Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives

Abstract

1. Introduction

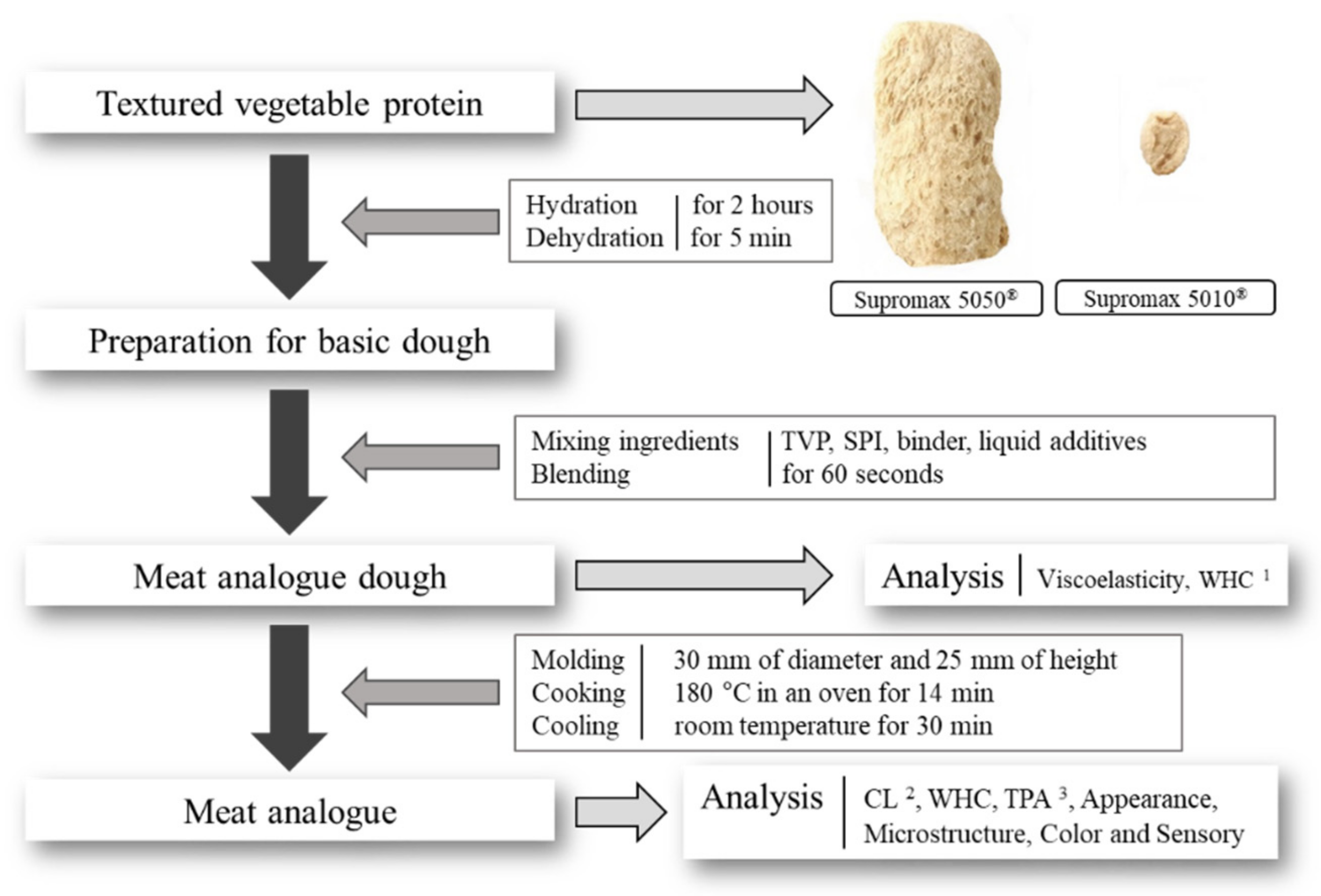

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Dynamic Rheological Properties

2.4. Cooking Loss (CL)

2.5. Water Holding Capacity

2.6. Texture Profile Analysis (TPA)

2.7. Visible Appearance

2.8. Color Analysis

2.9. Microstructure

2.10. Sensory Evaluation

2.11. Statistical Analysis

3. Results and Discussion

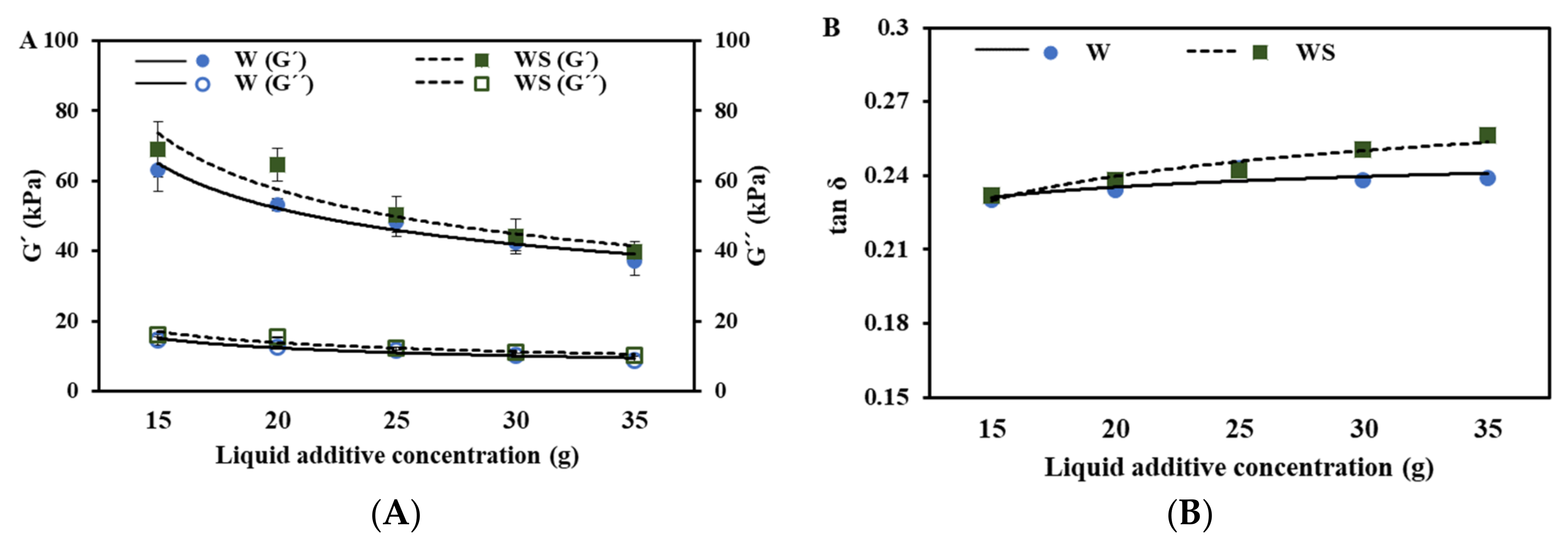

3.1. Dynamic Rheological Properties

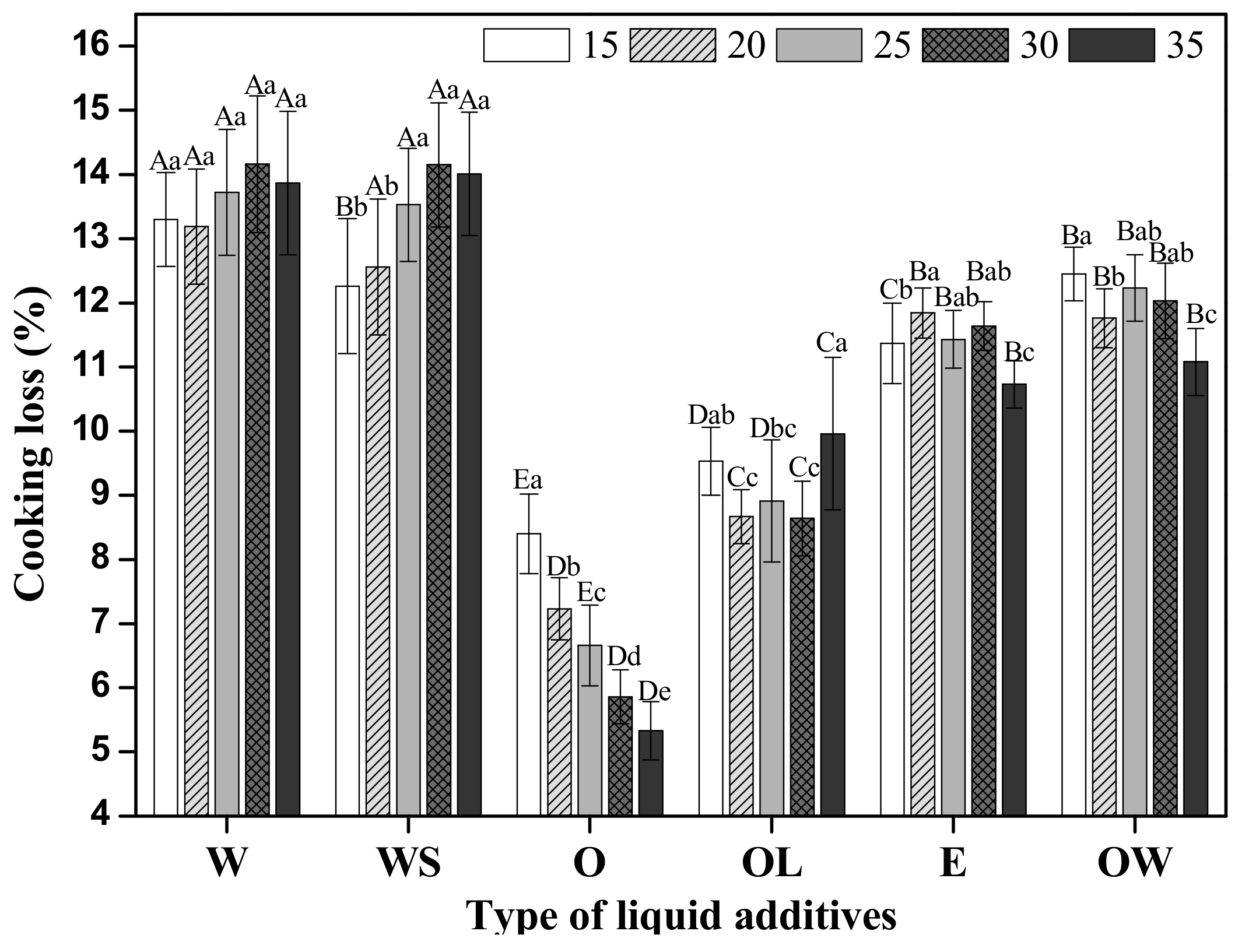

3.2. Cooking Loss

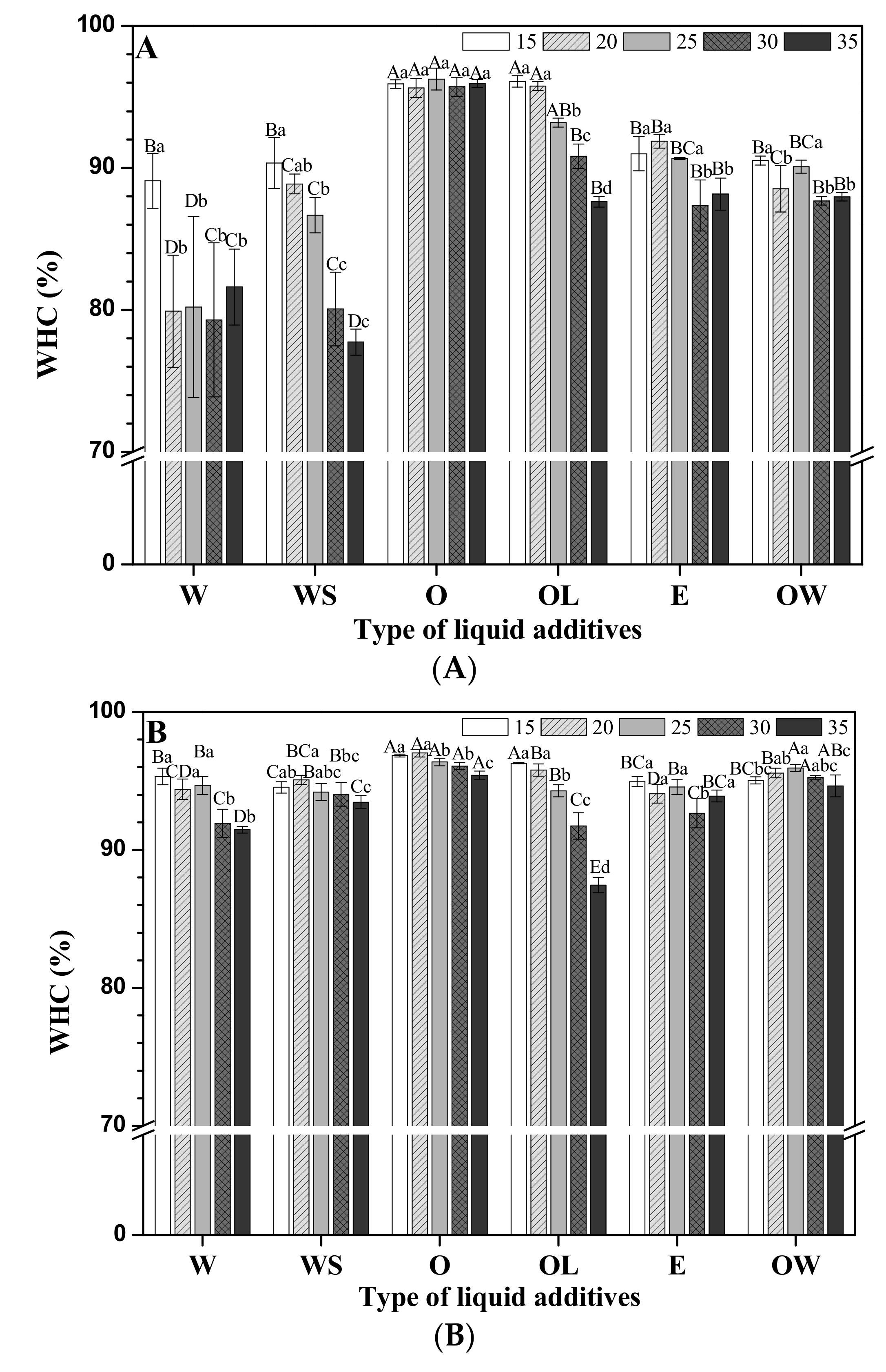

3.3. Water Holding Capacity

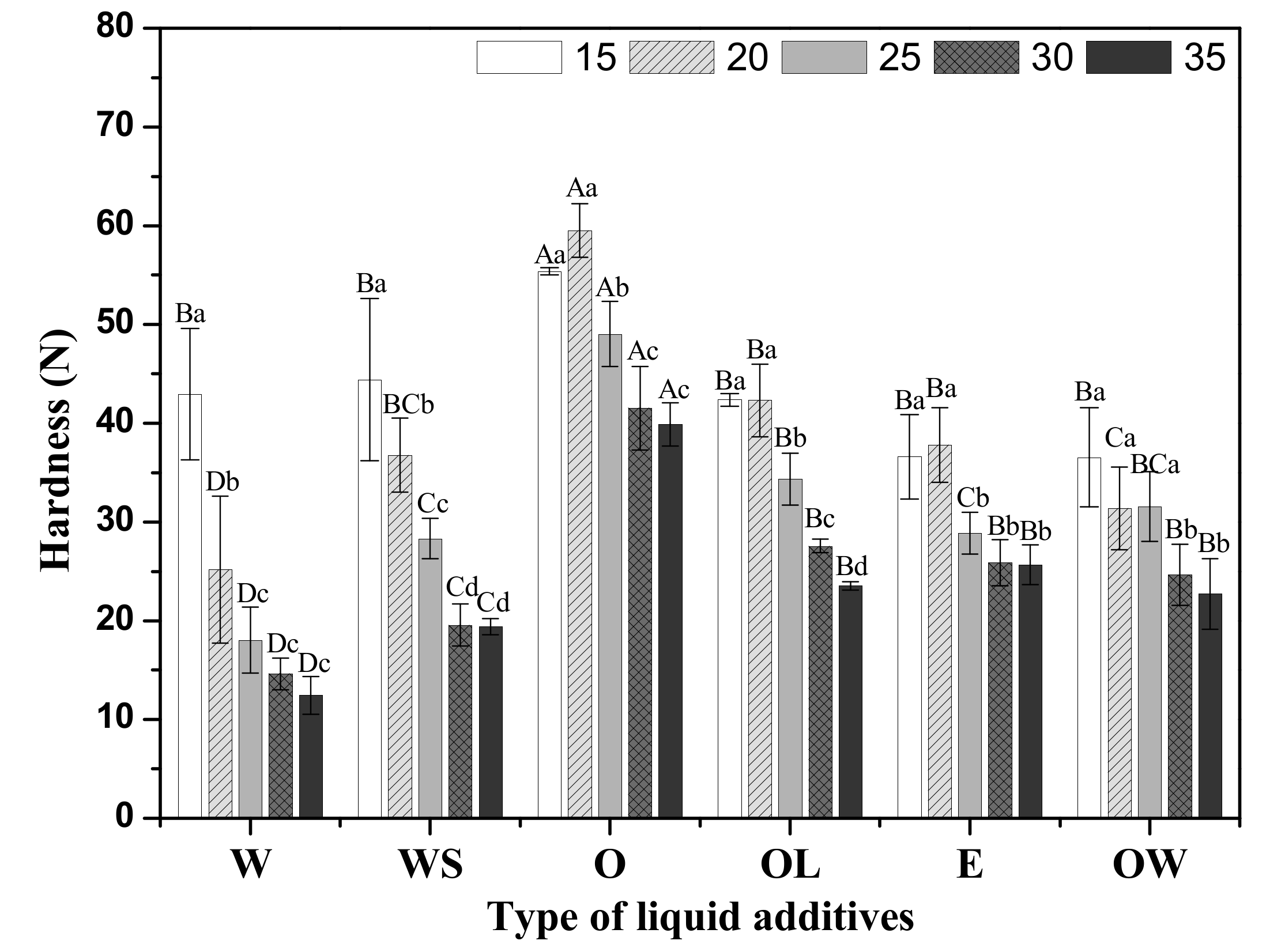

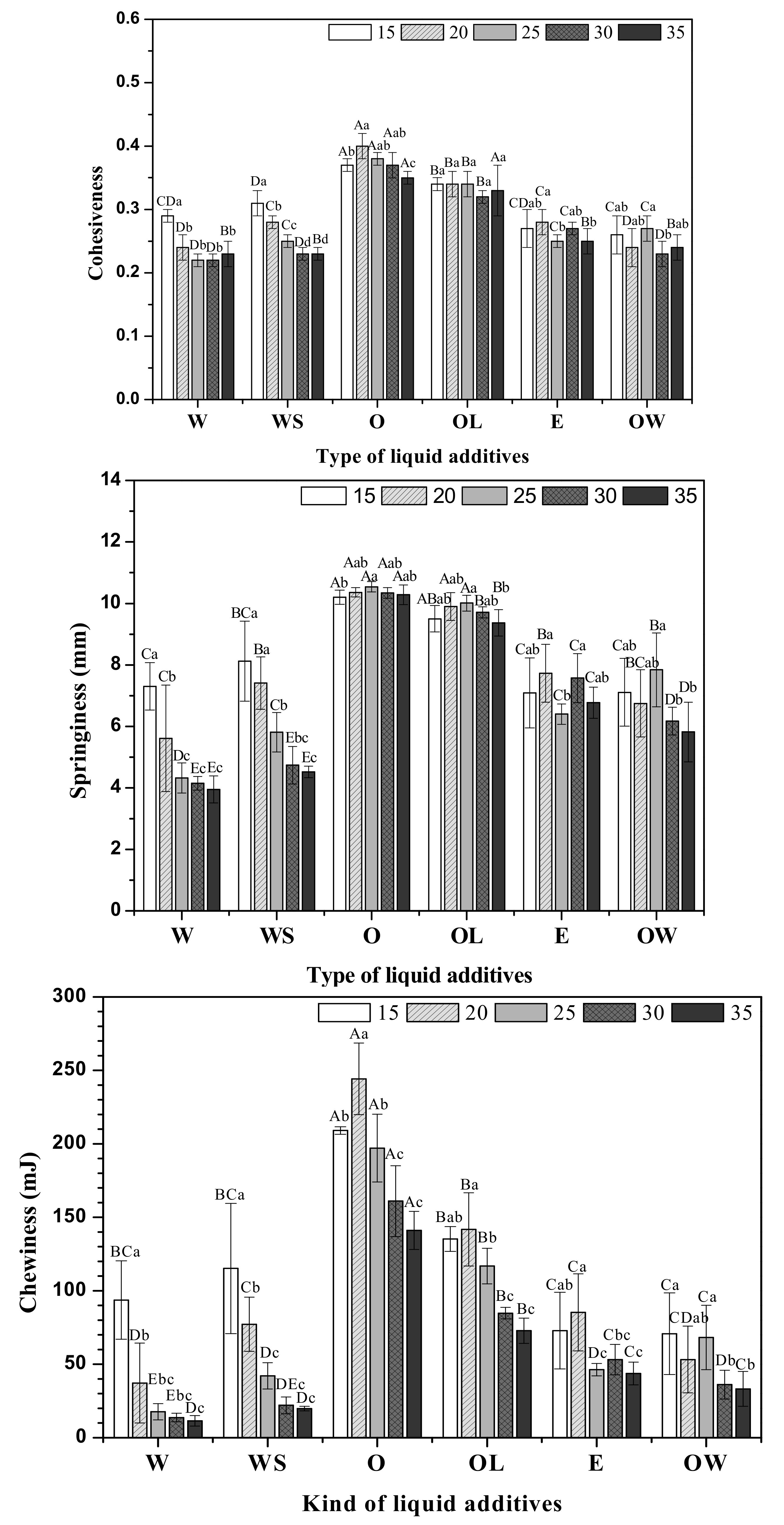

3.4. Texture Profile Analysis

3.5. Color Analysis

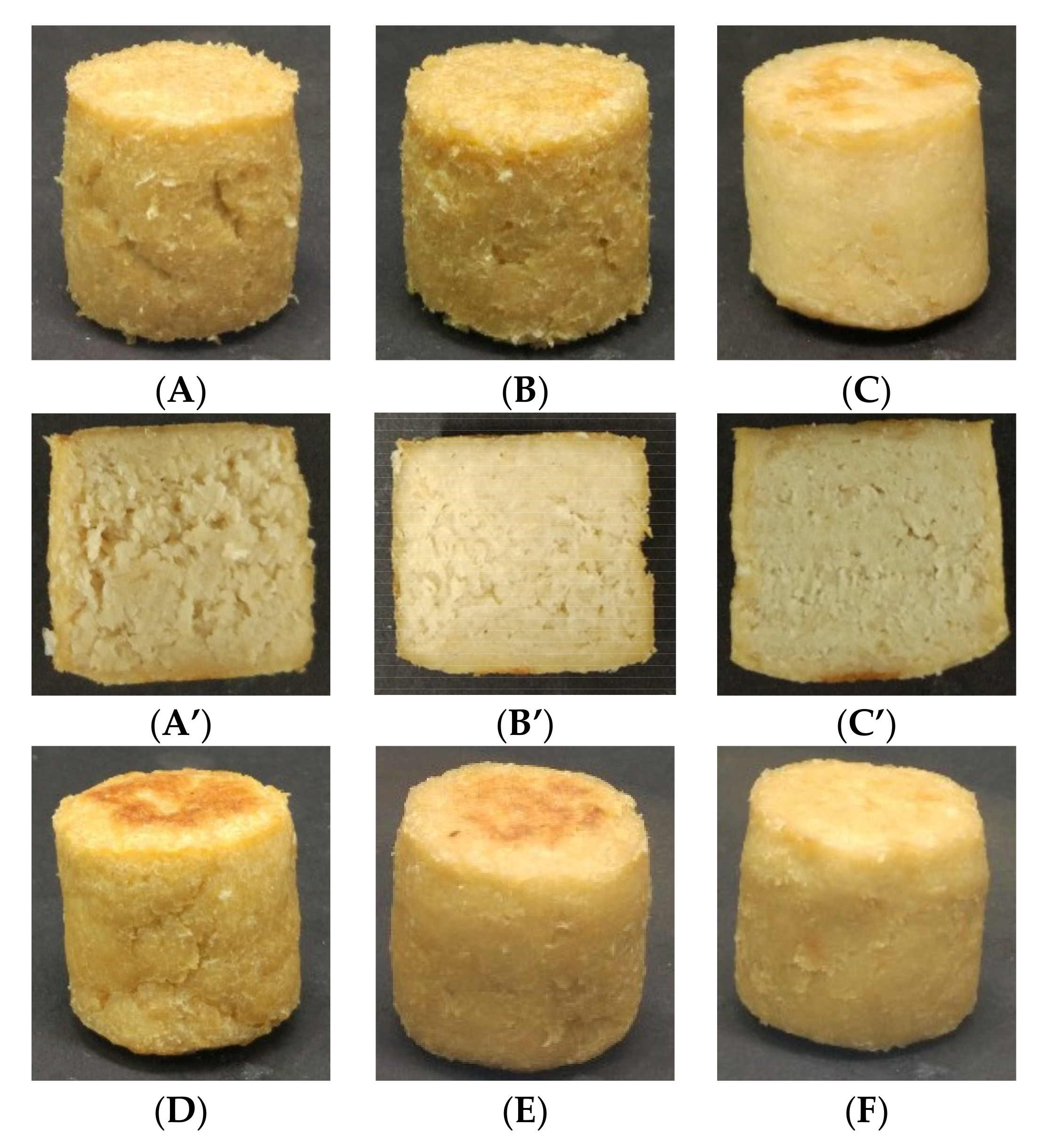

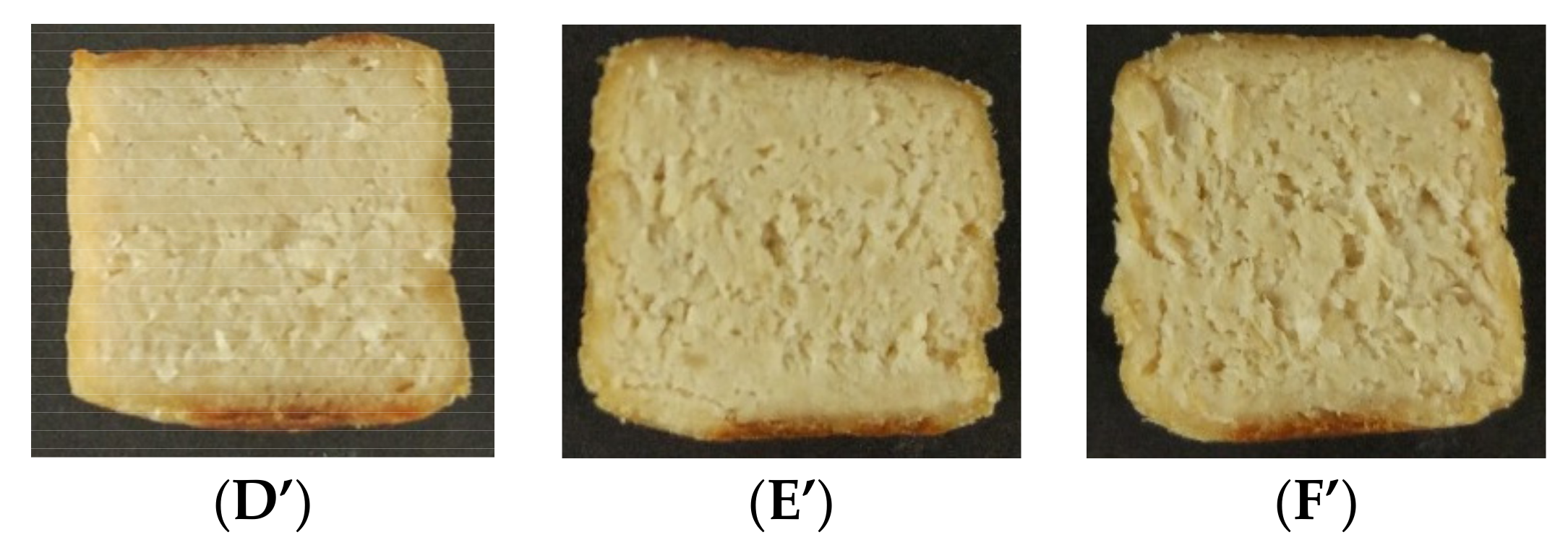

3.6. Visible Appearance

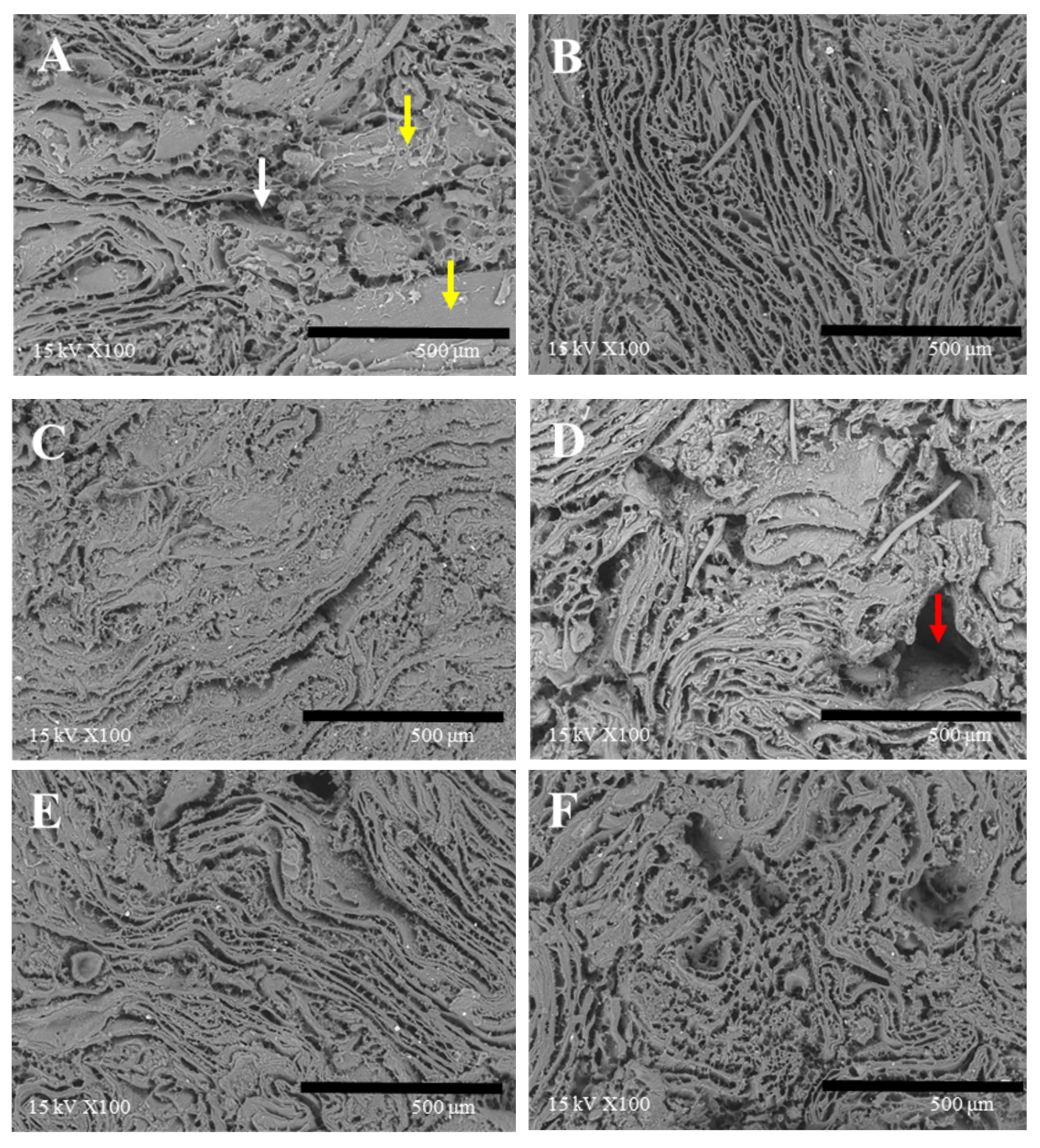

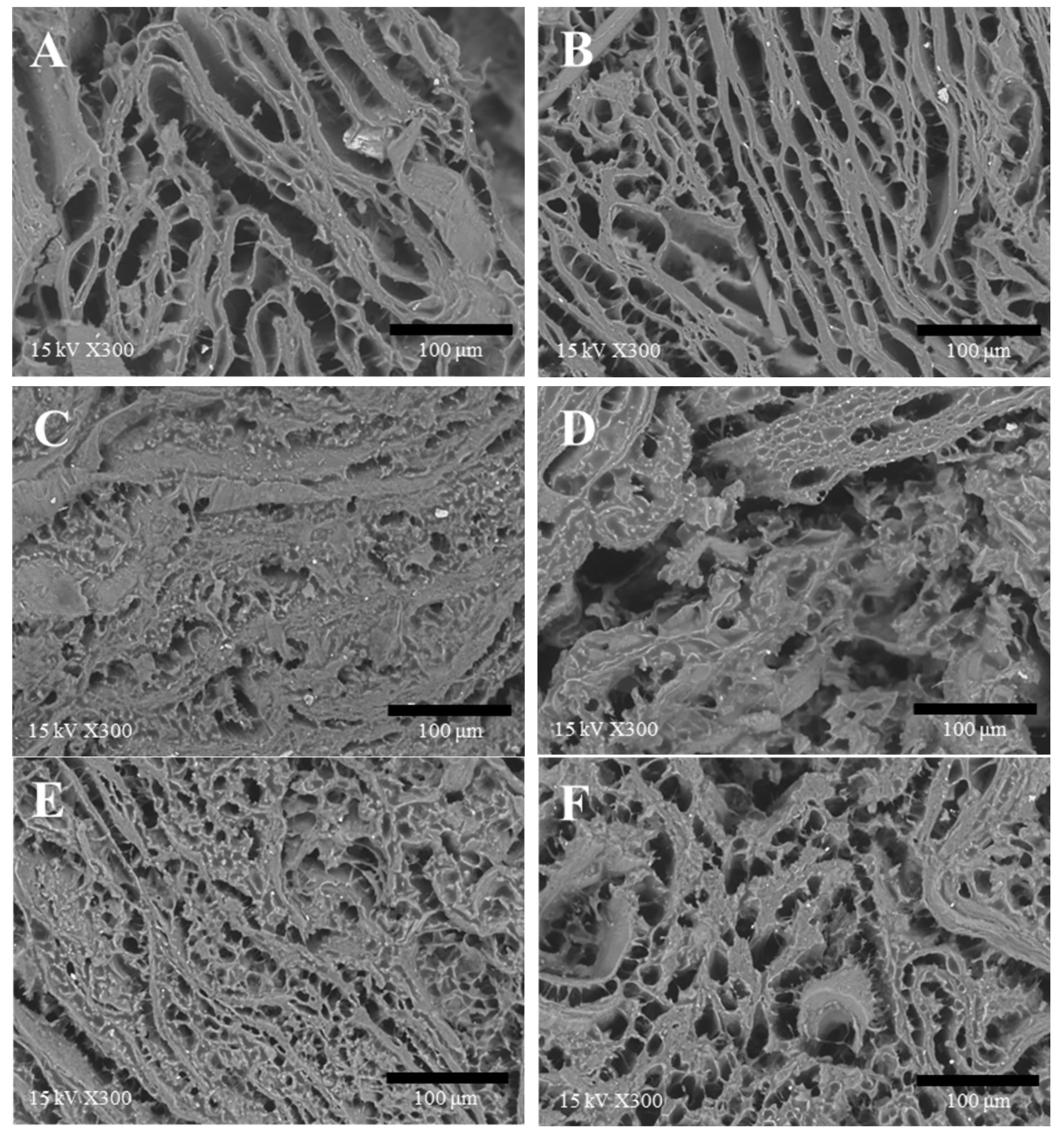

3.7. Microstructure

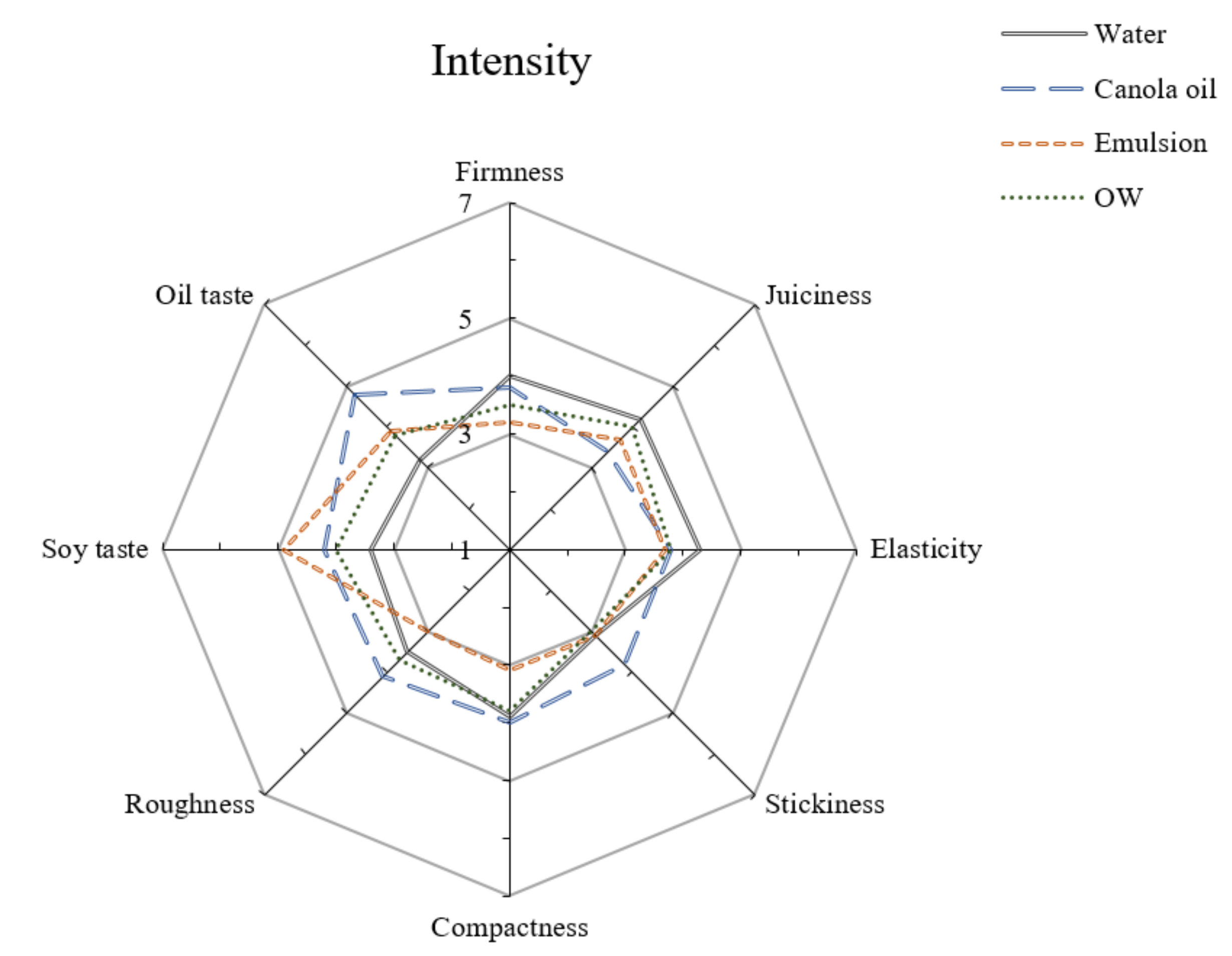

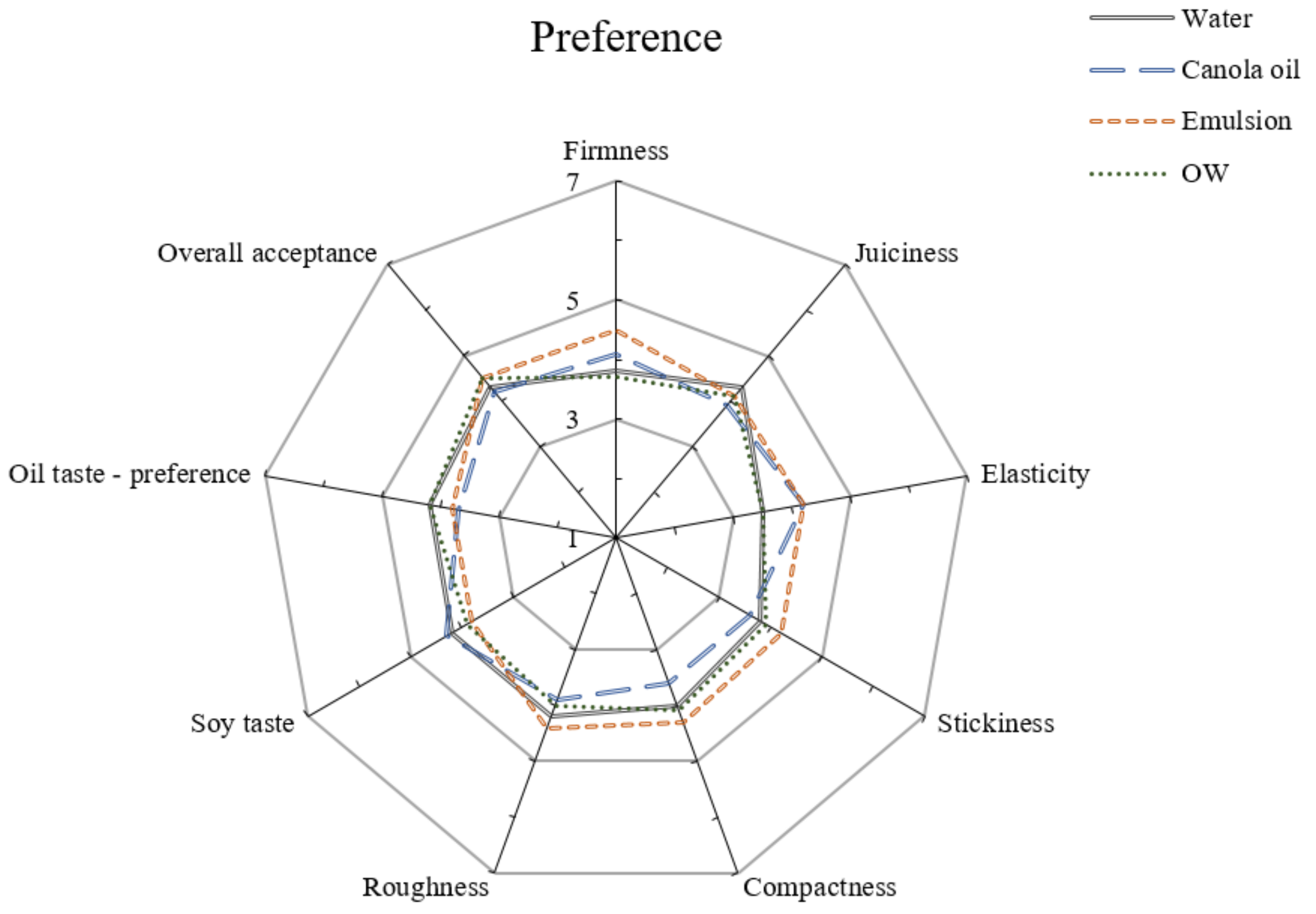

3.8. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Apostolidis, C.; McLeay, F. Should we stop meating like this? Reducing meat consumption through substitution. Food Policy 2016, 65, 74–89. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Boom, R.M.; Goot, A.J. Structuring processes for meat analogues. Trends Food Sci. Technol. 2018, 81, 25–36. [Google Scholar] [CrossRef]

- Hoek, A.C.; Luning, P.A.; Weijzen, P.; Engels, W.; Kok, F.J.; de Graaf, C. Replacement of meat by meat substitutes. A survey on person- and product-related factors in consumer acceptance. Appetite 2011, 56, 662–673. [Google Scholar] [CrossRef]

- Samard, S.; Ryu, G.H. A comparison of physicochemical characteristics, texture, and structure of meat analogue and meats. J. Sci. Food Agric. 2018, 99, 2708–2715. [Google Scholar] [CrossRef]

- Carballo, J.; Barreto, G.; Colmenero, F.J. Starch and Egg White lnfluence on Properties of Bologna Sausage as Related to Fat Content. J. Food Sci. 1995, 60, 673–677. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Duda, Z. Effect of fat content and soy protein/carrageenan mix on the quality characteristics of comminuted, scalded sausages. Meat Sci. 2000, 56, 181–188. [Google Scholar] [CrossRef]

- Yoo, S.S.; Kook, S.H.; Park, S.Y.; Shim, J.H.; Chin, K.B. Physicochemical characteristics, textural properties and volatile compounds in comminuted sausages as affected by various fat levels and fat replacers. Int. J. Food Sci. Technol. 2007, 42, 1114–1122. [Google Scholar] [CrossRef]

- Baek, K.H.; Utama, D.T.; Lee, S.G.; An, B.K.; Lee, S.K. Effects of Replacing Pork Back Fat with Canola and Flaxseed Oils on Physicochemical Properties of Emulsion Sausages from Spent Layer Meat. Asian Australas. J. Anim. Sci. 2016, 29, 865–871. [Google Scholar] [CrossRef]

- Kyriakopoulu, K.; Dekkers, B.; Van der Goot, A.J. Plant-based meat analogues. In Sustainable Meat Production and Processing; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 103–126. [Google Scholar] [CrossRef]

- Paneras, E.D.; Bloukas, J.G. Vegetable Oils Replace Pork Backfat for Low-Fat Frankfurters. J. Food Sci. 1994, 59, 725–728. [Google Scholar] [CrossRef]

- Barbut, S.; Marangoni, A. Organogels use in meat processing—Effects of fat/oil type and heating rate. Meat Sci. 2019, 149, 9–13. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Wang, H.; Janz, J.A.M. Effect of canola oil emulsion injection on processing characteristics and consumer acceptability of three muscles from mature beef. Meat Sci. 2012, 93. [Google Scholar] [CrossRef] [PubMed]

- Serdaroğlu, M.; Öztürk, B.; Urgu, M. Emulsion characteristics, chemical and textural properties of meat systems produced with double emulsions as beef fat replacers. Meat Sci. 2016, 117, 187–195. [Google Scholar] [CrossRef] [PubMed]

- Freire, M.; Bou, R.; Cofrades, S.; Solas, M.T.; Jimenez-Colmenero, F. Double emulsions to improve frankfurter lipid content: Impact of perilla oil and pork backfat. J. Sci. Food Agric. 2016, 96, 900–908. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liang, J.; Jiang, L.; Li, Y.; Wang, J.; Zhang, H.; Li, D.; Han, F.; Li, Q.; Wang, R.; et al. Effect of the interaction between myofibrillar protein and heat-induced soy protein isolates on gel properties. CyTA-J. Food 2015, 13, 527–534. [Google Scholar] [CrossRef]

- Xia, W.; Ma, L.; Chen, X.; Li, X.; Zhang, Y. Physicochemical and structural properties of composite gels prepared with myofibrillar protein and lecithin at various ionic strengths. Food Hydrocoll. 2018, 82, 135–143. [Google Scholar] [CrossRef]

- Pathare, P.B.; Roskilly, A.P. Quality and Energy Evaluation in Meat Cooking. Food Eng. Rev. 2016, 8, 435–447. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Cittadini, A.; Munekata, P.E.; Domínguez, R. Physicochemical properties of foal meat as affected by cooking methods. Meat Sci. 2015, 108, 50–54. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Texture and Chemical Characteristics of Soy Protein Meat Analog Extruded at High Moisture. J. Food Sci. 2000, 65, 264–269. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, Q. Dynamic rheological properties of wheat flour dough and proteins. Trends Food Sci. Technol. 2007, 18, 132–138. [Google Scholar] [CrossRef]

- Roccia, P.; Ribotta, P.D.; Pérez, G.T.; León, A.E. Influence of soy protein on rheological properties and water retention capacity of wheat gluten. LWT-Food Sci. Technol. 2009, 42, 358–362. [Google Scholar] [CrossRef]

- Azizi, M.H.; Rajabzadeh, N.; Riahi, E. Effect of mono-diglyceride and lecithin on dough rheological characteristics and quality of flat bread. Lebensm. Wiss. Technol. Food Sci. 2003, 36, 189–193. [Google Scholar] [CrossRef]

- Gómez, I.; Ibañez, F.C.; Beriain, M.J. Physicochemical and sensory properties of sous vide meat and meat analog products marinated and cooked at different temperature-time Combinations. Int. J. Food Prop. 2019, 22, 1693–1708. [Google Scholar] [CrossRef]

- Mottola, M.; Vico, R.V.; Villanueva, M.E.; Fanani, M.L. Alkyl esters of l-ascorbic acid: Stability, surface behaviour and interaction with phospholipid monolayers. J. Colloid Interface Sci. 2015, 457, 232–242. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Bae, J.; Wi, G.; Kim, H.T.; Cho, Y.; Choi, M.J. Physicochemical properties and sensory evaluation of meat analog mixed with different liquid materials as an animal fat substitute. Food Eng. Prog. 2019, 23, 62–68. [Google Scholar] [CrossRef]

- Huang, X.; Li, C.; Yang, F.; Xie, L.; Xu, X.; Zhou, Y.; Pan, S. Interactions and gel strength of mixed myofibrillar with soy protein, 7S globulin and enzyme-hydrolyzed soy proteins. Eur. Food Res. Technol. 2010, 231, 751–762. [Google Scholar] [CrossRef]

- Gosenca, M.; Bešter-Rogac, M.; Gašperlin, M. Lecithin based lamellar liquid crystals as a physiologically acceptable dermal delivery system for ascorbyl palmitate. Eur. J. Pharm. Sci. 2013, 50, 114–122. [Google Scholar] [CrossRef]

- Kim, H.W.; Setyabrata, D.; Lee, Y.J.; Jones, O.G.; Kim, Y.H.B. Pre-treated mealwork larvae and silkworm pupae as a novel protein ingredient in emulsion sausages. Innov. Food Sci. Emerg. Technol. 2016, 38, 116–123. [Google Scholar] [CrossRef]

- Youssef, M.K.; Barbut, S. Fat reduction in comminuted meat products-effects of beef fat, regular and pre-emulsified canola oil. Meat Sci. 2011, 87, 356–360. [Google Scholar] [CrossRef]

- Youssef, M.K.; Barbut, S. Physicochemical Effects of the Lipid Phase and Protein Level on Meat Emulsion Stability, Texture, and Microstructure. J. Food Sci. 2010, 75, S108–S114. [Google Scholar] [CrossRef]

- Lee, J.; Kim, H.; Choi, M.J.; Cho, Y. Improved Physicochemical Properties of Pork Patty Supplemented with Oil-in-Water Nanoemulsion. Korean J. Food Sci. Anim. Resour. 2020, 40, 262–273. [Google Scholar] [CrossRef]

- Souza, D.N.D.; Mullan, B.P.; Pethick, D.W.; Pluske, J.R.; Dunshea, F.R. Nutritional strategies affect carcass and pork quality but have no effect on intramuscular fat content of pork. Anim. Prod. Sci. 2012, 52, 276–282. [Google Scholar] [CrossRef]

- Zhuang, X.; Han, M.; Kang, Z.; Wang, K.; Bai, Y.; Xu, X.; Zhou, G. Effects of the sugarcane dietary fiber and pre-emulsified sesame oil on low-fat meat batter physicochemical property, texture, and microstructure. Meat Sci. 2016, 113, 107–115. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Colmenero, F.; Herrero, A.; Pintado, T.; Solas, M.T.; Ruiz-Capillas, C. Influence of emulsified olive oil stabilizing system used for pork backfat replacement in frankfurters. Food Res. Int. 2010, 113, 107–115. [Google Scholar] [CrossRef]

- Selani, M.M.; Shirado, G.A.N.; Margiotta, G.B.; Saldana, E.; Spada, F.P.; Piedade, S.M.S.; Contreras-Castillo, C.J.; Canniatti-Brazaca, S.G. Effects of pineapple byproduct and canola oil as fat replacers on physicochemical and sensory qualities of low-fat beef burger. Meat Sci. 2016, 112, 69–76. [Google Scholar] [CrossRef]

| Types of Liquid Additives 3 | Mixing Ratios | |||

|---|---|---|---|---|

| Liquid Additive Concentration (g) | TVP 1 (g) | SPI 2(g) | Binder (g) | |

| W | 15 | 100 | 4.5 | 3.0 |

| 20 | 100 | 4.5 | 3.0 | |

| 25 | 100 | 4.5 | 3.0 | |

| 30 | 100 | 4.5 | 3.0 | |

| 35 | 100 | 4.5 | 3.0 | |

| WS 4 | 15 | 100 | 4.5 | 3.0 |

| 20 | 100 | 4.5 | 3.0 | |

| 25 | 100 | 4.5 | 3.0 | |

| 30 | 100 | 4.5 | 3.0 | |

| 35 | 100 | 4.5 | 3.0 | |

| O | 15 | 100 | 4.5 | 3.0 |

| 20 | 100 | 4.5 | 3.0 | |

| 25 | 100 | 4.5 | 3.0 | |

| 30 | 100 | 4.5 | 3.0 | |

| 35 | 100 | 4.5 | 3.0 | |

| OL 4 | 15 | 100 | 4.5 | 3.0 |

| 20 | 100 | 4.5 | 3.0 | |

| 25 | 100 | 4.5 | 3.0 | |

| 30 | 100 | 4.5 | 3.0 | |

| 35 | 100 | 4.5 | 3.0 | |

| E 5 | 15 | 100 | 4.5 | 3.0 |

| 20 | 100 | 4.5 | 3.0 | |

| 25 | 100 | 4.5 | 3.0 | |

| 30 | 100 | 4.5 | 3.0 | |

| 35 | 100 | 4.5 | 3.0 | |

| OW 6 | 15 | 100 | 4.5 | 3.0 |

| 20 | 100 | 4.5 | 3.0 | |

| 25 | 100 | 4.5 | 3.0 | |

| 30 | 100 | 4.5 | 3.0 | |

| 35 | 100 | 4.5 | 3.0 | |

| Color | ||||

|---|---|---|---|---|

| Treatments | Concentration (g) | L* | a* | b* |

| W | 15 | 62.32 ± 4.02 Cc | 2.21 ± 0.23 ABb | 16.19 ± 0.62 Ac |

| 20 | 62.61 ± 1.12 Dc | 1.91 ± 0.07 Bc | 16.25 ± 0.15 Bc | |

| 25 | 64.55 ± 2.47 Dbc | 1.93 ± 0.16 Ac | 16.47 ± 0.68 Ac | |

| 30 | 65.72 ± 1.71 Cab | 2.62 ± 0.25 Aa | 17.60 ± 0.39 Ab | |

| 35 | 67.81 ± 1.04 Ca | 2.62 ± 0.14 Aa | 18.22 ± 0.27 Aa | |

| WS | 15 | 61.64 ± 0.90 Cb | 2.34 ± 0.03 Aa | 16.19 ± 0.26 Ab |

| 20 | 61.58 ± 0.59 Db | 2.23 ± 0.06 Aab | 16.07 ± 0.17 BCb | |

| 25 | 62.41 ± 1.11 Eb | 2.10 ± 0.19 Abc | 16.25 ± 0.20 ABb | |

| 30 | 64.54 ± 0.93 Ca | 2.21 ± 0.23 Bab | 16.55 ± 0.77 Bab | |

| 35 | 65.38 ± 1.34 Da | 1.98 ± 0.15 Bc | 17.05 ± 0.76 Ba | |

| O | 15 | 65.26 ± 0.52 Bd | 2.07 ± 0.14 BCa | 15.63 ± 0.30 Ba |

| 20 | 67.64 ± 0.73 Bc | 1.90 ± 0.09 Ba | 15.84 ± 0.34 Ca | |

| 25 | 68.94 ± 1.34 Bb | 1.65 ± 0.17 Bb | 15.37 ± 0.44 Ca | |

| 30 | 72.12 ± 1.46 Aa | 1.28 ± 0.04 Ec | 15.69 ± 0.96 Ba | |

| 35 | 69.41 ± 0.73 Bb | 1.52 ± 0.23 Cb | 16.03 ± 0.52 Ca | |

| OL | 15 | 65.96 ± 1.40 Ba | 2.26 ± 0.31 ABa | 16.02 ± 0.17 ABbc |

| 20 | 65.87 ± 1.10 Ca | 2.23 ± 0.14 Aa | 16.14 ± 0.20 Bb | |

| 25 | 66.80 ± 0.19 Ca | 1.95 ± 0.17 Ab | 15.87 ± 0.29 Bc | |

| 30 | 65.77 ± 1.23 Ca | 1.93 ± 0.13 Cb | 16.20 ± 0.03 Bb | |

| 35 | 63.89 ± 0.66 Eb | 2.01 ± 0.26 Bab | 16.57 ± 0.07 BCa | |

| E | 15 | 68.82 ± 0.62 Ac | 1.73 ± 0.04 Da | 16.36 ± 0.20 Aa |

| 20 | 70.09 ± 0.83 Ab | 1.75 ± 0.08 Ca | 16.52 ± 0.23 Aa | |

| 25 | 70.75 ± 0.58 Ab | 1.48 ± 0.08 Bb | 16.31 ± 0.04 ABa | |

| 30 | 70.08 ± 0.41 Bb | 1.54 ± 0.10 Db | 16.36 ± 0.38 Ba | |

| 35 | 71.70 ± 0.54 Aa | 1.32 ± 0.02 Cc | 16.32 ± 0.28 Ca | |

| OW | 15 | 68.52 ± 0.56 Ab | 1.98 ± 0.04 Ca | 16.19 ± 0.03 Ab |

| 20 | 69.17 ± 0.97 Ab | 1.89 ± 0.05 Ba | 16.17 ± 0.15 Bb | |

| 25 | 70.51 ± 0.80 ABa | 1.65 ± 0.01 Bb | 16.17 ± 0.09 ABb | |

| 30 | 69.21 ± 0.73 Bb | 1.74 ± 0.05 Cb | 16.52 ± 0.09 Ba | |

| 35 | 70.51 ± 0.36 Ba | 1.51 ± 0.14 Cc | 16.13 ± 0.07 Cb | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461. https://doi.org/10.3390/foods9040461

Wi G, Bae J, Kim H, Cho Y, Choi M-J. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods. 2020; 9(4):461. https://doi.org/10.3390/foods9040461

Chicago/Turabian StyleWi, Gihyun, Junhwan Bae, Honggyun Kim, Youngjae Cho, and Mi-Jung Choi. 2020. "Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives" Foods 9, no. 4: 461. https://doi.org/10.3390/foods9040461

APA StyleWi, G., Bae, J., Kim, H., Cho, Y., & Choi, M.-J. (2020). Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods, 9(4), 461. https://doi.org/10.3390/foods9040461