The Influence of Composition and Manufacturing Approach on the Physical and Rehydration Properties of Milk Protein Concentrate Powders

Abstract

:1. Introduction

2. Materials and Methods

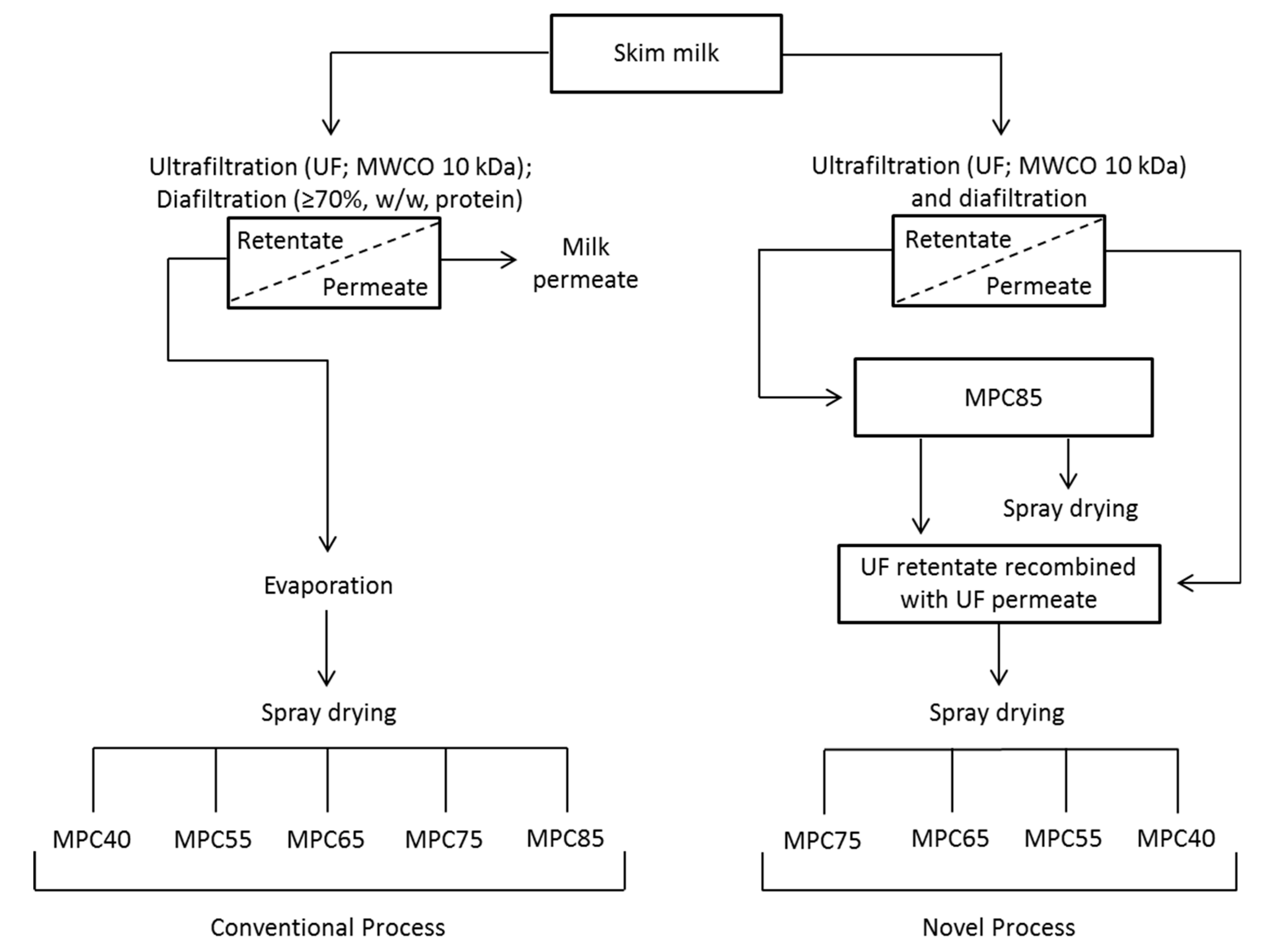

2.1. Manufacture of Milk Protein Concentrate Powders

2.2. Compositional Analysis of Milk Protein Concentrate Powders

2.3. Bulk Density, Particle Density, Occluded, and Interstitial Air

2.4. Powder Particle Size Distribution

2.5. Powder Flowability and Compressibility

2.6. Scanning Electron Microscopy

2.7. Wettability of Milk Protein Concentrate Powders

2.8. Particle Size Distribution of Milk Protein Concentrate Dispersions

2.9. Powder Solubility

2.10. Statistical Analysis

3. Results

3.1. Composition of Milk Protein Concentrate Powders

3.2. Physical Properties of Milk Protein Concentrate Powders

3.2.1. Powder Particle Size

3.2.2. Density

3.2.3. Flowability

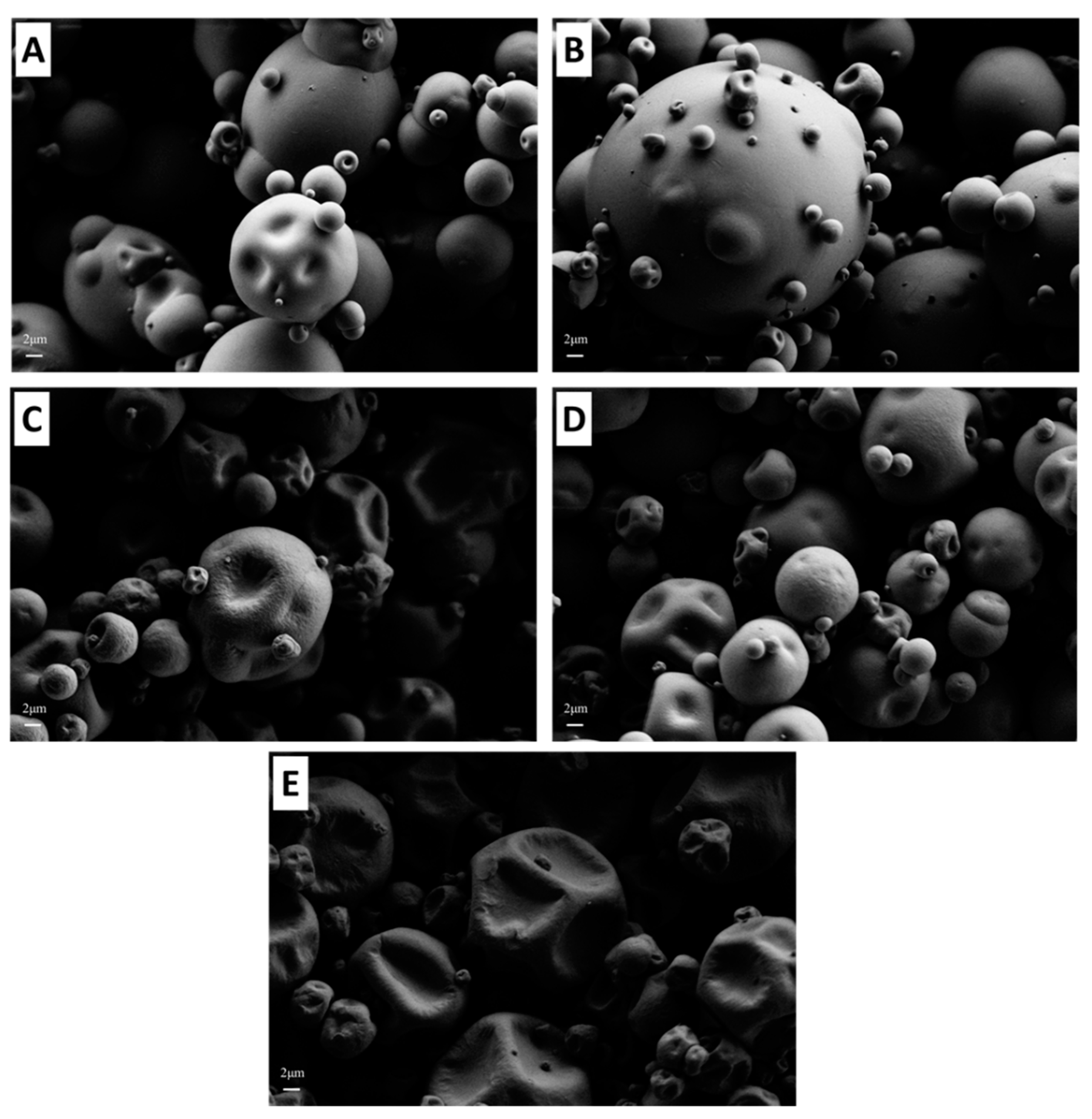

3.2.4. Microstructure

3.3. Wettability of Milk Protein Concentrate Powders

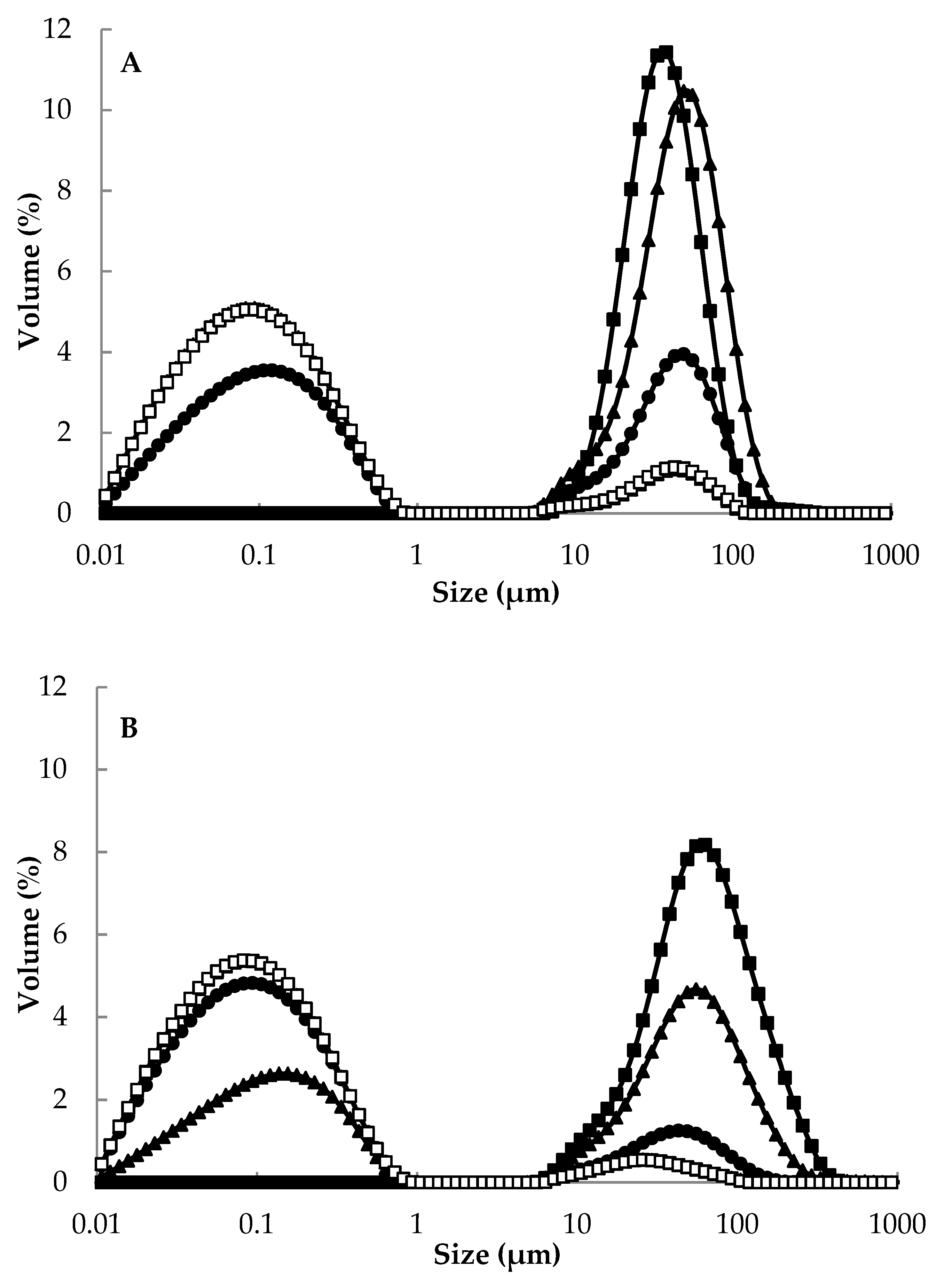

3.4. Dissolution and Solubility of Milk Protein Concentrate Powders

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Henchion, M.; Hayes, M.; Mullen, A.M.; Fenelon, M.; Tiwari, B. Future protein supply and demand: Strategies and factors influencing a sustainable equilibrium. Foods 2017, 6, 53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singh, H. Interactions of milk proteins during the manufacture of milk powders. Lait 2007, 87, 413–423. [Google Scholar] [CrossRef]

- Huffman, L.; Harper, W.J. Maximizing the value of milk through separation technologies. J. Dairy Sci. 1999, 82, 2238–2244. [Google Scholar] [CrossRef]

- Mistry, V.V.; Hassan, H.N. Delactosed, high milk protein powder. 1. Manufacture and composition. J. Dairy Sci. 1991, 74, 1163–1169. [Google Scholar] [CrossRef]

- Sikand, V.; Tong, P.S.; Roy, S.; Rodriguez-Saona, L.E.; Murray, B.A. Solubility of commercial milk protein concentrates and milk protein isolates. J. Dairy Sci. 2011, 94, 6194–6202. [Google Scholar] [CrossRef]

- Sikand, V.; Tong, P.S.; Vink, S.; Walker, J. Effect of powder source and processing conditions on the solubility of milk protein concentrates 80. Milchwissenschaft 2012, 67, 300–303. [Google Scholar]

- Mimouni, A.; Deeth, H.C.; Whittaker, A.K.; Gidley, M.J.; Bhandari, B.R. Investigation of the microstructure of milk protein concentrate powders during rehydration: Alterations during storage. J. Dairy Sci. 2010, 93, 463–472. [Google Scholar] [CrossRef]

- Crowley, S.V.; Desautel, B.; Gazi, I.; Kelly, A.L.; Huppertz, T.; O'Mahony, J.A. Rehydration characteristics of milk protein concentrate powders. J. Food Eng. 2015, 149, 105–113. [Google Scholar] [CrossRef]

- Havea, P. Protein interactions in milk protein concentrate powders. Int. Dairy J. 2006, 16, 415–422. [Google Scholar] [CrossRef]

- Mimouni, A.; Deeth, H.C.; Whittaker, A.K.; Gidley, M.J.; Bhandari, B.R. Rehydration process of milk protein concentrate powder monitored by static light scattering. Food Hydrocoll. 2009, 23, 1958–1965. [Google Scholar] [CrossRef]

- Schuck, P.; Mejean, S.; Dolivet, A.; Gaiani, C.; Banon, S.; Scher, J.; Jeantet, R. Water transfer during rehydration of micellar casein powders. Lait 2007, 87, 425–432. [Google Scholar] [CrossRef] [Green Version]

- Gaiani, C.; Schuck, P.; Scher, J.; Desobry, S.; Banon, S. Dairy powder rehydration: Influence of protein state, incorporation mode, and agglomeration. J. Dairy Sci. 2007, 90, 570–581. [Google Scholar] [CrossRef]

- Fyfe, K.N.; Kravchuk, O.; Le, T.; Deeth, H.C.; Nguyen, A.V.; Bhandari, B. Storage induced changes to high protein powders: Influence on surface properties and solubility. J. Sci. Food Agric. 2011, 9, 2566–2575. [Google Scholar] [CrossRef]

- Gazi, I.; Huppertz, T. Influence of protein content and storage conditions on the solubility of caseins and whey proteins in milk protein concentrates. Int. Dairy J. 2015, 6, 22–30. [Google Scholar] [CrossRef]

- Thomas, M.E.C.; Scher, J.; Desobry-Banon, S.; Desobry, S. Milk powders ageing: Effect on physical and functional properties. Crit. Rev. Food Sci. Nutr. 2004, 44, 297–322. [Google Scholar] [CrossRef] [PubMed]

- Le, T.T.; Bhandari, B.; Deeth, H.C. Chemical and physical changes in milk protein concentrate (MPC80) powder during storage. J. Agric. Food Chem. 2011, 59, 5465–5473. [Google Scholar] [CrossRef] [PubMed]

- Anema, S.G.; Pinder, D.N.; Hunter, R.J.; Hemar, Y. Effects of storage temperature on the solubility of milk protein concentrate (MPC85). Food Hydrocoll. 2006, 20, 386–393. [Google Scholar] [CrossRef]

- Crowley, S.V.; Kelly, A.L.; Schuck, P.; Jeantet, R.; O’Mahony, J.A. Rehydration and solubility characteristics of high-protein dairy powders. In Advanced Dairy Chemistry. Volume 1B: Proteins: Applied aspects, 4th ed.; McSweeney, P.L.H., O’Mahony, J.A., Eds.; Springer: New York, NY, USA, 2016; pp. 99–131. [Google Scholar] [CrossRef]

- Augustin, M.A.; Sanguansri, P.; Williams, R.; Andrews, H. High shear treatment of concentrates and drying conditions influence the solubility of milk protein concentrate powders. J. Dairy Res. 2012, 79, 459–468. [Google Scholar] [CrossRef]

- Fang, Y.; Rogers, S.; Selomulya, C.; Chen, X.D. Functionality of milk protein concentrate: Effect of spray drying temperature. Biochem Eng. J. 2012, 62, 101–105. [Google Scholar] [CrossRef]

- Haque, E.; Bhandari, B.R.; Gidley, M.J.; Deeth, H.C.; Whittaker, A.K. Ageing-induced solubility loss in milk protein concentrate powders: Effect of protein conformational modifications and interactions with water. J. Sci. Food Agric. 2010, 91, 2576–2581. [Google Scholar] [CrossRef]

- Gaiani, C.; Ehrhardt, J.J.; Scher, J.; Hardy, J.; Desobry, S.; Banon, S. Surface composition of dairy powders observed by X-ray photoelectron spectroscopy and effects on their rehydration properties. Colloids Surf. B 2006, 49, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Schuck, P.; Le Floch-Fouéré, C.; Jeantet, R. Changes in functional properties of milk protein powders: Effects of vacuum concentration and drying. Dry. Technol. 2013, 31, 13–14. [Google Scholar] [CrossRef]

- Maidannyk, V.; McSweeney, D.J.; Hogan, S.A.; Miao, S.; Montgomery, S.; Auty, M.A.E.; McCarthy, N.A. Water sorption and hydration in spray-dried milk protein powders: Selected physicochemical properties. Food Chem. 2020, 304, 125418. [Google Scholar] [CrossRef] [PubMed]

- ISO/IDF. Dried Milk and Dried Milk Products—Determination of Fat Content—Gravimetric Method (Reference Method); ISO 1736:2009 (IDF 9:2008); International Organization for Standardization: Brussels, Belgium, 2008. [Google Scholar]

- GEA Niro. A2a—Powder bulk density; GEA Process Engineering A/S: Gladsaxevej, Denmark, 2006. [Google Scholar]

- GEA Niro. A11a—Particle Density, Occluded Air and Interstitial Air by Air Pycnometer; GEA Process Engineering A/S: Gladsaxevej, Denmark, 2006. [Google Scholar]

- Fitzpatrick, J.J.; Barry, K.; Delaney, C.; Keogh, K. Assessment of the flowability of spray-dried milk powders for chocolate manufacture. Lait 2005, 85, 269–277. [Google Scholar] [CrossRef] [Green Version]

- Schuck, P.; Dolivet, A.; Jeantet, R. Determination of flowability and floodability indices. In Analytical Methods for Food and Dairy Powders, 1st ed.; Schuck, P., Dolivet, A., Jeantet, R., Eds.; Wiley-Blackwell: West Sussex, UK, 2012; pp. 129–143. [Google Scholar]

- GEA Niro. A5b—Wettability IDF method; GEA Process Engineering A/S: Gladsaxevej, Denmark, 2009. [Google Scholar]

- Fitzpatrick, J.J.; Lauwe, A.V.; Coursol, M.; O’Brien, A.; Fitzpatrick, K.L.; Ji, J.; Miao, S. Investigation of the rehydration of food powders by comparing the behaviour of twelve powders with different properties. Powder Technol. 2016, 297, 340–348. [Google Scholar] [CrossRef]

- Karlsson, A.O.; Ipsen, R.; Schrader, K.; Ardo, Y. Relationship between physical properties of casein micelles and rheology of skim milk concentrate. J. Dairy Sci. 2005, 88, 3784–3797. [Google Scholar] [CrossRef]

- Sauer, A.; Doehner, I.; Moraru, C.I. Steady shear rheological properties of micellar casein concentrates obtained by membrane filtration as a function of shear rate, concentration and temperature. J. Dairy Sci. 2012, 95, 5569–5579. [Google Scholar] [CrossRef]

- Crowley, S.V.; Gazi, I.; Kelly, A.L.; Huppertz, T.; O’Mahony, J.A. Influence of protein concentration on the physical characteristics and flow properties of milk protein concentrate powders. J. Food Eng. 2014, 135, 31–38. [Google Scholar] [CrossRef]

- Deeth, H.C.; Hartanto, J. Chemistry of Milk—role of constituents in evaporation and drying. In Dairy Powders and Concentrated Products, 1st ed.; Tamine, A.Y., Ed.; Wiley-Blackwell: West Sussex, UK, 2009; pp. 1–27. [Google Scholar]

- Walstra, P.; Wouters, J.T.M.; Geurts, T.J. Concentration processes. In Dairy Science and Technology, 2nd ed.; CRC Press: Florida, FL, USA, 2006; pp. 297–335. [Google Scholar]

- Rupp, L.S.; Molitor, M.S.; Lucey, J.A. Effect of processing methods and protein content of the concentrate on the properties of milk protein concentrate with 80% protein. J. Dairy Sci. 2018, 101, 7702–7713. [Google Scholar] [CrossRef]

- Eshpari, H.; Tong, P.S.; Corredig, M. Changes in the physical properties, solubility, and heat stability of milk protein concentrates prepared from partially acidified milk. J. Dairy Sci. 2014, 97, 7394–7401. [Google Scholar] [CrossRef]

- Skanderby, M.; Westergaard, V.; Partridge, A.; Muir, D.D. Dried milk products. In Dairy Powders and Concentrated Products, 1st ed.; Tamime, A.Y., Ed.; Wiley-Blackwell: West Sessex, UK, 2009; pp. 180–234. [Google Scholar]

- Turchiuli, C.; Eloualia, Z.; El Mansouri, N.; Dumoulin, E. Fluidised bed agglomeration: Agglomerates shape and end-use properties. Powder Technol. 2005, 157, 168–175. [Google Scholar] [CrossRef]

- Kelly, G.M.; O’Mahony, J.A.; Kelly, A.L.; Huppertz, T.; Kennedy, D.; O’Callaghan, D.J. Influence of protein concentration on surface composition and physico-chemical properties of spray dried milk protein concentrate powders. Int. Dairy J. 2015, 51, 34–40. [Google Scholar] [CrossRef]

- Tamime, A.Y.; Robinson, R.K.; Michel, M. Microstructure of concentrated and dried milk products. In Structure of Dairy Products, 1st ed.; Tamime, A.Y., Ed.; Blackwell Publishing Ltd.: Oxford, UK, 2007; pp. 104–133. [Google Scholar]

- Sadek, C.; Li, H.; Schuck, P.; Fallourd, Y.; Pradeau, N.; Le Floch-Fouéré, C.; Jeantet, R. To what extent do whey and casein micelle proteins influence the morphology and properties of the resulting powder? Dry. Technol. 2014, 32, 1540–1551. [Google Scholar] [CrossRef]

- Tan, S.; Ebrahimi, A.; Langrish, T. Smart release-control of microencapsulated ingredients from milk protein tablets using spray drying and heating. Food Hydrocoll. 2019, 92, 181–188. [Google Scholar] [CrossRef]

- Tan, S.; Hadinoto, K.; Ebrahimi, A.; Langrish, T. Fabrication of novel casein gel with controlled release property via acidification, spray drying and tableting approach. Colloids Surf. B 2019, 177, 329–337. [Google Scholar] [CrossRef]

- Horne, D.S. Casein Interactions: Casting Light on the Black Boxes, the Structure in Dairy Products. Int. Dairy J. 1998, 8, 171–177. [Google Scholar] [CrossRef]

- Bouvier, J.M.; Collado, M.; Gardiner, D.; Scott, M.; Schuck, P. Physical and rehydration properties of milk protein concentrates: Comparison of spray-dried and extrusion-porosifed powders. Dairy Sci. Technol. 2013, 93, 387–399. [Google Scholar] [CrossRef] [Green Version]

| MPC | Protein | Lactose | Fat | Ash | Moisture | Ash:Protein |

|---|---|---|---|---|---|---|

| (%, w/w) | ||||||

| MPC85 | 84.7 ± 0.9 | 1.37 | 2.07 | 6.88 a ± 0.1 | 6.68 a ± 0.3 | 0.08 |

| MPC75 | 74.1 ± 0.8 | 12.6 | 1.59 | 6.99 b ± 0.0 | 5.19 b ± 0.1 | 0.09 |

| MPC65 | 63.6 ± 0.7 | 22.8 | 1.34 | 7.17 c ± 0.0 | 5.49 b ± 0.1 | 0.11 |

| MPC55 | 53.7 ± 1.3 | 33.4 | 1.17 | 7.43 d ± 0.0 | 5.09 b ± 0.0 | 0.14 |

| MPC40 | 38.9 ± 0.6 | 48.2 | 0.87 | 7.82 e ± 0.0 | 4.59 c ± 0.0 | 0.20 |

| MPC | pp | pb | pt | Via | Voa | D90 | D[4,3] |

|---|---|---|---|---|---|---|---|

| (g/cm3) | mL/100 g | μm | |||||

| MPC85 | 1.00 a ± 0.0 | 0.29 a ± 0.0 | 0.35 a ± 0.0 | 190 a ± 7.8 | 32.2 a ± 0.1 | 127 a ± 4.5 | 57.3 a ± 2.9 |

| MPC75 | 1.08 b ± 0.0 | 0.32 b ± 0.0 | 0.38 b ± 0.0 | 173 a ± 5.6 | 25.5 b ± 0.4 | 76.1 b ± 1.4 | 37.5 b ± 0.7 |

| MPC65 | 1.14 c ± 0.0 | 0.34 c ± 0.0 | 0.41 c ± 0.0 | 155 b ± 3.1 | 20.5 c ± 0.8 | 47.4 c ± 1.0 | 25.5 c ± 0.4 |

| MPC55 | 1.18 d ± 0.0 | 0.39 d ± 0.0 | 0.44 d ± 0.0 | 141 b ± 10 | 17.5 d ± 1.1 | 36.3 d ± 0.8 | 19.9 d ± 0.6 |

| MPC40 | 1.14 c ± 0.0 | 0.40 d ± 0.0 | 0.43 cd ± 0.0 | 143 b ± 0.8 | 21.1 c ± 0.7 | 35.9 d ± 0.3 | 18.8 d ± 0.2 |

| MPC | i | JC | CI (%) | HR | Wettability (%) | Solubility (%) |

|---|---|---|---|---|---|---|

| MPC85 | 2.1 ± 0.1 | Cohesive | 41.2 a ± 1.5 | 1.71 | 14.7 a ± 1.8 | 83.0 a ± 2.2 |

| MPC75 | 2.1 ± 0.0 | Cohesive | 42.1 a ± 0.7 | 1.73 | 17.5 a ± 2.0 | 92.9 b ± 1.6 |

| MPC65 | 2.0 ± 0.3 | Cohesive | 41.9 a ± 2.6 | 1.73 | 49.3 b ± 1.1 | 98.0 c ± 1.3 |

| MPC55 | 2.2 ± 0.2 | Cohesive | 35.0 b ± 1.3 | 1.55 | 48.3 b ± 1.1 | 98.5 c ± 1.1 |

| MPC40 | 2.6 ± 0.2 | Cohesive | 32.4 b ± 1.8 | 1.50 | 48.3 b ± 0.9 | 98.1 c ± 0.8 |

| MPC | D90 (μm) | D[4,3] (μm) | ||

| 23 °C | 50 °C | 23 °C | 50 °C | |

| MPC85 | 68.9 a ± 5.4 | 156 a ± 11 | 40.7 a ± 2.9 | 76.4 a ± 4.3 |

| MPC75 | 92.6 b ± 4.2 | 98.2 b ± 2.2 | 51.7 b ± 1.9 | 36.7 a ± 3.5 |

| MPC65 | 59.7 c ± 2.1 | 25.6 c ± 11 | 18.3 c ± 1.6 | 6.68 a ± 1.9 |

| MPC55 | 13.1 d ± 4.6 | 0.39 d ± 0.0 | 4.57 d ± 0.3 | 1.98 b ± 0.2 |

| MPC40 | 6.30 e ± 5.8 | 0.41 d ± 0.1 | 4.25 d ± 0.3 | 2.06 b ± 0.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

McSweeney, D.J.; Maidannyk, V.; Montgomery, S.; O’Mahony, J.A.; McCarthy, N.A. The Influence of Composition and Manufacturing Approach on the Physical and Rehydration Properties of Milk Protein Concentrate Powders. Foods 2020, 9, 236. https://doi.org/10.3390/foods9020236

McSweeney DJ, Maidannyk V, Montgomery S, O’Mahony JA, McCarthy NA. The Influence of Composition and Manufacturing Approach on the Physical and Rehydration Properties of Milk Protein Concentrate Powders. Foods. 2020; 9(2):236. https://doi.org/10.3390/foods9020236

Chicago/Turabian StyleMcSweeney, David J., Valentyn Maidannyk, Sharon Montgomery, James A. O’Mahony, and Noel A. McCarthy. 2020. "The Influence of Composition and Manufacturing Approach on the Physical and Rehydration Properties of Milk Protein Concentrate Powders" Foods 9, no. 2: 236. https://doi.org/10.3390/foods9020236

APA StyleMcSweeney, D. J., Maidannyk, V., Montgomery, S., O’Mahony, J. A., & McCarthy, N. A. (2020). The Influence of Composition and Manufacturing Approach on the Physical and Rehydration Properties of Milk Protein Concentrate Powders. Foods, 9(2), 236. https://doi.org/10.3390/foods9020236