Effect of Co-Fermentation with Lactic Acid Bacteria and K. marxianus on Physicochemical and Sensory Properties of Goat Milk

Abstract

1. Introduction

2. Materials and Methods

2.1. Microorganism and Materials

2.2. Goat Yogurt Manufacture

2.3. Viable Counts of Total LAB and K. marxianus

2.4. Analysis of pH and Titratable Acidity

2.5. Rheological Measurements

2.6. Electronic Nose

2.7. SPME-GC-MS Analysis of Volatile Flavor Compounds

2.8. Sensory Evaluation

2.9. Statistical Analyses

3. Results and Discussion

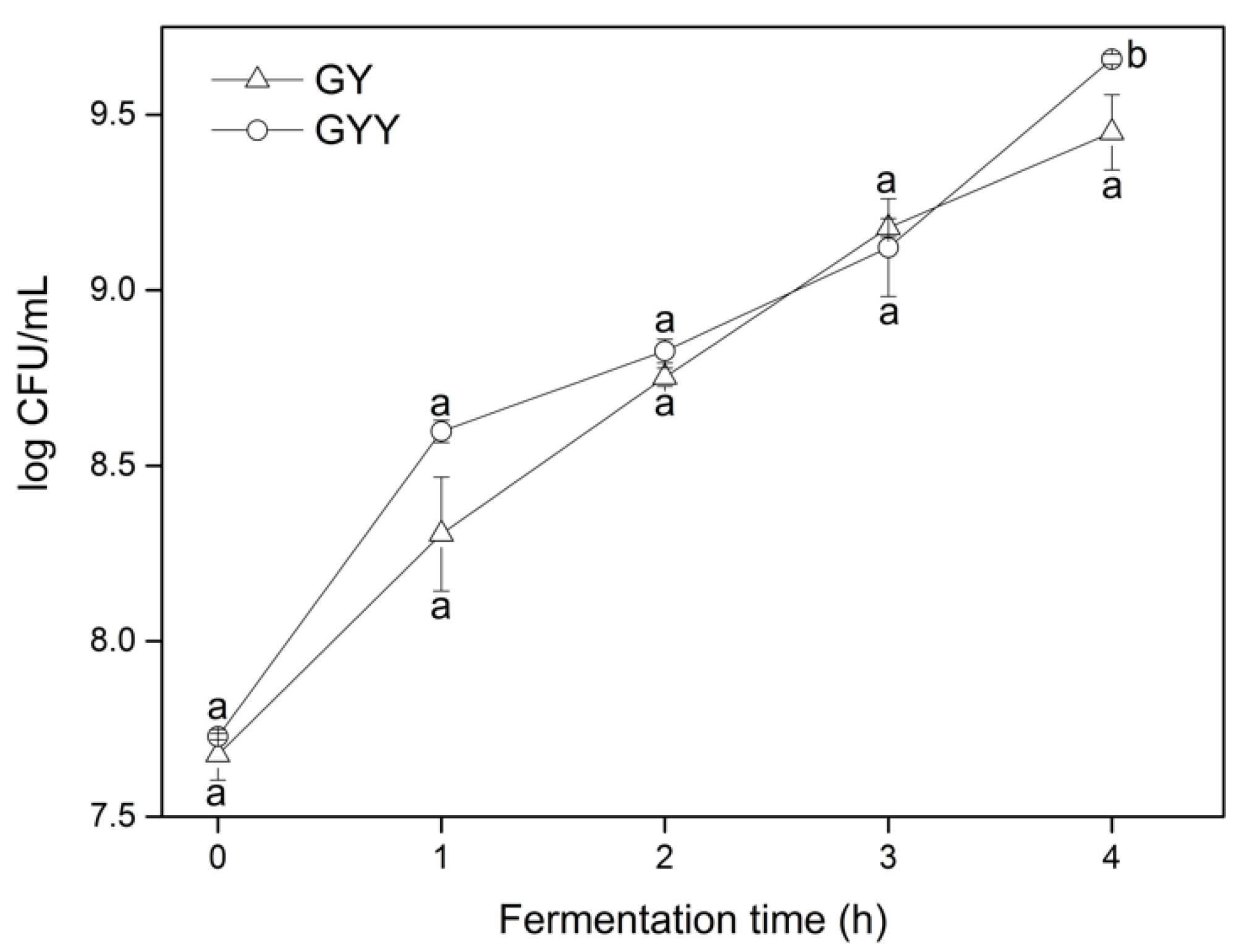

3.1. The Growth and Acidification Performance of LAB

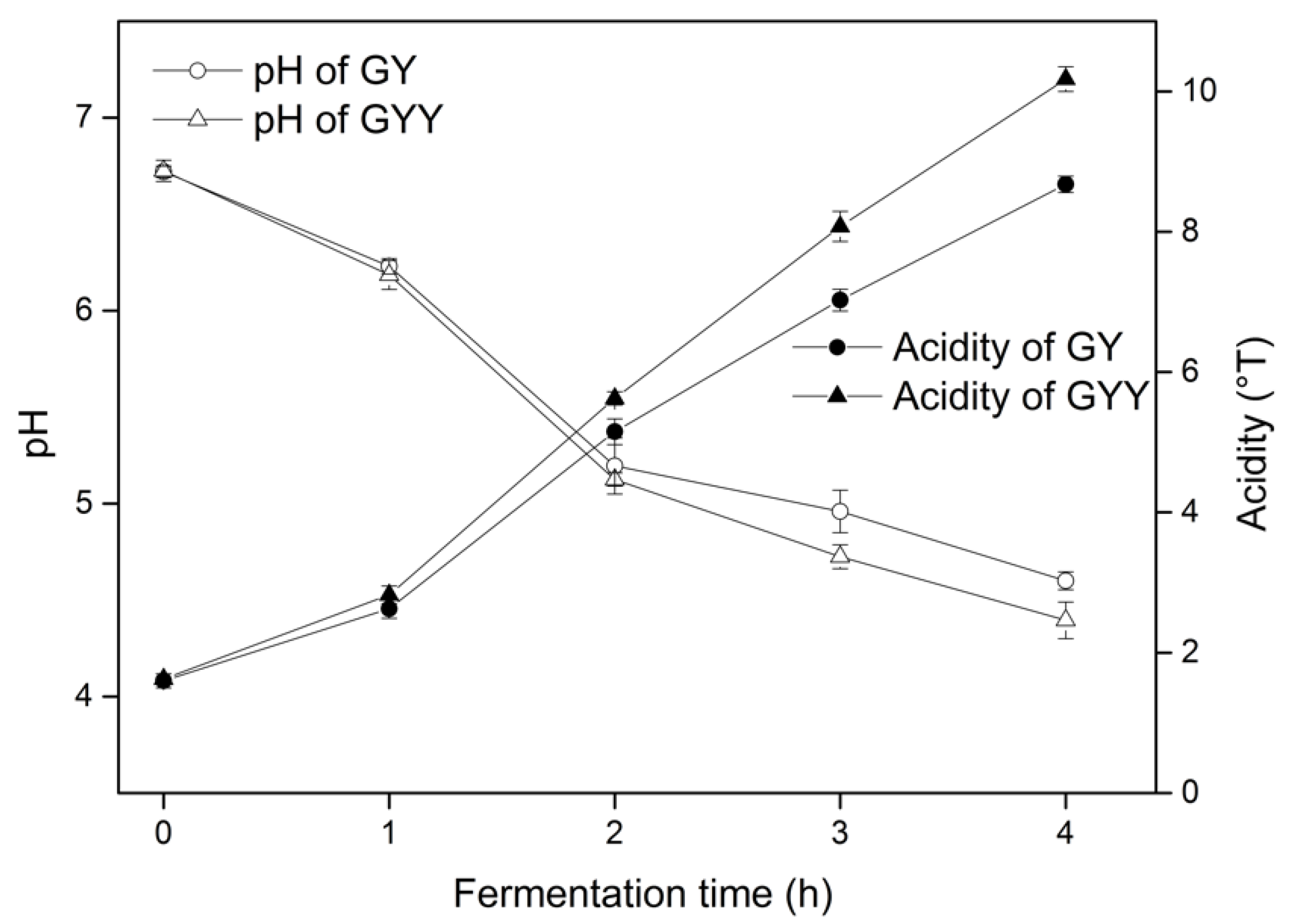

3.2. Rheological Properties of GM, GY, and GYY

3.3. E-nose Analysis of Volatile Compounds in Goat Milk Samples

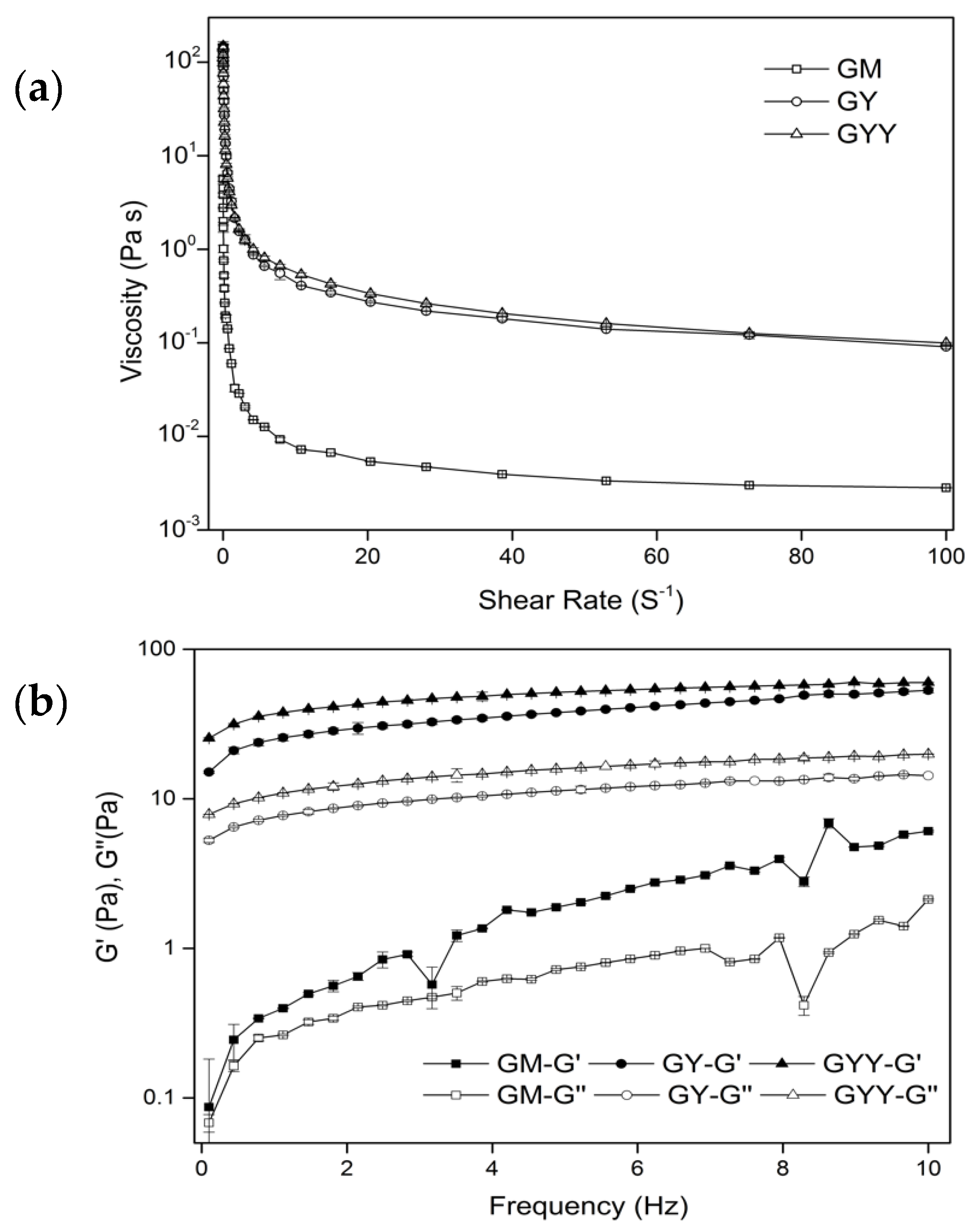

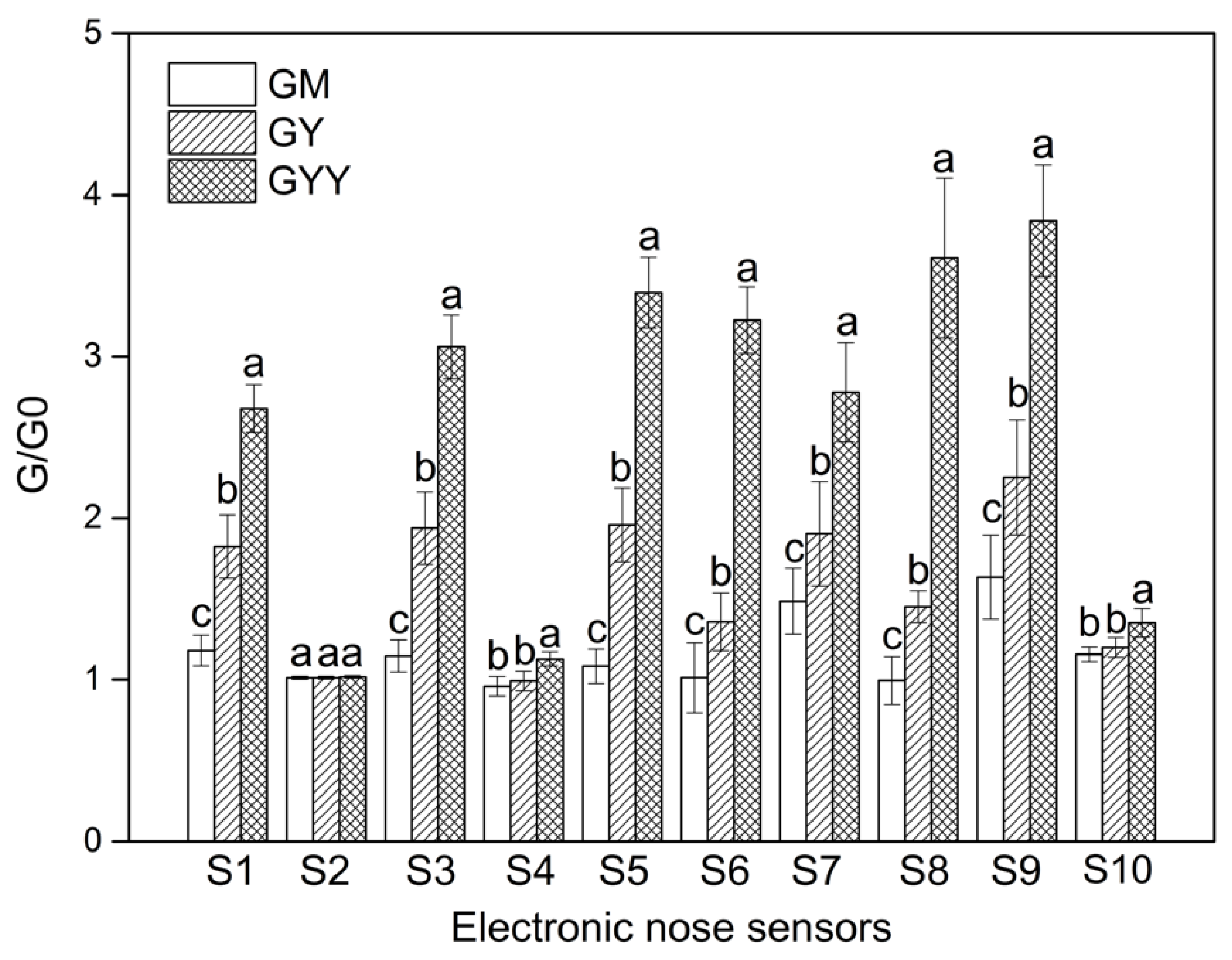

3.3.1. E-nose Sensors Response Signal of Volatile Compounds in Goat Milk Samples

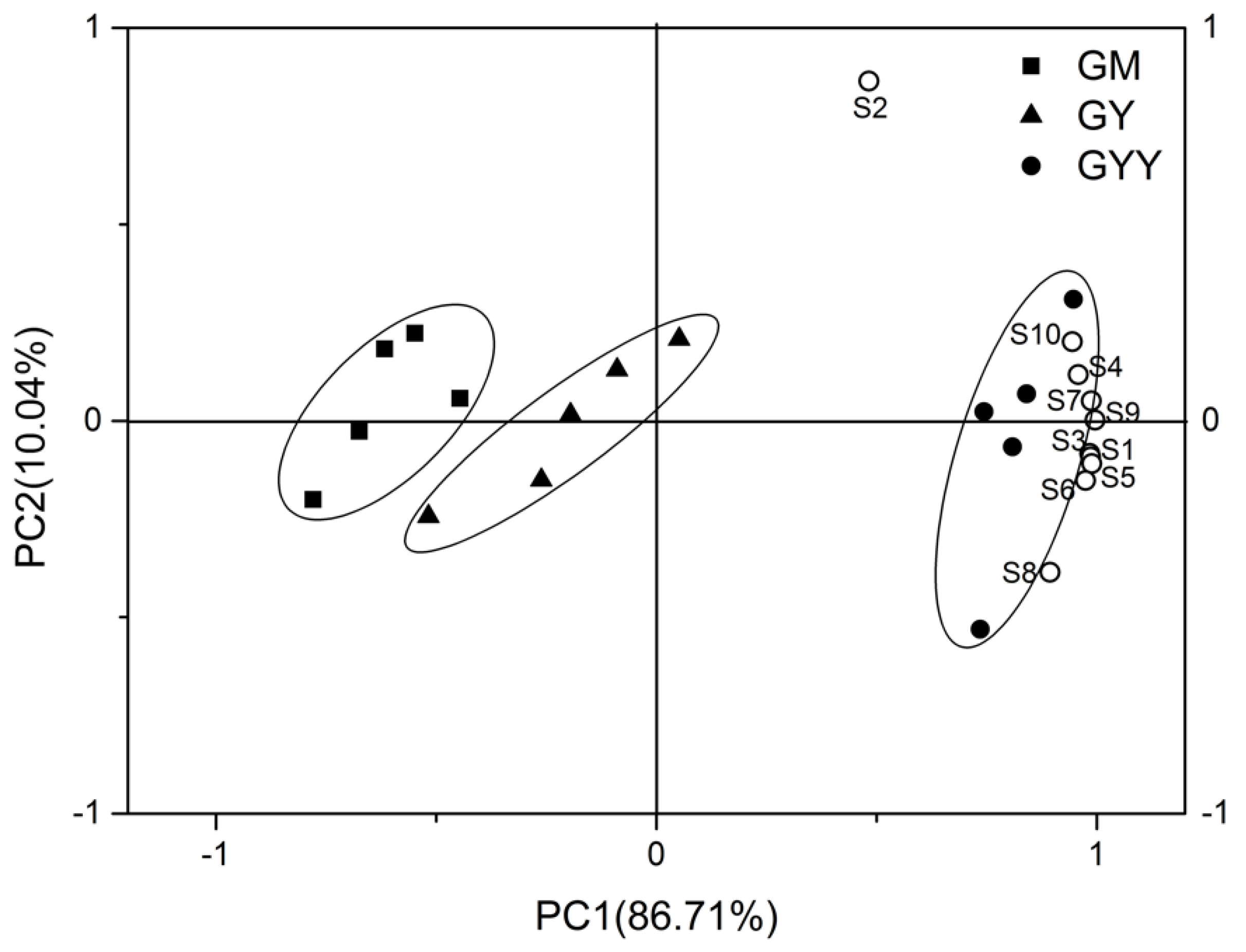

3.3.2. Principal Component Analysis of E-nose Response

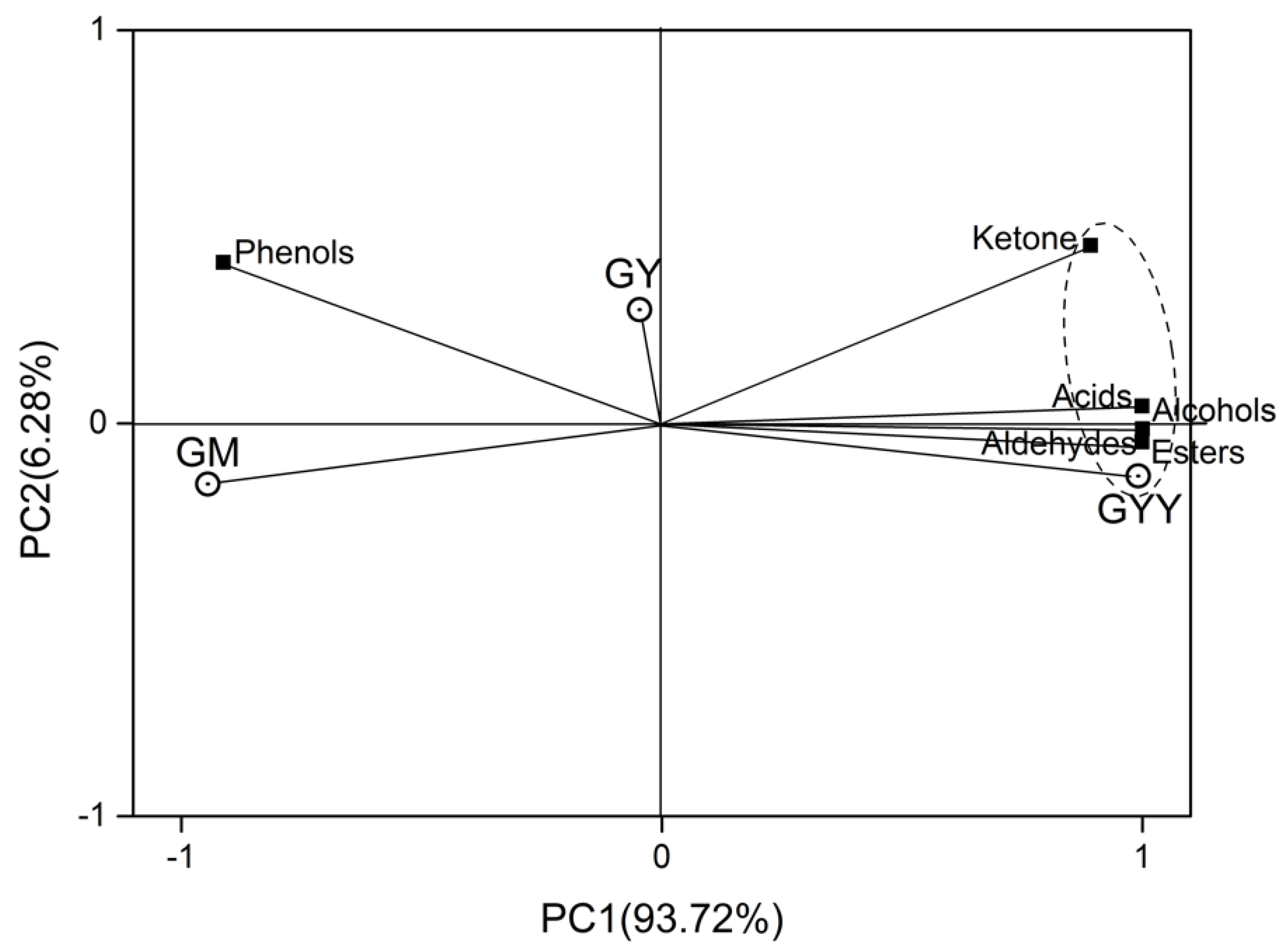

3.4. Volatile Organic Compounds in GM, GY, and GYY from SPME-GC-MS

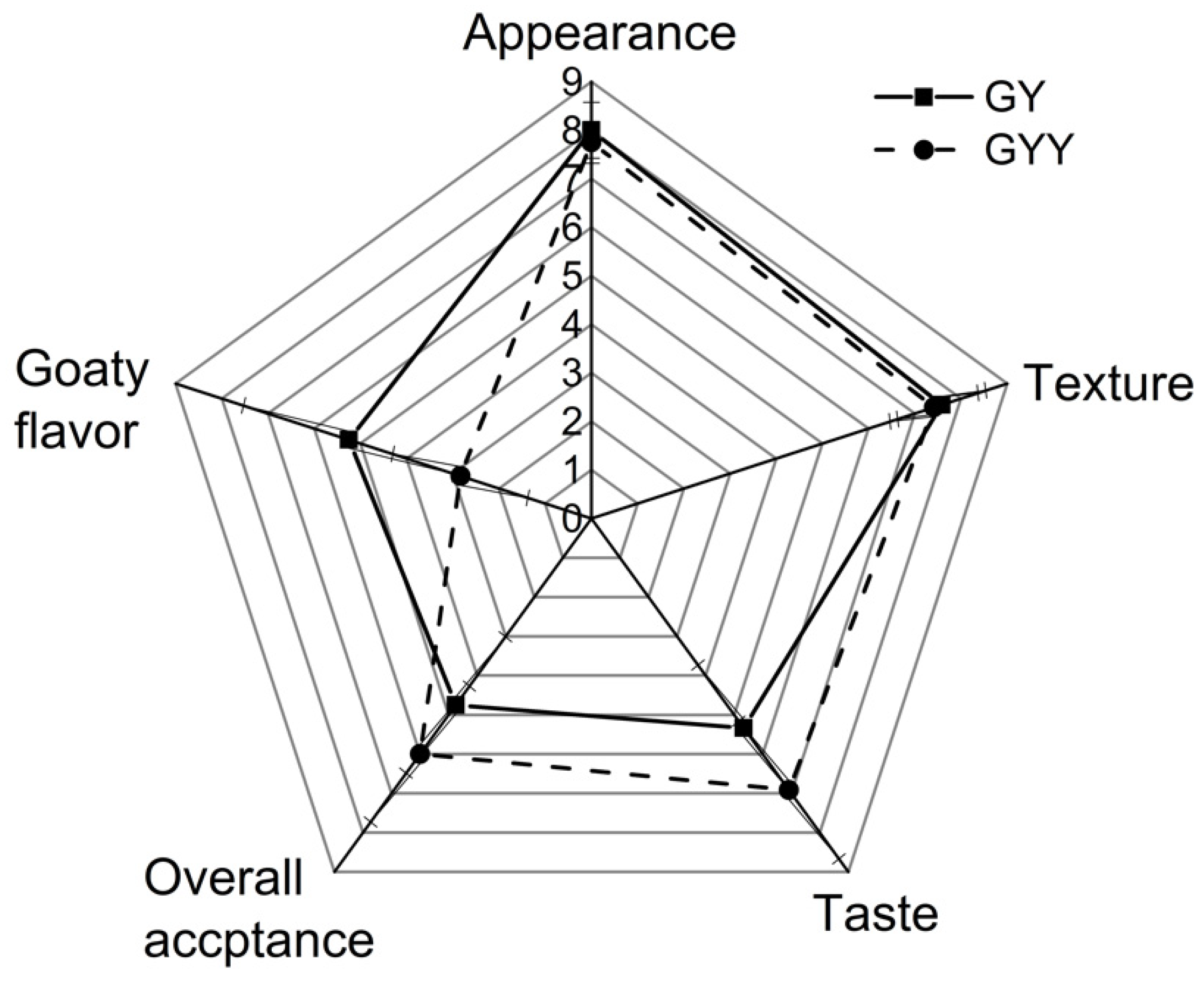

3.5. Sensory Properties of Two Different Goat Yogurt Samples

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Park, Y.W. Goat milk-chemistry and nutrition. In Handbook of Milk of Non-Bovine Mammals; Park, Y.W., Haenlein, G.F.W., Eds.; Blackwell: Oxford, UK, 2017; pp. 42–83. [Google Scholar]

- Hodgkinson, A.J.; Wallace, O.A.; Smolenski, G.; Prosser, C.G. Gastric digestion of cow and goat milk: Peptides derived from simulated conditions of infant digestion. Food Chem. 2019, 276, 619–625. [Google Scholar] [CrossRef] [PubMed]

- Haenlein, G.F.W. Goat milk in human nutrition. Small Rumin. Res. 2004, 51, 155–163. [Google Scholar] [CrossRef]

- Yang, C.J.; Ding, W.; Ma, L.J.; Jia, R. Discrimination and characterization of different intensities of goaty flavor in goat milk by means of an electronic nose. J. Dairy Sci. 2015, 98, 55–67. [Google Scholar] [CrossRef] [PubMed]

- BoyCheVa, S.; Dimitrov, T.; NayDeNoVa, N.; MihayloVa, G. Quality characteristics of yogurt from goat’s milk, supplemented with fruit juice. Czech J. Food Sci. 2011, 29, 24–30. [Google Scholar] [CrossRef]

- Costa, M.P.; Balthazar, C.F.; Franco, R.M.; Mársico, E.T.; Cruz, A.G.; Junior, C.C. Changes in expected taste perception of probiotic and conventional yogurts made from goat milk after rapidly repeated exposure. J. Dairy Sci. 2014, 97, 2610–2618. [Google Scholar] [CrossRef]

- Young, O.A.; Gupta, R.B.; Sadooghy-Saraby, S. Effects of cyclodextrins on the flavor of goat milk and its yogurt. J. Food Sci. 2012, 77, 122–127. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C.; Gao, F.; Xu, Y.; Guo, M. Effects of polymerized whey protein on goaty flavor and texture properties of fermented goat milk in comparison with β-cyclodextrin. J. Dairy Res. 2018, 85, 465–471. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.N.; Guo, M.R. Effects of addition of strawberry juice pre- or postfermentation on physiochemical and sensory properties of fermented goat milk. J. Dairy Sci. 2019, 102, 4978–4988. [Google Scholar] [CrossRef]

- Mituniewicz–Małek, A.; Zielińska, D.; Ziarno, M. Probiotic monocultures in fermented goat milk beverages – sensory quality of final product. Int. J. Dairy Technol. 2019, 72, 240–247. [Google Scholar] [CrossRef]

- Slačanac, V.; Božanić, R.; Hardi, J.; Rezessyné Szabó, J.U.D.I.T.; Lučan, M.; Krstanović, V. Nutritional and therapeutic value of fermented caprine milk. Int. J. Dairy Technol. 2010, 63, 171–189. [Google Scholar] [CrossRef]

- Jia, R.; Chen, H.; Chen, H.; Ding, W. Effects of fermentation with Lactobacillus rhamnosus GG on product quality and fatty acids of goat milk yogurt. J. Dairy Sci. 2016, 99, 221–227. [Google Scholar] [CrossRef] [PubMed]

- Cais-Sokolińska, D.; Wójtowski, J.; Pikul, J.; Danków, R.; Majcher, M.; Teichert, J.; Bagnicka, E. Formation of volatile compounds in kefir made of goat and sheep milk with high polyunsaturated fatty acid content. J. Dairy Sci. 2015, 98, 6692–6705. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz-Ersan, L.; Ozcan, T.; Akpinar-Bayizit, A.; Sahin, S. The antioxidative capacity of kefir produced from goat milk. Int. J. Chem. Eng. Appl. 2016, 7, 22–26. [Google Scholar] [CrossRef]

- Fontán, M.C.G.; Martínez, S.; Franco, I.; Carballo, J. Microbiological and chemical changes during the manufacture of kefir made from cows’ milk, using a commercial starter culture. Int. Dairy J. 2006, 16, 762–767. [Google Scholar] [CrossRef]

- Dertli, E.; Çon, A.H. Microbial diversity of traditional kefir grains and their role on kefir aroma. LWT Food Sci. Technol. 2017, 85, 151–157. [Google Scholar] [CrossRef]

- Wu, H.; Rui, X.; Li, W.; Chen, X.; Jiang, M.; Dong, M. Mung bean (Vigna radiata) as probiotic food through fermentation with Lactobacillus plantarum B1-6. LWT Food Sci. Technol. 2015, 63, 445–451. [Google Scholar] [CrossRef]

- Zheng, Z.; Lin, X. Study on application of medical diagnosis by electronic nose. World Sci. Technol. 2012, 14, 2115–2119. [Google Scholar] [CrossRef]

- Pan, L.; Zhang, W.; Zhu, N.; Mao, S.; Tu, K. Early detection and classification of pathogenic fungal disease in post-harvest strawberry fruit by electronic nose and gas chromatography-mass spectrometry. Food Res. Int. 2014, 62, 162–168. [Google Scholar] [CrossRef]

- Pan, D.D.; Wu, Z.; Peng, T.; Zeng, X.Q.; Li, H. Volatile organic compounds profile during milk fermentation by Lactobacillus pentosus and correlations between volatiles flavor and carbohydrate metabolism. J. Dairy Sci. 2014, 97, 624–631. [Google Scholar] [CrossRef]

- Yang, X.; Peppard, T. Solid-phase microextraction for flavor analysis. J. Agric. Food Chem. 1994, 42, 1925–1930. [Google Scholar] [CrossRef]

- Zhou, T.; Huo, R.; Kwok, L.Y.; Li, C.; Ma, Y.; Mi, Z.; Chen, Y. Effects of applying Lactobacillus helveticus H9 as adjunct starter culture in yogurt fermentation and storage. J. Dairy Sci. 2019, 102, 223–235. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 8586: Sensory Analysis—General Guidelines for the Selection, Raining and Monitoring of Selected Assessors and Expert Ensory Assessors; International Organization for Standardization (ISO): Geneva, Switzerland, 2012. [Google Scholar]

- Ghosh, D.; Chattoraj, D.K.; Chattopadhyay, P. Studies on changes in microstructure and proteolysis in cow and soy milk curd during fermentation using lactic cultures for improving protein bioavailability. J. Food Sci. Technol. 2013, 50, 979–985. [Google Scholar] [CrossRef]

- Chaves-López, C.; Serio, A.; Paparella, A.; Martuscelli, M.; Corsetti, A.; Tofalo, R.; Suzzi, G. Impact of microbial cultures on proteolysis and release of bioactive peptides in fermented milk. Food Microbiol. 2014, 42, 117–121. [Google Scholar] [CrossRef]

- Zhang, D.D.; Liu, J.L.; Jiang, T.M.; Li, L.; Fang, G.Z.; Liu, Y.P.; Chen, L.J. Influence of Kluyveromyces marxianus on proteins, peptides, and amino acids in Lactobacillus-fermented milk. Food Sci. Biotechnol. 2017, 26, 739–748. [Google Scholar] [CrossRef]

- Li, C.; Song, J.; Kwok, L.Y.; Wang, J.; Dong, Y.; Yu, H.; Chen, Y. Influence of Lactobacillus plantarum on yogurt fermentation properties and subsequent changes during postfermentation storage. J. Dairy Sci. 2017, 100, 2512–2525. [Google Scholar] [CrossRef]

- Mufandaedza, J.; Viljoen, B.C.; Feresu, S.B.; Gadaga, T.H. Antimicrobial properties of lactic acid bacteria and yeast-LAB cultures isolated from traditional fermented milk against pathogenic Escherichia coli and Salmonella enteritidis strains. Int. J. Food Microbiol. 2006, 108, 147–152. [Google Scholar] [CrossRef]

- Ahtesh, F.B.; Apostolopoulos, V.; Stojanovska, L.; Shah, N.P.; Mishra, V.K. Effects of fermented skim milk drink by Kluyveromyces marxianus LAF4 co-cultured with lactic acid bacteria to release angiotensin-converting enzyme inhibitory activities. Int. J. Dairy Technol. 2018, 71, 130–140. [Google Scholar] [CrossRef]

- Behare, P.V.; Singh, R.; Tomar, S.K.; Nagpal, R.; Kumar, M.; Mohania, D. Effect of exopolysaccharide-producing strains of Streptococcus thermophilus on technological attributes of fat-free lassi. J. Dairy Sci. 2010, 93, 2874–2879. [Google Scholar] [CrossRef]

- Damin, M.R.; Alcântara, M.R.; Nunes, A.P.; Oliveira, M.N.D. Effects of milk supplementation with skim milk powder, whey protein concentrate and sodium caseinate on acidification kinetics, rheological properties and structure of nonfat stirred yogurt. LWT Food Sci. Technol. 2009, 42, 1744–1750. [Google Scholar] [CrossRef]

- Bensmira, M.; Nsabimana, C.; Jiang, B. Effects of fermentation conditions and homogenization pressure on the rheological properties of Kefir. LWT Food Sci. Technol. 2010, 43, 1180–1184. [Google Scholar] [CrossRef]

- Gutiérrez-Méndez, N.; Vallejo-Cordoba, B.; González-Córdova, A.F.; Nevárez-Moorillón, G.V.; Rivera-Chavira, B. Evaluation of aroma generation of Lactococcus lactis with an electronic nose and sensory analysis. J. Dairy Sci. 2008, 91, 49–57. [Google Scholar] [CrossRef]

- Narvhus, J.A.; Gadaga, T.H. The role of interaction between yeasts and lactic acid bacteria in African fermented milks: A review. Int. J. Food Microbiol. 2003, 86, 51–60. [Google Scholar] [CrossRef]

- Settachaimongkon, S.; Nout, M.R.; Fernandes, E.C.A.; Hettinga, K.A.; Vervoort, J.M.; van Hooijdonk, T.C.; van Valenberg, H.J. Influence of different proteolytic strains of Streptococcus thermophilus in co-culture with Lactobacillus delbrueckii subsp. bulgaricus on the metabolite profile of set-yoghurt. Int. J. Food Microbiol. 2014, 177, 29–36. [Google Scholar] [CrossRef]

- De Souza, J.V.; Dias, F.S. Protective, technological, and functional properties of select autochthonous lactic acid bacteria from goat dairy products. Curr. Opin. Food Sci. 2017, 13, 1–9. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Wang, M.; Guo, M. Chemical, physiochemical, and microstructural properties, and probiotic survivability of fermented goat milk using polymerized whey protein and starter culture Kefir Mild 01. J. Food Sci. 2017, 82, 2650–2658. [Google Scholar] [CrossRef]

- Ranjitha, K.; Narayana, C.K.; Roy, T.K. Aroma profile of fruit juice and wine prepared from Cavendish banana (Musa sp., Group AAA) cv. Robusta. J. Hortic. Sci. 2013, 8, 217–223. [Google Scholar]

- Gadaga, T.H.; Mutukumira, A.N.; Narvhus, J.A. The growth and interaction of yeasts and lactic acid bacteria isolated from Zimbabwean naturally fermented milk in UHT milk. Int. J. Food. Microbiol. 2001, 68, 21–32. [Google Scholar] [CrossRef]

| Sensor Number | Sensor Name | General Description | Typical Targets and Limit of Detection |

|---|---|---|---|

| S1 | W1C | Aromatic compound | Toluene, 10 ppm |

| S2 | W5S | Oxynitride | NO2, 1 ppm |

| S3 | W3C | Ammonia, aromatic compounds | Benzene, 10 ppm |

| S4 | W6S | Hydrogen | H2, 0.1 ppm |

| S5 | W5C | Alkanes, aromatic compounds | Propane, 1 ppm |

| S6 | W1S | Broad Methane | CH3, 100 ppm |

| S7 | W1W | Sulfides, terpenes and sulfur organic | H2S, 1 ppm |

| S8 | W2S | Broad alcohols, partially aromatic compounds | CO, 100 ppm |

| S9 | W2W | Aromatics, organic sulfides | H2S, 1ppm |

| S10 | W3S | Alkanes, especially methane | CH3, 100 ppm |

| Compound Identified | GM | GY | GYY | ||||

|---|---|---|---|---|---|---|---|

| Content/log10 (Peak Area) | RPA (%) | Content/log10 (Peak Area) | RPA (%) | Content/log10 (Peak Area) | RPA (%) | ||

| Acids | Acetic acid | 8.6 ± 0.06 a | 7.97 | 7.96 ± 0.1 b | 6.09 | 0 ± 0 c | 0.00 |

| Butyric acid | 0 ± 0 b | 0.00 | 8.23 ± 0.05 a | 6.30 | 7.96 ± 0.17 a | 4.94 | |

| Caproic | 8.56 ± 0.03 b | 7.94 | 9.03 ± 0.04 a | 6.91 | 9.16 ± 0.04 a | 5.68 | |

| Benzoic acid | 0 ± 0 b | 0.00 | 9.01 ± 0.07 a | 6.89 | 9.47 ± 0.1 a | 5.87 | |

| Heptanoic acid | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 8.06 ± 0.08 a | 5.00 | |

| Caprylic | 8.54 ± 0.05 b | 7.91 | 9.13 ± 0.05 a | 6.99 | 9.26 ± 0.09 a | 5.74 | |

| N-nonanoic acid | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 7.91 ± 0.12 a | 4.90 | |

| Capric acid | 8.66 ± 0.06 b | 8.03 | 8.58 ± 0.07 b | 6.57 | 9.35 ± 0.08 a | 5.80 | |

| Trans-2-hexenyl hexanoic acid | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 7.89 ± 0.19 a | 4.89 | |

| Tridecanoic acid | 0 ± 0 b | 0.00 | 7.79 ± 0.03 a | 5.96 | 7.88 ± 0.05 a | 4.89 | |

| Palmitic acid | 8.44 ± 0.09 a | 7.82 | 8.23 ± 0.09 a | 6.30 | 7.74 ± 0.09 b | 4.80 | |

| Ricinoleic acid | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 8.21 ± 0.18 a | 5.09 | |

| Subtotals | 42.79 | 39.68 | 67.94 | 52.01 | 92.84 | 57.60 | |

| Alcohols | 2,3-butanediol | 7.98 ± 0.13 a | 7.39 | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 |

| Hexyl alcohol | 0 ± 0 b | 0.00 | 8.16 ± 0.13 a | 6.24 | 0 ± 0 b | 0.00 | |

| 2-methyl-2,4-pentanediol | 0 ± 0 b | 0.00 | 7.76 ± 0.06 a | 5.94 | 0 ± 0 b | 0.00 | |

| Phenethyl alcohol | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 9.27 ± 0.16 a | 5.75 | |

| Isooctyl alcohol | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 8.04 ± 0.12 a | 4.99 | |

| Undecyl alcohol | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 8.23 ± 0.06 a | 5.11 | |

| Subtotals | 7.98 | 7.39 | 15.91 | 12.18 | 25.54 | 15.84 | |

| Esters | Methyl glyoxylate | 0 ± 0 b | 0.00 | 8.07 ± 0.16 a | 6.18 | 0 ± 0 b | 0.00 |

| Ethyl acetate | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 9.9 ± 0.23 a | 6.14 | |

| Isoamyl acetate | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 8.42 ± 0.15 a | 5.22 | |

| Dodecanolide | 7.7 ± 0.12 a | 7.13 | 7.39 ± 0.1 a | 5.66 | 7.73 ± 0.11 a | 4.79 | |

| Subtotals | 7.69 | 7.13 | 8.07 ± 0.16 a | 11.84 | 26.04 | 16.15 | |

| Aldehydes | Hexanal | 8.25 ± 0.04 a | 7.65 | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 |

| Nonanal | 8.56 ± 0.06 a | 7.94 | 7.81 ± 0.05 b | 5.98 | 0 ± 0 b | 0.00 | |

| Benzenepropanal | 8.55 ± 0.15 a | 7.92 | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | |

| Undecanal | 7.43 ± 0.21 a | 6.88 | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | |

| Subtotals | 32.78 | 30.39 | 7.81 | 5.98 | 0.00 | 0.00 | |

| Ketone | 3-hydroxy-2-butanone | 0 ± 0 b | 0.00 | 7.81 ± 0.11 a | 5.98 | 8.63 ± 0.31 a | 5.35 |

| 2-heptanone | 8.47 ± 0.05 a | 7.85 | 0 ± 0 b | 0.00 | 0.00 | 0.00 | |

| 2-nonanone | 0 ± 0 b | 0.00 | 8.1 ± 0.06 a | 6.20 | 0 ± 0 b | 0.00 | |

| Methylnonylketone | 0 ± 0 b | 0.00 | 0 ± 0 b | 0.00 | 8.15 ± 0.18 a | 5.05 | |

| Subtotals | 8.47 | 7.85 | 15.91 | 12.18 | 16.77 | 10.40 | |

| Phenols | Dihydroeugenol | 8.14 ± 0.05 a | 7.55 | 7.59 ± 0.09 b | 5.81 | 0 ± 0 c | 0.00 |

| Subtotals | 8.14 | 7.55 | 7.59 | 5.81 | 0.00 | 0.00 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Huang, L.; Xing, G.; Xu, X.; Tu, C.; Dong, M. Effect of Co-Fermentation with Lactic Acid Bacteria and K. marxianus on Physicochemical and Sensory Properties of Goat Milk. Foods 2020, 9, 299. https://doi.org/10.3390/foods9030299

Huang Z, Huang L, Xing G, Xu X, Tu C, Dong M. Effect of Co-Fermentation with Lactic Acid Bacteria and K. marxianus on Physicochemical and Sensory Properties of Goat Milk. Foods. 2020; 9(3):299. https://doi.org/10.3390/foods9030299

Chicago/Turabian StyleHuang, Zhihai, Lu Huang, Guangliang Xing, Xiao Xu, Chuanhai Tu, and Mingsheng Dong. 2020. "Effect of Co-Fermentation with Lactic Acid Bacteria and K. marxianus on Physicochemical and Sensory Properties of Goat Milk" Foods 9, no. 3: 299. https://doi.org/10.3390/foods9030299

APA StyleHuang, Z., Huang, L., Xing, G., Xu, X., Tu, C., & Dong, M. (2020). Effect of Co-Fermentation with Lactic Acid Bacteria and K. marxianus on Physicochemical and Sensory Properties of Goat Milk. Foods, 9(3), 299. https://doi.org/10.3390/foods9030299