Si3N4 Nanoparticle Reinforced Si3N4 Nanofiber Aerogel for Thermal Insulation and Electromagnetic Wave Transmission

Abstract

1. Introduction

2. Results and Discussion

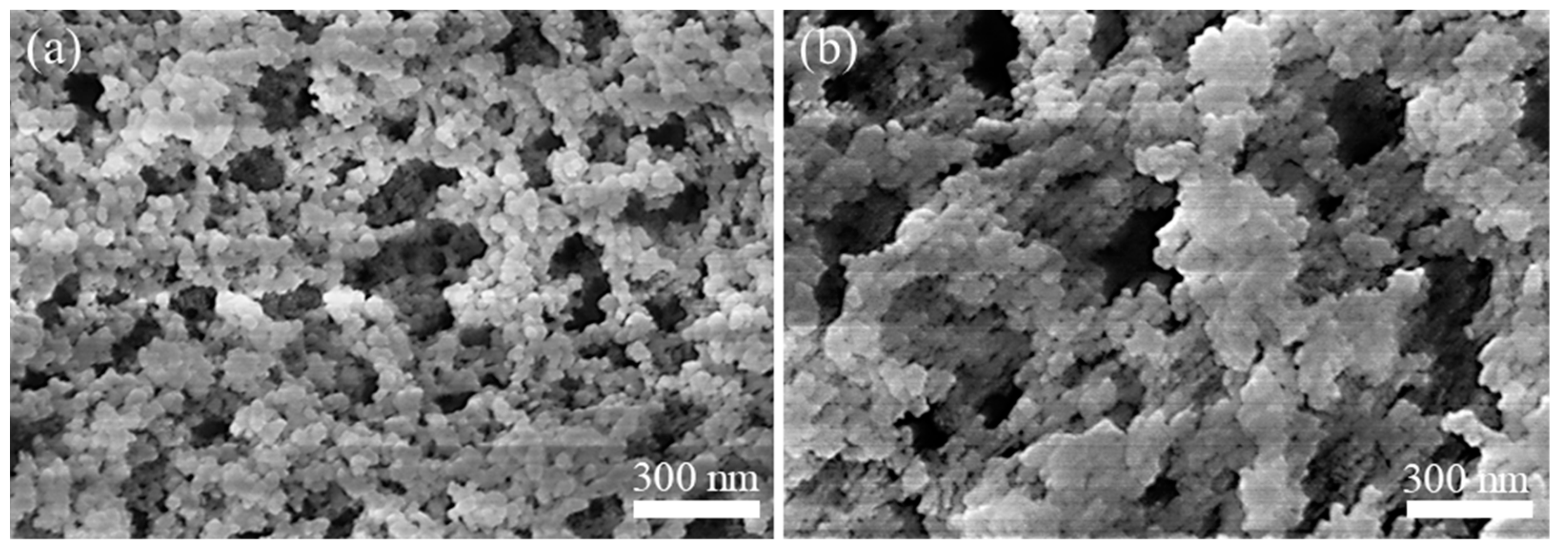

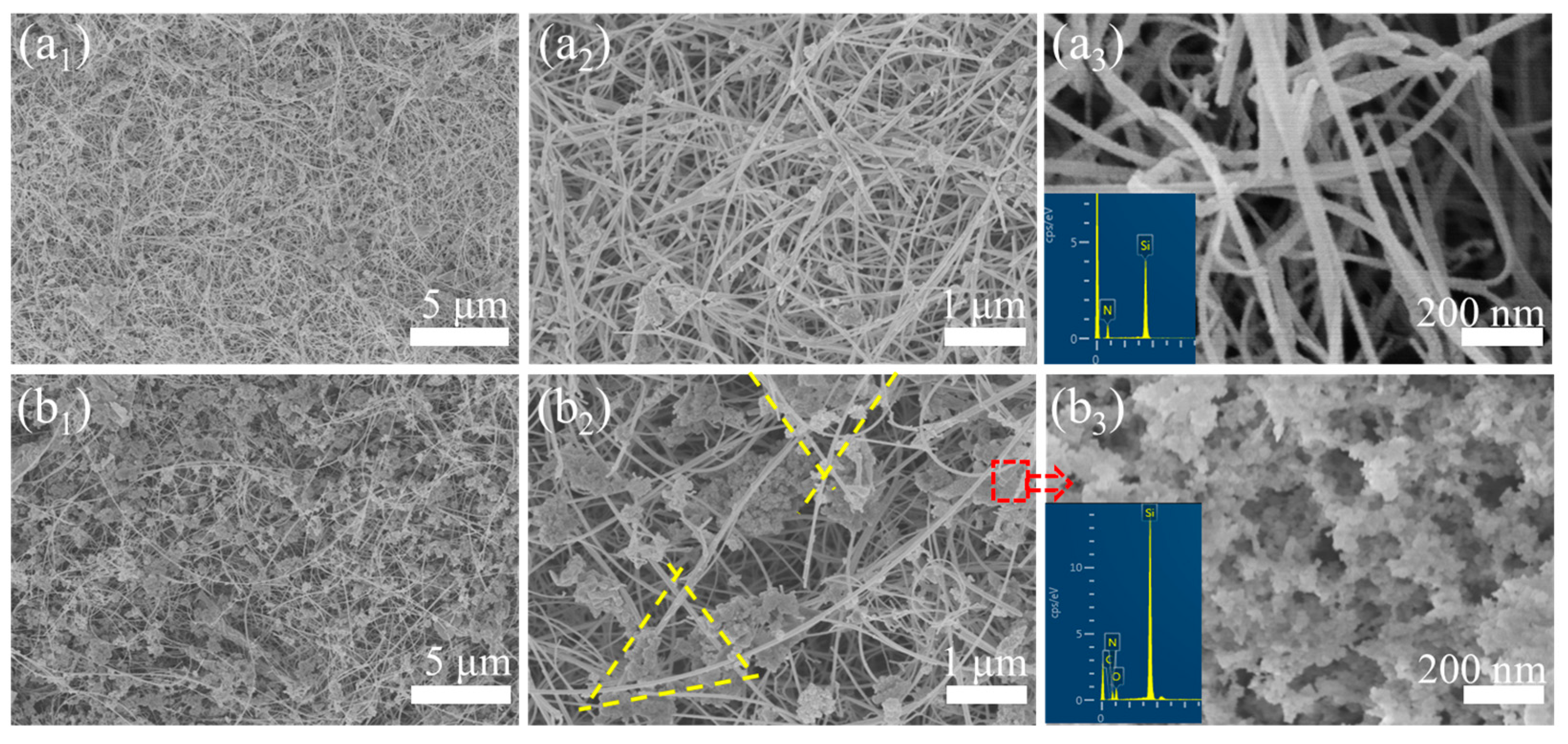

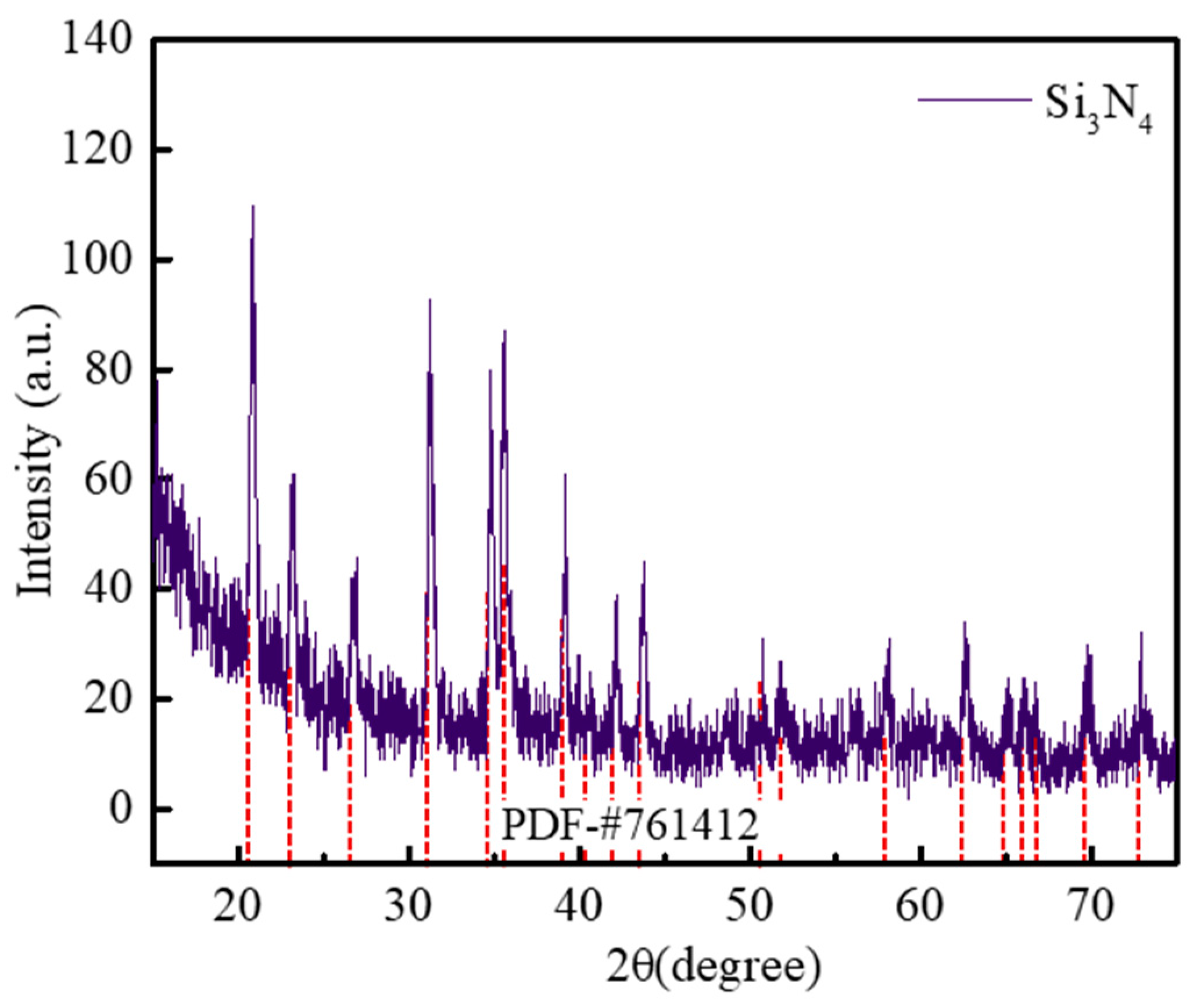

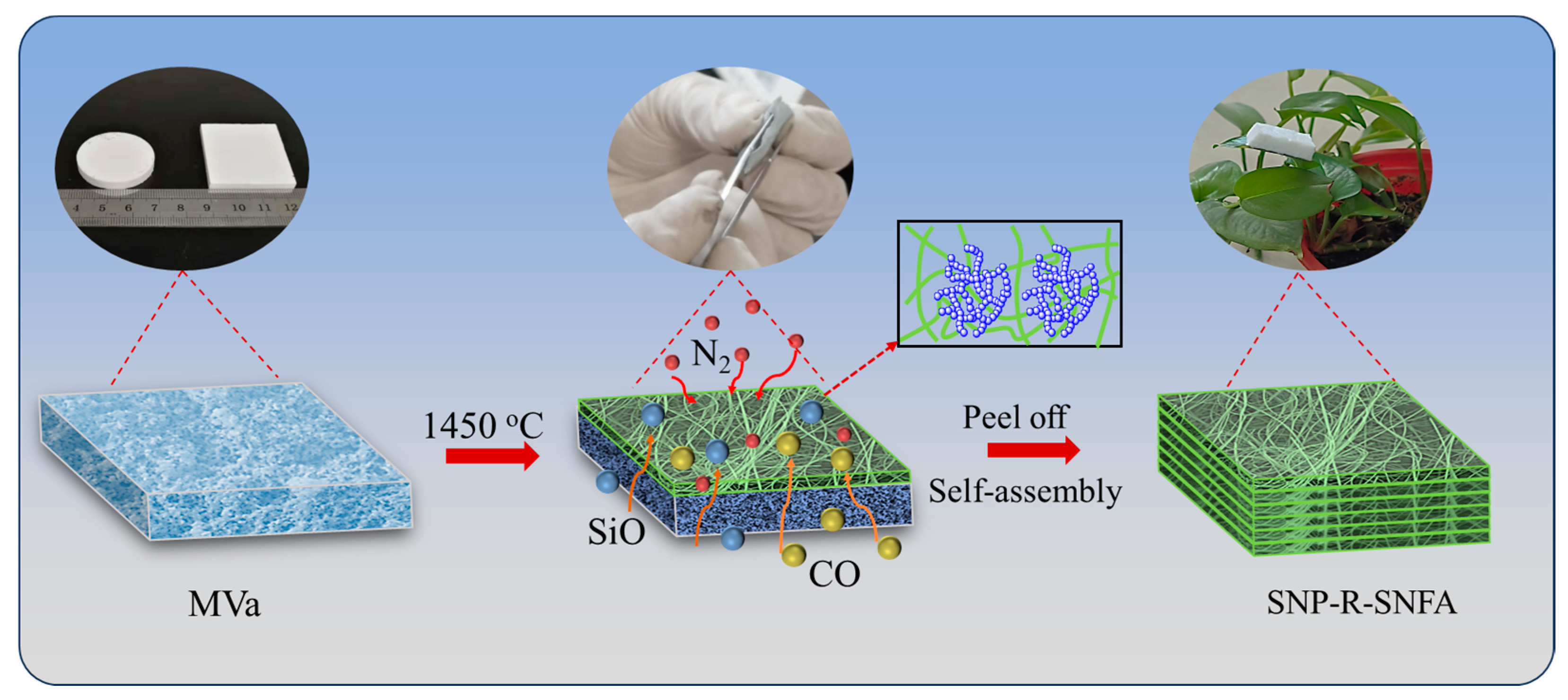

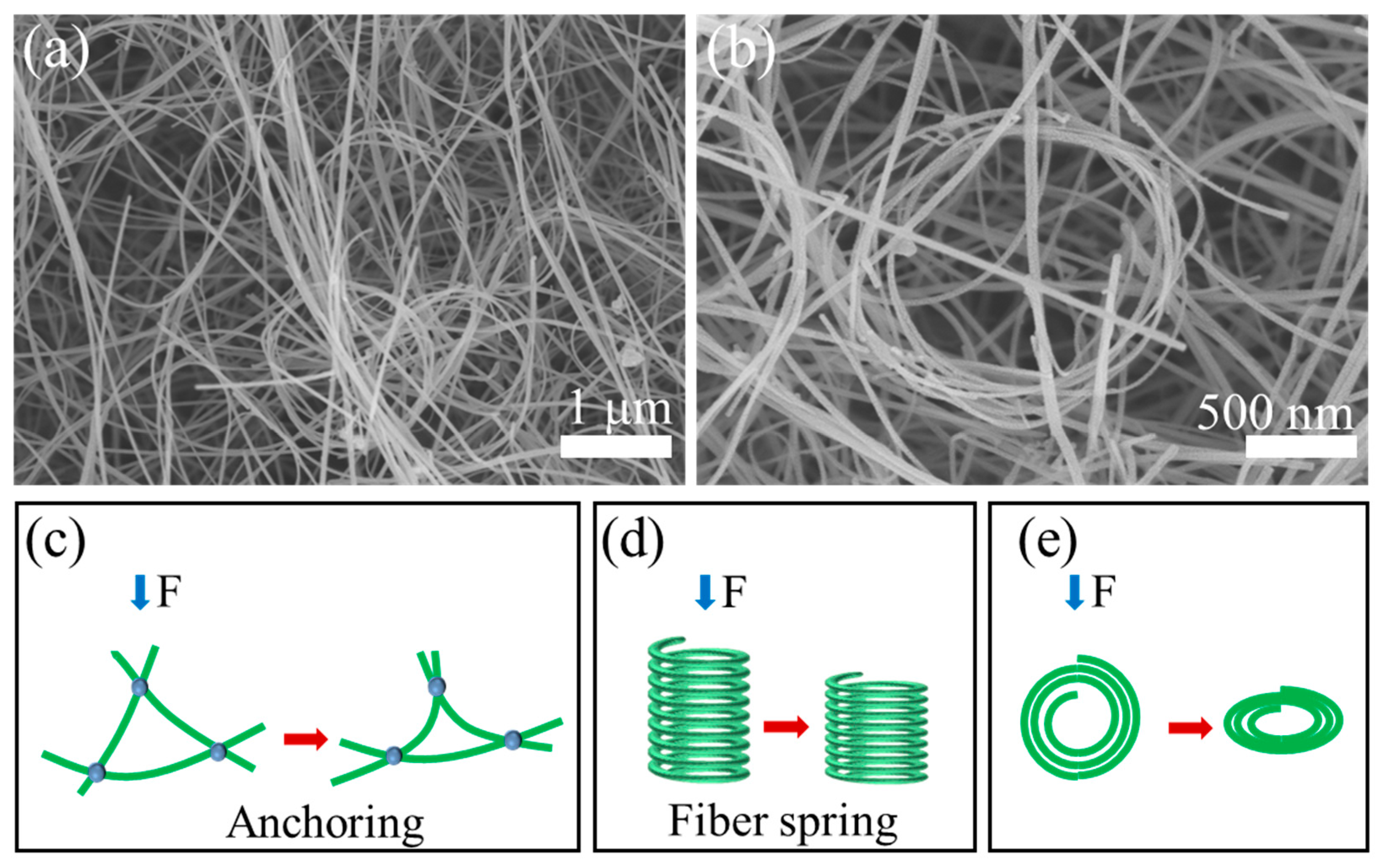

2.1. Microstructure Formation Mechanism

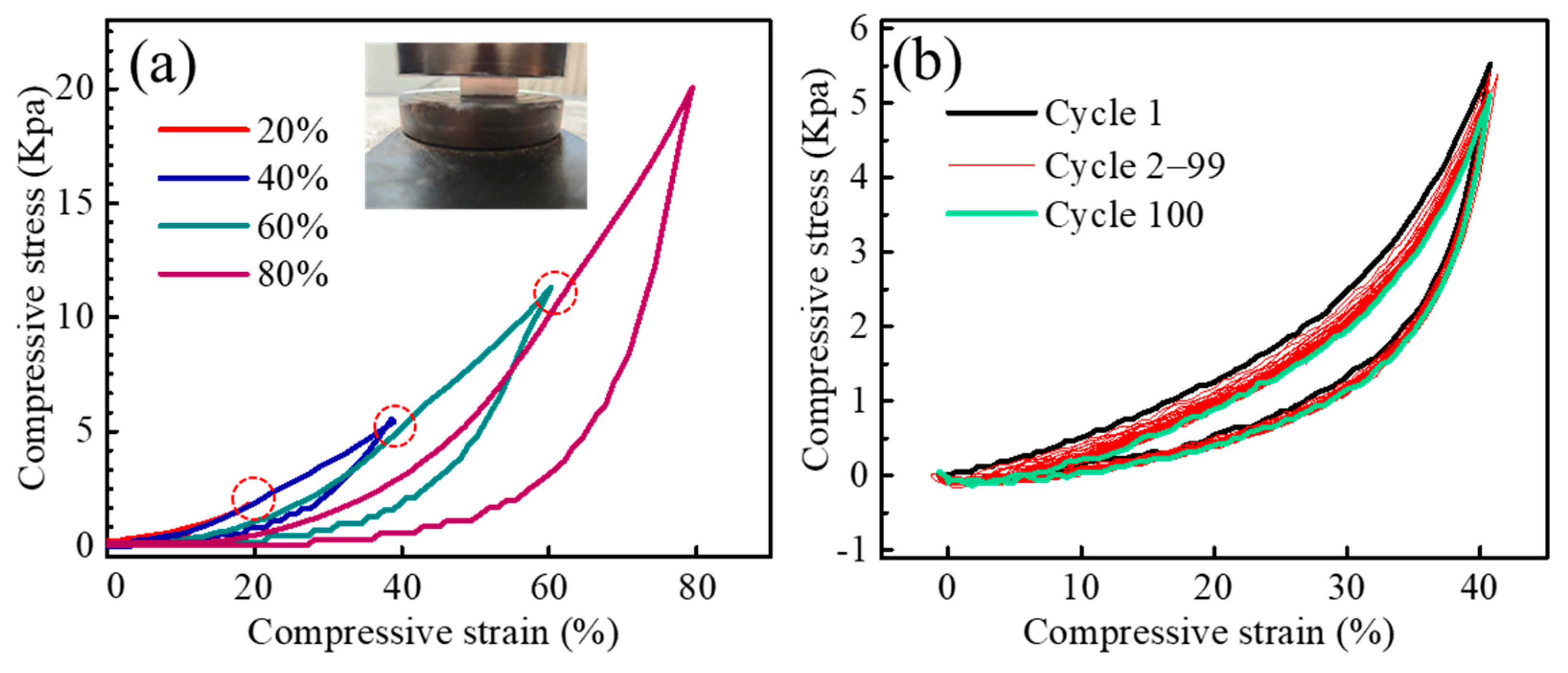

2.2. Compression Performance and Reinforcement Mechanism

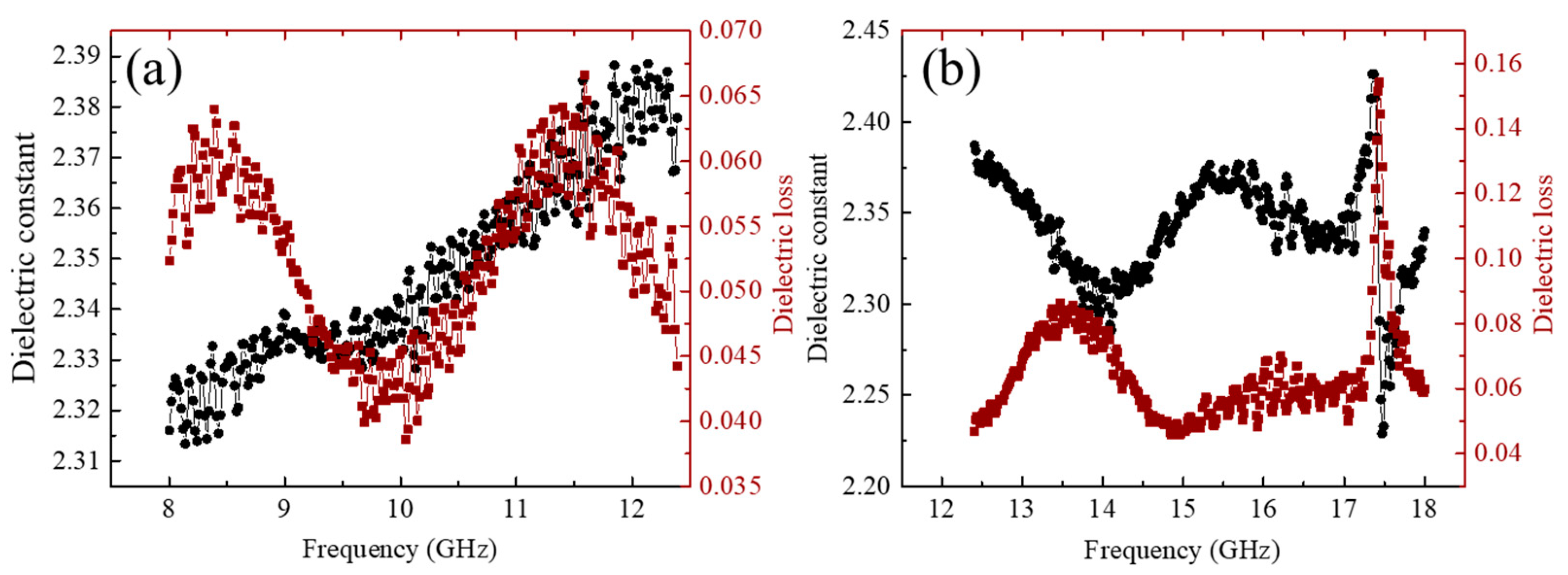

2.3. Dielectric Properties

2.4. Thermal Insulation Characterizations

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Preparation of Organosilane Aerogels

4.3. Preparation of the SNP-R-SNFA

4.4. Characterization

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Du, A.; Zhou, B.; Zhang, Z.; Shen, J. A special material or a new state of matter: A review and reconsideration of the aerogel. Materials 2013, 6, 941–968. [Google Scholar] [CrossRef]

- Aney, S.; Pandit, P.; Ratke, L.; Milow, B.; Rege, A. On the origin of power-scaling exponents in silica aerogels. J. Sol-Gel Sci. Technol. 2023, 114, 98–105. [Google Scholar] [CrossRef]

- Gu, X.; Chen, J.; Zhu, S.; Zhao, Q.; Zhang, Y.; Su, Q. Application of whisker-toughened aerogel to recycling of used polyurethane sheets. Gels 2024, 10, 793. [Google Scholar] [CrossRef]

- Liu, L.; Li, L.; Hu, Y.; Feng, J.; Jiang, Y.; Feng, J. Effect of fiber characteristics on the structure and properties of quartz fiber felt reinforced silica-polybenzoxazine aerogel composites. Gels 2024, 10, 613. [Google Scholar] [CrossRef]

- Kong, Y.; Zhang, J.; Zhao, Z.; Jiang, X.; Shen, X. Monolithic silicon nitride-based aerogels with large specific surface area and low thermal conductivity. Ceram. Int. 2019, 45, 16331–16337. [Google Scholar] [CrossRef]

- An, Z.; Zhang, R.; Fang, D. Synthesis of monolithic SiC aerogels with high mechanical strength and low thermal conductivity. Ceram. Int. 2019, 45, 11368–11374. [Google Scholar] [CrossRef]

- Rewatkar, P.M.; Taghvaee, T.; Saeed, A.M.; Donthula, S.; Mandal, C.; Chandrasekaran, N.; Leventis, T.; Shruthi, T.K.; Sotiriou-Leventis, C.; Leventis, N. Sturdy, monolithic SiC and Si3N4 aerogels from compressed polymer-cross-linked silica xerogel powders. Chem. Mater. 2018, 30, 1635–1647. [Google Scholar] [CrossRef]

- Chang, X.; Cheng, X.; Yin, X.; Che, R.; Yu, J.; Liu, Y.-T.; Ding, B. Multimode thermal gating based on elastic ceramic-carbon nanowhisker/nanofiber aerogels by strain engineering strategy. ACS Nano 2025, 19, 10421–10432. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, F.; Jiang, K.; Fan, B.; Wang, H.; Zhang, R.; Li, H.; Chen, Y. Preparation of BN@SiO2 nanofiber ceramic aerogel with ultralight, wave-transparent and heat-insulating for microwave sintering furnace. Ceram. Int. 2024, 50, 34519–34526. [Google Scholar] [CrossRef]

- Wu, H.; Chen, Y.; Chen, Q.; Ding, Y.; Zhou, X.; Gao, H.; Jin, Y. Synthesis of flexible aerogel composites reinforced with electrospun nanofibers and microparticles for thermal insulation. J. Nanomater. 2013, 2013, 375093. [Google Scholar] [CrossRef]

- Dang, S.; Guo, J.; Deng, Y.; Yu, H.; Zhao, H.; Wang, D.; Zhao, Y.; Song, C.; Chen, J.; Ma, M.; et al. Highly-buckled nanofibrous ceramic aerogels with ultra-large stretchability and tensile-insensitive thermal insulation. Adv. Mater. 2024, 37, 241519. [Google Scholar] [CrossRef] [PubMed]

- Biesuz, M.; Tomasi, M.; Santhosh, B.; Sglavo, V.M.; Sorarù, G.D. Polymer-derived Si3N4 nanofelts as a novel oil spills clean-up architecture. J. Environ. Chem. Eng. 2020, 8, 104134. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Zhao, F.; Li, C.; Sheng, H.; Li, H. Fire-resistant and hydrophobic paper based on Si3N4@PDMS core-shell nanowires with 3D interlocking structure. Ceram. Int. 2023, 49, 28002–28010. [Google Scholar] [CrossRef]

- Tong, Z.; Ji, H.; Li, X.; Liu, Z. Microstructure control and optimization of low temperature pressureless sintered silicon nitride-barium aluminosilicate composites. J. Eur. Ceram. Soc. 2020, 40, 4177–4183. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.S.; Zhang, L.T.; Cheng, L.F.; Xu, Y.D. Characterization and properties of Si3N4 radome material prepared by chemical vapor infiltration. J. Inorg. Mater. 2006, 21, 979–985. [Google Scholar]

- Guo, K.; Lu, J.; Guo, Q. A facile method of massively producing three-dimensional silicon nitride nanowire cloth. Mater. Lett. 2016, 185, 222–225. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Xiao, C.; Li, H.; Li, H. Thermal insulating Si3N4@SiO2 nanowire aerogel with excellent mechanical performance at high-temperatures up to 1300 °C. Nano Res. 2025, 18, 94907008. [Google Scholar] [CrossRef]

- Tong, Z.; Zhang, B.; Yu, H.; Yan, X.; Xu, H.; Li, X.; Ji, H. Si3N4 nanofibrous aerogel with in situ growth of SiOx coating and nanowires for oil/water separation and thermal insulation. ACS Appl. Mater. Interfaces 2021, 13, 22765–22773. [Google Scholar] [CrossRef] [PubMed]

- Dirè, S.; Tagliazucca, V.; Callone, E.; Quaranta, A. Effect of functional groups on condensation and properties of sol-gel silica nanoparticles prepared by direct synthesis from organoalkoxysilanes. Mater. Chem. Phys. 2011, 126, 909–917. [Google Scholar] [CrossRef]

- Tong, Z.; Yan, B.; Zhang, B.; Xu, H.; Li, X.; Ji, H. Preparation and textural evolution: From organosilane aerogel to SiOC aerogels. Ceram. Int. 2022, 48, 5468–5475. [Google Scholar] [CrossRef]

- Dong, X.; Wu, J.; Zhou, Q.; Wang, W.; Zhang, X.; Zhang, L.; He, R. Mechanical and dielectric properties of Si3N4-SiO2 ceramics prepared by digital light processing based 3D printing and oxidation sintering. Ceram. Int. 2023, 49, 29699–29708. [Google Scholar] [CrossRef]

- Hu, B.; Gai, L.; Liu, Y.; Wang, P.; Yu, S.; Zhu, L.; Han, X.; Du, Y. State-of-the-art in carbides/carbon composites for electromagnetic wave absorption. iScience 2023, 26, 107876. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Li, M.; Wang, H.; Niu, M.; Lu, D.; Cai, Z. Resilient Si3N4 nanobelt aerogel as fire-resistant and electromagnetic wave-transparent thermal insulator. ACS Appl. Mater. Interfaces 2019, 11, 15795–15803. [Google Scholar] [CrossRef]

- Zhang, N.; Xiang, D. Self-assembling of versatile Si3N4@SiO2 nanofibre sponges by direct nitridation of photovoltaic silicon waste. J. Hazard. Mater. 2021, 419, 126385. [Google Scholar] [CrossRef]

- Ni, H.; Lu, D.; Zhuang, L.; Guo, P.; Xu, L.; Li, M.; Hu, W.; Ni, Z.; Su, L.; Peng, K.; et al. Tailoring mechanical properties of a ceramic nanowire aerogel with pyrolytic carbon for in situ resilience at 1400 °C. ACS Nano 2024, 18, 15950–15957. [Google Scholar] [CrossRef]

- Su, L.; Wang, H.; Niu, M.; Fan, X.; Ma, M.; Shi, Z.; Guo, S.W. Ultralight, recoverable, and high-temperature-resistant SiC nanowire aeroge. ACS Nano 2018, 12, 3103–3111. [Google Scholar] [CrossRef]

- Wu, Z.; Li, C.; Liang, H.; Chen, J.; Yu, S. Ultralight, flexible, and fire-resistant carbon nanofiber aerogels from bacterial cellulose. Angew. Chem. Int. Ed. 2013, 52, 2925–2929. [Google Scholar] [CrossRef]

- Si, Y.; Yu, J.; Tang, X.; Ge, J.; Ding, B. Ultralight nanofibre-assembled cellular aerogels with superelasticity and multifunctionality. Nat. Commun. 2014, 5, 5802. [Google Scholar] [CrossRef]

- Si, Y.; Wang, X.; Dou, L.; Yu, J.; Ding, B. Ultralight and fire-resistant ceramic nanofibrous aerogels with temperature-invariant superelasticity. Sci. Adv. 2018, 4, eaas8925. [Google Scholar] [CrossRef]

- Dou, L.; Zhang, X.; Cheng, X.; Ma, Z.; Wang, X.; Si, Y.; Yu, J.; Ding, B. Hierarchical cellular structured ceramic nanofibrous aerogels with temperature-invariant superelasticity for thermal insulation. ACS Appl. Mater. Interfaces 2019, 11, 29056–29064. [Google Scholar] [CrossRef] [PubMed]

- Xie, W.; Xie, J.; Li, S.; Liu, J.; Xiao, X.; Wen, Q.; Ding, T. Transparent and durable terahertz absorber based on enhanced wave-ion interaction. Adv. Funct. Mater. 2024, 2418541. [Google Scholar] [CrossRef]

- Xiang, D.; He, Q.; Lan, D.; Wang, Y.; Yin, X. Regulating the phase composition and microstructure of F3Si/SiC nanofiber composites to enhance electromagnetic wave absorption. Chem. Eng. J. 2024, 498, 155406. [Google Scholar] [CrossRef]

- Mei, X.; You, Y.; Qu, K.; Peng, K.; Wu, F.; Li, M.; Li, K.; Liu, F.; Fu, Y.; Si, Y. Electrospinning-impregnation: Producing hydrophobic polyimide composites with superior dielectric properties. Compos. Sci. Technol. 2025, 261, 111016. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Lu, Z.; Cheng, R.; Zheng, H. Hollow ZnO/ZnFe2O4 microspheres anchored graphene aerogels as a high-efficiency microwave absorber with thermal insulation and hydrophobic performances. Carbon 2023, 203, 397–409. [Google Scholar] [CrossRef]

- Shu, Y.; Zhao, T.; Abdul, J.; Li, X.; Yang, L.; Luo, F. High-efficient electromagnetic wave absorption of coral-like Co/CoO/RGO hybrid aerogels with good hydrophobic and thermal insulation properties. Chem. Eng. J. 2023, 471, 144535. [Google Scholar] [CrossRef]

- Lu, X.; Zhu, D.; Li, X.; Wang, Y. Architectural design and interfacial engineering of CNTs@ZnIn2S4 heterostructure/cellulose aerogel for efficient electromagnetic wave absorption. Carbon 2022, 197, 209–217. [Google Scholar] [CrossRef]

- Fu, K.; Zhao, J.; Liu, F.; Wu, L.; Jin, Z.; Yang, Y.; Qiao, J.; Wang, Z.; Wang, F.; Liu, J. Enhanced electromagnetic wave absorption of nitrogen-doped reduced graphene oxide aerogels with LaFeO cluster modifications. Carbon 2023, 210, 118071. [Google Scholar] [CrossRef]

- Su, X.; Wang, J.; Han, M.; Liu, Y.; Zhang, B.; Huo, S.; Wu, Q.; Liu, Y.; Xu, H. Broadband electromagnetic wave absorption using pure carbon aerogel by synergistically modulating propagation path and carbonization degree. J. Colloid Interface Sci. 2023, 652, 780–788. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, C.; Yang, T.; Gao, N.; Zhang, Y.; Zhu, J.; He, X.; Shao, J.; Li, S.; Zhang, M.; et al. Bio-inspired gradient poly(lactic acid) nanofibers for active capturing of PM0.3 and real-time respiratory monitoring. J. Hazard. Mater. 2024, 474, 134781. [Google Scholar] [CrossRef]

- Dong, L.; Xi, Q.; Chen, D.; Guo, J.; Nakayama, T.; Li, Y.; Liang, Z.; Zhou, J.; Xu, X.; Li, B. Dimensional crossover of heat conduction in amorphous polyimide nanofibers. Natl. Sci. Rev. 2018, 5, 500–506. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, L.; Ye, F.; Zhao, K. Amorphous/nanocrystalline, lightweight, wave-transparent boron nitride nanobelt aerogel for thermal insulation. ACS Appl. Mater. Interfaces 2023, 15, 47405–47414. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Zhang, B.; Zhong, Z.; Ye, J.; Zhang, J.; Fang, Z.; Ye, F. Reusable, high specific surface areas, and excellent thermal stability Al2O3-SiO2 aerogel composites as high-temperature thermal insulators for radome applications. J. Alloys Compd. 2024, 984, 173990. [Google Scholar] [CrossRef]

- Liu, C.; He, T.; Hu, C.; Qian, Q.; Hao, Y.; Xu, L.; Lu, H.; Ji, G. The optimized design of sandwich structured SiO2/C@SiC/SiO2 composites through numerical simulation for temperature-resistant radar and infrared compatible stealth. Adv. Funct. Mater. 2024, 35, 2416108. [Google Scholar] [CrossRef]

- Song, L.; Zhang, F.; Chen, Y.; Guan, L.; Zhu, Y.; Chen, M.; Wang, H.; Putra, B.R.; Zhang, R.; Fan, B. Multifunctional SiC@SiO2 nanofiber aerogel with ultrabroadband electromagnetic wave absorption. Nano-Micro Lett. 2022, 14, 152. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, C.; Li, N.; Guo, W.; Li, Y.; Yang, P.; Zhang, S.; Wang, Z. Highly oriented SiC@SiO2 ceramic fiber aerogels with good anisotropy of the thermal conductivity and high-temperature resistance. Adv. Sci. 2025, 2416740. [Google Scholar] [CrossRef]

- Biesuz, M.; Zera, E.; Tomasi, M.; Jana, P.; Ersen, O.; Baaziz, W.; Lindemann, A.; Sorarù, G.D. Polymer-derived Si3N4 nanofelts for flexible, high temperature, lightweight and easy-manufacturable super-thermal insulators. Appl. Mater. Today 2020, 20, 100648. [Google Scholar] [CrossRef]

- Yang, R.; Chen, G.; Dresselhaus, M.S. Thermal conductivity modeling of core-shell and tubular nanowires. Nano Lett. 2005, 5, 1111–1115. [Google Scholar] [CrossRef]

- Donadio, D.; Galli, G. Temperature dependence of the thermal conductivity of thin silicon nanowires. Nano Lett. 2010, 10, 847–851. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, Y.; Wang, S.; Wang, X.; Yu, J.; Zhang, S.; Ding, B. Ultrathin aerogel-structured micro/nanofiber metafabric via dual air-gelation synthesis for self-sustainable heating. Nat. Commun. 2024, 15, 6416. [Google Scholar] [CrossRef]

- Zhang, Z.; Ouyang, Y.; Cheng, Y.; Chen, J.; Li, N.; Zhang, G. Size-dependent phononic thermal transport in low-dimensional nanomaterials. Phys. Rep. 2020, 860, 1–26. [Google Scholar] [CrossRef]

- Shi, T.; Jing, J.; Qian, Z.; Wu, G.; Tian, G.; Liu, H.; Wang, X. Sandwich-structured fluorinated polyimide aerogel/paraffin phase-change composites simultaneously enables gradient thermal protection and electromagnetic wave transmission. Adv. Sci. 2025, 12, 2411758. [Google Scholar] [CrossRef] [PubMed]

- Xiong, F.; Zhou, J.; Jin, Y.; Zhang, Z.; Qin, M.; Han, H.; Shen, Z.; Han, S.; Geng, X.; Jia, K.; et al. Thermal shock protection with scalable heat-absorbing aerogels. Nat. Commun. 2024, 15, 7125. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, Z.; Yan, X.; Liu, Y.; Zhao, Y.; Li, K. Si3N4 Nanoparticle Reinforced Si3N4 Nanofiber Aerogel for Thermal Insulation and Electromagnetic Wave Transmission. Gels 2025, 11, 324. https://doi.org/10.3390/gels11050324

Tong Z, Yan X, Liu Y, Zhao Y, Li K. Si3N4 Nanoparticle Reinforced Si3N4 Nanofiber Aerogel for Thermal Insulation and Electromagnetic Wave Transmission. Gels. 2025; 11(5):324. https://doi.org/10.3390/gels11050324

Chicago/Turabian StyleTong, Zongwei, Xiangjie Yan, Yun Liu, Yali Zhao, and Kexun Li. 2025. "Si3N4 Nanoparticle Reinforced Si3N4 Nanofiber Aerogel for Thermal Insulation and Electromagnetic Wave Transmission" Gels 11, no. 5: 324. https://doi.org/10.3390/gels11050324

APA StyleTong, Z., Yan, X., Liu, Y., Zhao, Y., & Li, K. (2025). Si3N4 Nanoparticle Reinforced Si3N4 Nanofiber Aerogel for Thermal Insulation and Electromagnetic Wave Transmission. Gels, 11(5), 324. https://doi.org/10.3390/gels11050324