Assessing Mechanical and Rheological Properties of Potato Puree: Effect of Different Ingredient Combinations and Cooking Methods on the Feasibility of 3D Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

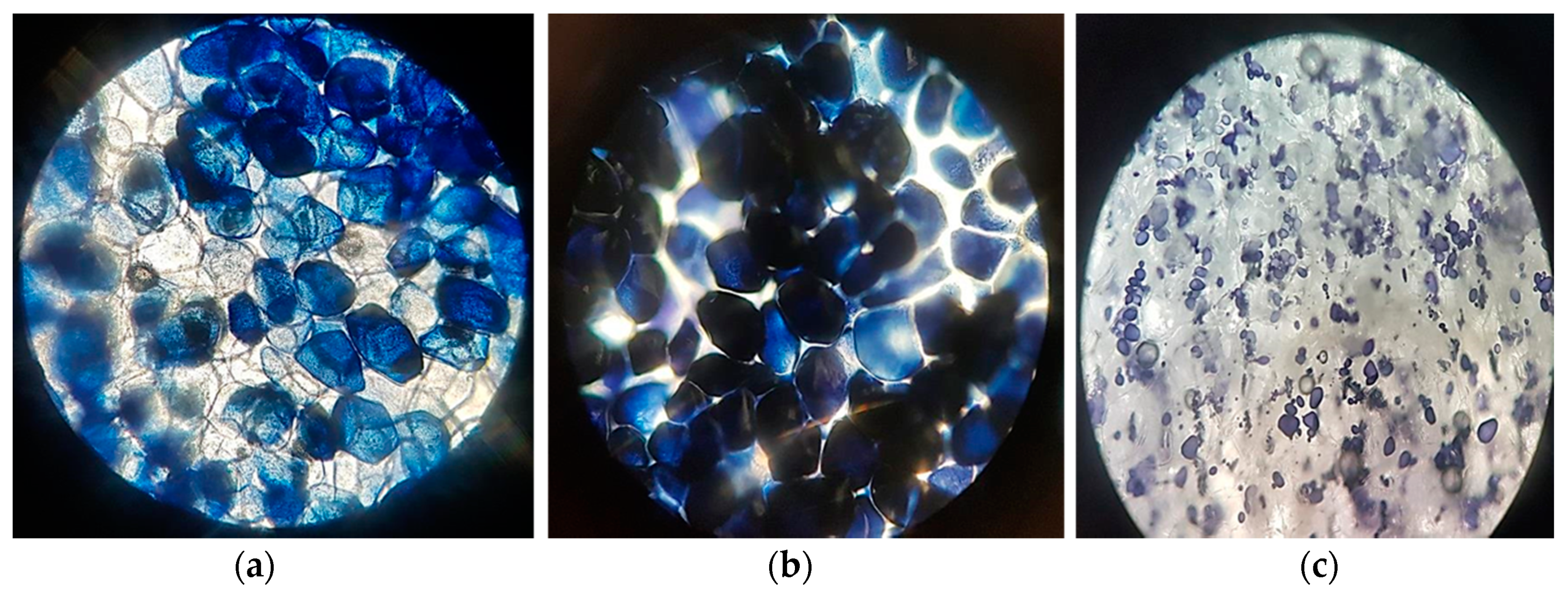

2.2. Microscopic Observations

2.3. Mechanical Characteristics

2.4. Steady Rheological Measurements, Thixotropy, Yield Stress

2.5. 3D Food Printing Conditions

2.6. Statistical Analysis

3. Results and Discussion

3.1. Microscopic Observations

3.2. Effect of Added Substrate on Mechanical Properties in Boiled and Microwaved Potatoes

3.3. Effect of the Type of Added Substrate and Cooking Treatment on Rheological Characteristics

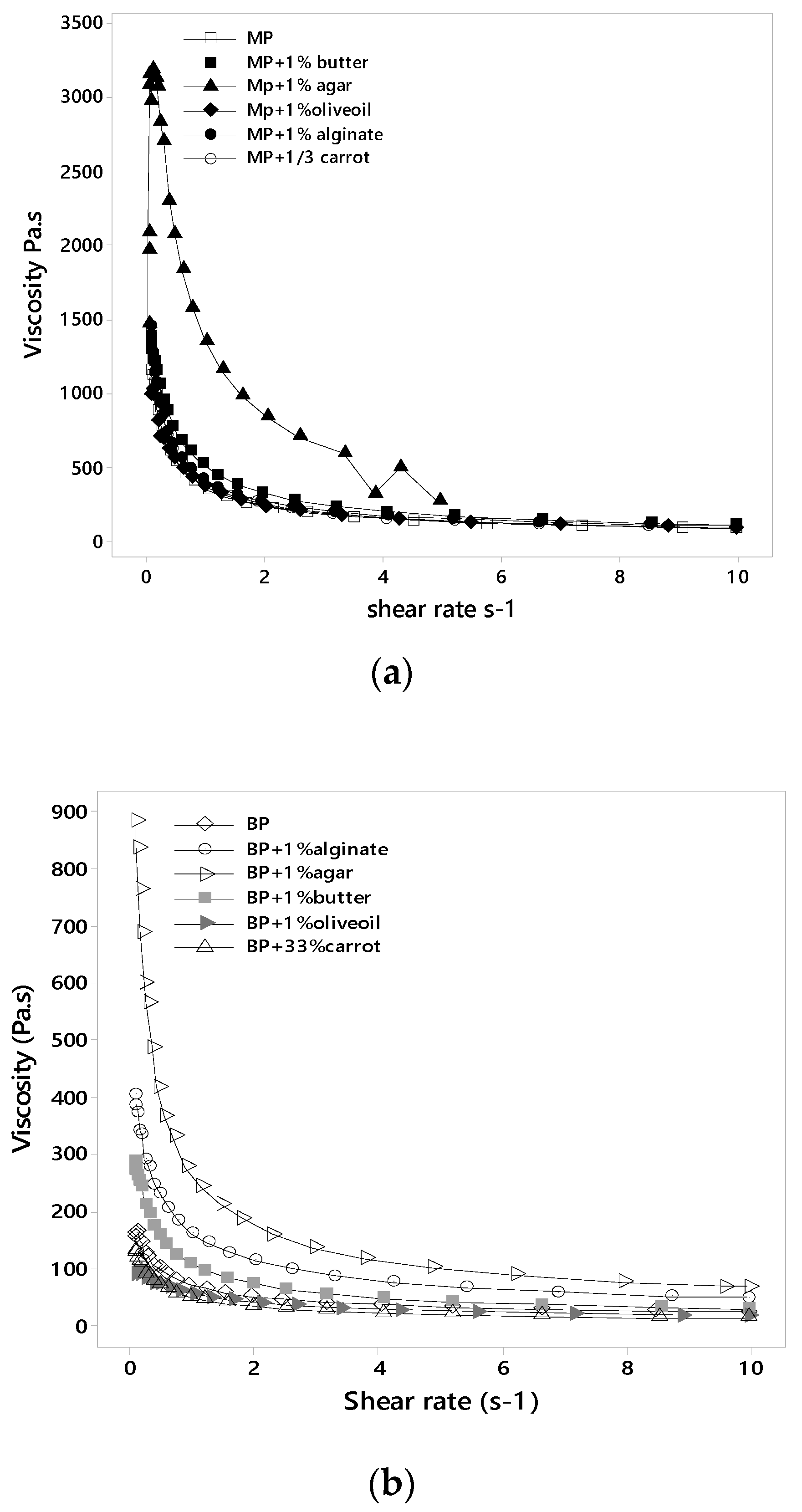

3.3.1. Viscosity

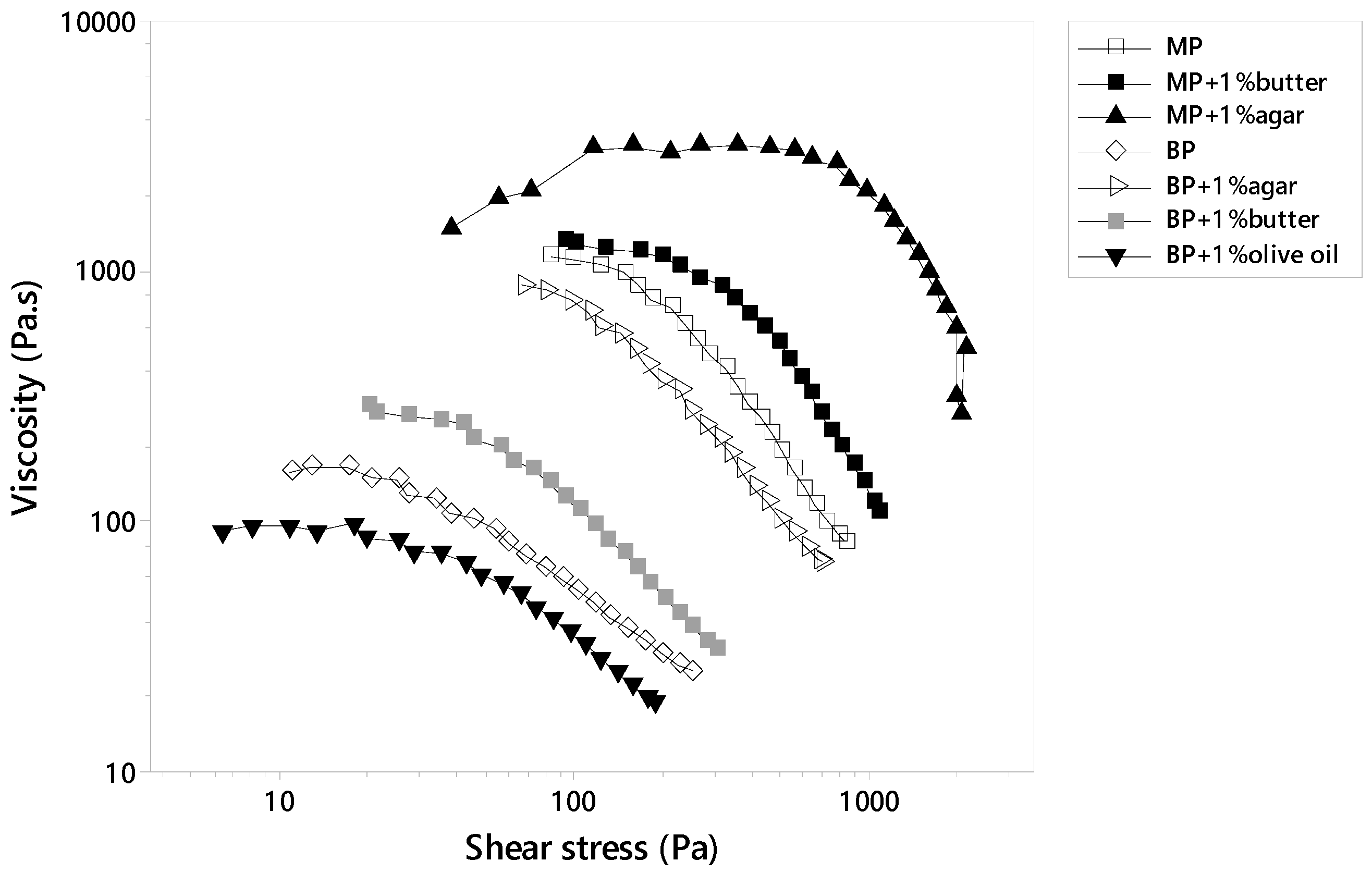

3.3.2. Yield Stress

3.3.3. Thixotropy

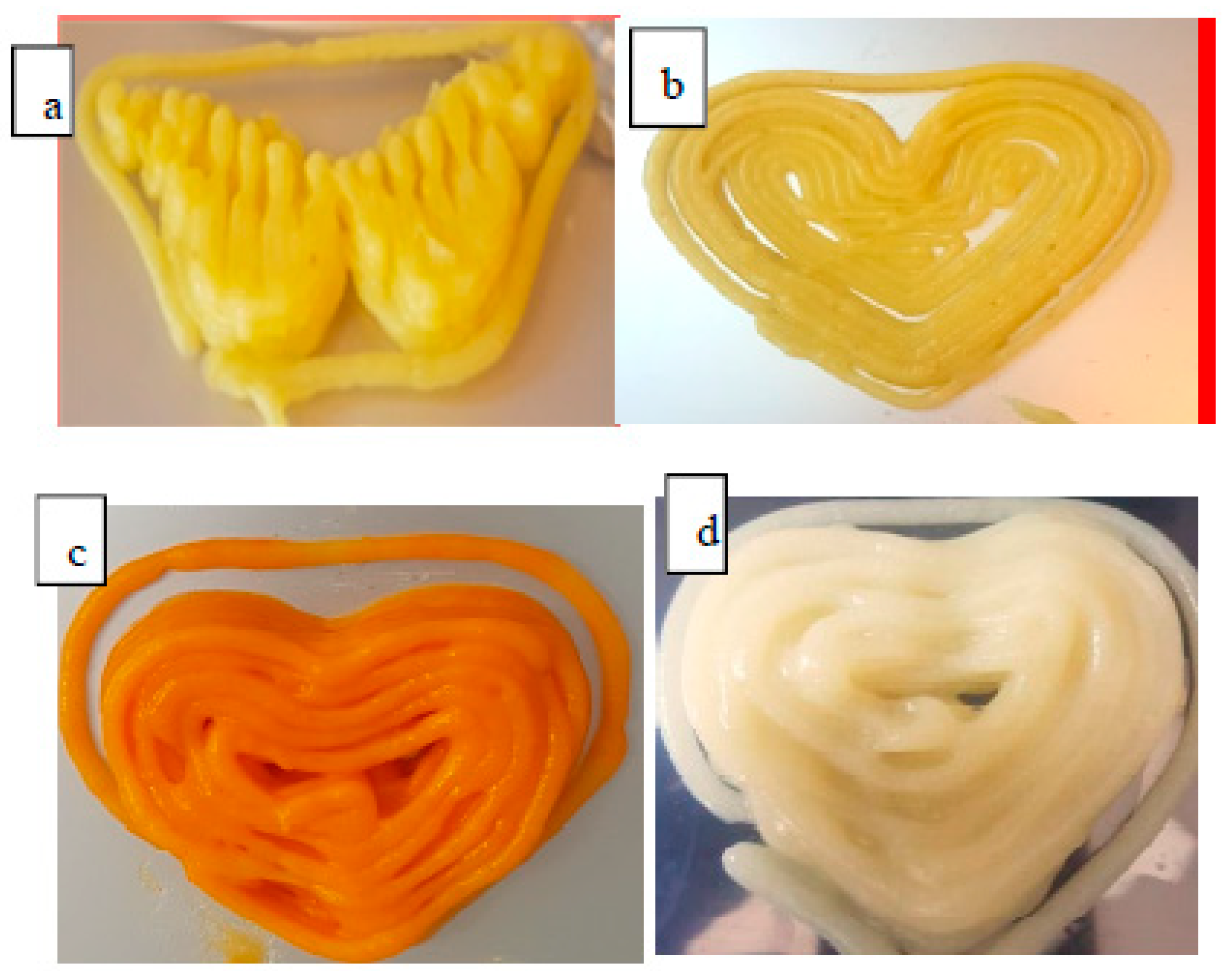

3.4. Effect of Different Ingredient Combinations on the Feasibility of 3D Printing Trials

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- BeMiller, J.N. Pasting, paste, and gel properties of starch–hydrocolloid combinations. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

- Dankar, I.; Pujolà, M.; El Omar, F.; Sepulcre, F.; Haddarah, A. Impact of Mechanical and Microstructural Properties of Potato Puree-Food Additive Complexes on Extrusion-Based 3D Printing. Food Bioprocess Technol. 2018, 1–11. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B. Effect of gums on the rheological, microstructural and extrusion printing characteristics of mashed potatoes. Int. J. Biol. Macromol. 2018, 117, 1179–1187. [Google Scholar] [CrossRef] [PubMed]

- Hamilton, C.A.; Alici, G.; in het Panhuis, M. 3D printing Vegemite and Marmite: Redefining “breadboards”. J. Food Eng. 2017, 220, 83–88. [Google Scholar] [CrossRef]

- Severini, C.; Azzollini, D.; Albenzio, M.; Derossi, A. On printability, quality and nutritional properties of 3D printed cereal based snacks enriched with edible insects. Food Res. Int. 2018, 106, 666–676. [Google Scholar] [CrossRef] [PubMed]

- Chaisawang, M.; Suphantharika, M. Effects of guar gum and xanthan gum additions on physical and rheological properties of cationic tapioca starch. Carbohydr. Polym. 2005, 61, 288–295. [Google Scholar] [CrossRef]

- Dankar, I.; Haddarah, A.; El Omar, F.; Sepulcre, F.; Pujolà, M. Assessing the microstructural and rheological changes induced by food additives on potato puree. Food Chem. 2018, 240, 304–313. [Google Scholar] [CrossRef] [PubMed]

- Chao, C.; Yu, J.; Wang, S.; Copeland, L.; Wang, S. Mechanisms Underlying the Formation of Complexes between Maize Starch and Lipids. J. Agric. Food Chem. 2018, 66, 272–278. [Google Scholar] [CrossRef] [PubMed]

- Sabatino, A.D.I.; Morera, R.; Ciccocioppo, R.; Cazzola, P.; Gotti, S.; Tinozzi, F.P.; Corazza, G.R. Oral butyrate for mildly to moderately active Crohn’s disease. Aliment. Pharmacol. Ther. 2005, 22, 789–794. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Xu, X.M.; Guo, S.D. Rheological, texture and sensory properties of low-fat mayonnaise with different fat mimetics. LWT Food Sci. Technol. 2007, 40, 946–954. [Google Scholar] [CrossRef]

- Tabilo-Munizaga, G.; Barbosa-Cánovas, G.V. Rheology for the food industry. J. Food Eng. 2005, 67, 147–156. [Google Scholar] [CrossRef]

- Ormerod, A.; Ralfs, J.; Jobling, S.; Gidley, M. The influence of starch swelling on the material properties of cooked potatoes. J. Mater. Sci. 2002, 7, 1667–1673. [Google Scholar] [CrossRef]

- Moorthy, S.N. Physicochemical and functional properties of tropical tuber starches: A review. Starch Staerke 2002, 54, 559–592. [Google Scholar] [CrossRef]

- Anderson, A.; Gekos, V.; Lind, I.; Oliveira, F.; Oste, R. Effect of Preheating on Potato Texture. 1994. Available online: http://repositorio.ucp.pt/bitstream/10400.14/4439/3/Effect%20of%20preheating.pdf (accessed on 13 October 2019).

- Singh, N.; Kaur, L.; Ezekiel, R.; Guraya, H.S. Microstructural, cooking and textural characteristics of potato (Solanum tuberosum L) tubers in relation to physicochemical and functional properties of their flours. J. Sci. Food Agric. 2005, 85, 1275–1284. [Google Scholar] [CrossRef]

- Yang, Y.; Achaerandio, I.; Pujolà, M. Effect of the intensity of cooking methods on the nutritional and physical properties of potato tubers. Food Chem. 2016, 197, 1301–1310. [Google Scholar] [CrossRef] [PubMed]

- Kaufmann, N.; Andersen, U.; Wiking, L. The effect of cooling rate and rapeseed oil addition on the melting behavior, texture and microstructure of anhydrous milk fat. Int. Dairy J. 2012, 25, 73–79. [Google Scholar]

- Rønholt, S.; Buldo, P.; Mortensen, K.; Andersen, U.; Knudsen, J.C.; Wiking, L. The effect of butter grains on physical properties of butter-like emulsions. J. Dairy Sci. 2014, 97, 1929–1938. [Google Scholar] [CrossRef]

- Yousefi, A.R.; Razavi, S.M.A. Steady shear flow behavior and thixotropy of wheat starch gel: Impact of chemical modification, concentration and saliva addition. J. Food Process Eng. 2015, 39, 31–43. [Google Scholar] [CrossRef]

- Srikanlaya, C.; Therdthai, N.; Ritthiruangdej, P.; Zhou, W. Effect of butter content and baking condition on characteristics of the gluten-free dough and bread. Int. J. Food Sci. Technol. 2017, 52, 1904–1913. [Google Scholar] [CrossRef]

- Wright, A.J.; Scanlon, M.G.; Hartel, R.W.; Marangoni, A.G. Rheological Properties of Milkfat and Butter. J. Food Sci. 2008, 66, 1056–1071. [Google Scholar] [CrossRef]

- Tárrega, A.; Durán, L.; Costell, E. Flow behaviour of semi-solid dairy desserts. Effect of temperature. Int. Dairy J. 2004, 14, 345–353. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179. [Google Scholar] [CrossRef]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2017, 1–8. [Google Scholar] [CrossRef]

| Samples | Firmness (Kg) | Consistency (Kg s) | Cohesiveness (Kg) |

|---|---|---|---|

| MP | 0.52 ± 0.03 d,e | 6.42 ± 0.65 d,e | 0.49 ± 0.004 d,e |

| MP + 1% agar | 1.54 ± 0.10 a | 18.40 ± 1.73 a | 1.55 ± 0.06 a |

| MP + 1% alginate | 0.80 ± 0.03 b | 9.87 ± 0.04 b | 0.73 ± 0.04 b |

| MP + 1% butter | 0.77 ± 0.02 b | 9.16 ± 0.30 b,c | 0.72 ± 0.01 b |

| MP + 1/3 carrot | 0.63 ± 0.04 c | 7.55 ± 0.11 c,d | 0.61 ± 0.05 c |

| MP + 1% olive oil | 0.58 ± 0.01 c,d | 7.09 ± 0.31 d,e | 0.55 ± 0.05 c,d |

| BP | 0.14 ± 0.004 g,h | 1.64 ± 0.09 f,g | 0.11 ± 0.006 g,h |

| BP + 1% agar | 0.43 ± 0.008 e | 5.51 ± 0.14 e | 0.42 ± 0.02 e |

| BP + 1% alginate | 0.27 ± 0.008 f | 3.35 ± 0.11 f | 0.24 ± 0.007 f |

| BP + 1% butter | 0.19 ± 0.003 f,g,h | 2.30 ± 0.06 f,g | 0.17 ± 0.006 f,g,h |

| BP + 1/3 carrot | 0.12 ± 0.006 h | 1.44 ± 0.07 g | 0.09 ± 0.005 h |

| BP + 1% olive oil | 0.11 ± 0.01 h | 1.36 ± 0.09 g | 0.09 ± 0.003 h |

| Microwave carrot | 0.51 ± 0.02 d,e | 6.08 ± 0.36 d,e | 0.47 ± 0.04 d,e |

| Boiled carrot | 0.23 ± 0.01 f,g | 2.70 ± 0.24 f,g | 0.19 ± 0.01 f,g |

| Microwaved Potato Samples | Thixotropy | Yield Stress (Pa) | Boiled Potato | Thixotropy (Pa·s−1) | Yield Stress (Pa) |

|---|---|---|---|---|---|

| (Pa·s−1) | Samples | ||||

| MP | 2231 | 280 | BP | 458.64 | 42 |

| MP + 1% agar | 8713 | 1250 | BP + 1% agar | 1791.67 | 200 |

| MP + 1% alginate | 2972 | 260 | BP + 1% alginate | 1105.78 | 120 |

| MP + 1% butter | 4633.5 | 330 | BP + 1% butter | 744.97 | 80 |

| MP + 1/3 carrot | 2866 | 280 | BP + 1/3 carrot | 371.73 | 40 |

| MP + 1% olive oil | 2885.25 | 245 | BP + 1% olive oil | 412.73 | 34 |

| Microwaved Potatosamples with | Advantages | Disadvantages |

|---|---|---|

| MP | Stable end product | Fill in of the shape not 100% ensured |

| Smooth extrusion | ||

| Withstand the printed shape over time | ||

| MP + 1% agar | Easily hand-able post printing | Poor fluidity |

| Precise definite dimension of layers | Retarded extrusion | |

| Great resistance to compressed deformation | Non-continuous flow | |

| Highest stable structured product for a long time post deposition | Rough surface structure | |

| MP + 1% alginate | Stable end product with clearly observed details | Some plugging while extruding due to alginate coagulation ability |

| Layers coincide perfectly | ||

| Smooth surface | ||

| Withstand the printed shape over time | ||

| Hand-able post printing | ||

| MP + 1% butter | Smooth continuous extrusion | |

| Creamy surface | ||

| Proper arrangement of above layers | ||

| Retaining structure integrity | ||

| Withstand the printed shape over time | ||

| Removable | ||

| MP + 1/3 carrot | Soft surface | Works better with flat-base support product |

| Smooth continuous extrusion | Poor printing in fine-thin base supported product | |

| Hold up the weight of the up deposited layers | Sticky | |

| Stable product | Susceptibility to deformation upon removal | |

| MP + 1% olive oil | Details are submissive | |

| Less precise printing | ||

| Less stable end product | ||

| Spreads after printing | ||

| Non-hand able post printing |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dankar, I.; Haddarah, A.; Sepulcre, F.; Pujolà, M. Assessing Mechanical and Rheological Properties of Potato Puree: Effect of Different Ingredient Combinations and Cooking Methods on the Feasibility of 3D Printing. Foods 2020, 9, 21. https://doi.org/10.3390/foods9010021

Dankar I, Haddarah A, Sepulcre F, Pujolà M. Assessing Mechanical and Rheological Properties of Potato Puree: Effect of Different Ingredient Combinations and Cooking Methods on the Feasibility of 3D Printing. Foods. 2020; 9(1):21. https://doi.org/10.3390/foods9010021

Chicago/Turabian StyleDankar, Iman, Amira Haddarah, Francesc Sepulcre, and Montserrat Pujolà. 2020. "Assessing Mechanical and Rheological Properties of Potato Puree: Effect of Different Ingredient Combinations and Cooking Methods on the Feasibility of 3D Printing" Foods 9, no. 1: 21. https://doi.org/10.3390/foods9010021

APA StyleDankar, I., Haddarah, A., Sepulcre, F., & Pujolà, M. (2020). Assessing Mechanical and Rheological Properties of Potato Puree: Effect of Different Ingredient Combinations and Cooking Methods on the Feasibility of 3D Printing. Foods, 9(1), 21. https://doi.org/10.3390/foods9010021