Transfer of Graphene with Protective Oxide Layers

Abstract

1. Introduction

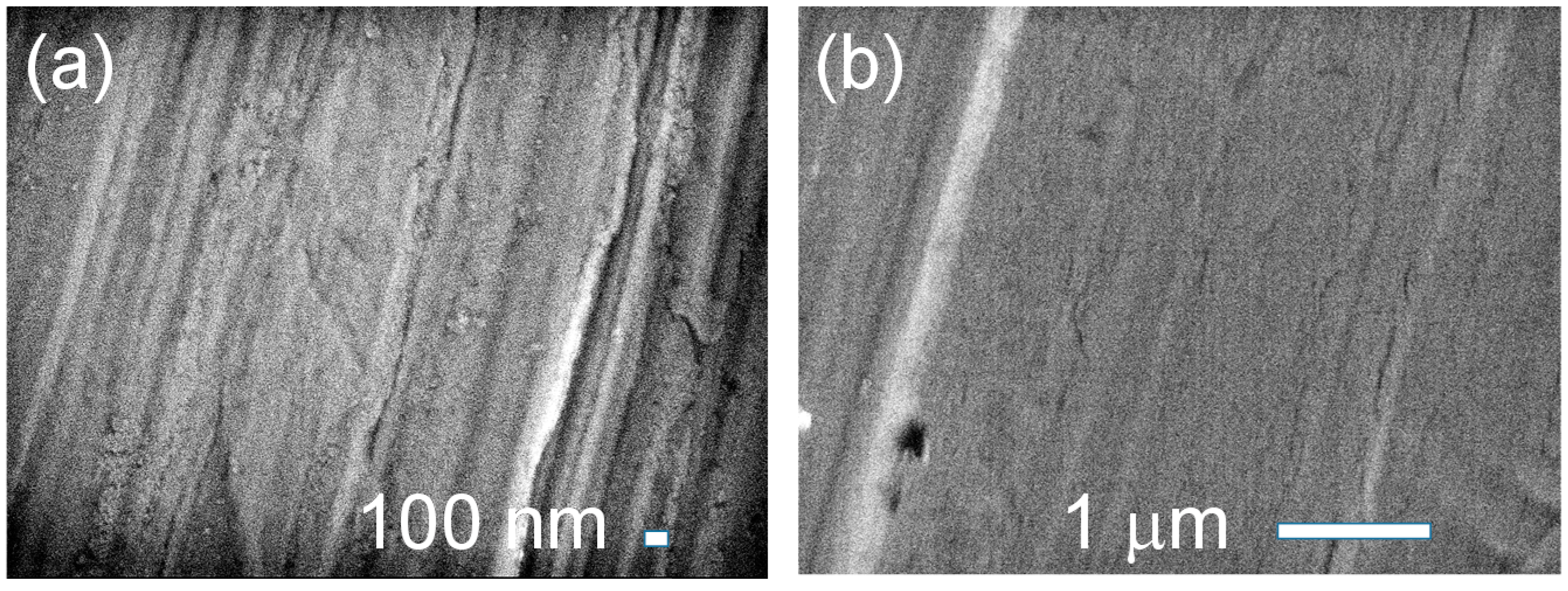

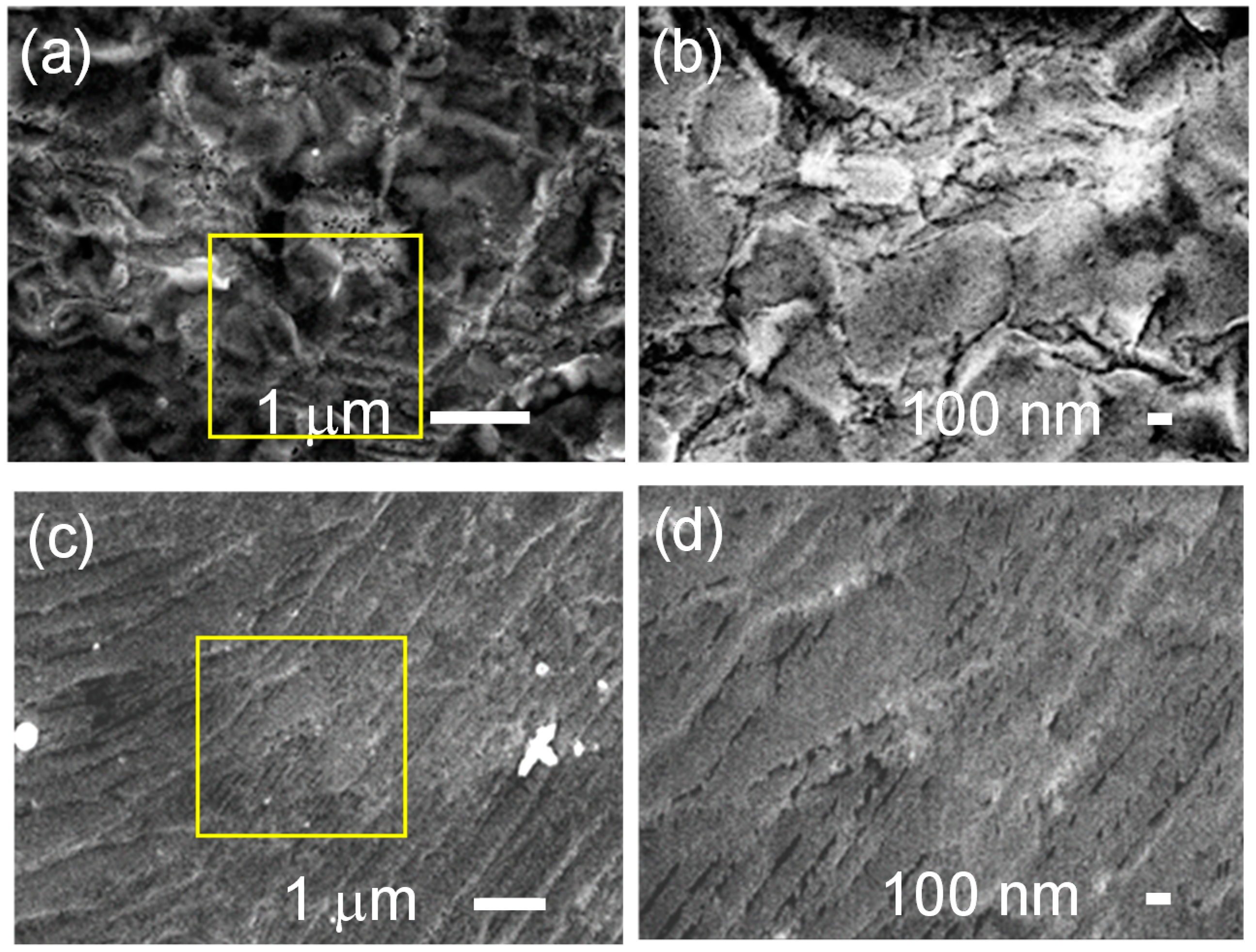

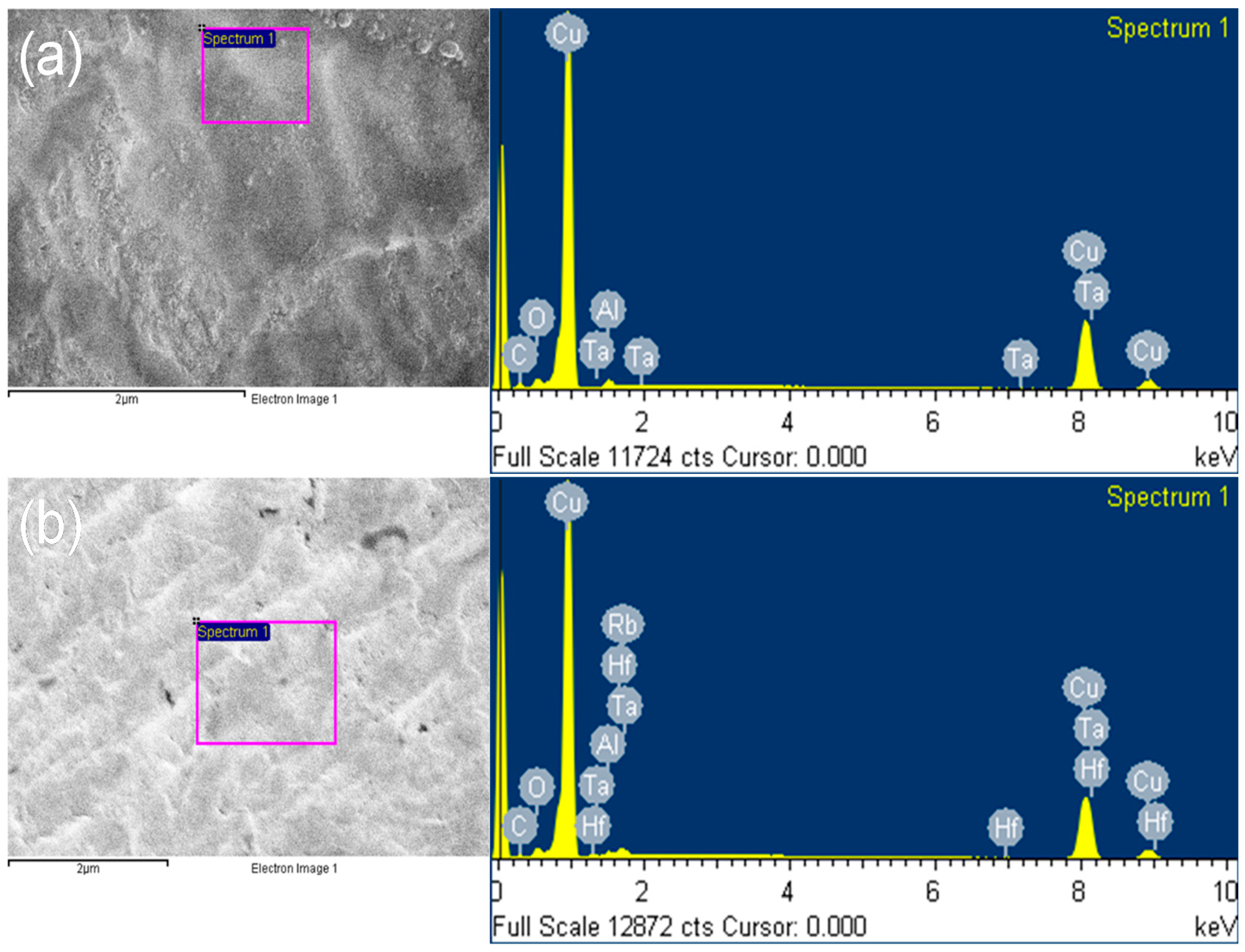

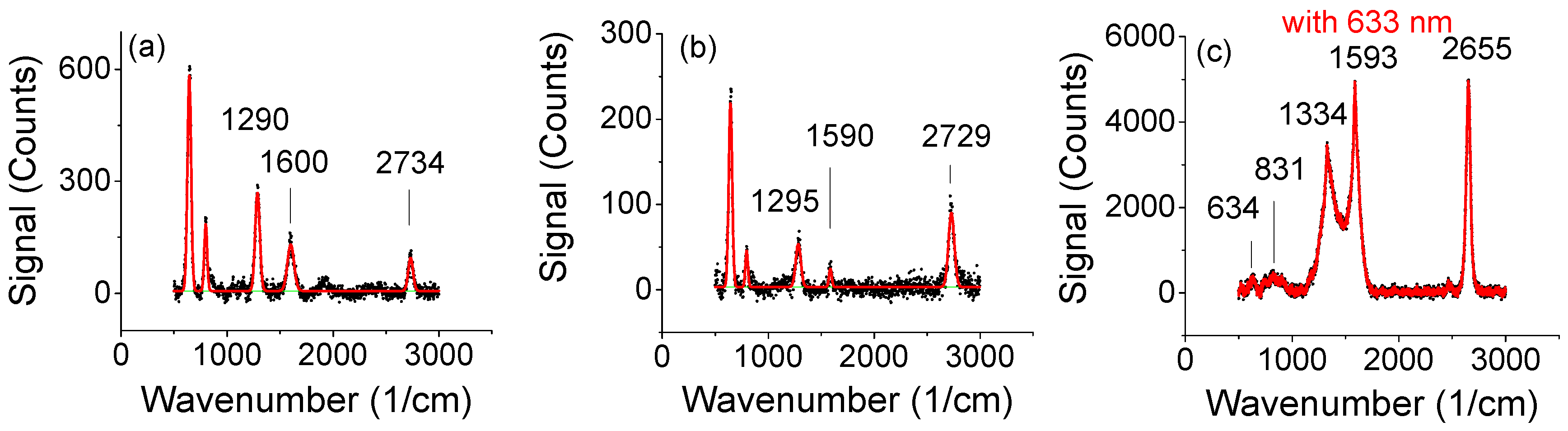

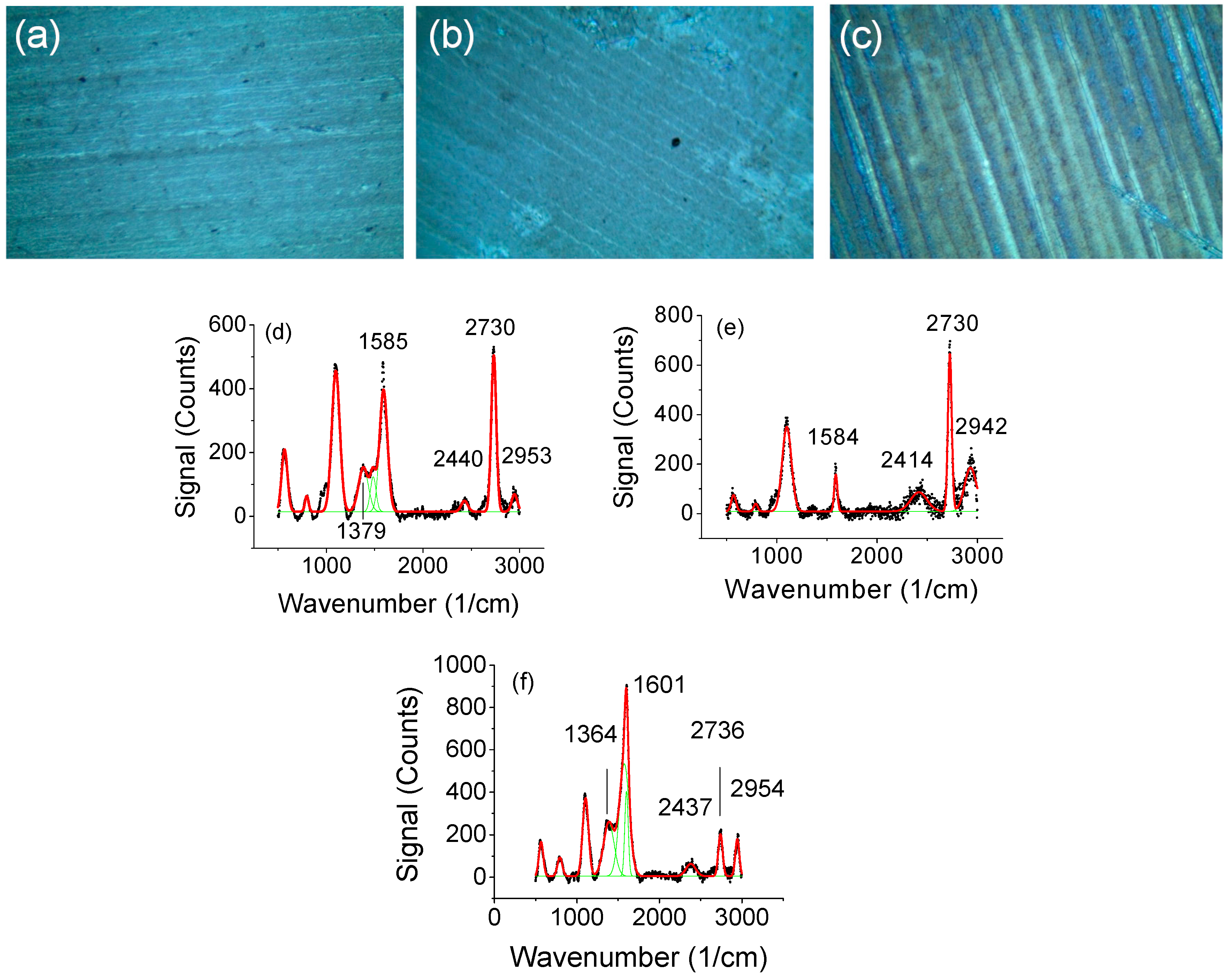

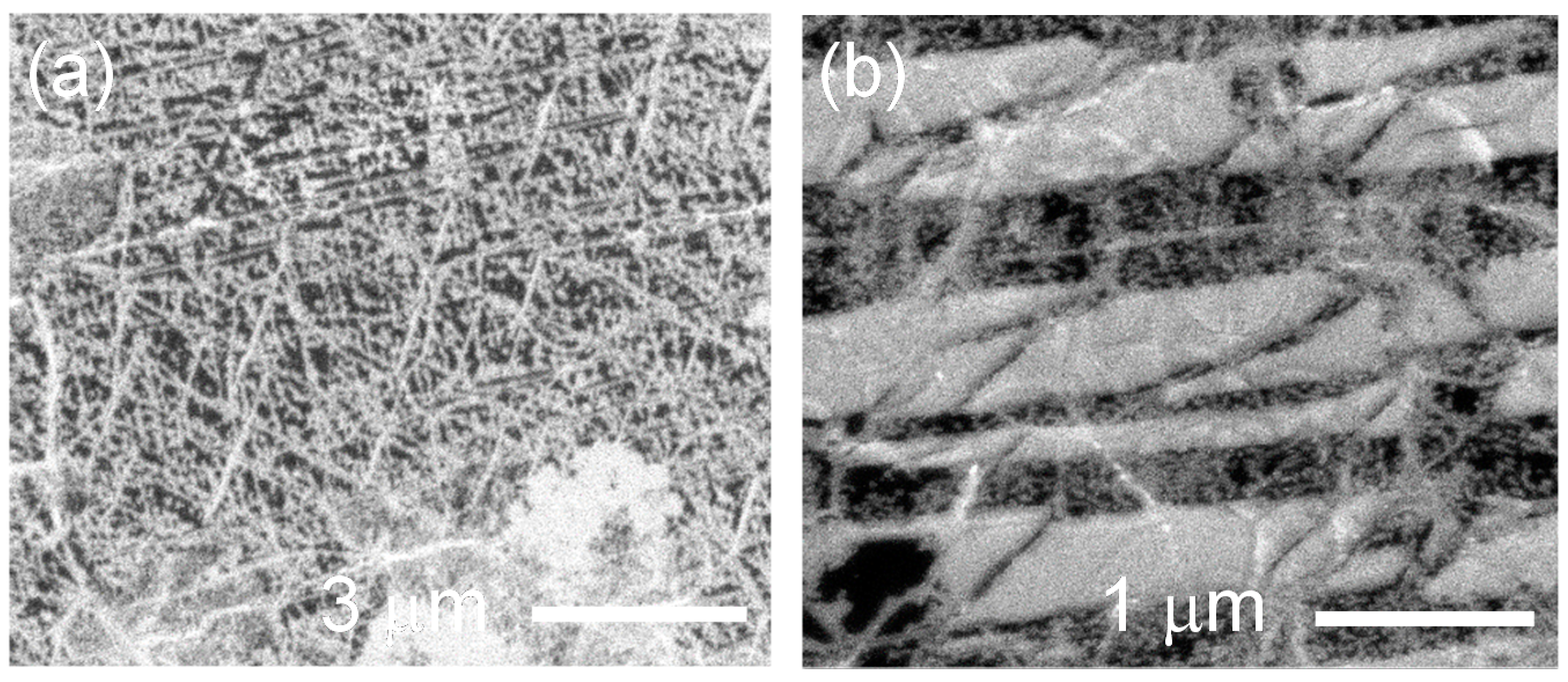

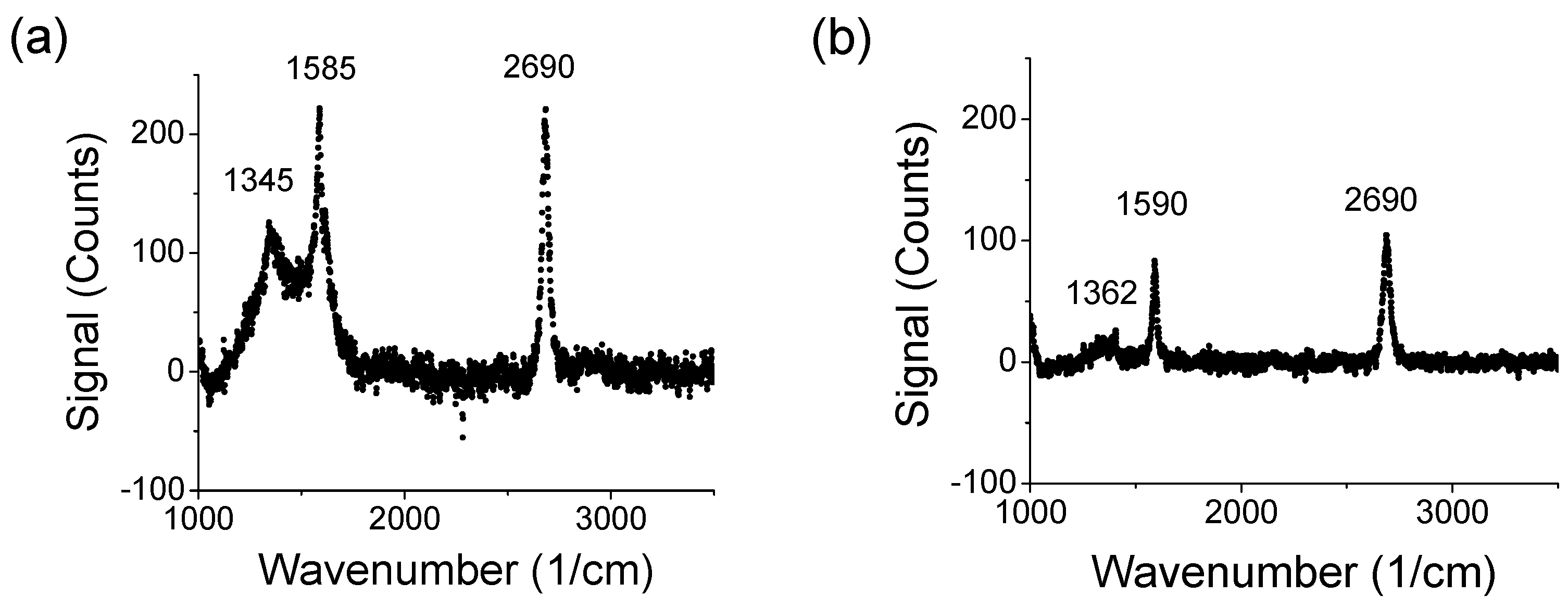

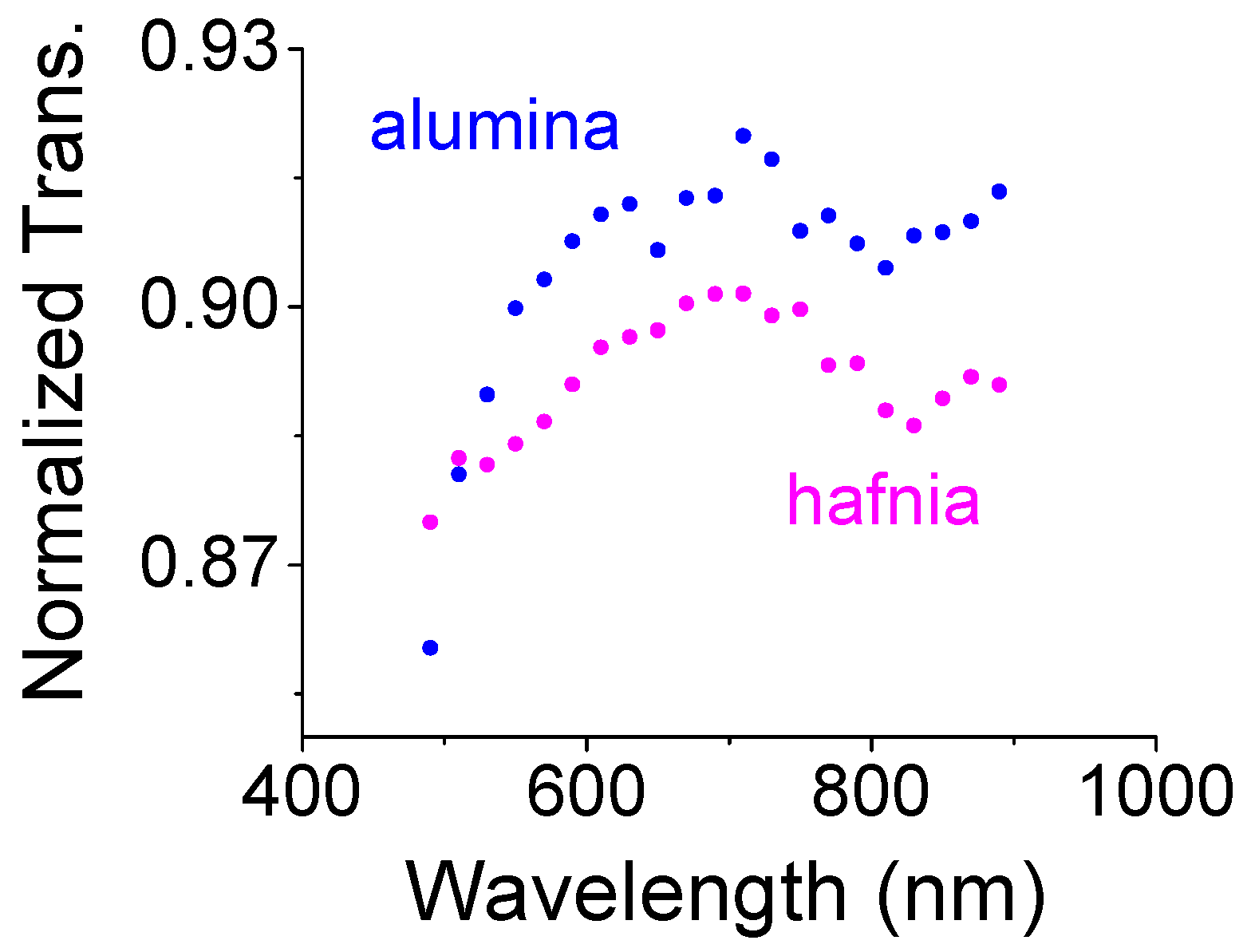

2. Experiment and Initial Characterization

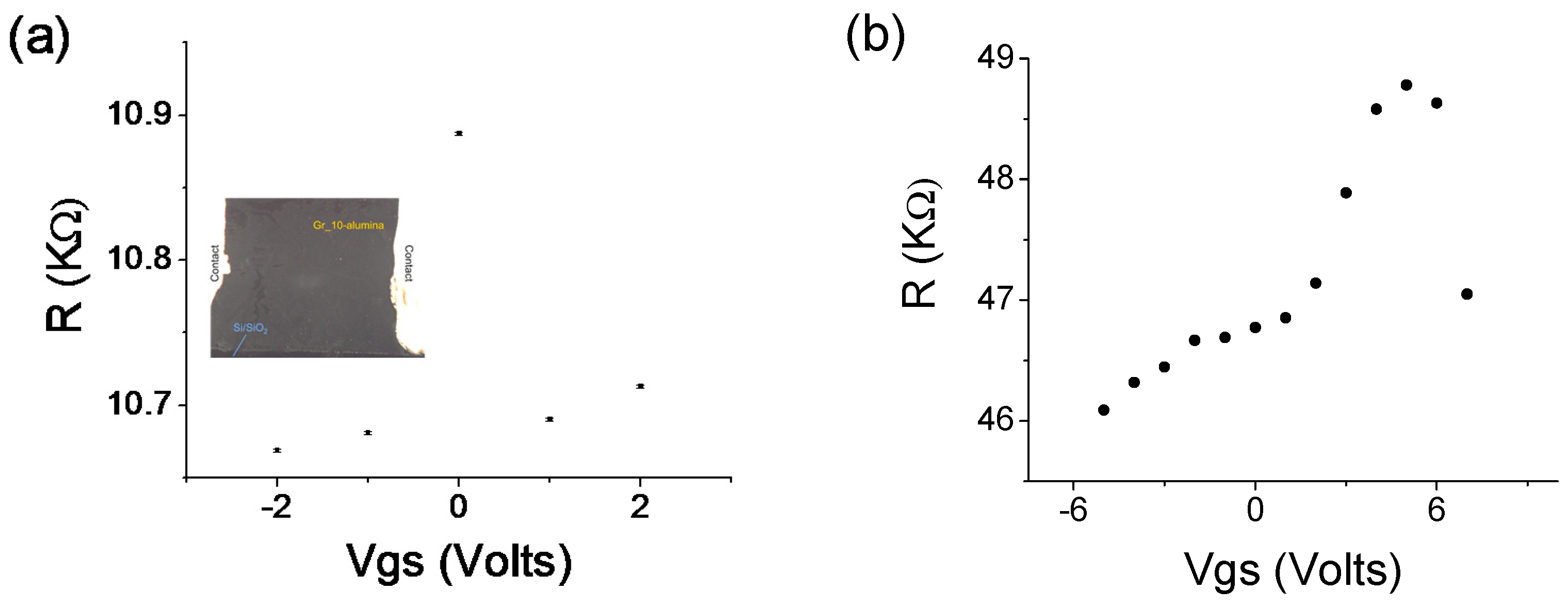

3. Transferred Films

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Suk, J.W.; Kitt, A.; Magnuson, C.W.; Hao, Y.; Ahmed, S.; An, J.; Swan, A.K.; Goldberg, B.B.; Ruoff, R.S. Transfer of CVD-Grown Monolayer Graphene onto Arbitrary Substrates. ACS Nano 2011, 5, 6916–6924. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Bae, S.; Jang, H.; Jang, S.; Zhu, S.-E.; Sim, S.H.; Song, Y.I.; Hong, B.H.; Ahn, J.-H. Wafer-scale synthesis and transfer of graphene films. Nano Lett. 2010, 10, 490–493. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Ren, W.; Xu, H.; Jin, L.; Wang, Z.; Ma, T.; Ma, L.; Zhang, Z.; Fu, Q.; Peng, L.; et al. Repeated growth and bubbling transfer of graphene with millimetre-size single-crystal grains using platinum. Nat. Commun. 2012, 3, 699. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Kim, Y.; Shin, H.-J.; Lee, C.; Lee, D.; Moon, C.-Y.; Lim, J.; Jun, S.C. Clean transfer of graphene and its effect on contact resistance. Appl. Phys. Lett. 2013, 103, 103104. [Google Scholar] [CrossRef]

- Ko, P.J.; Takahashi, H.; Koide, S.; Sakai, H.; Thu, T.V.; Okada, H.; Sandhu, A. Simple method to transfer graphene from metallic catalytic substrates to flexible surfaces without chemical etching. J. Phys. Conf. Ser. 2013, 433, 012002. [Google Scholar] [CrossRef]

- Boscá, A.; Pedrós, J.; Martínez, J.; Palacios, T.; Calle, F. Automatic graphene transfer system for improved material quality and efficiency. Sci. Rep. 2016, 6, 21676. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Gong, X.; Gai, J. Progress and Challenges in Transfer of Large-Area Graphene. Films Adv. Sci. 2016, 3, 1500343. [Google Scholar] [CrossRef]

- Wang, M.C.; Moestopo, W.P.; Takekuma, S.; Barna, S.F.; Haasch, R.T.; Nam, S. A sustainable approach to large area transfer of graphene and recycling of the copper substrate. J. Mater. Chem. C 2017, 5, 11226–11232. [Google Scholar] [CrossRef]

- van Ngoc, H.; Qian, Y.; Han, S.K.; Kang, D.J. PMMA-Etching-Free Transfer of Wafer-scale Chemical Vapor Deposition Two-dimensional Atomic Crystal by a Water Soluble Polyvinyl Alcohol Polymer Method. Sci. Rep. 2016, 6, 33096. [Google Scholar] [CrossRef]

- Meric, I.; Han, M.Y.; Young, A.F.; Özyilmaz, B.; Kim, P.; Shepard, K.L. Current Saturation in Zero-Bandgap, Top-Gated Graphene Field-Effect Transistors. Nat. Nanotechnol. 2008, 3, 654–659. [Google Scholar] [CrossRef]

- Zou, K.; Hong, X.; Keefer, D.; Zhu, J. Deposition of High-Quality HfO2 on Graphene and the Effect of Remote Oxide Phonon Scattering. Phys. Rev. Lett. 2010, 105, 126601. [Google Scholar] [CrossRef] [PubMed]

- Alles, H.; Aarik, J.; Aidla, A.; Fay, A.; Kozlova, J.; Niilisk, A.; Pärs, M.; Rähn, M.; Wiesner, M.; Hakonen, P.; Sammelselg, V. Atomic Layer Deposition of HfO2 on Graphene from HfCl4 and H2O. Cent. Eur. J. Phys. 2011, 9, 319–324. [Google Scholar] [CrossRef]

- Moon, J.S.; Curtis, D.; Hu, M.; Wong, D.; McGuire, C.; Campbell, P.M.; Jernigan, G.; Tedesco, J.L.; VanMil, B.; Myers-Ward, R.; et al. Epitaxial Graphene RF Field-Effect Transistors on Si-Face 6H-SiC Substrates. IEEE Electron Dev. Lett. 2009, 30, 650–652. [Google Scholar] [CrossRef]

- Kim, S.; Nah, J.; Jo, I.; Shahrjerdi, D.; Colombo, L.; Yao, Z.; Tutuc, E.; Banerjee, S.K. Realization of a High Mobility Dual-Gated Graphene Field-Effect Transistor with Al2O3 Dielectric. Appl. Phys. Lett. 2009, 94, 062107. [Google Scholar] [CrossRef]

- Wang, X.; Tabakman, S.M.; Dai, H. Atomic Layer Deposition of Metal Oxides on Pristine and Functionalized Graphene. J. Am. Chem. Soc. 2008, 130, 8152–8153. [Google Scholar] [CrossRef] [PubMed]

- Farmer, D.B.; Chiu, H.-Y.; Lin, Y.-M.; Jenkins, K.A.; Xia, F.; Avouris, P. Utilization of a Buffered Dielectric to Achieve High Field-Effect Carrier Mobility in Graphene Transistors. Nano Lett. 2009, 9, 4474–4478. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.; Park, S.-Y.; Kim, H.-C.; Cho, K.J.; Vogel, E.M.; Kim, M.J.; Wallace, R.M.; Kim, J. Conformal Al2O3 Dielectric Layer Deposited by Atomic Layer Deposition for Graphene-Based Nanoelectronics. Appl. Phys. Lett. 2008, 92, 203102. [Google Scholar] [CrossRef]

- Lee, B.; Mordi, G.; Kim, M.J.; Chabal, Y.J.; Vogel, R.M.; Wallace, R.M.; Cho, K.J.; Colombo, L.; Kim, J. Characteristics of High-k Al2O3 Dielectric Using Ozone-Based Atomic Layer Deposition for Dual-Gated Graphene Devices. Appl. Phys. Lett. 2010, 97, 043107. [Google Scholar] [CrossRef]

- Zheng, L.; Cheng, X.; Cao, D.; Wang, G.; Wang, Z.; Xu, D.; Xia, C.; Shen, L.; Yu, Y.; Shen, D. Improvement of Al2O3Films on Graphene Grown by Atomic Layer Deposition with Pre-H2O Treatment. ACS Appl. Mater. Interfaces 2014, 6, 7014–7019. [Google Scholar] [CrossRef] [PubMed]

- Cabrero-Vilatela, A.; Alexander-Webber, J.A.; Sagade, A.A.; Aria, A.I.; Braeuninger-Weimer, P.; Martin, M.; Weatherup, R.S.; Hofmann, S. Atomic layer deposited oxide films as protective interface layers for integrated graphene transfer. Nanotechnology 2017, 28, 485201. [Google Scholar] [CrossRef] [PubMed]

- Dlubak, B.; Kidambi, P.R.; Weatherup, R.S.; Hofmann, S.; Robertson, J. Substrate-assisted nucleation of ultra-thin dielectric layers on graphene by atomic layer deposition. Appl. Phys. Lett. 2012, 100, 173113. [Google Scholar] [CrossRef]

- Gulotty, R.; Das, S.; Liu, Y.; Sumant, A.V. Effect of hydrogen flow during cooling phase to achieve uniform and repeatable growth of bilayer graphene on copper foils over large area. Carbon 2014, 77, 341–350. [Google Scholar] [CrossRef]

- Groner, M.D.; Elam, J.W.; Fabreguette, F.H.; George, S.M. Electrical characterization of thin Al2O3 films grown by atomic layer deposition on silicon and various metal substrates. Thin Solid Films 2012, 413, 186–197. [Google Scholar] [CrossRef]

- Marta, B.; Leordean, C.; Istvan, T.; Botiz, I.; Astilean, S. Efficient etching-free transfer of high quality, large-area CVD grown graphene onto polyvinyl alcohol films. Appl. Surf. Sci. 2016, 363, 613–618. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Solid State Communications. Raman spectroscopy of graphene and graphite: Disorder, electron–phonon coupling, doping and nonadiabatic effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Miikkulainen, V.; Leskelä, M.; Ritala, M.; Puurunen, R.L. Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. J. Appl. Phys. 2013, 113, 101. [Google Scholar] [CrossRef]

- Määttänen, A.; Vehkamäki, H.; Lauri, A.; Napari, I.; Kulmala, M. Two-component heterogeneous nucleation kinetics and an application to Mars. J. Chem. Phys. 2007, 127, 134710. [Google Scholar] [CrossRef] [PubMed]

- Stauffer, D. Kinetic theory of two-component (“hetero-molecular”) nucleation and condensation. J. Aerosol Sci. 1976, 7, 319–333. [Google Scholar] [CrossRef]

- Lv, R.; Li, Q.; Botello-Mendez, A.R.; Hayashi, T.; Wang, B.; Berkdemir, A.; Hao, Q.; Elıas, A.L.; Cruz-Silva, R.; Gutierrez, H.R.; et al. Nitrogen-doped graphene: Beyond single substitution and enhanced molecular sensing. Sci. Rep. 2012, 2, 586. [Google Scholar] [CrossRef]

- Li, Z.; Kinloch, I.A.; Young, R.J. The role of interlayer adhesion in graphene oxide upon its reinforcement of nanocomposites. Philos. Trans. R. Soc. A 2015, 374. [Google Scholar] [CrossRef]

- Banhart, F.; Kotakoski, J.; Krasheninnikov, A.V. Structural Defects in Graphene. ACS Nano 2011, 5, 26–41. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.T.; Zalalutdinov, M.K.; Cress, C.D.; Culbertson, J.C.; Friedman, A.L.; Merrill, A.; Landi, B.J. Graphene Strained by Defects. ACS Nano 2017, 11, 4745–4752. [Google Scholar] [CrossRef] [PubMed]

- Das, A.; Isana, S.P.; Chakraborty, B.; Piscanec, S.; Saha, S.K.; Waghmare, U.V.; Novoselov, K.S.; Krishnamurthy, H.R.; Geim, A.K.; Ferrari, A.C.; et al. Monitoring dopants by Raman scattering in an electrochemically top-gated graphene transistor. Nat. Nano 2008, 3, 210–215. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grebel, H.; Stan, L.; Sumant, A.V.; Liu, Y.; Gosztola, D.; Ocola, L.; Fisher, B. Transfer of Graphene with Protective Oxide Layers. ChemEngineering 2018, 2, 58. https://doi.org/10.3390/chemengineering2040058

Grebel H, Stan L, Sumant AV, Liu Y, Gosztola D, Ocola L, Fisher B. Transfer of Graphene with Protective Oxide Layers. ChemEngineering. 2018; 2(4):58. https://doi.org/10.3390/chemengineering2040058

Chicago/Turabian StyleGrebel, Haim, Liliana Stan, Anirudha V. Sumant, Yuzi Liu, David Gosztola, Leonidas Ocola, and Brandon Fisher. 2018. "Transfer of Graphene with Protective Oxide Layers" ChemEngineering 2, no. 4: 58. https://doi.org/10.3390/chemengineering2040058

APA StyleGrebel, H., Stan, L., Sumant, A. V., Liu, Y., Gosztola, D., Ocola, L., & Fisher, B. (2018). Transfer of Graphene with Protective Oxide Layers. ChemEngineering, 2(4), 58. https://doi.org/10.3390/chemengineering2040058