Characteristics, Occurrence, Detection and Detoxification of Aflatoxins in Foods and Feeds

Abstract

1. Introduction

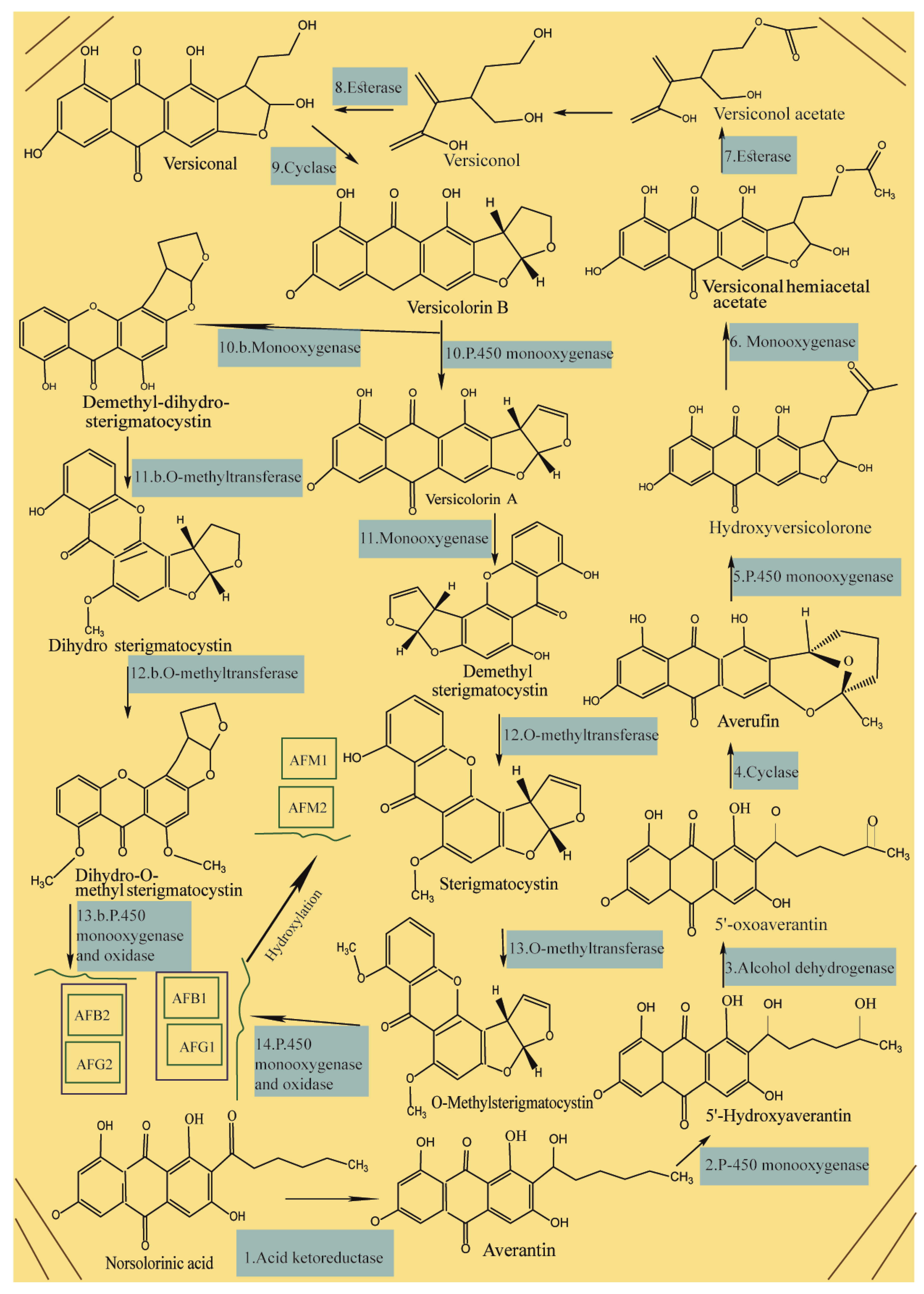

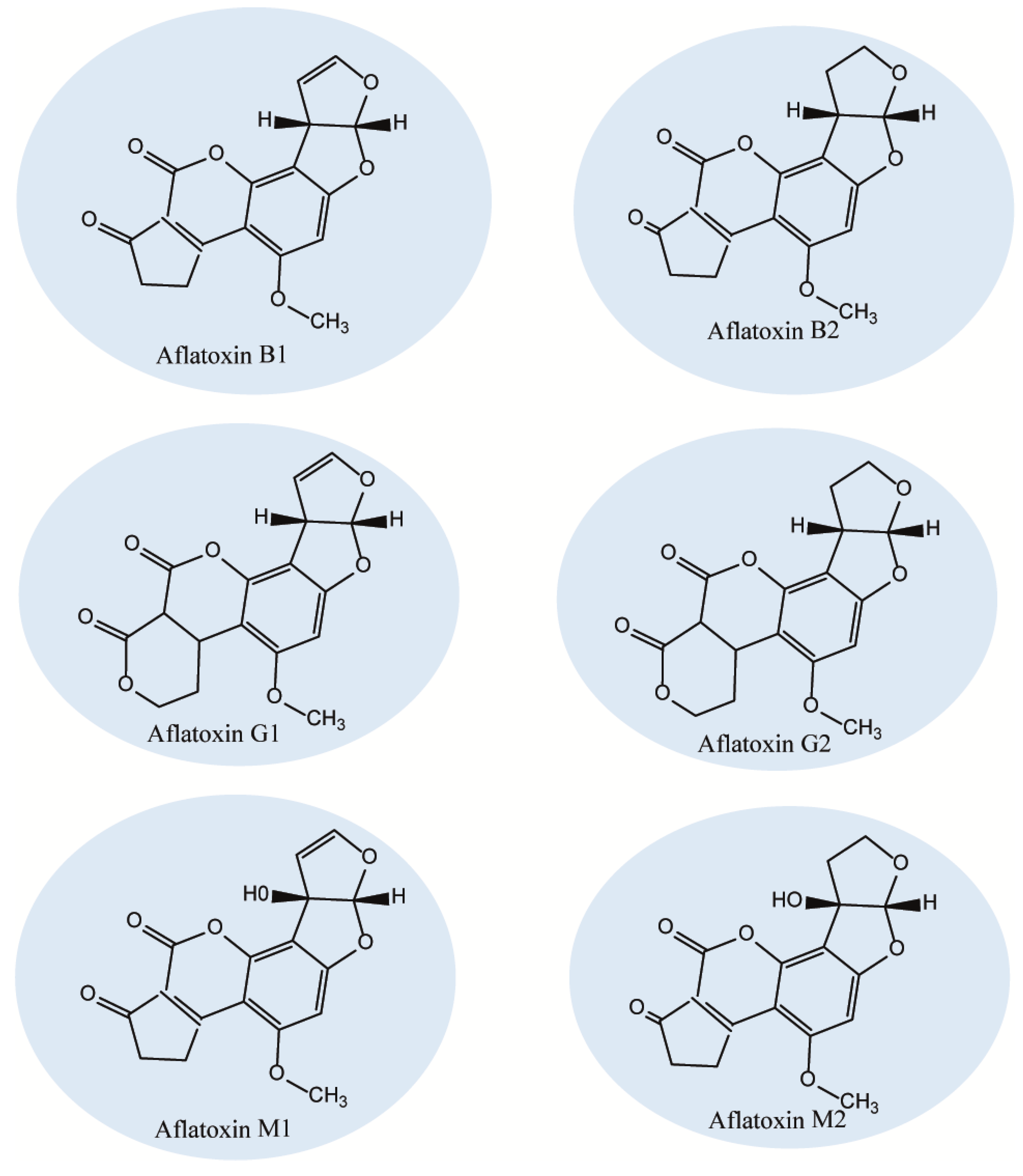

2. Characteristics of Aflatoxins

3. Contamination of Foods and Feeds

4. AF Detection Strategies

5. Toxicity and Health Impacts of Aflatoxins

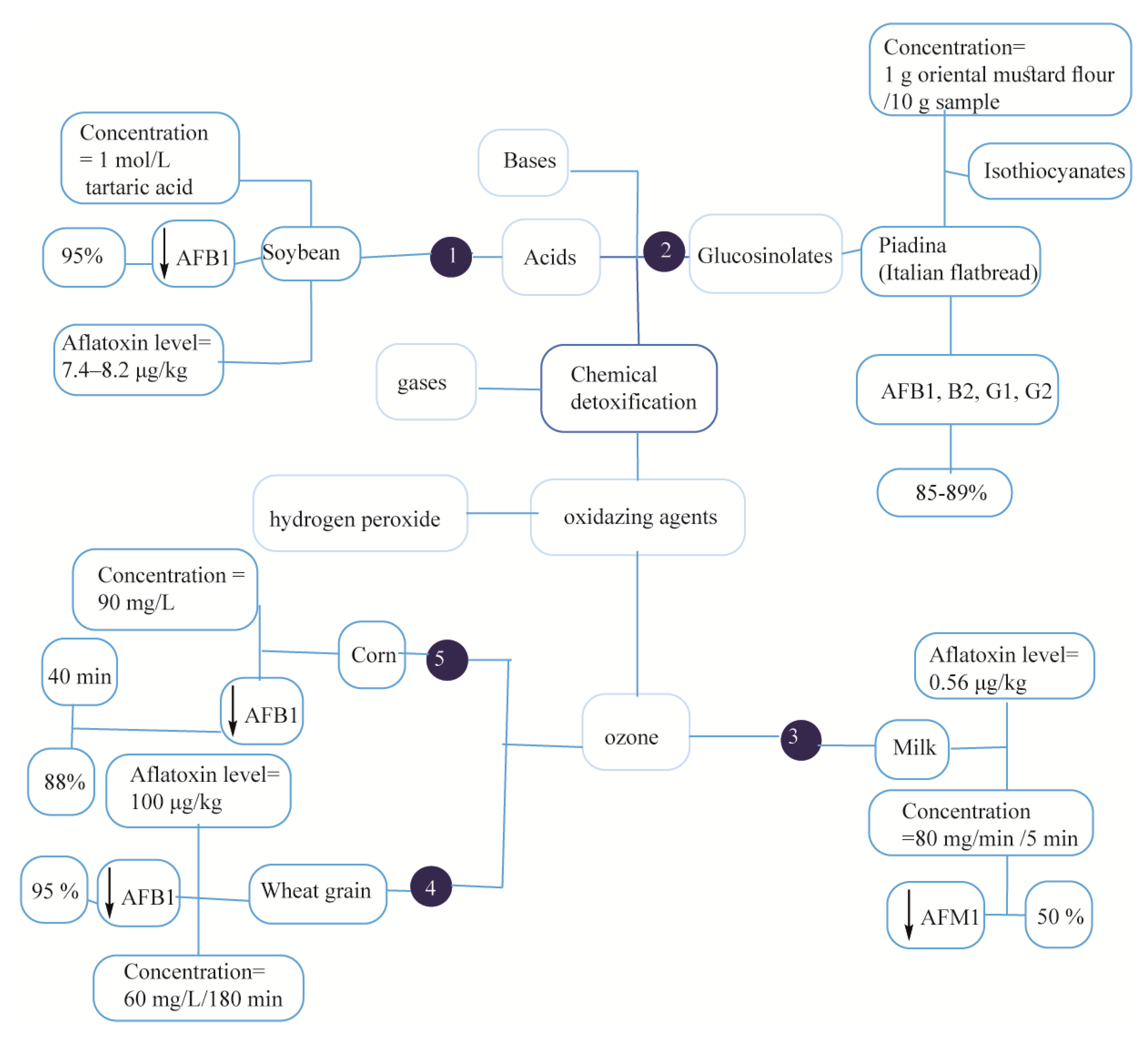

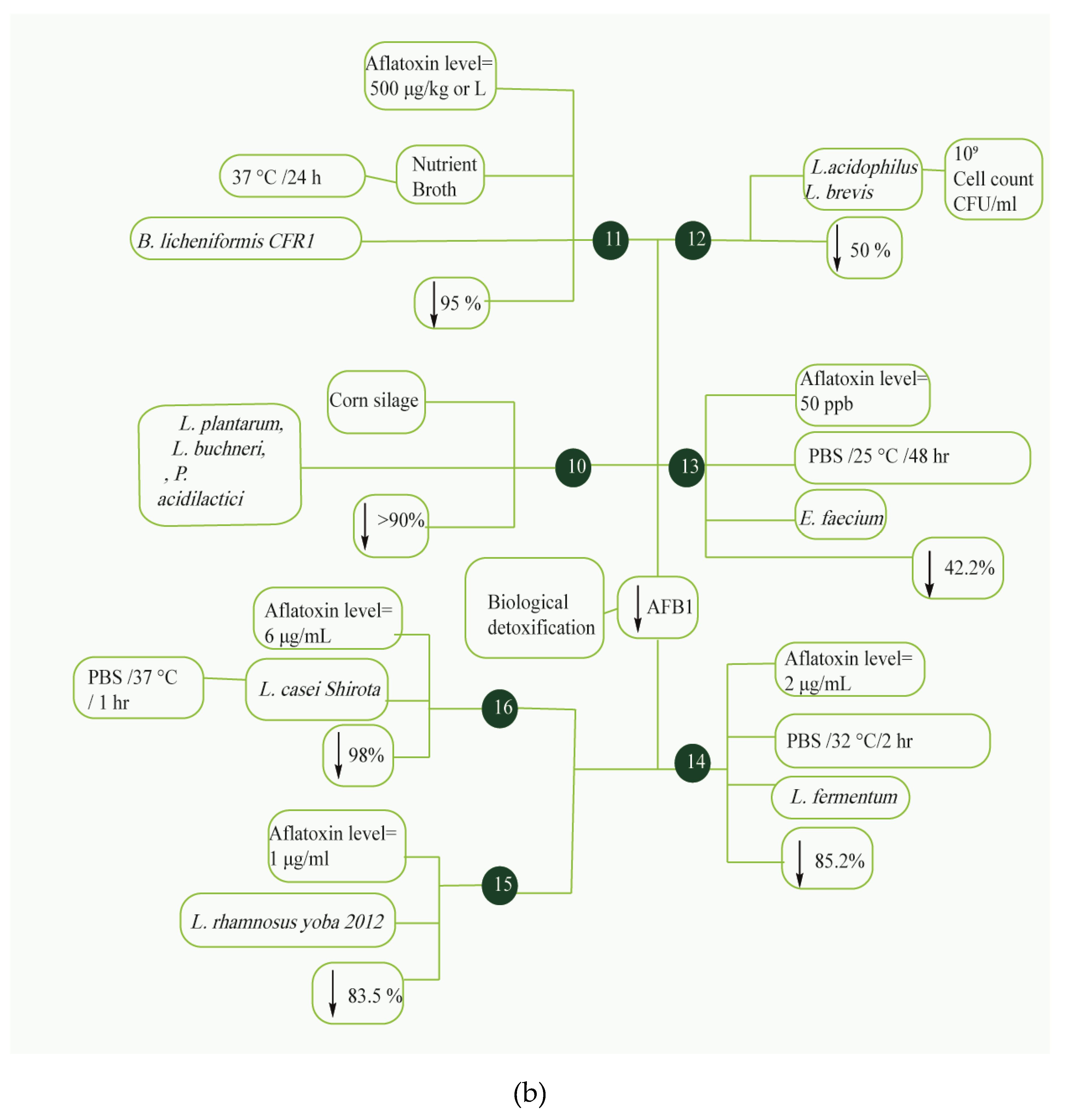

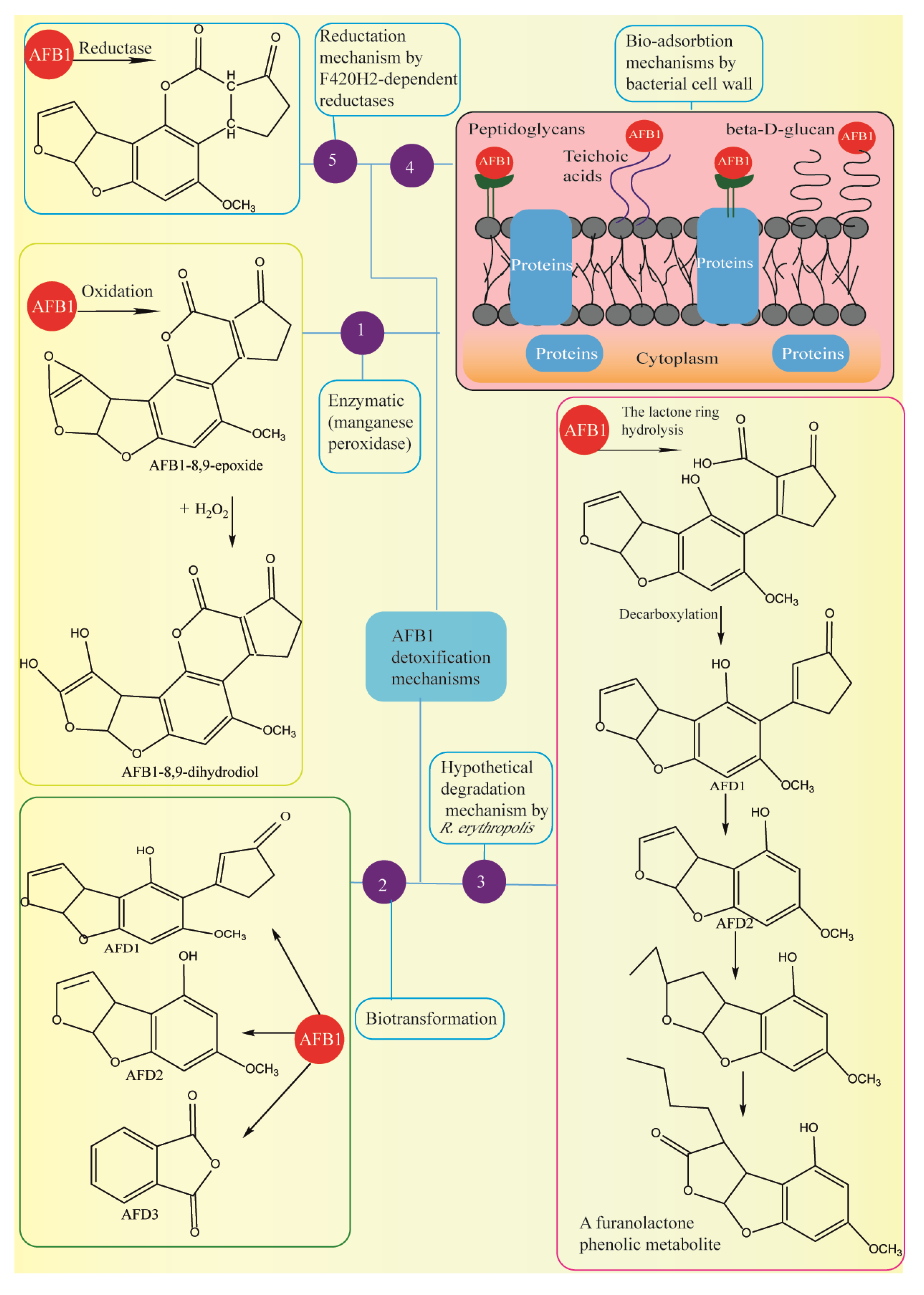

6. Methods of Aflatoxin Detoxification

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Salvo, A.; La Torre, G.L.; Mangano, V.; Casale, K.E.; Bartolomeo, G.; Santini, A.; Granata, T.; Dugo, G. Toxic inorganic pollutants in foods from agricultural producing areas of Southern Italy: Level and risk assessment. Ecotoxicol. Environ. Saf. 2018, 148, 114–124. [Google Scholar] [CrossRef]

- Mikušová, P.; Šrobárová, A.; Sulyok, M.; Santini, A. Fusarium fungi and associated metabolites presence on grapes from Slovakia. Mycotoxin Res. 2013, 29, 97–102. [Google Scholar] [CrossRef] [PubMed]

- Santini, A.; Meca Ritieni, A. Fusaproliferin, Beauvericin, and Enniatins: Occurrence in food—A review. World Mycotoxin J. 2012, 5, 71–81. [Google Scholar] [CrossRef]

- Ketney, O.; Santini, A.; Oancea, S. Recent aflatoxin survey data in milk and milk products: A review. Int. J. Dairy Technol. 2017, 70, 1–12. [Google Scholar] [CrossRef]

- Santini, A.; Raiola, A.; Ferrantelli, V.; Giangrosso, G.; Macaluso, A.; Bognanno, M.; Galvano, F.; Ritieni, A. Aflatoxin M1 in raw, UHT milk and dairy products in Sicily (Italy). Food Add. Contam. Part B Survel. 2013, 6, 181–186. [Google Scholar] [CrossRef] [PubMed]

- Santini, A.; Mikušová, P.; Sulyok, M.; Krska, R.; Labuda, R.; Šrobárová, A. Penicillium strains isolated from Slovak grape berries taxonomy assessment by secondary metabolite profile. Mycotoxin Res. 2014, 30, 213–220. [Google Scholar] [CrossRef] [PubMed]

- Santini, A.; Ferracane, R.; Meca, G.; Ritieni, A. Comparison and improvement of the existing methods for the determination of aflatoxins in human serum by LC-MS/MS. Anal. Methods 2010, 2, 884–889. [Google Scholar] [CrossRef]

- Santini, A.; Ferracane, R.; Meca, G.; Ritieni, A. Overview of analytical methods for beauvericin and fusaproliferin in food matrices. Anal. Bioanal. Chem. 2009, 395, 1253. [Google Scholar] [CrossRef]

- Mikušová, P.; Ritieni, A.; Santini, A.; Juhasová, G.; Šrobárová, A. Contamination by moulds of grape berries in Slovakia. Food Add. Contam. 2010, 27, 738–747. [Google Scholar] [CrossRef]

- Ritieni, A.; Santini, A.; Mussap, M.; Ferracane, R.; Bosco, P.; Gazzolo, D.; Galvano, F. Simultaneous determination of mycotoxins in biological fluids by LC-MS/MS. Front. Biosci. 2010, E2, 151–158. [Google Scholar] [CrossRef]

- Santini, A.; Novellino, E. Nutraceuticals: Beyond the diet before the drugs. Curr. Bioact. Comp. 2014, 10, 1–12. [Google Scholar] [CrossRef]

- Durazzo, A.; Lucarini, M.; Santini, A. Nutraceuticals in human health. Foods. 2020, 9, 370. [Google Scholar] [CrossRef] [PubMed]

- Santini, A.; Tenore, G.C.; Novellino, E. Nutraceuticals: A paradigm of proactive medicine. Eur. J. Pharm. Sci. 2017, 96, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Abenavoli, L.; Izzo, A.A.; Milić, N.; Cicala, C.; Santini, A.; Capasso, R. Milk thistle (Silybum marianum): A concise overview on its chemistry, pharmacological, and nutraceutical uses in liver diseases. Phytother. Res. 2018, 32, 2202–2213. [Google Scholar] [CrossRef]

- Daliu, P.; Santini, A.; Novellino, E. A decade of nutraceutical patents: Where are we now in 2018? Exp. Opin. Therap. Pat. 2018, 28, 875–882. [Google Scholar] [CrossRef]

- Durazzo, A.; D’Addezio, L.; Camilli, E.; Piccinelli, R.; Turrini, A.; Marletta, L.; Marconi, S.; Lucarini, M.; Lisciani, S.; Gabrielli, P.; et al. From plant compounds to botanicals and back: A current snapshot. Molecules 2018, 23, 1844. [Google Scholar] [CrossRef]

- Durazzo, A. Extractable and Non-extractable polyphenols: An overview. In Non-Extractable Polyphenols and Carotenoids: Importance in Human Nutrition and Health; Saura-Calixto, F., Pérez-Jiménez, J., Eds.; Royal Society of Chemistry: London, UK, 2018; pp. 1–37. [Google Scholar]

- Durazzo, A.; Lucarini, M. A current shot and re-thinking of antioxidant research strategy. Braz. J. Anal. Chem. 2018, 5, 9–11. [Google Scholar] [CrossRef]

- Santini, A.; Novellino, E. Nutraceuticals-shedding light on the grey area between pharmaceuticals and food. Expert Rev. Clin. Pharmacol. 2018, 11, 545–547. [Google Scholar] [CrossRef]

- Santini, A.; Cammarata, S.M.; Capone, G.; Ianaro, A.; Tenore, G.C.; Pani, L.; Novellino, E. Nutraceuticals: Opening the debate for a regulatory framework. Br. J. Clin. Pharmacol. 2018, 84, 659–672. [Google Scholar] [CrossRef]

- Daliu, P.; Santini, A.; Novellino, E. From pharmaceuticals to nutraceuticals: Bridging disease prevention and management. Expert Rev. Clin. Pharmacol. 2019, 12, 1–7. [Google Scholar] [CrossRef]

- Durazzo, A.; Lucarini, M. Extractable and Non-extractable antioxidants. Molecules 2019, 24, 1933. [Google Scholar] [CrossRef] [PubMed]

- Durazzo, A.; Lucarini, M.; Souto, E.B.; Cicala, C.; Caiazzo, E.; Izzo, A.A.; Novellino, E.; Santini, A. Polyphenols: A concise overview on the chemistry, occurrence and human health. Phyt. Res. 2019, 33, 2221–2243. [Google Scholar] [CrossRef] [PubMed]

- Abrunhosa, L.; Morales, H.; Soares, C.; Calado, T.; Vila-Cha, A.S.; Pereira, M.; Venancio, A. A Review of Mycotoxins in Food and Feed Products in Portugal and Estimation of Probable Daily Intakes. Crit. Rev. Food Sci. Nutr. 2016, 56, 249–265. [Google Scholar] [CrossRef] [PubMed]

- Adeyeye, S.A.O. Fungal mycotoxins in foods: A review. Cogent. Food Agric. 2016, 2. [Google Scholar] [CrossRef]

- Smith, M.C.; Madec, S.; Coton, E.; Hymery, N. Natural Co-Occurrence of Mycotoxins in Foods and Feeds and Their in vitro Combined Toxicological Effects. Toxins 2016, 8, 94. [Google Scholar] [CrossRef] [PubMed]

- Moretti, A.; Logrieco, A.F.; Susca, A. Mycotoxins: An Underhand Food Problem. Methods Mol. Biol. 2017, 1542, 3–12. [Google Scholar] [CrossRef]

- Nleya, N.; Adetunji, M.C.; Mwanza, M. Current Status of Mycotoxin Contamination of Food Commodities in Zimbabwe. Toxins 2018, 10, 89. [Google Scholar] [CrossRef]

- Taniwaki, M.H.; Pitt, J.I.; Magan, N. Aspergillus species and mycotoxins: Occurrence and importance in major food commodities. Curr. Opin. Food Sci. 2018, 23, 38–43. [Google Scholar] [CrossRef]

- Haque, M.A.; Wang, Y.; Shen, Z.; Li, X.; Kashif Saleemi, M.; He, C. Mycotoxin contamination and control strategy in human, domestic animal and poultry: A review. Microb. Pathogenesis. 2020, 142, 104095. [Google Scholar] [CrossRef]

- Gonçalves, B.L.; Coppa, C.F.S.C.; Neeff, D.V.D.; Corassin, C.H.; Oliveira, C.A.F. Mycotoxins in fruits and fruit-based products: Occurrence and methods for decontamination. Toxin Rev. 2019, 38, 263–272. [Google Scholar] [CrossRef]

- Emmott, A. Market-led aflatoxin interventions: Smallholder groundnut value chains in Malawi. Int. Food Policy Res. Inst. 2013, 20. Available online: http://cdm15738.contentdm.oclc.org/utils/getfile/collection/p15738coll2/id/127878/filename/128089.pdf (accessed on 12 May 2020).

- Da Rocha, M.E.B.; Freire, F.d.C.O.; Maia, F.E.F.; Guedes, M.I.F.; Rondina, D. Mycotoxins and their effects on human and animal health. Food Control 2014, 36, 159–165. [Google Scholar] [CrossRef]

- Palumbo, R.; Crisci, A.; Venâncio, A.; Cortiñas Abrahantes, J.; Dorne, J.L.; Battilani, P.; Toscano, P. Occurrence and Co-Occurrence of Mycotoxins in Cereal-Based Feed and Food. Microorganisms 2020, 8, 74. [Google Scholar] [CrossRef] [PubMed]

- Ayofemi Olalekan Adeyeye, S. Aflatoxigenic fungi and mycotoxins in food: A review. Crit. Rev. Food Sci. Nutr. 2020, 60, 709–721. [Google Scholar] [CrossRef] [PubMed]

- Ukwuru, M.U.; Ohaegbu, C.G.; Muritala, A. An Overview of Mycotoxin Contamination of Foods and Feeds. J. Biochem. Microb. Toxicol. 2017, 1, 101. [Google Scholar]

- Monson, M.; Coulombe, R.; Reed, K. Aflatoxicosis: Lessons from Toxicity and Responses to Aflatoxin B1 in Poultry. Agriculture 2015, 5, 742–777. [Google Scholar] [CrossRef]

- Gacem, M.A.; Ould El Hadj-Khelil, A. Toxicology, biosynthesis, bio-control of aflatoxin and new methods of detection. Asian Pac. J. Trop. Biomed. 2016, 6, 808–814. [Google Scholar] [CrossRef]

- Kumar, V. Aflatoxins: Properties, Toxicity and Detoxification. Int. J. Food Sci. Nutr. 2018, 6. [Google Scholar] [CrossRef]

- Benkerroum, N. Retrospective and Prospective Look at Aflatoxin Research and Development from a Practical Standpoint. Int. J. Environ. Res. 2019, 16, 3633. [Google Scholar] [CrossRef]

- Martinez-Miranda, M.M.; Rosero-Moreano, M.; Taborda-Ocampo, G. Occurrence, dietary exposure and risk assessment of aflatoxins in arepa, bread and rice. Food Control 2019, 98, 359–366. [Google Scholar] [CrossRef]

- Rushing, B.R.; Selim, M.I. Aflatoxin B1: A review on metabolism, toxicity, occurrence in food, occupational exposure, and detoxification methods. Food Chem. Toxicol. 2019, 124, 81–100. [Google Scholar] [CrossRef] [PubMed]

- Winter, G.; Pereg, L. A review on the relation between soil and mycotoxins: Effect of aflatoxin on field, food and finance. Eur. J. Soil Sci. 2019, 70, 882–897. [Google Scholar] [CrossRef]

- Sharma, A.C.; Proshad, R.; Kormoker, T.; Islam, M.S.; Chandra, K. A review on aflatoxins in stored grain food, their sources, mechanisms and possible health hazard. Arch. Agric. Environ. Sci. 2018, 3, 416–423. [Google Scholar] [CrossRef]

- Gholami-Shabani, M.; Shams-Ghahfarokhi, M.; Razzaghi-Abyaneh, M. Aflatoxins and aflatoxigenic fungi in Iran: A systematic review of the past, present, and future. Mycol. Iran. 2017, 4, 65–84. [Google Scholar]

- Hedayati, M.T.; Omran, S.M.; Soleymani, A.; Armaki, M.T. Aflatoxins in food products in Iran: A review of the literature. Jundishapur J. Microbiol. 2016, 9, e33235. [Google Scholar] [CrossRef]

- Alvarado, A.M.; Zamora-Sanabria, R.; Granados-Chinchilla, F. A focus on aflatoxins in feedstuffs: Levels of contamination, prevalence, control strategies, and impacts on animal health. Aflatoxin Control Anal. Detect. Health Risks 2017, 1, 116–152. [Google Scholar] [CrossRef]

- Shad, Z.M.; Ghavami, M.; Atungulu, G.G. Occurrence of Aflatoxin in Dairy Cow Feed Ingredients and Total Mixed Ration. Appl. Eng. Agric. 2019, 35, 679–686. [Google Scholar] [CrossRef]

- Ndagijimana, R.; Shahbaz, U.; Sun, X. Aflatoxin B1 in Food and Feed: An Overview on Prevalence, Determination and Control Tactics. JAIR 2020, 8, 144. [Google Scholar]

- Pour, S.H.; Mahmoudi, S.; Masoumi, S.; Rezaie, S.; Barac, A.; Ranjbaran, M.; Oliya, S.; Mehravar, F.; Sasani, E.; Noorbakhsh, F. Aflatoxin M1 contamination level in Iranian milk and dairy products: A systematic review and meta-analysis. World Mycotoxin J. 2020, 13, 67–82. [Google Scholar] [CrossRef]

- Taghizadeh, S.F.; Rezaee, R.; Badiebostan, H.; Giesy, J.P.; Karimi, G. Occurrence of mycotoxins in rice consumed by Iranians: A probabilistic assessment of risk to health. Food Addit. Contam. A 2020, 37, 342–354. [Google Scholar] [CrossRef]

- Kumar, P.; Mahato, D.K.; Kamle, M.; Mohanta, T.K.; Kang, S.G. Aflatoxins: A global concern for food safety, human health and their management. Front. Microbiol. 2017, 7, 2170. [Google Scholar] [CrossRef]

- USDA. Grain, Fungal Diseases and Mycotoxin Reference; United States Grain Inspection, Packers and Stockyards Administration: Washington, DC, USA, 2016. Available online: https://www.ams.usda.gov/sites/default/files/media/FungalDiseaseandMycotoxinReference2017.pdf (accessed on 12 May 2020).

- IARC (International Agency for Research on Cancer). Agents Classified by the IARC Monographs. 2014, Volume 1–113. Available online: http://monographs.iarc.fr/ENG/Classification/index.php (accessed on 12 May 2020).

- European Commission. The Rapid Alert System for Food and Feed (RASFF) Annual Report; European Community: Luxembourg, 2008. [Google Scholar]

- Bennett, J.W.; Klich, M. Mycotoxins. Clin. Microbiol. Rev. 2003, 16, 497. [Google Scholar] [CrossRef] [PubMed]

- Guchi, E. Implication of aflatoxin contamination in agricultural products. Am. J. Food Nutr. 2015, 3, 12–20. [Google Scholar]

- Battilani, P.; Toscano, P.; Van der Fels-Klerx, H.J.; Moretti, A.; Camardo Leggieri, M.; Brera, C.; Rortais, A.; Goumperis, T.; Robinson, T. Aflatoxin B1 contamination in maize in Europe increases due to climate change. Sci. Rep. 2016, 6, 24328. [Google Scholar] [CrossRef] [PubMed]

- Moretti, A.; Pascale, M.; Logrieco, A.F. Mycotoxin risks under a climate change scenario in Europe. Trends Food Sci. Technol. 2019, 84, 38–40. [Google Scholar] [CrossRef]

- Coppock, R.W.; Christian, R.G.; Jacobsen, B.J. Chapter 69—Aflatoxins. In Veterinary Toxicology, 3rd ed.; Gupta, R.C., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 983–994. [Google Scholar] [CrossRef]

- Schmidt-Heydt, M.; Rüfer, C.E.; Abdel-Hadi, A.; Magan, N.; Geisen, R. The production of aflatoxin B 1 or G 1 by Aspergillus parasiticus at various combinations of temperature and water activity is related to the ratio of aflS to aflR expression. Mycotoxin Res. 2010, 26, 241–246. [Google Scholar] [CrossRef]

- Gallo, A.; Solfrizzo, M.; Epifani, F.; Panzarini, G.; Perrone, G. Effect of temperature and water activity on gene expression and aflatoxin biosynthesis in Aspergillus flavus on almond medium. Int. J. Food Microbiol. 2016, 217, 162–169. [Google Scholar] [CrossRef]

- Bernáldez, V.; Córdoba, J.J.; Magan, N.; Peromingo, B.; Rodríguez, A. The influence of ecophysiological factors on growth, aflR gene expression and aflatoxin B1 production by a type strain of Aspergillus flavus. LWT Food Sci. Technol. 2017, 83, 283–291. [Google Scholar] [CrossRef]

- Lv, C.; Jin, J.; Wang, P.; Dai, X.; Liu, Y.; Zheng, M.; Xing, F. Interaction of water activity and temperature on the growth, gene expression and aflatoxin production by Aspergillus flavus on paddy and polished rice. Food Chem. 2019, 293, 472–478. [Google Scholar] [CrossRef]

- Gizachew, D.; Chang, C.H.; Szonyi, B.; De La Torre, S.; Ting, W.T.E. Aflatoxin B1 (AFB1) production by Aspergillus flavus and Aspergillus parasiticus on ground Nyjer seeds: The effect of water activity and temperature. Int. J. Food Microbiol. 2019, 296, 8–13. [Google Scholar] [CrossRef]

- Al-Gabr, H.M.; Ye, C.; Zhang, Y.; Khan, S.; Lin, H.; Zheng, T. Effects of carbon, nitrogen and pH on the growth of Aspergillus parasiticus and aflatoxins production in water. J. Environ. Biol. 2013, 34, 353. [Google Scholar]

- Amare, M.G.; Keller, N.P. Molecular mechanisms of Aspergillus flavus secondary metabolism and development. Fungal Genet. Biol. 2014, 66, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Ehrlich, K.C. Aflatoxin Biosynthetic Pathway and Pathway Genes; INTECH Open Access Publisher: London, UK, 2011. [Google Scholar]

- Roze, L.V.; Hong, S.Y.; Linz, J.E. Aflatoxin biosynthesis: Current frontiers. Annu. Rev. Food Sci. Technol. 2013, 4, 293–311. [Google Scholar] [CrossRef] [PubMed]

- Caceres, I.; Khoury, A.A.; Khoury, R.E.; Lorber, S.; Oswald, I.P.; Khoury, A.E.; Atoui, A.; Puel, O.; Bailly, J.-D. Aflatoxin Biosynthesis and Genetic Regulation: A Review. Toxins 2020, 12, 150. [Google Scholar] [CrossRef] [PubMed]

- Abrar, M.; Anjum, F.M.; Butt, M.S.; Pasha, I.; Randhawa, M.A.; Saeed, F.; Waqas, K. Aflatoxins: Biosynthesis, occurrence, toxicity, and remedies. Crit. Rev. Food Sci. Nutr. 2013, 53, 862–874. [Google Scholar] [CrossRef]

- Ehrlich, K.C.; Li, P.; Scharfenstein, L.; Chang, P.K. HypC, the anthrone oxidase involved in aflatoxin biosynthesis. Appl. Environ. Microbiol. 2010, 76, 3374–3377. [Google Scholar] [CrossRef]

- Crawford, J.M.; Dancy, B.C.; Hill, E.A.; Udwary, D.W.; Townsend, C.A. Identification of a starter unit acyl-carrier protein transacylase domain in an iterative type I polyketide synthase. Proc. Natl. Acad. Sci. USA 2006, 103, 16728–16733. [Google Scholar] [CrossRef]

- Crawford, J.M.; Thomas, P.M.; Scheerer, J.R.; Vagstad, A.L.; Kelleher, N.L.; Townsend, C.A. Deconstruction of iterative multidomain polyketide synthase function. Science 2008, 320, 243–246. [Google Scholar] [CrossRef]

- Crawford, J.M.; Vagstad, A.L.; Ehrlich, K.C.; Townsend, C.A. Starter unit specificity directs genome mining of polyketide synthase pathways in fungi. Bioorg. Chem. 2008, 36, 16–22. [Google Scholar] [CrossRef]

- Zhou, R.; Linz, J.E. Enzymatic function of the Nor-1 protein in aflatoxin biosynthesis in Aspergillus parasiticus. Appl. Environ. Microbiol. 1999, 65, 5639–5641. [Google Scholar] [CrossRef]

- Yu, J.; Bhatnagar, D.; Cleveland, T.E. Completed sequence of aflatoxin pathway gene cluster in Aspergillus parasiticus1. FEBS Lett. 2004, 564, 126–130. [Google Scholar] [CrossRef]

- Chang, P.-K.; Yu, J.; Ehrlich, K.C.; Boue, S.M.; Montalbano, B.G.; Bhatnagar, D.; Cleveland, T.E. adhA in Aspergillus parasiticus is involved in conversion of 5′-hydroxyaverantin to averufin. Appl. Environ. Microbiol. 2000, 66, 4715–4719. [Google Scholar] [CrossRef] [PubMed]

- Sakuno, E.; Wen, Y.; Hatabayashi, H.; Arai, H.; Aoki, C.; Yabe, K.; Nakajima, H. Aspergillus parasiticus cyclase catalyzes two dehydration steps in aflatoxin biosynthesis. Appl. Environ. Microbiol. 2005, 71, 2999–3006. [Google Scholar] [CrossRef] [PubMed]

- Sakuno, E.; Yabe, K.; Nakajima, H. Involvement of two cytosolic enzymes and a novel intermediate, 5′-oxoaverantin, in the pathway from 5′-hydroxyaverantin to averufin in aflatoxin biosynthesis. Appl. Environ. Microbiol. 2003, 69, 6418–6426. [Google Scholar] [CrossRef] [PubMed]

- Wen, Y.; Hatabayashi, H.; Arai, H.; Kitamoto, H.K.; Yabe, K. Function of the cypX and moxY genes in aflatoxin biosynthesis in Aspergillus parasiticus. Appl. Environ. Microbiol. 2005, 71, 3192–3198. [Google Scholar] [CrossRef] [PubMed]

- Chang, P.-K.; Yabe, K.; Yu, J. The Aspergillus parasiticus estA-encoded esterase converts versiconal hemiacetal acetate to versiconal and versiconol acetate to versiconol in aflatoxin biosynthesis. Appl. Environ. Microbiol. 2004, 70, 3593–3599. [Google Scholar] [CrossRef]

- Lin, B.-K.; Anderson, J.A. Purification and properties of versiconal cyclase from Aspergillus parasiticus. Arch. Biochem. Biophys. 1992, 293, 67–70. [Google Scholar] [CrossRef]

- Kelkar, H.S.; Skloss, T.W.; Haw, J.F.; Keller, N.P.; Adams, T.H. Aspergillus nidulans stcL encodes a putative cytochrome P-450 monooxygenase required for bisfuran desaturation during aflatoxin/sterigmatocystin biosynthesis. J. Biol. Chem. 1997, 272, 1589–1594. [Google Scholar] [CrossRef]

- Ehrlich, K.C.; Montalbano, B.; Boué, S.M.; Bhatnagar, D. An aflatoxin biosynthesis cluster gene encodes a novel oxidase required for conversion of versicolorin A to sterigmatocystin. Appl. Environ. Microbiol. 2005, 71, 8963–8965. [Google Scholar] [CrossRef]

- Henry, K.M.; Townsend, C.A. Ordering the reductive and cytochrome P450 oxidative steps in demethylsterigmatocystin formation yields general insights into the biosynthesis of aflatoxin and related fungal metabolites. J. Am. Chem. Soc. 2005, 127, 3724–3733. [Google Scholar] [CrossRef]

- Yu, J.; Woloshuk, C.P.; Bhatnagar, D.; Cleveland, T.E. Cloning and characterization of avfA and omtB genes involved in aflatoxin biosynthesis in three Aspergillus species. Gene 2000, 248, 157–167. [Google Scholar] [CrossRef]

- Ehrlich, K.C.; Chang, P.-K.; Yu, J.; Cotty, P.J. Aflatoxin biosynthesis cluster gene cypA is required for G aflatoxin formation. Appl. Environ. Microbiol. 2004, 70, 6518–6524. [Google Scholar] [CrossRef] [PubMed]

- Price, M.S.; Yu, J.; Nierman, W.C.; Kim, H.S.; Pritchard, B.; Jacobus, C.A.; Bhatnagar, D.; Cleveland, T.E.; Payne, G.A. The aflatoxin pathway regulator AflR induces gene transcription inside and outside of the aflatoxin biosynthetic cluster. FEMS Microbiol. Lett. 2006, 255, 275–279. [Google Scholar] [CrossRef] [PubMed]

- Ehrlich, K.C.; Scharfenstein, L.L.; Montalbano, B.G.; Chang, P.-K. Are the genes nadA and norB involved in formation of aflatoxin G1? Int. J. Mol. Sci. 2008, 9, 1717–1729. [Google Scholar] [CrossRef]

- Ehrlich, K.C.; Yu, J. Aflatoxin-like gene clusters and how they evolved. In Mycotoxins in Food, Feed and Bioweapons; Springer: Berlin/Heidelberg, Germany, 2009; pp. 65–75. [Google Scholar]

- Cai, J.; Zeng, H.; Shima, Y.; Hatabayashi, H.; Nakagawa, H.; Ito, Y.; Adachi, Y.; Nakajima, H.; Yabe, K. Involvement of the nadA gene in formation of G-group aflatoxins in Aspergillus parasiticus. Fung. Genet. Biol. 2008, 45, 1081–1093. [Google Scholar] [CrossRef]

- Ehrlich, K.C. Predicted roles of the uncharacterized clustered genes in aflatoxin biosynthesis. Toxins 2009, 1, 37–58. [Google Scholar] [CrossRef]

- Yu, J. Current understanding on aflatoxin biosynthesis and future perspective in reducing aflatoxin contamination. Toxins 2012, 4, 1024–1057. [Google Scholar] [CrossRef]

- Zeng, H.; Hatabayashi, H.; Nakagawa, H.; Cai, J.; Suzuki, R.; Sakuno, E.; Tanaka, T.; Ito, Y.; Ehrlich, K.C.; Nakajima, H. Conversion of 11-hydroxy-O-methylsterigmatocystin to aflatoxin G 1 in Aspergillus parasiticus. Appl. Microbiol. Biotechnol. 2011, 90, 635–650. [Google Scholar] [CrossRef]

- Kensler, T.W.; Roebuck, B.D.; Wogan, G.N.; Groopman, J.D. Aflatoxin: A 50-year odyssey of mechanistic and translational toxicology. Toxicol. Sci. 2011, 120 (Suppl. 1), S28–S48. [Google Scholar] [CrossRef]

- Zinedine, A.; Mañes, J. Occurrence and legislation of mycotoxins in food and feed from Morocco. Food Control 2009, 20, 334–344. [Google Scholar] [CrossRef]

- Iqbal, S.Z.; Jinap, S.; Pirouz, A.; Faizal, A.A. Aflatoxin M1 in milk and dairy products, occurrence and recent challenges: A review. Trends Food Sci. Technol. 2015, 46, 110–119. [Google Scholar] [CrossRef]

- De Ruyck, K.; De Boevre, M.; Huybrechts, I.; De Saeger, S. Dietary mycotoxins, co-exposure, and carcinogenesis in humans: Short review. Mutat. Res. 2015, 766, 32–41. [Google Scholar] [CrossRef] [PubMed]

- Jaimez, J.; Fente, C.; Vazquez, B.; Franco, C.; Cepeda, A.; Mahuzier, G.; Prognon, P. Application of the assay of aflatoxins by liquid chromatography with fluorescence detection in food analysis. J. Chromatogr. A 2000, 882, 1–10. [Google Scholar] [CrossRef]

- Sirhan, A.Y.; Tan, G.H.; Al-Shunnaq, A.; Abdulra’uf, L.; Wong, R.C. QuEChERS-HPLC method for aflatoxin detection of domestic and imported food in Jordan. J. Liq. Chromatogr. Relat. Technol. 2014, 37, 321–342. [Google Scholar] [CrossRef]

- Tomlins, K.; Jewers, K.; Coker, R. Evaluation of non-polar bonded-phases for the clean-up of maize extracts prior to aflatoxin assay by HPTLC. Chromatographia 1989, 27, 67–70. [Google Scholar] [CrossRef]

- Keller, N.P.; Turner, G.; Bennett, J.W. Fungal secondary metabolism - from biochemistry to genomics. Nat. Rev. Microbiol. 2005, 3, 937–947. [Google Scholar] [CrossRef] [PubMed]

- Mousavi Khaneghah, A.; Eş, I.; Raeisi, S.; Fakhri, Y. Aflatoxins in cereals: State of the art. J. Food Saf. 2018, 38, e12532. [Google Scholar] [CrossRef]

- Ismail, A.; Akhtar, S.; Riaz, M.; Gong, Y.Y.; Routledge, M.N.; Naeem, I. Prevalence and Exposure Assessment of Aflatoxins Through Black Tea Consumption in the Multan City of Pakistan and the Impact of Tea Making Process on Aflatoxins. Front. Microbiol. 2020, 11, 446. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, W.; Yue, P.; Wang, Q.; Li, Y.; Pei, X.; Zeng, P. High occurrence of aflatoxin B1 in Pixian Doubanjiang, a typical condiment in Chinese cuisine. Food Control 2020, 110, 107034. [Google Scholar] [CrossRef]

- Bumbangi, N.; Muma, J.; Choongo, K.; Mukanga, M.; Velu, M.; Veldman, F.; Hatloy, A.; Mapatano, M. Occurrence and factors associated with aflatoxin contamination of raw peanuts from Lusaka district’s markets, Zambia. Food Control 2016, 68, 291–296. [Google Scholar] [CrossRef]

- Prelle, A.; Spadaro, D.; Garibaldi, A.; Gullino, M.L. Co-occurrence of aflatoxins and ochratoxin A in spices commercialized in Italy. Food Control 2014, 39, 192–197. [Google Scholar] [CrossRef]

- Kara, G.N.; Ozbey, F.; Kabak, B. Co-occurrence of aflatoxins and ochratoxin A in cereal flours commercialised in Turkey. Food Control 2015, 54, 275–281. [Google Scholar] [CrossRef]

- Janić Hajnal, E.; Kos, J.; Krulj, J.; Krstović, S.; Jajić, I.; Pezo, L.; Šarić, B.; Nedeljković, N. Aflatoxins contamination of maize in Serbia: The impact of weather conditions in 2015. Food Addit. Contam. Part A 2017, 34, 1999–2010. [Google Scholar] [CrossRef] [PubMed]

- Duarte, S.; Almeida, A.; Teixeira, A.; Pereira, A.; Falcão, A.; Pena, A.; Lino, C. Aflatoxin M1 in marketed milk in Portugal: Assessment of human and animal exposure. Food Control 2013, 30, 411–417. [Google Scholar] [CrossRef]

- Sumantri, I.; Purwanti, F.; Nuryono, N.; Agus, A. Estimation of Aflatoxin M1 Exposure through Consumption of Various Dairy Milk Products in Yogyakarta, Indonesia. J. Vet. 2019, 20, 58–64. [Google Scholar]

- Xiong, J.; Peng, L.; Zhou, H.; Lin, B.; Yan, P.; Wu, W.; Liu, Y.; Wu, L.; Qiu, Y. Prevalence of aflatoxin M1 in raw milk and three types of liquid milk products in central-south China. Food Control 2020, 108, 106840. [Google Scholar] [CrossRef]

- Daou, R.; Afif, C.; Joubrane, K.; Khabbaz, L.R.; Maroun, R.; Ismail, A.; El Khoury, A. Occurrence of aflatoxin M1 in raw, pasteurized, UHT cows’ milk, and dairy products in Lebanon. Food Control 2020, 111, 107055. [Google Scholar] [CrossRef]

- Quevedo-Garza, P.A.; Amador-Espejo, G.G.; Salas-García, R.; Ramos-Peña, E.G.; Trujillo, A.-J. Aflatoxin M1 determination in infant formulae distributed in Monterrey, Mexico. Toxins 2020, 12, 100. [Google Scholar] [CrossRef]

- Nabwire, W.R.; Ombaka, J.; Dick, C.P.; Strickland, C.; Tang, L.; Xue, K.S.; Wang, J.-S. Aflatoxin in household maize for human consumption in Kenya, East Africa. Food Addit. Contam. Part B 2020, 13, 45–51. [Google Scholar] [CrossRef]

- Katsurayama, A.M.; Martins, L.M.; Iamanaka, B.T.; Fungaro, M.H.P.; Silva, J.J.; Frisvad, J.C.; Pitt, J.I.; Taniwaki, M.H. Occurrence of Aspergillus section Flavi and aflatoxins in Brazilian rice: From field to market. Int. J. Food Microbiol. 2018, 266, 213–221. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Q.; Huang, J.; Ma, L.; Chen, Z.; Wang, F. Aflatoxin B1 and sterigmatocystin in wheat and wheat products from supermarkets in China. Food Addit. Contam. Part B 2018, 11, 9–14. [Google Scholar] [CrossRef] [PubMed]

- De Roma, A.; Rossini, C.; Ritieni, A.; Gallo, P.; Esposito, M. A survey on the Aflatoxin M1 occurrence and seasonal variation in buffalo and cow milk from Southern Italy. Food Control 2017, 81, 30–33. [Google Scholar] [CrossRef]

- Bahrami, R.; Shahbazi, Y.; Nikousefat, Z. Aflatoxin M1 in milk and traditional dairy products from west part of Iran: Occurrence and seasonal variation with an emphasis on risk assessment of human exposure. Food Control 2016, 62, 250–256. [Google Scholar] [CrossRef]

- Granados-Chinchilla, F.; Molina, A.; Chavarría, G.; Alfaro-Cascante, M.; Bogantes, D.; Murillo Williams, A. Aflatoxins occurrence through the food chain in Costa Rica: Applying the One Health approach to mycotoxin surveillance. Food Control 2017, 82, 217–226. [Google Scholar] [CrossRef]

- Heshmati, A.; Zohrevand, T.; Khaneghah, A.M.; Mozaffari Nejad, A.S.; Sant’Ana, A.S. Co-occurrence of aflatoxins and ochratoxin A in dried fruits in Iran: Dietary exposure risk assessment. Food Chem. Toxicol. 2017, 106, 202–208. [Google Scholar] [CrossRef] [PubMed]

- Commission of the European Communities (CET). Commission Regulation (EC) No 1881/2006 of 19 December 2006 Setting Maximum Levels for Certain Contaminants in Foodstuffs; O. L. EU. L346; Commission of the European Communities: Brussels, Belgium, 2006; p. 5e24. [Google Scholar]

- Lippolis, V.; Irurhe, O.; Porricelli, A.C.R.; Cortese, M.; Schena, R.; Imafidon, T.; Oluwadun, A.; Pascale, M. Natural co-occurrence of aflatoxins and ochratoxin A in ginger (Zingiber officinale) from Nigeria. Food Control 2017, 73, 1061–1067. [Google Scholar] [CrossRef]

- Singh, P.; Cotty, P.J. Aflatoxin contamination of dried red chilies: Contrasts between the United States and Nigeria, two markets differing in regulation enforcement. Food Control 2017, 80, 374–379. [Google Scholar] [CrossRef]

- AlFaris, N.A.; Wabaidur, S.M.; Alothman, Z.A.; Altamimi, J.Z.; Aldayel, T.S. Fast and efficient immunoaffinity column cleanup and liquid chromatography-tandem mass spectrometry method for the quantitative analysis of aflatoxins in baby food and feeds. J. Sep. Sci. 2020. [Google Scholar] [CrossRef]

- Carvalho, K.; Gonçalves, G.; Lopes, A.; Santos, E.; Vargas, E.; Magalhães, W. Modelling uncertainty estimation for the determination of aflatoxin M1 in milk by visual and densitometric thin-layer chromatography with immunoaffinity column clean-up. Food Addit. Contam. Part A 2012, 29, 679–693. [Google Scholar] [CrossRef]

- Musundire, R.; Osuga, I.M.; Cheseto, X.; Irungu, J.; Torto, B. Aflatoxin contamination detected in nutrient and anti-oxidant rich edible stink bug stored in recycled grain containers. PLoS ONE 2016, 11, 1–16. [Google Scholar] [CrossRef]

- Asadi, M. Separation and quantification of aflatoxins in grains using modified dispersive liquid–liquid microextraction combined with high-performance liquid chromatography. J. Food Meas. Charact. 2020, 14, 925–930. [Google Scholar] [CrossRef]

- Wu, C.; Hu, L.; Xia, J.; Xu, G.; Luo, K.; Liu, D.; Duan, H.; Cheng, S.; Xiong, Y.; Lai, W. Comparison of immunochromatographic assays based on fluorescent microsphere and quantum-dot submicrobead for quantitative detection of aflatoxin M1 in milk. J. Dairy Sci. 2017, 100, 2501–2511. [Google Scholar] [CrossRef] [PubMed]

- Vaz, A.; Cabral Silva, C.A.; Rodrigues, P.; Venâncio, A. Detection Methods for Aflatoxin M1 in Dairy Products. Microorganisms 2020, 8, 246. [Google Scholar] [CrossRef] [PubMed]

- Hamed, A.M.; Abdel-Hamid, M.; Gámiz-Gracia, L.; García-Campaña, A.M.; Arroyo-Manzanares, N. Determination of aflatoxins in plant-based milk and dairy products by dispersive liquid–liquid microextraction and high-performance liquid chromatography with fluorescence detection. Anal. Lett. 2019, 52, 363–372. [Google Scholar] [CrossRef]

- Ouakhssase, A.; Chahid, A.; Choubbane, H.; Aitmazirt, A.; Addi, E.A. Optimization and validation of a liquid chromatography/tandem mass spectrometry (LC-MS/MS) method for the determination of aflatoxins in maize. Heliyon 2019, 5, e01565. [Google Scholar] [CrossRef]

- Mohammedi-Ameur, S.; Dahmane, M.; Brera, C.; Kardjadj, M.; Ben-Mahdi, M.H. Occurrence and seasonal variation of aflatoxin M1 in raw cow milk collected from different regions of Algeria. Vet. World. 2020, 13, 433–439. [Google Scholar] [CrossRef]

- Selvolini, G.; Lettieri, M.; Tassoni, L.; Gastaldello, S.; Grillo, M.; Maran, C.; Marrazza, G. Electrochemical enzyme-linked oligonucleotide array for aflatoxin B1 detection. Talanta 2019, 203, 49–57. [Google Scholar] [CrossRef]

- Wang, C.; Sun, L.; Zhao, Q. A simple aptamer molecular beacon assay for rapid detection of aflatoxin B1. Chin. Chem Lett. 2019, 30, 1017–1020. [Google Scholar] [CrossRef]

- Zhongzhi, H.; Limiao, D. Aflatoxin contaminated degree detection by hyperspectral data using band index. Food Chem. Toxicol. 2020, 137, 111159. [Google Scholar] [CrossRef]

- Tao, F.; Yao, H.; Hruska, Z.; Burger, L.W.; Rajasekaran, K.; Bhatnagar, D. Recent development of optical methods in rapid and non-destructive detection of aflatoxin and fungal contamination in agricultural products. Trends Analyt. Chem. 2018, 100, 65–81. [Google Scholar] [CrossRef]

- Rui, C.; He, J.; Li, Y.; Liang, Y.; You, L.; He, L.; Li, K.; Zhang, S. Selective extraction and enrichment of aflatoxins from food samples by mesoporous silica FDU-12 supported aflatoxins imprinted polymers based on surface molecularly imprinting technique. Talanta 2019, 201, 342–349. [Google Scholar] [CrossRef] [PubMed]

- Kimuli, D.; Wang, W.; Jiang, H.; Zhao, X.; Chu, X. Application of SWIR hyperspectral imaging and chemometrics for identification of aflatoxin B 1 contaminated maize kernels. Infrared Phys. Technol. 2018, 89. [Google Scholar] [CrossRef]

- Kaur, P.; Singh, R.; Rai, T.; Sharma, N.S.; Arora, A. Evaluation of a Real time polymerase chain reaction assay for the detection of aflatoxin/sterigmatocystin producing strains of Aspergillus spp. Indian J. Anim. Res. 2017, 51. [Google Scholar] [CrossRef]

- Rotimi, O.A.; Rotimi, S.O.; Duru, C.U.; Ebebeinwe, O.J.; Abiodun, A.O.; Oyeniyi, B.O.; Faduyile, F.A. Acute aflatoxin B1–Induced hepatotoxicity alters gene expression and disrupts lipid and lipoprotein metabolism in rats. Toxicol. Rep. 2017, 4, 408–414. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Park, S.-H.; Do, K.H.; Kim, D.; Moon, Y. Interference with mutagenic aflatoxin B1-induced checkpoints through antagonistic action of ochratoxin A in intestinal cancer cells: A molecular explanation on potential risk of crosstalk between carcinogens. Oncotarget 2016, 7, 39627. [Google Scholar] [CrossRef]

- Sirma, A.J.; Makita, K.; Grace Randolph, D.; Senerwa, D.; Lindahl, J.F. Aflatoxin exposure from milk in rural Kenya and the contribution to the risk of liver cancer. Toxins 2019, 11, 469. [Google Scholar] [CrossRef]

- Mohsenzadeh, M.S.; Hedayati, N.; Riahi-Zanjani, B.; Karimi, G. Immunosuppression following dietary aflatoxin B1 exposure: A review of the existing evidence. Toxin Rev. 2016, 35, 121–127. [Google Scholar] [CrossRef]

- Makhlouf, M.M. Histological and ultrastructural study of AflatoxinB1 induced neurotoxicity in Sciatic nerve of adult male Albino rats. Ultrastruct. Pathol. 2020, 44, 52–60. [Google Scholar] [CrossRef]

- Ferreira, R.G.; Cardoso, M.V.; de Souza Furtado, K.M.; Espíndola, K.M.M.; Amorim, R.P.; Monteiro, M.C. Epigenetic alterations caused by aflatoxin b1: A public health risk in the induction of hepatocellular carcinoma. Trans. Res. 2019, 204, 51–71. [Google Scholar] [CrossRef]

- El Khoury, D.; Fayjaloun, S.; Nassar, M.; Sahakian, J.; Aad, P.Y. Updates on the Effect of Mycotoxins on Male Reproductive Efficiency in Mammals. Toxins 2019, 11, 515. [Google Scholar] [CrossRef]

- Chen, C.; Mitchell, N.J.; Gratz, J.; Houpt, E.R.; Gong, Y.; Egner, P.A.; Groopman, J.D.; Riley, R.T.; Showker, J.L.; Svensen, E.; et al. Exposure to aflatoxin and fumonisin in children at risk for growth impairment in rural Tanzania. Environ. Int. 2018, 115, 29–37. [Google Scholar] [CrossRef] [PubMed]

- Gong, Y.Y.; Watson, S.; Routledge, M. Aflatoxin Exposure and Associated Human Health Effects, a Review of Epidemiological Studies. Food Saf. 2016, 4, 14–27. [Google Scholar] [CrossRef] [PubMed]

- Alsayyah, A.; ElMazoudy, R.; Al-Namshan, M.; Al-Jafary, M.; Alaqeel, N. Chronic neurodegeneration by aflatoxin B1 depends on alterations of brain enzyme activity and immunoexpression of astrocyte in male rats. Ecotoxicol. Environ. Saf. 2019, 182, 109407. [Google Scholar] [CrossRef] [PubMed]

- Wangia, R.N.; Tang, L.; Wang, J.-S. Occupational exposure to aflatoxins and health outcomes: A review. J. Environ. Sci. Health C Environ. Carcinog. Ecotoxicol. Rev. 2019, 37, 215–234. [Google Scholar] [CrossRef]

- Mahato, D.K.; Lee, K.E.; Kamle, M.; Devi, S.; Dewangan, K.N.; Kumar, P.; Kang, S.G. Aflatoxins in Food and Feed: An Overview on Prevalence, Detection and Control Strategies. Front. Microbiol. 2019, 10. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EC) No 1126/2007 of 28 September 2007 amending regulation (EC) no 1881/2006 setting maximum levels for certain contaminants in foodstuffs as regards Fusarium toxins in maize and maize products. Off. J. Eur. Union L. 2007, 255, 14–17. [Google Scholar]

- European Commission. Commission Regulation (EC) No 165/2010 of 26 February 2010 amending Regulation (EC) No 1881/2006 setting maximum levels for certain contaminants in foodstuffs as regards aflatoxins. Off. J. Eur. Union L. 2010, 50, 8–12. [Google Scholar]

- Wu, F. Mycotoxin Reduction in Bt Corn: Potential Economic, Health, and Regulatory Impacts. Transgenic Res. 2006, 15, 277–289. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 12 May 2020).

- FDA (Food and Drug Administration). Bad Bug Book: Food-Borne Pathogenic Microorganisms and Natural Toxins, 2nd ed.; FDA: Washington, DC, USA, 2012. Available online: http://www.fda.gov/downloads/Food/FoodborneIllnessContaminants/UCM297627.pdf (accessed on 12 May 2020).

- Li, H.; Guan, K.; Zuo, Z.; Wang, F.; Peng, X.; Fang, J.; Cui, H.; Zhou, Y.; Ouyang, P.; Su, G. Effects of aflatoxin B1 on the cell cycle distribution of splenocytes in chickens. J. Toxicol. Pathol. 2019, 32, 27–36. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.; Chen, Y.; Ni, C.; Chen, X.; Zhang, L.; Xu, X.; Chen, M.; Ma, X.; Zhan, H.; et al. Aflatoxin B1 impairs leydig cells through inhibiting AMPK/mTOR-mediated autophagy flux pathway. Chemosphere 2019, 233, 261–272. [Google Scholar] [CrossRef]

- Liu, W.; Wang, L.; Zheng, C.; Liu, L.; Wang, J.; Li, D.; Tan, Y.; Zhao, X.; He, L.; Shu, W. Microcystin-LR increases genotoxicity induced by aflatoxin B1 through oxidative stress and DNA base excision repair genes in human hepatic cell lines. Environ. Pollut. 2018, 233, 455–463. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Chen, K.; Yuan, S.; Peng, X.; Fang, J.; Wang, F.; Cui, H.; Chen, Z.; Yuan, J.; Geng, Y. Effects of aflatoxin B1 on oxidative stress markers and apoptosis of spleens in broilers. Toxicol. Ind. Health 2013, 32, 278–284. [Google Scholar] [CrossRef] [PubMed]

- Weng, M.W.; Lee, H.W.; Choi, B.; Wang, H.T.; Hu, Y.; Mehta, M.; Desai, D.; Amin, S.; Zheng, Y.; Tang, M.S. AFB1 hepatocarcinogenesis is via lipid peroxidation that inhibits DNA repair, sensitizes mutation susceptibility and induces aldehyde-DNA adducts at p53 mutational hotspot codon 249. Oncotarget 2017, 8, 18213–18226. [Google Scholar] [CrossRef] [PubMed]

- Trebak, F.; Alaoui, A.; Alexandre, D.; El Ouezzani, S.; Anouar, Y.; Chartrel, N.; Magoul, R. Impact of aflatoxin B1 on hypothalamic neuropeptides regulating feeding behavior. NeuroToxicology 2015, 49, 165–173. [Google Scholar] [CrossRef]

- Peng, X.; Chen, K.; Chen, J.; Fang, J.; Cui, H.; Zuo, Z.; Deng, J.; Chen, Z.; Geng, Y.; Lai, W. Aflatoxin B1 affects apoptosis and expression of Bax, Bcl-2, and Caspase-3 in thymus and bursa of fabricius in broiler chickens. Environ. Toxicol. 2016, 31, 1113–1120. [Google Scholar] [CrossRef]

- Zhu, Y.; Hassan, Y.; Watts, C.; Zhou, T. Innovative Technologies for the Mitigation of Mycotoxins in Animal Feed and Ingredients—A Review of Recent Patents. Anim. Feed Sci. Technol. 2016, 216. [Google Scholar] [CrossRef]

- Udomkun, P.; Wiredu, A.N.; Nagle, M.; Muller, J.; Vanlauwe, B.; Bandyopadhyay, R. Innovative technologies to manage aflatoxins in foods and feeds and the profitability of application—A review. Food Control 2017, 76, 127–138. [Google Scholar] [CrossRef]

- Ismail, A.; Gonçalves, B.L.; de Neeff, D.V.; Ponzilacqua, B.; Coppa, C.F.S.C.; Hintzsche, H.; Sajid, M.; Cruz, A.G.; Corassin, C.H.; Oliveira, C.A.F. Aflatoxin in foodstuffs: Occurrence and recent advances in decontamination. Food Res. Int. 2018, 113, 74–85. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, X.; Li, J. Updating techniques on controlling mycotoxins—A review. Food Control 2018, 89, 123–132. [Google Scholar] [CrossRef]

- Peng, Z.; Chen, L.; Zhu, Y.; Huang, Y.; Hu, X.; Wu, Q.; Nüssler, A.K.; Liu, L.; Yang, W. Current major degradation methods for aflatoxins: A review. Trends Food. Sci. Tech. 2018, 80, 155–166. [Google Scholar] [CrossRef]

- Lee, J.; Her, J.Y.; Lee, K.G. Reduction of aflatoxins (B(1), B(2), G(1), and G(2)) in soybean-based model systems. Food Chem. 2015, 189, 45–51. [Google Scholar] [CrossRef] [PubMed]

- Saladino, F.; Bordin, K.; Manyes, L.; Luciano, F.B.; Mañes, J.; Fernández-Franzón, M.; Meca, G. Reduction of the aflatoxins B1, B2, G1 and G2 in Italian piadina by isothiocyanates. LWT 2016, 70, 302–308. [Google Scholar] [CrossRef]

- Mohammadi, H.; Mazloomi, S.M.; Eskandari, M.H.; Aminlari, M.; Niakousari, M. The Effect of Ozone on Aflatoxin M1, Oxidative Stability, Carotenoid Content and the Microbial Count of Milk. Ozone Sci. Eng. 2017, 39, 447–453. [Google Scholar] [CrossRef]

- Savi, G.D.; Piacentini, K.C.; Scussel, V.M. Ozone Treatment Efficiency in Aspergillus and Penicillium Growth Inhibition and Mycotoxin Degradation of Stored Wheat Grains (Triticum aestivum L.). J. Food Process. Preserv. 2015, 39, 940–948. [Google Scholar] [CrossRef]

- Luo, X.; Wang, R.; Wang, L.; Li, Y.; Bian, Y.; Chen, Z. Effect of ozone treatment on aflatoxin B1 and safety evaluation of ozonized corn. Food Control 2014, 37, 171–176. [Google Scholar] [CrossRef]

- Rastegar, H.; Shoeibi, S.; Yazdanpanah, H.; Amirahmadi, M.; Khaneghah, A.M.; Campagnollo, F.B.; Sant’Ana, A.S. Removal of aflatoxin B1 by roasting with lemon juice and/or citric acid in contaminated pistachio nuts. Food Control 2017, 71, 279–284. [Google Scholar] [CrossRef]

- Rushing, B.R.; Selim, M.I. Effect of dietary acids on the formation of aflatoxin B2a as a means to detoxify aflatoxin B1. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2016, 33, 1456–1467. [Google Scholar] [CrossRef]

- Chen, R.; Ma, F.; Li, P.-W.; Zhang, W.; Ding, X.-X.; Zhang, Q.; Li, M.; Wang, Y.-R.; Xu, B.-C. Effect of ozone on aflatoxins detoxification and nutritional quality of peanuts. Food Chem. 2014, 146, 284–288. [Google Scholar] [CrossRef]

- Iqbal, S.; Ahmad, I.; Asi, M.; Zuber, M.; Shahid, M.; Parveen, I. Effect of γ irradiation on fungal load and aflatoxins reduction in red chillies. Radiat. Phys. Chem. 2013, 82, 80–84. [Google Scholar] [CrossRef]

- Markov, K.; Mihaljević, B.; Domijan, A.-M.; Pleadin, J.; Delaš, F.; Frece, J. Inactivation of aflatoxigenic fungi and the reduction of aflatoxin B1 in vitro and in situ using gamma irradiation. Food Control 2015, 54, 79–85. [Google Scholar] [CrossRef]

- Ghanghro, A.B.; Channa, M.J.; Sheikh, A.S.; Nizamani, S.M.; Ghanghro, I.H. Assessment of aflatoxin level in stored wheat of godowns of Hyderabad division and decontamination by uv radiation. Int. J. Biosci. 2016, 8, 8–16. [Google Scholar]

- Mao, J.; He, B.; Zhang, L.; Li, P.; Zhang, Q.; Ding, X.; Zhang, W. A Structure Identification and Toxicity Assessment of the Degradation Products of Aflatoxin B(1) in Peanut Oil under UV Irradiation. Toxins 2016, 8, 332. [Google Scholar] [CrossRef] [PubMed]

- Kaur, B.; Sharma, N.; Sharma, S.; Bobade, H.; Singh, B. Effect of processing on reduction of aflatoxins in contaminated wheat. J. Res. 2014, 51, 163–167. [Google Scholar]

- Zheng, H.; Wei, S.; Xu, Y.; Fan, M. Reduction of aflatoxin B1 in peanut meal by extrusion cooking. LWT Food Sci. Technol. 2015, 64, 515–519. [Google Scholar] [CrossRef]

- Kanapitsas, A.; Batrinou, A.; Aravantinos, A.; Markaki, P. Effect of γ-radiation on the production of aflatoxin B1 by Aspergillus parasiticus in raisins (Vitis vinifera L.). Radiat. Phys. Chem. 2015, 106, 327–332. [Google Scholar] [CrossRef]

- Wang, B.; Mahoney, N.E.; Pan, Z.; Khir, R.; Wu, B.; Ma, H.; Zhao, L. Effectiveness of pulsed light treatment for degradation and detoxification of aflatoxin B1 and B2 in rough rice and rice bran. Food Control 2016, 59, 461–467. [Google Scholar] [CrossRef]

- Moussa, A. Efficacy of Kaolin and Bentonite Clay to Reduce Aflatoxin M1 Content in Contaminated Milk and Effects on Milk Quality. Pak. Vet. J. 2019. [Google Scholar] [CrossRef]

- Wang, M.; Hearon, S.E.; Phillips, T.D. A high capacity bentonite clay for the sorption of aflatoxins. Food Addit. Contam. Part A 2020, 37, 332–341. [Google Scholar] [CrossRef]

- Harkai, P.; Szabó, I.; Cserháti, M.; Krifaton, C.; Risa, A.; Radó, J.; Balázs, A.; Berta, K.; Kriszt, B. Biodegradation of aflatoxin-B1 and zearalenone by Streptomyces sp. collection. Int. Biodeterior. Biodegrad. 2016, 108, 48–56. [Google Scholar] [CrossRef]

- Ji, C.; Fan, Y.; Zhao, L. Review on biological degradation of mycotoxins. Anim. Nutr. 2016, 2, 127–133. [Google Scholar] [CrossRef]

- Verheecke, C.; Liboz, T.; Mathieu, F. Microbial degradation of aflatoxin B1: Current status and future advances. Int. J. Food Microbiol. 2016, 237, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Adebo, O.A.; Njobeh, P.B.; Gbashi, S.; Nwinyi, O.C.; Mavumengwana, V. Review on microbial degradation of aflatoxins. Crit. Rev. Food Sci Nutr. 2017, 57, 3208–3217. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, B.; Gonçalves, C.; Rosim, R.; Oliveira, C.; Corassin, C. Evaluations of Different Sources of Saccharomyces cerevisiae to Binding Capacity of Aflatoxin B1 Utilizing their Adsorption Isotherms. J. Food Chem. Nanotech. 2017, 3. [Google Scholar] [CrossRef]

- Kim, S.; Lee, H.; Lee, S.; Lee, J.; Ha, J.; Choi, Y.; Yoon, Y.; Choi, K.-H. Invited review: Microbe-mediated aflatoxin decontamination of dairy products and feeds. J. Dairy Sci. 2017, 100, 871–880. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Eisa Ahmed, M.F.; Sangare, L.; Zhao, Y.; Selvaraj, J.N.; Xing, F.; Wang, Y.; Yang, H.; Liu, Y. Novel Aflatoxin-Degrading Enzyme from Bacillus shackletonii L7. Toxins 2017, 9, 36. [Google Scholar] [CrossRef] [PubMed]

- Mwakinyali, S.E.; Ding, X.; Ming, Z.; Tong, W.; Zhang, Q.; Li, P. Recent development of aflatoxin contamination biocontrol in agricultural products. Biol. Control 2019, 128, 31–39. [Google Scholar] [CrossRef]

- Rad, A.H.; Javadi, M.; Kafil, H.S.; Pirouzian, H.R.; Khaleghi, M. The safety perspective of probiotic and non-probiotic yoghurts: A review. Food Qual. Saf. 2019, 3, 9–14. [Google Scholar] [CrossRef]

- Sadeghi, A.; Ebrahimi, M.; Raeisi, M.; Nematollahi, Z. Biological control of foodborne pathogens and aflatoxins by selected probiotic LAB isolated from rice bran sourdough. Biol. Control 2019, 130, 70–79. [Google Scholar] [CrossRef]

- Sadiq, F.A.; Yan, B.; Tian, F.; Zhao, J.; Zhang, H.; Chen, W. Lactic Acid Bacteria as Antifungal and Anti-Mycotoxigenic Agents: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1403–1436. [Google Scholar] [CrossRef]

- Śliżewska, K.; Cukrowska, B.; Smulikowska, S.; Cielecka-Kuszyk, J. The Effect of Probiotic Supplementation on Performance and the Histopathological Changes in Liver and Kidneys in Broiler Chickens Fed Diets with Aflatoxin B1. Toxins 2019, 11, 112. [Google Scholar] [CrossRef]

- Wochner, K.F.; Moreira, M.C.C.; Kalschne, D.L.; Colla, E.; Drunkler, D.A. Detoxification of Aflatoxin B1 and M1 by Lactobacillus acidophilus and prebiotics in whole cow’s milk. J. Food Saf. 2019, 39, e12670. [Google Scholar] [CrossRef]

- Mahmood Fashandi, H.; Abbasi, R.; Mousavi Khaneghah, A. The detoxification of aflatoxin M1 by Lactobacillus acidophilus and Bifidobacterium spp.: A review. J. Food Process. Preserv. 2018, 42, e13704. [Google Scholar] [CrossRef]

- Ahlberg, S.; Randolph, D.; Okoth, S.; Lindahl, J. Aflatoxin Binders in Foods for Human Consumption-Can This be Promoted Safely and Ethically? Toxins 2019, 11, 410. [Google Scholar] [CrossRef]

- Assaf, J.C.; Nahle, S.; Chokr, A.; Louka, N.; Atoui, A.; El Khoury, A. Assorted Methods for Decontamination of Aflatoxin M1 in Milk Using Microbial Adsorbents. Toxins 2019, 11, 304. [Google Scholar] [CrossRef] [PubMed]

- Azeem, N.; Nawaz, M.; Anjum, A.A.; Saeed, S.; Sana, S.; Mustafa, A.; Yousuf, M.R. Activity and Anti-Aflatoxigenic Effect of Indigenously Characterized Probiotic Lactobacilli against Aspergillus flavus-A Common Poultry Feed Contaminant. Animals 2019, 9, 166. [Google Scholar] [CrossRef] [PubMed]

- Ben Taheur, F.; Kouidhi, B.; Al Qurashi, Y.M.A.; Ben Salah-Abbès, J.; Chaieb, K. Review: Biotechnology of mycotoxins detoxification using microorganisms and enzymes. Toxicon 2019, 160, 12–22. [Google Scholar] [CrossRef]

- Chiocchetti, G.M.; Jadán-Piedra, C.; Monedero, V.; Zúñiga, M.; Vélez, D.; Devesa, V. Use of lactic acid bacteria and yeasts to reduce exposure to chemical food contaminants and toxicity. Crit. Rev. Food Sci. Nutr. 2019, 59, 1534–1545. [Google Scholar] [CrossRef]

- Elghandour, M.M.Y.; Tan, Z.L.; Abu Hafsa, S.H.; Adegbeye, M.J.; Greiner, R.; Ugbogu, E.A.; Cedillo Monroy, J.; Salem, A.Z.M. Saccharomyces cerevisiae as a probiotic feed additive to non and pseudo-ruminant feeding: A review. J. Appl. Microbiol. 2019, 28, 658–674. [Google Scholar] [CrossRef]

- Li, C.H.; Li, W.Y.; Hsu, I.N.; Liao, Y.Y.; Yang, C.Y.; Taylor, M.C.; Liu, Y.F.; Huang, W.H.; Chang, H.H.; Huang, H.L.; et al. Recombinant Aflatoxin-Degrading F420H2-Dependent Reductase from Mycobacterium smegmatis Protects Mammalian Cells from Aflatoxin Toxicity. Toxins 2019, 11, 259. [Google Scholar] [CrossRef]

- Saladino, F.; Luz, C.; Manyes, L.; Fernández-Franzón, M.; Meca, G. In vitro antifungal activity of lactic acid bacteria against mycotoxigenic fungi and their application in loaf bread shelf life improvement. Food Control 2016, 67, 273–277. [Google Scholar] [CrossRef]

- Assaf, J.C.; Atoui, A.; Khoury, A.E.; Chokr, A.; Louka, N. A comparative study of procedures for binding of aflatoxin M1 to Lactobacillus rhamnosus GG. Braz. J. Microbiol. 2018, 49, 120–127. [Google Scholar] [CrossRef] [PubMed]

- Sarlak, Z.; Rouhi, M.; Mohammadi, R.; Khaksar, R.; Mortazavian, A.M.; Sohrabvandi, S.; Garavand, F. Probiotic biological strategies to decontaminate aflatoxin M1 in a traditional Iranian fermented milk drink (Doogh). Food Control 2017, 71, 152–159. [Google Scholar] [CrossRef]

- Sevim, S.; Topal, G.G.; Tengilimoglu-Metin, M.M.; Sancak, B.; Kizil, M. Effects of inulin and lactic acid bacteria strains on aflatoxin M1 detoxification in yoghurt. Food Control 2019, 100, 235–239. [Google Scholar] [CrossRef]

- Barukčić, I.; Bilandžić, N.; Markov, K.; Jakopović, K.L.; Božanić, R. Reduction in aflatoxin M1 concentration during production and storage of selected fermented milks. Int. J. Dairy Technol. 2018, 71, 734–740. [Google Scholar] [CrossRef]

- Panwar, R.; Kumar, N.; Kashyap, V.; Ram, C.; Kapila, R. Aflatoxin M1 Detoxification Ability of Probiotic Lactobacilli of Indian Origin in In vitro Digestion Model. Probiotics Antimicrob. 2019, 11, 460–469. [Google Scholar] [CrossRef] [PubMed]

- Zeinvand-Lorestani, H.; Sabzevari, O.; Setayesh, N.; Amini, M.; Nili-Ahmadabadi, A.; Faramarzi, M.A. Comparative study of in vitro prooxidative properties and genotoxicity induced by aflatoxin B1 and its laccase-mediated detoxification products. Chemosphere 2015, 135, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Taheur, F.B.; Fedhila, K.; Chaieb, K.; Kouidhi, B.; Bakhrouf, A.; Abrunhosa, L. Adsorption of aflatoxin B1, zearalenone and ochratoxin A by microorganisms isolated from Kefir grains. Int. J. Food Microbiol. 2017, 251, 1–7. [Google Scholar] [CrossRef]

- Ma, Z.X.; Amaro, F.X.; Romero, J.J.; Pereira, O.G.; Jeong, K.C.; Adesogan, A.T. The capacity of silage inoculant bacteria to bind aflatoxin B1 in vitro and in artificially contaminated corn silage. J. Dairy Sci. 2017, 100, 7198–7210. [Google Scholar] [CrossRef]

- Raksha Rao, K.; Vipin, A.V.; Hariprasad, P.; Anu Appaiah, K.A.; Venkateswaran, G. Biological detoxification of Aflatoxin B1 by Bacillus licheniformis CFR1. Food Control 2017, 71, 234–241. [Google Scholar] [CrossRef]

- Sadeghi, A.R.; Ebrahimi, M.; Sadeghi, B. Effect of Isolated Lactobacillus acidophilus and Lactobacillus brevis on Growth of Aspergillus flavus and Reduction of Aflatoxin B1. RUMS J. 2016, 15, 3–16. [Google Scholar]

- Fernandez Juri, M.G.; Dalcero, A.M.; Magnoli, C.E. In vitro aflatoxin B1 binding capacity by two Enterococcus faecium strains isolated from healthy dog faeces. J. Appl. Microbiol. 2015, 118, 574–582. [Google Scholar] [CrossRef] [PubMed]

- Kumara, S.S.; Bashisht, A.; Venkateswaran, G.; Hariprasad, P.; Gayathri, D. Characterization of Novel Lactobacillus fermentum from Curd Samples of Indigenous Cows from Malnad Region, Karnataka, for their Aflatoxin B1 Binding and Probiotic Properties. Probiotics Antimicrob. 2019, 11, 1100–1109. [Google Scholar] [CrossRef] [PubMed]

- Wacoo, A.P.; Mukisa, I.M.; Meeme, R.; Byakika, S.; Wendiro, D.; Sybesma, W.; Kort, R. Probiotic Enrichment and Reduction of Aflatoxins in a Traditional African Maize-Based Fermented Food. Nutrients 2019, 11, 265. [Google Scholar] [CrossRef] [PubMed]

- Liew, W.P.; Nurul-Adilah, Z.; Than, L.T.L.; Mohd-Redzwan, S. The Binding Efficiency and Interaction of Lactobacillus casei Shirota Toward Aflatoxin B1. Front. Microbiol. 2018, 9, 1503. [Google Scholar] [CrossRef] [PubMed]

- Lahtinen, S.J.; Haskard, C.A.; Ouwehand, A.C.; Salminen, S.J.; Ahokas, J.T. Binding of aflatoxin B1 to cell wall components of Lactobacillus rhamnosus strain GG. Food Addit. Contam. 2004, 21, 158–164. [Google Scholar] [CrossRef] [PubMed]

- Hernandez-Mendoza, A.; Garcia, H.S.; Steele, J.L. Screening of Lactobacillus casei strains for their ability to bind aflatoxin B1. Food. Chem. Toxicol. 2009, 47, 1064–1068. [Google Scholar] [CrossRef] [PubMed]

- Yiannikouris, A.; André, G.; Poughon, L.; François, J.; Dussap, C.-G.; Jeminet, G.; Bertin, G.; Jouany, J.-P. Chemical and Conformational Study of the Interactions Involved in Mycotoxin Complexation with β-d-Glucans. Biomacromolecules 2006, 7, 1147–1155. [Google Scholar] [CrossRef]

- Rabie, M.; Abd El-Wahed, E.M.; Moustafa, M.G.; El-Zahar, K.; Abdel-Zaher, A.M. The Role of Probiotic Bacteria in Protecting against Aflatoxin M1 Contamination in Milk and Certain Dairy Products. J. Food Dairy Sci. 2019, 10, 93–99. [Google Scholar] [CrossRef]

- Martínez, M.P.; Magnoli, A.P.; González Pereyra, M.L.; Cavaglieri, L. Probiotic bacteria and yeasts adsorb aflatoxin M1 in milk and degrade it to less toxic AFM1-metabolites. Toxicon 2019, 172, 1–7. [Google Scholar] [CrossRef]

- Samuel, M.S.; Sivaramakrishna, A.; Mehta, A. Degradation and detoxification of aflatoxin B1 by Pseudomonas putida. Int. Biodeterior. Biodegrad. 2014, 86, 202–209. [Google Scholar] [CrossRef]

- Eshelli, M.; Harvey, L.; Edrada-Ebel, R.; McNeil, B. Metabolomics of the bio-degradation process of aflatoxin B1 by actinomycetes at an initial pH of 6.0. Toxins 2015, 7, 439–456. [Google Scholar] [CrossRef] [PubMed]

- Chlebicz, A.; Śliżewska, K. In Vitro Detoxification of Aflatoxin B1, Deoxynivalenol, Fumonisins, T-2 Toxin and Zearalenone by Probiotic Bacteria from Genus Lactobacillus and Saccharomyces cerevisiae Yeast. Probiotics Antimicrob. 2019. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Song, W.J.; Zhang, N.Y.; Tan, J.; Krumm, C.S.; Sun, L.H.; Qi, D.S. Biodetoxification of aflatoxin B1 in cottonseed meal by fermentation of Cellulosimicrobium funkei in duckling diet. Poult. Sci. 2016, 96, 923–930. [Google Scholar] [CrossRef] [PubMed]

- Hontanaya, C.; Meca, G.; Luciano, F.B.; Mañes, J.; Font, G. Inhibition of aflatoxin B1, B2, G1 and G2 production by Aspergillus parasiticus in nuts using yellow and oriental mustard flours. Food Control 2015, 47, 154–160. [Google Scholar] [CrossRef]

- Wang, J.; Ogata, M.; Hirai, H.; Kawagishi, H. Detoxification of aflatoxin B1 by manganese peroxidase from the white-rot fungus Phanerochaete sordida YK-624. FEMS Microbiol. Lett. 2011, 314, 164–169. [Google Scholar] [CrossRef] [PubMed]

- Taylor, M.C.; Jackson, C.J.; Tattersall, D.B.; French, N.; Peat, T.S.; Newman, J.; Briggs, L.J.; Lapalikar, G.V.; Campbell, P.M.; Scott, C.; et al. Identification and characterization of two families of F420H2-dependent reductases from Mycobacteria that catalyse aflatoxin degradation. Mol. Microbiol. 2010, 78, 561–575. [Google Scholar] [CrossRef]

- Das, A.; Bhattacharya, S.; Palaniswamy, M.; Angayarkanni, J. Aflatoxin B1 degradation during co-cultivation of Aspergillus flavus and Pleurotus ostreatus strains on rice straw. 3 Biotech. 2015, 5, 279–284. [Google Scholar] [CrossRef]

- Naseer, R.; Sultana, B.; Khan, M.Z.; Naseer, D.; Nigam, P. Utilization of waste fruit-peels to inhibit aflatoxins synthesis by Aspergillus flavus: A biotreatment of rice for safer storage. Bioresour. Technol. 2014, 172, 423–428. [Google Scholar] [CrossRef]

- Sultana, B.; Naseer, R.; Nigam, P. Utilization of agro-wastes to inhibit aflatoxins synthesis by Aspergillus parasiticus: A biotreatment of three cereals for safe long-term storage. Bioresour. Technol. 2015, 197, 443–450. [Google Scholar] [CrossRef]

- Cimmino, A.; Andolfi, A.; Troise, C.; Zonno, M.C.; Santini, A.; Tuzi, A.; Vurro, M.; Ash, G.; Evidente, A. Phomentrioloxin: A Novel Phytotoxic Pentasubstituted Geranylcyclohexentriol Produced by Phomopsis sp., a Potential Mycoherbicide for Carthamus lanathus Biocontrol. J. Nat. Prod. 2012, 75, 1130–1137. [Google Scholar] [CrossRef]

| Aflatoxin Type | Food/Feed Type | Area of Origin | Sample Size | Mean and/or Median Levels | Range Levels | Analysis Method | Reference |

|---|---|---|---|---|---|---|---|

| AFB1 | Black tea | Pakistan | +76% | 0.11 and 16.17 μg·kg−1 | 0.08–8.24 μg·kg−1 | HPLC | [105] |

| AFB1 | Chinese condiment (Doubanjiang) | China | +34% | 4.78 ± 0.16 μg·kg−1 | 1.26–16.41 μg·kg−1 | ELISA | [106] |

| AFB1 | Peanuts | Zambia | +44% | 0.45 μg·kg−1 | 0.015–46.60 μg·kg−1 | HPLC | [107] |

| AFB1 | Spices | Italy | +15% | 0.30 μg·kg−1 | 0.59–5.38 μg·kg−1 | HPLC | [108] |

| AFB1 | Maize flour | Turkey | +66% | 0.20 μg·kg−1 | 0.041–1.12 μg·kg−1 | HPLC | [109] |

| AFB1 | Maize | Serbia | +57% | 11.4 ± 14.5 μg·kg−1 | 1.3–88.8 μg·kg−1 | HPLC | [110] |

| AFM1 | Milk | Portugal | +27% | 23.4 ± 24.0 ng·L−1 | 0.005–0.069 μg·kg−1 | ELISA | [111] |

| AFM1 | Milk | Indonesia | +95% | 216 ng·L−1 | 24–570 ng·L−1 | ELISA | [112] |

| AFM1 | Milk | China | +80% | 23.7 ng·L−1 | 5.1–104.4 ng·L−1 | ELISA and LC-MS/MS | [113] |

| AFM1 | Milk | Lebanon | +58% | 0.035 µg·L−1 | 0.011–0.440 μg·kg−1 | HPLC | [114] |

| AFM1 | Infant formulae | Mexico | +20% | 40 ± 99 ng·L−1 | 40–450 ng·L−1 | HPLC | [115] |

| AFB1, AFB2, AFG1, and AFG2 | Household maize | Kenya | +100% | 62.5 μg·kg−1 | 2.14–411 μg·kg−1 | UHPLC | [116] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazhand, A.; Durazzo, A.; Lucarini, M.; Souto, E.B.; Santini, A. Characteristics, Occurrence, Detection and Detoxification of Aflatoxins in Foods and Feeds. Foods 2020, 9, 644. https://doi.org/10.3390/foods9050644

Nazhand A, Durazzo A, Lucarini M, Souto EB, Santini A. Characteristics, Occurrence, Detection and Detoxification of Aflatoxins in Foods and Feeds. Foods. 2020; 9(5):644. https://doi.org/10.3390/foods9050644

Chicago/Turabian StyleNazhand, Amirhossein, Alessandra Durazzo, Massimo Lucarini, Eliana B. Souto, and Antonello Santini. 2020. "Characteristics, Occurrence, Detection and Detoxification of Aflatoxins in Foods and Feeds" Foods 9, no. 5: 644. https://doi.org/10.3390/foods9050644

APA StyleNazhand, A., Durazzo, A., Lucarini, M., Souto, E. B., & Santini, A. (2020). Characteristics, Occurrence, Detection and Detoxification of Aflatoxins in Foods and Feeds. Foods, 9(5), 644. https://doi.org/10.3390/foods9050644