Cytotoxicity and Characterization of Ultrafine Particles from Desktop Three-Dimensional Printers with Multiple Filaments

Abstract

:1. Introduction

2. Materials and Methods

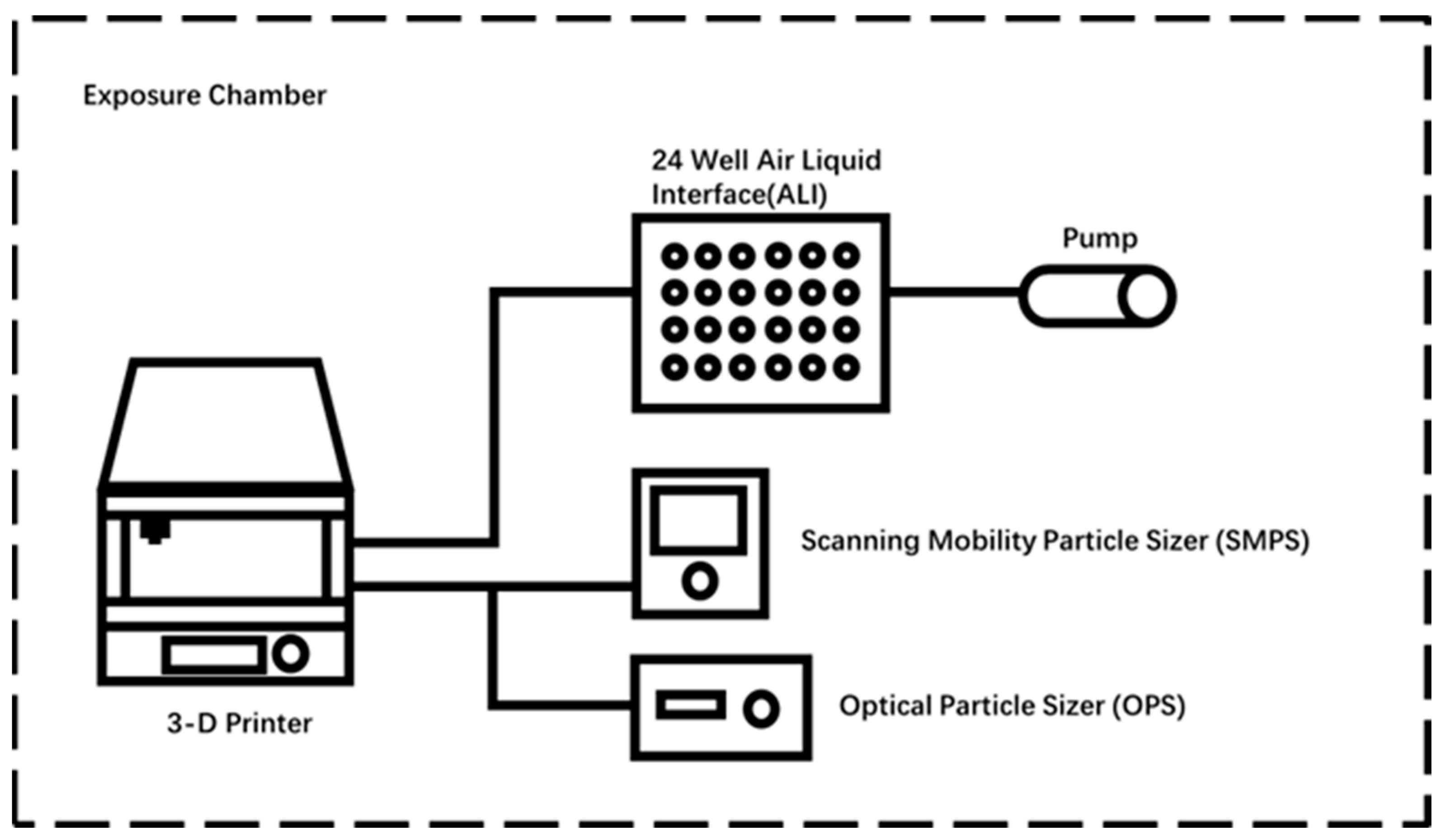

2.1. Exposure System Description

2.2. Aerosol Measurement

2.3. Cytotoxicity Assessments

2.4. Statistical Analysis

3. Results and Discussion

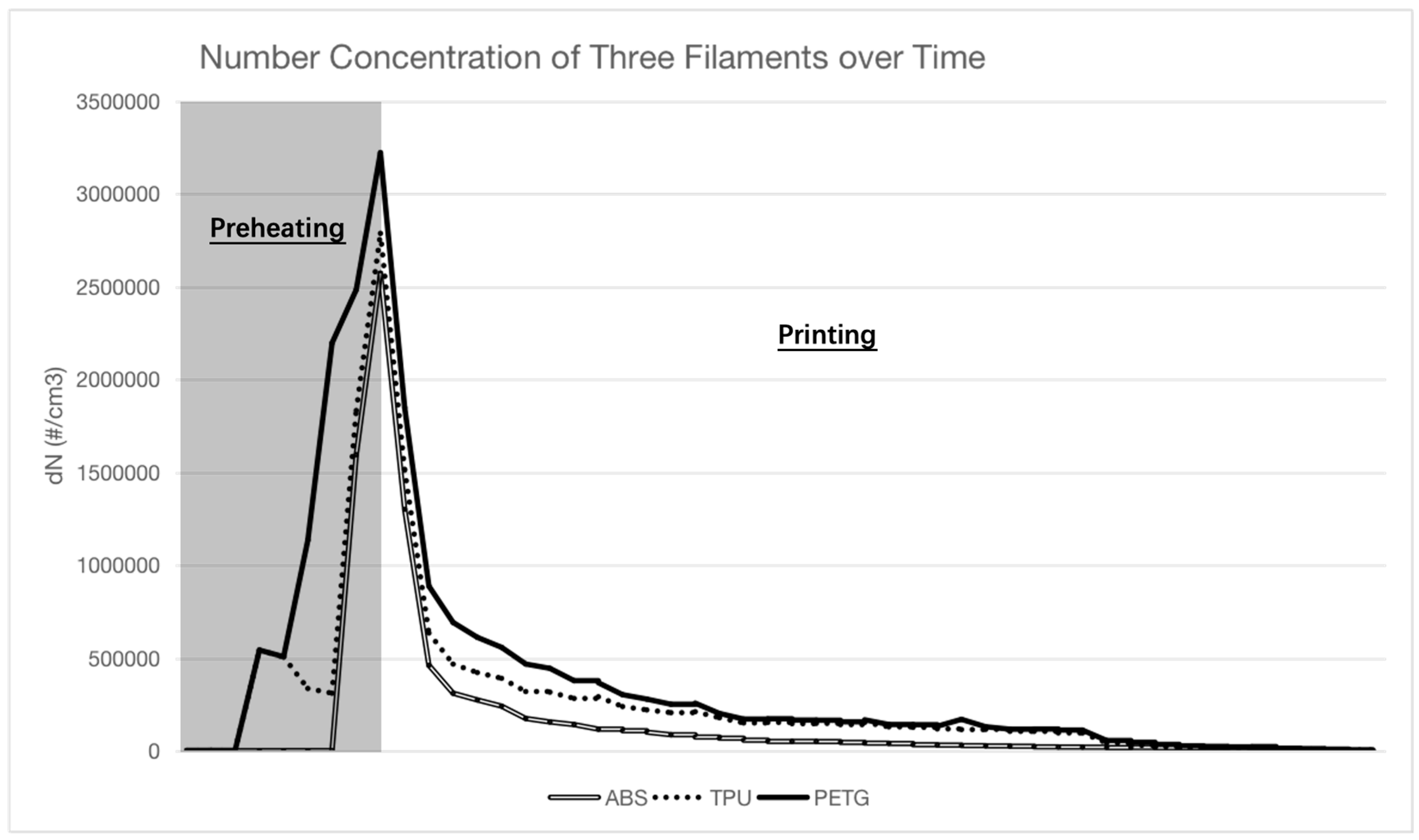

3.1. Aerosol Measurements

3.2. Cytotoxicity Assessments

3.3. Health Implications

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Weber, R.J. Characterization of particle emissions from consumer fused deposition modeling 3D printers. Aerosol Sci. Technol. 2017, 51, 1275–1286. [Google Scholar] [CrossRef]

- Zhang, Q.; Pardo, M.; Rudich, Y.; Kaplan-Ashiri, I.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Weber, R.J. Chemical composition and toxicity of particles emitted from a consumer-level 3D printer using various materials. Environ. Sci. Technol. 2019, 53, 12054–12061. [Google Scholar] [CrossRef]

- Floyd, E.L.; Wang, J.; Regens, J.L. Fume emissions from a low-cost 3-D printer with various filaments. J. Occup. Environ. Hyg. 2017, 14, 523–533. [Google Scholar] [CrossRef] [PubMed]

- Fischer, E.; Dietrich-Gümperlein, G.; Karrasch, S.; Nowak, D.; Jörres, R.A.; Schierl, R. Acute health effects of desktop 3D printing (fused deposition modeling) using acrylonitrile butadiene styrene and polylactic acid materials: An experimental exposure study in human volunteers. Indoor Air 2018, 28, 611–623. [Google Scholar]

- Min, K.; Li, Y.; Wang, D.; Chen, B.; Ma, M.; Hu, L.; Liu, Q.; Jiang, G. 3D Printing-Induced fine particle and volatile organic compound emission: An emerging health risk. Environ. Sci. Technol. Lett. 2021, 8, 616–625. [Google Scholar] [CrossRef]

- Krajnak, K.; Farcas, M.; McKinney, W.; Waugh, S.; Mandler, K.; Jackson, M.; Matheson, J.; Thomas, T.; Qian, Y. Inhalation of particulate and emissions from 3 dimensional (3D) printers: Effects on the olfactory bulb (OB) and hypothalamic-pituitary-endocrine axes. FASEB J. 2021, 35 (Suppl. S1). [Google Scholar] [CrossRef]

- Frank, E.A.; Carreira, V.S.; Birch, M.E.; Yadav, J.S. Carbon Nanotube and Asbestos Exposures Induce Overlapping but Distinct Profiles of Lung Pathology in Non-Swiss Albino CF-1 Mice. Toxicol. Pathol. 2016, 44, 211–225. [Google Scholar] [CrossRef] [PubMed]

- House, R.; Rajaram, N.; Tarlo, S.M. Case report of asthma associated with 3D printing. Occup. Med. 2017, 67, 652–654. [Google Scholar] [CrossRef]

- Azimi, P.; Zhao, D.; Pouzet, C.; Crain, N.E.; Stephens, B. Emissions of ultrafine particles and volatile organic compounds from commercially available desktop three-dimensional printers with multiple filaments. Environ. Sci. Technol. 2016, 50, 1260–1268. [Google Scholar] [CrossRef] [PubMed]

- Afshar-Mohajer, N.; Wu, C.Y.; Ladun, T.; Rajon, D.A.; Huang, Y. Characterization of particulate matters and total VOC emissions from a binder jetting 3D printer. Build. Environ. 2015, 93, 293–301. [Google Scholar] [CrossRef]

- Byrley, P.; Wallace, M.A.G.; Boyes, W.K.; Rogers, K. Particle and volatile organic compound emissions from a 3D printer filament extruder. Sci. Total Environ. 2020, 736, 139604. [Google Scholar] [CrossRef]

- Stephens, B.; Azimi, P.; El Orch, Z.; Ramos, T. Ultrafine particle emissions from desktop 3D printers. Atmos. Environ. 2013, 79, 334–339. [Google Scholar] [CrossRef]

- Poikkimäki, M.; Koljonen, V.; Leskinen, N.; Närhi, M.; Kangasniemi, O.; Kausiala, O.; Maso, M.D. Nanocluster aerosol emissions of a 3D printer. Environ. Sci. Technol. 2019, 53, 13618–13628. [Google Scholar] [CrossRef]

- Jorge, J.H.; Giampaolo, E.T.; Machado, A.L.; Vergani, C.E. Cytotoxicity of denture base acrylic resins: A literature review. J. Prosthet. Dent. 2003, 90, 190–193. [Google Scholar] [CrossRef]

- Jia, G.; Wang, H.; Yan, L.; Wang, X.; Pei, R.; Yan, T.; Zhao, Y.; Guo, X. Cytotoxicity of carbon nanomaterials: Single-wall nanotube, multi-wall nanotube, and fullerene. Environ. Sci. Technol. 2005, 39, 1378–1383. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo, L.G.; Einecke, G.; Allanach, K.; Mengel, M.; Sis, B.; Mueller, T.F.; Halloran, P.F. The transcriptome of human cytotoxic T cells: Measuring the burden of CTL-associated transcripts in human kidney transplants. Am. J. Transplant. 2008, 8, 637–646. [Google Scholar] [CrossRef]

| Filaments | Extruder Temperature (°C) | Bed Temperature (°C) |

|---|---|---|

| Blank | 24 | 24 |

| ABS | 220 | 85 |

| TPU | 220 | 50 |

| PETG | 220 | 24 |

| Filaments | Median | Mean | Min, Max | Std. Deviation | p-Value |

|---|---|---|---|---|---|

| Blank | 1002.2 | 1002.2 | 1002.2, 1002.2 | 0 | N/A |

| ABS | 25,898.3 | 155,056.5 | 1754.5, 2.572 × 106 | 433,084.5 | <0.001 |

| TPU | 15,879.2 | 117,212.3 | 956.1, 540,033.3 | 116,981.3 | <0.001 |

| PETG | 95,525.8 | 124,563.0 | 950.7, 1.885 × 106 | 306,704.8 | <0.001 |

| Filaments | GM | GSD | Mean |

|---|---|---|---|

| Blank | 62.94 | 1.93 | 77.65 |

| ABS | 66.01 | 1.75 | 75.99 |

| TPU | 60.90 | 1.77 | 70.65 |

| PETG | 49.89 | 1.75 | 57.81 |

| Filaments | F | p-Value | df | |

|---|---|---|---|---|

| ABS | 289.90 | 2.62 × 10−6 * | 7 | |

| 45 min | TPU | 2.60 | 0.18 | 5 |

| PETG | 7.37 | 0.042 * | 6 | |

| ABS | 30.70 | 0.005 * | 5 | |

| 90 min | TPU | 2.10 | 0.22 | 5 |

| PETG | 0.32 | 0.60 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, R.; Mohammed, A.N.; Yadav, J.S.; Wang, J. Cytotoxicity and Characterization of Ultrafine Particles from Desktop Three-Dimensional Printers with Multiple Filaments. Toxics 2023, 11, 720. https://doi.org/10.3390/toxics11090720

Fang R, Mohammed AN, Yadav JS, Wang J. Cytotoxicity and Characterization of Ultrafine Particles from Desktop Three-Dimensional Printers with Multiple Filaments. Toxics. 2023; 11(9):720. https://doi.org/10.3390/toxics11090720

Chicago/Turabian StyleFang, Runcheng, Afzaal Nadeem Mohammed, Jagjit Singh Yadav, and Jun Wang. 2023. "Cytotoxicity and Characterization of Ultrafine Particles from Desktop Three-Dimensional Printers with Multiple Filaments" Toxics 11, no. 9: 720. https://doi.org/10.3390/toxics11090720

APA StyleFang, R., Mohammed, A. N., Yadav, J. S., & Wang, J. (2023). Cytotoxicity and Characterization of Ultrafine Particles from Desktop Three-Dimensional Printers with Multiple Filaments. Toxics, 11(9), 720. https://doi.org/10.3390/toxics11090720