Applicability of Pulsed Electric Field (PEF) Pre-Treatment for a Convective Two-Step Drying Process

Abstract

1. Introduction

2. Material and Methods

2.1. Onion Samples

2.2. Pulsed Electric Fields (PEF) Treatment

2.3. Convective Drying Process

2.4. Analysis of Quality Parameters

2.4.1. Diffusion Coefficient

2.4.2. Colour and Blisters

2.4.3. Shrinkage

2.4.4. Pyruvic Acid

2.4.5. Rehydration

2.5. Statistics

3. Results and Discussion

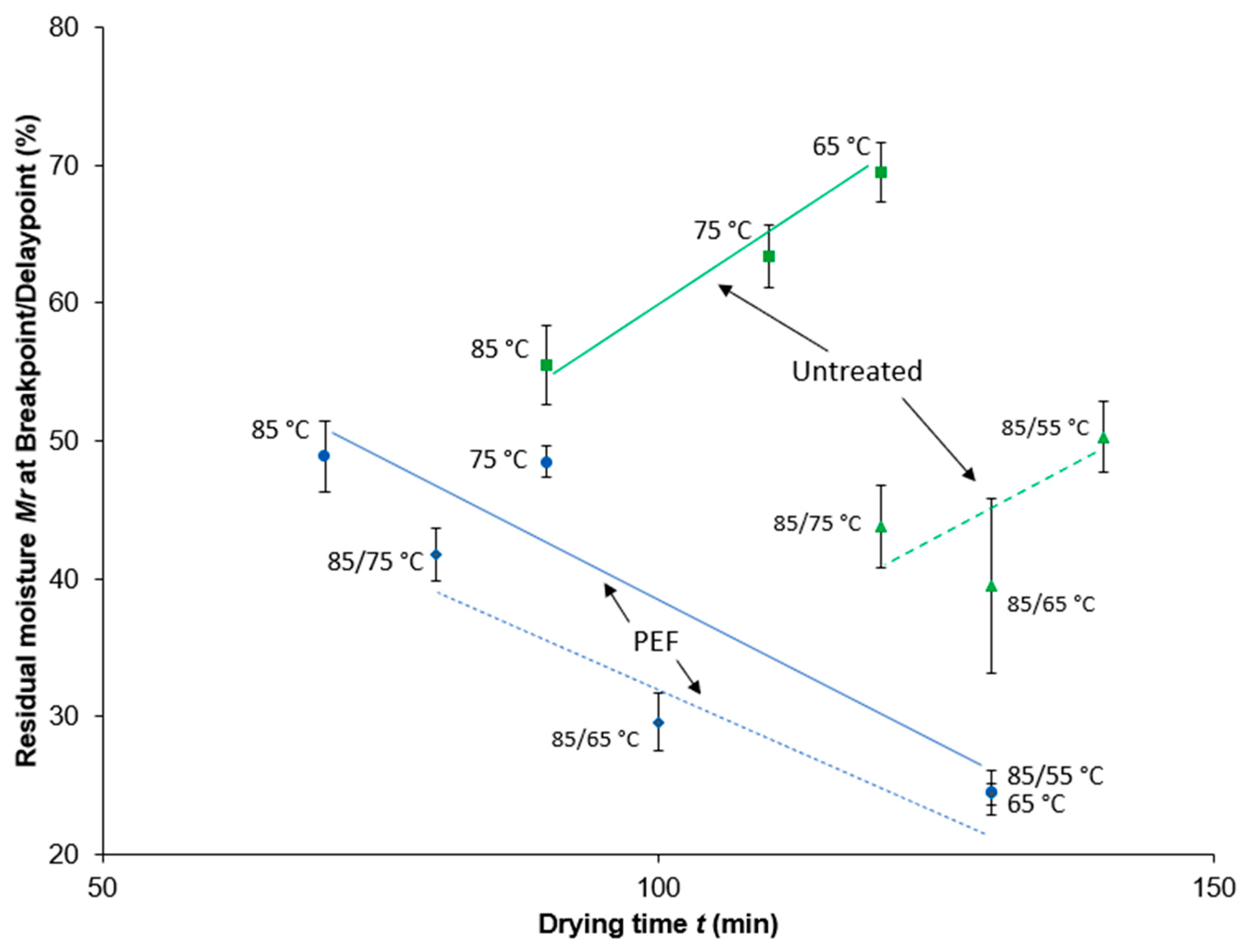

3.1. Constant Drying Temperature and Breakpoint (BP) Determination

3.2. Drying Profile and Delaypoint Determination

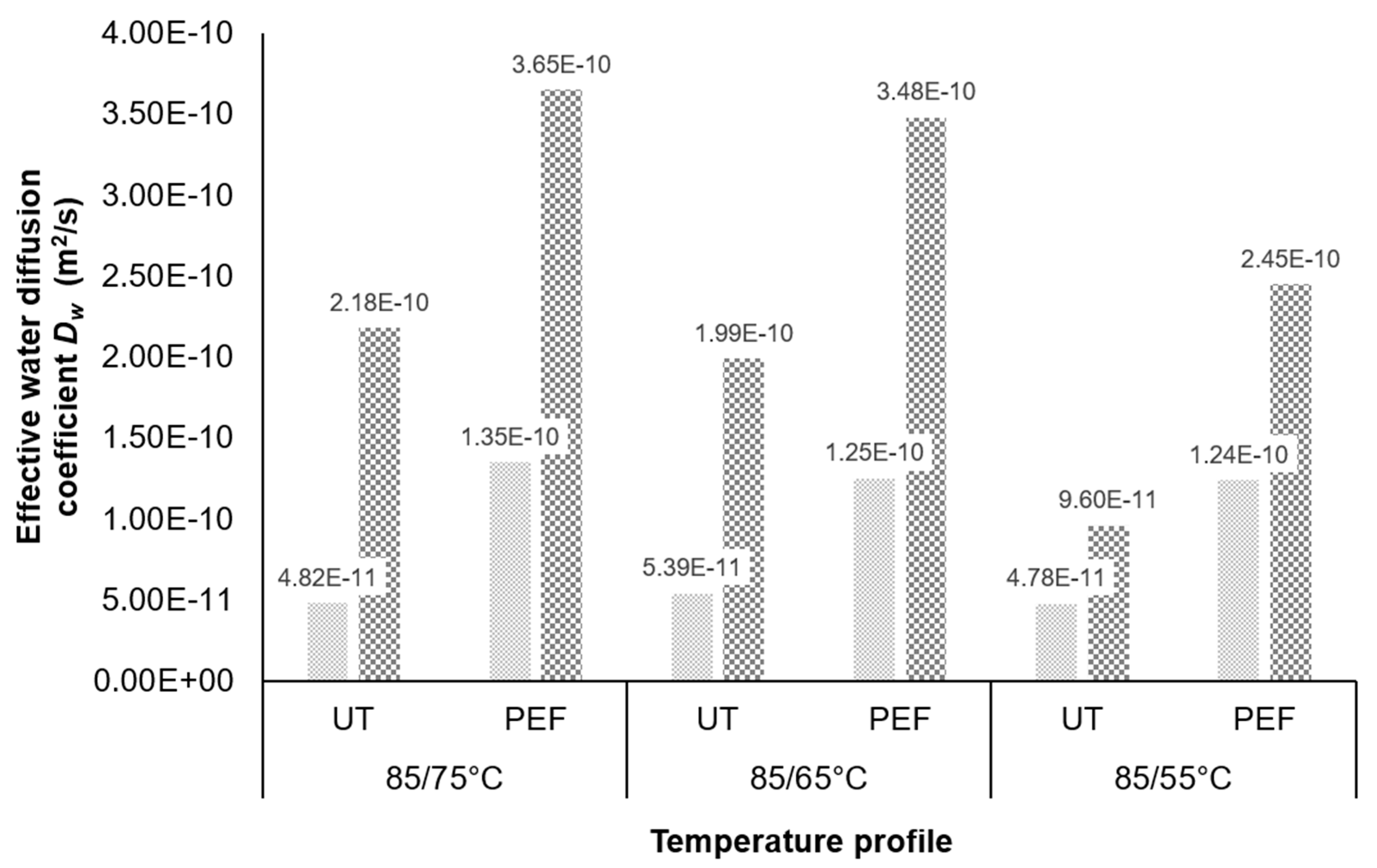

3.3. Diffusion Coefficient

3.4. Quality Analysis

3.4.1. Colour

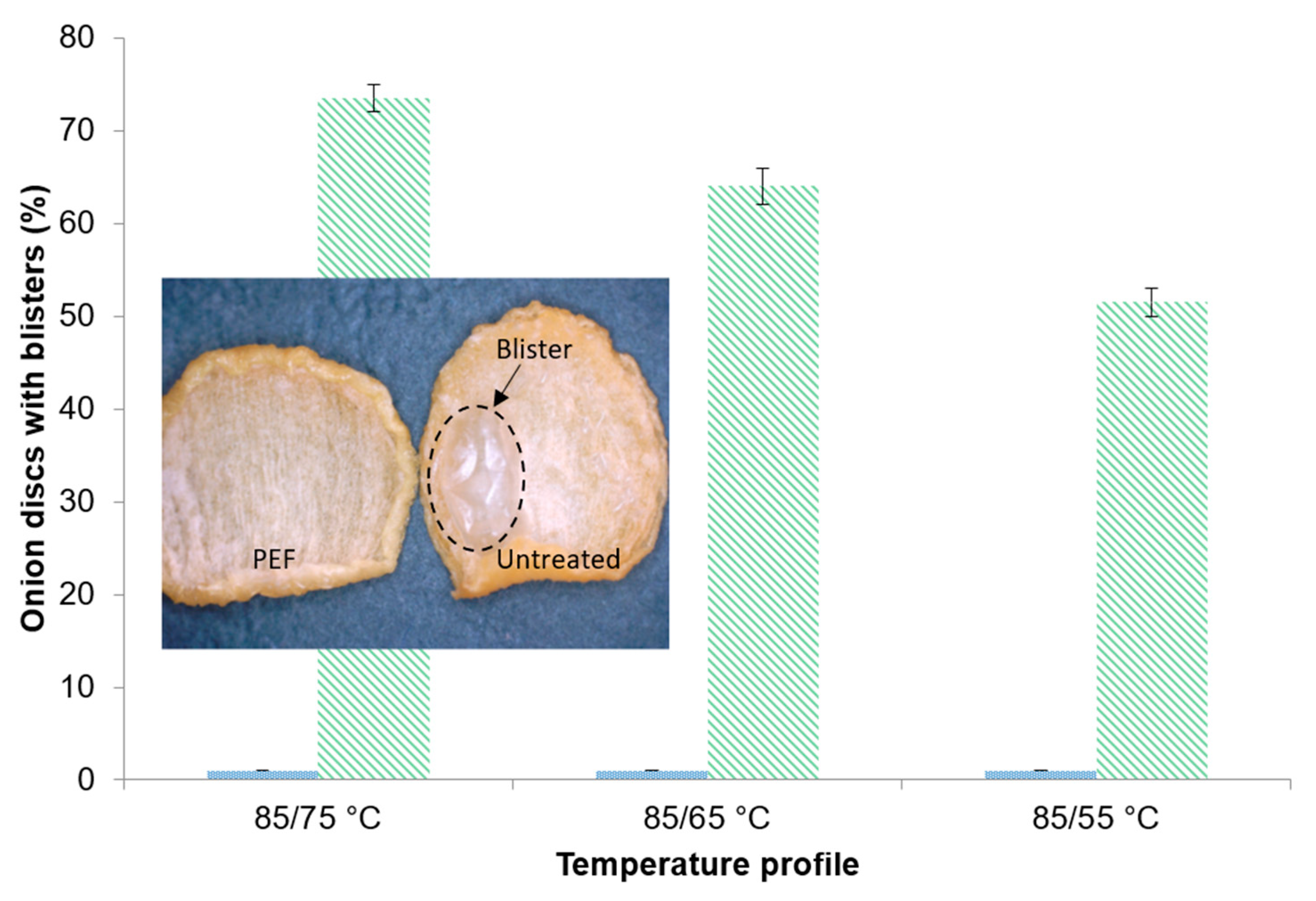

3.4.2. Blisters

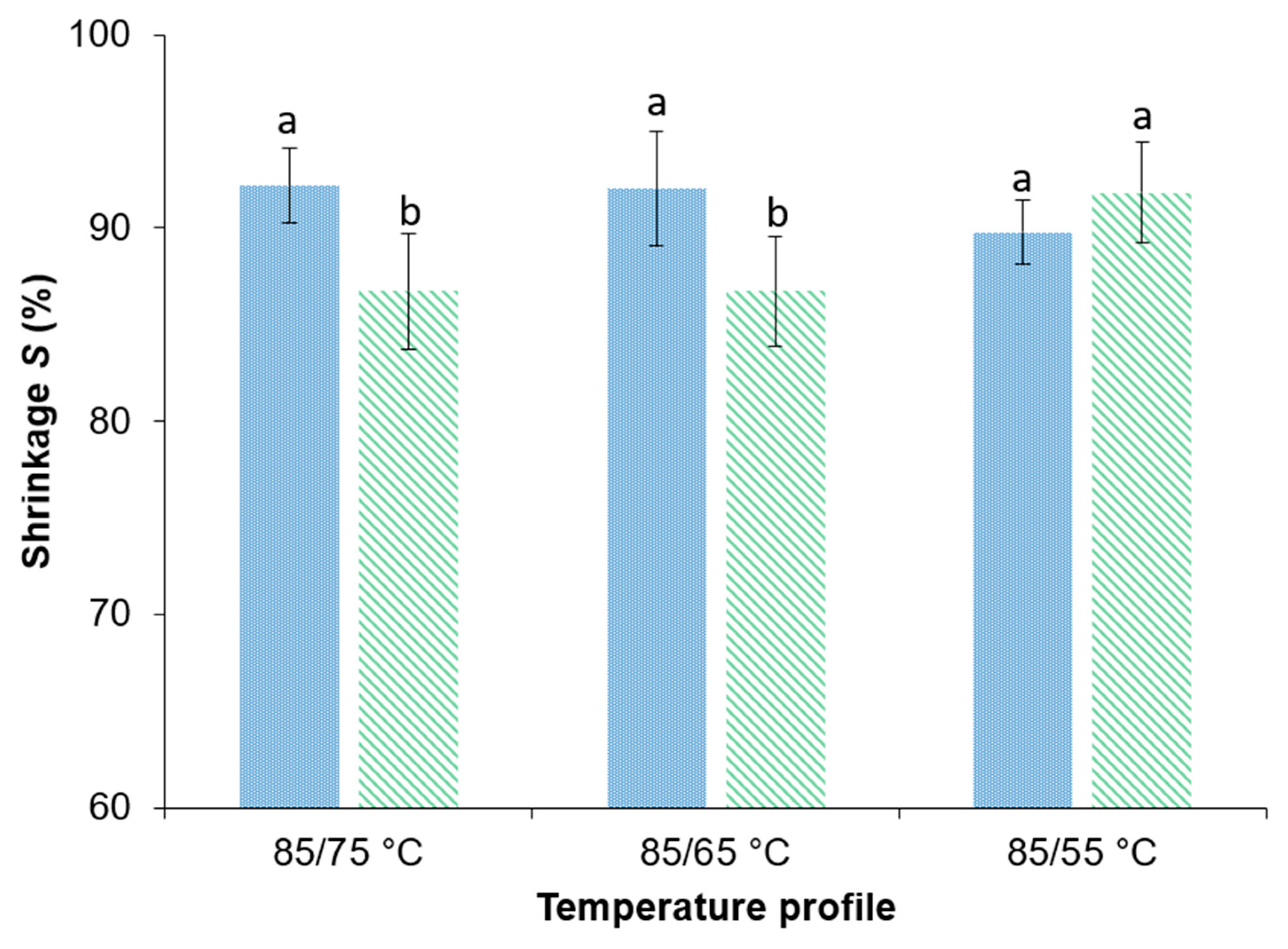

3.4.3. Shrinkage

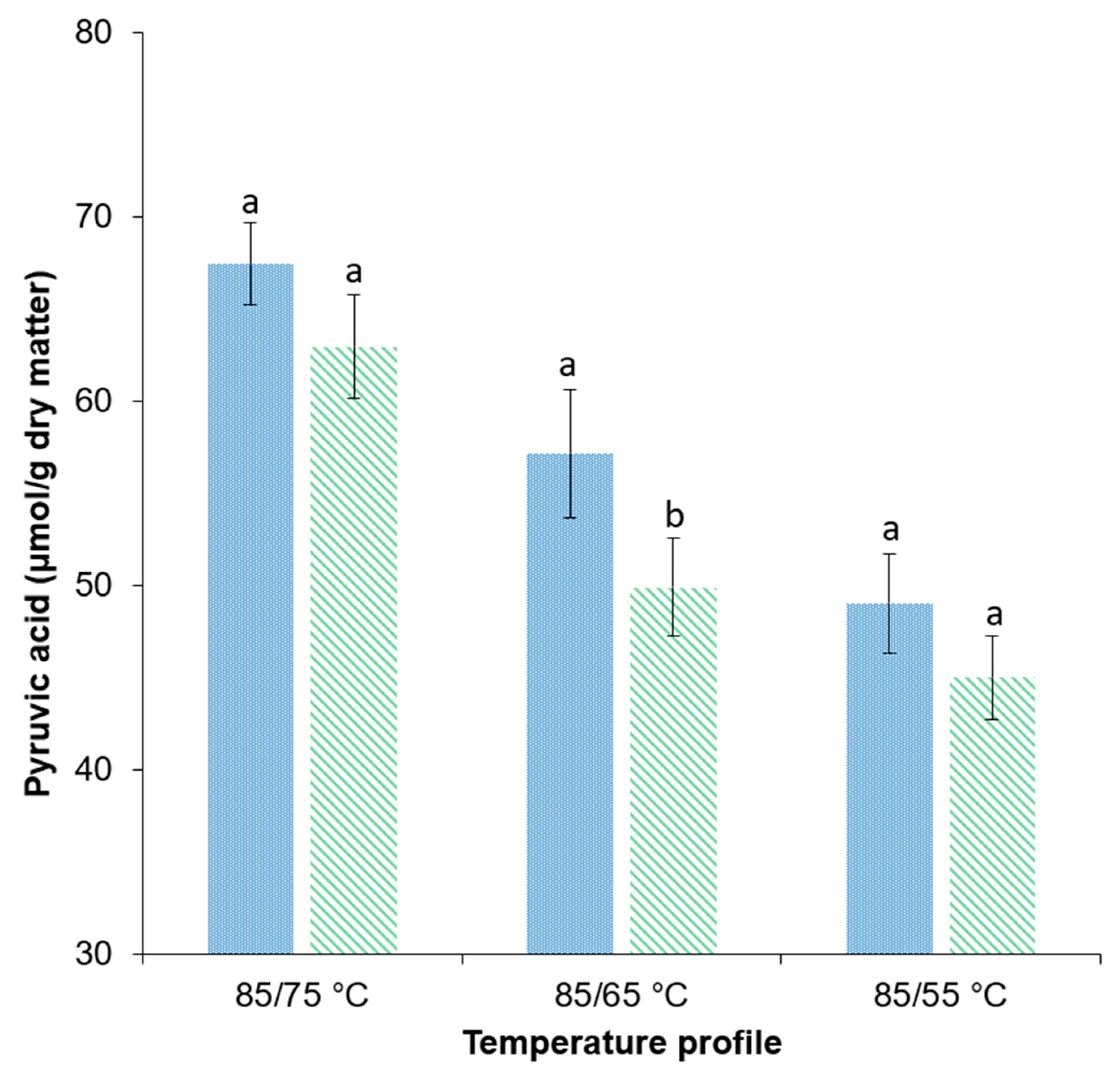

3.4.4. Pyruvic Acid

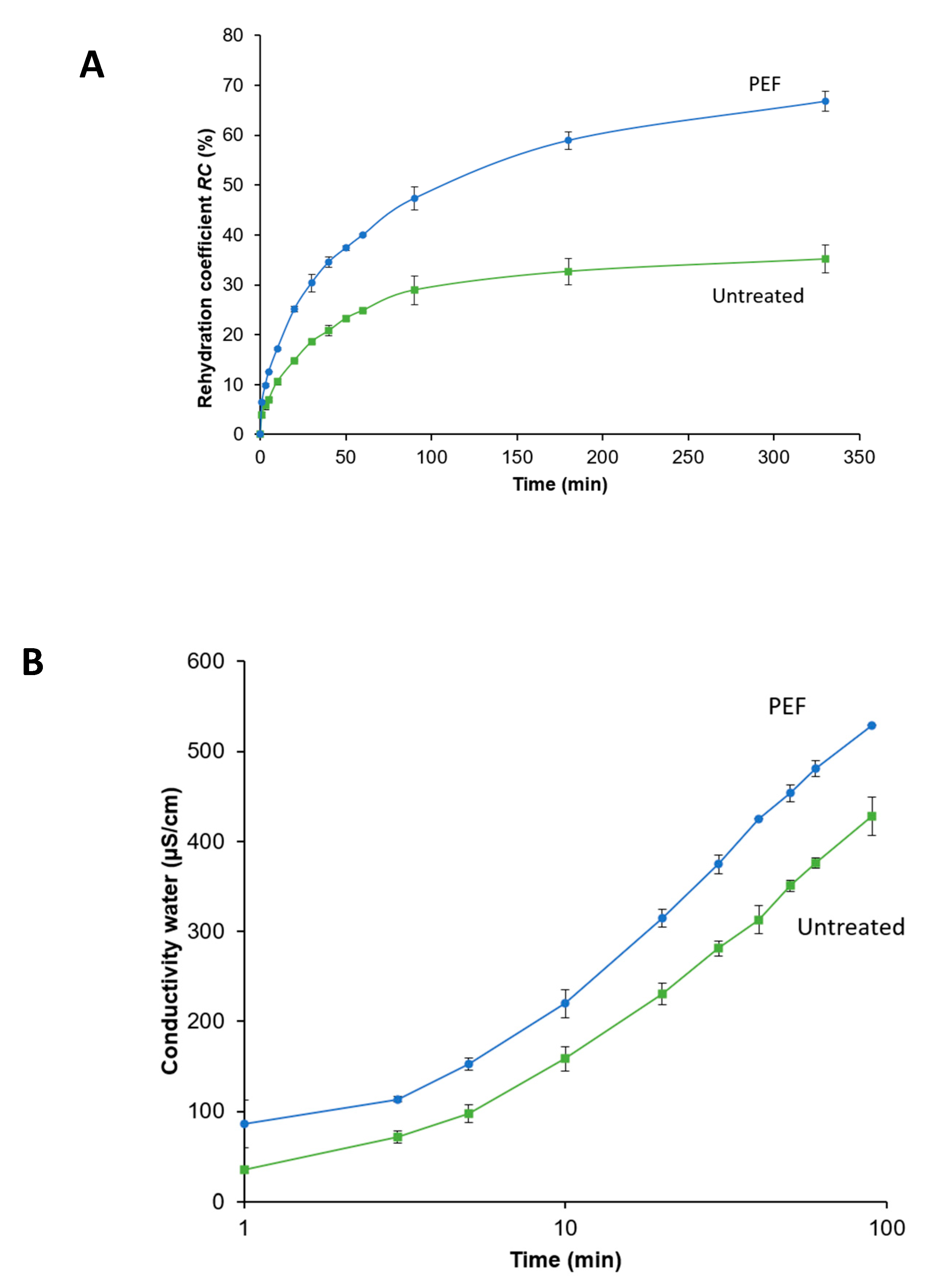

3.4.5. Rehydration

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Naderinezhad, S.; Etesami, N.; Najafabady, A.P.; Falavarjani, M.G. Mathematical modeling of drying of potato slices in a forced convective dryer based on important parameters. Food Sci. Nutr. 2016, 4, 110–118. [Google Scholar] [CrossRef]

- Jain, D.; Pathare, P.B. Selection and evaluation of thin layer drying models for infrared radiative and convective drying of onion slices. Biosyst. Eng. 2004. [Google Scholar] [CrossRef]

- Schuchmann, H.P.; Schuchmann, H. Lebensmittelverfahrenstechnik: Rohstoffe, Prozesse, Produkte; WILEYVCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005. [Google Scholar]

- Toepfl, S.; Knorr, D. Pulsed electric fields as a pretreatment technique in drying processes. Stewart Postharvest Rev. 2006. [Google Scholar] [CrossRef]

- Chou, S.K.; Chua, K.J. New hybrid drying technologies for heat sensitive foodstuffs. Trends Food Sci. Technol. 2001. [Google Scholar] [CrossRef]

- Singh, R.P. Energy in Food Processing; Elsevier Science Pub. Co. Inc.: New York, NY, USA, 1986. [Google Scholar]

- Liu, C.; Pirozzi, A.; Ferrari, G.; Vorobiev, E.; Grimi, N. Effects of pulsed electric fields on vacuum drying and quality characteristics of dried carrot. Food Bioprocess Technol. 2020, 13, 45–52. [Google Scholar] [CrossRef]

- Sagar, V.R.; Suresh Kumar, P. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef]

- Somogy, L.; Luh, B. Commercial Fruit Processing; Woodroof, J., Ed.; Springer: Dordrecht, The Netherlands, 1986. [Google Scholar]

- Heindl, A. Praxisbuch Bandtrocknung; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 3-642-53905-X. [Google Scholar]

- del Valle, J.M.; Aranguiz, V.; Leon, H. Effects of blanching and calcium infiltration on PPO activity, texture, microstructure and kinetics of osmotic dehydration of apple tissue. Food Res. Int. 1998, 31, 557–569. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Rodrigues, S.; Law, C.L.; Mujumdar, A.S. Drying of exotic tropical fruits: A comprehensive review. Food Bioprocess Technol. 2011. [Google Scholar] [CrossRef]

- Colina-Coca, C.; de Ancos, B.; Sánchez-Moreno, C. Nutritional composition of processed onion: S-Alk(en)yl-l-cysteine sulfoxides, organic acids, sugars, minerals, and vitamin C. Food Bioprocess Technol. 2014. [Google Scholar] [CrossRef]

- Benítez, V.; Mollá, E.; Martín-Cabrejas, M.A.; Aguilera, Y.; López-Andréu, F.J.; Terry, L.A.; Esteban, R.M. The impact of pasteurisation and sterilisation on bioactive compounds of onion by-products. Food Bioprocess Technol. 2013. [Google Scholar] [CrossRef]

- Grewal, M.K.; Jha, S.N.; Patil, R.T.; Dhatt, A.S.; Kaur, A.; Jaiswal, P. A less energy intensive process for dehydrating onion. J. Food Sci. Technol. 2015, 52, 1131–1137. [Google Scholar] [CrossRef] [PubMed]

- Mujumdar, A.S.; Law, C.L. Drying technology: Trends and applications in postharvest processing. Food Bioprocess Technol. 2010. [Google Scholar] [CrossRef]

- Ostermeier, R.; Giersemehl, P.; Siemer, C.; Töpfl, S.; Jäger, H. Influence of pulsed electric field (PEF) pre-treatment on the convective drying kinetics of onions. J. Food Eng. 2018, 237, 110–117. [Google Scholar] [CrossRef]

- Ade-Omowaye, B.I.O.; Taiwo, K.A.; Eshtiaghi, N.M.; Angersbach, A.; Knorr, D. Comparative evaluation of the effects of pulsed electric field and freezing on cell membrane permeabilisation and mass transfer during dehydration of red bell peppers. Innov. Food Sci. Emerg. Technol. 2003, 4, 177–188. [Google Scholar] [CrossRef]

- Ade-Omowaye, B.I.O.; Angersbach, A.; Taiwo, K.A.; Knorr, D. Use of pulsed electric field pre-treatment to improve dehydration characteristics of plant based foods. Trends Food Sci. Technol. 2001, 12, 285–295. [Google Scholar] [CrossRef]

- Alam, M.D.R.; Lyng, J.G.; Frontuto, D.; Marra, F.; Cinquanta, L. Effect of pulsed electric field pretreatment on drying kinetics, color, and texture of parsnip and carrot. J. Food Sci. 2018, 83, 2159–2166. [Google Scholar] [CrossRef]

- Angersbach, A.; Knorr, D. Anwendung elektrischer hochspannungsimpulse als vorbehandlungsverfahren zur beeinflussung der trocknungscharakteristika und rehydratationseigenschaften von kartoffelwürfeln. Food/Nahrung 1997, 41, 194–200. [Google Scholar] [CrossRef]

- Abenoza, M.; Benito, M.; Saldaña, G.; Álvarez, I.; Raso, J.; Sánchez-Gimeno, A.C. Effects of pulsed electric field on yield extraction and quality of olive oil. Food Bioprocess Technol. 2013, 6, 1367–1373. [Google Scholar] [CrossRef]

- Liu, Z.; Esveld, E.; Vincken, J.P.; Bruins, M.E. Pulsed electric field as an alternative pre-treatment for drying to enhance polyphenol extraction from fresh tea leaves. Food Bioprocess Technol. 2019, 12, 183–192. [Google Scholar] [CrossRef]

- Adedeji, A.A.; Gachovska, T.K.; Ngadi, M.O.; Raghavan, G.S.V. Effect of pretreatments on drying characteristics of okra. Dry. Technol. 2008, 26, 1251–1256. [Google Scholar] [CrossRef]

- Amami, E.; Khezami, L.; Vorobiev, E.; Kechaou, N. Effect of pulsed electric field and osmotic dehydration pretreatment on the convective drying of carrot tissue. Dry. Technol. 2008. [Google Scholar] [CrossRef]

- Arevalo, P.; Ngadi, M.O.; Bazhal, M.I.; Raghavan, G.S.V. Impact of pulsed electric fields on the dehydration and physical properties of apple and potato slices. Dry. Technol. 2004. [Google Scholar] [CrossRef]

- Gachovska, T.K.; Adedeji, A.A.; Ngadi, M.; Raghavan, G.V.S. Drying characteristics of pulsed electric field-treated carrot. Dry. Technol. 2008, 26, 1244–1250. [Google Scholar] [CrossRef]

- Wiktor, A.; Iwaniuk, M.; Śledź, M.; Nowacka, M.; Chudoba, T.; Witrowa-Rajchert, D. Drying kinetics of apple tissue treated by pulsed electric field. Dry. Technol. 2013. [Google Scholar] [CrossRef]

- Wiktor, A.; Nowacka, M.; Dadan, M.; Rybak, K.; Lojkowski, W.; Chudoba, T.; Witrowa-Rajchert, D. The effect of pulsed electric field on drying kinetics, color, and microstructure of carrot. Dry. Technol. 2016, 34, 1286–1296. [Google Scholar] [CrossRef]

- Shynkaryk, M.V.; Lebovka, N.I.; Vorobiev, E. Pulsed electric fields and temperature effects on drying and rehydration of red beetroots. Dry. Technol. 2008. [Google Scholar] [CrossRef]

- Töpfl, S. Pulsed Electric Fields (PEF) for Permeabilization of Cell Membranes in Food- and Bioprocessing. Applications, Process and Equipment Design and Cost Analysis. Ph.D. Thesis, Technical University of Berlin, Berlin, Germany, 2006. [Google Scholar] [CrossRef]

- Ersus, S.; Barrett, D.M. Determination of membrane integrity in onion tissues treated by pulsed electric fields: Use of microscopic images and ion leakage measurements. Innov. Food Sci. Emerg. Technol. 2010. [Google Scholar] [CrossRef]

- Liu, T.; Burritt, D.J.; Oey, I. Understanding the effect of Pulsed Electric Fields on multilayered solid plant foods: Bunching onions (Allium fistulosum) as a model system. Food Res. Int. 2019. [Google Scholar] [CrossRef]

- Gehrmann, D.; Esper, G.; Schuchmann, H. (Eds.) Trocknungstechnik in der Lebensmittelindustrie; B. Behr’s Verlag GmbH & Co. KG.: Hamburg, Germany, 2009. [Google Scholar]

- Crank, J. The Mathematics of Diffusion; Clarendon Press: Oxford, UK, 1975. [Google Scholar]

- Rastogi, N.K.; Raghavarao, K.; Niranjan, K.; Knorr, D. Recent developments in osmotic dehydration: Methods to enhance mass transfer. Trends Food Sci. Technol. 2002, 13, 48–59. [Google Scholar] [CrossRef]

- Bal, L.M.; Kar, A.; Satya, S.; Naik, S.N. Kinetics of colour change of bamboo shoot slices during microwave drying. Int. J. Food Sci. Technol. 2011. [Google Scholar] [CrossRef]

- Khalloufi, S.; Ratti, C. Quality deterioration of freeze-dried foods as explained by their glass transition temperature and internal structure. J. Food Sci. 2006. [Google Scholar] [CrossRef]

- Schwimmer, S.; Weston, W.J. Onion flavor and odor enzymatic development of pyruvic acid in onion as a measure of pungency. J. Agric. Food Chem. 1961. [Google Scholar] [CrossRef]

- Anthon, G.E.; Barrett, D.M. Modified method for the determination of pyruvic acid with dinitrophenylhydrazine in the assessment of onion pungency. J. Sci. Food Agric. 2003. [Google Scholar] [CrossRef]

- Abayomi, L.A.; Terry, L.A. Implications of spatial and temporal changes in concentration of pyruvate and glucose in onion (Allium cepa L.) bulbs during controlled atmosphere storage. J. Sci. Food Agric. 2009, 89, 683–687. [Google Scholar] [CrossRef]

- Meda, L.; Ratti, C. Rehydration of freeze-dried strawberries at varying temperatures. J. Food Process Eng. 2005. [Google Scholar] [CrossRef]

- Eshtiaghi, M.N.; Knorr, D. High electric field pulse pretreatment: Potential for sugar beet processing. J. Food Eng. 2002. [Google Scholar] [CrossRef]

- Jemai, A.B.; Vorobiev, E. Enhanced leaching from sugar beet cossettes by pulsed electric field. J. Food Eng. 2003. [Google Scholar] [CrossRef]

- Revaskar, V.A.; Pisalkar, P.S.; Pathare, P.B.; Sharma, G.P. Dehydration kinetics of onion slices in osmotic and air convective drying process. Res. Agric. Eng. 2014. [Google Scholar] [CrossRef]

- Mota, C.L.; Luciano, C.; Dias, A.; Barroca, M.J.; Guiné, R.P.F. Convective drying of onion: Kinetics and nutritional evaluation. Food Bioprod. Process. 2010. [Google Scholar] [CrossRef]

- Bourdoux, S.; Li, D.; Rajkovic, A.; Devlieghere, F.; Uyttendaele, M. Performance of drying technologies to ensure microbial safety of dried fruits and vegetables. Compr. Rev. Food Sci. Food Saf. 2016, 15, 1056–1066. [Google Scholar] [CrossRef]

- Rastogi, N.K.; Eshtiaghi, M.N.; Knorr, D. Accelerated mass transfer during osmotic dehydration of high intensity electrical field pulse pretreated carrots. J. Food Sci. 1999, 64, 1020–1023. [Google Scholar] [CrossRef]

- Heindl, A.; Müller, J. Konservierung von arznei- und gewürzpflanzen—Technische trocknung. In Handbuch des Arznei- und Gewürzpflanzenbaus; Hoppe, B., Ed.; Verein für Arznei- und Gewürzpflanzen Saluplanta e.V.: Bernburg, Germany, 2010. [Google Scholar]

- Toepfl, S.; Siemer, C.; Heinz, V. Chapter 8—Effect of high-intensity electric field pulses on solid foods. In Emerging Technologies for Food Processing; Academic Press: Cambridge, MA, USA, 2014; ISBN 9780124114791. [Google Scholar]

- Zimmermann, U.; Pilwat, G.; Riemann, F. Dielectric breakdown of cell membranes. Biophys. J. 1974, 14, 881–899. [Google Scholar] [CrossRef]

- Ayadi, M.; Mabrouk, S.B.; Zouari, I.; Bellagi, A. Kinetic study of the convective drying of spearmint. J. Saudi Soc. Agric. Sci. 2014. [Google Scholar] [CrossRef]

- Parniakov, O.; Bals, O.; Lebovka, N.; Vorobiev, E. Effects of pulsed electric fields assisted osmotic dehydration on freezing-thawing and texture of apple tissue. J. Food Eng. 2016. [Google Scholar] [CrossRef]

- Mitra, J.; Shrivastava, S.L.; Rao, P.S. Onion dehydration: A review. J. Food Sci. Technol. 2012. [Google Scholar] [CrossRef]

- Lewicki, P.P.; Witrowa-Rajchert, D.; Nowak, D. Effect of drying mode on drying kinetics of onion. Dry. Technol. 1998, 16, 59–81. [Google Scholar] [CrossRef]

- Lewicki, P.P.; Witrowa-Rajchert, D.; Pomaranska-Lazuka, W.; Nowak, D. Rehydration properties of dried onion. Int. J. Food Prop. 1998. [Google Scholar] [CrossRef]

- Tiwari, B.K.; Patras, A.; Brunton, N.; Cullen, P.J.; O’Donnell, C.P. Effect of ultrasound processing on anthocyanins and color of red grape juice. Ultrason. Sonochem. 2010. [Google Scholar] [CrossRef]

- Glomb, M.A. Moderne Lebensmittelchemie; Fischer, M., Glomb, M., Eds.; Behr’s Verlag: Hamburg, Germany, 2015. [Google Scholar]

- Ebermann, R.; Elmadfa, I. Lehrbuch Lebensmittelchemie und Ernährung; Springer-Verlag Wien: Wien, Austria, 2014; ISBN 9780874216561. [Google Scholar]

- Jaeger, H.; Janositz, A.; Knorr, D. The Maillard reaction and its control during food processing. The potential of emerging technologies. Pathol. Biol. (Paris) 2010. [Google Scholar] [CrossRef]

- Arnoldi, A. Thermal processing and food quality. In Thermal Technologies in Food Processing; Richardson, P., Ed.; Woodhead Publishing Limited: Sawston, UK, 2001. [Google Scholar]

- Parniakov, O.; Barba, F.J.; Grimi, N.; Lebovka, N.; Vorobiev, E. Impact of pulsed electric fields and high voltage electrical discharges on extraction of high-added value compounds from papaya peels. Food Res. Int. 2014. [Google Scholar] [CrossRef]

- Faridnia, F.; Burritt, D.J.; Bremer, P.J.; Oey, I. Innovative approach to determine the effect of pulsed electric fields on the microstructure of whole potato tubers: Use of cell viability, microscopic images and ionic leakage measurements. Food Res. Int. 2015, 77, 556–564. [Google Scholar] [CrossRef]

- Aguilar, C.N.; Anzaldúa-Morales, A.; Talamás, R.; Gastélum, G. Low-temperature blanch improves textural quality of french-fries. J. Food Sci. 1997, 62, 568–571. [Google Scholar] [CrossRef]

- Aguiló-Aguayo, I.; Hossain, M.B.; Brunton, N.; Lyng, J.; Valverde, J.; Rai, D.K. Pulsed electric fields pre-treatment of carrot purees to enhance their polyacetylene and sugar contents. Innov. Food Sci. Emerg. Technol. 2014, 23, 79–86. [Google Scholar] [CrossRef]

- Krokida, M.K.; Maroulis, Z.B. Kinetics on color changes during drying of some fruits and vegetables. Dry. Technol. 1998. [Google Scholar] [CrossRef]

- Adam, E.; Mühlbauer, W.; Esper, A.; Wolf, W.; Spiess, W. Quality changes of onion (Allium cepa L.) as affected by the drying process. Nahrung 2000, 44, 32–37. [Google Scholar] [CrossRef]

- Parniakov, O.; Bals, O.; Lebovka, N.; Vorobiev, E. Pulsed electric field assisted vacuum freeze-drying of apple tissue. Innov. Food Sci. Emerg. Technol. 2016. [Google Scholar] [CrossRef]

- Sahoo, N.R.; Bal, L.M.; Pal, U.S.; Sahoo, D. Impact of pretreatment and drying methods on quality attributes of onion shreds. Food Technol. Biotechnol. 2015. [Google Scholar] [CrossRef]

- Luengo, E.; Álvarez, I.; Raso, J. Improving the pressing extraction of polyphenols of orange peel by pulsed electric fields. Innov. Food Sci. Emerg. Technol. 2013. [Google Scholar] [CrossRef]

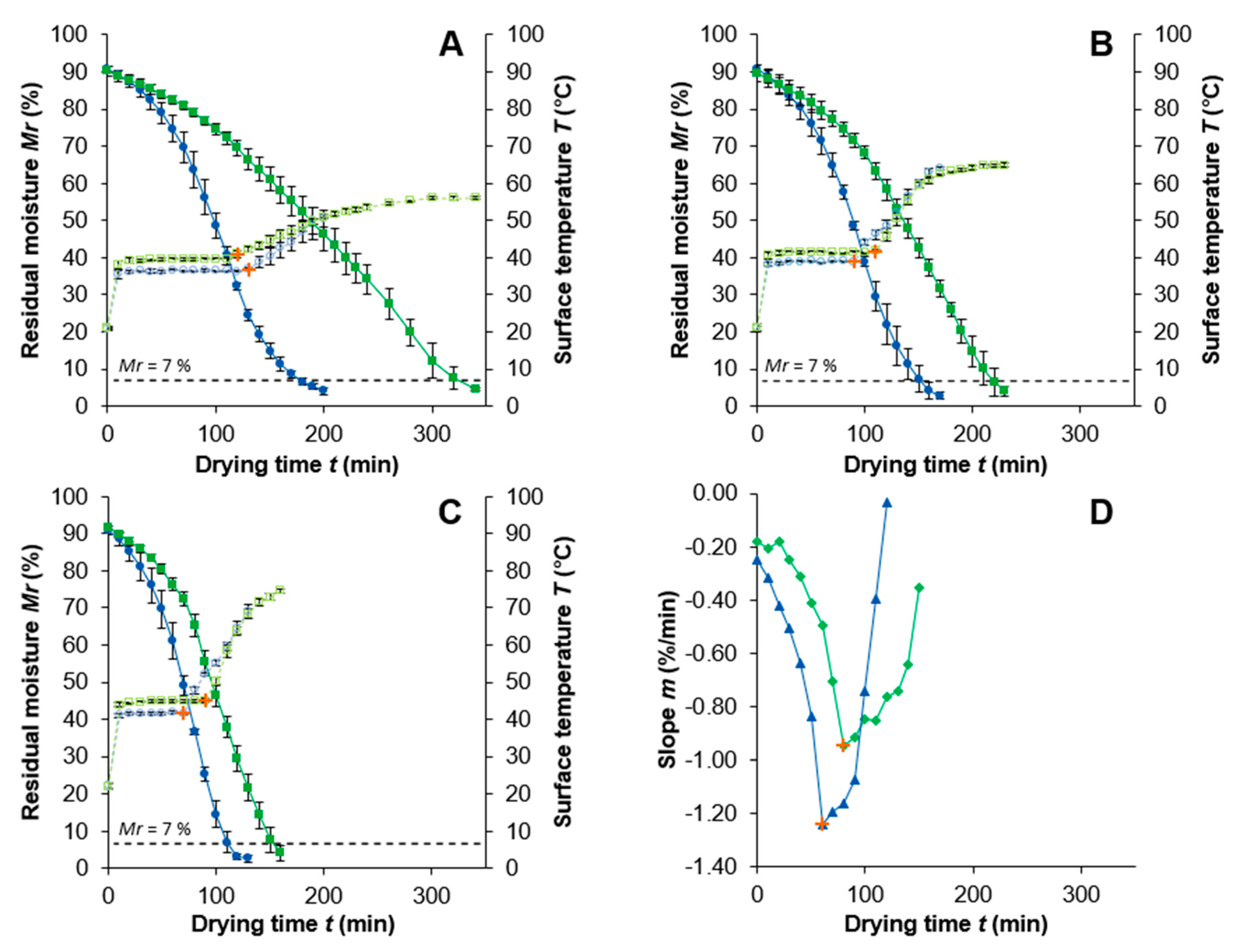

Pulsed Electric Field (PEF);

Pulsed Electric Field (PEF);  Untreated) and residual moisture Mr (%) (

Untreated) and residual moisture Mr (%) ( PEF;

PEF;  Untreated) for the drying time t (min) of onion samples dried at different constant drying temperatures (A: 65 °C; B: 75 °C; C: 85 °C). The PEF treatment was W = 4 kJ/kg, E = 1.07 kV/cm. (D): Slope m (%/min) of the residual moisture curves for the drying time t (min) dried at 85 °C (

Untreated) for the drying time t (min) of onion samples dried at different constant drying temperatures (A: 65 °C; B: 75 °C; C: 85 °C). The PEF treatment was W = 4 kJ/kg, E = 1.07 kV/cm. (D): Slope m (%/min) of the residual moisture curves for the drying time t (min) dried at 85 °C ( PEF;

PEF;  Untreated).

Untreated).  represents the breakpoint (BP).

represents the breakpoint (BP).

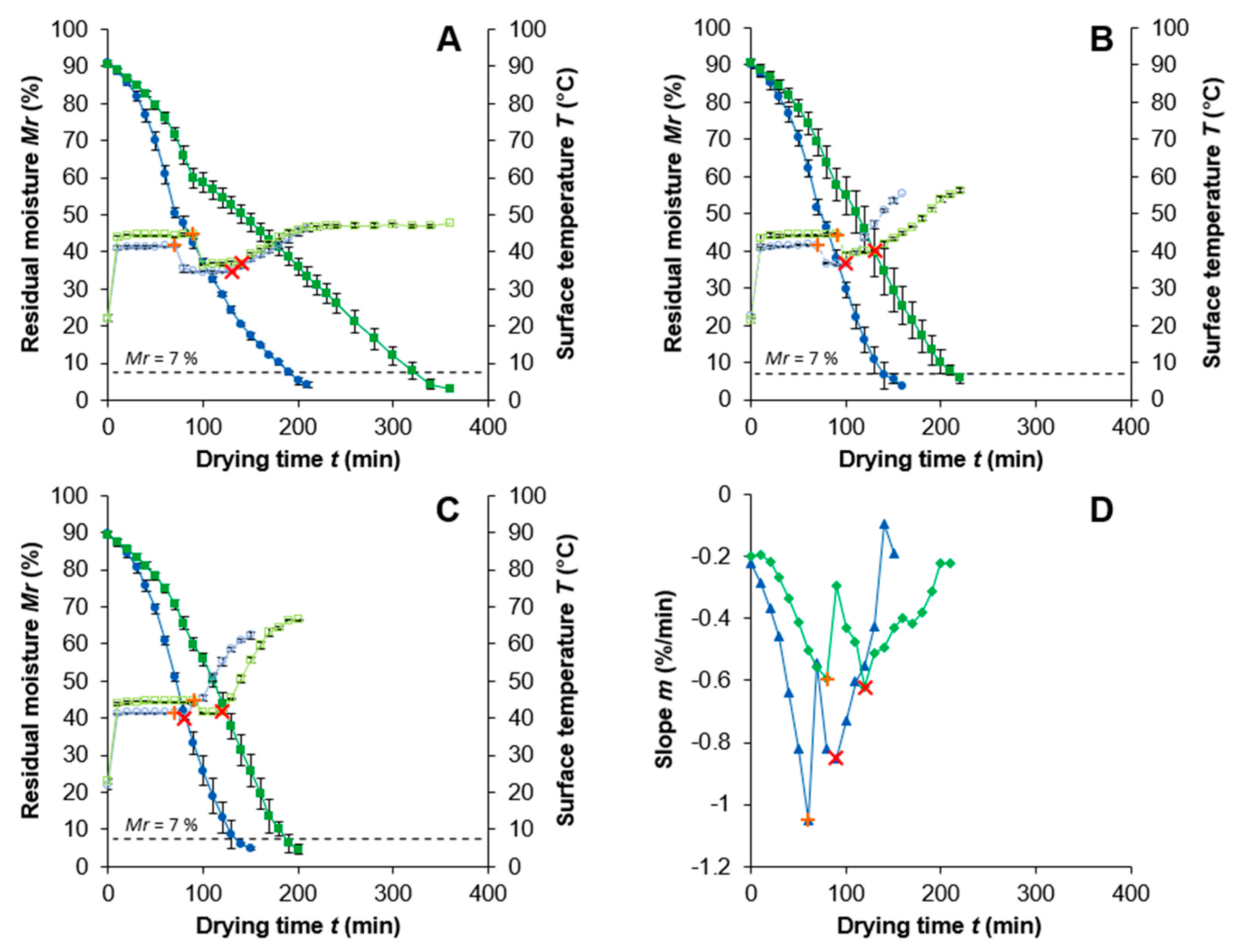

Pulsed Electric Field (PEF);

Pulsed Electric Field (PEF);  Untreated) and residual moisture Mr (%) (

Untreated) and residual moisture Mr (%) ( PEF;

PEF;  Untreated) for the drying time t (min) of onion samples dried at different constant drying temperatures (A: 65 °C; B: 75 °C; C: 85 °C). The PEF treatment was W = 4 kJ/kg, E = 1.07 kV/cm. (D): Slope m (%/min) of the residual moisture curves for the drying time t (min) dried at 85 °C (

Untreated) for the drying time t (min) of onion samples dried at different constant drying temperatures (A: 65 °C; B: 75 °C; C: 85 °C). The PEF treatment was W = 4 kJ/kg, E = 1.07 kV/cm. (D): Slope m (%/min) of the residual moisture curves for the drying time t (min) dried at 85 °C ( PEF;

PEF;  Untreated).

Untreated).  represents the breakpoint (BP).

represents the breakpoint (BP).

PEF;

PEF;  Untreated) and residual moisture Mr (%) (

Untreated) and residual moisture Mr (%) ( PEF;

PEF;  Untreated) for the drying time t (min) of onion samples dried at 85 °C until reaching the

Untreated) for the drying time t (min) of onion samples dried at 85 °C until reaching the  breakpoint (BP) where the temperature was reduced (A: 55 °C; B: 65 °C; C: 75 °C). The PEF treatment was W = 4 kJ/kg, E = 1.07 kV/cm. (D): Slope m (%/min) of the residual moisture curves for the drying time t (min) dried at 85 °C and 65 °C (

breakpoint (BP) where the temperature was reduced (A: 55 °C; B: 65 °C; C: 75 °C). The PEF treatment was W = 4 kJ/kg, E = 1.07 kV/cm. (D): Slope m (%/min) of the residual moisture curves for the drying time t (min) dried at 85 °C and 65 °C ( PEF;

PEF;  Untreated)

Untreated)  represents the delaypoint (DP).

represents the delaypoint (DP).

PEF;

PEF;  Untreated) and residual moisture Mr (%) (

Untreated) and residual moisture Mr (%) ( PEF;

PEF;  Untreated) for the drying time t (min) of onion samples dried at 85 °C until reaching the

Untreated) for the drying time t (min) of onion samples dried at 85 °C until reaching the  breakpoint (BP) where the temperature was reduced (A: 55 °C; B: 65 °C; C: 75 °C). The PEF treatment was W = 4 kJ/kg, E = 1.07 kV/cm. (D): Slope m (%/min) of the residual moisture curves for the drying time t (min) dried at 85 °C and 65 °C (

breakpoint (BP) where the temperature was reduced (A: 55 °C; B: 65 °C; C: 75 °C). The PEF treatment was W = 4 kJ/kg, E = 1.07 kV/cm. (D): Slope m (%/min) of the residual moisture curves for the drying time t (min) dried at 85 °C and 65 °C ( PEF;

PEF;  Untreated)

Untreated)  represents the delaypoint (DP).

represents the delaypoint (DP).

represents the Dw for 85 °C until reaching the BP, and

represents the Dw for 85 °C until reaching the BP, and  represents the Dw after the BP until end of drying applying a reduced temperature (75–55 °C).

represents the Dw after the BP until end of drying applying a reduced temperature (75–55 °C).

represents the Dw for 85 °C until reaching the BP, and

represents the Dw for 85 °C until reaching the BP, and  represents the Dw after the BP until end of drying applying a reduced temperature (75–55 °C).

represents the Dw after the BP until end of drying applying a reduced temperature (75–55 °C).

PEF pre-treated and

PEF pre-treated and  untreated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples dried at different drying profiles until reaching an Mr of ≤7%. Exemplary footage of blister formation of an untreated sample in comparison to a PEF-pretreated sample.

untreated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples dried at different drying profiles until reaching an Mr of ≤7%. Exemplary footage of blister formation of an untreated sample in comparison to a PEF-pretreated sample.

PEF pre-treated and

PEF pre-treated and  untreated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples dried at different drying profiles until reaching an Mr of ≤7%. Exemplary footage of blister formation of an untreated sample in comparison to a PEF-pretreated sample.

untreated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples dried at different drying profiles until reaching an Mr of ≤7%. Exemplary footage of blister formation of an untreated sample in comparison to a PEF-pretreated sample.

untreated and

untreated and  PEF pre-treated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples with a residual moisture content of ≤7% after convective drying at different drying profiles. a-b For each bar, means followed by the same letter are not significantly different (p > 0.05). Statistical testing was performed for each temperature profile.

PEF pre-treated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples with a residual moisture content of ≤7% after convective drying at different drying profiles. a-b For each bar, means followed by the same letter are not significantly different (p > 0.05). Statistical testing was performed for each temperature profile.

untreated and

untreated and  PEF pre-treated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples with a residual moisture content of ≤7% after convective drying at different drying profiles. a-b For each bar, means followed by the same letter are not significantly different (p > 0.05). Statistical testing was performed for each temperature profile.

PEF pre-treated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples with a residual moisture content of ≤7% after convective drying at different drying profiles. a-b For each bar, means followed by the same letter are not significantly different (p > 0.05). Statistical testing was performed for each temperature profile.

untreated and

untreated and  PEF-pretreated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples with a residual moisture content of ≤7% after convective drying at different drying profiles. a-b For each bar, means followed by the same letter are not significantly different (p > 0.05). Statistical testing was performed for each temperature profile.

PEF-pretreated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples with a residual moisture content of ≤7% after convective drying at different drying profiles. a-b For each bar, means followed by the same letter are not significantly different (p > 0.05). Statistical testing was performed for each temperature profile.

untreated and

untreated and  PEF-pretreated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples with a residual moisture content of ≤7% after convective drying at different drying profiles. a-b For each bar, means followed by the same letter are not significantly different (p > 0.05). Statistical testing was performed for each temperature profile.

PEF-pretreated (W = 4 kJ/kg, E = 1.07 kV/cm) onion samples with a residual moisture content of ≤7% after convective drying at different drying profiles. a-b For each bar, means followed by the same letter are not significantly different (p > 0.05). Statistical testing was performed for each temperature profile.

| Drying Profile (°C) | ΔL* (–) | Δa* (–) | Δb* (–) | ΔE (–) |

|---|---|---|---|---|

| 85/75 °C | −2.40 | 0.10 | 5.12 | 5.65 |

| 85/65 °C | 0.36 | 0.36 | −1.38 | 1.47 |

| 85/55 °C | −2.20 | 3.23 | 1.74 | 4.28 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostermeier, R.; Parniakov, O.; Töpfl, S.; Jäger, H. Applicability of Pulsed Electric Field (PEF) Pre-Treatment for a Convective Two-Step Drying Process. Foods 2020, 9, 512. https://doi.org/10.3390/foods9040512

Ostermeier R, Parniakov O, Töpfl S, Jäger H. Applicability of Pulsed Electric Field (PEF) Pre-Treatment for a Convective Two-Step Drying Process. Foods. 2020; 9(4):512. https://doi.org/10.3390/foods9040512

Chicago/Turabian StyleOstermeier, Robin, Oleksii Parniakov, Stefan Töpfl, and Henry Jäger. 2020. "Applicability of Pulsed Electric Field (PEF) Pre-Treatment for a Convective Two-Step Drying Process" Foods 9, no. 4: 512. https://doi.org/10.3390/foods9040512

APA StyleOstermeier, R., Parniakov, O., Töpfl, S., & Jäger, H. (2020). Applicability of Pulsed Electric Field (PEF) Pre-Treatment for a Convective Two-Step Drying Process. Foods, 9(4), 512. https://doi.org/10.3390/foods9040512