Potentials and Pitfalls on the Use of Passion Fruit By-Products in Drinkable Yogurt: Physicochemical, Technological, Microbiological, and Sensory Aspects

Abstract

1. Introduction

2. Materials and Methods

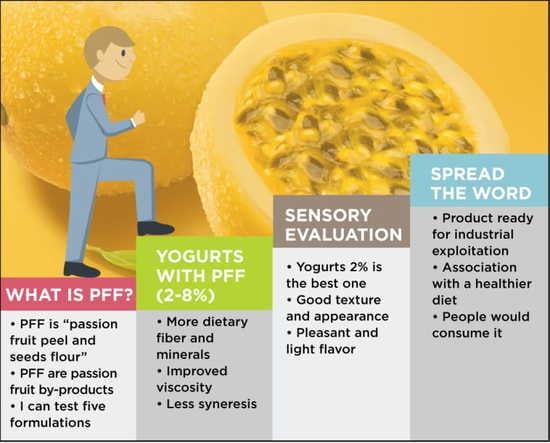

2.1. Passion Fruit By-Products

2.2. Passion Fruit Flour (PFF)

2.3. Preparation of Milk and Drinkable Yogurt Manufacturing

- (1)

- Commercial yogurt: plain drinkable yogurt acquired in the local market (reference material);

- (2)

- Plain yogurt: experimental drinkable yogurt made without passion fruit pulp or PFF (control);

- (3)

- Yogurt 0%: experimental drinkable yogurt made with 20% of passion fruit pulp and without PFF; and

- (4)

- Yogurt 2%, 4%, 6%, and 8% (w/w): experimental drinkable yogurts made with 20% of passion fruit pulp and 2%, 4%, 6%, or 8% (w/w) of PFF, respectively.

2.4. Proximate Composition and Mineral Content

2.5. Physicochemical Analyses

2.6. Microbiological Analyses

2.7. Sensory Evaluation

2.8. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition

3.2. Mineral Content

3.3. Physicochemical Analyses

3.4. Microbiological Evaluation

3.5. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Do Espírito Santo, A.P.E.; Perego, P.; Converti, A.; Oliveira, M.N. Influence of milk type and adittion of passion fruit peel powder on fermetation kinetics, texture profile and bacterial viability in probiotic yoghurts. LWT-Food Sci. Technol. 2012, 47, 393–399. [Google Scholar] [CrossRef]

- Córdova, K.R.V.; Gama, T.M.M.T.B.; Winter, C.M.G.; Kaskantzis Neto, G.; Freitas, R.J.S. Características físico-químicas da casca do maracujá amarelo (Passiflora edulis flavicarpa Degener) obtida por secagem. CEPPA Bull. 2005, 23, 221–230. [Google Scholar] [CrossRef]

- Morais, D.R.; Rotta, E.M.; Sargi, S.C.; Bonafe, E.G.; Suzuki, R.M.; Souza, N.E.; Matsushita, M.; Visentainer, J.V. Proximate composition, mineral contents and fatty acid composition of different parts and dried peels of tropical fruits cultivated in Brazil. J. Braz. Chem. Soc. 2017, 28, 308–318. [Google Scholar] [CrossRef]

- Ambigaipalan, P.; de Camargo, A.C.; Shahidi, F. Phenolic compounds of pomegranate byproducts (outer skin, mesocarp, divider membrane) and their antioxidant activities. J. Agric. Food Chem. 2016, 64, 6584–6604. [Google Scholar] [CrossRef] [PubMed]

- Ambigaipalan, P.; de Camargo, A.C.; Shahidi, F. Identification of phenolic antioxidants and bioactives of pomegranate seeds following juice extraction using HPLC-DAD-ESI-MSn. Food Chem. 2017, 221, 1883–1894. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira, W.P.; Biasoto, A.C.T.; Marques, V.F.; Santos, I.M.; Magalhaes, K.; Correa, L.C.; Negro-Dellacqua, M.; Miranda, M.S.; de Camargo, A.C.; Shahidi, F. Phenolics from winemaking by-products better decrease VLDL-cholesterol and triacylglycerol levels than those of red wine in Wistar rats. J. Food Sci. 2017, 82, 2432–2437. [Google Scholar] [CrossRef] [PubMed]

- Ayoub, M.; de Camargo, A.C.; Shahidi, F. Antioxidants and bioactivities of free, esterified and insoluble-bound phenolics from berry seed meals. Food Chem. 2016, 197, 221–232. [Google Scholar] [CrossRef] [PubMed]

- De Camargo, A.C.; Regitano-d’Arce, M.A.B.; Rasera, G.B.; Canniatti-Brazaca, S.G.; do Prado-Silva, L.; Alvarenga, V.O.; Sant’Ana, A.S.; Shahidi, F. Phenolic acids and flavonoids of peanut by-products: Antioxidant capacity and antimicrobial effects. Food Chem. 2017, 237, 538–544. [Google Scholar] [CrossRef] [PubMed]

- Cazarin, C.B.B.; Rodriguez-Nogales, A.; Algieri, F.; Utrilla, M.P.; Rodriguez-Cabezas, M.E.; Garrido-Mesa, J.; Guerra-Hernandez, E.; Braga, P.A.D.; Reyes, F.G.R.; Marostica, M.R.; et al. Intestinal anti-inflammatory effects of Passiflora edulis peel in the dextran sodium sulphate model of mouse colitis. J. Funct. Foods 2016, 26, 565–576. [Google Scholar] [CrossRef]

- Selani, M.M.; Bianchini, A.; Ratnayake, W.S.; Flores, R.A.; Massaroli, A.P.; de Alencar, S.M.; Canniatti Brazaca, S.G. Physicochemical, functional and antioxidant properties of tropical co-products. Plant Foods Hum. Nutr. 2016, 71, 137–144. [Google Scholar] [CrossRef] [PubMed]

- Arioui, F.; Saada, D.J.; Cheriguene, A. Physicochemical and sensory quality of yogurt incorporated with pectin from peel of Citrus sinensis. Food Sci. Nutr. 2017, 5, 358–364. [Google Scholar] [CrossRef] [PubMed]

- Toledo, N.M.V.; Nunes, L.P.; Silva, P.P.M.; Spoto, M.H.F.; Canniatti-Brazaca, S.G. Influence of pineapple, apple and melon by-products on cookies: Physicochemical and sensory aspects. Int. J. Food Sci. Technol. 2017, 52, 1185–1192. [Google Scholar] [CrossRef]

- Miocinovic, J.; Tomic, N.; Dojnov, B.; Tomasevic, I.; Stojanovic, S.; Djekic, I.; Vujcic, Z. Application of new insoluble dietary fibres from triticale as supplement in yoghurt—Effects on physico-chemical, rheological and quality properties. J. Sci. Food Agric. 2018, 98, 1291–1299. [Google Scholar] [CrossRef] [PubMed]

- Clemens, R.; Kranz, S.; Mobley, A.R.; Nicklasm, T.A.; Raimondi, M.P.; Rodriguez, J.C.; Slavin, J.L.; Warshaw, H. Filling America’s fiber intake gap: Summary of a roundtable to probe realistic solutions with a focus on grain-based foods. J. Nutr. 2012, 142, S1390–S1401. [Google Scholar] [CrossRef] [PubMed]

- Karnopp, A.R.; Oliveira, K.G.; de Andrade, E.F.; Postingher, B.M.; Granato, D. Optimization of an organic yogurt based on sensorial, nutritional, and functional perspectives. Food Chem. 2017, 233, 401–411. [Google Scholar] [CrossRef] [PubMed]

- Ramos, L.R.; Santos, J.S.; Daguer, H.; Valese, A.C.; Cruz, A.G.; Granato, D. Analytical optimization of a phenolic-rich herbal extract and supplementation in fermented milk containing sweet potato pulp. Food Chem. 2017, 221, 950–958. [Google Scholar] [CrossRef] [PubMed]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2011, 124, 411–421. [Google Scholar] [CrossRef]

- Sharma, S.K.; Bansal, S.; Mangal, M.; Dixit, A.K.; Gupta, R.K.; Mangal, A.K. Utilization of food processing by-products as dietary, functional, and novel fiber: A review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1647–1661. [Google Scholar] [CrossRef] [PubMed]

- Hoppert, K.; Zahn, S.; Jaenecke, L.; Mai, R.; Hoffmann, S.; Rohm, H. Consumer acceptance of regular and reduced-sugar yogurt enriched with different types of dietary fiber. Int. Dairy J. 2013, 28, 1–7. [Google Scholar] [CrossRef]

- Yi, T.; Huang, X.; Pan, S.; Wang, L. Physicochemical and functional properties of micronized jincheng orange by-products (Citrus sinensis Osbeck) dietary fiber and its application as a fat replacer in yogurt. Int. J. Food Sci. Nutr. 2014, 65, 565–572. [Google Scholar] [CrossRef] [PubMed]

- Raju, P.N.; Pal, D. Effect of dietary fibers on physico-chemical, sensory and textural properties of Misti Dahi. J. Food Sci. Technol. 2014, 51, 3124–3133. [Google Scholar] [CrossRef] [PubMed]

- Perina, N.P.; Granato, D.; Hirota, C.; Cruz, A.G.; Bogsan, C.S.B.; Oliveira, M.N. Effect of vegetal oil emulsion and passion fruit peel-powder on sensory acceptance of functional yogurt. Food Res. Int. 2015, 70, 134–141. [Google Scholar] [CrossRef]

- Tamime, A.Y.; Robinson, R.K. Tamime and Robinson's Yogurt: Science and Technology; CRC Press: Boca Ratón, FL, USA, 2007. [Google Scholar]

- Bamforth, C.W.; Ward, R.E. The Oxford Handbook of Food Fermentations; Oxford University Press: New York, NY, USA, 2014. [Google Scholar]

- IDF-International Dairy Federation. Fermented Milks–Determination of Titratable Acidity–Potentiometric Method; IDF 150:2012; BSI: London, UK, 2012. [Google Scholar]

- AOAC-Association of Official Analytical Chemists. Official Methods of Analysis of AOAC International; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Asp, N.G.; Johansson, C.G.; Hallmer, H.; Siljestroem, M. Rapid enzimatic assay of insoluble and soluble dietary fiber. J. Agric. Food Chem. 1983, 31, 476–482. [Google Scholar] [CrossRef] [PubMed]

- Dello Staffolo, M.; Bertola, N.; Martino, M.; Bevilacqua, A. Influence of dietary fiber addition on sensory and rheological properties of yogurt. Int. Dairy J. 2004, 14, 263–268. [Google Scholar] [CrossRef]

- Downes, F.P.; Ito, K. Compendium of Methods for the Microbiological Examination of Food; American Public Health Association: Washington, DC, USA, 2001. [Google Scholar]

- Stone, H.S.; Sidel, J.L. Sensory Evaluation Practices; Academic Press: Orlando, FL, USA, 1993. [Google Scholar]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Springer Science & Business Media: New York, NY, USA, 2010. [Google Scholar]

- Meilgaard, M.C.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques; CRC Press: Boca Ratón, FL, USA, 2006. [Google Scholar]

- Almaraz, R.S.; Fuentes, M.M.; Milla, S.P.; Plaza, B.L.; Lopez, L.M.B.; Candela, C.G. Fiber-type indication among different pathologies. Nutr. Hosp. 2015, 31, 2372–2383. [Google Scholar] [CrossRef]

- Bingham, S.A.; Day, N.E.; Luben, R.; Ferrari, P.; Slimani, N.; Norat, T.; Clavel-Chapelon, F.; Kesse, E.; Nieters, A.; Boeing, H.; et al. Dietary fibre in food and protection against colorectal cancer in the European prospective investigation into cancer and nutrition (EPIC): An observational study. Lancet 2003, 361, 1496–1501. [Google Scholar] [CrossRef]

- Eshak, E.S.; Iso, H.; Date, C.; Kikuchi, S.; Watanabe, Y.; Wada, Y.; Wakai, K.; Tamakoshi, A.J.S.G. Dietary fiber intake is associated with reduced risk of mortality from cardiovascular disease among Japanese men and women. J. Nutr. 2010, 140, 1445–1453. [Google Scholar] [CrossRef] [PubMed]

- Post, R.E.; Mainous, A.G.; King, D.E.; Simpson, K.N. Dietary fiber for the treatment of type 2 diabetes mellitus: A meta-analysis. J. Am. Board Fam. Med. 2012, 25, 16–23. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hruby, A.; Bernstein, A.M.; Ley, S.H.; Wang, D.D.; Chiuve, S.E.; Sampson, L.; Rexrode, K.M.; Rimm, E.B.; Willett, W.C.; et al. Saturated fats compared with unsaturated fats and sources of carbohydrates in relation to risk of coronary heart disease: A prospective cohort study. J. Am. Coll. Cardiol. 2015, 66, 1538–1548. [Google Scholar] [CrossRef] [PubMed]

- National Institutes of Health. Dietary Reference Intakes (DRIs): Recommended Dietary Allowances and Adequate Intakes, Elements. Available online: https://www.ncbi.nlm.nih.gov/books/NBK56068/table/summarytables.t3/?report=objectonly (accessed on 14 May 2018).

- García-Perez, F.J.; Lario, Y.; Férnandez-López, J.; Sayas, E.; Pérez-Alvarez, J.A.; Sendra, E. Effect of orange fiber addition on yogurt color during fermentation and cold storage. Color Res. Appl. 2005, 30, 457–463. [Google Scholar] [CrossRef]

- Tseng, A.; Zhao, Y. Wine grape pomace as antioxidant dietary fibre for enhancing nutritional value and improving storability of yogurt and salad dressing. Food Chem. 2013, 138, 356–365. [Google Scholar] [CrossRef] [PubMed]

- Hashim, I.B.; Khalil, A.H.; Afifi, H.S. Quality characteristics and consumer acceptance of yogurt fortified with date fiber. J. Dairy Sci. 2009, 92, 5403–5407. [Google Scholar] [CrossRef] [PubMed]

- Loveday, S.M.; Sarkar, A.; Singh, H. Innovative yoghurts: Novel processing technologies for improving acid milk gel texture. Trends Food Sci. Technol. 2013, 33, 5–20. [Google Scholar] [CrossRef]

- Ramirez-Santiago, C.; Ramos-Solis, L.; Lobato-Calleros, C.; Peña-Valdivia, C.; Vernon-Carter, E.J.; Alvarez-Ramírez, J. Enrichment of stirred yogurt with soluble dietary fiber from Pachyrhizus erosus L. Urban: Effect on syneresis, microstructure and rheological properties. J. Food Eng. 2010, 101, 229–235. [Google Scholar] [CrossRef]

- Aportela-Palacios, A.; Sosa-Morales, M.E.; Vélez-Ruiz, J.F. Rheological and physicochemical behavior of fortified yogurt with fiber and calcium. J. Texture Stud. 2005, 36, 333–349. [Google Scholar] [CrossRef]

- Izadi, Z.; Nasirpour, A.; Garoosi, G.A.; Tamjidi, F. Rheological and physical properties of yogurt enriched with phytosterol during storage. J. Food Sci. Technol. 2015, 52, 5341–5346. [Google Scholar] [CrossRef] [PubMed]

- Brasil. Ministério da Saúde. Agência Nacional de Vigilância Sanitária. Resolução n° 12, de 02 de Janeiro de 2001. Aprova o Regulamento Técnico Sobre Padrões Microbiológicos Para Alimentos. Available online: http://portal.anvisa.gov.br/documents/33880/2568070/RDC_12_2001.pdf/15ffddf6-3767-4527-bfac-740a0400829b (accessed on 14 May 2018).

- Akalin, A.S.; Fenderya, S.; Akbulut, N. Viability and activity of bifidobacteria in yoghurt containing fructooligosaccharide during refrigerated storage. Int. J. Food Sci. Technol. 2004, 39, 613–621. [Google Scholar] [CrossRef]

- FAO/WHO-Food and Agriculture Organization of the United Nations/World Health Organization. Codex Alimentarius–Milk and Milk Products. 2011. Available online: http://www.fao.org/docrep/015/i2085e/i2085e00.pdf (accessed on 18 January 2018).

- Ledenbach, L.H.; Marshall, R.T. Microbiological Spoilage of Dairy Products. In Compendium of the Microbiological Spoilage of Foods and Beverages; Sperber, W.H., Doyle, M.P., Eds.; Springer: New York, NY, USA, 2009. [Google Scholar]

- De Camargo, A.C.; Regitano-d’Arce, M.A.B.; Gallo, C.R.; Shahidi, F. Gamma-irradiation induced changes in microbiological status, phenolic profile and antioxidant activity of peanut skin. J. Funct. Foods 2015, 12, 129–143. [Google Scholar] [CrossRef]

- Shah, N.N.A.K.; Shamsudin, R.; Rahman, R.A.; Adzahan, N.M. Fruit juice production using ultraviolet pasteurization: A review. Beverages 2016, 2, 22. [Google Scholar] [CrossRef]

- Vogado, C.O.; Leandro, E.S.; Zandonadi, R.P.; Alencar, E.R.; Ginani, V.C.; Nakano, E.Y.; Habú, S.; Aguiar, P.A. Enrichment of probiotic fermented milk with green banana pulp: Characterization microbiological, physicochemical and sensory. Nutrients 2018, 10, 427. [Google Scholar] [CrossRef] [PubMed]

- Gahruie, H.H.; Eskandari, M.H.; Mesbahi, G.; Hanifpour, M.A. Scientific and technical aspects of yogurt fortification: A review. Food Sci. Hum. Well. 2015, 4, 1–8. [Google Scholar] [CrossRef]

- Spínola, V.; Pinto, J.; Castilho, P.C. Identification and quantification of phenolic compounds of selected fruits from Madeira Island by HPLC-DAD–ESI-MS and screening for their antioxidant activity. Food Chem. 2015, 173, 14–30. [Google Scholar] [CrossRef] [PubMed]

| Passion Fruit Ingredients | Drinkable Yogurts | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Passion Fruit Pulp | Passion Fruit Peel and Seeds Flour | Commercial Yogurt | Plain Yogurt | Yogurt 0% PFF | Yogurt 2% PFF | Yogurt 4% PFF | Yogurt 6% PFF | Yogurt 8% PFF | |

| Moisture (g) | 90.0 ± 1.3 1 | 7.1 ± 0.3 | 82.0 ± 0.0 a2 | 77.4 ± 0.2 c | 78.7 ± 0.8 b | 77.7 ± 0.6 c | 76.0 ± 0.8 d | 74.7 ± 0.8 e | 73.2 ± 0.1 f |

| Ash (g) | 0.7 ± 0.0 | 5.3 ± 0.0 | 0.8 ± 0.0 e | 1.3 ± 0.0 c | 1.2 ± 0.0 d | 1.2 ± 0.0 cd | 1.3 ± 0.1 b | 1.3 ± 0.0 b | 1.4 ± 0.0 a |

| Proteins (g) | 1.0 ± 0.0 | 8.7 ± 0.3 | 3.9 ± 0.3 a | 4.5 ± 0.4 a | 4.0 ± 0.5 a | 4.1 ± 0.5 a | 4.2 ± 0.5 a | 4.1 ± 0.5 a | 4.3 ± 0.2 a |

| Lipids (g) | 0.5 ± 0.0 | 9.9 ± 0.6 | 2.8 ± 0.0 cd | 2.9 ± 0.0 ab | 2.4 ± 0.0 f | 2.6 ± 0.0 e | 2.7 ± 0.0 d | 2.9 ± 0.0 bc | 3.0 ± 0.0 a |

| Carbohydrates (g) | 6.1 ± 1.1 | 5.0 ± 0.2 | 10.5 ± 0.1 | 13.9 ± 0.1 | 13.4 ± 0.6 | 12.8 ± 0.6 | 13.0 ± 0.8 | 12.9 ± 1.2 | 12.8 ± 0.4 |

| DF (g) | 1.7 ± 0.2 | 64.0 ± 0.4 | 0.0 ± 0.0 f | 0.0 ± 0.0 f | 0.3 ± 0.0 e | 1.6 ± 0.1 d | 2.8 ± 0.1 c | 4.1 ± 0.1 b | 5.3 ± 0.2 a |

| IDF (g) | 0.9 ± 0.4 | 50.4 ± 0.4 | 0.0 ± 0.0 e | 0.0 ± 0.0 e | 0.2 ± 0.0 e | 1.2 ± 0.0 d | 2.1 ± 0.1 c | 3.1 ± 0.1 b | 4.0 ± 0.2 a |

| SDF (g) | 0.8 ± 0.2 | 13.6 ± 0.7 | 0.0 ± 0.0 f | 0.0 ± 0.0 f | 0.1 ± 0.0 e | 0.4 ± 0.0 d | 0.7 ± 0.0 c | 1.0 ± 0.0 b | 1.3 ± 0.0 a |

| P (mg) | 13.4 ± 0.0 | 11.6 ± 1.1 | 94.9 ± 0.6 f | 131 ± 2.2 a | 122.4 ± 0.4 b | 113.7 ± 2.9 e | 117.5 ± 0.3 de | 124.0 ± 1.2 b | 118.9 ± 0.8 cd |

| K (mg) | 172.9 ± 3.8 | 164.9 ± 8.6 | 133.1 ± 0.3 g | 180.4 ± 0.0 f | 196.2 ± 2.9 e | 225.0 ± 0.0 d | 247.3 ± 3.1 c | 306.5 ± 0.0 b | 316.2 ± 3.6 a |

| Ca (mg) | 5.6 ± 0.0 | 21.7 ± 1.5 | 95.2 ± 1.5 e | 194.5 ± 5.9 a | 190.4 ± 1.5 a | 138.8 ± 0.6 d | 164.0 ± 1.9 b | 160.7 ± 0.0 b | 148.4 ± 2.3 c |

| Mg (mg) | 23. ± 1.3 | 23.7 ± 2.9 | 8.4 ± 1.1 d | 10.2 ± 1.4 bcd | 9.5 ± 0.0 cd | 11.1 ± 0.0 bc | 12.6 ± 0.0 b | 15.7 ± 0.0 a | 15.3 ± 1.4 a |

| S (mg) | 15.6 ± 1.1 | 12.3 ± 1.1 | 26.4 ± 1.1d | 38.3 ± 0.7 a | 35.2 ± 2.2 c | 35.3 ± 0.7 bc | 36.1 ± 0.4 abc | 38.5 ± 0.4 a | 38.1 ± 0.3 ab |

| Na (mg) | 15 ± 1.7 | 7.3 ±1.1 | 41.9 ± 2.5 d | 72.2 ± 0.0 a | 59.7 ± 2.9 b | 69.9 ± 3.0 a | 51.3 ± 0.0 c | 56.5 ± 3.4bc | 60.4 ± 3.6 b |

| Cu (mg) | 0.1 ± 0.0 | 0.1 ± 0.0 | 0.1 ± 0.0 b | 0.1 ± 0.0 ab | 0.0 ± 0.0 b | 0.1 ± 0.0 ab | 0.1 ± 0.0 ab | 0.0 ± 0.0 b | 0.1 ± 0.0 a |

| Fe (mg) | 0.8 ± 0.3 | 0.6 ± 0.0 | 0.5 ± 0.2 a | 0.4 ± 0.1 a | 0.5 ± 0.2 a | 0.6 ± 0.3 a | 0.5 ± 0.1 a | 0.7 ± 0.1 a | 0.8 ± 0.2 a |

| Mn (mg) | 0.1 ± 0.0 | 0.3 ± 0.0 | 0.00 ± 0.0 e | 0.00 ± 0.0 e | 0.00 ± 0.0 e | 0.1 ± 0.0 cd | 0.1 ± 0.0 bc | 0.2 ± 0.0 ab | 0.2 ± 0.0 a |

| Zn (mg) | 0.5 ± 0.0 | 0.4 ± 0.0 | 0.6 ± 0.1 a | 0.7 ± 0.0 a | 0.7 ± 0.2 a | 0.8 ± 0.2 a | 0.8 ± 0.2 a | 0.7 ± 0.0 a | 0.8 ± 0.2 a |

| L | 48.4 ± 0.1 | 60.1 ± 0.9 | 77.0 ± 0.5 a | 76.3 ± 0.0 a | 73.9 ± 0.3 b | 67.8 ± 0.4 c | 64.7 ± 0.6 d | 60.8 ± 1.1 e | 59.4 ± 1.0 f |

| C | 40.1 ± 0.1 | 31.6 ± 1.2 | 8.7 ± 0.1 d | 7.9 ± 0.1 e | 22. ± 0.4 a | 19.6 ± 0.2 b | 19.3 ± 0.2 b | 18.2 ± 0.8 c | 19.2 ± 0.4 b |

| h (º) | 85.7 ± 0.1 | 82.5 ± 1.5 | 107.1 ± 0.8 a | 107.2 ± 0.8 a | 96.7 ± 0.1 b | 93.9 ± 0.4 c | 92.2 ± 0.9 d | 91 ± 0.5 e | 90 ± 0.5 e |

| pH | 3.20 ± 0.03 | 3.72 ± 0.05 | 4.05 ± 0.03 d | 4.57 ± 0.02 a | 4.42 ± 0.03 b | 4.31 ± 0.02 c | 4.28 ± 0.01 c | 4.26 ± 0.02 c | 4.30 ± 0.01 c |

| Viscosity (cP) | NA | NA | NA | 6731 ± 7.2 d | 4918 ± 5.9 f | 5531 ± 6.9 e | 7897± 9.3 c | 11838 ± 8.5 b | 21487 ± 7.6 a |

| pH | ||||

| Drinkable yogurt with PFF (%) | Storage time (days) | |||

| 7 | 14 | 21 | 28 | |

| Plain * | 4.57 ± 0.01 1a2A3 | 4.46 ± 0.01 aB | 4.34 ± 0.02 aC | 4.30 ± 0.02 aC |

| 0 | 4.42 ± 0.01 bA | 4.29 ± 0.01 bB | 4.05 ± 0.01 cC | 4.01 ± 0.01 bD |

| 2 | 4.31 ± 0.01 cA | 4.19 ± 0.02 cdB | 4.08 ± 0.01 bC | 3.99 ± 0.01 bD |

| 4 | 4.28 ± 0.02 cdA | 4.17 ± 0.01 dB | 4.05 ± 0.02 bcC | 4.00 ± 0.03 bD |

| 6 | 4.26 ± 0.02 dA | 4.16 ± 0.02 dB | 4.04 ± 0.01 cC | 4.03 ± 0.01 bC |

| 8 | 4.30 ± 0.02 cdA | 4.20 ± 0.01 cB | 4.09 ± 0.01 bC | 4.03 ± 0.01 bD |

| Syneresis (%) | ||||

| Drinkable yogurt with PFF (%) | Storage time (days) | |||

| 7 | 14 | 21 | 28 | |

| Plain * | 25.0 ± 0.6 aC | 31.5 ± 0.5 aB | 39.2 ± 0.6 aA | 41.7 ± 1.8 aA |

| 0 | 24.0 ± 1.0 aB | 28.8 ± 0.3 bA | 31.3 ± 1.6 bA | 32.0 ± 2.2 bA |

| 2 | 17.0 ± 0.6 bD | 22.5 ± 0.5 acC | 26.9 ± 1.0 cB | 31.1 ± 0.8 bA |

| 4 | 12.2 ± 0.9 cD | 17.6 ± 0.4 dC | 20.8 ± 0.2 dB | 22.7 ± 0.4 cA |

| 6 | 2.50 ± 0.2 dC | 6.30 ± 0.3 eB | 8.80 ± 0.3 eA | 9.40 ± 0.3 dA |

| 8 | 2.20 ± 0.1 dB | 2.20 ± 0.1 fB | 2.80 ± 0.3 fA | 3.20 ± 0.3 eA |

| Storage Time (days) | Drinkable Yogurt with PFF (%) | |||||

|---|---|---|---|---|---|---|

| Plain * | 0 | 2 | 4 | 6 | 8 | |

| Lactic acid bacteria (log CFU/g) | ||||||

| 0 | 8.63 1a2A3 | 8.38 dA | 8.45 cA | 8.34 dA | 8.49 bA | 8.32 dA |

| 7 | 8.43 aB | 8.11 cB | 8.28 bB | 7.99 dB | 8.30 bB | 8.04 cdB |

| 14 | 7.92 aC | 7.69 dC | 7.75 bC | 7.72 cC | 7.63 eC | 7.61 eC |

| 21 | 7.60 aD | 7.23 dD | 7.25 dD | 7.41 cD | 7.46 bC | 7.04 eD |

| 28 | 6.99 aE | 6.82 dE | 6.81 dE | 6.86 cE | 6.89 bE | 6.72 eE |

| Yeast and mold (log CFU/g) | ||||||

| 0 | <1 aC | <1 aC | <1 Ad | <1 aD | <1 aD | <1 aD |

| 7 | <1 aC | <1 aC | <1 aD | <1 aD | <1 aD | <1 aD |

| 14 | <1 dC | <1 dC | 1.68 cC | 1.64 cC | 1.84 bC | 1.92 aC |

| 21 | 1.43 fB | 1.62 eB | 1.99 dB | 2.11 cB | 2.20 bB | 2.25 aB |

| 28 | 1.94 eA | 2.15 dA | 2.40 cA | 2.61 bA | 2.59 bA | 2.71 aA |

| Descriptive Terms (Attributes) | Definition | Reference |

|---|---|---|

| Appearance | ||

| 1. Color | Refers to the drinkable yogurt’s color and can range from yellow to brown |

|

| 2. Attractiveness | Refers to the desire to consume the drinkable yogurt |

|

| 3. Brightness | Refers to color lightness |

|

| 4. Homogeneity | Refers to the uniformity of the drinkable yogurt; there aren’t black spots, bubbles, or fibers |

|

| Aroma | ||

| 5. Expected | Refers to the aroma of a drinkable yogurt with fiber when compared to a passion fruit-based yogurt |

|

| 6. Sweet | Refers to the drinkable yogurt’s sweetness |

|

| Flavor | ||

| 7. Expected | Refers to the flavor of a drinkable yogurt with fiber when compared to a passion fruit-based yogurt |

|

| 8. Sweet | Refers to the drinkable yogurt’s sweetness |

|

| 9. Bitter | Refers to the bitter taste of the drinkable yogurt |

|

| Texture | ||

| 10. Expected | Refers to the texture of a drinkable yogurt with fiber when compared to a passion fruit-based yogurt |

|

| 11. Consistency | Refers to the firmness of the drinkable yogurt |

|

| 12. Viscosity | Refers to the slip resistance of the drinkable yogurt |

|

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Toledo, N.M.V.; De Camargo, A.C.; Ramos, P.B.M.; Button, D.C.; Granato, D.; Canniatti-Brazaca, S.G. Potentials and Pitfalls on the Use of Passion Fruit By-Products in Drinkable Yogurt: Physicochemical, Technological, Microbiological, and Sensory Aspects. Beverages 2018, 4, 47. https://doi.org/10.3390/beverages4030047

De Toledo NMV, De Camargo AC, Ramos PBM, Button DC, Granato D, Canniatti-Brazaca SG. Potentials and Pitfalls on the Use of Passion Fruit By-Products in Drinkable Yogurt: Physicochemical, Technological, Microbiological, and Sensory Aspects. Beverages. 2018; 4(3):47. https://doi.org/10.3390/beverages4030047

Chicago/Turabian StyleDe Toledo, Nataly Maria Viva, Adriano Costa De Camargo, Paula Bortolotto Mendes Ramos, David Charles Button, Daniel Granato, and Solange Guidolin Canniatti-Brazaca. 2018. "Potentials and Pitfalls on the Use of Passion Fruit By-Products in Drinkable Yogurt: Physicochemical, Technological, Microbiological, and Sensory Aspects" Beverages 4, no. 3: 47. https://doi.org/10.3390/beverages4030047

APA StyleDe Toledo, N. M. V., De Camargo, A. C., Ramos, P. B. M., Button, D. C., Granato, D., & Canniatti-Brazaca, S. G. (2018). Potentials and Pitfalls on the Use of Passion Fruit By-Products in Drinkable Yogurt: Physicochemical, Technological, Microbiological, and Sensory Aspects. Beverages, 4(3), 47. https://doi.org/10.3390/beverages4030047