Production of Mycelium Mats for Textile Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Biological Material

2.2. Growth Conditions

2.3. Treatment of Mycelium Mats

2.4. Characterisation of Mycelium Mats

2.4.1. Thickness Determination

2.4.2. Tear Strength

2.4.3. Water Absorption

2.4.4. Mycelial Density

2.4.5. Sewing

2.5. Statistical Analysis

3. Results

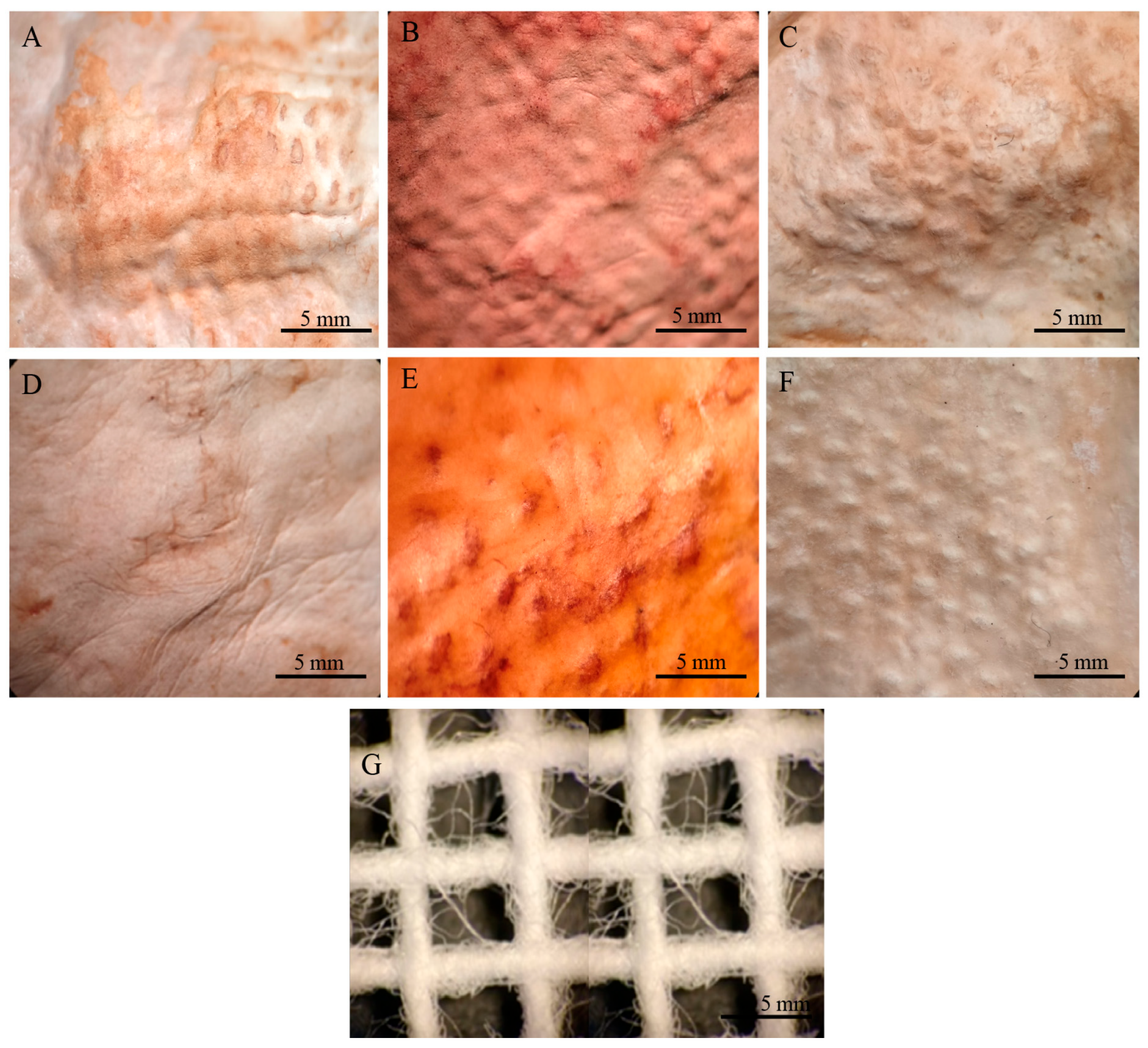

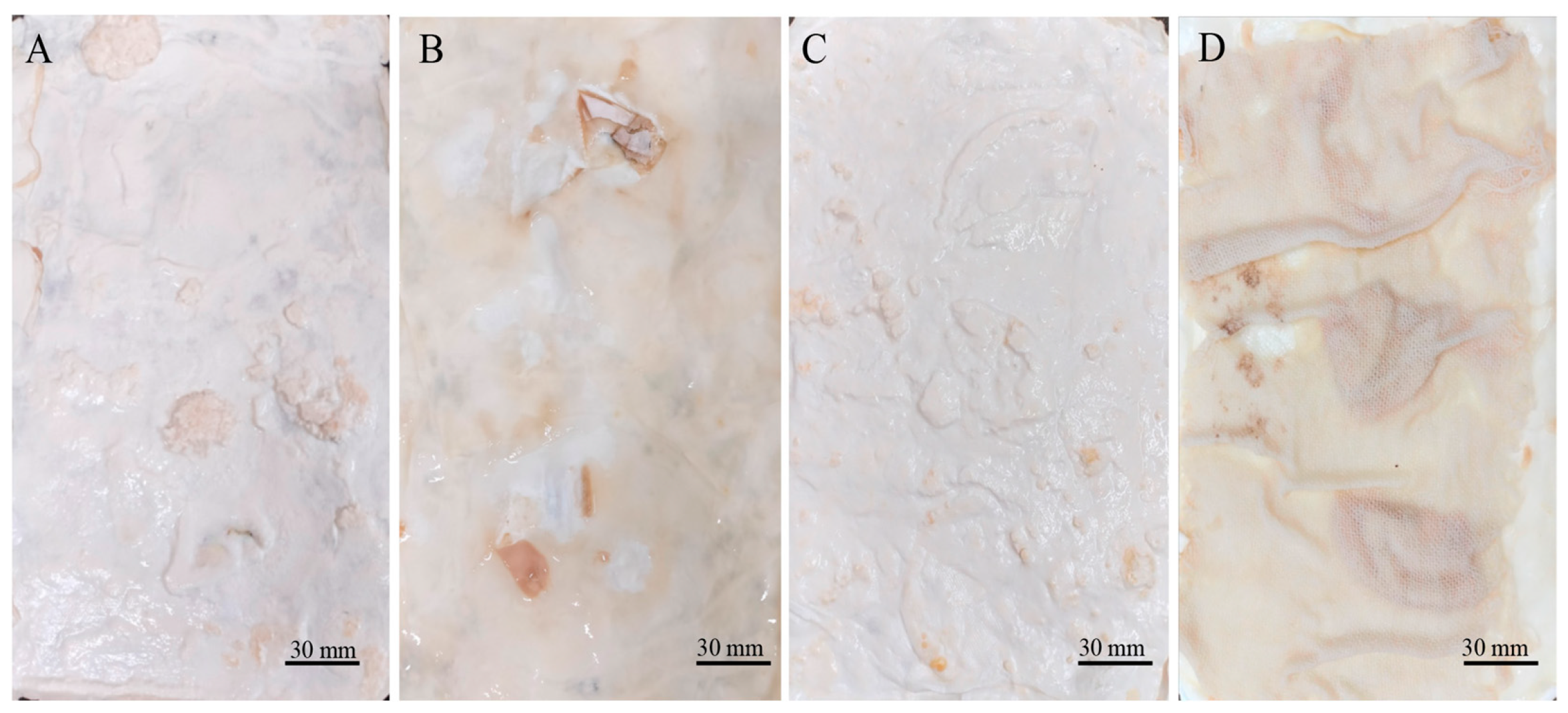

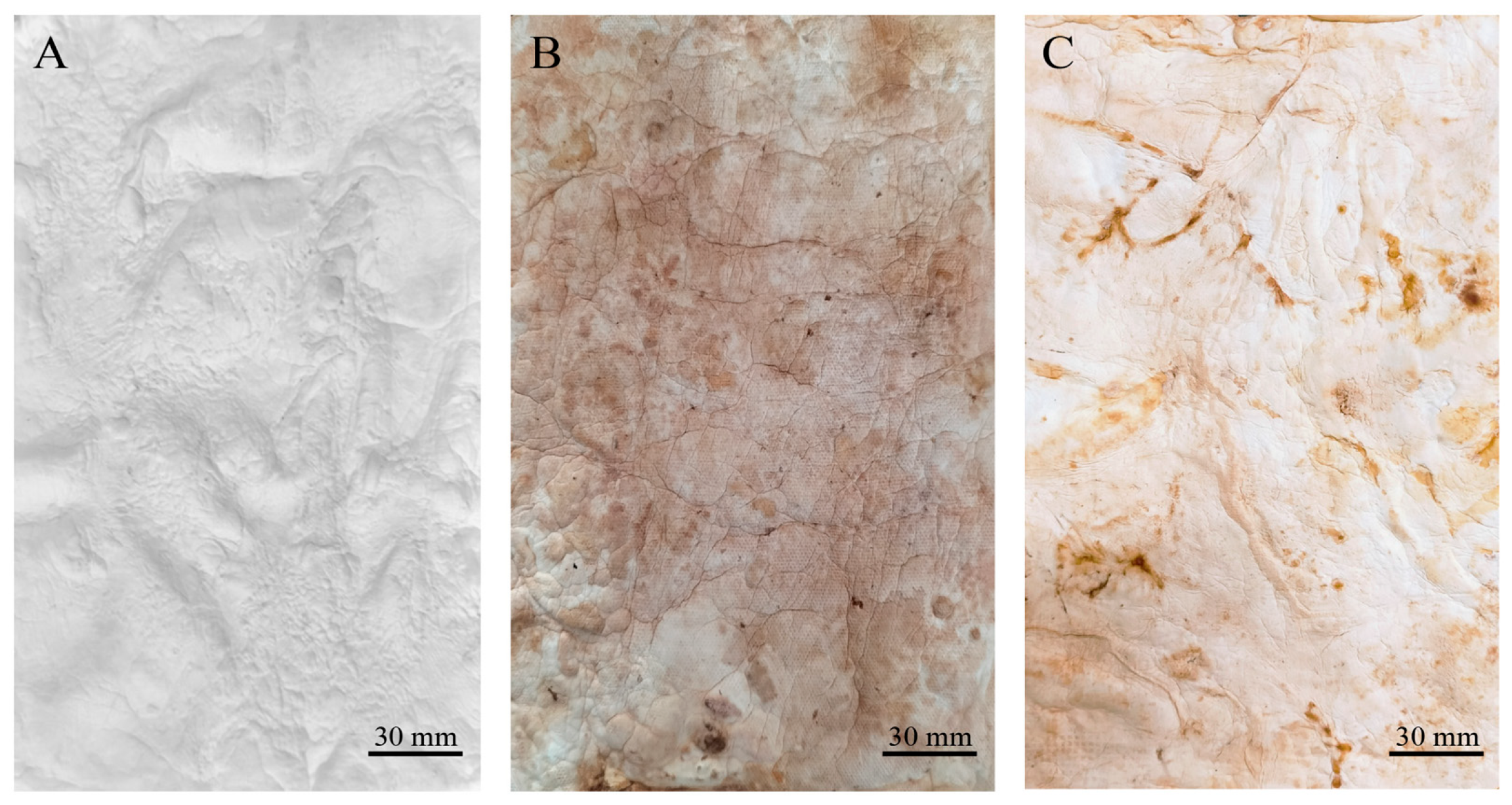

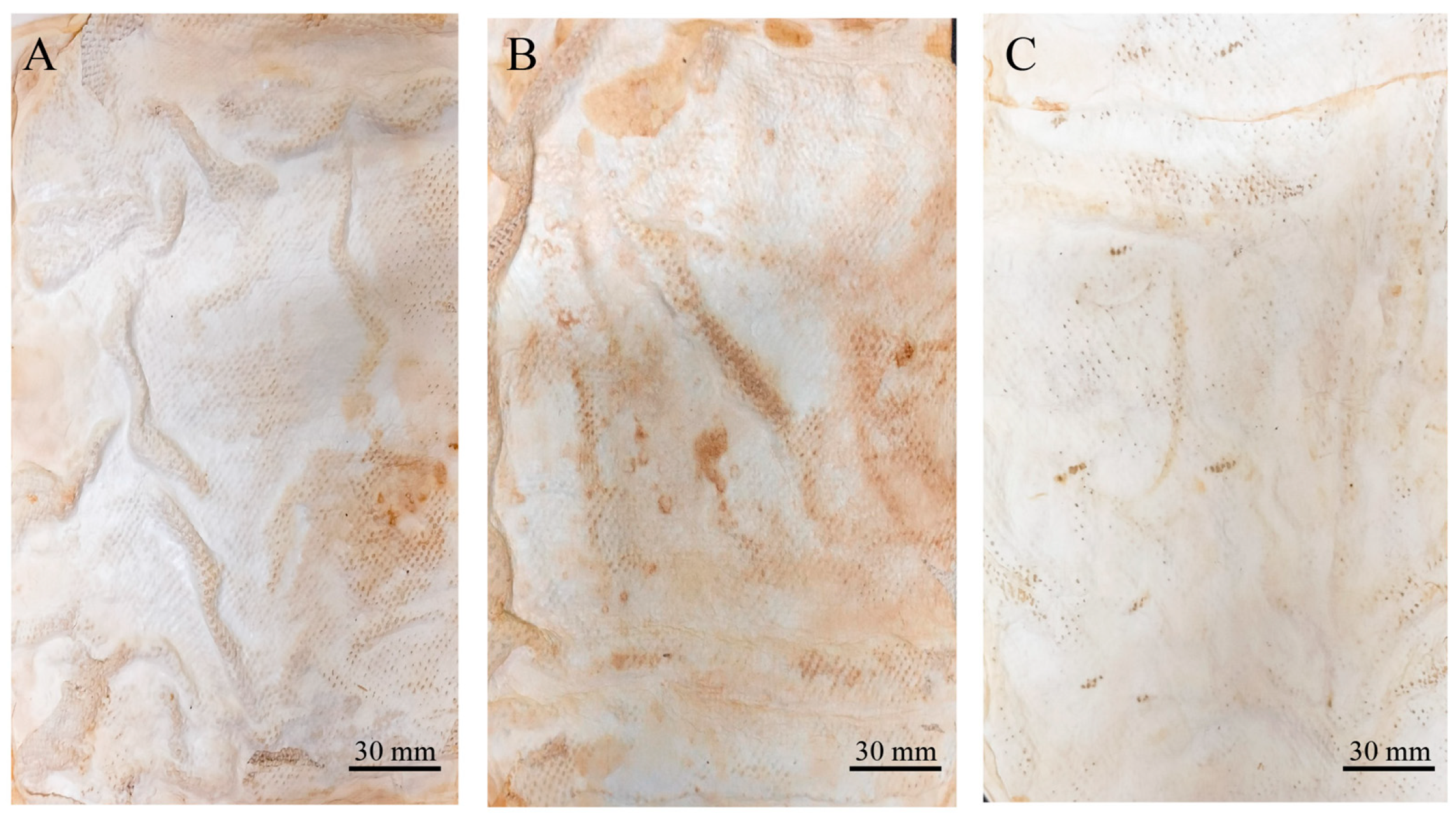

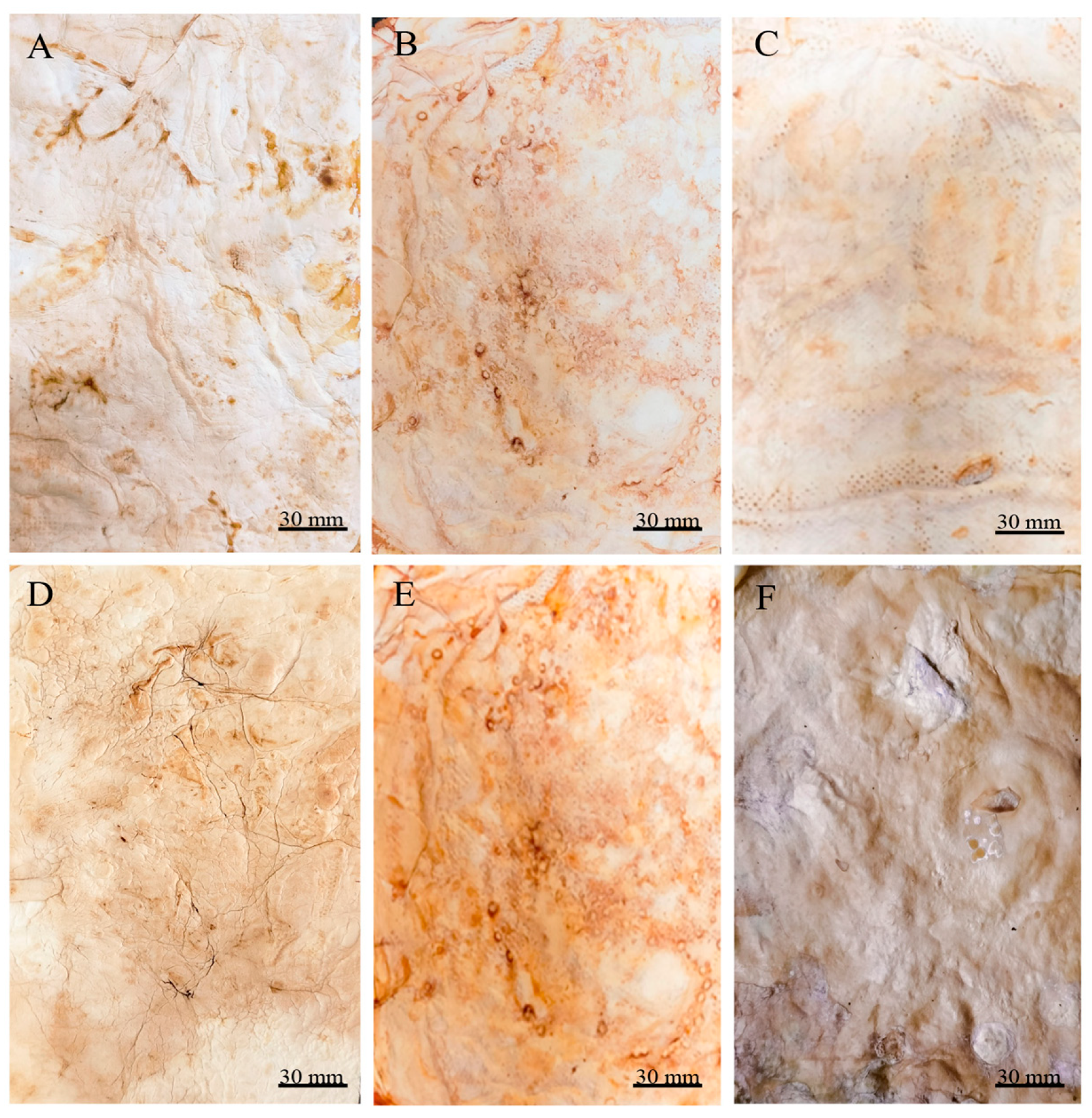

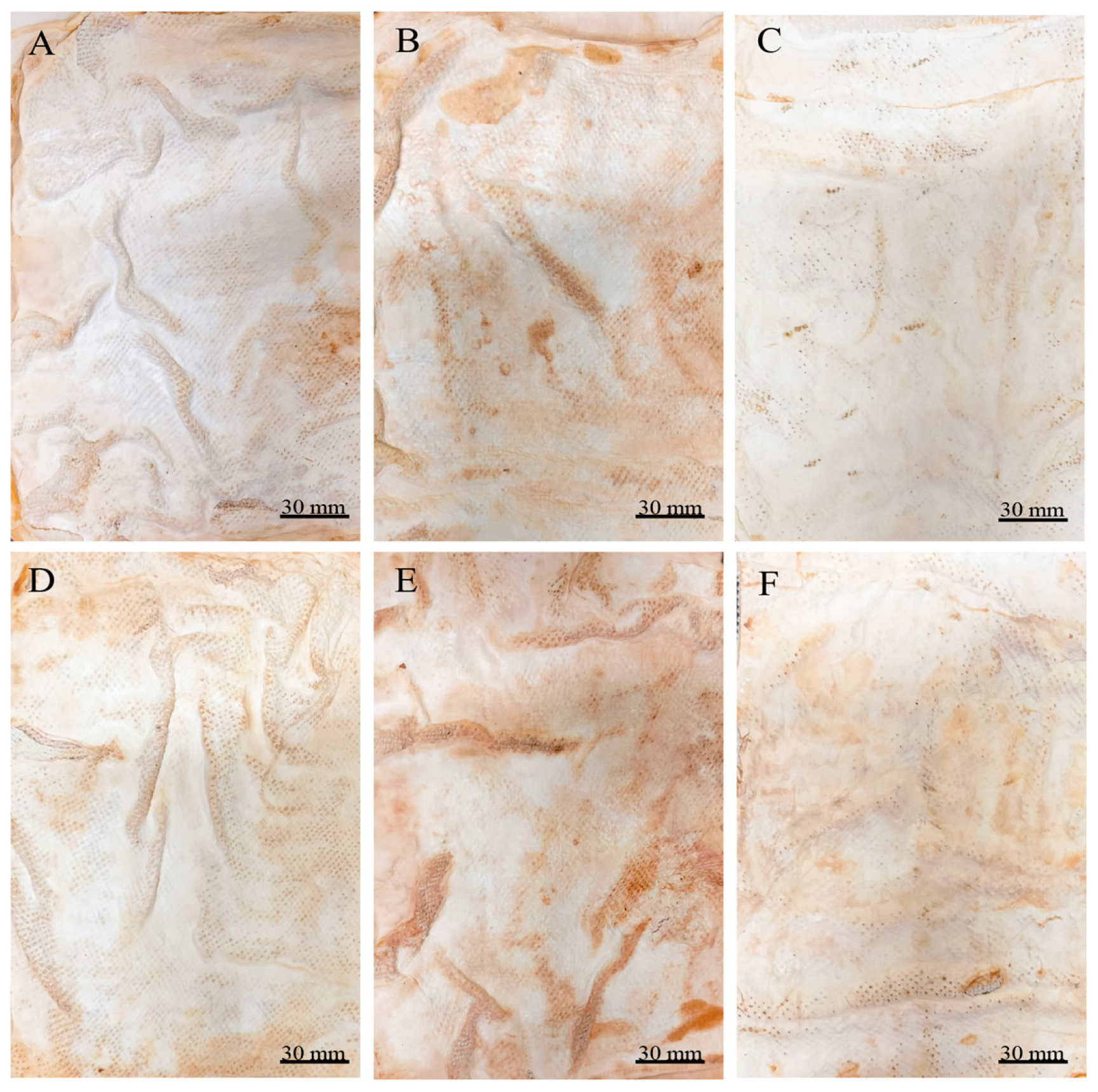

3.1. Obtaining Mycelium Mats

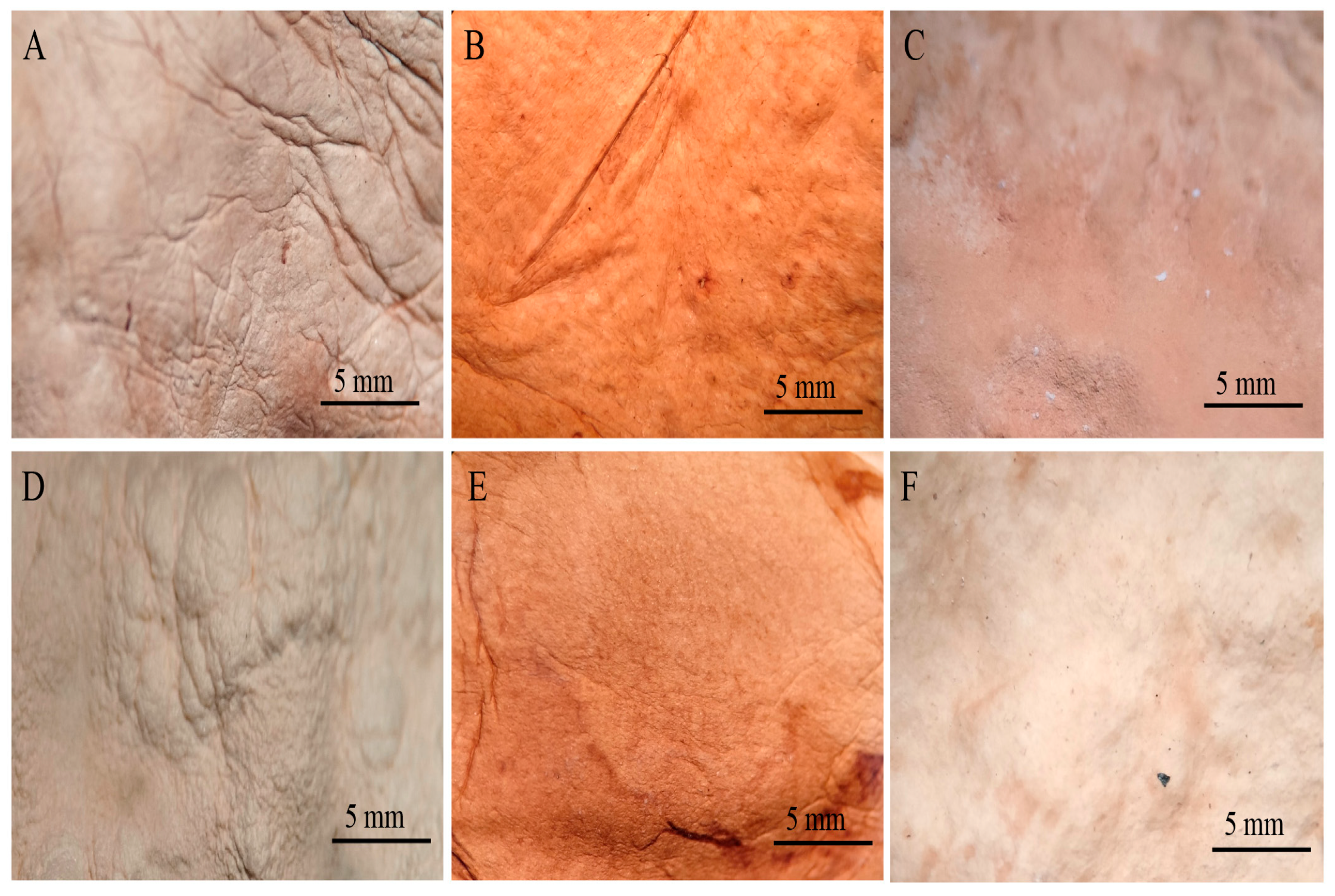

3.2. Treatment of Mycelium Mats

3.3. Characterisation of the Mycelium Mats

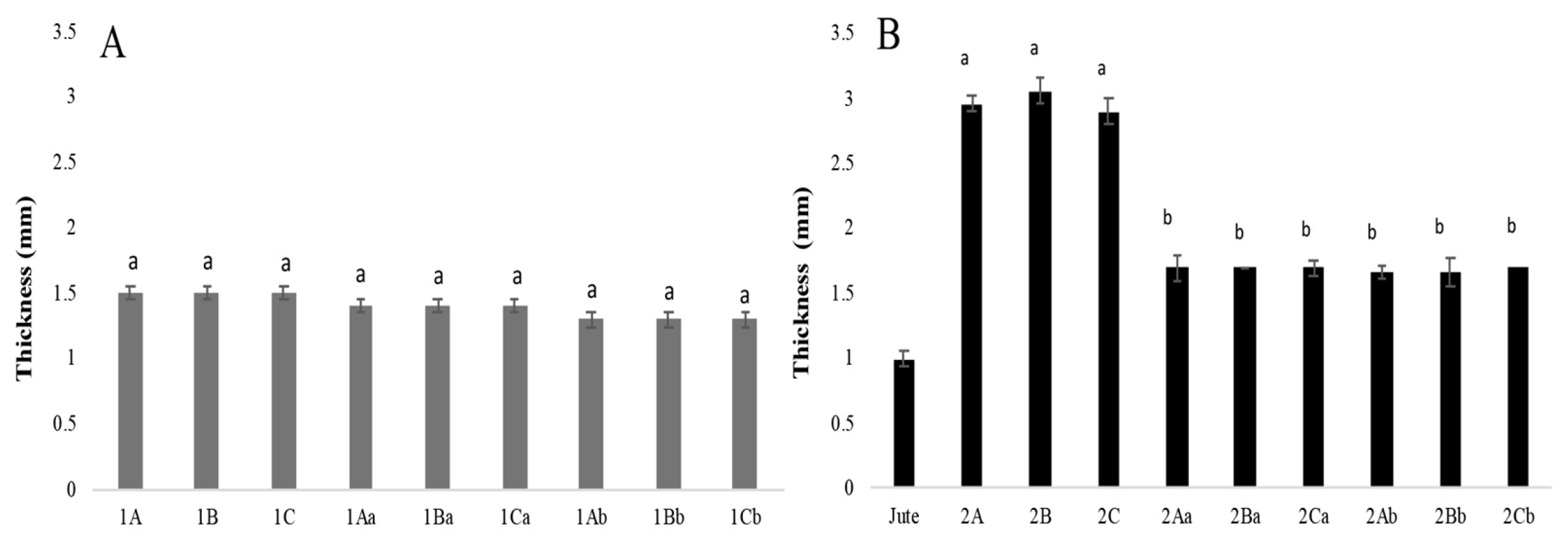

3.3.1. Thickness

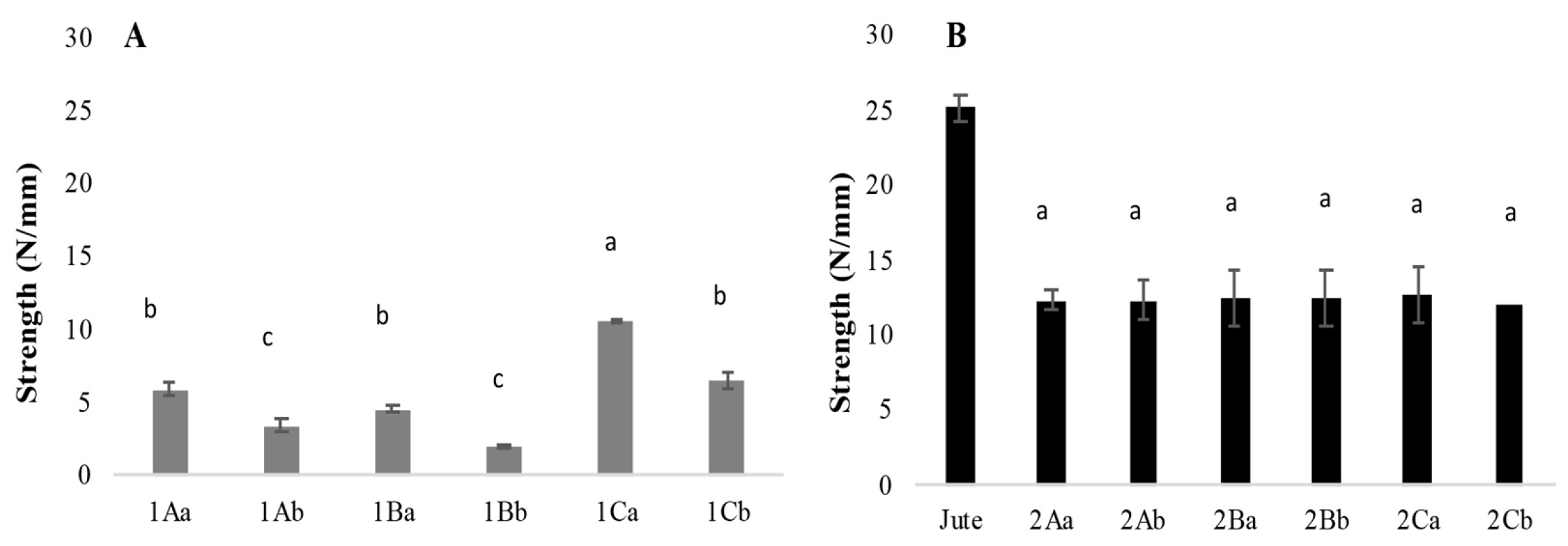

3.3.2. Tear Strength

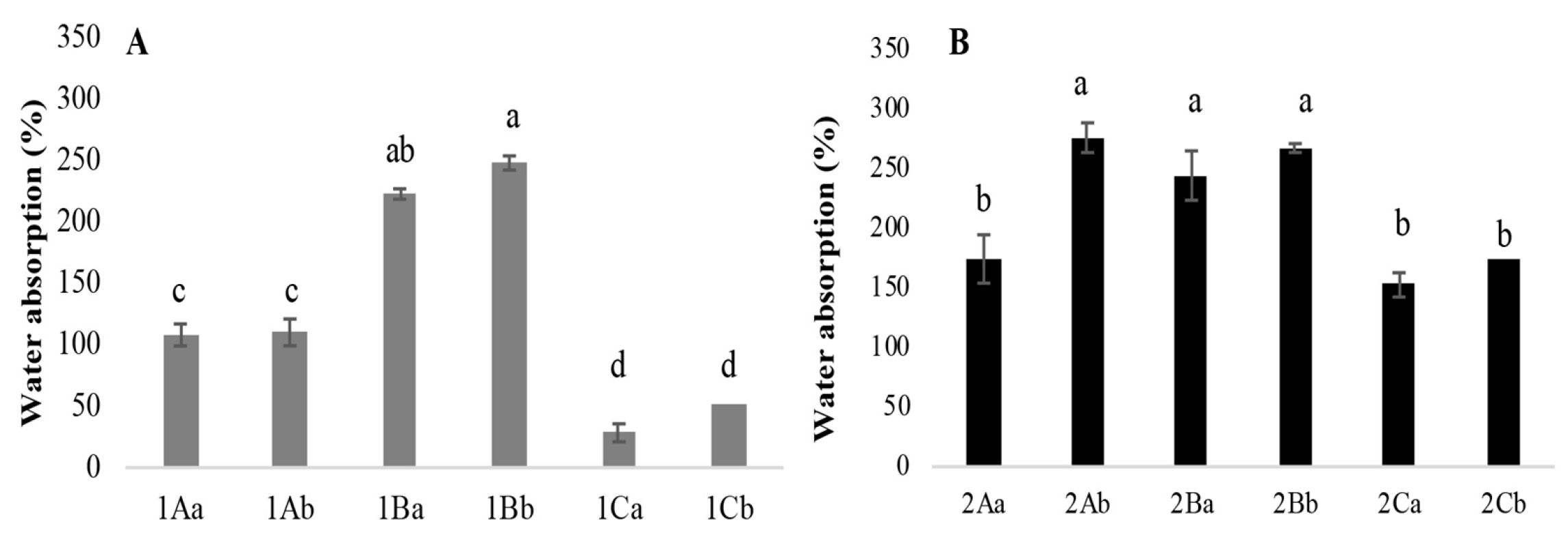

3.3.3. Water Absorption

3.3.4. Mycelial Density

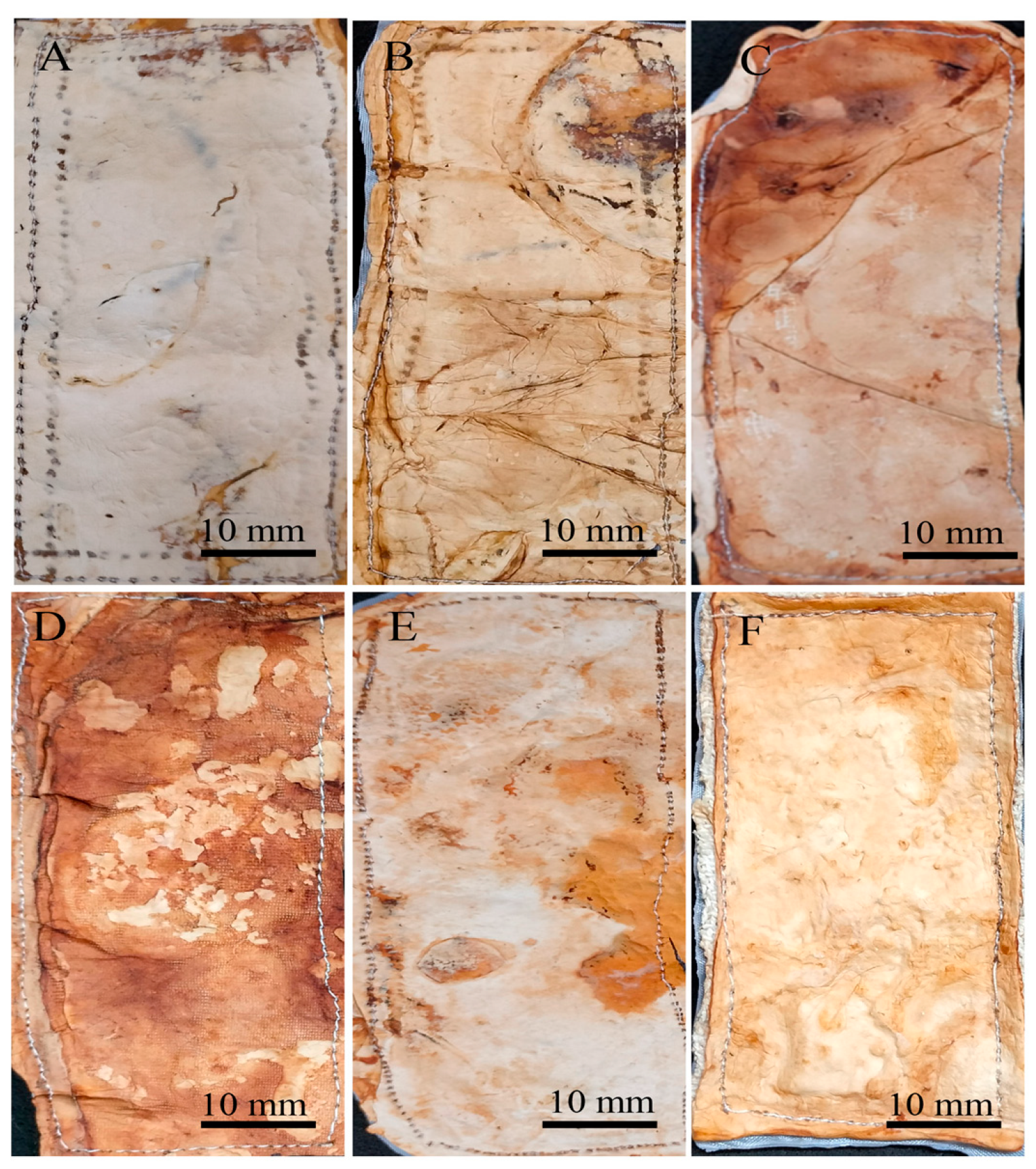

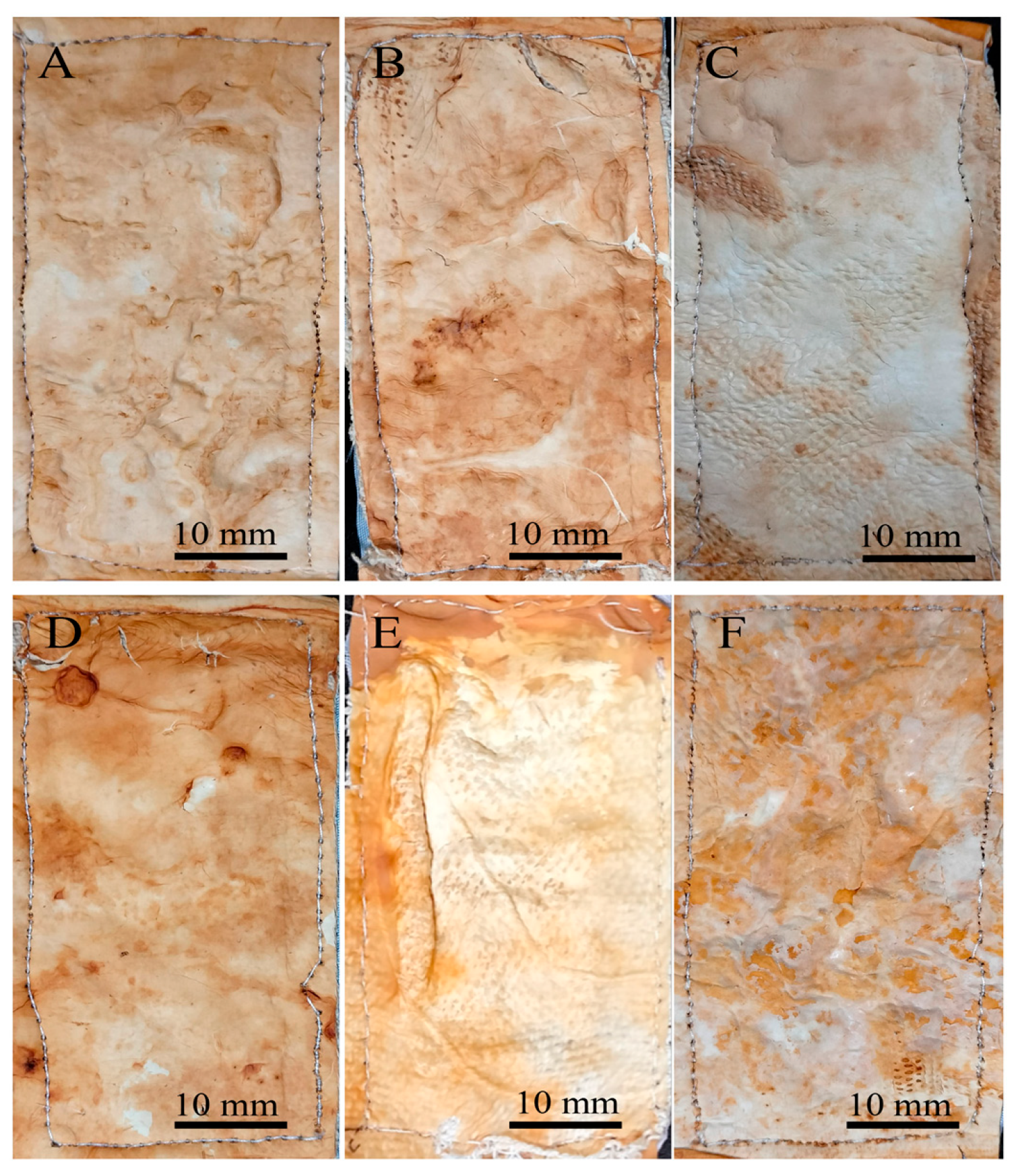

3.3.5. Sewing Performance

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 1A | Mycelium mats + aluminium potassium sulphate |

| 1B | Mycelium mats + tannins |

| 1C | Mycelium mats + citric acid |

| 1Aa | Mycelium mats + aluminium potassium sulphate +air-dried |

| 1Ba | Mycelium mats + tannins + air-dried |

| 1Ca | Mycelium mats + citric acid + air-dried |

| 1Ab | Mycelium mats + aluminium potassium sulphate + dried at 65 °C |

| 1Bb | Mycelium mats + tannins + dried at 65 °C |

| 1Cb | Mycelium mats + citric acid + dried at 65 °C |

| 2A | Supported mycelium mats + aluminium potassium sulphate |

| 2B | Supported mycelium mats + tannins |

| 2C | Supported mycelium mats + citric acid |

| 2Aa | Supported mycelium mats + aluminium potassium sulphate + air-dried |

| 2Ba | Supported mycelium mats + tannins + air-dried |

| 2Ca | Supported mycelium mats + citric acid + air-dried |

| 2Ab | Supported mycelium mats + aluminium potassium sulphate + dried at 65 °C |

| 2Bb | Supported mycelium mats + tannins + dried at 65 °C |

| 2Cb | Supported mycelium mats + citric acid + dried at 65 °C |

| HEMIM | Mycological Herbarium of Morelos |

| K2HPO4 | Potassium phosphate dibasic |

| KH2PO4·H2O | Monopotassium phosphate monohydrate |

| MBSCs | Mycelium-based sandwich composites |

| MBFs | Mycelium-based foams |

| MgSO4 | Magnesium sulphate |

| N/mm | Newton per millimetre |

| PMMs | Pure mycelial materials |

| PDA | Potato dextrose agar |

References

- Cerimi, K.; Akkaya, K.C.; Pohl, C.; Schmidt, B.; Neubauer, P. Fungi as source for new bio-based materials: A patent review. Fungal Biol. Biotechnol. 2019, 6, 17. [Google Scholar] [CrossRef]

- Malabadi, R.B.; Kolkar, K.P.; Chalannavar, R.K.; Baijnath, H. Plant based leather production-an update. World J. Adv. Eng. Eng. Technol. Sci. 2025, 14, 31–59. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Peeters, E. Recent technological innovations in mycelium materials as leather substitutes: A patent review. Front. Bioeng. Biotechnol. 2023, 11, 1204861. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, B.; Gu, C.; Shen, C.; Yin, S.; Aamir, M.; Li, F. Are we underestimating the sources of microplastic pollution in terrestrial environment? J. Hazard. Mater. 2020, 400, 123228. [Google Scholar] [CrossRef]

- Material Innovation Initiative 2023, Next-Gen Material Report. Available online: https://materialinnovation.org/reports/2023-state-of-the-industry-report-next-gen-materials/ (accessed on 26 June 2025).

- Jones, M.; Bhat, T.; Huynh, T.; Kandare, E.; Yuen, R.; Wang, C.H.; John, S. Waste-derived low-cost mycelium composite construction materials with improved fire safety. Fire Mater. 2018, 42, 816–825. [Google Scholar] [CrossRef]

- Parhizi, Z.; Dearnaley, J.; Kauter, K.; Mikkelsen, D.; Pal, P.; Shelley, T.; Burey, P.P. The fungus among us: Innovations and applications of mycelium-based composites. J. Fungi 2025, 11, 549. [Google Scholar] [CrossRef]

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Savino, E. Physico-mechanical and thermodynamic properties of mycelium-based biocomposites: A review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef]

- Madusanka, C.; Udayanga, D.; Nilmini, R.; Rajapaksha, S.; Hewawasam, C.; Manamgoda, D.; Vasco-Correa, J. A review of recent advances in fungal mycelium based composites. Discov. Mater. 2024, 4, 13. [Google Scholar] [CrossRef]

- Vandelook, S.; Elsacker, E.; Van Wylick, A.; De Laet, L.; Peeters, E. Current state and future prospects of pure mycelium materials. Fungal Biol. Biotechnol. 2021, 8, 20. [Google Scholar] [CrossRef] [PubMed]

- Raman, J.; Kim, D.S.; Kim, H.S.; Oh, D.S.; Shin, H.J. Mycofabrication of mycelium-based leather from brown-rot fungi. J. Fungi 2022, 8, 317. [Google Scholar] [CrossRef] [PubMed]

- Karana, E.; Blauwhoff, D.; Hultink, E.J.; Camere, S. When the material grows: A case study on designing (with) mycelium-based materials. Int. J. Des. 2018, 12, 119–136. Available online: http://www.ijdesign.org/index.php/IJDesign/article/view/2918 (accessed on 1 June 2025).

- Angelova, G.V.; Brazkova, M.S.; Krastanov, A.I. Renewable mycelium based composite–sustainable approach for lignocellulose waste recovery and alternative to synthetic materials—A review. Z. Naturforschung C 2021, 76, 431–442. [Google Scholar] [CrossRef]

- International Standard ISO 9073-3:2023; Part 3: Determination of Tensile Strength and Elongation at Break Using the Strip Method. ISO: Geneva, Switzerland, 2023. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:9073:-3:ed-2:v1:en (accessed on 10 January 2023).

- Irbe, I.; Loris, G.D.; Filipova, I.; Andze, L.; Skute, M. Characterization of self-growing biomaterials made of fungal mycelium and various lignocellulose-containing ingredients. Mater. Lett. 2022, 15, 7608. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Zwawi, M.; Taqi Mehran, M.; Kanthasamy, R.; Bahadar, A. Jute based bio and hybrid composites and their applications. Fibers 2019, 7, 77. [Google Scholar] [CrossRef]

- Grimm, D.; Wösten, H.A.B. Mushroom cultivation in the circular economy. Appl. Microbiol. Biotechnol. 2018, 102, 7795–7803. [Google Scholar] [CrossRef]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Bucinell, R.; Tudryn, G. Manufacturing of biocomposite sandwich structures using mycelium-bound cores and preforms. J. Manuf. Process 2017, 28, 50–59. [Google Scholar] [CrossRef]

- Haneef, M.; Ceseracciu, L.; Canale, C.; Bayer, I.S.; Heredia-Guerrero, J.A.; Athanassiou, A. Advanced materials from fungal mycelium: Fabrication and tuning of physical properties. Sci. Rep. 2017, 7, 41292. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Morphology and mechanics of fungal mycelium. Sci. Rep. 2017, 7, 13070. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Bae, B.; Kim, M.; Kim, S.; Ro, H.S. Growth characteristics of polyporales mushrooms for the mycelial mat formation. Mycobiology 2021, 49, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Nussbaum, N.; Von Wyl, T.; Gandia, A.; Romanens, E.; Rühs, P.A.; Fischer, P. Impact of malt concentration in solid substrate on mycelial growth and network connectivity in Ganoderma species. Sci. Rep. 2023, 13, 21051. [Google Scholar] [CrossRef]

- Cartabia, M.; Girometta, C.E.; Milanese, C.; Baiguera, R.M.; Buratti, S.; Branciforti, D.S.; Vadivel, D.; Girella, A.; Babbini, S.; Savino, E. Collection and characterization of wood decay fungal strains for developing pure mycelium mats. J. Fungi 2021, 7, 1008. [Google Scholar] [CrossRef] [PubMed]

- Index Fungorum. Available online: https://www.indexfungorum.org/names/names.asp (accessed on 9 September 2025).

- López Nava, J.A.; Méndez González, J.; Ruelas Chacón, X.; Nájera Luna, J.A. Assessment of edible fungi and films bio-based material simulating expanded polystyrene. Mater. Manuf. Process 2016, 31, 1085–1090. [Google Scholar] [CrossRef]

- Appels, F.V.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.; Dijksterhuis, J.; Wösten, H.A. Fabrication factors influencing mechanical, moisture-and water-related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Appels, F.V.W.; van den Brandhof, J.G.; Dijksterhuis, J.; de Kort, G.W.; Wösten, H.A.B. Fungal mycelium classified in different material families based on glycerol treatment. Commun. Biol. 2020, 3, 334. [Google Scholar] [CrossRef] [PubMed]

- Attias, N.; Reid, M.; Mijowska, S.C.; Dobryden, I.; Isaksson, M.; Pokroy, B. Biofabrication of nanocellulose–mycelium hybrid materials. Adv. Sustain. Syst. 2020, 5, 2000196. [Google Scholar] [CrossRef]

- Moreno Ríos, C.E.; Loja Herrera, P.M.; García Saavedra, E.; Dávila Ruiz, B. Determinación de parámetros tecnológicos en curtición vegetal de piel de paiche (Arapaima gigas) con extracto de quebracho (Schinopsis balansae) y mimosa (Acacia dealbata) para el aprovechamiento industrial ambientalmente sostenible. Ind. Data 2023, 26, 25–52. [Google Scholar] [CrossRef]

- NTP 241.021:2022; FOOTWEAR. Men’s Footwear. Requirements and Test Methods. 5th Edition. [Unpublished Manuscript Online]. Peruvian Technical Standards: Lima, Peru, 2022.

- NTP 241.022:2022; FOOTWEAR. Ladies Footwear. Requirements and Test Methods. 5th Edition. [Unpublished Manuscript Online]. Peruvian Technical Standards: Lima, Peru, 2022.

- NTP 241.023:2022; FOOTWEAR. Casual Footwear. Requirements and Test Methods. 5th Edition. [Unpublished Manuscript Online]. Peruvian Technical Standards: Lima, Peru, 2022.

- Tišma, M.; Žnidaršič-Plazl, P.; Šelo, G.; Tolj, I.; Šperanda, M.; Bucić-Kojić, A.; Planinić, M. Trametes versicolor in lignocellulose-based bioeconomy: State of the art, challenges and opportunities. Bioresour. Technol. 2021, 330, 124997. [Google Scholar] [CrossRef]

- Jones, M.; Weiland, K.; Kujundzic, M.; Theiner, J.; Kählig, H.; Kontturi, E.; Mautner, A. Waste-derived low-cost mycelium nanopapers with tunable mechanical and surface properties. Biomacromolecules 2019, 20, 3513–3523. [Google Scholar] [CrossRef]

- Bentangan, M.A.; Nugroho, A.R.; Hartantyo, R.; Ilman, R.Z.; Ajidarma, E.; Nurhadi, M.Y. Mycelium Material, Its Method to Produce and Usage as Leather Substitute. 2020. Available online: https://patents.google.com/patent/WO2020136448A1/en?oq=WO2020136448A1 (accessed on 1 April 2024).

- Szilvay, G.; Laine, C.; Barrantes, M.A.; Suhonen, A.; Boer, H.; Penttilä, M. Methods of Making Non-Woven Materials from Mycelium. 2021. Available online: https://patents.google.com/patent/WO2021136883A1/en?oq=WO2021136883A1 (accessed on 20 April 2025).

- Hanson, M.; Wypych, A. Databook of Curatives and Crosslinkers, 2nd ed.; Chem Tec Publishing: Toronto, Canada, 2024; p. 660. ISBN 9781774670323. [Google Scholar]

- Silva, V. Overview of the leather industry and pollution impact. U Porto J. Eng. 2021, 7, 1–15. [Google Scholar] [CrossRef]

- Kasmudjiastuti, E.; Pidhatika, B.; Griyanitasari, G.; Pahlawan, I.F. The effect of alum addition on shrinkage temperature, chemical properties, and morphology in the manufacture of vegetable-tanned leather. IOP Conf. Ser. Mater. Sci. Eng. 2019, 602, 012044. [Google Scholar] [CrossRef]

- Gandia, A.; van den Brandhof, J.G.; Appels, F.V.; Jones, M.P. Flexible fungal materials: Shaping the future. Trends Biotechnol. 2021, 39, 1321–1331. [Google Scholar] [CrossRef] [PubMed]

- Appels, F.V.; Dijksterhuis, J.; Lukasiewicz, C.E.; Jansen, K.M.; Wösten, H.A.; Krijgsheld, P. Hydrophobin gene deletion and environmental growth conditions impact mechanical properties of mycelium by affecting the density of the material. Sci. Rep. 2018, 8, 4703. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero-Cedillo, R.K.; Robledo-Leal, E.R.; Aguilar-Marcelino, L.; Acosta-Urdapilleta, M.d.L.; Téllez-Téllez, M. Production of Mycelium Mats for Textile Applications. J. Fungi 2025, 11, 700. https://doi.org/10.3390/jof11100700

Romero-Cedillo RK, Robledo-Leal ER, Aguilar-Marcelino L, Acosta-Urdapilleta MdL, Téllez-Téllez M. Production of Mycelium Mats for Textile Applications. Journal of Fungi. 2025; 11(10):700. https://doi.org/10.3390/jof11100700

Chicago/Turabian StyleRomero-Cedillo, Reyes K., Efrén R. Robledo-Leal, Liliana Aguilar-Marcelino, Ma. de Lourdes Acosta-Urdapilleta, and Maura Téllez-Téllez. 2025. "Production of Mycelium Mats for Textile Applications" Journal of Fungi 11, no. 10: 700. https://doi.org/10.3390/jof11100700

APA StyleRomero-Cedillo, R. K., Robledo-Leal, E. R., Aguilar-Marcelino, L., Acosta-Urdapilleta, M. d. L., & Téllez-Téllez, M. (2025). Production of Mycelium Mats for Textile Applications. Journal of Fungi, 11(10), 700. https://doi.org/10.3390/jof11100700