104705. [Google Scholar] [CrossRef]

- Ye, H.Z.; Zhang, Y.; Yu, Z.M.; Mu, J. Effects of cellulose, hemicellulose, and lignin on the morphology and mechanical properties of metakaolin-based geopolymer. Constr. Build. Mater. 2018, 173, 10–16. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Wu, H.; Shen, A.; Cheng, Q.; Cai, Y.; Ren, G.; Pan, H.; Deng, S. A review of recent developments in application of plant fibers as reinforcements in concrete. J. Clean. Prod. 2023, 419, 138265. [Google Scholar] [CrossRef]

- Yan, L.B.; Chouw, N.; Jayaraman, K. Flax fibre and its composites-A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Lucka-Gabor, M.; Gutowski, V.S. The effects of acetylation on properties of flax fibre and its polypropylene composites. Express Polym. Lett. 2008, 2, 413–422. [Google Scholar] [CrossRef]

- Amel, B.A.; Paridah, M.T.; Sudin, R.; Anwar, U.M.K.; Hussein, A.S. Effect of fiber extraction methods on some properties of kenaf bast fiber. Ind. Crops Prod. 2013, 46, 117–123. [Google Scholar] [CrossRef]

- Ren, W.; Zhang, D.; Zhou, Y.; Wang, H.; Xia, L.; Tan, C.; Guo, F.; Zhang, X.; Yang, R.; Yu, Y. Lignin’s complex role in lignocellulosic biomass Recalcitrance: A case study on bamboo. Chem. Eng. J. 2024, 490, 151422. [Google Scholar] [CrossRef]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical composition of natural fibers and its influence on their mechanical properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Charai, M.; Mghazli, M.O.; Channouf, S.; El hammouti, A.; Jagadesh, P.; Moga, L.; Mezrhab, A. Lightweight waste-based gypsum composites for building temperature and moisture control using coal fly ash and plant fibers. Constr. Build. Mater. 2023, 393, 132092. [Google Scholar] [CrossRef]

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural fiber reinforced composites. Polym. Rev. 2012, 52, 259–320. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, Z.; Jiang, M.; Xu, X.; Wang, Z.; Hui, D. Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Compos. Part B Eng. 2015, 78, 153–161. [Google Scholar] [CrossRef]

- Dicker, M.P.M.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Jo, B.W.; Chakraborty, S.; Kim, H. Efficacy of alkali-treated jute as fibre reinforcement in enhancing the mechanical properties of cement mortar. Mater. Struct. 2016, 49, 1093–1104. [Google Scholar] [CrossRef]

- Elsaid, A.; Dawood, M.; Seracino, R.; Bobko, C. Mechanical properties of kenaf fiber reinforced concrete. Constr. Build. Mater. 2011, 25, 1991–2001. [Google Scholar] [CrossRef]

- Ren, G.; Yao, B.; Huang, H.; Gao, X. Influence of sisal fibers on the mechanical performance of ultra-high performance concretes. Constr. Build. Mater. 2021, 286, 122958. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Ren, G.; Chen, T.; Gao, X.; Su, A. Insights into thermal stability and interface bond performance of sisal fiber in ultra-high performance concrete under different curing conditions. Cem. Concr. Compos. 2023, 137, 104910. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Antico, F.C.; Burbano-Garcia, C.; Concha-Riedel, J.; Norambuena-Contreras, J.; Concha, J.; Saavedra Flores, E.I. Experimental evaluation of adobe mixtures reinforced with jute fibers. Constr. Build. Mater. 2021, 276, 122127. [Google Scholar] [CrossRef]

- da Costa Santos, A.C.; Archbold, P. Suitability of surface-treated flax and hemp fibers for concrete reinforcement. Fibers 2022, 10, 101. [Google Scholar] [CrossRef]

- Tang, W.; Monaghan, R.; Sajjad, U. Investigation of physical and mechanical properties of cement mortar incorporating waste cotton fibres. Sustainability 2023, 15, 8779. [Google Scholar] [CrossRef]

- Mugume, R.B.; Karubanga, A.; Kyakula, M. Impact of addition of banana fibres at varying fibre length and content on mechanical and microstructural properties of concrete. Adv. Civ. Eng. 2021, 2021, 9422352. [Google Scholar] [CrossRef]

- Xia, C.; Wu, C.; Liu, K.; Jiang, K. Study on the durability of bamboo fiber asphalt mixture. Materials 2021, 14, 1667. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.; An, P.; Cui, S.; Sun, S.; Zhang, J.; Tuo, T. Effect of modification methods of wheat straw fibers on water absorbency and mechanical properties of wheat straw fiber cement-based composites. Adv. Mater. Sci. Eng. 2020, 2020, 5031025. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Reis, J.M.L. Sisal fiber polymer mortar composites: Introductory fracture mechanics approach. Constr. Build. Mater. 2012, 37, 177–180. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.W.; Ye, L. Sisal fibre and its composites: A review of recent developments. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Zhou, L.M. Nanoscale evaluation of multi-layer interfacial mechanical properties of sisal fiber reinforced composites by nanoindentation technique. Compos. Sci. Technol. 2017, 152, 211–221. [Google Scholar] [CrossRef]

- Belaadi, A.; Bezazi, A.; Bourchak, M.; Scarpa, F. Tensile static and fatigue behaviour of sisal fibres. Mater. Des. 2013, 46, 76–83. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Du, G.; Wu, Z.; Meng, Y. Variation in physical and mechanical properties of hemp stalk fibers along height of stem. Ind. Crops Prod. 2013, 42, 344–348. [Google Scholar] [CrossRef]

- Shahzad, A. A study in physical and mechanical properties of hemp fibres. Adv. Mater. Sci. Eng. 2013, 2013, 325085. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- da Costa Correia, V.; Santos, S.F.; Soares Teixeira, R.; Savastano Junior, H. Nanofibrillated cellulose and cellulosic pulp for reinforcement of the extruded cement based materials. Constr. Build. Mater. 2018, 160, 376–384. [Google Scholar] [CrossRef]

- Reixach, R.; Claramunt, J.; Chamorro, M.À.; Llorens, J.; Pareta, M.M.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M. On the path to a new generation of cement-based composites through the use of lignocellulosic micro/nanofibers. Materials 2019, 12, 1584. [Google Scholar] [CrossRef] [PubMed]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef] [PubMed]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Mohr, B.J.; Biernacki, J.J.; Kurtis, K.E. Microstructural and chemical effects of wet/dry cycling on pulp fiber-cement composites. Cem. Concr. Res. 2006, 36, 1240–1251. [Google Scholar] [CrossRef]

- Dinakar, P.; Babu, K.G.; Santhanam, M. Corrosion behaviour of blended cements in low and medium strength concretes. Cem. Concr. Compos. 2007, 29, 136–145. [Google Scholar] [CrossRef]

- Castoldi, R.D.; de Souza, L.M.S.; Silva, F.D. Comparative study on the mechanical behavior and durability of polypropylene and sisal fiber reinforced concretes. Constr. Build. Mater. 2019, 211, 617–628. [Google Scholar] [CrossRef]

- Castoldi, R.d.S.; de Souza, L.M.S.; Souto, F.; Liebscher, M.; Mechtcherine, V.; de Andrade Silva, F. Effect of alkali treatment on physical-chemical properties of sisal fibers and adhesion towards cement-based matrices. Constr. Build. Mater. 2022, 345, 128363. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Improving degradation resistance of sisal fiber in concrete through fiber surface treatment. Appl. Surf. Sci. 2014, 289, 511–523. [Google Scholar] [CrossRef]

- Booya, E.; Gorospe, K.; Ghaednia, H.; Das, S. Durability properties of engineered pulp fibre reinforced concretes made with and without supplementary cementitious materials. Compos. Part B Eng. 2019, 172, 376–386. [Google Scholar] [CrossRef]

- Lv, C.; Liu, J. Alkaline degradation of plant fiber reinforcements in geopolymer: A Review. Molecules 2023, 28, 1868. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Ismail, H. Effect of acetylation and coupling agent treatments upon biological degradation of plant fibre reinforced polyester composites. Polym. Test. 2000, 20, 65–75. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; Silva, F.d.A.; Fairbairn, E.M.R.; Filho, J.d.A.M. Durability of compression molded sisal fiber reinforced mortar laminates. Constr. Build. Mater. 2009, 23, 2409–2420. [Google Scholar] [CrossRef]

- Jamshaid, H.; Ali, H.; Mishra, R.K.; Nazari, S.; Chandan, V. Durability and accelerated ageing of natural fibers in concrete as a sustainable construction material. Materials 2023, 16, 6905. [Google Scholar] [CrossRef]

- Rangrazian, M.; Madandoust, R.; Mahjoub, R.; Raftari, M. Experimental investigations on the engineering properties of pozzolanic concrete reinforced with fibers and the reduction of CO2 emissions: A case study on local mineral pozzolan. Mater. Today Commun. 2023, 34, 105129. [Google Scholar] [CrossRef]

- Le, H.T.; Ludwig, H.M. Effect of rice husk ash and other mineral admixtures on properties of self-compacting high performance concrete. Mater. Des. 2016, 89, 156–166. [Google Scholar] [CrossRef]

- Poletanovic, B.; Dragas, J.; Ignjatovic, I.; Komljenovic, M.; Merta, I. Physical and mechanical properties of hemp fibre reinforced alkali-activated fly ash and fly ash/slag mortars. Constr. Build. Mater. 2020, 259, 119677. [Google Scholar] [CrossRef]

- Page, J.; Khadraoui, F.; Gomina, M.; Boutouil, M. Enhancement of the long-term mechanical performance of flax fiber-reinforced cementitious composites by using alternative binders. J. Build. Eng. 2021, 40, 102323. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Utilization of rice husk ash in green natural fiber-reinforced cement composites: Mitigating degradation of sisal fiber. Cem. Concr. Res. 2016, 81, 94–111. [Google Scholar] [CrossRef]

- Tsegaye Beyene, M.; Kingne, F.; Tsangouri, E.; Kadi, M.E.; Adugna Demissie, T.; Rahier, H.; Van Hemelrijck, D.; Tysmans, T. Effect of matrix modification on the durability of cementitious composites reinforced with aligned Ensete fibre. Constr. Build. Mater. 2023, 363, 129706. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 2020, 244, 118382. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Sikora, P.; Mijowska, E.; Kukułka, W.; Stephan, D. Boosting portland cement-free composite performance via alkali-activation and reinforcement with pre-treated functionalised wheat straw. Ind. Crops Prod. 2022, 178, 114648. [Google Scholar] [CrossRef]

- Beckermann, G.W.; Pickering, K.L. Engineering and evaluation of hemp fibre reinforced polypropylene composites: Fibre treatment and matrix modification. Compos. Part A Appl. Sci. Manuf. 2008, 39, 979–988. [Google Scholar] [CrossRef]

- Antwi-Afari, B.A.; Mutuku, R.; Kabubo, C.; Mwero, J.; Mengo, W.K. Influence of fiber treatment methods on the mechanical properties of high strength concrete reinforced with sisal fibers. Heliyon 2024, 10, e29760. [Google Scholar] [CrossRef]

- Nensok, M.H.; Mydin, M.A.O.; Awang, H. Optimization of mechanical properties of cellular lightweight concrete with alkali treated banana fiber. Rev. Constr. 2021, 20, 491–511. [Google Scholar]

- Jiang, D.; Cui, S.; Xu, F.; Tuo, T. Impact of leaf fibre modification methods on compatibility between leaf fibres and cement-based materials. Constr. Build. Mater. 2015, 94, 502–512. [Google Scholar] [CrossRef]

- Liu, J.; Xie, X.; Li, L. Experimental study on mechanical properties and durability of grafted nano-SiO2 modified rice straw fiber reinforced concrete. Constr. Build. Mater. 2022, 347, 128575. [Google Scholar] [CrossRef]

- Jiang, D.; Lv, S.; Jiang, D.; Xu, H.; Kang, H.; Song, X.; He, S. Effect of modification methods on water absorption and strength of wheat straw fiber and its cement-based composites. J. Build. Eng. 2023, 71, 106466. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, W.; Li, L. Effects of Nano-SiO2 grafting on improving the interfacial and mechanical properties of concrete with rice straw fibers. Constr. Build. Mater. 2023, 398, 132516. [Google Scholar] [CrossRef]

- Shang, X.; Yang, J.; Song, Q.; Wang, L. Efficacy of modified rice straw fibre on properties of cementitious composites. J. Clean. Prod. 2020, 276, 124184. [Google Scholar] [CrossRef]

- Poletanovic, B.; Janotka, I.; Janek, M.; Bacuvcik, M.; Merta, I. Influence of the NaOH-treated hemp fibres on the properties of fly-ash based alkali-activated mortars prior and after wet/dry cycles. Constr. Build. Mater. 2021, 309, 125072. [Google Scholar] [CrossRef]

- de Klerk, M.D.; Kayondo, M.; Moelich, G.M.; de Villiers, W.I.; Combrinck, R.; Boshoff, W.P. Durability of chemically modified sisal fibre in cement-based composites. Constr. Build. Mater. 2020, 241, 117835. [Google Scholar] [CrossRef]

- Ferreira, N.; Rodrigues, L.; Silva, S.; Silva, E.; Silva, C.J.; Oliveira, C.; Oliveira, F. Hybrid yarn structures as a promising approach for thermoplastic biocomposites. J. Compos. Mater. 2024, 58, 3171–3196. [Google Scholar] [CrossRef]

- Karthik, A.; Bhuvaneshwaran, M.; Kumar, M.S.S.; Palanisamy, S.; Palaniappan, M.; Ayrilmis, N. A review on surface modification of plant fibers for enhancing properties of biocomposites. Chemistryselect 2024, 9, e202400650. [Google Scholar] [CrossRef]

- Zhao, L.; Ding, Y.X.; Li, S.J.; Song, Y.; Gong, H.; Zhang, Y.M. Silane treatment for sisal fibers to improve the degradation resistance and interface with cement matrix. Constr. Build. Mater. 2024, 429, 136435. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Xu, R.; Kasal, B. Microstructural analysis, physical, chemical components and tensile properties of coir fibre long-term exposed in Ca(OH)2 as representative of concrete pore solution. J. Clean. Prod. 2023, 385, 135693. [Google Scholar] [CrossRef]

- Hajiha, H.; Sain, M.; Mei, L.H. Modification and characterization of hemp and sisal fibers. J. Nat. Fibers 2014, 11, 144–168. [Google Scholar] [CrossRef]

- Boulos, L.; Foruzanmehr, M.R.; Tagnit-Hamou, A.; Elkoun, S.; Robert, M. Wetting analysis and surface characterization of flax fibers modified with zirconia by sol-gel method. Surf. Coat. Technol. 2017, 313, 407–416. [Google Scholar] [CrossRef]

- Teixeira, F.P.; Martins Gomes, O.d.F.; Silva, F.d.A. Degradation mechanisms of curaua, hemp, and sisal fibers exposed to elevated temperatures. BioResources 2019, 14, 1494–1511. [Google Scholar] [CrossRef]

- Nair, K.C.M.; Diwan, S.M.; Thomas, S. Tensile properties of short sisal fiber reinforced polystyrene composites. J. Appl. Polym. Sci. 1996, 60, 1483–1497. [Google Scholar] [CrossRef]

- Baruah, P.; Talukdar, S. A comparative study of compressive, flexural, tensile and shear strength of concrete with fibres of different origins. Indian Concr. J. 2007, 81, 17–24. [Google Scholar]

- Singh, N.K.; Rai, B. A review of fiber synergy in hybrid fiber reinforced concrete. J. Appl. Eng. Sci. 2018, 8, 41–50. [Google Scholar] [CrossRef]

- Sambucci, M.; Nouri, S.M.; Tayebi, S.T.; Valente, M. Synergic effect of recycled carbon fibers and microfibrillated cellulose gel for en-hancing the mechanical properties of cement-based materials. Gels 2023, 9, 981. [Google Scholar] [CrossRef]

- Tian, H.; Zhang, Y.X.; Ye, L.; Yang, C. Mechanical behaviours of green hybrid fibre-reinforced cementitious composites. Constr. Build. Mater. 2015, 95, 152–163. [Google Scholar] [CrossRef]

- Kouta, N.; Saliba, J.; Saiyouri, N. Effect of flax fibers on early age shrinkage and cracking of earth concrete. Constr. Build. Mater. 2020, 254, 119315. [Google Scholar] [CrossRef]

- Gupta, M.; Kumar, M. Effect of nano silica and coir fiber on compressive strength and abrasion resistance of concrete. Constr. Build. Mater. 2019, 226, 44–50. [Google Scholar] [CrossRef]

- Awwad, E.; Mabsout, M.; Hamad, B.; Farran, M.T.; Khatib, H. Studies on fiber-reinforced concrete using industrial hemp fibers. Constr. Build. Mater. 2012, 35, 710–717. [Google Scholar] [CrossRef]

- Kriker, A.; Debicki, G.; Bali, A.; Khenfer, M.M.; Chabannet, M. Mechanical properties of date palm fibres and concrete reinforced with date palm fibres in hot-dry climate. Cem. Concr. Compos. 2005, 27, 554–564. [Google Scholar] [CrossRef]

- Machaka, M.; Khatib, J.; Baydoun, S.; Elkordi, A.; Assaad, J.J. The effect of adding phragmites australis fibers on the properties of concrete. Buildings 2022, 12, 278. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Effect of basalt fibers on mechanical properties of calcium carbonate whisker-steel fiber reinforced concrete. Constr. Build. Mater. 2018, 192, 742–753. [Google Scholar] [CrossRef]

- Sultana, N.; Hossain, S.M.Z.; Alam, M.S.; Hashish, M.M.A.; Islam, M.S. An experimental investigation and modeling approach of response surface methodology coupled with crow search algorithm for optimizing the properties of jute fiber reinforced concrete. Constr. Build. Mater. 2020, 243, 118216. [Google Scholar] [CrossRef]

- Sridhar, J.; Gobinath, R.; Kirgiz, M.S. Evaluation of artificial neural network predicted mechanical properties of jute and bamboo fiber reinforced concrete along with silica fume. J. Nat. Fibers 2023, 20, 2162186. [Google Scholar] [CrossRef]

- Meng, W.; Yao, Y.; Mobasher, B.; Khayat, K.H. Effects of loading rate and notch-to-depth ratio of notched beams on flexural performance of ultra-high-performance concrete. Cem. Concr. Compos. 2017, 83, 349–359. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Thanushan, K.; Sathiparan, N. Mechanical performance and durability of banana fibre and coconut coir reinforced cement stabilized soil blocks. Materialia 2022, 21, 101309. [Google Scholar] [CrossRef]

- Ali, B.; Azab, M.; Ahmed, H.; Kurda, R.; Ouni, M.H.E.; Elhag, A.B. Investigation of physical, strength, and ductility characteristics of concrete reinforced with banana (Musaceae) stem fiber. J. Build. Eng. 2022, 61, 105024. [Google Scholar] [CrossRef]

- Ajouguim, S.; Page, J.; Djelal, C.; Waqif, M.; Saâdi, L. Impact of Alfa fibers morphology on hydration kinetics and mechanical properties of cement mortars. Constr. Build. Mater. 2021, 293, 123514. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Characterisation of cotton fibre-reinforced geopolymer composites. Compos. Pt. B-Eng. 2013, 50, 1–6. [Google Scholar] [CrossRef]

- Miah, M.J.; Li, Y.; Paul, S.C.; Babafemi, A.J.; Jang, J.G. Mechanical strength, shrinkage, and porosity of mortar reinforced with areca nut husk fibers. Constr. Build. Mater. 2023, 363, 129688. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Mechanically pulped sisal as reinforcement in cementitious matrices. Cem. Concr. Compos. 2003, 25, 311–319. [Google Scholar] [CrossRef]

- Dawood, E.T.; Ramli, M. Mechanical properties of high strength flowing concrete with hybrid fibers. Constr. Build. Mater. 2012, 28, 193–200. [Google Scholar] [CrossRef]

- Xu, R.; He, T.; Da, Y.; Liu, Y.; Li, J.; Chen, C. Utilizing wood fiber produced with wood waste to reinforce autoclaved aerated concrete. Constr. Build. Mater. 2019, 208, 242–249. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Mehrali, M.; Alengaram, U.J.; Jumaat, M.Z. High tensile strength fly ash based geopolymer composite using copper coated micro steel fiber. Constr. Build. Mater. 2016, 112, 629–638. [Google Scholar] [CrossRef]

- Li, J.; Yu, Y.; Kim, T.; Hajimohammadi, A. Unveiling the underlying mechanisms of tensile behaviour enhancement in fibre reinforced foam concrete. Constr. Build. Mater. 2023, 398, 132509. [Google Scholar] [CrossRef]

- Zhang, A.; Liu, K.; Li, J.; Song, R.; Guo, T. Static and dynamic tensile properties of ultra-high performance concrete (UHPC) reinforced with hybrid sisal fibers. Constr. Build. Mater. 2024, 411, 134492. [Google Scholar] [CrossRef]

- Islam, M.S.; Ahmed, S.J.U. Influence of jute fiber on concrete properties. Constr. Build. Mater. 2018, 189, 768–776. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Yousef, R.A.; Abduljabbar, H.A.; Sufian, M. Effect of coconut fiber length and content on properties of high strength concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef]

- Lecompte, T.; Perrot, A.; Subrianto, A.; Le Duigou, A.; Ausias, G. A novel pull-out device used to study the influence of pressure during processing of cement-based material reinforced with coir. Constr. Build. Mater. 2015, 78, 224–233. [Google Scholar] [CrossRef]

- Diamond, S.; Huang, J. The ITZ in concrete-a different view based on image analysis and SEM observations. Cem. Concr. Compos. 2001, 23, 179–188. [Google Scholar] [CrossRef]

- Merta, I.; Tschegg, E.K. Fracture energy of natural fibre reinforced concrete. Constr. Build. Mater. 2013, 40, 991–997. [Google Scholar] [CrossRef]

- Ahmed, S.; Ali, M. Use of agriculture waste as short discrete fibers and glass-fiber-reinforced-polymer rebars in concrete walls for enhancing impact resistance. J. Clean. Prod. 2020, 268, 122211. [Google Scholar] [CrossRef]

- Bai, Y.-l.; Yan, Z.-W.; Jia, J.-F.; Ozbakkaloglu, T.; Liu, Y. Dynamic compressive behavior of concrete confined with unidirectional natural flax FRP based on SHPB tests. Compos. Struct. 2021, 259, 113233. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. Behaviour of CFRC beams strengthened by FFRP laminates under static and impact loadings. Constr. Build. Mater. 2017, 155, 956–964. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, X.; Mo, Z.; Chouw, N.; Li, Z.; Xu, Z.D. A comparative study of impact behaviour between natural flax and glass FRP confined concrete composites. Constr. Build. Mater. 2020, 241, 117997. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wang, D. Static and dynamic compressive properties of ultra-high performance concrete (UHPC) with hybrid steel fiber reinforcements. Cem. Concr. Compos. 2017, 79, 148–157. [Google Scholar] [CrossRef]

- Quan, W.; Huang, W.; An, Y.; Miao, X.; Chen, Z. The effect of natural bamboo fiber and basalt fiber on the properties of autoclaved aerated concrete. Constr. Build. Mater. 2023, 377, 131153. [Google Scholar] [CrossRef]

- Hao, H.; Song, J.; Chen, M.; Yan, X.; Zhang, K. Rheological and mechanical properties of oil-well cement reinforced by hybrid inorganic fibers. Constr. Build. Mater. 2023, 377, 131002. [Google Scholar] [CrossRef]

- Zhang, S.; Qiao, W.-G.; Chen, P.-C.; Xi, K. Rheological and mechanical properties of microfine-cement-based grouts mixed with microfine fly ash, colloidal nanosilica and superplasticizer. Constr. Build. Mater. 2019, 212, 10–18. [Google Scholar] [CrossRef]

- Sawsen, C.; Fouzia, K.; Mohamed, B.; Moussa, G. Effect of flax fibers treatments on the rheological and the mechanical behavior of a cement composite. Constr. Build. Mater. 2015, 79, 229–235. [Google Scholar] [CrossRef]

- Gwon, S.; Shin, M. Rheological properties of cement pastes with cellulose microfibers. J. Mater. Res. Technol. 2021, 10, 808–818. [Google Scholar] [CrossRef]

- Paukszta, D.; Borysiak, S. The influence of processing and the polymorphism of lignocellulosic fillers on the structure and properties of composite materials—A review. Materials 2013, 6, 2747–2767. [Google Scholar] [CrossRef] [PubMed]

- Peled, A.; Bentur, A. Geometrical characteristics and efficiency of textile fabrics for reinforcing cement composites. Cem. Concr. Res. 2000, 30, 781–790. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Characteristics of hemp fabric reinforced nanoclay–cement nanocomposites. Cem. Concr. Compos. 2014, 50, 27–35. [Google Scholar] [CrossRef]

- Aldahdooh, M.A.; Muhamad Bunnori, N.; Megat Johari, M.A. Development of green ultra-high performance fiber reinforced concrete containing ultrafine palm oil fuel ash. Constr. Build. Mater. 2013, 48, 379–389. [Google Scholar] [CrossRef]

- Palanikumar, K.; Ramesh, M.; Hemachandra Reddy, K. Experimental investigation on the mechanical properties of green hybrid sisal and glass fiber reinforced polymer composites. J. Nat. Fibers 2016, 13, 321–331. [Google Scholar] [CrossRef]

- Lin, C.; Kanstad, T.; Jacobsen, S.; Ji, G. Bonding property between fiber and cementitious matrix: A critical review. Constr. Build. Mater. 2023, 378, 131169. [Google Scholar] [CrossRef]

- Rao, J.; Zhou, Y.; Fan, M. Revealing the interface structure and bonding mechanism of coupling agent treated WPC. Polymers 2018, 10, 266. [Google Scholar] [CrossRef]

- Naik, D.L.; Sharma, A.; Chada, R.R.; Kiran, R.; Sirotiak, T. Modified pullout test for indirect characterization of natural fiber and cementitious matrix interface properties. Constr. Build. Mater. 2019, 208, 381–393. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Al-Kheetan, M.; Ewens, P.; Wang, T.; Zhuang, J. Investigation of the interfacial bonding between flax/wool twine and various cementitious matrices in mortar composites. Constr. Build. Mater. 2020, 239, 117833. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Pepe, M.; Martinelli, E.; de Andrade Silva, F.; Toledo Filho, R.D. Influence of natural fibers characteristics on the interface mechanics with cement based matrices. Compos. Part B Eng. 2018, 140, 183–196. [Google Scholar] [CrossRef]

- Zanjani Zadeh, V.; Bobko, C.P. Nano-mechanical properties of internally cured kenaf fiber reinforced concrete using nanoindentation. Cem. Concr. Compos. 2014, 52, 9–17. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

| Plant fiber | Cellulose (%) | Hemicellulose (%) | Pectin (%) | Lignin (%) | Ref. |

|---|---|---|---|---|---|

| Abaca | 62.5 | 21 | 0.8 | 12 | [57] |

| Alfa | 45.4 | 38.5 | - | 14.9 | [58] |

| Bagasse | 37 | 21 | 10 | 22 | [57] |

| Banana | 62.5 | 12.5 | 4 | 7.5 | [59] |

| Bamboo | 34.5 | 20.5 | - | 26 | [60] |

| Coir | 46 | 0.3 | 4 | 45 | [61] |

| Cotton | 89 | 4 | 6 | 0.75 | [62] |

| Flax | 72.5 | 14.5 | 0.9 | 2.5 | [57] |

| Hemp | 74.4 | 17.9 | 3.7 | 1.7 | [61] |

| Jute | 67 | 16 | 0.2 | 9 | [63] |

| Kenaf | 53.5 | 21 | 2 | 17 | [64] |

| Pineapple | 80.5 | 17.5 | 4 | 8.3 | [62] |

| Ramie | 72 | 14 | 2.0 | 0.8 | [62] |

| Sisal | 60 | 11.5 | 1.2 | 8 | [65] |

| Fiber Type | Relative Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Specific Modulus (GPa·cm3/g) | Elongation at Failure (%) |

|---|---|---|---|---|---|

| Abaca | 1.5 | 400–980 | 6.2–20 | 9 | 1.0–10 |

| Bamboo | 0.6–1.1 | 140–800 | 11–32 | 25 | 2.5–3.7 |

| Banana | 1.35 | 500 | 12 | 9 | 1.5–9 |

| Coir | 1.15–1.46 | 95–230 | 2.8–6 | 4 | 15–51.4 |

| Cotton | 1.5–1.6 | 287–800 | 5.5–12.6 | 6 | 3–10 |

| Flax | 1.4–1.5 | 343–2000 | 27.6–103 | 45 | 1.2–3.3 |

| Hemp | 1.4–1.5 | 270–900 | 23.5–90 | 40 | 1–3.5 |

| Jute | 1.3–1.49 | 320–800 | 30 | 30 | 1–1.8 |

| Ramie | 1.0–1.55 | 400–1000 | 24.5–128 | 60 | 1.2–4.0 |

| Sisal | 1.33–1.5 | 363–700 | 9.0–38 | 17 | 2.0–7.0 |

| Modification Methods | Cons | Pros | Refs. |

|---|---|---|---|

| Alkali treatment | Simple to operate | Has the risk of damaging the strength of PF | [113,114] |

| Water retting | Benefit for the interface between PF and cement matrix | Consumes water and contributes to water eutrophication | [115] |

| Plasma treatment | Modifies surface of PF without affecting the bulk properties | [116] | |

| Thermal treatment | Simple to operate | Has the risk of leading to thermal degradation of PF | [117] |

| Acetylation treatment | Exhibit excellent capacity to remove the defects on the surface of PF | [114] |

| Fiber Type | Recommended Dosage Range (%) | Matrix | Ref. |

|---|---|---|---|

| Sisal | 1–3 | Concrete | [65] |

| Flax | 0.1–0.2 | Concrete | [29] |

| Coconut | 1–2 | Concrete | [39] |

| Hemp | 0.5 | Concrete | [129] |

| Jute | 0.2–0.4 | Mortar | [27] |

| Banana | 0.1–0.25 | Concrete | [71] |

| Date palm | 0.5 | Mortar | [33] |

| Mechanical Parameter | Formula |

|---|---|

| Bonding strength () | |

| Pull-out energy () | |

| Interfacial sliding shear strength () | |

| Apparent interfacial shear strength (IFSS) | |

| Pull-out strength () |

| Property | Method | Feature | Applications in Interface Analysis | Ref. |

|---|---|---|---|---|

| Micromechanical performance | Acoustic emission | Strength of the interface zone | The intensity of the acoustic emision signal represents the difficulty of disrupting the ITZ | [34] |

| Observation of interphase | SEM | Microstructural morphology | Investigation of the interfacial characteristics between sisal fibers and the cementitious matrix | [67] |

| Observation of interphase | SEM | Microstructural morphology | Investigation of the effect of surface-coated silane coupling agent (SCA) and nano-SiO2 (NS) on the interfacial bonding ability of sisal fibers in cementitious composites | [26] |

| Micromechanical properties | Nanoindentation | Hardness and indentation modulus of the ITZ | It was examined how internal curing affected the fiber–matrix inter-face region’s microstructure | [174] |

| Interphase composites | EDS | Determination of the material’s composition on the fiber surface | Identifying fiber pull-out patterns by examining whether mortar particles are present on the fiber surface | [171] |

| Observation of interphase | SEM | Microstructural morphology | Investigating the effect of different pH substrates on plant fiber degradation as well as ITZ | [30] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Zhang, X.; Guo, J.; Zheng, Y.; Gao, Z. Mechanical Properties of Cement-Based Gel Composites Reinforced by Plant Fiber: A Review. Gels 2025, 11, 362. https://doi.org/10.3390/gels11050362

Zhang P, Zhang X, Guo J, Zheng Y, Gao Z. Mechanical Properties of Cement-Based Gel Composites Reinforced by Plant Fiber: A Review. Gels. 2025; 11(5):362. https://doi.org/10.3390/gels11050362

Chicago/Turabian StyleZhang, Peng, Xiao Zhang, Jinjun Guo, Yuanxun Zheng, and Zhen Gao. 2025. "Mechanical Properties of Cement-Based Gel Composites Reinforced by Plant Fiber: A Review" Gels 11, no. 5: 362. https://doi.org/10.3390/gels11050362

APA StyleZhang, P., Zhang, X., Guo, J., Zheng, Y., & Gao, Z. (2025). Mechanical Properties of Cement-Based Gel Composites Reinforced by Plant Fiber: A Review. Gels, 11(5), 362. https://doi.org/10.3390/gels11050362