Holistic Approach to the Uncertainty in Shelf Life Prediction of Frozen Foods at Dynamic Cold Chain Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Basic Principles

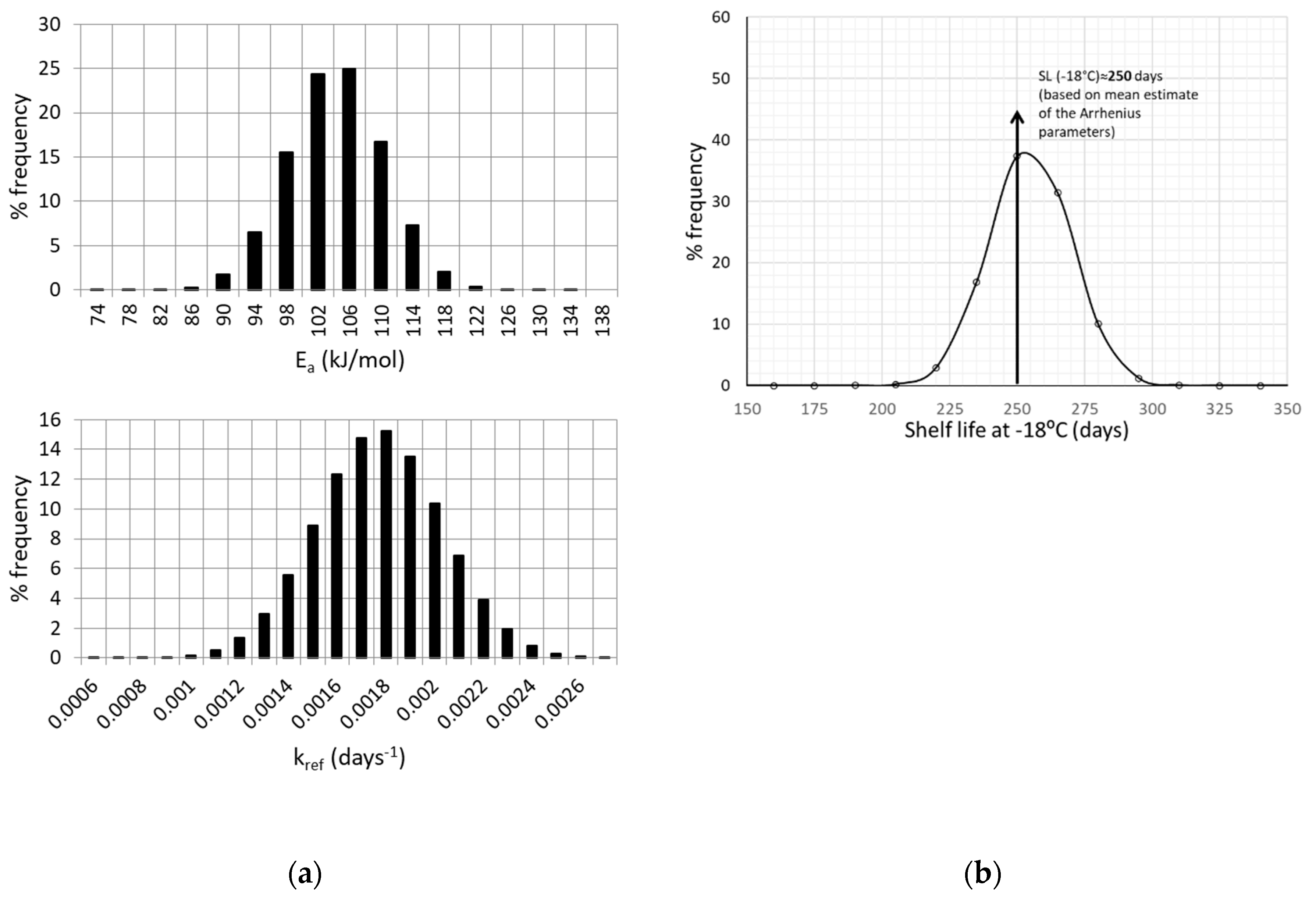

2.2. Model Development and Determination of the Uncertainty of Kinetic Parameters

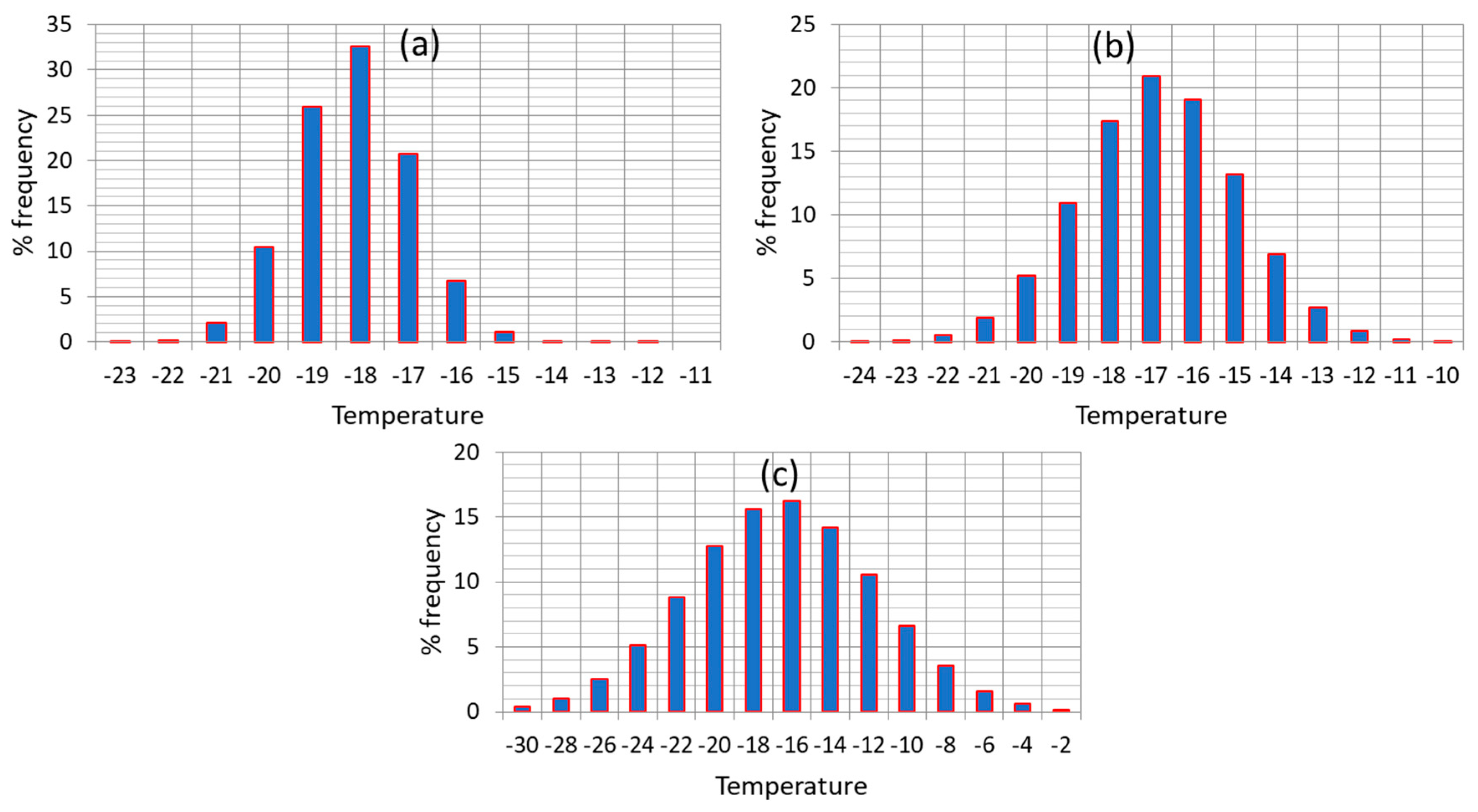

2.3. Determination of the Variability of Temperature Conditions in the Cold Chain

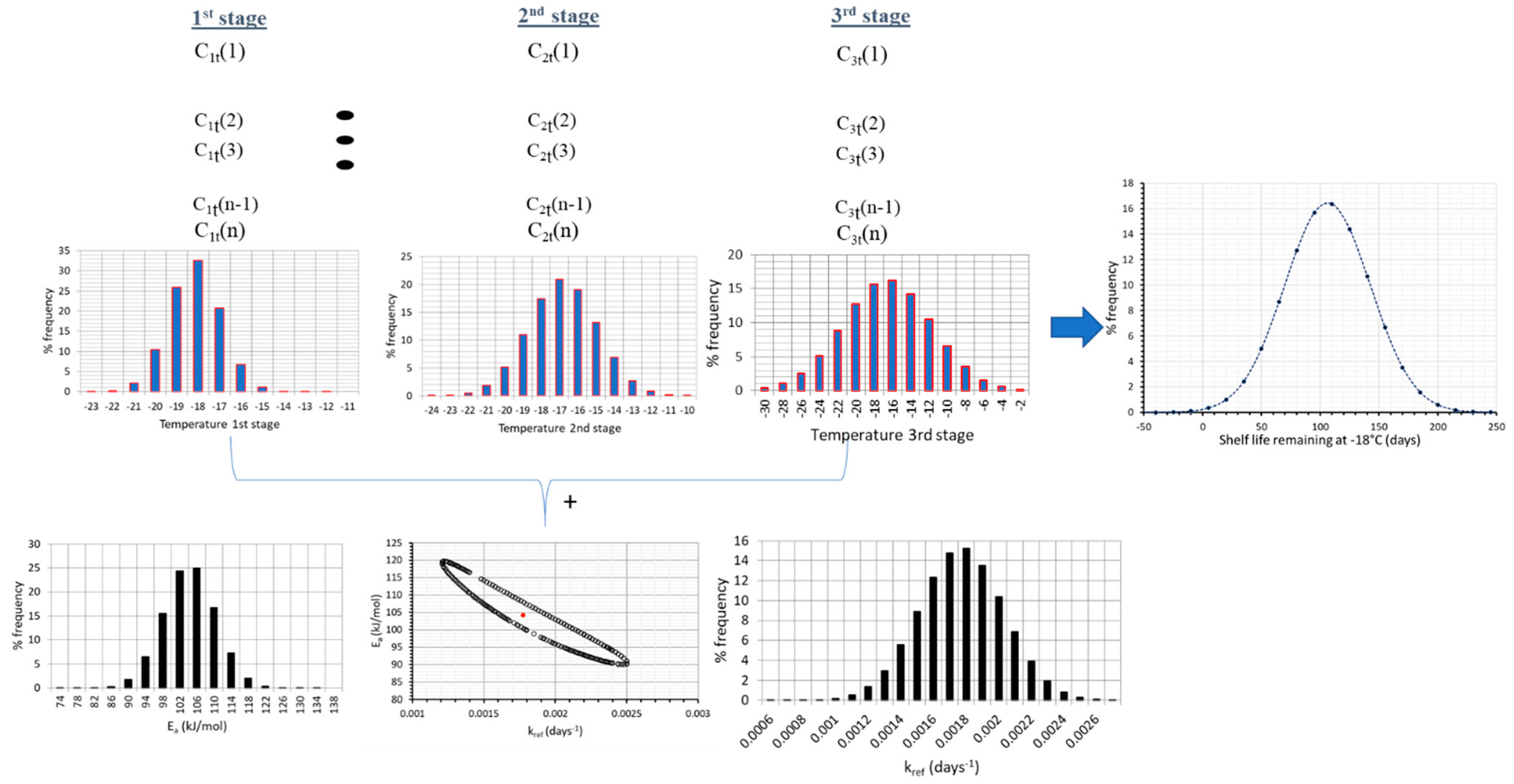

2.4. Shelf Life Assessment and Uncertainty Determination

3. Results

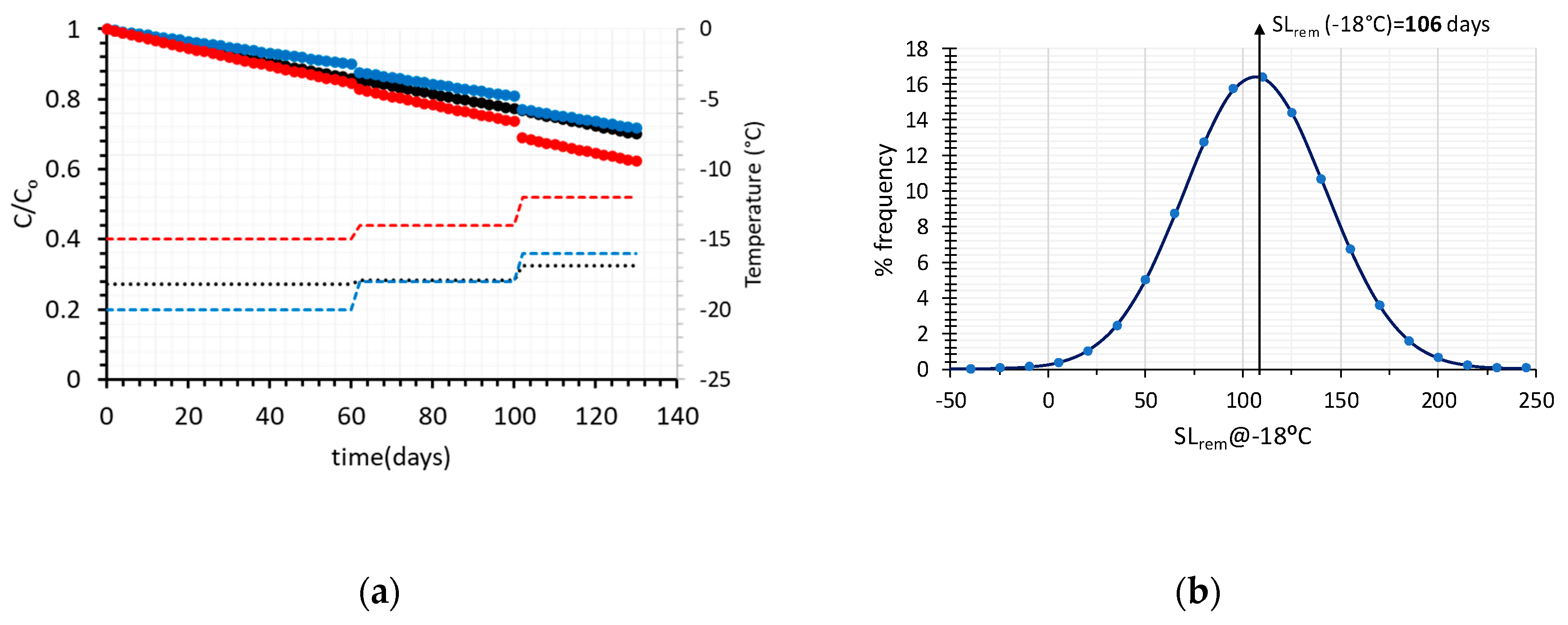

3.1. Application of the Holistic Approach to Shelf Life Prediction in the Frozen Green Peas Cold Chain

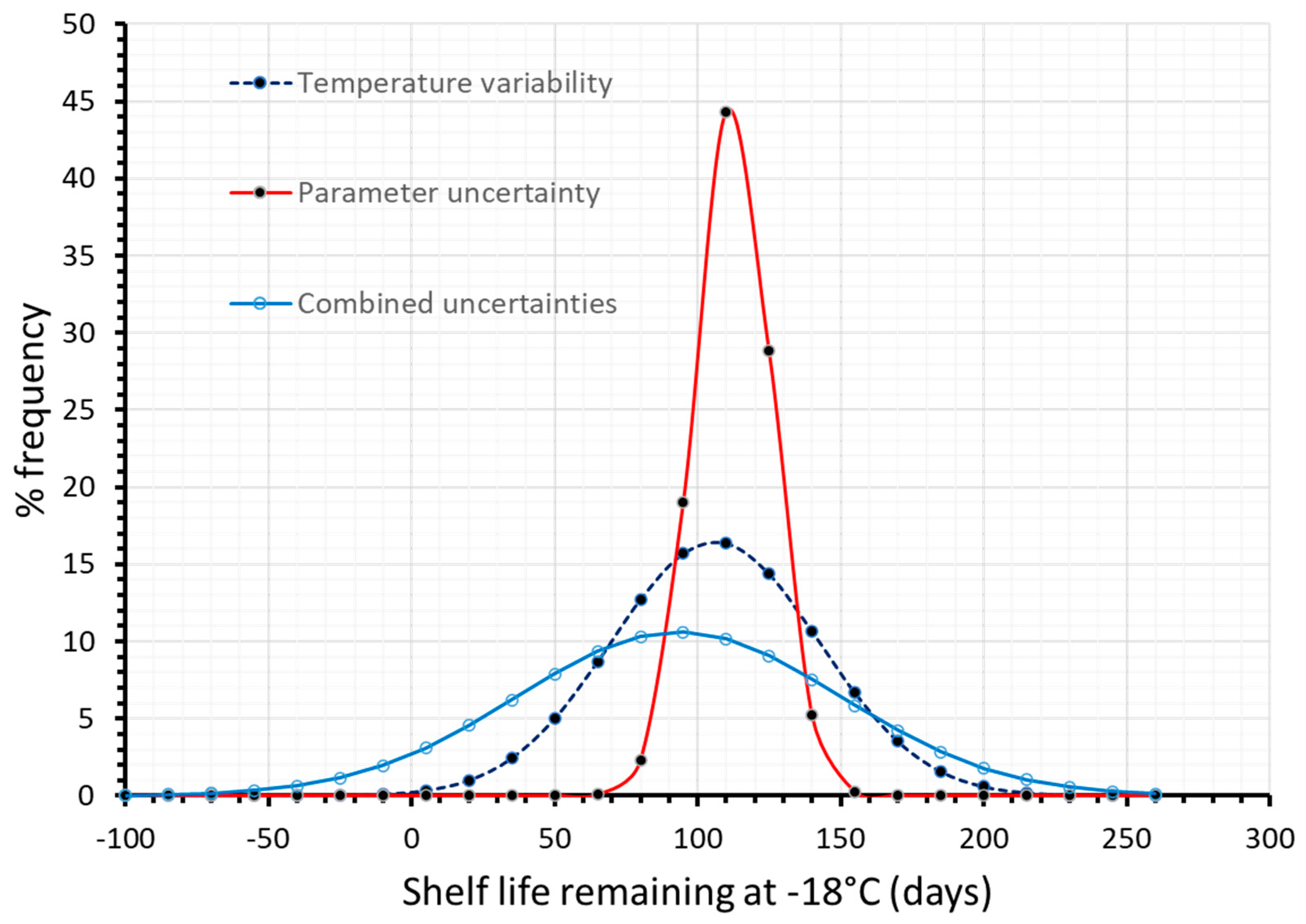

3.2. Effect of Parameter Uncertainty

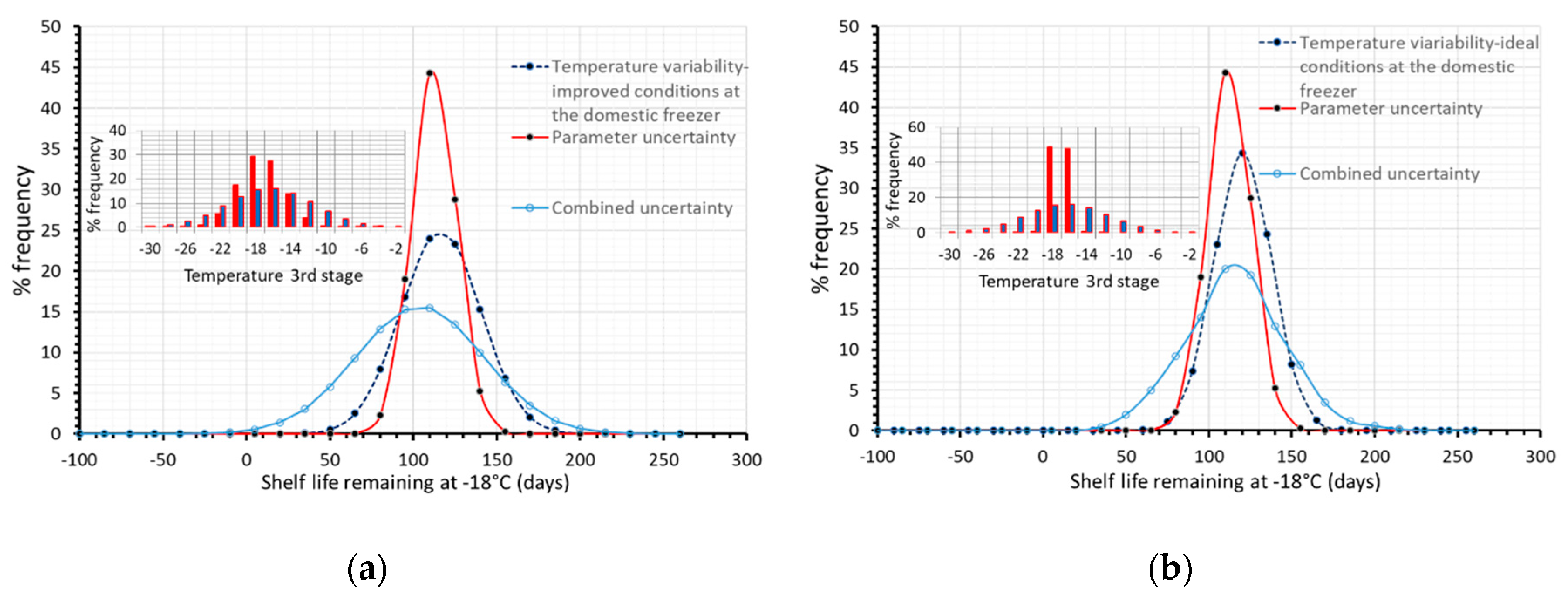

3.3. Effect of Temperature Variability

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Boekel, M. Statistical Aspects of Kinetic Modeling for Food Science Problems. J. Food Sci. 1996, 61, 477–486. [Google Scholar] [CrossRef]

- Taoukis, P.S.; Labuza, T.P.; Saguy, S. Kinetics of food deterioration and shelf-life prediction. In Handbook of Food Engineering Practice; Valentas, K.J., Rotstein, E., Singh, R.P., Eds.; CRC Press: New York, NY, USA, 1997. [Google Scholar]

- Van Boekel, M. Kinetic Modeling of Food Quality: A Critical Review. Compr. Rev. Food Sci. Food Saf. 2008, 7, 144–158. [Google Scholar] [CrossRef]

- Celli, G.B.; Ghanem, A.; Brooks, M.S.-L. Influence of freezing process and frozen storage on the quality of fruits and fruit products. Food Rev. Int. 2015, 32, 280–304. [Google Scholar] [CrossRef]

- English, M.; Keough, J.M.; McSweeney, M.B.; Razul, M.S.G.; James, M.K. Impact of a Novel Cryoprotectant Blend on the Sensory Quality of Frozen Lobster (Homarus americanus). J. Food Sci. 2019, 84, 1547–1553. [Google Scholar] [CrossRef]

- Nübling, S.; Hägele, F.; Schweiggert, R.; Carle, R.; Schmidt, H.; Weiss, A. Effect of Different Wash Water Additives and Deep-Frozen Storage on the Quality of Curly Parsley (Petroselinum crispum var. crispum). Food Bioprocess Technol. 2018, 12, 158–165. [Google Scholar] [CrossRef]

- Cartagena, L.; Puértolas, E.; De Marañón, I.M. Evolution of quality parameters of high pressure processing (HPP) pretreated albacore (Thunnus alalunga) during long-term frozen storage. Innov. Food Sci. Emerg. Technol. 2020, 62, 102334. [Google Scholar] [CrossRef]

- Karlsdóttir, M.G.; Sveinsdottir, K.; Kristinsson, H.G.; Villot, D.; Craft, B.D.; Arason, S. Effect of thermal treatment and frozen storage on lipid decomposition of light and dark muscles of saithe (Pollachius virens). Food Chem. 2014, 164, 476–484. [Google Scholar] [CrossRef]

- Corradini, M.G.; Amézquita, A.; Normand, M.D.; Peleg, M. Modeling and predicting non-isothermal microbial growth using general purpose software. Int. J. Food Microbiol. 2006, 106, 223–228. [Google Scholar] [CrossRef]

- Periago, P.; Van Zuijlen, A.; Fernández, P.; Klapwijk, P.; Ter Steeg, P.; Corradini, M.G.; Peleg, M. Estimation of the non-isothermal inactivation patterns of Bacillus sporothermodurans IC4 spores in soups from their isothermal survival data. Int. J. Food Microbiol. 2004, 95, 205–218. [Google Scholar] [CrossRef]

- Valdramidis, V.; Geeraerd, A.; Bernaerts, K.; Van Impe, J. Microbial dynamics versus mathematical model dynamics: The case of microbial heat resistance induction. Innov. Food Sci. Emerg. Technol. 2006, 7, 80–87. [Google Scholar] [CrossRef]

- Charoenrein, S.; Harnkarnsujarit, N. Food Freezing and Non-Equilibrium States. In Non-Equilibrium States and Glass Transitions in Foods: Processing Effects and Product-Specific Implications; Elsevier: Amsterdam, The Netherlands, 2017; pp. 39–62. [Google Scholar]

- Reid, D.S.; Sajjaanantakul, T.; Lillford, P.J.; Charoenrein, S. Water Properties in Food, Health, Pharmaceutical and Biological Systems: ISOPOW 10; Blackwell Publishing: Hoboken, NJ, USA, 2010. [Google Scholar]

- Giannakourou, M.C.; Stoforos, N.G. A Theoretical Analysis for Assessing the Variability of Secondary Model Thermal Inactivation Kinetic Parameters. Foods 2017, 6, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Conesa, R.; Periago, P.M.; Esnoz, A.; Palop, A. Prediction of Bacillus subtilis spore survival after a combined non-isothermal-isothermal heat treatment. Eur. Food Res. Technol. 2003, 217, 319–324. [Google Scholar] [CrossRef]

- Huang, L.; Vinyard, B.T. Direct Dynamic Kinetic Analysis and Computer Simulation of Growth of Clostridium perfringens in Cooked Turkey during Cooling. J. Food Sci. 2016, 81, M692–M701. [Google Scholar] [CrossRef] [PubMed]

- Huang, L. Determination of thermal inactivation kinetics of Listeria monocytogenes in chicken meats by isothermal and dynamic methods. Food Control. 2013, 33, 484–488. [Google Scholar] [CrossRef]

- Huang, L. Dynamic determination of kinetic parameters, computer simulation, and probabilistic analysis of growth of Clostridium perfringens in cooked beef during cooling. Int. J. Food Microbiol. 2015, 195, 20–29. [Google Scholar] [CrossRef] [PubMed]

- Huang, L. Growth of Staphylococcus aureus in Cooked Potato and Potato Salad-A One-Step Kinetic Analysis. J. Food Sci. 2015, 80. [Google Scholar] [CrossRef]

- Wawire, M.; Oey, I.; Mathooko, F.M.; Njoroge, C.K.; Shitanda, D.; Hendrickx, M. Kinetics of Thermal Inactivation of Peroxidase and Color Degradation of African Cowpea (Vigna unguiculata) Leaves. J. Food Sci. 2015, 81, 56. [Google Scholar] [CrossRef]

- Huang, L. IPMP Global Fit–A one-step direct data analysis tool for predictive microbiology. Int. J. Food Microbiol. 2017, 262, 38–48. [Google Scholar] [CrossRef]

- Martino, K.G.; Marks, B.P. Comparing Uncertainty Resulting from Two-Step and Global Regression Procedures Applied to Microbial Growth Models. J. Food Prot. 2007, 70, 2811–2818. [Google Scholar] [CrossRef]

- Haralampu, S.G.; Saguy, I.; Karel, M. Estimation of Arrhenius Model Parameters Using Three Least Squares Methods. J. Food Process. Preserv. 1985, 9, 129–143. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Liu, B.; Dong, Q. One-Step Analysis for Listeria monocytogenes Growth in Ready-to-Eat Braised Beef at Dynamic and Static Conditions. J. Food Prot. 2019, 82, 1820–1827. [Google Scholar] [CrossRef] [PubMed]

- Giannakourou, M.; Taoukis, P.S. Meta-analysis of Kinetic Parameter Uncertainty on Shelf Life Prediction in the Frozen Fruits and Vegetable Chain. Food Eng. Rev. 2018, 11, 14–28. [Google Scholar] [CrossRef]

- Aspridou, Z.; Koutsoumanis, K.P. Individual cell heterogeneity as variability source in population dynamics of microbial inactivation. Food Microbiol. 2015, 45, 216–221. [Google Scholar] [CrossRef] [PubMed]

- Channon, H.; Hamilton, A.; D’Souza, D.; Dunshea, F.R. Estimating the impact of various pathway parameters on tenderness, flavour and juiciness of pork using Monte Carlo simulation methods. Meat Sci. 2016, 116, 58–66. [Google Scholar] [CrossRef] [PubMed]

- Wesolek, N.; Roudot, A.-C. Assessing aflatoxin B1 distribution and variability in pistachios: Validation of a Monte Carlo modeling method and comparison to the Codex method. Food Control 2016, 59, 553–560. [Google Scholar] [CrossRef]

- Sui, X.; Zhou, W. Monte Carlo modelling of non-isothermal degradation of two cyanidin-based anthocyanins in aqueous system at high temperatures and its impact on antioxidant capacities. Food Chem. 2014, 148, 342–350. [Google Scholar] [CrossRef] [PubMed]

- Dolan, K.D.; Yang, L.; Trampel, C. Nonlinear regression technique to estimate kinetic parameters and confidence intervals in unsteady-state conduction-heated foods. J. Food Eng. 2007, 80, 581–593. [Google Scholar] [CrossRef]

- Valdramidis, V.; Geeraerd, A.; Bernaerts, K.; Van Impe, J. Identification of non-linear microbial inactivation kinetics under dynamic conditions. Int. J. Food Microbiol. 2008, 128, 146–152. [Google Scholar] [CrossRef]

- Schwaab, M.; Lemos, L.P.; Pinto, J.C. Optimum reference temperature for reparameterization of the Arrhenius equation. Part 2: Problems involving multiple reparameterizations. Chem. Eng. Sci. 2008, 63, 2895–2906. [Google Scholar] [CrossRef]

- Schwaab, M.; Pinto, J.C. Optimum reference temperature for reparameterization of the Arrhenius equation. Part 1: Problems involving one kinetic constant. Chem. Eng. Sci. 2007, 62, 2750–2764. [Google Scholar] [CrossRef]

- Bernaerts, K.; Servaes, R.D.; Kooyman, S.; Versyck, K.J.; Van Impe, J.F. Optimal temperature input design for estimation of the Square Root model parameters: Parameter accuracy and model validity restrictions. Int. J. Food Microbiol. 2002, 73, 145–157. [Google Scholar] [CrossRef]

- Claeys, W.L.; Ludikhuyze, L.R.; Van Loey, A.M.; Hendrickx, M.E. Inactivation kinetics of alkaline phosphatase and lactoperoxidase, and denaturation kinetics of β-lactoglobulin in raw milk under isothermal and dynamic temperature conditions. J. Dairy Res. 2001, 68, 95–107. [Google Scholar] [CrossRef] [PubMed]

- Fernández, A.; Ocio, M.; Fernández, P.; Martínez, A. Effect of heat activation and inactivation conditions on germination and thermal resistance parameters of Bacillus cereus spores. Int. J. Food Microbiol. 2001, 63, 257–264. [Google Scholar] [CrossRef]

- Fernández, A.; Ocio, M.; Fernández, P.; Rodrigo, M.; Martinez, A. Application of nonlinear regression analysis to the estimation of kinetic parameters for two enterotoxigenic strains ofBacillus cereus spores. Food Microbiol. 1999, 16, 607–613. [Google Scholar] [CrossRef]

- Goula, A.M.; Prokopiou, P.; Stoforos, N.G. Thermal degradation kinetics of l-carnitine. J. Food Eng. 2018, 231, 91–100. [Google Scholar] [CrossRef]

- Jewell, K. Comparison of 1-step and 2-step methods of fitting microbiological models. Int. J. Food Microbiol. 2012, 160, 145–161. [Google Scholar] [CrossRef]

- Taoukis, P.S.; Tsironi, T.N.; Giannakourou, M.C. Reaction kinetics. In Food Engineering Handbook; CRC Press: Boca Raton, FL, USA, 2014; pp. 550–591. [Google Scholar]

- Taoukis, P.S.; Giannakourou, M.C.; Tsironi, T.N. Monitoring and control of the cold chain. In Handbook of Frozen Food Processing and Packaging; CRC Press: Boca Raton, FL, USA, 2016; pp. 290–317. [Google Scholar]

- Taoukls, P.S.; Giannakourou, M.C. Modelling food quality. Food Sci. Technol. (Lond.) 2018, 32, 38–43. [Google Scholar]

- Terefe, N.S.; Van Loey, A.; Hendrickx, M. Modelling the kinetics of enzyme-catalysed reactions in frozen systems: The alkaline phosphatase catalysed hydrolysis of di-sodium-p-nitrophenyl phosphate. Innov. Food Sci. Emerg. Technol. 2004, 5, 335–344. [Google Scholar] [CrossRef]

- Terefe, N.; Hendrickx, M. Kinetics of the Pectin Methylesterase Catalyzed De-Esterification of Pectin in Frozen Food Model Systems. Biotechnol. Prog. 2002, 18, 221–228. [Google Scholar] [CrossRef]

- Giannakourou, M.; Taoukis, P. Stability of Dehydrofrozen Green Peas Pretreated with Nonconventional Osmotic Agents. J. Food Sci. 2003, 68, 2002–2010. [Google Scholar] [CrossRef]

- Peleg, M.; Engel, R.; Gonzalez-Martinez, C.; Corradini, M.G. Non-Arrhenius and non-WLF kinetics in food systems. J. Sci. Food Agric. 2002, 82, 1346–1355. [Google Scholar] [CrossRef]

- Peleg, M.; Normand, M.D.; Corradini, M.G. The Arrhenius Equation Revisited. Crit. Rev. Food Sci. Nutr. 2012, 52, 830–851. [Google Scholar] [CrossRef] [PubMed]

- Martins, R.C.; Lopes, I.; Silva, C.L. Accelerated life testing of frozen green beans (Phaseolus vulgaris, L.) quality loss kinetics: Colour and starch. J. Food Eng. 2005, 67, 339–346. [Google Scholar] [CrossRef]

- Corradini, M.G.; Peleg, M. Shelf-life estimation from accelerated storage data. Trends Food Sci. Technol. 2007, 18, 37–47. [Google Scholar] [CrossRef]

- Giannakourou, M.; Taoukis, P. Kinetic modelling of vitamin C loss in frozen green vegetables under variable storage conditions. Food Chem. 2003, 83, 33–41. [Google Scholar] [CrossRef]

- Mishra, D.K.; Dolan, K.D.; Yang, L. Confidence intervals for modeling anthocyanin retention in grape pomace during non isothermal heating. J. Food Sci. 2008, 73, E9–E15. [Google Scholar] [CrossRef]

- Draper, N.; Smith, H. Applied Regression Analysis; John Wiley & Sons: New York, NY, USA, 1981. [Google Scholar]

- Motulsky, H.J.; Christopoulos, A. Fitting Models to Biological Data Using Linear and Nonlinear Regression. A Practical Guide to Curve Fitting; Oxford University Press: New York, NY, USA, 2004; pp. 110–117. [Google Scholar]

- Gogou, E.; Derens, E.; Alvarez, G.; Taoukis, P. Field Test Monitoring of the Food Cold Chain in European Markets. Refrigeration Science and Technology. 2014, pp. 548–554. Available online: https://hal.archives-ouvertes.fr/hal-02156175/ (accessed on 2 June 2020).

- Gogou, E.; Katsaros, G.; Derens, E.; Álvarez, G.; Taoukis, P. Cold chain database development and application as a tool for the cold chain management and food quality evaluation. Int. J. Refrig. 2015, 52, 109–121. [Google Scholar] [CrossRef]

- Giannakourou, M.; Taoukis, P. Application of a TTI-based Distribution Management System for Quality Optimization of Frozen Vegetables at the Consumer End. J. Food Sci. 2003, 68, 201–209. [Google Scholar] [CrossRef]

- Smid, J.; Verloo, D.; Barker, G.; Havelaar, A. Strengths and weaknesses of Monte Carlo simulation models and Bayesian belief networks in microbial risk assessment. Int. J. Food Microbiol. 2010, 139, S57–S63. [Google Scholar] [CrossRef] [PubMed]

- Duret, S.; Gwanpua, S.G.; Hoang, H.M.; Guillier, L.; Flick, D.; Geeraerd, A.; Laguerre, O. Identification of the significant factors in food quality using global sensitivity analysis and the accept-and-reject algorithm. Part I: Methodology. J. Food Eng. 2015, 148, 53–57. [Google Scholar] [CrossRef]

- Barreto, H.; Howland, F.M. Introductory Econometrics: Using Monte Carlo Simulation with Microsoft Excel®; Cambridge University Press: New York, NY, USA, 2006. [Google Scholar]

- Singh, M.; Markeset, T. Fuzzy reliability analysis of corroded oil and gas pipes. In Safety, Reliability and Risk Analysis: Theory, Methods and Applications; Martorell, S., Soares, C.G., Barnett, J., Eds.; Taylor & Francis Group: London, UK, 2008; pp. 2945–2955. [Google Scholar]

- Huang, L.; Li, C. Growth of Clostridium perfringens in cooked chicken during cooling: One-step dynamic inverse analysis, sensitivity analysis, and Markov Chain Monte Carlo simulation. Food Microbiol. 2019, 85, 103285. [Google Scholar] [CrossRef] [PubMed]

- Mastwijk, H.; Timmermans, R.; Van Boekel, M. The Gauss-Eyring model: A new thermodynamic model for biochemical and microbial inactivation kinetics. Food Chem. 2017, 237, 331–341. [Google Scholar] [CrossRef] [PubMed]

- Dagnas, S.; Gougouli, M.; Onno, B.; Koutsoumanis, K.P.; Membré, J.-M. Quantifying the effect of water activity and storage temperature on single spore lag times of three moulds isolated from spoiled bakery products. Int. J. Food Microbiol. 2017, 240, 75–84. [Google Scholar] [CrossRef] [PubMed]

- Ndraha, N.; Sung, W.-C.; Hsiao, H.-I. Evaluation of the cold chain management options to preserve the shelf life of frozen shrimps: A case study in the home delivery services in Taiwan. J. Food Eng. 2019, 242, 21–30. [Google Scholar] [CrossRef]

- Destercke, S.; Chojnacki, E. Handling dependencies between variables with imprecise probabilistic models. In Safety, Reliability and Risk Analysis: Theory, Methods and Applications; Martorell, S., Soares, C.G., Barnett, J., Eds.; Taylor & Francis Group: London, UK, 2008; pp. 697–702. [Google Scholar]

- Evrendilek, G.A.; Avsar, Y.K.; Evrendilek, F. Modelling stochastic variability and uncertainty in aroma active compounds of PEF-treated peach nectar as a function of physical and sensory properties, and treatment time. Food Chem. 2016, 190, 634–642. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giannakourou, M.; Taoukis, P. Holistic Approach to the Uncertainty in Shelf Life Prediction of Frozen Foods at Dynamic Cold Chain Conditions. Foods 2020, 9, 714. https://doi.org/10.3390/foods9060714

Giannakourou M, Taoukis P. Holistic Approach to the Uncertainty in Shelf Life Prediction of Frozen Foods at Dynamic Cold Chain Conditions. Foods. 2020; 9(6):714. https://doi.org/10.3390/foods9060714

Chicago/Turabian StyleGiannakourou, Maria, and Petros Taoukis. 2020. "Holistic Approach to the Uncertainty in Shelf Life Prediction of Frozen Foods at Dynamic Cold Chain Conditions" Foods 9, no. 6: 714. https://doi.org/10.3390/foods9060714

APA StyleGiannakourou, M., & Taoukis, P. (2020). Holistic Approach to the Uncertainty in Shelf Life Prediction of Frozen Foods at Dynamic Cold Chain Conditions. Foods, 9(6), 714. https://doi.org/10.3390/foods9060714