From Sugar of Grape to Alcohol of Wine: Sensorial Impact of Alcohol in Wine

Abstract

:1. General Introduction

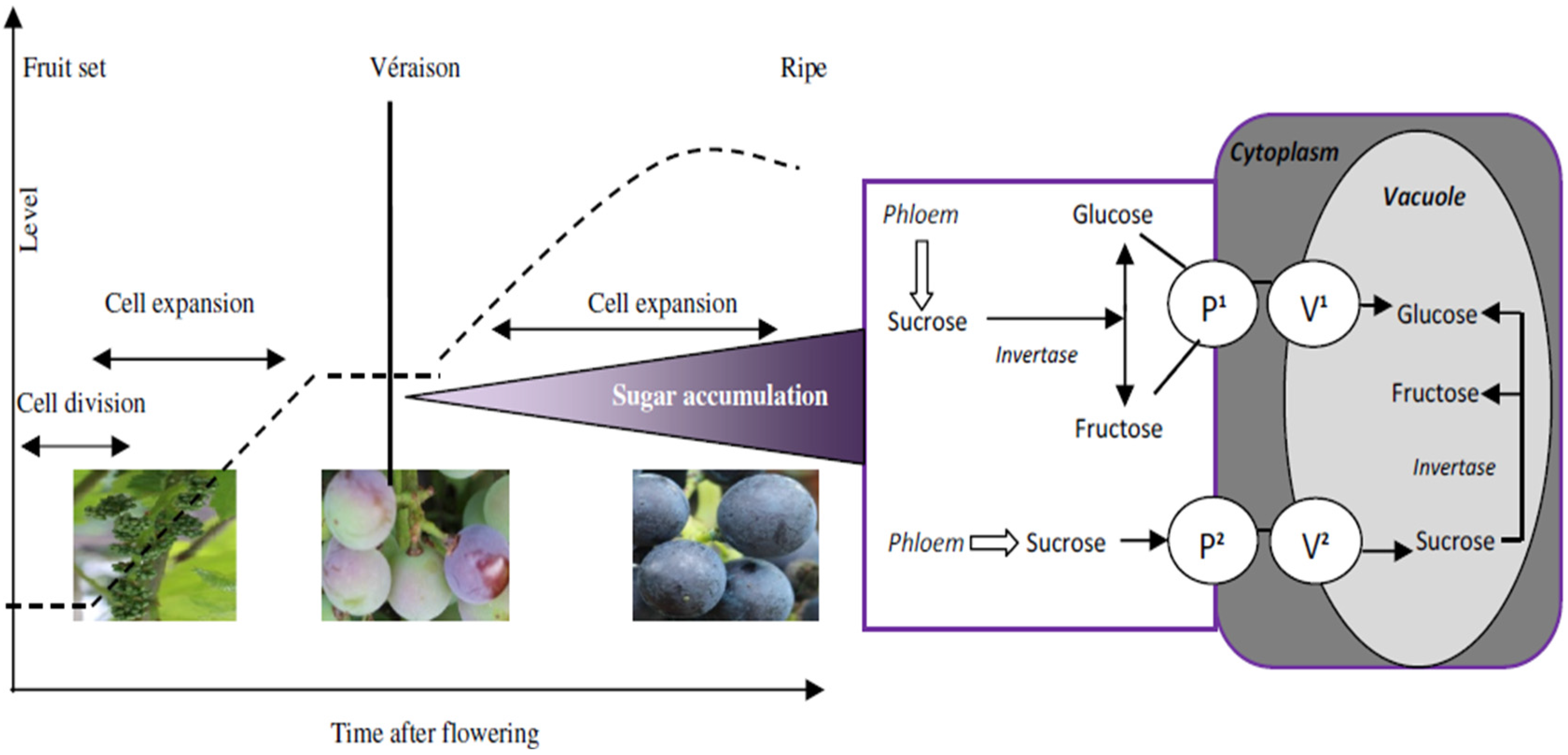

2. Grape Berry Composition—Sugars

3. Sugar Accumulation during Grape Ripening

4. Factors that Affect the Sugar Accumulation and Level in Grape Berries

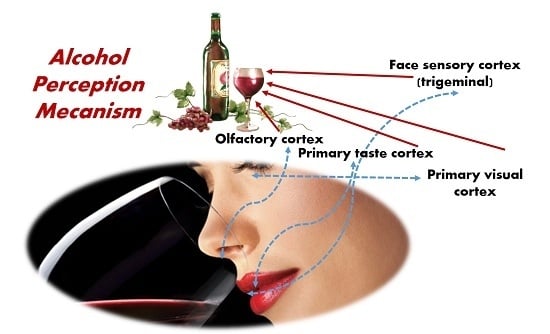

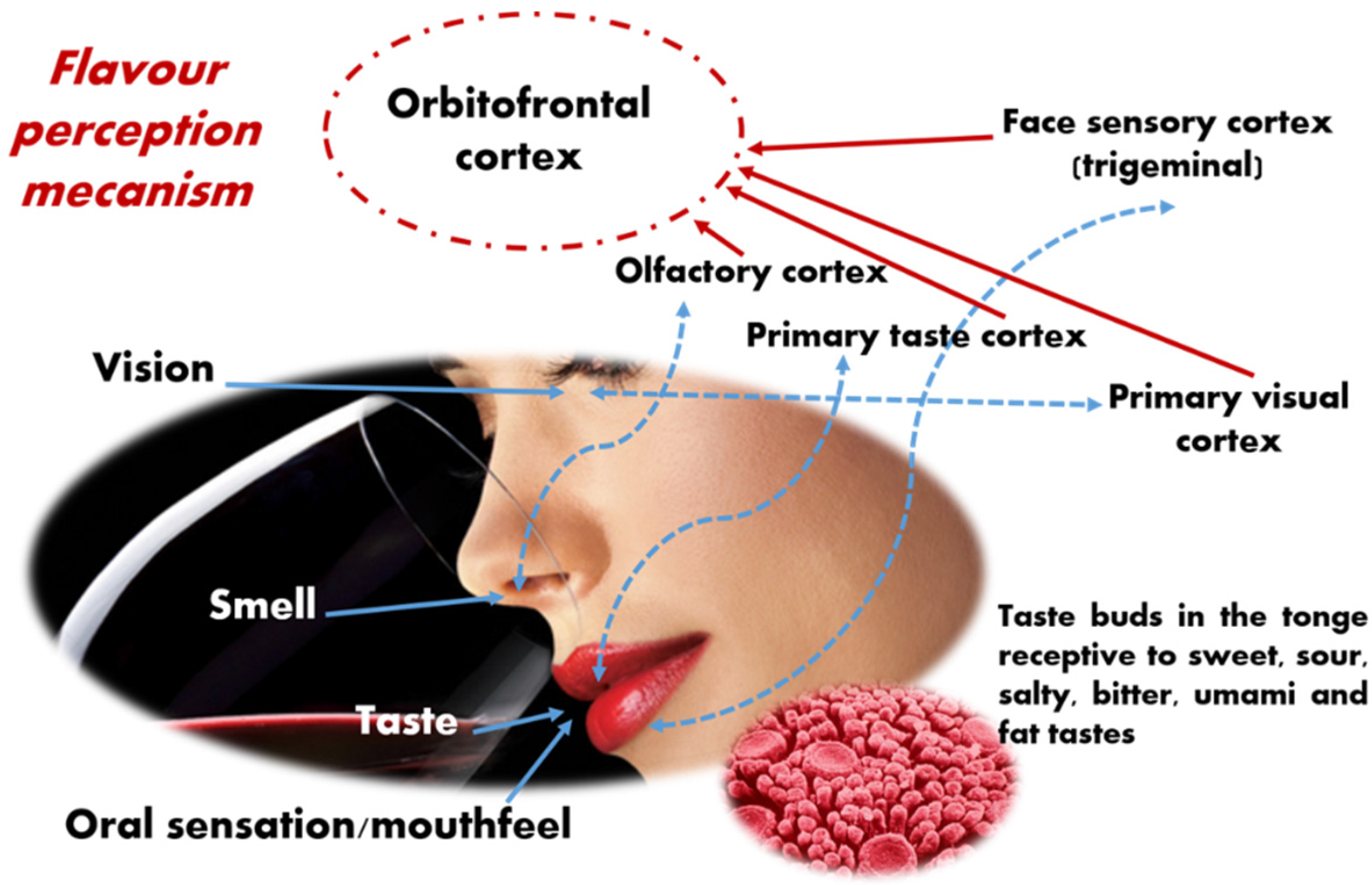

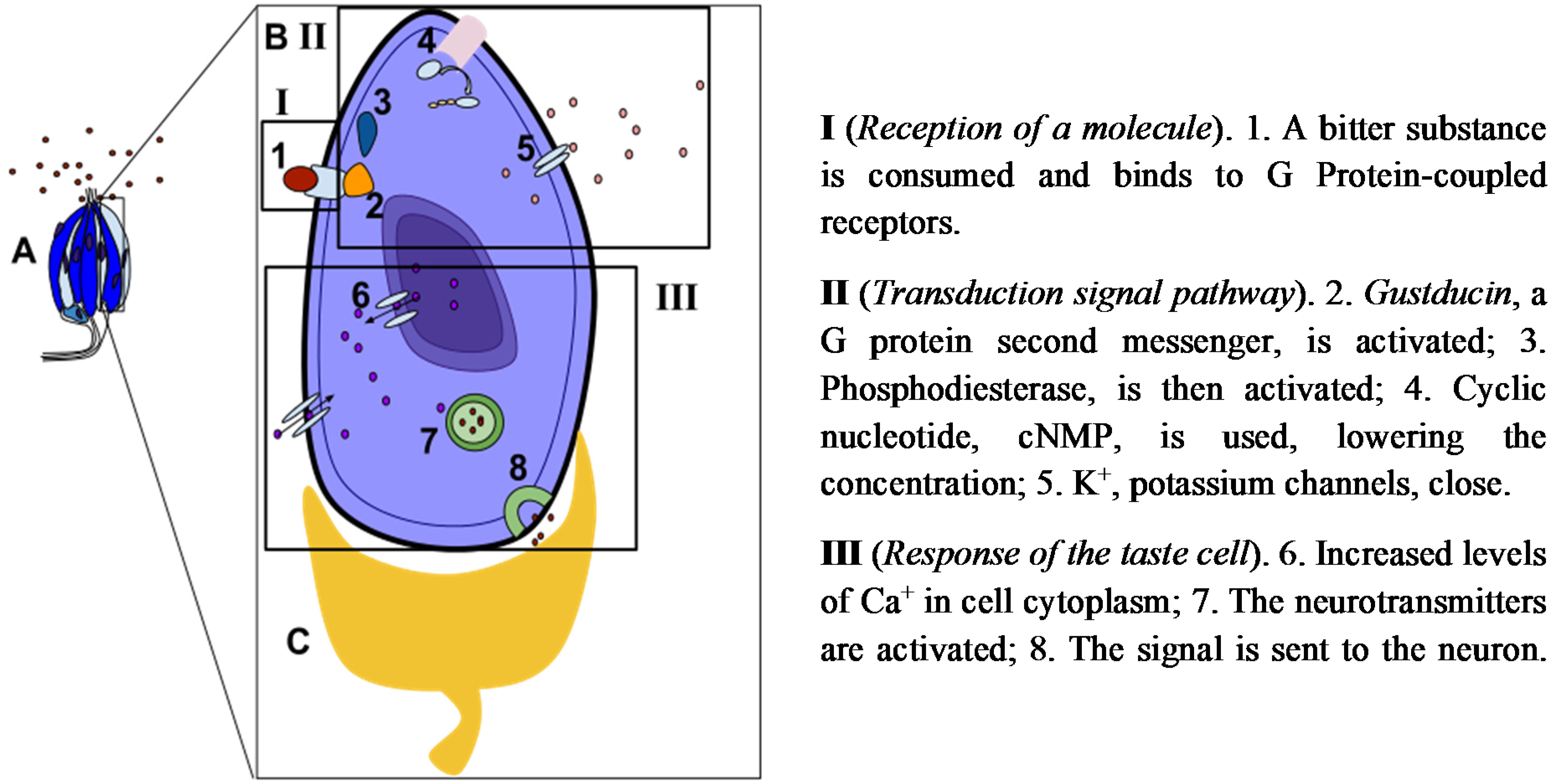

5. Psychophysiology of Alcohol Perception

6. The Effects of Ethanol on the Body and Other Sensory Characteristics of Wines

7. Technological Practical to Reduce the Wine Alcohol Content and Their Sensorial Impact

8. Final Remarks

Author Contributions

Conflicts of Interest

References

- Goldner, M.C.; Zamora, M.C.; di Leo Lira, P.; Gianninoto, H.; Bandoni, A. Effect of ethanol level in the perception of aroma attributes and the detection of volatile compounds in red wine. J. Sens. Stud. 2009, 24, 243–257. [Google Scholar] [CrossRef]

- Fontoin, H.; Saucier, C.; Teissedre, P.L.; Glories, Y. Effect of pH, ethanol and acidity on astringency and bitterness of grape seed tannin oligomers in model wine solution. Food Qual. Preference 2008, 19, 286–291. [Google Scholar] [CrossRef]

- Meillon, S.; Urbano, C.; Schlich, P. Contribution of the temporal dominance of sensations (TDS) method to the sensory description of subtle differences in partially dealcoholized red wines. Food Qual. Preference 2009, 20, 490–499. [Google Scholar] [CrossRef]

- Pickering, G.J.; Heatherbell, D.A.; Vanhanen, L.P.; Barnes, M.F. The effect of ethanol concentration on the temporal perception of viscosity and density in white wine. Am. J. Enol. Vitic. 1998, 49, 306–318. [Google Scholar]

- Fischer, U.; Noble, A.C. The effect of ethanol, catechin concentration, and pH on sourness and bitterness of wine. Am. J. Enol. Vitic. 1994, 45, 6–10. [Google Scholar]

- Jones, G.V.; White, M.A.; Cooper, O.R.; Storchmann, K. Climate change and global wine quality. Clim. Chang. 2005, 73, 319–343. [Google Scholar] [CrossRef]

- Koufos, G.; Mavromatis, T.; Koundouras, S.; Fyllasd, N.M.; Jones, G.V. Viticulture-climate relationships in Greece: The impacts of recent climate trends on harvest date variation. Int. J. Climatol. 2013, 34, 1445–1459. [Google Scholar] [CrossRef]

- Labanda, J.; Vichi, S.; Llorens, J.; López-Tamames, E. Membrane separation technology for the reduction of alcoholic degree of a white model wine. LWT Food Sci. Technol. 2009, 42, 1390–1395. [Google Scholar] [CrossRef]

- Masson, J.; Aurier, P.; D’hauteville, F. Effects of non-sensory cues on perceived quality: The case of low-alcohol wine. Int. J. Wine Bus. Res. 2008, 20, 215–229. [Google Scholar] [CrossRef]

- Saliba, A.J.; Ovington, L.A.; Moran, C.C. Consumer demand for low-alcohol wine in an Australian sample. Int. J. Wine Res. 2013, 5, 1–8. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Classification of mouthfeel characteristics of beverages. In Food Rheology and Texture; Sherman, P., Ed.; Academic Press: London, UK, 1979; pp. 1–20. [Google Scholar]

- Szczesniak, A.S. Psychorheology and texture as factors controlling the consumer acceptance of food. Cereal Foods World 1990, 35, 1201–1205. [Google Scholar]

- Noble, A.C.; Arnold, R.A.; Buechsenstein, J.; Leach, E.J.; Schmidt, J.O.; Stern, P.M. Modification of a standardized system of wine aroma terminology. Am. J. Enol. Vitic. 1987, 38, 143–146. [Google Scholar]

- Smith, A.K.; June, H.; Noble, A.C. Effects of viscosity on the bitterness and astringency of grape seed tannin. Food Qual. Preference 1996, 7, 161–166. [Google Scholar] [CrossRef]

- Hollowood, T.A.; Linforth, R.S.T.; Taylor, A.J. The effect of viscosity on the perception of flavour. Chem. Senses 2002, 27, 583–589. [Google Scholar] [CrossRef] [PubMed]

- Yanniotis, S.; Kotseridis, G.; Orfanidou, A.; Petraki, A. Effect of ethanol, dry extract and glycerol on the viscosity of wine. J. Food Eng. 2007, 81, 399–403. [Google Scholar] [CrossRef]

- Da Porto, C.; Cordaro, F.; Marcassa, N. Effects of carbohydrate and noncarbohydrate sweeteners on the orange spirit volatile compounds. Food Sci. Technol. 2006, 39, 159–165. [Google Scholar] [CrossRef]

- Walker, S.; Prescott, J. The influence of solution viscosity and different viscosifying agents of apple juice flavour. J. Sens. Stud. 2000, 15, 285–307. [Google Scholar] [CrossRef]

- Dalton, P.; Doolittle, N.; Nagata, H.; Breslin, P.A.S. The merging of the senses: Integration of subthreshold taste and smell. Nat. Neurosci. 2000, 3, 431–432. [Google Scholar] [CrossRef] [PubMed]

- Cichero, J.A.Y.; Jackson, O.J.; Halley, P.J.; Murdoch, B.E. How thick is thick? Multicenter study of the rheological and material property characteristics of meal time fluids and videofluoroscopy fluids. Dysphagia 2000, 15, 188–200. [Google Scholar] [CrossRef] [PubMed]

- Pankiewicz, U.; Jamroz, J. Evaluation of Physicochemical and Sensory Properties of Ethanol Blended with Pear Nectar. Czech J. Food Sci. 2013, 31, 66–71. [Google Scholar]

- Carroll, D.E.; Hoover, M.W.; Nesbitt, W.B. Sugar and organic acid concentrations in cultivars of muscadine grapes. J. Am. Soc. Hortic. Sci. 1971, 96, 737–740. [Google Scholar]

- Shiraishi, M. Three descriptors for sugars to evaluate grape germplasm. Euphytica 1993, 71, 99–106. [Google Scholar] [CrossRef]

- Dai, Z.W.; Ollat, N.; Gomès, E.; Decroocq, S.; Tandonnet, J.-P.; Bordenave, L.; Pieri, P.; Hilbert, G.; Kappel, C.; van Leeuwen, C.; et al. Ecophysiological, genetic, and molecular causes of variation in grape berry weight and composition: A review. Am. J. Enol. Vitic. 2011, 62, 413–425. [Google Scholar] [CrossRef]

- Shiraishi, M.; Fujishima, H.; Chijiwa, H. Evaluation of table grape genetic resources for sugar, organic acid, and amino acid composition of berries. Euphytica 2010, 174, 1–13. [Google Scholar] [CrossRef]

- Liu, H.F.; Wu, B.H.; Fan, P.G.; Li, S.H.; Li, L.S. Sugar and acid concentrations in 98 grape cultivars analyzed by principal component analysis. J. Sci. Food Agric. 2006, 86, 1526–1536. [Google Scholar] [CrossRef]

- Conde, B.C.; Silva, P.; Fontes, N.; Dias, A.C.P.; Tavares, R.M.; Sousa, M.J.; Agasse, A.; Delrot, S.; Geros, H. Biochemical changes throughout grape berry development and fruit and wine quality. Food 2007, 1, 1–22. [Google Scholar]

- Boss, P.K.; Davies, C. Molecular biology of sugar and anthocyanin accumulation in grape berries. In Molecular Biology and Biotechnology of the Grapevine; Roubelakis-Angelakis, K.A, Ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2001; pp. 1–33. [Google Scholar]

- Williams, L.E.; Lemoine, R.; Sauer, N. Sugar transporters in higher plants—A diversity of roles and complex regulation. Trends Plant Sci. 2000, 5, 283–290. [Google Scholar] [CrossRef]

- Robinson, S.P.; Davies, C. Molecular biology of grape berry ripening. Aust. J. Grape Wine Res. 2000, 6, 175–188. [Google Scholar] [CrossRef]

- Coombe, B.G. Research on Development and Ripening of the Grape Berry. Am. J. Enol. Vitic. 1992, 43, 101–110. [Google Scholar]

- Fillion, L.; Ageorges, A.; Picaud, S.; Coutos-Thevenot, P.; Lemoine, R.; Romieu, C.; Delrot, S. Cloning and expression of a hexose transporter gene expressed during the ripening of grape berry. Plant Physiol. 1999, 120, 1083–1093. [Google Scholar] [CrossRef] [PubMed]

- Hawker, J.S. Changes in the activities of enzymes concerned with sugar metabolism during the development of grape berries. Phytochemistry 1969, 8, 9–17. [Google Scholar] [CrossRef]

- Kühn, C.; Franceschi, V.R.; Schulz, A.; Lemoine, R.; Frommer, W.B. Macromolecular trafficking indicated by localization and turnover of sucrose transporters in enucleate sieve elements. Science 1997, 275, 1298–1300. [Google Scholar] [CrossRef] [PubMed]

- Delrot, S.; Atanassova, R.; Maurousset, L. Regulation of sugar, amino acid and peptide plant membrane transporters. Biochim. Biophys. Acta 2000, 1465, 281–306. [Google Scholar] [CrossRef]

- Octave, S.; Emborabé, B.E.; Fleurat-Lessard, P.; Bergès, T.; Roblin, G. Modifications of plant cell activities by polypeptides secreted by Eutypa lata, a vineyard fungal pathogen. Physiol. Plant. 2006, 128, 103–115. [Google Scholar] [CrossRef]

- Esteban, M.A.; Villanueva, M.J.; Lissarrague, J.R. Relalationships between different berry components in Tempranillo (Vitis vinifera L.) grapes from irrigated and non-irrigated vines during ripening. J. Sci. Food Agric. 2002, 82, 1136–1146. [Google Scholar] [CrossRef]

- Jordão, A.M.; Ricardo-da-Silva, J.M.; Laureano, O. Influência da rega na composição fenólica das uvas tintas da casta Touriga Francesa (Vitis vinifera L.). Cienc. Tecnol. Aliment. 1998, 2, 60–73. [Google Scholar] [CrossRef]

- Esteban, M.A.; Villanueva, M.J.; Lissarrague, J.R. Effect of Irrigation on Changes in Berry Composition of Tempranillo during Maturation. Sugars, Organic Acids, and Mineral Elements. Am. J. Enol. Vitic. 1999, 50, 418–434. [Google Scholar]

- Orts, M.L.; Martínez-Cutillas, A.; López-Roca, J.M.; Gómez-Plaza, E. Effect of moderate irrigation on grape composition during ripening. J. Agric. Res. 2005, 3, 352–361. [Google Scholar]

- Intrigliolo, D.S.; Castel, J.R. Effects of Irrigation on the Performance of Grapevine cv. Tempranillo in Requena. Am. J. Enol. Vitic. 2008, 59, 30–38. [Google Scholar]

- Van Leeuwen, C.; Tregoat, O.; Choné, X.; Bois, B.; Pernet, D.; Gaudillère, J.-P. Vine water status is a key factor in grape ripening and vintage quality for red bordeaux wine. How can it be assessed for vineyard management purposes? J. Int. Sci. Vigne Vin. 2009, 43, 121–134. [Google Scholar]

- Hawker, J.S. Effect of temperature on lipid, starch and enzymes of starch metabolism in grape, tomato and broad bean-leaves. Phytochemistry 1982, 21, 33–36. [Google Scholar] [CrossRef]

- De Orduña, R. Climate change associated effects on grape and wine quality and production. Food Res. Int. 2010, 43, 1844–1855. [Google Scholar] [CrossRef]

- Huglin, P.; Schneider, C. Biologie et Ecologie de la Vigne; Tec & Doc Lavoisier: Commune, France, 1998. [Google Scholar]

- Kriedemann, P.; Smart, R. Effect of irradiance, temperature and leaf water potential on photosynthesis of vine leaves. Photosynthetica 1971, 5, 6–15. [Google Scholar]

- Coombe, B. Influence of temperature on composition and quality of grapes. In ISHS Acta Horticulturae, Proceedings of the International Symposium on Grapevine Canopy and Vigor Management, Davis, CA, USA, 14 August 1986; Volume XXII IHC, pp. 23–35.

- Keller, M. Managing grapevines to optimise fruit development in a challenging environment: A climate change primer for viticulturists. Aust. J. Grape Wine Res. 2009, 16, 56–69. [Google Scholar] [CrossRef]

- Keller, M. The Science of Grapevines: Anatomy and Physiology; Academic Press: New York, NY, USA, 2010. [Google Scholar]

- García-Martín, N.; Perez-Magariño, S.; Ortega-Heras, M.; González-Huerta, C.; Mihnea, M.; González-Sanjosé, M.L.; Palacio, L.; Prádanos, P.; Hernández, A. Sugar reduction in musts with nanofiltration membranes to obtain low alcohol-content wines. Sep. Purif. Technol. 2010, 76, 158–170. [Google Scholar] [CrossRef]

- Castellarin, S.; Matthews, M.; Gaspero, G.; Gambetta, G. Water deficits accelerate ripening and induce changes in gene expression regulating flavonoid biosynthesis in grape berries. Planta 2007, 227, 101–112. [Google Scholar] [CrossRef] [PubMed]

- Berli, F.J.; Moreno, D.; Piccoli, P.; Hespanhol-Viana, L.; Silva, M.F.; Bressan-Smith, R.; Cavagnaro, J.B.; Bottini, R. Abscisic acid is involved in the response of grape (Vitis vinifera L.) cv. Malbec leaf tissues to ultraviolet-B radiation by enhancing ultraviolet-absorbing compounds, antioxidant enzymes and membrane sterols. Plant Cell Environ. 2010, 33, 1–10. [Google Scholar] [PubMed]

- Duchêne, E.; Schneider, C. Grapevine and climatic changes: A glance at the situation in Alsace. Agron. Sustain. Dev. 2005, 24, 93–99. [Google Scholar] [CrossRef]

- Godden, P.; Gishen, M. Trends in the composition of Australian wine. Aust. N. Z. Wine Ind. J. 2005, 20, 21–46. [Google Scholar]

- Glanz, K.; Basil, M.; Maibach, E.; Goldberg, J.; Snyder, D. Why Americans eat what they do: Taste, nutrition, cost, convenience, and weight control concerns as influences on food consumption. J. Am. Diet. Assoc. 1998, 98, 1118–1126. [Google Scholar] [CrossRef]

- Moore, M.; Weiss, S. Reasons for non-drinking among Israeli adolescents of four religions. Drug Alcohol Depend. 1995, 38, 45–50. [Google Scholar] [CrossRef]

- Higgs, S.; Stafford, L.D.; Attwood, A.S.; Walker, S.C.; Terry, P. Cues that signal the alcohol content of a beverage and their effectiveness at altering drinking rates in young social drinkers. Alcohol Alcohol. 2008, 43, 630–635. [Google Scholar] [CrossRef] [PubMed]

- Lanier, S.A.; Hayes, J.E.; Duffy, V.B. Sweet and bitter tastes of alcoholic beverages mediate alcohol intake in of-age undergraduates. Physiol. Behav. 2005, 83, 821–831. [Google Scholar] [CrossRef] [PubMed]

- Redondo, N.; Gómez-Martíneza, S.; Marcos, A. Review Article—Sensory attributes of soft drinks and their influence on consumers’ preferences. Food Funct. 2014, 5, 1686–1694. [Google Scholar] [CrossRef] [PubMed]

- Allen, A.L.; Hayes, J.E.; McGeary, J.E. Polymorphisms in TRPV1 and TAS2Rs associate with sensations from sampled ethanol. Alcohol. Clin. Exp. Res. 2014, 38, 2550–2560. [Google Scholar] [CrossRef] [PubMed]

- Bartoshuk, L.M.; Conner, E.; Grubin, D.; Karrer, T.; Kochenbach, K.; Palsco, M.; Snow, D.; Pelchat, M.; Danovski, S. PROP supertasters and the perception of ethyl alcohol. Chem. Senses 1993, 18, 526–527. [Google Scholar]

- Mattes, R.D.; DiMeglio, D. Ethanol perception and ingestion. Physiol. Behav. 2001, 72, 217–229. [Google Scholar] [CrossRef]

- Hldavis4. Own Work & Template: Purves, Dale. Taste Receptors and the Transduction of Taste Signals. U.S. National Library of Medicine, n.d. Web. May–June 2015. Licensed under CC BY-SA 4.0 via Wikimedia Commons. Available online: https://commons.wikimedia.org/wiki/File:Signal_Transaction_of_Taste;_Bitter.svg#/media/File:Signal_Transaction_of_Taste;_Bitter.svg (accessed on 20 June 2015).

- Wooding, S.; Kim, U.K.; Bamshad, M.J.; Larsen, J.; Jorde, L.B.; Drayna, D. Natural Selection and Molecular Evolution in PTC, a Bitter-Taste Receptor Gene. Am. J. Hum. Genet. 2004, 74, 637–646. [Google Scholar] [CrossRef] [PubMed]

- Drayna, D.; Coon, H.; Kim, U.K.; Elsner, T.; Cromer, K.; Otterud, B.; Baird, L.; Peiffer, A.P.; Leppert, M. Genetic analysis of a complex trait in the Utah Genetic Reference Project: A major locus for PTC taste ability on chromosome 7q and a secondary locus on chromosome 16p. Hum. Genet. 2003, 112, 567–572. [Google Scholar] [PubMed]

- Kim, U.K.; Jorgenson, E.; Coon, H.; Leppert, M.; Risch, N.; Drayna, D. Positional cloning of the human quantitative trait locus underlying taste sensitivity to phenylthiocarbamide. Science 2003, 299, 1221–1225. [Google Scholar] [CrossRef] [PubMed]

- Duffy, V.B.; Davidson, A.C.; Kidd, J.R.; Kidd, K.K.; Speed, W.C.; Pakstis, A.J.; Reed, D.R.; Snyder, D.J.; Bartoshuk, L.M. Bitter receptor gene (TAS2R38), 6-n-propylthiouracil (PROP) bitterness and alcohol intake. Alcohol. Clin. Exp. Res. 2004, 28, 1629–1637. [Google Scholar] [CrossRef] [PubMed]

- Dotson, C.D.; Wallace, M.R.; Bartoshuk, L.M.; Logan, H.L. Variation in the gene TAS2R13 is associated with differences in alcohol consumption in patients with head and neck cancer. Chem. Senses 2012, 37, 737–744. [Google Scholar] [CrossRef] [PubMed]

- Tominaga, M.; Caterina, M.J.; Malmberg, A.B.; Rosen, T.A.; Gilbert, H.; Skinner, K.; Raumann, B.E.; Basbaum, A.I.; Julius, D. The cloned capsaicin receptor integrates multiple pain-producing stimuli. Neuron 1998, 21, 531–543. [Google Scholar] [CrossRef]

- Caterina, M.J.; Rosen, T.A.; Tominaga, M.; Brake, A.J.; Julius, D. A capsaicin-receptor homologue with a high threshold for noxious heat. Nature 1999, 398, 436–441. [Google Scholar] [PubMed]

- Trevisani, M.; Smart, D.; Gunthorpe, M.J.; Tognetto, M.; Barbieri, M.; Campi, B.; Amadesi, S.; Gray, J.; Jerman, J.C.; Brough, S.J.; et al. Ethanol elicits and potentiates nociceptor responses via the vanilloid receptor-1. Nat. Neurosci. 2002, 5, 546–551. [Google Scholar] [CrossRef] [PubMed]

- Blednov, Y.; Harris, R. Deletion of vanilloid receptor (TRPV1) in mice alters behavioral effects of ethanol. Neuropharmacology 2009, 56, 814–820. [Google Scholar] [CrossRef] [PubMed]

- Ferraro, F.M.; Hill, K.G.; Kaczmarek, H.J.; Coonfield, D.L.; Kiefer, S.W. Naltrexone modifies the palatability of basic tastes and alcohol in outbred male rats. Alcohol 2002, 27, 107–114. [Google Scholar] [CrossRef]

- Mennella, J.A. The transfer of alcohol to human milk: Sensory implications and effects on mother-infant interaction. In Alcohol and Alcoholism: Brain and Development; Spear, N.E., Spear, L.P., Hanningan, J.H., Goodlett, C.R., Eds.; Erlbaum: Hillsdale, NJ, USA, 1999; pp. 177–198. [Google Scholar]

- Molina, J.C.; Domínguez, H.D.; López, M.F.; Pepino, M.Y.; Faas, A.E. The role of fetal and infantile experience with alcohol in later recognition and acceptance patterns of the drug. In Alcohol and Alcoholism: Brain and Development; Spear, N.E., Spear, L.P., Hanningan, J.H., Goodlett, C.R., Eds.; Erlbaum: Hillsdale, NJ, USA, 1999; pp. 199–228. [Google Scholar]

- Buck, L.; Axel, R. A novel multigene family may encode odourant receptors: A molecular basis for odour recognition. Cell 1991, 65, 175–187. [Google Scholar] [CrossRef]

- Menco, B.P.; Morrison, E.E. Morphology of the mammalian olfactory epithelium: Form, fine structure, function, and pathology. In Handbook of Olfaction and Gustation; Doty, R., Ed.; Marcel Dekker: New York, NY, USA, 2003; pp. 17–49. [Google Scholar]

- Caterina, M.J.; Schumacher, M.A.; Tominaga, M.; Rosen, T.A.; Levine, J.D.; Julius, D. The capsaicin receptor: A heat-activated ion channel in the pain pathway. Nature 1997, 389, 816–824. [Google Scholar] [PubMed]

- Li, X.; Staszewski, L.; Xu, H.; Durick, K.; Zoller, M.; Adler, E. Human receptors for sweet and umami taste. Proc. Natl. Acad. Sci. USA 2002, 99, 4692–4696. [Google Scholar] [CrossRef] [PubMed]

- Nelson, G.; Hoon, M.A.; Chandrashekar, J.; Zhang, Y.; Ryba, N.J.; Zuker, C.S. Mammalian sweet taste receptors. Cell 2001, 106, 381–390. [Google Scholar] [CrossRef]

- Nelson, G.; Chandrashekar, J.; Hoon, M.A.; Feng, L.; Zhao, G.; Ryba, N.J.; Zuker, C.S. An amino-acid taste receptor. Nature 2002, 416, 199–202. [Google Scholar] [CrossRef] [PubMed]

- Margolskee, R.F. Molecular mechanisms of taste transduction. Pure Appl. Chem. 2002, 74, 1125–1133. [Google Scholar] [CrossRef]

- Gawel, R.; van sluyter, S.; Waters, E.J. The effects of ethanol and glycerol on the body and other sensory characteristics of Riesling wines. Aust. J. Grape Wine Res. 2007, 13, 38–45. [Google Scholar] [CrossRef]

- Gawel, R. The use of language by trained and untrained experienced wine tasters. J. Sens. Stud. 1997, 12, 267–284. [Google Scholar] [CrossRef]

- Amerine, M.A.; Roessler, E.B. Wines: Their Sensory Evaluation; Freeman, W.H., Ed.; W. H. Freeman & Co.: San Francisco, CA, USA, 1983. [Google Scholar]

- Nurgel, C.; Pickering, G. Contribution of glycerol, ethanol and sugar to the perception of viscosity and density elicited by model white wines. J. Texture Stud. 2005, 36, 303–325. [Google Scholar] [CrossRef]

- Guth, H.; Sies, A. Flavour of wines: Towards an understanding by reconstitution experiments and an analysis of ethanol’s effect on odour activity of key components. In Proceedings of the Eleventh Australian Wine Industry Technical Conference, Adelaide, Australia, 7–11 October 2001; Australian Wine Industry Technical Conference Inc.: Adelaide, Australia, 2002; pp. 128–139. [Google Scholar]

- Scinska, A.; Koros, E.; Habrat, B.; Kukwa, A.; Kostowski, W.; Bienkowski, P. Bitter and sweet components of ethanol taste in humans. Drug Alcohol Depend. 2000, 60, 199–206. [Google Scholar] [CrossRef]

- Joshi, V.K.; Sandhu, D.K. Influence of Ethanol Concentration, Addition of Spices Extract, and Level of Sweetness on Physico-chemical Characteristics and Sensory Quality of Apple Vermouth. Braz. Arch. Biol. Technol. 2000, 43, 537–545. [Google Scholar] [CrossRef]

- Noble, A.C. Why Do Wines Taste Bitter and Feel Astringent? In Chemistry of Wine Flavour; Waterhouse, A.L., Ebeler, S.E., Eds.; American Chemical Society: Washington, DC, USA, 1998; pp. 156–165. [Google Scholar]

- Conibear, H. Rising alcohol levels in wine—Is this a cause for concern? AIM Dig. 2006, 18, 1–17. [Google Scholar]

- Pickering, G.J. Low- and Reduced-alcohol Wine: A Review. J. Wine Res. 2000, 11, 129–144. [Google Scholar] [CrossRef]

- Meillon, S.; Viala, D.; Medel, M.; Urbano, C.; Guillot, G.; Schlich, P. Impact of partial alcohol reduction in Syrah wine on perceived complexity and temporality of sensations and link with preference. Food Qual. Preference 2010, 21, 732–740. [Google Scholar] [CrossRef]

- Kontoudakis, N.; Esteruelas, M.; Fort, F.; Canals, J.M.; Zamora, F. Use of unripe grapes harvested during cluster thinning as a method for reducing alcohol content and pH of wine. Aust. J. Grape Wine Res. 2011, 17, 230–238. [Google Scholar] [CrossRef]

- Casassa, L.F.; Beaver, C.W.; Mireles, M.; Larsen, R.C.; Hopfer, H.; Heymann, H.; Harbertson, J.F. Influence of Fruit Maturity, Maceration Length, and Ethanol Amount on Chemical and Sensory Properties of Merlot Wines. Am. J. Enol. Vitic. 2013, 64, 437–449. [Google Scholar] [CrossRef]

- Moutounet, M.; Bes, M.; Escudier, J. Las tecnologías de elaboración de vinos con bajo nivel de etanol. Available online: http://www.acenologia.com/ciencia84.htm (accessed on 30 October 2015).

- Massot, A.; Mietton-Peuchot, M.; Peuchot, C.; Milisic, V. Nanofiltration and reverse osmosis in winemaking. Desalination 2008, 231, 283–289. [Google Scholar] [CrossRef]

- King, E.S.; Dunn, R.L.; Heymann, H. The influence of alcohol on the sensory perception of red wines. Food Qual. Preference 2013, 28, 235–243. [Google Scholar] [CrossRef]

- Escudero, A.; Campo, E.; Fariña, L.; Cacho, J.; Ferreira, V. Analytical Characterization of the Aroma of Five Premium Red Wines. Insights into the Role of Odour Families and the Concept of Fruitiness of Wines. J. Agric. Food Chem. 2007, 55, 4501–4510. [Google Scholar] [CrossRef] [PubMed]

- Bisson, L.F. Stuck and sluggish fermentations. Am. J. Enol. Vitic. 1999, 50, 107–119. [Google Scholar]

- Harbertson, J.F.; Mireles, M.S.; Harwood, E.D.; Weller, K.M.; Ross, C.F. Chemical and Sensory Effects of Saignée, Water Addition, and Extended Maceration on High Brix Must. Am. J. Enol. Vitic. 2009, 60, 450–460. [Google Scholar]

- Quirós, M.; Rojas, V.; Gonzalez, R.; Morales, P. Selection of non-Saccharomyces yeast strains for reducing alcohol levels in wine by sugar respiration. Int. J. Food Microbiol. 2014, 181, 85–91. [Google Scholar] [CrossRef] [PubMed]

- Tamang, J.P.; Fleet, G.H. Yeasts diversity in fermented foods and beverages. In Yeast Biotechnology: Diversity and Applications; Satyanarayana, T., Kunze, G., Eds.; Springer: Dordrecht, The Netherlands, 2009; pp. 169–198. [Google Scholar]

- Tilloy, V.; Cadiére, A.; Ehsani, M.; Dequin, S. Microbiological strategies to reduce alcohol levels in wines. In Wine; Alcohol Level Reduction in Wine; Oenoviti International: Bordeaux, France, 2013; pp. 29–32. [Google Scholar]

- Kutyna, D.R.; Varela, C.; Henschke, P.A.; Chambers, P.J.; Stanley, G.A. Microbiological approaches to lowering ethanol concentration in wine. Trends Food Sci. Technol. 2010, 21, 293–302. [Google Scholar] [CrossRef]

- Diban, N.; Athes, V.; Bes, M.; Souchon, I. Ethanol and aroma compounds transfer study for partial dealcoholisation of wine using membrane contactor. J. Membrane Sci. 2008, 311, 136–146. [Google Scholar] [CrossRef]

- Catarino, M.; Mendes, A.; Madeira, L.M.; Ferreira, A. Alcohol removal from beer by reverse osmosis. Sep. Sci. Technol. 2007, 42, 3011–3027. [Google Scholar] [CrossRef]

- Meillon, S.; Urbano, C.; Guillot, G.; Schlich, P. Acceptability of partially dealcoholized wines—Measuring the impact of sensory and information cues on overall liking in real-life settings. Food Qual. Preference 2010, 21, 763–773. [Google Scholar] [CrossRef]

- Commission Regulation (EC) No. 606/2009 of 10 July 2009. Laying Down Certain Detailed Rules for Implementing Council Regulation (EC) No 479/2008 as Regards the Categories of Grapevine Products, Oenological Practices and the Applicable Restrictions. Available online: http://faolex.fao.org/docs/pdf/eur88930.pdf (accessed on 28 October 2015).

- Commission Regulation (EU) No. 144/2013 of February 19. Amending Regulation (EC) No 606/2009 as Regards Certain Oenological Practices and the Applicable Restrictions and Regulation (EC) No 436/2009 as Regards the Registering of These Practices in the Documents Accompanying Consignments of Wine Products and the Wine Sector Registers to be Kept. Available online: http://faolex.fao.org/docs/pdf/eur120800.pdf (accessed on 28 October 2015).

- Organisation Internationale de la Vigne et du Vin (OIV). Codex Oenologique International; Resolution OIV-ECO 433-2012; Organisation International de la Vigne et du Vin: Paris, France, 2012. [Google Scholar]

- Organisation Internationale de la Vigne et du Vin (OIV). Codex Oenologique International; Resolution OIV-OENO 394A-2012; Organisation International de la Vigne et du Vin: Paris, France, 2012. [Google Scholar]

- Gil, M.; Estévez, S.; Kontoudakis, N.; Fort, F.; Canals, J.M.; Zamora, F. Influence of partial dealcoholization by reverse osmosis on red wine composition and sensory characteristics. Eur. Food Res. Technol. 2013, 237, 481–488. [Google Scholar] [CrossRef]

- Liguori, L.; Russo, P.; Albanese, D.; di Matteo, M. Evolution of quality parameters during red wine dealcoholization by osmotic distillation. Food Chem. 2013, 140, 68–75. [Google Scholar] [CrossRef] [PubMed]

- King, E.S.; Heymann, H. The effect of reduced alcohol on the sensory profiles and consumer preferences of white wine. J. Sens. Stud. 2014, 29, 33–42. [Google Scholar] [CrossRef]

- Lisanti, M.T.; Gambuti, A.; Piombino, P.; Pessina, R.; Moio, L. Sensory study on partial dealcoholization of wine by osmotic distillation process. Bull. OIV 2011, 84, 95–105. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jordão, A.M.; Vilela, A.; Cosme, F. From Sugar of Grape to Alcohol of Wine: Sensorial Impact of Alcohol in Wine. Beverages 2015, 1, 292-310. https://doi.org/10.3390/beverages1040292

Jordão AM, Vilela A, Cosme F. From Sugar of Grape to Alcohol of Wine: Sensorial Impact of Alcohol in Wine. Beverages. 2015; 1(4):292-310. https://doi.org/10.3390/beverages1040292

Chicago/Turabian StyleJordão, António M., Alice Vilela, and Fernanda Cosme. 2015. "From Sugar of Grape to Alcohol of Wine: Sensorial Impact of Alcohol in Wine" Beverages 1, no. 4: 292-310. https://doi.org/10.3390/beverages1040292

APA StyleJordão, A. M., Vilela, A., & Cosme, F. (2015). From Sugar of Grape to Alcohol of Wine: Sensorial Impact of Alcohol in Wine. Beverages, 1(4), 292-310. https://doi.org/10.3390/beverages1040292