Wild Lactobacillus casei Group Strains: Potentiality to Ferment Plant Derived Juices

Abstract

1. Introduction

2. Materials and Methods

2.1. Bacterial Strains

2.2. Determination of Acid and Bile Salts Resistance

2.3. Fruit and Vegetables Juices Extraction, pH Measurement and Microbial Enumeration

2.4. Acidification Ability and EPS Production of LAB Strains in MRS and Juices

2.5. Statistical Analysis

3. Results

3.1. Resistance to Bile Salts and Acid Condition

3.2. Microbial Enumeration of Analyzed Juices

3.3. Acidification Ability of LAB Strains in Fresh Juices

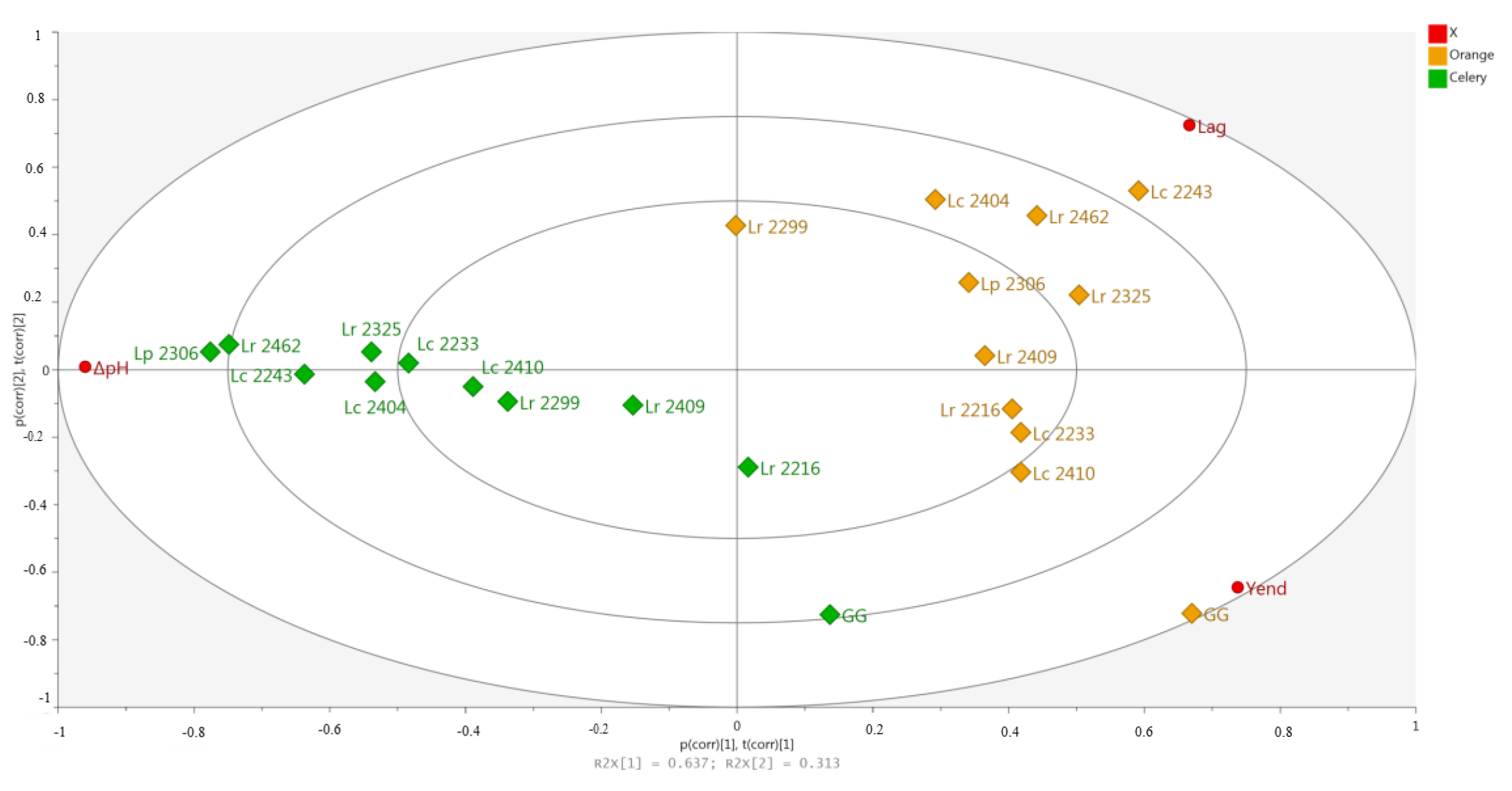

3.4. EPS Production

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aune, D.; Giovannucci, E.; Boffetta, P.; Fadnes, L.T.; Keum, N.N.; Norat, T.; Greenwood, D.C.; Riboli, E.; Vatten, L.J.; Tonstad, S. Fruit and vegetable intake and the risk of cardiovascular disease, total cancer and all-cause mortality-A systematic review and dose-response meta-analysis of prospective studies. Int. J. Epidemiol. 2017, 46, 1029–1056. [Google Scholar] [CrossRef]

- Wang, X.; Ouyang, Y.; Liu, J.; Zhu, M.; Zhao, G.; Bao, W.; Hu, F.B. Fruit and vegetable consumption and mortality from all causes, cardiovascular disease, and cancer: Systematic review and dose-response meta-analysis of prospective cohort studies. BMJ 2014, 349, 5472. [Google Scholar] [CrossRef]

- Yip, C.S.C.; Chan, W.; Fielding, R. The associations of fruit and vegetable intakes with burden of diseases: A systematic review of meta-analyses. J. Acad. Nutr. Diet. 2019, 119, 464–481. [Google Scholar] [CrossRef]

- Ferruzzi, M.G.; Tanprasertsuk, J.; Kris-Etherton, P.; Weaver, C.M.; Johnson, E.J. Perspective: The role of beverages as a source of nutrients and phytonutrients. Adv. Nutr. 2019, 1–17. [Google Scholar] [CrossRef]

- Agarwal, S.; Fulgoni, V.L.; Welland, D. Intake of 100% fruit juice is associated with improved diet quality of adults: NHANES 2013–2016 analysis. Nutrients 2019, 11, 2513. [Google Scholar] [CrossRef]

- Zheng, J.; Zhou, Y.; Li, S.; Zhang, P.; Zhou, T.; Xu, D.P.; Li, H. Bin effects and mechanisms of fruit and vegetable juices on cardiovascular diseases. Int. J. Mol. Sci. 2017, 18, 555. [Google Scholar] [CrossRef]

- Bigliardi, B.; Galati, F. Innovation trends in the food industry: The case of functional foods. Trends Food Sci. Technol. 2013, 31, 118–129. [Google Scholar] [CrossRef]

- Devlieghere, F.; Vermeiren, L.; Debevere, J. New preservation technologies: Possibilities and limitations. Int. Dairy J. 2004, 14, 273–285. [Google Scholar] [CrossRef]

- Gómez-López, V.M.; Devlieghere, F.; Bonduelle, V.; Debevere, J. Intense light pulses decontamination of minimally processed vegetables and their shelf-life. Int. J. Food Microbiol. 2005, 103, 79–89. [Google Scholar] [CrossRef]

- Elmnasser, N.; Guillou, S.; Leroi, F.; Orange, N.; Bakhrouf, A.; Federighi, M. Pulsed-Light system as a novel food decontamination technology: A review. Can. J. Microbiol. 2007, 53, 813–821. [Google Scholar] [CrossRef]

- Rehman, Z.U.; Islam, M.; Shah, W.H. Effect of microwave and conventional cooking on insoluble dietary fibre components of vegetables. Food Chem. 2003, 80, 237–240. [Google Scholar] [CrossRef]

- Zhang, D.; Hamauzu, Y. Phenolics, ascorbic acid, carotenoids and antioxidant activity of broccoli and their changes during conventional and microwave cooking. Food Chem. 2004, 88, 503–509. [Google Scholar] [CrossRef]

- Ordóñez-Santos, L.E.; Martínez-Girón, J. Thermal degradation kinetics of carotenoids, vitamin C and provitamin A in tree tomato juice. Int. J. Food Sci. Technol. 2019. [Google Scholar] [CrossRef]

- Caplice, E.; Fitzgerald, G.F. Food fermentations: Role of microorganisms in food production and preservation. Int. J. Food Microbiol. 1999, 50, 131–149. [Google Scholar] [CrossRef]

- Steinkraus, K. Indigenous Fermented; CRC Press: Boca Raton, FL, USA, 1995; ISBN 0824793528. [Google Scholar]

- Karovičová, J.; Kohajdová, Z. Lactic acid-fermented vegetable juices—Palatable and wholesome foods. Chem. Pap. 2005, 59, 143–148. [Google Scholar]

- Demir, N.; Bahçeci, K.S.; Acar, J. The effects of different initial lactobacillus plantarum concentrations on some properties of fermented carrot juice. J. Food Process. Preserv. 2006, 30, 352–363. [Google Scholar] [CrossRef]

- Di Cagno, R.; Coda, R.; De Angelis, M.; Gobbetti, M. Exploitation of vegetables and fruits through lactic acid fermentation. Food Microbiol. 2013, 33, 1–10. [Google Scholar] [CrossRef]

- Marsh, A.J.; Hill, C.; Ross, R.P.; Cotter, P.D. Fermented beverages with health-promoting potential: Past and future perspectives. Trends Food Sci. Technol. 2014, 38, 113–124. [Google Scholar] [CrossRef]

- Kandylis, P.; Pissaridi, K.; Bekatorou, A.; Kanellaki, M.; Koutinas, A.A. Dairy and non-dairy probiotic beverages. Curr. Opin. Food Sci. 2016, 7, 58–63. [Google Scholar] [CrossRef]

- Ranadheera, C.S.; Vidanarachchi, J.K.; Rocha, R.S.; Cruz, A.G.; Ajlouni, S. Probiotic delivery through fermentation: Dairy vs. non-dairy beverages. Fermentation 2017, 3, 67. [Google Scholar] [CrossRef]

- Harris, L.J.; Fleming, H.P.; Klaenhammer, T.R. Novel paired starter culture system for sauerkraut, consisting of a nisin-resistant Leuconostoc mesenteroides strain and a nisin-producing Lactococcus lactis strain. Appl. Environ. Microbiol. 1992, 58, 1484–1489. [Google Scholar] [CrossRef] [PubMed]

- Vasudha, S.; Mishra, H.N. Non dairy probiotic beverages. Int. Food Res. J. 2013, 20, 7–15. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO); World Health Organization (WHO). Guidelines for the Evaluation of Probiotics in Food; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy; World Health Organization (WHO): Geneva, Switzerland, 2002; pp. 1–11. [Google Scholar]

- Panghal, A.; Janghu, S.; Virkar, K.; Gat, Y.; Kumar, V.; Chhikara, N. Potential non-dairy probiotic products—A healthy approach. Food Biosci. 2018, 21, 80–89. [Google Scholar] [CrossRef]

- Helal, M.; Hussein, M.-D.; Osman, M.; Shalaby, A.S.; Ghaly, M. Production and prebiotic activity of exopolysaccharides derived from some probiotics. Egypt. Pharm. J. 2015, 14, 1. [Google Scholar] [CrossRef]

- Dal Bello, F.; Walter, J.; Hertel, C.; Hammes, W.P. In Vitro study of prebiotic properties of levan-type exopolysaccharides from Lactobacilli and non-digestible carbohydrates using denaturing gradient gel electrophoresis. Syst. Appl. Microbiol. 2001, 24, 232–237. [Google Scholar] [CrossRef] [PubMed]

- Mozzi, F.; Gerbino, E.; Font De Valdez, G.; Torino, M.I. Functionality of exopolysaccharides produced by lactic acid bacteria in an In Vitro gastric system. J. Appl. Microbiol. 2009, 107, 56–64. [Google Scholar] [CrossRef]

- Caggianiello, G.; Kleerebezem, M.; Spano, G. Exopolysaccharides produced by lactic acid bacteria: From health-promoting benefits to stress tolerance mechanisms. Appl. Microbiol. Biotechnol. 2016, 100, 3877–3886. [Google Scholar] [CrossRef]

- Bancalari, E.; Bernini, V.; Bottari, B.; Neviani, E.; Gatti, M. Application of impedance microbiology for evaluating potential acidifying performances of starter lactic acid bacteria to employ in milk transformation. Front. Microbiol. 2016, 7, 1–11. [Google Scholar] [CrossRef]

- Bancalari, E.; D’Incecco, P.; Savo Sardaro, M.L.; Neviani, E.; Pellegrino, L.; Gatti, M. Impedance microbiology to speed up the screening of lactic acid bacteria exopolysaccharide production. Int. J. Food Microbiol. 2019, 306, 108268. [Google Scholar] [CrossRef]

- Kleerebezem, M.; Vaughan, E.E. Probiotic and gut lactobacilli and bifidobacteria: Molecular approaches to study diversity and activity. Annu. Rev. Microbiol. 2009, 63, 269–290. [Google Scholar] [CrossRef]

- Mills, S.; Stanton, C.; Fitzgerald, G.F.; Ross, R.P. Enhancing the stress responses of probiotics for a lifestyle from gut to product and back again. Microb. Cell Fact. 2011, 10, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Bove, P.; Russo, P.; Capozzi, V.; Gallone, A.; Spano, G.; Fiocco, D. Lactobacillus plantarum passage through an oro-gastro-intestinal tract simulator: Carrier matrix effect and transcriptional analysis of genes associated to stress and probiosis. Microbiol. Res. 2013, 168, 351–359. [Google Scholar] [CrossRef] [PubMed]

- Boricha, A.A.; Shekh, S.L.; Pithva, S.P.; Ambalam, P.S.; Manuel Vyas, B.R. In Vitro evaluation of probiotic properties of Lactobacillus species of food and human origin. LWT 2019, 106, 201–208. [Google Scholar] [CrossRef]

- Begley, M.; Hill, C.; Gahan, C.G.M. Bile salt hydrolase activity in probiotics. Appl. Environ. Microbiol. 2006, 72, 1729–1738. [Google Scholar] [CrossRef] [PubMed]

- Charles-Rodríguez, A.V.; Nevárez-Moorillón, G.V.; Zhang, Q.H.; Ortega-Rivas, E. Comparison of thermal processing and pulsed electric fields treatment in pasteurization of apple juice. Food Bioprod. Process. 2007, 85, 93–97. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, L.J.; Rupasinghe, H.V. Effect of thermal and non-thermal pasteurisation on the microbial inactivation and phenolic degradation in fruit juice: A mini-review. J. Sci. Food Agric. 2013, 93, 981–986. [Google Scholar] [CrossRef]

- Lee, C.H. Lactic acid fermented foods and their benefits in Asia. Food Control. 1997, 8, 259–269. [Google Scholar] [CrossRef]

- Rhee, S.J.; Lee, J.E.; Lee, C.H. Importance of lactic acid bacteria in Asian fermented foods. Microb. Cell Fact. 2011, 10, 1–13. [Google Scholar] [CrossRef]

- Mucchetti, G.; Gatti, M.; Neviani, E. Electrical conductivity changes in milk caused by acidification: Determining factors. J. Dairy Sci. 1994, 77, 940–944. [Google Scholar] [CrossRef]

- Patel, A.R. Probiotic fruit and vegetable juices- recent advances and future perspective. Int. Food Res. J. 2017, 24, 1850–1857. [Google Scholar]

- Shori, A.B. Influence of food matrix on the viability of probiotic bacteria: A review based on dairy and non-dairy beverages. Food Biosci. 2016, 13, 1–8. [Google Scholar] [CrossRef]

- Gaucher, F.; Bonnassie, S.; Rabah, H.; Marchand, P.; Blanc, P.; Jeantet, R.; Jan, G. Review: Adaptation of beneficial propionibacteria, lactobacilli, and bifidobacteria improves tolerance toward technological and digestive stresses. Front. Microbiol. 2019, 10, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Boke, H.; Aslim, B.; Alp, G. The role of resistance to bile salts and acid tolerance of exopolysaccharides (EPSs) produced by yogurt starter bacteria. Arch. Biol. Sci. 2010, 62, 323–328. [Google Scholar] [CrossRef]

| Strain | Species | Isolation Matrix | ||||

|---|---|---|---|---|---|---|

| MRS HCl | MRS + bs 0.2 | MRS + bs 0.4 | ||||

| 2233 | L. | casei | PR cheese | ++ | ++ | ++ |

| 2243 | L. | casei | PR cheese | ++ | ++ | ++ |

| 2322 | L. | casei | PR cheese | ++ | ++ | ++ |

| 2326 | L. | casei | PR cheese | ++ | ++ | ++ |

| 2333 | L. | casei | PR cheese | ++ | + | + |

| 2337 | L. | casei | PR cheese | - | - | - |

| 2404 | L. | casei | PR cheese | ++ | ++ | ++ |

| 2405 | L. | casei | PR cheese | ++ | ++ | ++ |

| 2406 | L. | casei | PR cheese | ++ | - | - |

| 2407 | L. | casei | PR cheese | ++ | ++ | - |

| 2410 | L. | casei | PR cheese | ++ | ++ | ++ |

| 2413 | L. | casei | PR cheese | ++ | - | + |

| 2092 | L. | paracasei | GP cheese | ++ | ++ | - |

| 2302 | L. | paracasei | PR cheese | ++ | ++ | ++ |

| 2303 | L. | paracasei | PR cheese | ++ | ++ | ++ |

| 2306 | L. | paracasei | PR cheese | ++ | ++ | ++ |

| 2408 | L. | paracasei | PR cheese | ++ | ++ | + |

| 1019 | L. | rhamnosus | PR cheese | ++ | ++ | + |

| 1200 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 1473 | L. | rhamnosus | PR cheese | ++ | ++ | + |

| 1678 | L. | rhamnosus | PR curd | - | - | - |

| 2118 | L. | rhamnosus | GP cheese | ++ | ++ | + |

| 2190 | L. | rhamnosus | GP cheese | ++ | ++ | + |

| 2197 | L. | rhamnosus | Raw milk | ++ | + | + |

| 2203 | L. | rhamnosus | Raw milk | ++ | ++ | ++ |

| 2216 | L. | rhamnosus | Raw milk | ++ | ++ | ++ |

| 2222 | L. | rhamnosus | Raw milk | + | ++ | + |

| 2232 | L. | rhamnosus | PR curd | ++ | ++ | + |

| 2240 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2246 | L. | rhamnosus | PR cheese | + | ++ | + |

| 2247 | L. | rhamnosus | PR cheese | + | + | + |

| 2298 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2299 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2300 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2310 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2323 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2325 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2334 | L. | rhamnosus | PR cheese | ++ | ++ | + |

| 2335 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2336 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2352 | L. | rhamnosus | GP cheese | ++ | ++ | + |

| 2362 | L. | rhamnosus | GP cheese | ++ | ++ | + |

| 2400 | L. | rhamnosus | GP cheese | ++ | ++ | + |

| 2409 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2411 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2412 | L. | rhamnosus | PR cheese | ++ | - | + |

| 2414 | L. | rhamnosus | PR cheese | ++ | ++ | + |

| 2415 | L. | rhamnosus | PR cheese | ++ | ++ | ++ |

| 2416 | L. | rhamnosus | PR cheese | ++ | - | - |

| 2438 | L. | rhamnosus | Raw milk | - | - | - |

| 2462 | L. | rhamnosus | GP cheese | ++ | ++ | ++ |

| 2465 | L. | rhamnosus | GP cheese | ++ | ++ | + |

| 2466 | L. | rhamnosus | GP cheese | ++ | ++ | - |

| T0 | TMC | MRS | YPD | pH |

|---|---|---|---|---|

| Red beet | 5.93 ± 0.03 | 3.22 ± 0.01 | 4.43 ± 0.01 | 6.0 |

| Celery | 1.82 ± 0.01 | 1.30 ± 0.03 | 1.18 ± 0.02 | 5.8 |

| Orange | 1.82 ± 0.02 | 1.48 ± 0.01 | 2.47 ± 0.01 | 4.0 |

| T60 | TMC | MRS | YPD | pH |

| Celery | 4.5 ± 0.02 | 5.2 ± 0.1 | 1 ± 0.01 | 5.1 |

| Orange | 3.8 ± 0.1 | 2.6 ± 0.02 | 0.7 ± 0.01 | 3.9 |

| Species | Strains | Juice | Lag ± SD | yEnd ± SD | pH± SD | ΔpH |

|---|---|---|---|---|---|---|

| Lb. casei | 2233 | Celery | 3.88 h ± 0.15 | 4.75 kijl ± 0.25 | 4.5 c ± 0 | 1.3 |

| Lb. casei | 2243 | Celery | 4.00 h ± 0.30 | 5.02 kijgh ± 0.54 | 4.8a ± 0 | 1.0 |

| Lb. casei | 2404 | Celery | 3.46 h ± 0.43 | 4.99 kijh ± 0.12 | 4.7 b ± 0 | 1.1 |

| Lb. casei | 2410 | Celery | 3.55 h ± 0.09 | 5.10 ijgh ± 0.17 | 4.4 d ± 0 | 1.4 |

| Lb. paracasei | 2306 | Celery | 3.68 h ± 0.02 | 4.48 kjl ± 0.52 | 3.9 h ± 0 | 1.9 |

| Lb. rhamnosus | 2216 | Celery | 3.04 h ± 0.52 | 6.50 e ± 0.51 | 4.2 f ± 0 | 1.6 |

| Lb. rhamnosus | 2299 | Celery | 2.93 ih ± 0.44 | 5.16 igh ± 0.16 | 4 g ± 0 | 1.8 |

| Lb. rhamnosus | 2325 | Celery | 3.48 h± 0.47 | 4.40 kl ± 0.53 | 4.4 d ± 0 | 1.4 |

| Lb. rhamnosus | 2409 | Celery | 3.59 h ± 0.18 | 5.46 fgh ± 0.47 | 4.3 e ± 0 | 1.5 |

| Lb. rhamnosus | 2462 | Celery | 3.44 h ± 0.19 | 4.25 l ± 0.22 | 4.7 b ± 0 | 1.1 |

| Lb. rhamnosus | GG | Celery | 1.82 i ± 0.08 | 8.66 b ± 0.03 | 3.9 h ± 0 | 1.9 |

| Lb. casei | 2233 | Orange | 7.82 f ± 0.24 | 7.46 c ± 0.32 | 3.9 h ± 0 | 0.1 |

| Lb. casei | 2243 | Orange | 18.59 a ± 0.42 | 6.43 e ± 0.51 | 3.8 i ± 0 | 0.2 |

| Lb. casei | 2404 | Orange | 15.19 b ± 0.85 | 5.41 igh ± 0.22 | 3.8 i ± 0 | 0.2 |

| Lb. casei | 2410 | Orange | 6.56 g ± 0.60 | 7.80 c ± 0.24 | 3.7 j ± 0 | 0.3 |

| Lb. paracasei | 2306 | Orange | 12.37 c ± 0.55 | 6.08 fe ± 0.21 | 3.7 j ± 0 | 0.3 |

| Lb. rhamnosus | 2216 | Orange | 8.40 ef ± 0.87 | 7.19 dc ± 0.06 | 3.9 h ± 0 | 0.1 |

| Lb. rhamnosus | 2299 | Orange | 10.43 d ± 0.40 | 4.28 l ± 0.26 | 3.7 j ± 0 | 0.3 |

| Lb. rhamnosus | 2325 | Orange | 13.31 c ± 1.86 | 6.64 de ± 0.74 | 3.7 j ± 0 | 0.3 |

| Lb. rhamnosus | 2409 | Orange | 9.53 ed ± 1.80 | 6.53 de ± 0.66 | 3.7 j ± 0 | 0.3 |

| Lb. rhamnosus | 2462 | Orange | 14.98 b ± 0.88 | 5.66 fg ± 0.55 | 3.7 j ± 0 | 0.3 |

| Lb. rhamnosus | GG | Orange | 6.43 g ± 0.81 | 10.22 a ± 0.51 | 3.7 j ± 0 | 0.3 |

| Species | Strain | ∆E% MRS | ∆E% Celery | ∆E% Orange |

|---|---|---|---|---|

| Lb. casei | 2233 | 3.52 ± 1.92 | 4.35 ± 2.20 | 0.11 ± 0.22 |

| Lb. casei | 2243 | 1.75 ± 0.08 | 0.06 ± 0.04 | 0.49 ± 0.83 |

| Lb. casei | 2404 | 2.47 ± 0.66 | 0.61 ± 0.47 | 0.25 ± 0.03 |

| Lb. casei | 2410 | 2.07 ± 1.13 | 5.56 ± 2.32 | 0.21 ± 0.02 |

| Lb. paracasei | 2306 | 6.25 ± 2.49 | 2.81 ± 0.98 | 0.6 ± 0.01 |

| Lb. rhamnosus | 2216 | 4.28 ± 0.99 | 2.51 ± 1.34 | 0.55 ± 0.12 |

| Lb. rhamnosus | 2299 | 6.55 ± 2.94 | 4.43 ± 2.21 | 0.81 ± 0.42 |

| Lb. rhamnosus | 2325 | 4.25 ± 1.84 | 6.06 ± 0.61 | 0.1 ± 0.03 |

| Lb. rhamnosus | 2409 | 2.37 ± 0.67 | 5.83 ± 2.37 | 0.75 ± 0.08 |

| Lb. rhamnosus | 2462 | 2.43 ± 0.51 | 2.88 ± 1.67 | 0.45 ± 0.07 |

| Lb. rhamnosus | GG | 4.09 ± 1.62 | 3.04 ± 0.86 | 0.67 ± 0.12 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bancalari, E.; Castellone, V.; Bottari, B.; Gatti, M. Wild Lactobacillus casei Group Strains: Potentiality to Ferment Plant Derived Juices. Foods 2020, 9, 314. https://doi.org/10.3390/foods9030314

Bancalari E, Castellone V, Bottari B, Gatti M. Wild Lactobacillus casei Group Strains: Potentiality to Ferment Plant Derived Juices. Foods. 2020; 9(3):314. https://doi.org/10.3390/foods9030314

Chicago/Turabian StyleBancalari, Elena, Vincenzo Castellone, Benedetta Bottari, and Monica Gatti. 2020. "Wild Lactobacillus casei Group Strains: Potentiality to Ferment Plant Derived Juices" Foods 9, no. 3: 314. https://doi.org/10.3390/foods9030314

APA StyleBancalari, E., Castellone, V., Bottari, B., & Gatti, M. (2020). Wild Lactobacillus casei Group Strains: Potentiality to Ferment Plant Derived Juices. Foods, 9(3), 314. https://doi.org/10.3390/foods9030314