Addition of Broad Bean Hull to Wheat Flour for the Development of High-Fiber Bread: Effects on Physical and Nutritional Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Bread Preparation

2.3. Physical Properties

2.3.1. Specific Volume, Density and Weight Loss

2.3.2. Bread Crust and Crumb Color

2.4. Texture Analysis

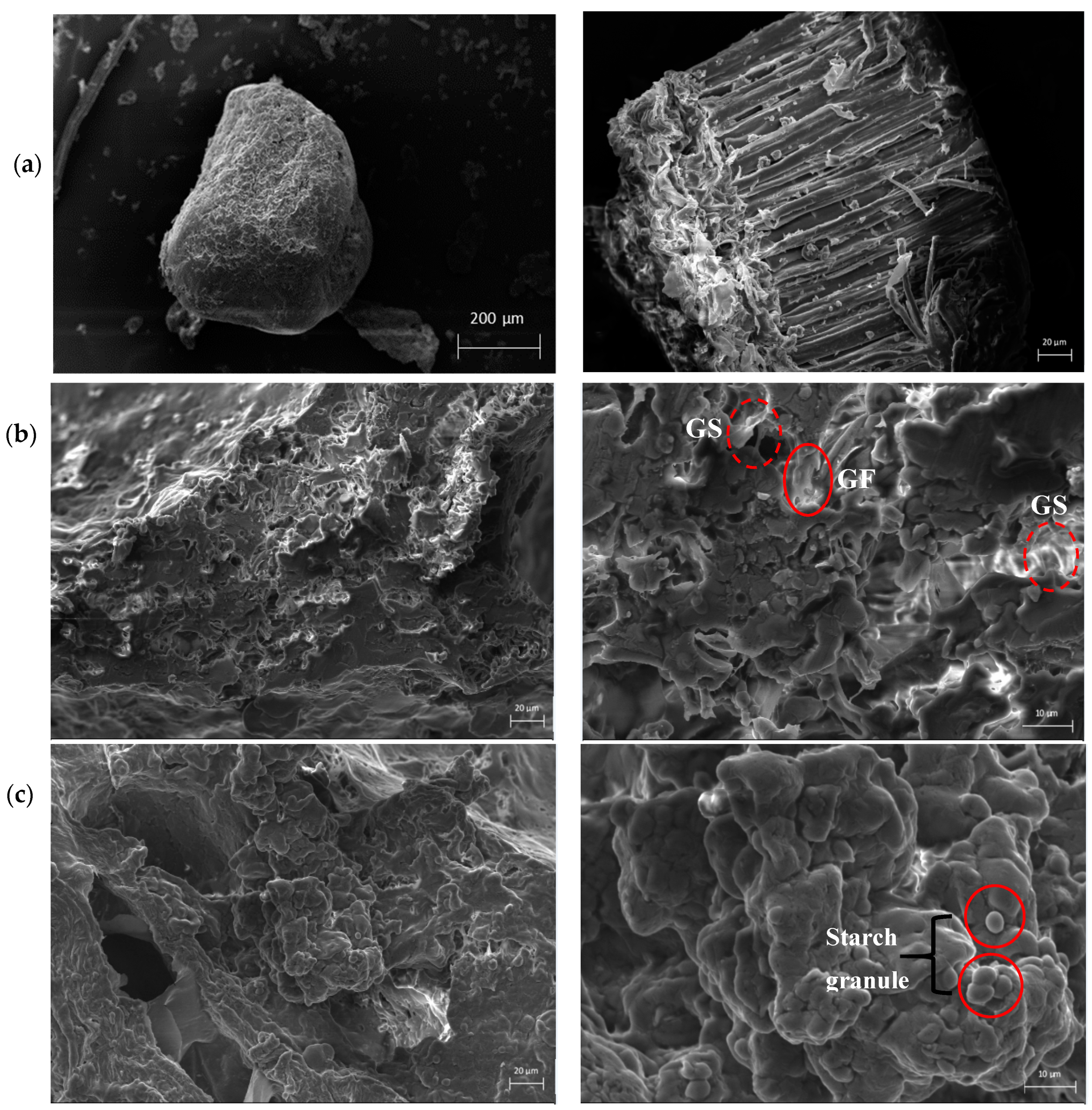

2.5. Scanning Electron Microscopy (SEM)

2.6. Nutritional Analysis

2.6.1. Proximate Composition Analysis of BBH Powder and Breads

2.6.2. Gluten Quantification

2.7. Statistical Analysis

3. Results and Discussion

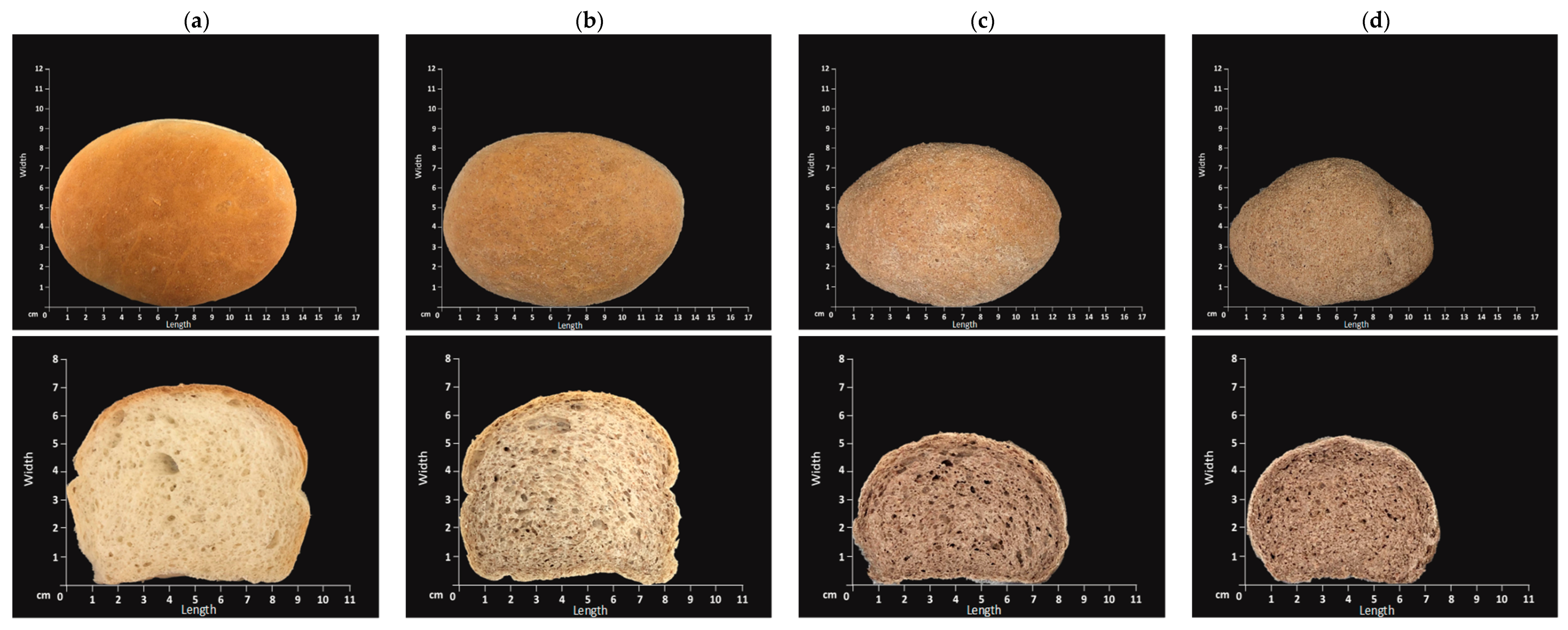

3.1. Physical Properties

3.1.1. Specific Volume, Density and Weight Loss

3.1.2. Bread Crust and Crumb Color

3.2. Texture Analysis

3.3. SEM

3.4. Nutritional Properties

3.4.1. Proximate Composition Analysis

3.4.2. Gluten Quantification

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yano, H. Recent practical researches in the development of gluten-free breads. NPJ Sci. Food 2019, 3, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gil-Humanes, J.; Piston, F.; Altamirano-Fortoul, R.; Real, A.; Comino, I.; Sousa, C.; Rosell, C.M.; Barro, F. Reduced-gliadin wheat bread: An alternative to the gluten-free diet for consumers suffering gluten-related pathologies. PLoS ONE 2014, 9, e90898. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rosell, C.M. The science of doughs and bread quality. In Flour and Breads and Their Fortification in Health and Disease Prevention; Preedy, V.R., Watson, R.R., Patel, V.B., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 3–14. [Google Scholar]

- Blandino, M.; Locatelli, M.; Sovrani, V.; Coisson, J.D.; Rolle, L.; Travaglia, F.; Giacosa, S.; Bordiga, M.; Scarpino, V.; Reyneri, A.; et al. Progressive pearling of barley kernel: Chemical characterization of pearling fraction and effect of their inclusion on the nutritional and technological properties of wheat bread. J. Agric. Food Chem. 2015, 63, 5875–5884. [Google Scholar] [CrossRef] [PubMed]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2011, 124, 411–421. [Google Scholar] [CrossRef]

- Peerajit, P.; Chiewchan, N.; Devahastin, S. Effects of pretreatment methods on health-related functional properties of high dietary fibre powder from lime residues. Food Chem. 2012, 132, 1891–1898. [Google Scholar] [CrossRef]

- Turco, V.L.; Potorti, A.G.; Rando, R.; Ravenda, P.; Dugo, G.; Di Bella, G. Functional properties and fatty acids profile of different beans varieties. Nat. Prod. Res. 2016, 30, 1–6. [Google Scholar] [CrossRef]

- Carmo, C.S.D.; Silventoinen, P.; Nordgård, C.T.; Poudroux, C.; Dessev, T.; Zobel, H.; Holtekjølen, A.K.; Draget, K.I.; Holopainen-Mantila, U.; Knutsen, S.H.; et al. Is dehulling of peas and faba beans necessary prior to dry fractionation for the production of protein-and starch-rich fractions? Impact on physical properties, chemical composition and techno-functional properties. J. Food Eng. 2020, 278, 109937. [Google Scholar] [CrossRef]

- Fendri, L.B.; Chaari, F.; Maaloul, M.; Kallel, F.; Abdelkafi, L.; Ellouz, C.S.; Ghribi-Aydi, D. Wheat bread enrichment by pea and broad bean pods fibers: Effect on dough rheology and bread quality. LWT 2016, 73, 584–591. [Google Scholar] [CrossRef]

- Encina-Zelada, C.R.; Cadavez, V.; Monteiro, F.; Teixeira, J.A.; Gonzales-Barron, U. Combined effect of xanthan gum and water content on physicochemical and textural properties of gluten-free batter and bread. Food Res. Int. 2018, 111, 544–555. [Google Scholar] [CrossRef] [Green Version]

- Pathak, D.; Majumdar, J.; Raychaudhuri, U.; Chakraborty, R. Characterisation of physicochemical properties in whole wheat bread after incorporation of ripe mango peel. J. Food Meas. Charact. 2016, 10, 554–561. [Google Scholar] [CrossRef]

- Food and Agricultural Organization of the United Nations. Food Energy: Methods of Analysis and Conversion Factors; Food and Agricultural Organization of the United Nations: Rome, Italy, 2003. [Google Scholar]

- Lee, S.C.; Prosky, L.; De Vries, J.W. Determination of Total, Soluble, and Insoluble Dietary Fiber in Foods—Enzymatic-Gravimetric Method, MES-TRIS Buffer: Collaborative Study. J. AOAC Int. 1992, 75, 396–416. [Google Scholar] [CrossRef]

- Englyst, H.N.; Hudson, G.J. Colorimetric method for routine measurement of dietary fiber as non-starch polysaccharides. A comparison with gas-liquid chromatography. Food Chem. 1987, 24, 63–76. [Google Scholar] [CrossRef]

- Awika, J.M. Effect of bioactive components on dough rheology, baking and extrusion. In Fruit and Cereal Bioactives: Sources, Chemistry, and Applications; Tokusoglu, O., Hall, C.A., III, Eds.; CRC Press: New York, NY, USA, 2011; pp. 337–344. [Google Scholar]

- Hemdane, S.; Jacobs, P.J.; Dornez, E.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Wheat (Triticum aestivum L.) Bran in bread making: A critical review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 28–42. [Google Scholar] [CrossRef] [Green Version]

- Gelroth, J.; Ranhotra, G.S. Food uses of fibre. In Handbook of Dietary Fibre; Cho, S.S., Dreher, M.L., Eds.; Marcel Dekker: New York, NY, USA, 2001; pp. 435–449. [Google Scholar]

- Rosell, C.M.; Rojas, J.A.; Barber, C.B.D. Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocoll. 2001, 15, 75–81. [Google Scholar] [CrossRef]

- Wang, M.; Hamer, R.J.; van Vliet, T.; Oudgenoeg, G. Interaction of water extractable pentosans with gluten protein: Effect on dough properties and gluten quality. J. Cereal Sci. 2002, 36, 25–37. [Google Scholar] [CrossRef]

- Sivam, A.S.; Sun-Waterhouse, D.; Quek, S.; Perera, C.O. Properties of bread dough with added fiber polysaccharides and phenolic antioxidants: A review. J. Food Sci. 2010, 75, R163–R174. [Google Scholar] [CrossRef] [Green Version]

- Tuncel, N.B.; Yilmaz, N.; Kocabiyik, H.; Uygur, A. The effect of infrared stabilised rice bran substitution on physicochemical and sensory properties of pan breads: Part I. J. Cereal Sci. 2014, 59, 155–161. [Google Scholar] [CrossRef]

- Ranawana, V.; McDougall, G.; Hayward, N.; Raikos, V. Vicia faba hull: A novel source of fibre, and a functional food with antidiabetic properties. Proc. Nutr. Soc. 2020, 79, E299. [Google Scholar] [CrossRef]

- Stevenson, L.; Phillips, F.; O’Sullivan, K.; Walton, J. Wheat bran: Its composition and benefits to health, a European Perspective. Int. J. Food Sci. Nutr. 2012, 63, 1001–1013. [Google Scholar] [CrossRef] [Green Version]

- Chareonthaikij, P.; Uan-On, T.; Prinyawiwatkul, W. Effects of pineapple pomace fibre on physicochemical properties of composite flour and dough, and consumer acceptance of fibre-enriched wheat bread. Int. J. Food Sci. Technol. 2016, 51, 1120–1129. [Google Scholar] [CrossRef]

- Zhang, D.; Moore, W.R. Wheat bran particle size effects on bread baking performance and quality. J. Sci. Food Agric. 1999, 79, 805–809. [Google Scholar] [CrossRef]

- Dhen, N.; Rejeb, I.B.; Boukhris, H.; Damergi, C.; Gargouri, M. Physicochemical and sensory properties of wheat-apricot kernels composite bread. LWT-Food Sci. Technol. 2018, 95, 262–267. [Google Scholar] [CrossRef]

- Anil, M. Using of hazelnut testa as a source of dietary fiber in breadmaking. J. Food Eng. 2007, 80, 61–67. [Google Scholar] [CrossRef]

- Purils, E. Bread baking: Technological considerations based on process modelling and simulation. J. Food Eng. 2011, 103, 92–102. [Google Scholar] [CrossRef]

- Bouaziz, F.; Abdeddayem, A.B.; Koubaa, M.; Ghorbel, R.E.; Chaabouni, S.E. Date seeds as a natural source of dietary fibers to improve texture and sensory properties of wheat bread. Foods 2020, 9, 737. [Google Scholar] [CrossRef]

- Laukova, M.; Kohajdova, Z.; Karovicova, J.; Kuchtova, V.; Minarovicova, L.; Tomasikova, L. Effects of cellulose fiber with different fiber length on rheological properties of wheat dough and quality of baked rolls. Food Sci. Technol. Int. 2017, 23, 490–499. [Google Scholar] [CrossRef]

- Kowalczewski, P.L.; Walkowiak, K.; Masewicz, L.; Duda, A.; Poliszko, N.; Rozanska, M.B.; Jezowski, P.; Tomkowiak, A.; Mildner-Szkudlarz, S.; Baranowska, H.M. Wheat bread enriched with raspberry and strawberry oilcakes: Effects on proximate composition, texture and water properties. Eur. Food Res. Technol. 2019, 245, 2591–2600. [Google Scholar] [CrossRef] [Green Version]

- Armero, E.; Collar, C. Texture properties of formulated wheat doughs: Relationships with dough and bread technological quality. Zeitschrift für Lebensmitteluntersuchung und-Forschung A 1997, 204, 136–145. [Google Scholar] [CrossRef]

- Aydogdu, A.; Sumnu, G.; Sahin, S. Effects of addition of different fibers on rheological characteristics of cake batter and quality of cakes. J. Food Sci. Technol. 2018, 55, 667–677. [Google Scholar] [CrossRef]

- Hoehnel, A.; Bez, J.; Petersen, I.L.; Amarowicz, R.; Juskiewicz, J.; Arendt, E.K.; Zannini, E. Enhancing the nutritional profile of regular wheat bread while maintaining technological quality and adequate sensory attributes. Food Funct. 2020, 11, 4732. [Google Scholar] [CrossRef]

- Macdiarmid, J.I.; Clark, H.; Whybrow, S.; Ruiter, H.D.; McNeil, G. Assessing national nutrition security: The UK reliance on imports to meet population energy and nutrient recommendation. PLoS ONE 2018, 13, e0192649. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sidhu, J.S.; Al-Hooti, S.N.; Al-Saqer, J.M. Effect of adding wheat bran and germ fractions on the chemical composition of high-fiber toast bread. Food Chem. 1999, 67, 365–371. [Google Scholar] [CrossRef]

- Kolodziejczyk, P.; Michniewicz, J.; Buchowski, M.S.; Paschke, H. Effects of fibre-rich rye milling fraction on the functional properties and nutritional quality of wholemeal rye bread. J. Food Sci. Technol. 2020, 57, 222–232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moron, B.; Bethune, M.T.; Comino, I.; Manyani, H.; Ferragud, M.; Lopez, M.C.; Cebolla, A.; Khosla, C.; Sousa, C. Toward the assessment of food toxicity for celiac patients: Characterisation of monoclonal antibodies to a main immunogenic gluten peptide. PLoS ONE 2008, 3, e2294. [Google Scholar] [CrossRef] [Green Version]

- Adams, G.G.; Kok, S.M.; Imran, S.; Harding, S.E.; Ilyas, M.; Tatham, A.S. The interaction of dietary fibres with disulphide bonds (S-S) and a potential strategy to reduce the toxicity of the gluten proteins in coeliac disease. Biotechnol. Genet. Eng. 2012, 28, 115–130. [Google Scholar] [CrossRef] [Green Version]

| Ingredient | Control | 11% | 21% | 31% | % of Flour |

|---|---|---|---|---|---|

| Quantity (g) | |||||

| Strong white wheat flour | 75 | 75 | 75 | 75 | |

| BBH | - | 9 | 20 | 34 | - |

| Yeast | 2 | 2 | 2 | 2 | 3 |

| Salt | 1.4 | 1.7 | 1.8 | 2.2 | 2 |

| Fat | 3.75 | 3.75 | 3.75 | 3.75 | 5 |

| Water (lukewarm) | 59 | 66 | 75 | 86 | 78.9 |

| Bread Type | Specific Volume (ml/g) | Density (g/mL) | Weight Loss (%) | Colour | |||||

|---|---|---|---|---|---|---|---|---|---|

| Crust | Crumb | ||||||||

| L* | WI | BI | L* | WI | BI | ||||

| Control | 4.11 ± 0.08 a | 0.24 ± 0.004 a | 13.79 ± 0.59 a | 51.90 ± 2.12 a | 40.07 ± 1.71 a | 113.52 ± 6.13 a | 62.65 ± 1.18 a | 59.91 ± 1.07 a | 26.75 ± 0.69 a |

| 11% | 3.65 ± 0.07 b | 0.27 ± 0.01 b | 12.83 ± 0.01 ab | 54.77 ± 0.64 b | 45.89 ± 0.54 b | 82.63 ± 2.88 b | 54.17 ± 1.47 b | 52.15 ± 1.32 b | 33.33 ± 0.52 a |

| 21% | 2.30 ± 0.03 c | 0.44 ± 0.01 c | 11.61 ± 0.51 bc | 55.25 ± 0.77 b | 51.29 ± 1.03 c | 48.15 ± 3.22 c | 35.55 ± 4.40 c | 34.25 ± 4.33 c | 51.74 ± 8.46 b |

| 31% | 1.65 ± 0.05 d | 0.61 ± 0.02 d | 11.17 ± 0.91 c | 43.47 ± 1.32 c | 41.56 ± 1.22 a | 46.88 ± 1.06 c | 40.67 ± 1.50 d | 38.89 ± 1.44 d | 49.83 ± 2.46 b |

| Content | Broad Bean Hull | |

|---|---|---|

| Energy (kcal) | 192 | |

| Ash | 2.5 | |

| Moisture | 9.0 | |

| Protein | 5.3 | |

| Fat | 0.4 | |

| Carbohydrate | 1.1 | |

| Fiber | 81.7 | |

| Rhamnose | 0.4 |

| Fucose | 0.1 | |

| Arabinose | 0.9 | |

| Xylose | 10.0 | |

| Mannose | 0.1 | |

| Galactose | 0.8 | |

| Glucose | 11.6 | |

| Uronic acid | 8.5 | |

| Bread Type | Hardness (g) | Resilience | Adhesiveness (mJ) | Cohesiveness | Springiness (mm) | Chewiness (mJ) |

|---|---|---|---|---|---|---|

| Control | 558.67 ± 37.19 a | 0.28 ± 0.02 a | 0.47 ± 0.34 a | 0.54 ± 0.02 a | 7.19 ± 0.20 a | 21.17 ± 1.62 a |

| 11% | 619.83 ± 35.40 a | 0.22 ± 0.02 b | 1.07 ± 0.73 ab | 0.47 ± 0.05 b | 7.32 ± 0.18 a | 21.08 ± 3.21 a |

| 21% | 2100.83 ± 344.69 b | 0.13 ± 0.01 c | 1.18 ± 0.89 ab | 0.37 ± 0.02 c | 6.60 ± 0.22 b | 50.53 ± 7.43 b |

| 31% | 4666.17 ± 215.03 c | 0.06 ± 0.01 d | 1.70 ± 0.80 b | 0.21 ± 0.01 d | 5.22 ± 0.42 c | 50.68 ± 3.84 b |

| Bread Type | Energy | Protein (g/100 g) | Available Carbohydrates (g/100 g) | Total Sugars (g/100 g) | Fat (g/100 g) | Dietary Fibre (g/100 g) | Sodium (mg/100 g) | Moisture (g/100 g) | Ash (g/100 g) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Kcal/100 g | kJ/100 g | Total Fat | Saturates | Mono-Unsaturates | Poly-Unsaturates | ||||||||

| Control | 269 ± 0.71 a | 1133 ± 4.24 a | 10.07 ± 0.08 a | 45.67 ± 0.18 a | 1.06 ± 0.01 a | 4.23 ± 0.01 a | 1.33 ± 0.01 a | 1.81 ± 0.01 a | 0.92 ± 0.00 a | 3.62 ± 0.06 a | 521 ± 3.54 a | 34.68 ± 0.18 a | 1.74 ± 0.03 a |

| 11% | 244 ± 1.41 b | 1029 ± 9.19 b | 9.12 ± 0.16 b | 39.56 ± 0.70 b | 0.71 ± 0.01 b | 3.60 ± 0.05 b | 1.13 ± 0.02 b | 1.55 ± 0.02 b | 0.77 ± 0.01 b | 8.53 ± 0.56 b | 525 ± 2.12 b | 37.31 ± 0.28 b | 1.90 ± 0.03 b |

| 21% | 223 ± 0.71 c | 935 ± 1.41 c | 8.19 ± 0.05 c | 32.78 ± 0.24c | 0.73 ± 0.00 b | 3.31 ± 0.06 b | 1.04 ± 0.01 c | 1.43 ± 0.02 c | 0.70 ± 0.01 b | 14.53 ± 0.06 c | 494 ± 0.71 c | 39.57 ± 0.21 c | 1.64 ± 0.01 c |

| 31% | 209 ± 0.00 d | 876 ± 0.00 d | 7.60 ± 0.06 d | 28.82 ± 0.23 d | 0.39 ± 0.01 c | 2.81 ± 0.03 c | 0.88 ± 0.01 d | 1.20 ± 0.01 d | 0.61 ± 0.01 c | 19.19 ± 0.22 d | 533 ± 1.41 b | 39.50 ± 0.11 c | 2.10 ± 0.03 d |

| Bread Type | Gluten (Ppm Per Loaf) | Gluten (mg/50 g Serving Size) | % Depletion in Gluten Per Loaf |

|---|---|---|---|

| Control | 18903.00 ± 11.00 a | 6246.00 ± 3.60 a | 0.00 |

| 11% | 17420.00 ± 107.00 a | 5712.00 ± 35.11 a | −8.00 |

| 21% | 13107.00 ± 523.00 b | 4229.00 ± 168.76 b | −31.00 |

| 31% | 7259.00 ± 748.00 c | 2335.00 ± 240.51 c | −62.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Q.; Ranawana, V.; Hayes, H.E.; Hayward, N.J.; Stead, D.; Raikos, V. Addition of Broad Bean Hull to Wheat Flour for the Development of High-Fiber Bread: Effects on Physical and Nutritional Properties. Foods 2020, 9, 1192. https://doi.org/10.3390/foods9091192

Ni Q, Ranawana V, Hayes HE, Hayward NJ, Stead D, Raikos V. Addition of Broad Bean Hull to Wheat Flour for the Development of High-Fiber Bread: Effects on Physical and Nutritional Properties. Foods. 2020; 9(9):1192. https://doi.org/10.3390/foods9091192

Chicago/Turabian StyleNi, Qianqian, Viren Ranawana, Helen E. Hayes, Nicholas J. Hayward, David Stead, and Vassilios Raikos. 2020. "Addition of Broad Bean Hull to Wheat Flour for the Development of High-Fiber Bread: Effects on Physical and Nutritional Properties" Foods 9, no. 9: 1192. https://doi.org/10.3390/foods9091192