Utilization of Grape Seed Extract as a Natural Antioxidant in the Technology of Meat Products Inoculated with a Probiotic Strain of LAB

Abstract

1. Introduction

2. Materials and Methods

2.1. Grape Seed Extract Preparation

2.1.1. Color Evaluation of Grape Seed Extract

2.1.2. Total Phenolics Contents (TPC) of Grape Seed Extract

2.1.3. Trolox Equivalent Antioxidant Capacity (TEAC) Assay of Grape Seed Extract

2.2. Probiotic Monoculture Preparation

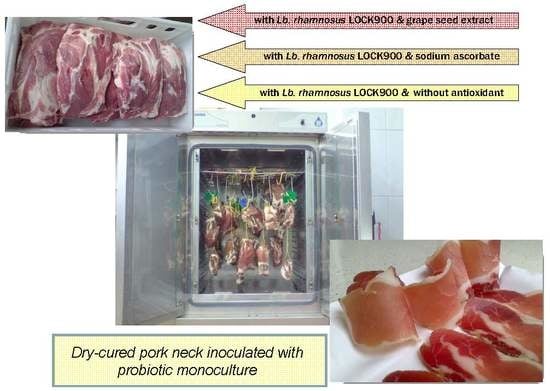

2.3. Manufacture of Dry-Fermented Necks

2.4. Microbiological Characteristics of Dry-Fermented Neck

2.4.1. Lactic Acids Bacteria (LAB) and Enterobacteriaceae (ENT) Counts of Meat Product

2.4.2. pH Value of Dry-Fermented Meat Product

2.5. Assessment of Oxidative Stability of Dry-Fermented Neck

2.5.1. Free Fatty Acids (FFA) of Meat Product

2.5.2. Thiobarbituric Acid Reactive Substances (TBArs) of Meat Product

2.6. Color Evaluation of Meat Product

2.7. Statistical Analysis

3. Results and Discussion

3.1. Grape Seed Extract Characterization

3.2. pH Value, LAB, and Enterobacteriaceae Counts of Dry-Fermented Neck

3.3. Oxidative Stability of Dry-Fermented Neck

3.4. Color Evaluation of Dry-Fermented Neck

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tang, G.-Y.; Zhao, C.-N.; Liu, Q.; Feng, X.-L.; Xu, X.-Y.; Cao, S.-Y.; Meng, X.; Li, S.; Gan, R.-Y.; Li, H.-B. Potential of grape wastes as a natural source of bioactive compounds. Molecules 2018, 23, 2598. [Google Scholar] [CrossRef]

- Maier, T.; Schiebe, A.; Kammerer, D.R.; Carle, R. Residues of grape (Vitis vinifera L.) seed oil production as a valuable source of phenolic antioxidants. Food Chem. 2009, 112, 551–559. [Google Scholar] [CrossRef]

- Pellegrini, N.; Serafini, M.; Colombi, B.; Del Rio, D.; Salvatore, S.; Bianchi, M.; Brighenti, F. Total antioxidant capacity of plant foods, beverages and oils consumed in Italy assessed by three different in vitro assays. J. Nutr. 2003, 133, 2812–2819. [Google Scholar] [CrossRef]

- Machado, N.F.L.; Domínguez-Perles, R. Addressing facts and gaps in the phenolics chemistry of winery by-products. Molecules 2017, 22, 286. [Google Scholar] [CrossRef]

- Brenes, A.; Viveros, A.; Chamorro, S.; Arija, I. Use of polyphenol-rich grape byproducts in monogastric nutrition. A review. Anim. Feed Sci. Technol. 2016, 211, 1–17. [Google Scholar] [CrossRef]

- Salakova, A.; Pavlik, Z.; Kamenik, J.; Cech, Z.; Steinhauserova, I. The use of extract from blue grapes in the manufacturing of dry sausages. Maso Int. 2012, 1, 39–43. [Google Scholar]

- Lorenzo, J.M.; Gonzalez-Rodriquez, R.M.; Sanchez, M.; Amado, I.R.; Franco, D. Effects of natural (grape seed and chestnut extract) and synthetic antioxidants (buthylated hydroxytoluene, BHT) on physical, chemical, microbiological and sensory characteristic of dry cured sausage “chorizo”. Food Res. Int. 2013, 54, 611–620. [Google Scholar] [CrossRef]

- Ribas-Agusti, A.; Gratacos-Cubarsi, M.; Sarraga, C.; Guardia, M.D.; Garcia-Regueiro, J.A.; Castellari, M. Stability of phenolic compounds in dry fermented sausages added with cocoa and grape seed extracts. LWT Food Sci. Technol. 2014, 57, 329–336. [Google Scholar] [CrossRef]

- Kulkarni, S.; De Santos, F.A.; Kattamuri, S.; Rossi, S.J.; Brewer, M.S. Effect of grape seed extract on oxidative, color and sensory stability of a pre-cooked, frozen, re-heated beef sausage model system. Meat Sci. 2011, 88, 139–144. [Google Scholar] [CrossRef]

- Reddy, G.V.; Sen, A.R.; Nair, P.N.; Reddy, K.S.; Reddy, K.K.; Kondaiah, N. Effects of grape seed extract on the oxidative and microbial stability of restructured mutton slices. Meat Sci. 2013, 95, 288–294. [Google Scholar] [CrossRef]

- Banon, S.; Diaz, P.; Rodriguez, M.; Garrido, M.D.; Price, A. Ascorbate, green tea and grape seed extracts increase the shelf life of low sulphite beef patties. Meat Sci. 2007, 77, 626–633. [Google Scholar] [CrossRef] [PubMed]

- Price, A.; Diaz, P.; Banon, S.; Garrido, M.D. Natural extracts versus sodium ascorbate to extend the shelf life of meat-based ready-to-eat meals. Food Sci. Technol. Int. 2013, 19, 427–438. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, F.; Zhuang, H.; Chen, X.; Li, L.; Chen, X.; Zhang, J. Effects of plant polyphenols and α-tocopherol on lipid oxidation, residual nitrites, biogenic amines, and N-nitrosamines formation during ripening and storage of dry-fermented bacon. LWT Food Sci. Technol. 2015, 60, 199–206. [Google Scholar] [CrossRef]

- Kumar, Y.; Yadav, D.N.; Ahmad, T.; Narsaiah, K. Recent trends in the use of natural antioxidants for meat and meat products. Compr. Rev. Food Sci. Food Saf. 2015, 14, 796–812. [Google Scholar] [CrossRef]

- Garcia-Lomillo, J.; Gonzalez-San Jose, M.L. Applications of wine pomace in the food industry: Approaches and functions. Compr. Rev. Food Sci. Food Saf. 2017, 16, 3–22. [Google Scholar] [CrossRef]

- Bagchi, D.; Bagchi, M.; Stohs, S.J.; Das, D.K.; Ray, S.D.; Kuszynski, C.A.; Joshi, S.S.; Pruess, H.G. Free radicals and grape seed proanthocyanidin extract: Importance in human health and disease prevention. Toxicology 2000, 148, 187–198. [Google Scholar] [CrossRef]

- Shi, J.; Yu, J.; Pohorly, J.E.; Kakuda, Y. Polyphenolics in grape seeds—Biochemistry and functionality. J. Med. Food 2003, 6, 291–299. [Google Scholar] [CrossRef]

- Guendez, R.; Kallithraka, S.; Makris, D.P.; Kefalas, P. Determination of low molecular weight polyphenolic constituents in grape (Vitis vinifera sp.) seed extracts: Correlation with antiradical activity. Food Chem. 2005, 89, 1–9. [Google Scholar] [CrossRef]

- Travaglia, F.; Bordiga, M.; Locatelli, M.; Coisson, J.D.; Arlorio, M. Polymeric proanthocyanidins in skins and seeds of 37 Vitis vinifera L. cultivars: A methodological comparative study. J. Food Sci. 2011, 76, 742–749. [Google Scholar] [CrossRef]

- Bagchi, D.; Swaroop, A.; Preuss, H.G.; Bagchi, M. Free radical scavenging, antioxidant and cancer chemoprevention by grape seed proanthocyanidin: An overview. Mutat. Res. 2014, 768, 69–73. [Google Scholar] [CrossRef]

- Carpenter, R.; O’Grady, M.N.; O’Callaghan, Y.C.; O’Brien, N.M.; Kerry, J.P. Evaluation of the antioxidant potential of grape seed and bearberry extracts in raw and cooked pork. Meat Sci. 2007, 76, 604–640. [Google Scholar] [CrossRef] [PubMed]

- Pacheco-Ordaz, R.; Wall-Medrano, A.; Goni, M.G.; Ramos-Clamont-Montfort, G.; Ayala-Zavala, J.F.; Gonzalez-Aguilar, G.A. Effect of phenolic compounds on the growth of selected probiotic and pathogenic bacteria. Lett. Appl. Microbiol. 2018, 66, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Bordiga, M.; Montella, R.; Travaglia, F.; Arlorio, M.; Coisson, J.D. Characterization of polyphenolic and oligosaccharidic fractions extracted from grape seeds followed by the evaluation of prebiotic activity related to oligosaccharides. Int. J. Food Sci. Technol. 2019, 54, 1283–1291. [Google Scholar] [CrossRef]

- Falowo, A.B.; Foyemi, P.O.; Muchenje, V. Natural antioxidant against lipid-protein oxidative deterioration in meat and meat products: A review. Food Res. Int. 2014, 64, 171–181. [Google Scholar] [CrossRef]

- Ruiz-Moyano, S.; Martin, A.; Benito, M.J.; Hernandez, A.; Casquete, R.; de Guia Cordoba, M. Application of Lactobacillus fermentum HL57 and Pedicoccus acidilactici SP979 as potential probiotics in the manufacture of traditional Iberian dry-fermented sausages. Food Microbiol. 2011, 28, 839–847. [Google Scholar] [CrossRef]

- Jiang, J.; Xiong, Y.I. Natural antioxidants as food and feed additives to promote health benefits and quality of meat products: A review. Meat Sci. 2016, 120, 107–117. [Google Scholar] [CrossRef]

- Neffe-Skocińska, K.; Jaworska, D.; Kołożyn-Krajewska, D.; Dolatowski, Z.J.; Jachacz-Jówko, L. The effect of LAB as probiotic starter culture and green tea extract addition on dry fermented pork loins quality. BioMed Res. Int. 2015, 2015, 452757. [Google Scholar] [CrossRef]

- Wójciak, K.M.; Libera, J.; Stasiak, D.M.; Kołożyn-Krajewska, D. Technological aspect of Lactobacillus acidophilus Bauer, Bifidobacterium animalis BB-12 and Lactobacillus rhamnosus LOCK900 use in dry-fermented pork neck and sausage. J. Food Proces. Preserv. 2017, 41, e12965. [Google Scholar] [CrossRef]

- Kęska, P.; Stadnik, J.; Wójciak, K.M.; Neffe-Skocińska, K. Physico-chemical and proteolytic changes during cold storage of dry-cured pork loins with probiotic strains of LAB. Int. J. Food Sci. Technol. 2019. [Google Scholar] [CrossRef]

- Aleksandrzak-Piekarczyk, T.; Koryszewska-Bagińska, A.; Bardowski, J. Genome sequence of the probiotic strain Lactobacillus rhamnosus (formerly Lactobacillus casei) LOCK900. Genome Announc. 2013, 1, e00640-13. [Google Scholar] [CrossRef]

- Libera, J.; Kononiuk, A.; Kęska, P.; Wójciak, K.M. Use of grape seed extract as a natural antioxidant additive in dry-fermented pork neck technology. Biotechnol. Food Sci. 2018, 82, 141–150. [Google Scholar]

- Commission Internationale de l‘Eclairage (CIE). Supplement No. 2 to CIE Publication No. 15 Colorimetry; Bureau Central de la CIE: Paris, France, 1987. [Google Scholar]

- Singleton, V.L.; Rossi, J. Colorimetry of total phenolics with phosphomolybdic–phosphotungstics acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 15214. Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Mesophilic Lactic Acid Bacteria—Colony—Count Technique at 30 °C; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- International Organization for Standardization. ISO 21528-2. Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Enterobacteriaceae—Part 2: Colony—Count Technique; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- International Organization for Standardization. ISO 2917. Meat and Meat Products—Measurement of pH—Reference Method; ISO: Geneva, Switzerland, 1999. [Google Scholar]

- Koniecko, E.S. Handbook for Meat Chemists; Avery Publishing Group, Inc.: Wayne, NJ, USA, 1979. [Google Scholar]

- Malik, A.H.; Sharma, B.D. Use of hurdle techniques to maintain the quality of vacuum packed buffalo meat during ambient storage temperatures. Afr. J. Food Sci. 2011, 5, 626–636. [Google Scholar]

- Pikul, J.; Leszczyński, D.E.; Kummerow, F.A. Evaluation of three modified TBA methods for measuring lipid oxidation in chicken meat. J. Agric. Food Chem. 1989, 37, 1309–1315. [Google Scholar] [CrossRef]

- Baydar, N.G.; Sagdic, O.; Ozkan, G.; Cetin, S. Determination of antibacterial effects and total phenolic contents of grape (Vitis vinifera L.) seed extracts. Int. J. Food Sci. Technol. 2006, 41, 799–804. [Google Scholar] [CrossRef]

- Jayaprakasha, G.K.; Selvi, T.; Sakariah, K.K. Antibacterial and antioxidant activities of grape (Vitis vinifera) seed extracts. Food Res. Int. 2003, 36, 117–122. [Google Scholar] [CrossRef]

- Mayer, R.; Stecher, G.; Wuerzner, R.; Silva, R.C.; Sultana, T.; Trojer, L.; Feuerstein, I.; Krieg, C.; Abel, G.; Popp, M.; et al. Proanthocyanidins: Target compounds as antibacterial agents. J. Agric. Food Chem. 2008, 56, 6959–6966. [Google Scholar] [CrossRef]

- Silvan, J.M.; Mingo, E.; Hidalgo, M.; De Pascual-Teresa, S.; Carrascosa, A.C.; Martinez-Rodriguez, A.J. Antibacterial activity of grape seed extract and its fractions against Campylobacter spp. Food Control 2013, 29, 25–31. [Google Scholar] [CrossRef]

| Sample | Curing Salt (g) | Grape Seed Extract (g) | Sodium Ascorbate (g) | Glucose (g) | Probiotic Monoculture (mL) |

|---|---|---|---|---|---|

| GSE | 30 | 2 | - | 12 | 2 (9.3 log cfu) |

| ASC | 30 | - | 1 | 12 | 2 (9.3 log cfu) |

| CON | 30 | - | - | 12 | 2 (9.3 log cfu) |

| Tests | Grape Seed Extract |

|---|---|

| Color parameters of extract: | |

| CIEL* | 27.7 ± 0.5 |

| CIEa* | 0.75 ± 0.3 |

| CIEb* | 11.2 ± 0.2 |

| ΔE*during exposure to light | 0.61 |

| Antioxidant properties of extract: | |

| TEAC Assay (mmol TE of mL−1) | 5.14 ± 0.8 |

| TPC Assay (mg GAE mL−1) | 6.74 ± 0.2 |

| Sample | Before Ripening | During Ripening | After Ripening | |

|---|---|---|---|---|

| Lactic acid bacteria | GSE | 5.71 ± 0.30 aA | 6.88 ± 0.28 aB | 6.93 ± 0.31 aB |

| ASC | 5.69 ± 0.29 aA | 6.38 ± 0.28 aB | 6.67 ± 0.29 aB | |

| CON | 5.81 ± 0.31 aA | 6.52 ± 0.26 aB | 7.15 ± 0.27 aC | |

| Enterobacteriaceae | GSE | 2.75 ± 0.30 bA | <1.00 ± 0.00 bB | <1.00 ± 0.00 bB |

| ASC | 5.32 ± 0.29 aA | 3.64 ± 0.25 aB | 1.99 ± 0.29 aC | |

| CON | 4.89 ± 0.30 aA | 3.94 ± 0.24 aB | 2.23 ± 0.26 aC | |

| pH value | GSE | 5.75 ± 0.06 aA | 5.50 ± 0.07 aB | 5.45 ± 0.05 aB |

| ASC | 5.66 ± 0.09 aA | 5.42 ± 0.08 aB | 5.40 ± 0.06 aB | |

| CON | 5.73 ± 0.11 aA | 5.47 ± 0.05 aB | 5.41 ± 0.07 aB |

| Sample | Before Ripening | During Ripening | After Ripening | |

|---|---|---|---|---|

| FFA | GSE | 0.43 ± 0.03 bA | 0.68 ± 0.03 bB | 0.96 ± 0.05 bC |

| ASC | 0.41 ± 0.03 bA | 0.65 ± 0.05 bB | 0.93 ± 0.05 bB | |

| CON | 0.55 ± 0.04 aA | 1.03 ± 0.04 aB | 1.49 ± 0.03 aC | |

| TBArs | GSE | 0.31 ± 0.03 aA | 0.36 ± 0.04 bA | 0.46 ± 0.05 bB |

| ASC | 0.29 ± 0.05 aA | 0.34 ± 0.05 bA | 0.53 ± 0.04 bB | |

| CON | 0.37 ± 0.04 aA | 0.57 ± 0.05 aB | 0.72 ± 0.05 aC |

| Sample | Before Ripening | During Ripening | After Ripening | |

|---|---|---|---|---|

| CIEL* | GSE | 48.63 ± 1.55 bA | 44.42 ± 1.46 aB | 44.19 ± 1.69 aB |

| ASC | 51.35 ± 2.40 aA | 45.00 ± 1.87 aB | 45.63 ± 1.71 aB | |

| CON | 52.57 ± 1.46 aA | 43.15 ± 2.06 aB | 40.01 ± 1.46 aB | |

| CIEa* | GSE | 10.26 ± 0.50 aA | 12.33 ± 0.66 aB | 13.36 ± 0.68 aB |

| ASC | 9.18 ± 0.57 bA | 10.28 ± 0.82 bA | 11.08 ± 0.68 bA | |

| CON | 9.18 ± 0.55 bA | 10.27 ± 0.85 bA | 11.73 ± 0.53 bA | |

| CIEb* | GSE | 11.67 ± 1.08 aA | 12.11 ± 0.93 aA | 12.32 ± 0.92 aA |

| ASC | 12.96 ± 0.88 aA | 12.78 ± 0.82 aA | 12.14 ± 0.98 aA | |

| CON | 11.48 ± 0.67 aA | 11.92 ± 0.60 aA | 11.13 ± 0.65 aA |

| Before Ripening (Time 0) | During Ripening (Time 1) | After Ripening (Time 2) | |

|---|---|---|---|

| ΔE*GSE-ASC | 3.20 | 2.23 | 2.70 |

| ΔE*GSE-CON | 4.09 | 2.43 | 4.64 |

| ΔE*ASC-CON | 1.92 | 2.04 | 5.75 |

| GSE | ASC | CON | |

| ΔE*time 1–time 0 | 4.71 | 6.45 | 9.49 |

| ΔE*time 2–time 0 | 5.45 | 6.08 | 12.82 |

| ΔE*time 2–time 1 | 1.08 | 1.20 | 3.55 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Libera, J.; Latoch, A.; Wójciak, K.M. Utilization of Grape Seed Extract as a Natural Antioxidant in the Technology of Meat Products Inoculated with a Probiotic Strain of LAB. Foods 2020, 9, 103. https://doi.org/10.3390/foods9010103

Libera J, Latoch A, Wójciak KM. Utilization of Grape Seed Extract as a Natural Antioxidant in the Technology of Meat Products Inoculated with a Probiotic Strain of LAB. Foods. 2020; 9(1):103. https://doi.org/10.3390/foods9010103

Chicago/Turabian StyleLibera, Justyna, Agnieszka Latoch, and Karolina Maria Wójciak. 2020. "Utilization of Grape Seed Extract as a Natural Antioxidant in the Technology of Meat Products Inoculated with a Probiotic Strain of LAB" Foods 9, no. 1: 103. https://doi.org/10.3390/foods9010103

APA StyleLibera, J., Latoch, A., & Wójciak, K. M. (2020). Utilization of Grape Seed Extract as a Natural Antioxidant in the Technology of Meat Products Inoculated with a Probiotic Strain of LAB. Foods, 9(1), 103. https://doi.org/10.3390/foods9010103