Development of a Millet Starch Edible Film Containing Clove Essential Oil

Abstract

1. Introduction

2. Material and Methods

2.1. Materials

2.2. Starch Extraction

2.3. Extraction of Essential Oil

2.4. Gas Chromatography-Mass Spectroscopy (GC-MS) Analysis

2.5. Preparation of the Starch Edible Film

2.6. Film Thickness

2.7. Mechanical Properties

2.8. Water Vapor Permeability

2.9. Oxygen Transmission Rate

2.10. DPPH Radical Scavenging Activity

2.11. Antimicrobial Activity Test

2.12. Statistical Analysis

3. Results and Discussion

3.1. Chemical Composition of Clove Oil

3.2. Physical, Mechanical, and Barrier Properties of Millet Starch Edible Films Incorporated with Cloves’ Essential Oil.

3.3. Free Radical Scavenging Activity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cho, S.Y.; Rhee, C. Mechanical properties and water vapor permeability of edible films made from fractionated soy proteins with ultrafiltration. LWT Food Sci. Technol. 2004, 37, 833–839. [Google Scholar] [CrossRef]

- Garcia, M.A.; Martino, M.N.; Zaritzky, N.E. Lipid addition to improve barrier properties of edible starch-based films and coatings. J. Food Sci. 2000, 65, 941–944. [Google Scholar] [CrossRef]

- Nirmala, M.J.; Samundeeswari, A.; Sankar, P.D. Natural plant resources in anti-cancer therapy—A review. Res. Plant Biol. 2011, 1, 1–14. [Google Scholar]

- Bonilla, J.; Atarés, L.; Vargas, M.; Chiralt, A. Effect of essential oils and homogenization conditions on properties of chitosan-based films. Food Hydrocoll. 2012, 26, 9–16. [Google Scholar] [CrossRef]

- Cagri, A.; Ustunol, Z.; Ryser, E.T. Antimicrobial edible films and coatings. J. Food Protect. 2004, 67, 833–848. [Google Scholar] [CrossRef] [PubMed]

- Ko, S.; Janes, M.; Hettiarachchy, N.; Johnson, M.G. Physical and chemical properties of edible films containing nisin and their action against Listeria monocytogenes. J. Food Sci. 2001, 66, 1006–1011. [Google Scholar] [CrossRef]

- Chiumarelli, M.; Hubinger, M.D. Stability, solubility, mechanical and barrier properties of cassava starch–Carnauba wax edible coatings to preserve fresh-cut apples. Food Hydrocoll. 2012, 28, 59–67. [Google Scholar] [CrossRef]

- Food and Agricultural Organisation. Countrystat, Economic; Food and Agricultural Organisation: Rome, Italy, 2009. [Google Scholar]

- Taylor, J.R. Sorghum and Millets: Taxonomy, History, Distribution, and Production. In Sorghum and Millets, 2nd ed.; AACC International Press: Washington, DC, USA, 2019; pp. 1–21. [Google Scholar]

- Freeman, J.E.; Bocan, B.J. Pearl millet: A potential crop for wet milling. 1973. Cereal Sci. Today 1973, 18, 69–73. [Google Scholar]

- Kim, J.Y.; Jang, K.C.; Park, B.R.; Han, S.I.; Choi, K.J.; Kim, S.Y.; Hwang, J. Physicochemical and antioxidative properties of selected barnyard millet (Echinochloa utilis) species in Korea. Food Sci. Biotechnol. 2011, 20, 461–469. [Google Scholar] [CrossRef]

- Krishnakumari, S.; Thayumanavan, B. Content of starch and sugars and in vitro digestion of starch by α-amylase in five minor millets. Plant Food. Hum. Nutr. 1995, 48, 327–333. [Google Scholar] [CrossRef]

- Weiwei, L.; Juan, X.; Beijiu, C.; Suwen, Z.; Qing, M.; Huan, M. Anaerobic biodegradation, physical and structural properties of normal and high-amylose maize starch films. Int. J. Agric. Biol. Eng. 2016, 9, 184–193. [Google Scholar]

- Sánchez-González, L.; Vargas, M.; González-Martínez, C.; Chiralt, A.; Cháfer, M. Use of essential oils in bioactive edible coatings: A review. Food Eng. Rev. 2011, 3, 1–16. [Google Scholar] [CrossRef]

- Burt, S. Essential oils: Their antibacterial properties and potential applications in foods-a review. Int. J. Food Microbiol. 2004, 94, 223–253. [Google Scholar] [CrossRef] [PubMed]

- Alsaad, A.J.A.; Altemimi, A.B.; Aziz, S.N.; Lakhssassi, N. Extraction and Identification of Cactus Opuntia dillenii Seed Oil and its Added Value for Human Health Benefits. Pharmacogn. J. 2019, 11, 1–9. [Google Scholar] [CrossRef]

- Lee, K.G.; Shibamoto, T. Antioxidant property of aroma extract isolated from clove buds. Syzygium aromaticum (L.) Merr. et Perry. Food Chem. 2001, 74, 443–448. [Google Scholar]

- Miyazawa, M.; Hisama, M. Antimutagenic activity of phenylpropanoids from clove (Syzygium aromaticum). J. Agric. Food Chem. 2003, 51, 6413–6422. [Google Scholar] [CrossRef]

- Gülçin, İ.; Elmastaş, M.; Aboul-Enein, H.Y. Antioxidant activity of clove oil-A powerful antioxidant source. Arab. J. Chem. 2012, 5, 489–499. [Google Scholar] [CrossRef]

- Bhupender, S.K.; Rajneesh, B.; Baljeet, S.Y. Physicochemical, functional, thermal and pasting properties of starches isolated from pearl millet cultivars. Int. Food Res. J. 2013, 20, 1555–1561. [Google Scholar]

- Natta, L.; Orapin, K.; Krittika, N.; Pantip, B. Essential oil from five Zingiberaceae for anti food-borne bacteria. Int. Food Res. J. 2008, 15, 337–346. [Google Scholar]

- Resianingrum, R.; Atmaka, W.; Khasanah, L.U.; Kawuiji, K.; Utami, R.; Praseptiangga, D. Characterization of cassava starch-based edible film enriched with lemongrass oil (Cymbopogon citratus). Nusantara Biosci. 2016, 8, 278–282. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Oxygen Gas Transmission Rate through Plastic Film and Sheeting Using Coulometric Sensor. In Annual Book of ASTM Standards; ASTM Publisher: Chicago, IL, USA; Philadelphia, PA, USA, 1986; pp. 387–393. [Google Scholar]

- ASTM. Standard Test Method for Water Vapor Transmission of Materials. Designation E96-95. In Annual Book of ASTM Standards; American Society for Testing and Materials: Philadelphia, PA, USA, 1995. [Google Scholar]

- Colla, E.; do Amaral Sobral, P.J.; Menegalli, F.C. Amaranthus cruentus flour edible films: Influence of stearic acid addition, plasticizer concentration, and emulsion stirring speed on water vapor permeability and mechanical properties. J. Agric. Food Chem. 2006, 54, 6645–6653. [Google Scholar] [CrossRef] [PubMed]

- Maizura, M.; Fazilah, A.; Norziah, M.H.; Karim, A.A. Antibacterial activity and mechanical properties of partially hydrolyzed sago starch–alginate edible film containing lemongrass oil. J. Food Sci. 2007, 72, C324–C330. [Google Scholar] [CrossRef] [PubMed]

- Tooraj, M.; Hossein, T.; Sayed, M.; Abdol, R. Antibacterial, antioxidant and optical properties of edible starch-chitosan composite film containing Thymus kotschyanus essential oil. Vet. Res. Forum. 2012, 3, 167–173. [Google Scholar]

- Chaieb, K.; Hajlaoui, H.; Zmantar, T.; Kahla-Nakbi, A.B.; Rouabhia, M.; Mahdouani, K.; Bakhrouf, A. The chemical composition and biological activity of clove essential oil, Eugenia caryophyllata (Syzigium aromaticum L. Myrtaceae): A short review. Phytother. Res. 2007, 21, 501–506. [Google Scholar] [CrossRef]

- Uddin, M.A.; Shahinuzzaman, M.; Rana, M.S.; Yaakob, Z. Study of chemical composition and medicinal properties of volatile oil from clove buds (Eugenia caryophyllus). Int. J. Pharm. Sci. Res. 2017, 8, 895–899. [Google Scholar]

- Nowak, K.; Ogonowski, J.; Jaworska, M.; Grzesik, K. Clove oil-properties and applications. Chemik 2012, 66, 145–152. [Google Scholar]

- Barceloux, D.G. Medical Toxicology of Natural Substances: Foods, Fungi, Medicinal Herbs, Plants, and Venomous Animals; John Wiley & Sons: Hoboken, NJ, USA, 2008; pp. 619–621. [Google Scholar]

- Oyedemi, S.O.; Okoh, A.I.; Mabinya, L.V.; Pirochenva, G.; Afolayan, A.J. The proposed mechanism of bactericidal action of eugenol, ∝-terpineol and γ-terpinene against Listeria monocytogenes, Streptococcus pyogenes, Proteus vulgaris and Escherichia coli. Afr. J. Biotechnol. 2009, 8, 1280–1286. [Google Scholar]

- Moon, S.; Kim, H.; Cha, J. Synergistic effect between clove oil and its major compounds and antibiotics against oral bacteria. Arch. Oral Biol. 2011, 56, 907–916. [Google Scholar] [CrossRef]

- Rana, I.; Rana, A.; Rajak, R. Evaluation of antifungal activity in essential oil of the Syzygium aromaticum (L.) by extraction, purification and analysis of its main component eugenol. Braz. J. Microbiol. 2011, 42, 1269–1277. [Google Scholar] [CrossRef]

- Vanin, A.; Orlando, T.; Piazza, P.; Puton, M.; Cansian, L.; Oliveora, D.; Paroul, N. Antimicrobial and antioxidant activities of clove essential oil and eugenyl acetate produced by enzymatic esterification. Appl. Biochem. Biotechnol. 2014, 174, 1286–1298. [Google Scholar] [CrossRef]

- Daniel, A.N.; Sartoretto, S.M.; Schmidt, G.; Caparroz-Assef, S.M.; Bersani-Amado, C.A.; Cuman, R.K.N. Anti-inflammatory and antinociceptive activities A of eugenol essential oil in experimental animal models. Rev. Brasil. Farmacogn. 2009, 19, 212–217. [Google Scholar] [CrossRef]

- Ghelardini, C.; Galeotti, N.; Mannelli, L.D.C.; Mazzanti, G.; Bartolini, A. Local anaesthetic activity of β-caryophyllene. II Farmaco 2011, 56, 387–389. [Google Scholar] [CrossRef]

- Sarpietro, M.G.; Di Sotto, A.; Accolla, M.L.; Castelli, F. Interaction of β-caryophyllene and β-caryophyllene oxide with phospholipid bilayers: Differential scanning calorimetry study. Thermochim. Acta 2015, 600, 28–34. [Google Scholar] [CrossRef]

- Dahham, S.; Tabana, Y.; Iqbal, M.; Ahamed, M.; Ezzat, M.; Majid, A.; Majid, A. The anticancer, antioxidant and antimicrobial properties of the sesquiterpene β-caryophyllene from the essential oil of Aquilaria crassna. Molecules 2015, 20, 11808–11829. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, R.B.; Rangari, V.D. Phytochemical investigation and evaluation of anti-inflammatory and anti-arthritic activities of essential oil of Strobilanthus ixiocephala Benth. Indian J Exp. Biol. 2003, 41, 890–894. [Google Scholar] [PubMed]

- Lucca, L.G.; de Matos, S.P.; Borille, B.T.; Dias, D.D.O.; Teixeira, H.F.; Veiga, V.F., Jr.; Koester, L.S. Determination of β-caryophyllene skin permeation/retention from crude copaiba oil (Copaifera multijuga Hayne) and respective oil-based nanoemulsion using a novel HS-GC/MS method. J. Pharm. Biomed. Anal. 2015, 104, 144–148. [Google Scholar] [CrossRef]

- Tinseth, G. Hop Aroma and Flavor, January/February, Brewing Techniques; Brewers Publications: Boulder, CO, USA, 1993. [Google Scholar]

- Rahman, M.M.; Garvey, M.; Piddock, L.J.; Gibbons, S. Antibacterial terpenes from the oleo-resin of Commiphora molmol (Engl.). Phytother. Res. 2008, 22, 1356–1360. [Google Scholar] [CrossRef]

- Fernandes, E.S.; Passos, G.F.; Medeiros, R.; da Cunha, F.M.; Ferreira, J.; Campos, M.M.; Calixto, J.B. Anti-inflammatory effects of compounds alpha-humulene and (−)-trans-caryophyllene isolated from the essential oil of Cordia verbenacea. Eur. J. Pharmacol. 2007, 569, 228–236. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Almasi, H. Physical properties of edible emulsified films based on carboxymethyl cellulose and oleic acid. Int. J. Biol. Macromol. 2011, 48, 44–49. [Google Scholar] [CrossRef]

- Prasetyaningrum, A.; Rokhati, N.; Kinasih, D.N.; Wardhani, F.D.N. Karakterisasi bioactive edible film dari komposit alginat dan lilin lebah sebagai bahan pengemas makanan biodegradable. Seminar Rekayasa Kimia Dan Proses 2010, 2, 1411–4216. [Google Scholar]

- Nugroho, A.A.; Basito, B.; Anandito, R.B.K. Kajian Pembuatan Edible Film Tapioka dengan Pengaruh Penambahan Pektin Beberapa Jenis Kulit Pisang Terhadap Karakteristik Fisik dan Mekanik. Jurnal Teknosains Pangan 2013, 2, 73–79. [Google Scholar]

- Warkoyo, W.; Rahardjo, B.; Marseno, D.W.; Karyadi, J.N.W. Sifat fisik, mekanik dan barrier edible film berbasis pati umbi kimpul (Xanthosoma sagittifolium) yang diinkorporasi dengan kalium sorbat. Agritech 2014, 34, 72–81. [Google Scholar]

- Pelissari, F.M.; Grossmann, M.V.; Yamashita, F.; Pineda, E.A.G. Antimicrobial, mechanical, and barrier properties of cassava starch-chitosan films incorporated with oregano essential oil. J. Agric. Food Chem. 2009, 57, 7499–7504. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Cheng, L.; Tan, L. Edible iron yam and maize starch convenient food flavoring packaging films with lemon essential oil as plasticization. Food Sci. Technol. 2018, 39, 971–979. [Google Scholar] [CrossRef]

- Péroval, C.; Debeaufort, F.; Despré, D.; Voilley, A. Edible arabinoxylan-based films. 1. Effects of lipid type on water vapor permeability, film structure, and other physical characteristics. J. Agric. Food Chem. 2002, 50, 3977–3983. [Google Scholar] [CrossRef]

- Souza, A.C.; Goto, G.E.O.; Mainardi, J.A.; Coelho, A.C.V.; Tadini, C.C. Cassava starch composite films incorporated with cinnamon essential oil: Antimicrobial activity, microstructure, mechanical and barrier properties. LWT Food Sci. Technol. 2013, 54, 346–352. [Google Scholar] [CrossRef]

- Galus, S. Functional properties of soy protein isolate edible films as affected by rapeseed oil concentration. Food Hydrocoll. 2018, 85, 233–241. [Google Scholar] [CrossRef]

- Bertuzzi, M.A.; Vidaurre, E.C.; Armada, M.; Gottifredi, J.C. Water vapor permeability of edible starch based films. J. Food Eng. 2007, 80, 972–978. [Google Scholar] [CrossRef]

- Shen, X.L.; Wu, J.M.; Chen, Y.; Zhao, G. Antimicrobial and physical properties of sweet potato starch films incorporated with potassium sorbate or chitosan. Food Hydrocoll. 2010, 24, 285–290. [Google Scholar] [CrossRef]

- Sothornvit, R.; Pitak, N. Oxygen permeability and mechanical properties of banana films. Food Res. Int. 2007, 40, 365–370. [Google Scholar] [CrossRef]

- Siracusa, V.; Romani, S.; Gigli, M.; Mannozzi, C.; Cecchini, J.; Tylewicz, U.; Lotti, N. Characterization of Active Edible Films based on Citral Essential Oil, Alginate and Pectin. Materials 2018, 11, 1980. [Google Scholar] [CrossRef] [PubMed]

- Atarés, L.; Chiralt, A. Essential oils as additives in biodegradable films and coatings for active food packaging. Trends Food Sci. Technol. 2016, 48, 51–62. [Google Scholar] [CrossRef]

- López, C.A.; de Vries, A.H.; Marrink, S.J. Amylose folding under the influence of lipids. Carbohydr. Res. 2012, 364, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Talón, E.; Vargas, M.; Chiralt, A.; González-Martínez, C. Antioxidant starch-based films with encapsulated eugenol. Application to sunflower oil preservation. Food Sci. Technol. 2019, 113, 108290. [Google Scholar] [CrossRef]

- Shojaee-Aliabadi, S.; Hosseini, H.; Mohammadifar, M.A.; Mohammadi, A.; Ghasemlou, M.; Ojagh, S.M.; Khaksar, R. Characterization of antioxidant-antimicrobial κ-carrageenan films containing Satureja hortensis essential oil. Int. J. Biol. Macromol. 2013, 52, 116–124. [Google Scholar] [CrossRef] [PubMed]

- Fernandes de Oliveira, A.; Sousa Pinheiro, L.; Souto Pereira, C.; Neves Matias, W. Albuquerque Gomes, R.; Souza Chaves, O.; Simões de Assis, T. Total phenolic content and antioxidant activity of some Malvaceae family species. Antioxidants 2012, 1, 33–43. [Google Scholar] [CrossRef] [PubMed]

- Baser, K.H.C.; Buchbauer, G. Handbook of Essential Oils: Science, Technology, and Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2015; pp. 1–320. [Google Scholar]

- Alma, M.H.; Ertas, M.; Nitz, S.; Kollmannsberger, H. Chemical composition and content of essential oil from the bud of cultivated Turkish clove (Syzygium aromaticum L.). BioResources 2007, 2, 265–269. [Google Scholar]

- Jirovetz, L.; Buchbauer, G.; Stoilova, I.; Stoyanova, A.; Krastanov, A.; Schmidt, E. Chemical composition and antioxidant properties of clove leaf essential oil. J. Agric. Food Chem. 2006, 54, 6303–6307. [Google Scholar] [CrossRef]

- Dashipour, A.; Khaksar, R.; Hosseini, H.; Shojaee-Aliabadi, S.; Kiandokht, G. Physical, antioxidant and antimicrobial characteristics of carboxymethyl cellulose edible film cooperated with clove essential oil. Zahedan J. Res. Med. Sci. 2014, 16, 34–42. [Google Scholar]

- Burt, S.A.; Reinders, R.D. Antibacterial activity of selected plant essential oils against Escherichia coli O157: H7. Lett. Appl. Microbiol. 2003, 36, 162–167. [Google Scholar] [CrossRef]

- Devi, K.P.; Nisha, S.A.; Sakthivel, R.; Pandian, S.K. Eugenol (an essential oil of clove) acts as an antibacterial agent against Salmonella typhi by disrupting the cellular membrane. J. Ethnopharmacol. 2010, 130, 107–115. [Google Scholar] [CrossRef] [PubMed]

- Mahcene, Z.; Khelil, A.; Hasni, S.; Akman, P.K.; Bozkurt, F.; Birech, K.; Goudjil, M.B.; Tornuk, F. Development and characterization of sodium alginate based active edible films incorporated with essential oils of some medicinal plants. Int. J. Biol. Macromol. 2020, 145, 124–132. [Google Scholar] [CrossRef] [PubMed]

- Atanasova-Pancevska, N.; Bogdanov, J.; Kungulovski, D. In Vitro Antimicrobial Activity and Chemical Composition of Two Essential Oils and Eugenol from Flower Buds of Eugenia caryophyllata. Open Biol. Sci. J. 2017, 3, 16–25. [Google Scholar] [CrossRef]

- Mohamed, S.G.; Badri, A.M. Antimicrobial Activity of Syzygium aromaticum and Citrus aurantifolia Essential Oils against Some Microbes in Khartoum, Sudan. EC Microbiol. 2017, 12, 253–259. [Google Scholar]

| No. | Compound | tR (min) | Molecular Weight | Composition % |

|---|---|---|---|---|

| 1 | Eugenol | 15.80 | 164.2 | 66.01 ± 0.23 |

| 2 | Caryophyllene | 16.59 | 204.36 | 19.88 ± 0.11 |

| 3 | Humulene | 16.96 | 204.35 | 3.75 ± 0.65 |

| 4 | Phenol, 2-methoxy-4-(2-propenyl)-acetate | 17.74 | 206.23 | 4.55 ± 0.17 |

| 5 | Caryophyllene oxide | 18.53 | 220.35 | 5.80 ± 0.21 |

| Film | TH (mm) | TS(MPa) | E (%) | WVP | PO2 | S (%) |

|---|---|---|---|---|---|---|

| Control | 0.120 ± 0.003 | 10.52 ± 0.05 | 9.3 ± 0.05 | 6.92 ± 0.088 | 19.70 ± 0.57 | 30.40 ± 0.3 |

| MS- films (1% CEO) | 0.130 ± 0.008 | 8.60 ± 0.08 | 7.43 ± 0.01 | 9.67 ± 0.088 | 24.50 ± 0.1 | 28.67 ± 0.14 |

| MS- films (2% CEO) | 0.135 ± 0.001 | 7.16 ± 0.05 | 6.25 ± 0.05 | 11.33 ± 0.033 | 26.25 ± 0.57 | 27.50 ± 0.8 |

| MS- films (3% CEO) | 0.150 ± 0.008 | 6.25 ± 0.03 | 5.67 ± 0.08 | 12.52 ± 0.08 | 28.87 ± 0.8 | 27.13 ± 0.145 |

| Film | % Inhibition of DPPH ± SD | |

|---|---|---|

| 30 Minutes Incubation | 90 Minutes Incubation | |

| Control | 0.3 ± 0.100 | 0.7 ± 0.057 |

| MS-films (1% CEO) | 13.88 ± 0.075 | 36.57 ± 0.337 |

| MS-films (2% CEO) | 17.50 ± 0.100 | 57.34 ± 0.020 |

| MS-films (3% CEO) | 23.22 ± 0.890 | 85.96 ± 0.14 |

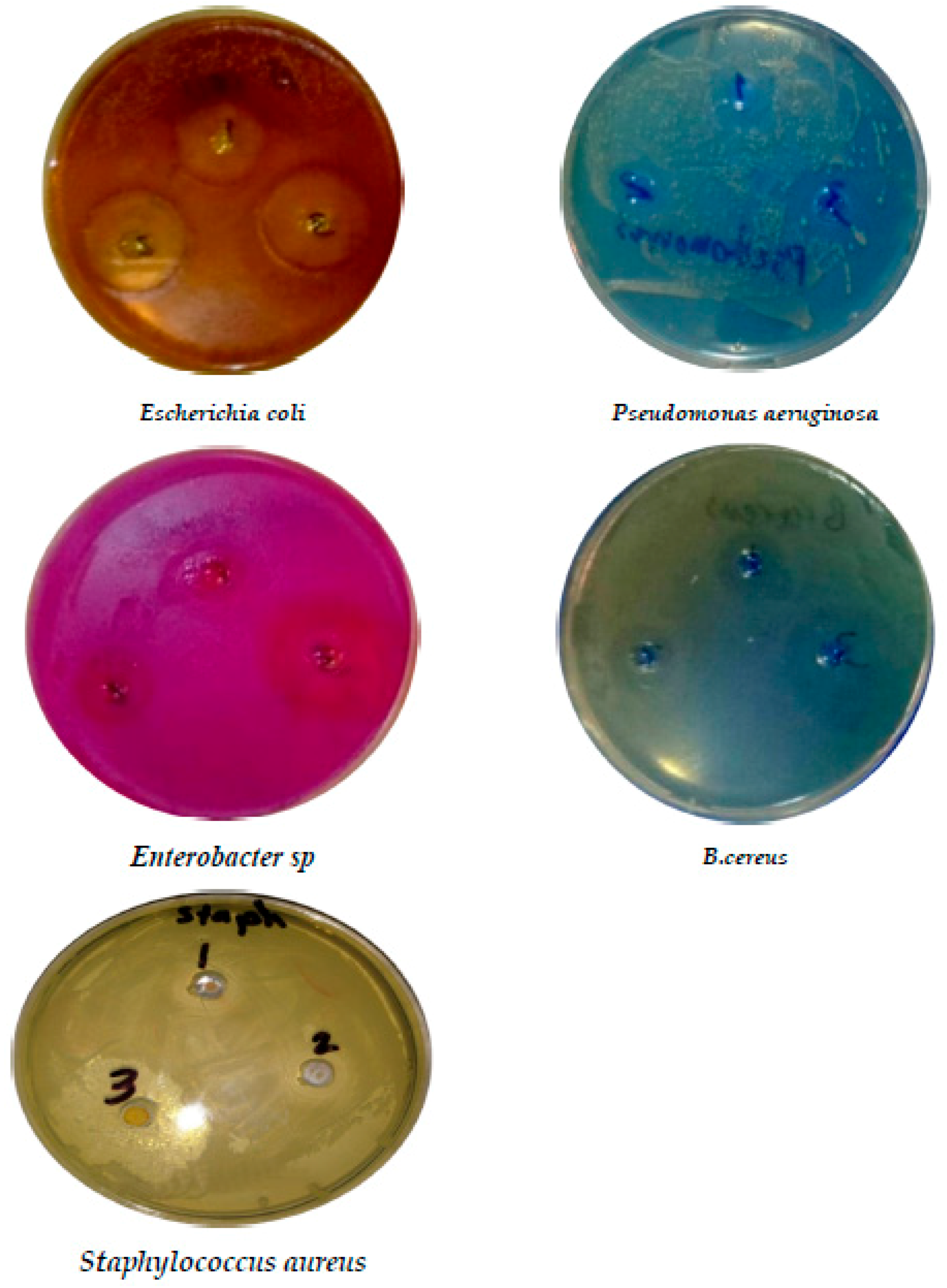

| No. | Standard Microorganisms | Zone of Inhibition (mm) | |||

|---|---|---|---|---|---|

| Concentration (%) | |||||

| Control (0) | 1 | 2 | 3 | ||

| Tasted Bacteria | |||||

| 1 | Escherichia coli | 0 | 16 ± 0.13 | 18 ± 0.16 | 23 ± 0.43 |

| 2 | Pseudomonas aeruginosa | 0 | 12 ± 0.15 | 14 ± 0.13 | 24 ± 0.32 |

| 3 | Enterobacter sp. | 0 | 14 ± 0.16 | 16 ± 0.11 | 27 ± 0.81 |

| 4 | B.cereus | 0 | 11 ± 0.34 | 12 ± 0.84 | 20 ± 0.52 |

| 5 | Staphylococcus aureus | 0 | 10 ± 0.58 | 11 ± 0.52 | 18 ± 0.95 |

| Tasted Fungi | |||||

| Trichoderma | 0 | 13 ± 0.65 | 27 ± 0.32 | 14 ± 0.76 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

G. Al-Hashimi, A.; Ammar, A.B.; G., L.; Cacciola, F.; Lakhssassi, N. Development of a Millet Starch Edible Film Containing Clove Essential Oil. Foods 2020, 9, 184. https://doi.org/10.3390/foods9020184

G. Al-Hashimi A, Ammar AB, G. L, Cacciola F, Lakhssassi N. Development of a Millet Starch Edible Film Containing Clove Essential Oil. Foods. 2020; 9(2):184. https://doi.org/10.3390/foods9020184

Chicago/Turabian StyleG. Al-Hashimi, Alaa, Altemimi B. Ammar, Lakshmanan G., Francesco Cacciola, and Naoufal Lakhssassi. 2020. "Development of a Millet Starch Edible Film Containing Clove Essential Oil" Foods 9, no. 2: 184. https://doi.org/10.3390/foods9020184

APA StyleG. Al-Hashimi, A., Ammar, A. B., G., L., Cacciola, F., & Lakhssassi, N. (2020). Development of a Millet Starch Edible Film Containing Clove Essential Oil. Foods, 9(2), 184. https://doi.org/10.3390/foods9020184