Use of Gum Cordia (Cordia myxa) as a Natural Starch Modifier; Effect on Pasting, Thermal, Textural, and Rheological Properties of Corn Starch

Abstract

1. Introduction

2. Materials and Methods

2.1. Collection of Raw Material

2.2. Extraction of Cordia Gum

2.3. Preparation of Starch-Gum Blends

2.4. Thermal Properties of Starch-Gum Blends

2.5. Pasting Behavior of Starch-Gum Blends

2.6. Freeze Thaw Stability of Gels

2.7. Textural Properties of Gels

2.8. Flow Behavior of Starch Gels

2.9. Dynamic Shear Properties of Starch Gels

2.10. Statistical Analysis

3. Results and Discussion

3.1. Thermal Properties of Starch-Gum Blends

3.2. Pasting Behavior of Starch-Gum Blends

3.3. Freeze Thaw Stability of Gels

3.4. Textural Properties of Gels

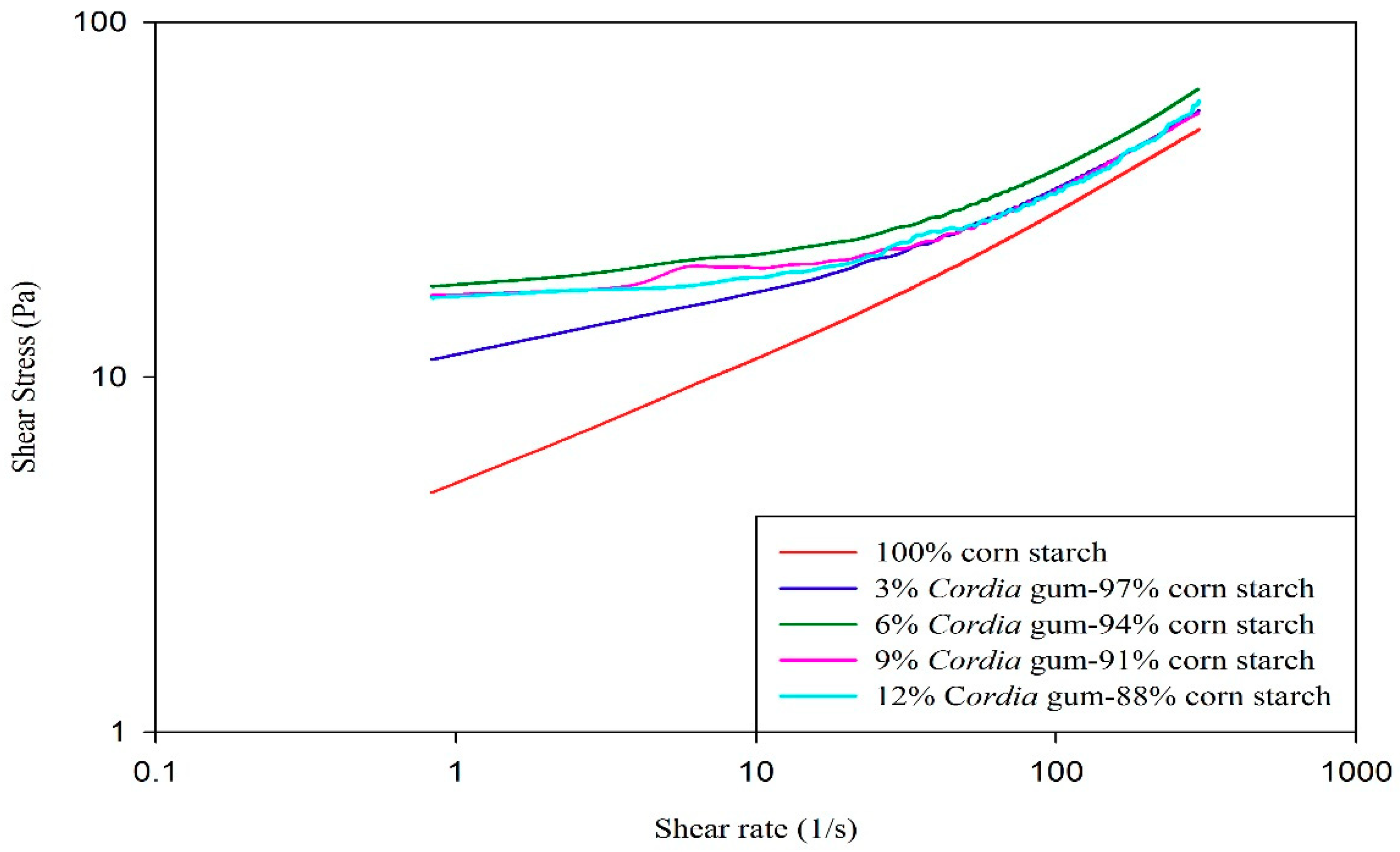

3.5. Flow Behavior of Starch Gels

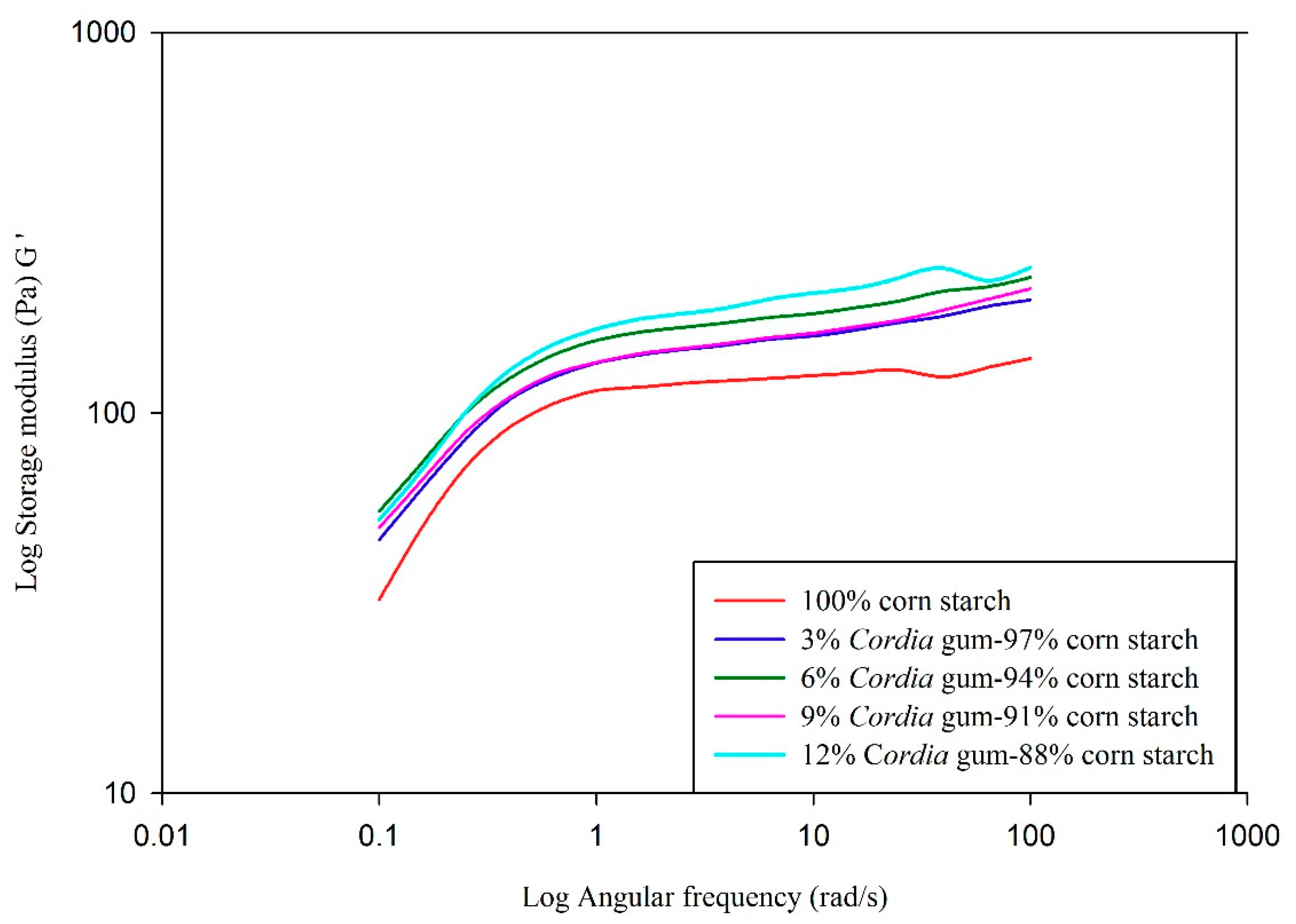

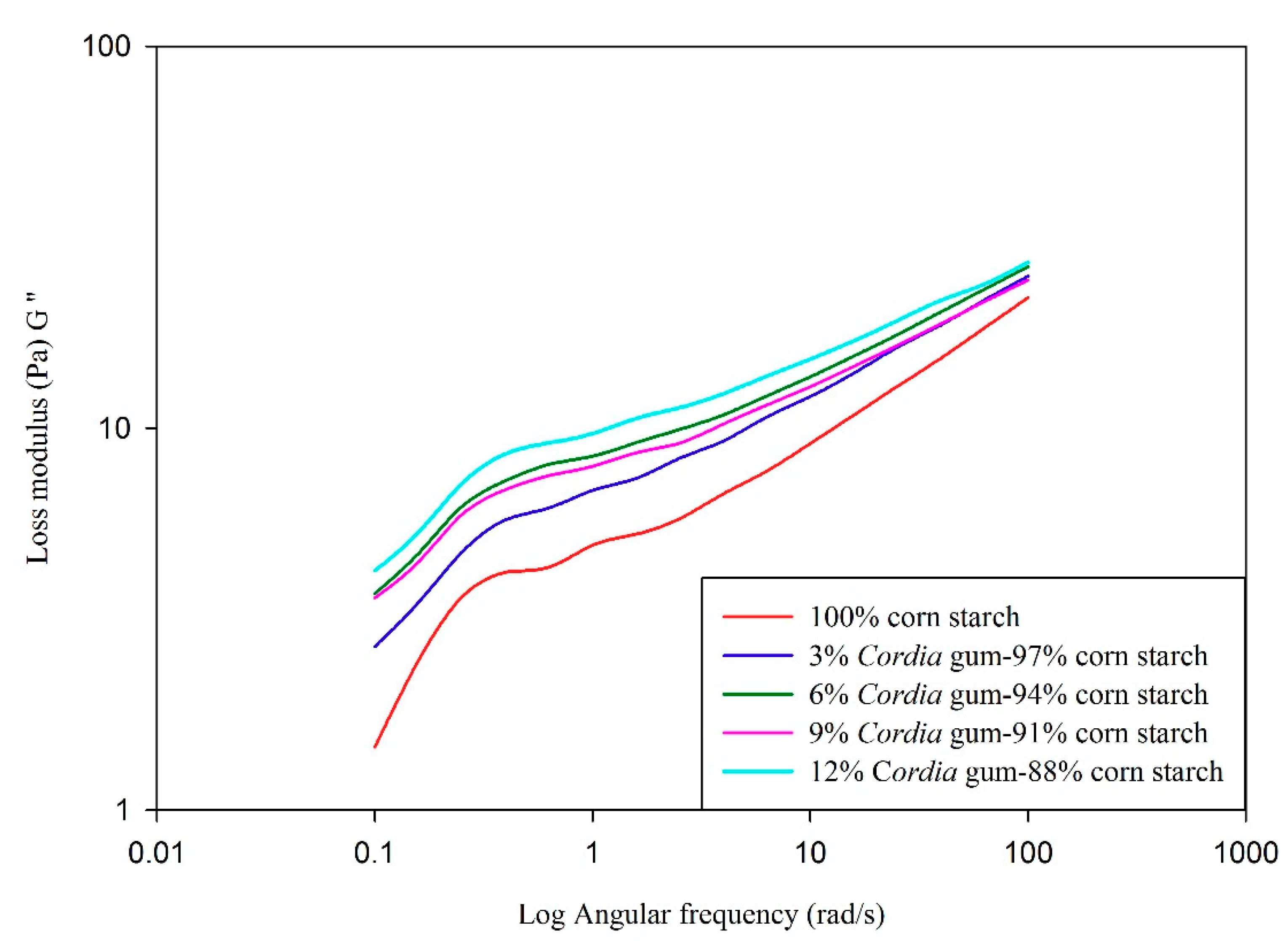

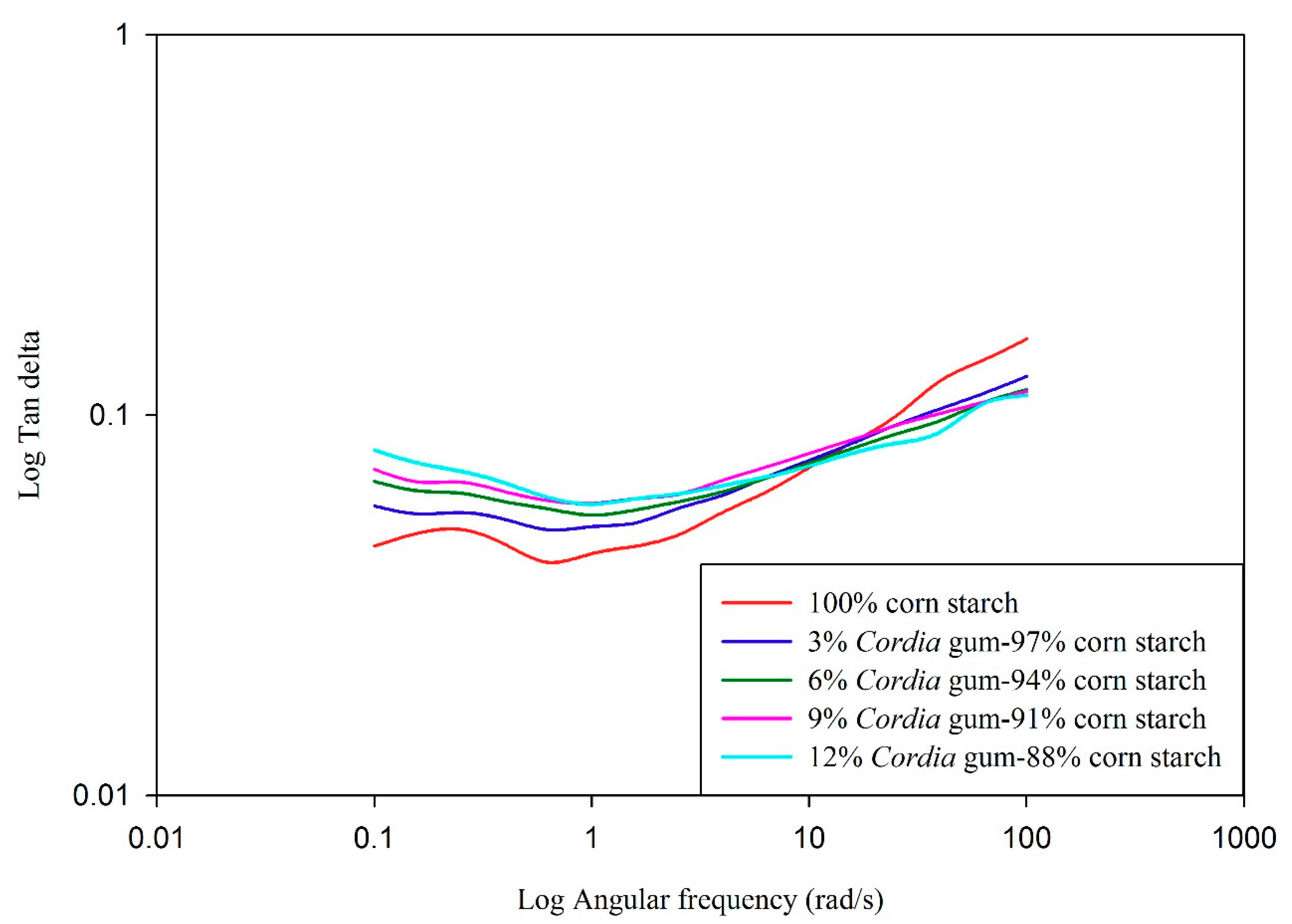

3.6. Dynamic Shear Properties of Starch Gels

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tester, R.F.; Karkalas, J.; Qi, X. Starch—Composition, fine structure and architecture. J. Cereal Sci. 2004, 39, 151–165. [Google Scholar] [CrossRef]

- Slattery, C.J.; Kavakli, I.H.; Okita, T.W. Engineering starch for increased quantity and quality. Trends Plant Sci. 2000, 5, 291–298. [Google Scholar] [CrossRef]

- Temsiripong, T.; Pongsawatmanit, R.; Ikeda, S.; Nishinari, K. Influence of xyloglucan on gelatinization and retrogradation of tapioca starch. Food Hydrocoll. 2005, 19, 1054–1063. [Google Scholar] [CrossRef]

- Pongsawatmanit, R.; Chantaro, P.; Nishinari, K. Thermal and rheological properties of tapioca starch gels with and without xanthan gum under cold storage. J. Food Eng. 2013, 117, 333–341. [Google Scholar] [CrossRef]

- Feng, T.; Gu, Z.; Jin, Z.; Zhuang, H. Rheological properties of rice starch–Mesona Blumes gum mixtures. J. Texture Stud. 2010, 41, 685–702. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Choi, H.-M.; Yoo, B.-S. Effect of various gums on flow properties and yield stress of Korean sweet potato starch. J. Korean Soc. Food Sci. Nutr. 2009, 38, 1253–1257. [Google Scholar] [CrossRef]

- Gawai, K.M.; Mudgal, S.P.; Prajapati, J.B. Stabilizers, colorants, and exopolysaccharides in yogurt. In Yogurt in Health and Disease Prevention; Elsevier: Cambridge, MA, USA, 2017; pp. 49–68. [Google Scholar]

- Saha, D.; Bhattacharya, S. Hydrocolloids as thickening and gelling agents in food: A critical review. J. Food Sci. Technol. 2010, 47, 587–597. [Google Scholar] [CrossRef]

- Alamri, M.; Mohamed, A.; Hussain, S.; Xu, J. Effect of okra extract on properties of wheat, corn and rice starches. J. Food Agric. Environ. 2012, 10, 217–222. [Google Scholar]

- Alamri, M.S. Sweet potato/potato starch and Abelmoschus esculentus-gum blends: Thermal and textural properties. Starch Stärke 2014, 66, 132–141. [Google Scholar] [CrossRef]

- Alamri, M.S.; Mohamed, A.A.; Hussain, S. Effect of okra gum on the pasting, thermal, and viscous properties of rice and sorghum starches. Carbohydr. Polym. 2012, 89, 199–207. [Google Scholar] [CrossRef] [PubMed]

- Alamri, M.S.; Mohamed, A.A.; Hussain, S. Effects of alkaline-soluble okra gum on rheological and thermal properties of systems with wheat or corn starch. Food Hydrocoll. 2013, 30, 541–551. [Google Scholar] [CrossRef]

- Chaisawang, M.; Suphantharika, M. Effects of guar gum and xanthan gum additions on physical and rheological properties of cationic tapioca starch. Carbohydr. Polym. 2005, 61, 288–295. [Google Scholar] [CrossRef]

- Feng, T.; Ye, R.; Zhuang, H.; Fang, Z.; Chen, H. Thermal behavior and gelling interactions of Mesona Blumes gum and rice starch mixture. Carbohydr. Polym. 2012, 90, 667–674. [Google Scholar] [CrossRef]

- Funami, T.; Kataoka, Y.; Omoto, T.; Goto, Y.; Asai, I.; Nishinari, K. Effects of non-ionic polysaccharides on the gelatinization and retrogradation behavior of wheat starch. Food Hydrocoll. 2005, 19, 1–13. [Google Scholar] [CrossRef]

- Lee, H.Y.; Jo, W.; Yoo, B. Rheological and microstructural characteristics of rice starch–tara gum mixtures. Int. J. Food Prop. 2017, 20, 1879–1889. [Google Scholar] [CrossRef]

- Alami, R.; Macksad, A.; Jundī, A.R. Medicinal Plants in Kuwait; Al-Assriya: Kuwait City, Kuwait, 1972. [Google Scholar]

- Keshani-Dokht, S.; Emam-Djomeh, Z.; Yarmand, M.-S.; Fathi, M. Extraction, chemical composition, rheological behavior, antioxidant activity and functional properties of Cordia myxa mucilage. Int. J. Biol. Macromol. 2018, 118, 485–493. [Google Scholar] [CrossRef]

- Thirupathi, K.; Kumar, S.S.; Raju, V.; Ravikumar, B.; Krishna, D.; Mohan, G.K. A review of medicinal plants of the genus Cordia: Their chemistry and pharmacological uses. J. Nat. Remedies 2008, 8, 1–10. [Google Scholar]

- Benhura, M.A.N.; Chidewe, C.K. The emulsifying properties of a polysaccharide isolated from the fruit of Cordia abyssinica. Int. J. Food Sci. Technol. 2004, 39, 579–583. [Google Scholar] [CrossRef]

- Dinda, S.C.; Mukharjee, B. Gum cordia—A new tablet binder and emulsifier. Acta Pharm. Sci. 2009, 51, 189–198. [Google Scholar]

- Mahmood, K.; Alamri, M.; Mohamed, A.; Hussain, S.; Abdu Qasem, A. Gum cordia: Physico-functional properties and effect on dough rheology and pan bread quality. Qual. Assur. Saf. Crop. Foods 2015, 7, 569–579. [Google Scholar] [CrossRef]

- Haq, M.A.; Alam, M.J.; Hasnain, A. Gum Cordia: A novel edible coating to increase the shelf life of Chilgoza (Pinus gerardiana). LWT Food Sci. Technol. 2013, 50, 306–311. [Google Scholar] [CrossRef]

- Benhura, M.; Chidewe, C. Characterization of the polysaccharide material that is isolated from the fruit of Cordia abyssinica. Afr. J. Biochem. Res. 2011, 5, 95–101. [Google Scholar]

- Torres, M.; Moreira, R.; Chenlo, F.; Morel, M.H. Effect of water and guar gum content on thermal properties of chestnut flour and its starch. Food Hydrocoll. 2013, 33, 192–198. [Google Scholar] [CrossRef]

- Lee, M.; Baek, M.; Cha, D.; Park, H.; Lim, S. Freeze–thaw stabilization of sweet potato starch gel by polysaccharide gums. Food Hydrocoll. 2002, 16, 345–352. [Google Scholar] [CrossRef]

- Biliaderis, C. Structures and phase transitions of starch polymers. ChemInform 1998, 29. [Google Scholar] [CrossRef]

- Krüger, A.; Ferrero, C.; Zaritzky, N.E. Modelling corn starch swelling in batch systems: Effect of sucrose and hydrocolloids. J. Food Eng. 2003, 58, 125–133. [Google Scholar] [CrossRef]

- Liu, H.; Eskin, N.M.; Cui, S.W. Interaction of wheat and rice starches with yellow mustard mucilage. Food Hydrocoll. 2003, 17, 863–869. [Google Scholar] [CrossRef]

- Da Silva Costa, R.A.; Bonomo, R.C.F.; Rodrigues, L.B.; Santos, L.S.; Veloso, C.M. Improvement of texture properties and syneresis of arrowroot (Maranta arundinacea) starch gels by using hydrocolloids (guar gum and xanthan gum). J. Sci. Food Agric. 2020, 100, 3204–3211. [Google Scholar] [CrossRef]

- Chaisawang, M.; Suphantharika, M. Pasting and rheological properties of native and anionic tapioca starches as modified by guar gum and xanthan gum. Food Hydrocoll. 2006, 20, 641–649. [Google Scholar] [CrossRef]

- Singh, A.; Geveke, D.J.; Yadav, M.P. Improvement of rheological, thermal and functional properties of tapioca starch by using gum arabic. LWT 2017, 80, 155–162. [Google Scholar] [CrossRef]

- Shi, X.; BeMiller, J.N. Effects of food gums on viscosities of starch suspensions during pasting. Carbohydr. Polym. 2002, 50, 7–18. [Google Scholar] [CrossRef]

- Von Borries-Medrano, E.; Jaime-Fonseca, M.R.; Aguilar-Méndez, M.A. Tapioca starch-galactomannan systems: Comparative studies of rheological and textural properties. Int. J. Biol. Macromol. 2019, 122, 1173–1183. [Google Scholar] [CrossRef] [PubMed]

- Haq, M.A.; Abid, H.; Khalid, J.; Haider, M.S. Extraction and characterization of gum from Cordia myxa. Asian J. Chem. 2014, 26, 122–126. [Google Scholar] [CrossRef]

- BeMiller, J.N. Pasting, paste, and gel properties of starch–hydrocolloid combinations. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

- Krystyjan, M.; Adamczyk, G.; Sikora, M.; Tomasik, P. Long-term storage stability of selected potato starch–non-starchy hydrocolloid binary gels. Food Hydrocoll. 2013, 31, 270–276. [Google Scholar] [CrossRef]

- Funami, T. Functions of food polysaccharides to control the gelatinization and retrogradation behaviors of starch in an aqueous system in relation to the macromolecular characteristics of food polysaccharides. Food Sci. Technol. Res. 2009, 15, 557–568. [Google Scholar] [CrossRef][Green Version]

- Techawipharat, J.; Suphantharika, M.; BeMiller, J.N. Effects of cellulose derivatives and carrageenans on the pasting, paste, and gel properties of rice starches. Carbohydr. Polym. 2008, 73, 417–426. [Google Scholar] [CrossRef]

- Xiao, Y.; Shen, M.; Luo, Y.; Ren, Y.; Han, X.; Xie, J. Effect of Mesona chinensis polysaccharide on the pasting, rheological, and structural properties of tapioca starch varying in gelatinization temperatures. Int. J. Biol. Macromol. 2020, 156, 137–143. [Google Scholar] [CrossRef]

- Belorio, M.; Marcondes, G.; Gómez, M. Influence of psyllium versus xanthan gum in starch properties. Food Hydrocoll. 2020, 105, 105843. [Google Scholar] [CrossRef]

- Huang, C.C. Physicochemical, pasting and thermal properties of tuber starches as modified by guar gum and locust bean gum. Int. J. Food Sci. Technol. 2009, 44, 50–57. [Google Scholar] [CrossRef]

- Mali, S.; Ferrero, C.; Redigonda, V.; Beleia, A.; Grossmann, M.; Zaritzky, N. Influence of pH and hydrocolloids addition on yam (Dioscorea alata) starch pastes stability. LWT Food Sci. Technol. 2003, 36, 475–481. [Google Scholar] [CrossRef]

- Liu, H.; Eskin, N.M.; Cui, S.W. Effects of yellow mustard mucilage on functional and rheological properties of buckwheat and pea starches. Food Chem. 2006, 95, 83–93. [Google Scholar] [CrossRef]

- Pongsawatmanit, R.; Temsiripong, T.; Ikeda, S.; Nishinari, K. Influence of tamarind seed xyloglucan on rheological properties and thermal stability of tapioca starch. J. Food Eng. 2006, 77, 41–50. [Google Scholar] [CrossRef]

- Arocas, A.; Sanz, T.; Fiszman, S. Improving effect of xanthan and locust bean gums on the freeze-thaw stability of white sauces made with different native starches. Food Hydrocoll. 2009, 23, 2478–2484. [Google Scholar] [CrossRef]

- Sikora, M.; Kowalski, S.; Tomasik, P. Binary hydrocolloids from starches and xanthan gum. Food Hydrocoll. 2008, 22, 943–952. [Google Scholar] [CrossRef]

- Gibiński, M.; Kowalski, S.; Sady, M.; Krawontka, J.; Tomasik, P.; Sikora, M. Thickening of sweet and sour sauces with various polysaccharide combinations. J. Food Eng. 2006, 75, 407–414. [Google Scholar] [CrossRef]

- Sikora, M.; Kowalski, S.; Krystyjan, M.; Krawontka, J.; Sady, M. Optimization of cornstarch/xanthan gum content for thickening of cocoa syrups. J. Food Qual. 2007, 30, 682–702. [Google Scholar] [CrossRef]

- Hussain, S. Native rice starch and linseed gum blends: Effect on the pasting, thermal and rheological properties. Czech J. Food Sci. 2015, 33, 556–563. [Google Scholar] [CrossRef]

- Zheng, Y.; Sun, W.; Yang, W.; Chen, S.; Liu, D.; Tian, J.; Ye, X. The influence of xanthan gum on rheological properties and in vitro digestibility of kudzu (Pueraria lobata) starch. Starch Stärke 2020, 72, 1900139. [Google Scholar] [CrossRef]

- Huang, M.; Kennedy, J.; Li, B.; Xu, X.; Xie, B. Characters of rice starch gel modified by gellan, carrageenan, and glucomannan: A texture profile analysis study. Carbohydr. Polym. 2007, 69, 411–418. [Google Scholar] [CrossRef]

- Achayuthakan, P.; Suphantharika, M. Pasting and rheological properties of waxy corn starch as affected by guar gum and xanthan gum. Carbohydr. Polym. 2008, 71, 9–17. [Google Scholar] [CrossRef]

- Cheng, H. Xanthan Gum and Locust Bean Gum in Confectionery Use. U.S. Patent No 4,219,582, 26 August 1980. [Google Scholar]

- Kaur, L.; Singh, J.; Singh, H.; McCarthy, O. Cassia gum: A novel galactomannan for use in starch based foods. Getreidetechnologie 2009, 63, 11–25. [Google Scholar]

- Yu, S.; Ma, Y.; Sun, D.-W. Effects of freezing rates on starch retrogradation and textural properties of cooked rice during storage. LWT Food Sci. Technol. 2010, 43, 1138–1143. [Google Scholar] [CrossRef]

- Yu, S.; Ma, Y.; Sun, D.-W. Impact of amylose content on starch retrogradation and texture of cooked milled rice during storage. J. Cereal Sci. 2009, 50, 139–144. [Google Scholar] [CrossRef]

- Teng, L.; Chin, N.; Yusof, Y. Rheological and textural studies of fresh and freeze-thawed native sago starch–sugar gels. II. Comparisons with other starch sources and reheating effects. Food Hydrocoll. 2013, 31, 156–165. [Google Scholar] [CrossRef]

- Marshall, S.G.; Vaisey, M. Sweetness perception in relation to some textural characteristics of hydrocolloid gels. J. Texture Stud. 1972, 3, 173–185. [Google Scholar] [CrossRef]

- Yoo, D.; Kim, C.; Yoo, B. Steady and dynamic shear rheology of rice starch-galactomannan mixtures. Starch Stärke 2005, 57, 310–318. [Google Scholar] [CrossRef]

- Chantaro, P.; Pongsawatmanit, R.; Nishinari, K. Effect of heating–cooling on rheological properties of tapioca starch paste with and without xanthan gum. Food Hydrocoll. 2013, 31, 183–194. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.-J.; Li, D.; Özkan, N.; Chen, X.D.; Mao, Z.-H. Effect of flaxseed gum addition on rheological properties of native maize starch. J. Food Eng. 2008, 89, 87–92. [Google Scholar] [CrossRef]

- Chang, Y.H.; Cui, S.W. Steady and dynamic shear rheological properties of extrusion modified fenugreek gum solutions. Food Sci. Biotechnol. 2011, 20, 1663–1668. [Google Scholar] [CrossRef]

- Freitas, R.; Gorin, P.; Neves, J.; Sierakowski, M.-R. A rheological description of mixtures of a galactoxyloglucan with high amylose and waxy corn starches. Carbohydr. Polym. 2003, 51, 25–32. [Google Scholar] [CrossRef]

- Alloncle, M.; Lefebvre, J.; Llamas, G.; Doublier, J. A rheological characterization of cereal starch-galactomannan mixtures. Cereal Chem. 1989, 66, 90–93. [Google Scholar]

- Shahzad, S.A.; Hussain, S.; Alamri, M.S.; Mohamed, A.A.; Ahmed, A.S.; Ibraheem, M.A.; Qasem, A.; Akram, A. Use of hydrocolloid gums to modify the pasting, thermal, rheological, and textural properties of sweet potato starch. Int. J. Polym. Sci. 2019, 2019, 6308591. [Google Scholar] [CrossRef]

| 0% | 3% | 6% | 9% | 12% | |

|---|---|---|---|---|---|

| ΔH (J/g) | 12.08 ± 0.19d | 12.97 ± 0.07c | 13.26 ± 0.11b | 13.63 ± 0.10a | 11.86 ± 0.06e |

| OT (°C) | 66.34 ± 0.15e | 68.66 ± 0.15d | 70.13 ± 0.20c | 70.62 ± 0.08b | 71.34 ± 0.12a |

| PT (°C) | 70.96 ± 0.52e | 74.03 ± 0.09d | 75.22 ± 0.11c | 76.61 ± 0.20b | 77.66 ± 0.15a |

| Sample | PV (cP) | Trough (cP) | BD (cP) | FV (cP) | SB (cP) | Peak Time (Min) | PT (°C) |

|---|---|---|---|---|---|---|---|

| 0% | 2002 ± 24.04d | 921 ± 42.43d | 1081 ± 18.38d | 1915 ± 39.60d | 994 ± 2.83e | 5.07 ± 0.00a | 75.93 ± 0.11a |

| 3% | 2911 ± 34.65c | 1118 ± 33.23c | 1793 ± 1.41c | 2558 ± 12.20c | 1441 ± 33.23d | 4.74 ± 0.09b | 74.50 ± 0.07b |

| 6% | 3134 ± 28.28b | 1110 ± 34.65c | 2025 ± 62.93c | 2986 ± 20.51a | 1876 ± 14.14a | 4.57 ± 0.05c | 74.08 ± 0.18b |

| 9% | 3234 ± 26.16a | 1182 ± 18.39bc | 2052 ± 44.55bc | 2894 ± 2.12c | 1712 ± 20.51b | 4.57 ± 0.05c | 74.20 ± 0.07b |

| 12% | 3269 ± 33.23a | 1338 ±7.78a | 1931 ± 25.46a | 3032 ± 15.56a | 1695 ± 7.78c | 4.60 ± 0.00c | 74.28 ± 0.04b |

| Sample | 1st 4 Days | 2nd 4 Days | Total |

|---|---|---|---|

| 0% | 1.06 ± 0.17a | 10.02 ± 0.43a | 11.08 ± 0.60a |

| 3% | 0d | 0.84 ± 0.11e | 0.84 ± 0.11e |

| 6% | 0d | 1.52 ± 0.09d | 1.52 ± 0.09d |

| 9% | 0.12 ± 0.02c | 4.73 ± 0.07c | 4.85 ± 0.09c |

| 12% | 0.30 ± 0.03b | 7.67 ± 0.50b | 7.97 ± 0.53b |

| Sample | Hardness (g) | Cohesiveness | Springiness (mm) | Adhesiveness (mJ) | Chewiness (g.mm) |

|---|---|---|---|---|---|

| 0% | 168 ± 14.84a | 0.40 ± 0.01e | 10.15 ± 0.07a | 1.60 ± 0.14a | 683 ± 40.86e |

| 3% | 231 ± 8.48d | 0.44 ± 0.02d | 10.3 ± 0.14a | 1.05 ± 0.07b | 1034 ± 1.74d |

| 6% | 278 ± 4.94b | 0.52 ± 0.00a | 10.15 ± 0.07a | 0.75 ± 0.07c | 1479 ± 3.84a |

| 9% | 245 ± 4.96c | 0.49 ± 0.01b | 10.1 ± 0.03a | 0.60 ± 0.00d | 1210 ± 10.43b |

| 12% | 233 ± 2.12d | 0.48 ± 0.00c | 10.25 ± 0.07a | 0.43 ± 0.04e | 1144 ± 18.33c |

| 0% | 3% | 6% | 9% | 12% | |

|---|---|---|---|---|---|

| n | 0.17 ± 0.01e | 0.36 ± 0.02d | 0.41 ± 0.05c | 0.56 ± 0.03a | 0.50 ± 0.01b |

| K (Pa sn) | 0.65 ± 0.01c | 0.69 ± 0.05b | 0.72 ± 0.02b | 0.75 ± 0.06a | 0.76 ± 0.02a |

| R2 | 0.97 ± 0.01a | 0.98 ± 0.01a | 0.99 ± 0.03a | 0.98 ± 0.03a | 0.98 ± 0.02a |

| 0% | 3% | 6% | 9% | 12% | |

|---|---|---|---|---|---|

| G′ (Pa) | 123 ± 2.3 | 156 ± 4.6 | 178 ± 3.4 | 157 ± 5.2 | 199 ± 2.2 |

| G″ (Pa) | 7.72 ± 0.4 | 10.70 ± 0.2 | 12.15 ± 0.4 | 11.49 ± 0.7 | 13.68 ± 0.5 |

| Tan delta (δ) | 0.062 | 0.068 | 0.068 | 0.073 | 0.069 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, S.; Mohamed, A.A.; Alamri, M.S.; Ibraheem, M.A.; Qasem, A.A.A.; Shahzad, S.A.; Ababtain, I.A. Use of Gum Cordia (Cordia myxa) as a Natural Starch Modifier; Effect on Pasting, Thermal, Textural, and Rheological Properties of Corn Starch. Foods 2020, 9, 909. https://doi.org/10.3390/foods9070909

Hussain S, Mohamed AA, Alamri MS, Ibraheem MA, Qasem AAA, Shahzad SA, Ababtain IA. Use of Gum Cordia (Cordia myxa) as a Natural Starch Modifier; Effect on Pasting, Thermal, Textural, and Rheological Properties of Corn Starch. Foods. 2020; 9(7):909. https://doi.org/10.3390/foods9070909

Chicago/Turabian StyleHussain, Shahzad, Abdellatif A. Mohamed, Mohamed Saleh Alamri, Mohamed A. Ibraheem, Akram A. Abdo Qasem, Syed Ali Shahzad, and Ibrahim A. Ababtain. 2020. "Use of Gum Cordia (Cordia myxa) as a Natural Starch Modifier; Effect on Pasting, Thermal, Textural, and Rheological Properties of Corn Starch" Foods 9, no. 7: 909. https://doi.org/10.3390/foods9070909

APA StyleHussain, S., Mohamed, A. A., Alamri, M. S., Ibraheem, M. A., Qasem, A. A. A., Shahzad, S. A., & Ababtain, I. A. (2020). Use of Gum Cordia (Cordia myxa) as a Natural Starch Modifier; Effect on Pasting, Thermal, Textural, and Rheological Properties of Corn Starch. Foods, 9(7), 909. https://doi.org/10.3390/foods9070909