Stabilization of Crystalline Carotenoids in Carrot Concentrate Powders: Effects of Drying Technology, Carrier Material, and Antioxidants

Abstract

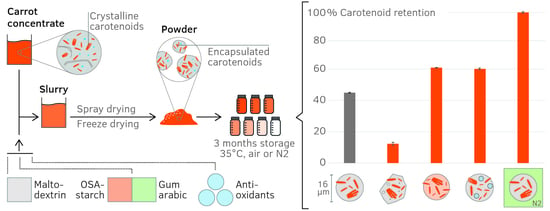

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Tested Recipe Parameters

2.3. Slurry Production

2.4. Spray Drying and Freeze Drying

2.5. Dry Matter Content

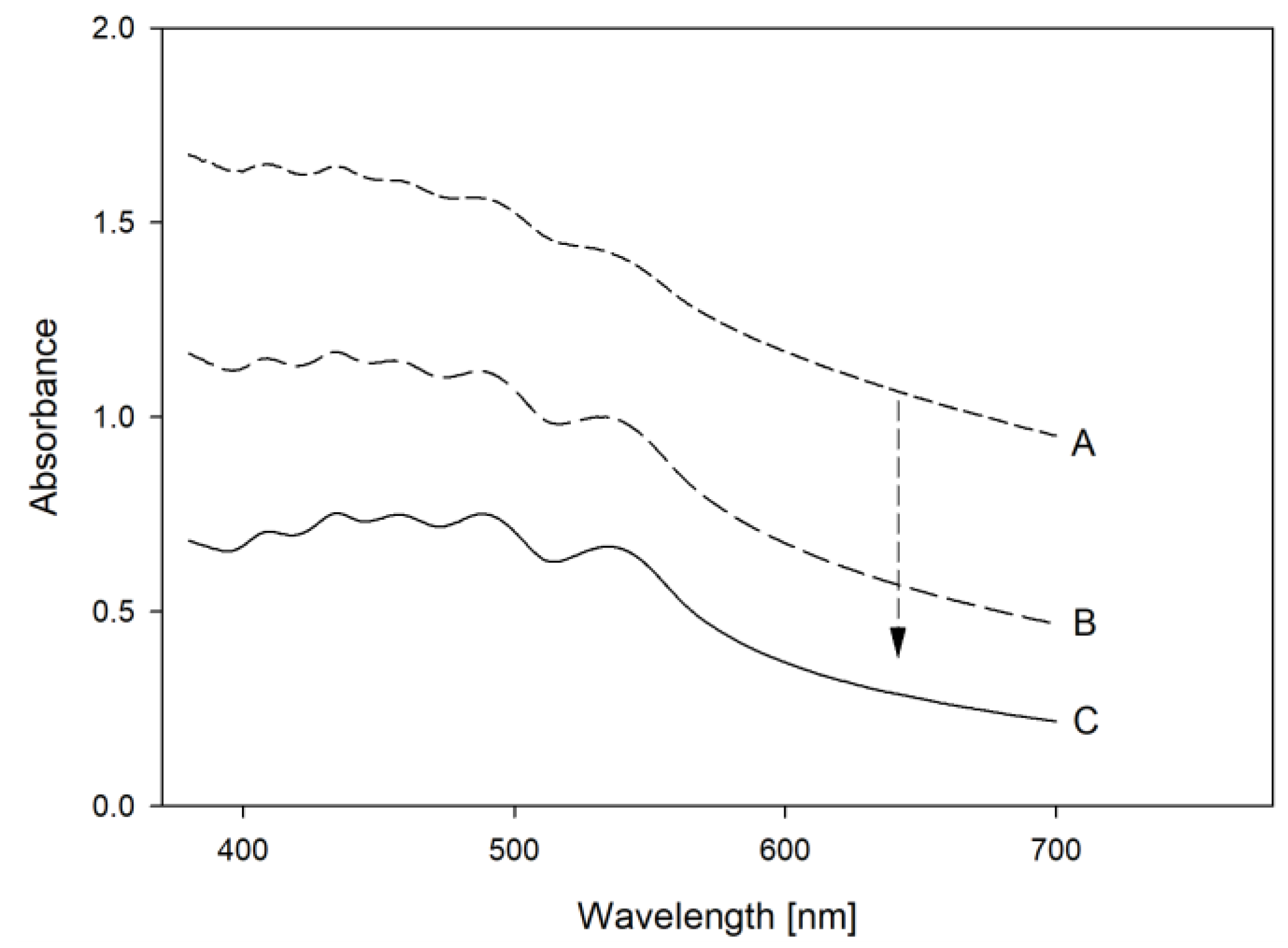

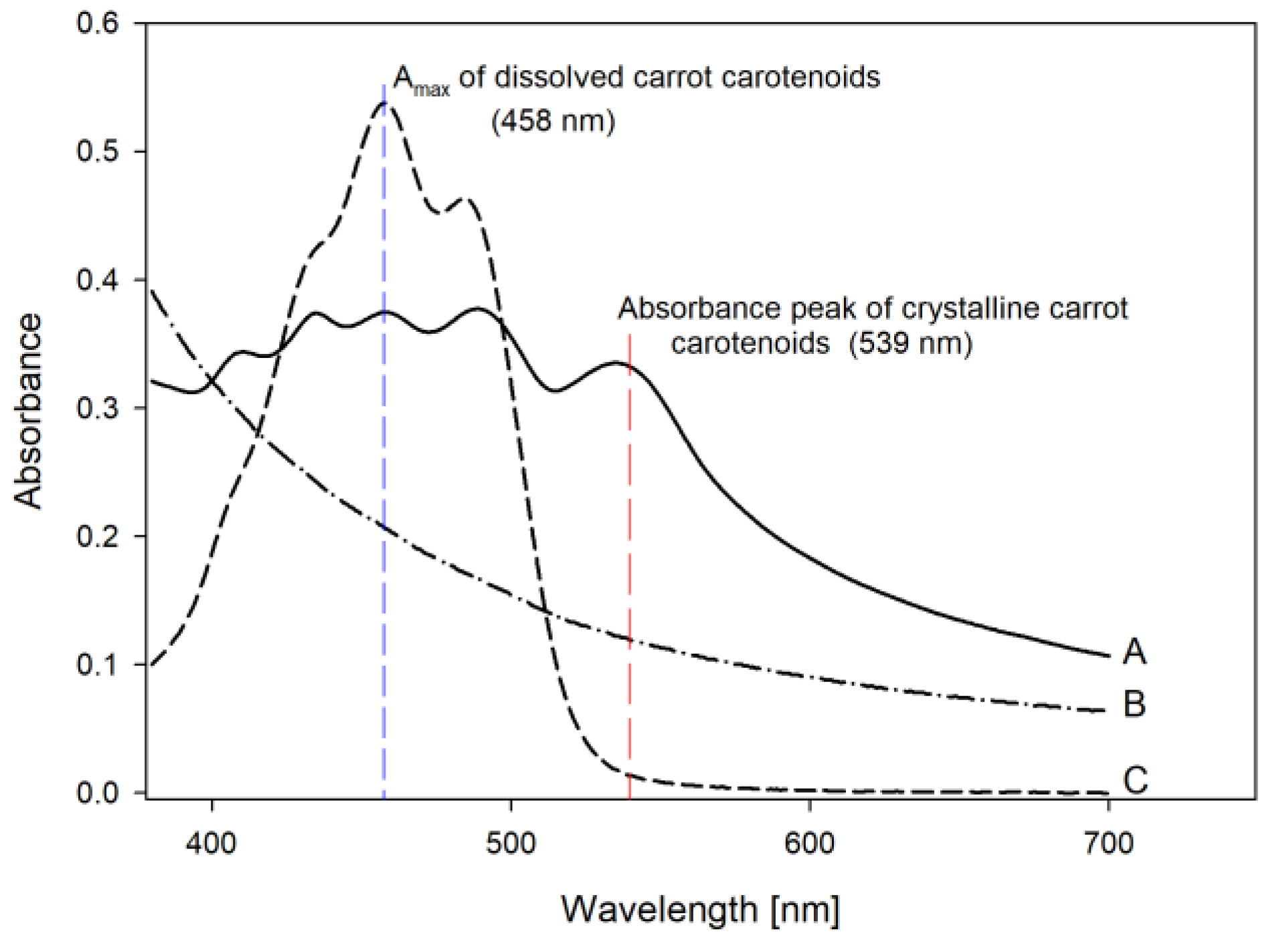

2.6. Assessment of the Physical State of Carotenoids

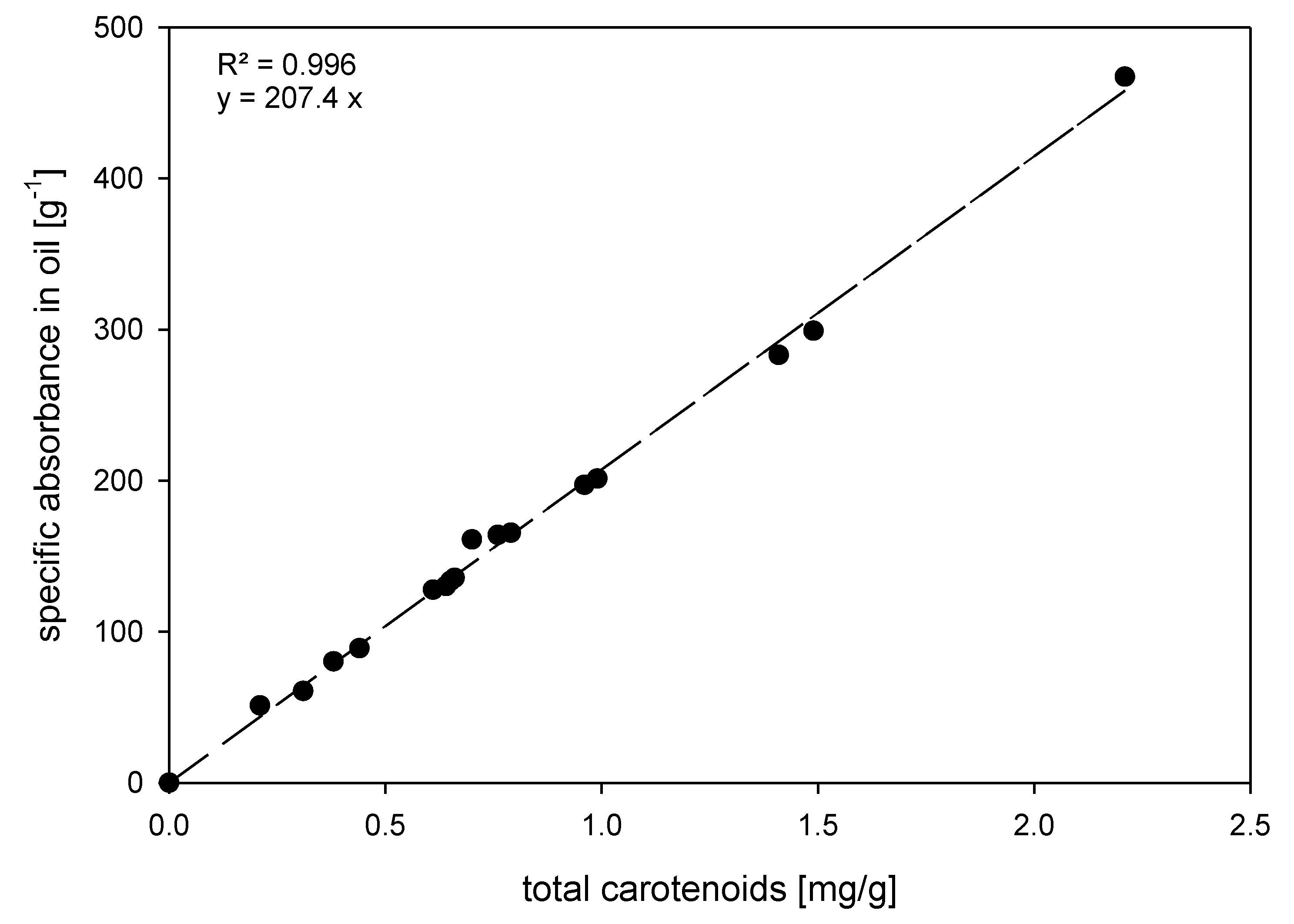

2.7. Total Carotenoid Content

2.8. Surface Carotenoid (SC) and Encapsulated Carotenoids (EC)

2.9. Carotenoid Recovery, Encapsulation Efficiency, and Carotenoid Retention

2.10. Particle Size and Morphology

2.11. Storage Study

2.12. Statistical Analysis

3. Results and Discussion

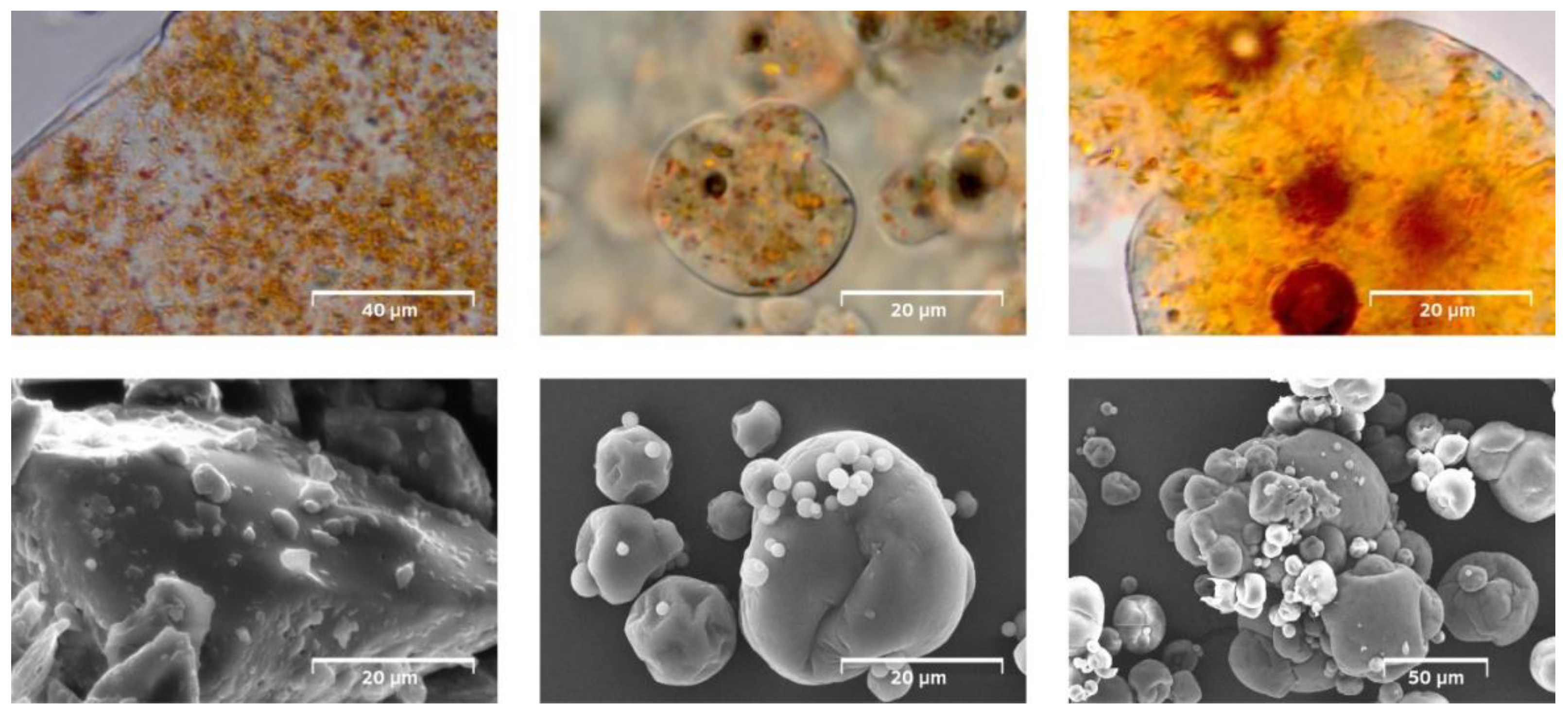

3.1. Powder Particle Morphology and Component Distribution

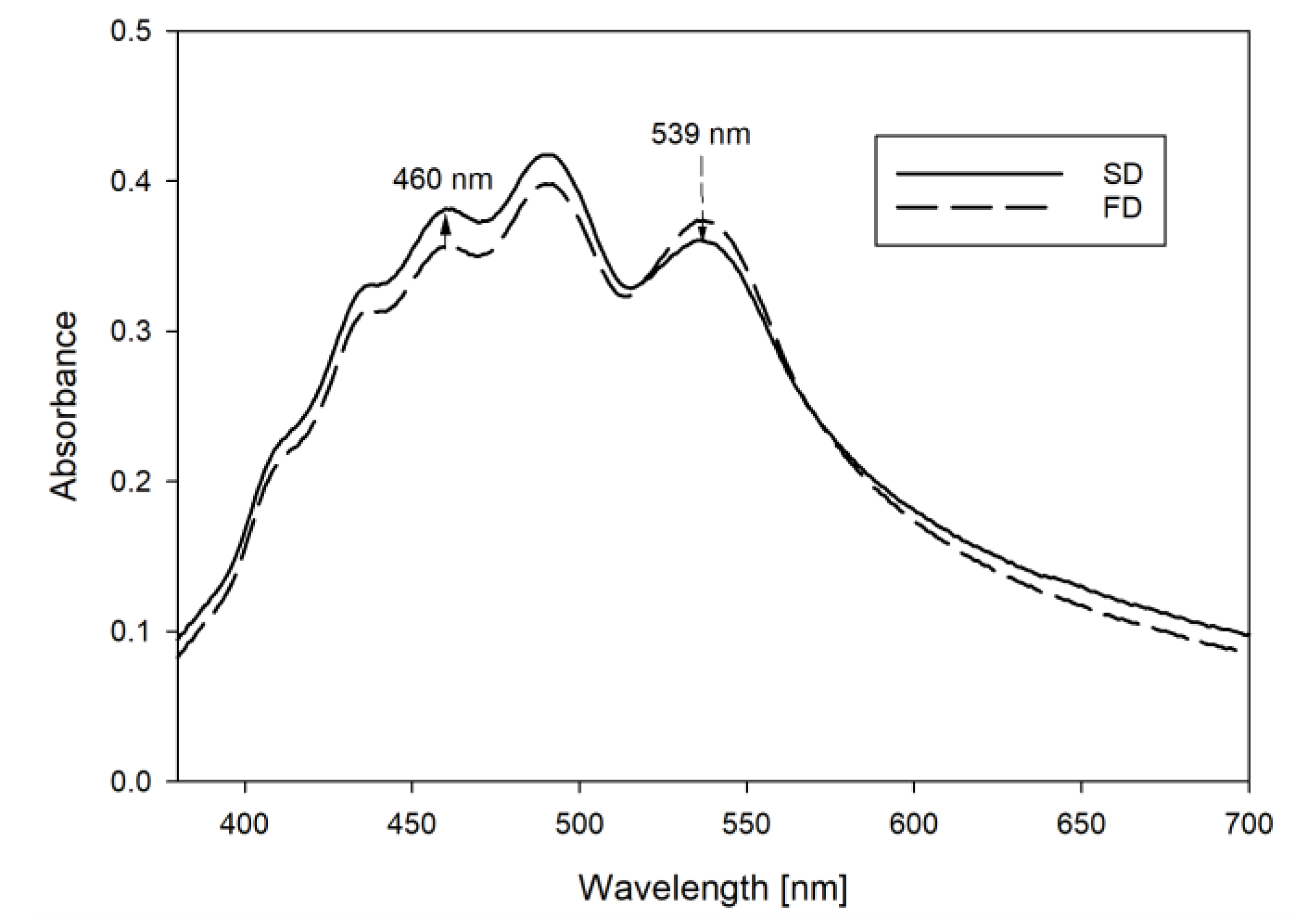

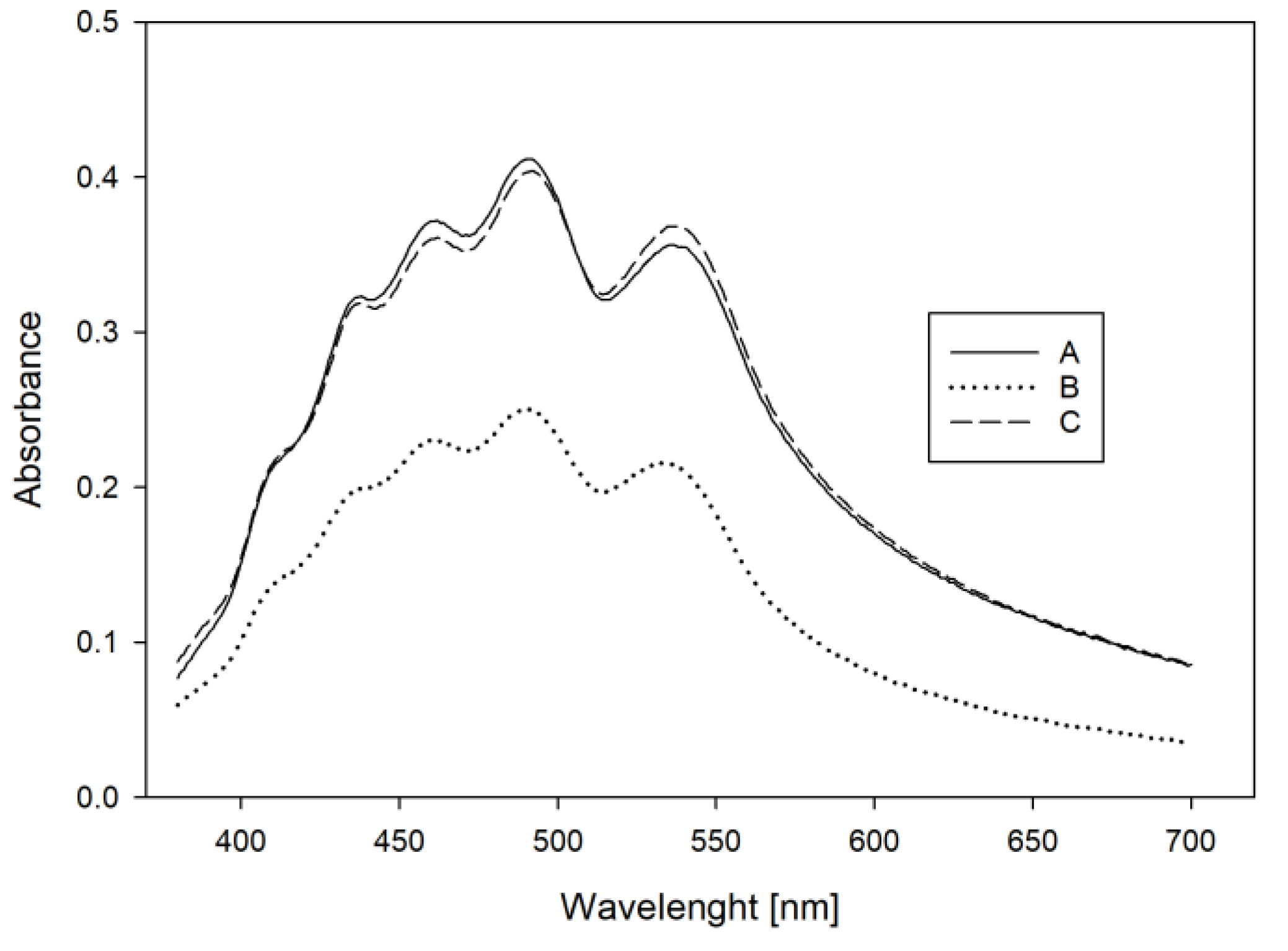

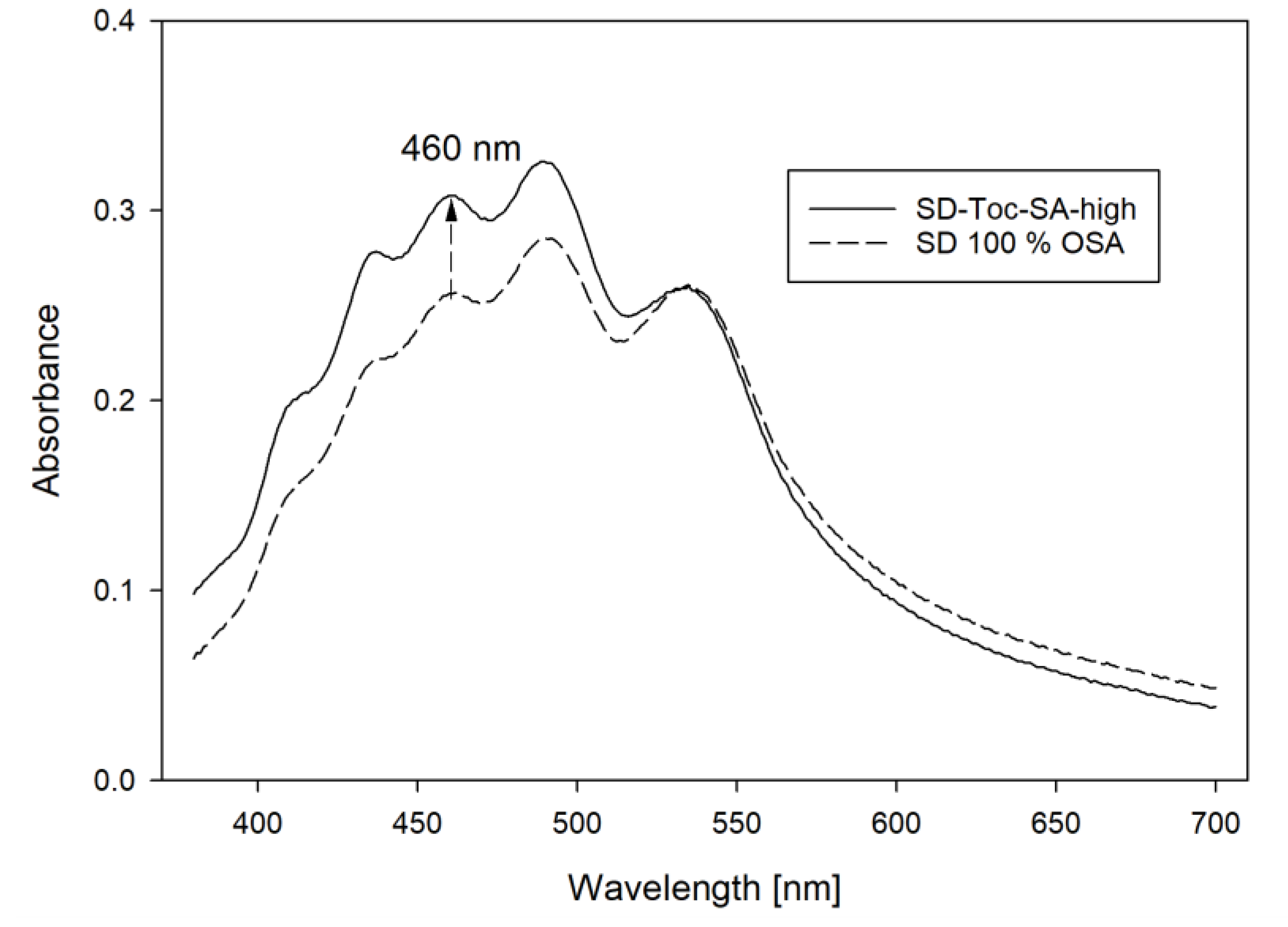

3.2. Impact on Processing on Carrot Carotenoid Content and UV/Vis Absorbance

3.3. Impact of Ambient Oxygen on the Carotenoid Degradation during Storage

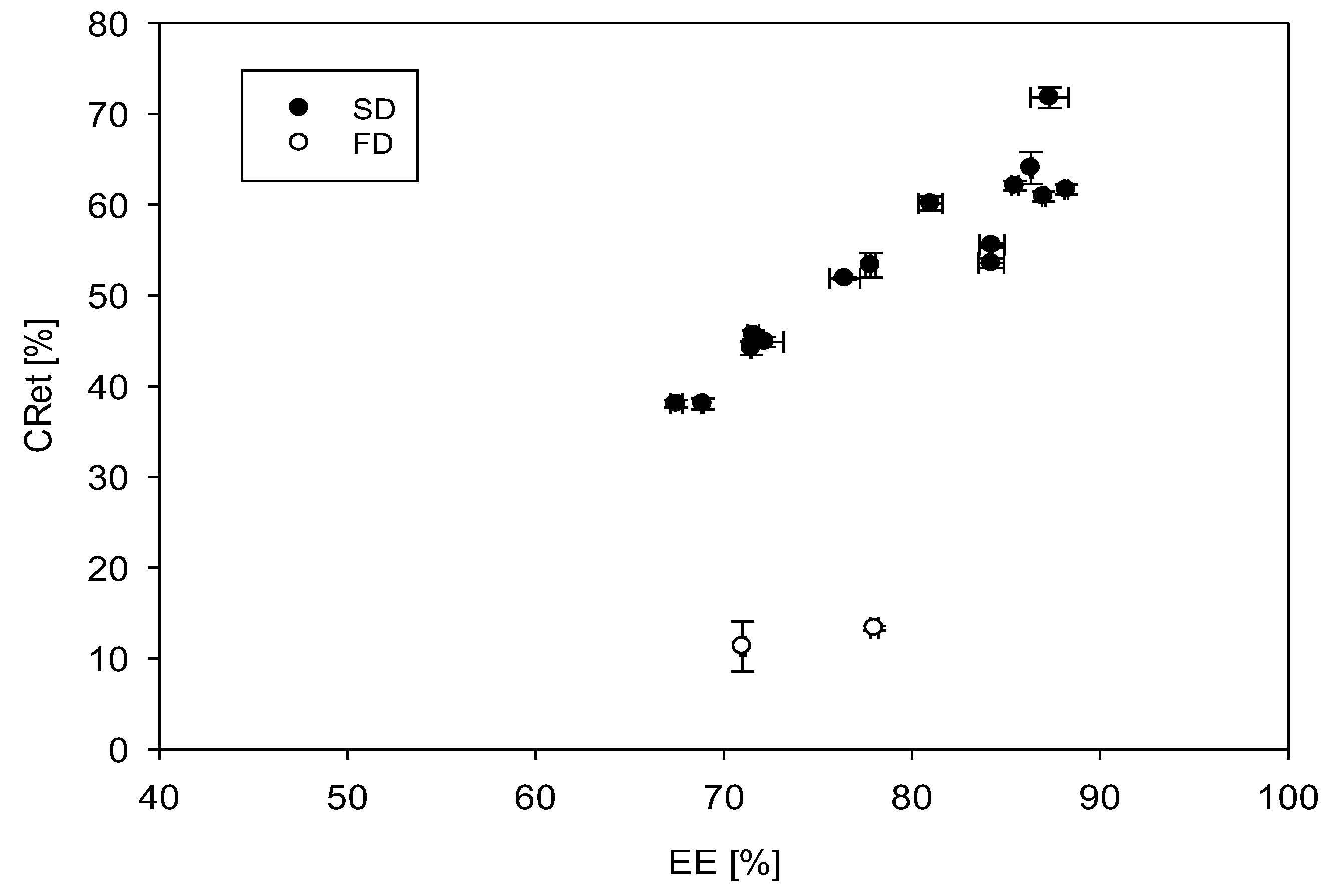

3.4. Encapsulation Efficiency and Drying Process as Impact Factors for Carotenoid Retention during Storage

3.5. Impact of Functional Additives on the Stability of Carotenoids in Carrot Concentrate Powders

3.5.1. Effect of Surface-Active Carrier

3.5.2. Effect of Antioxidant Addition

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Boon, C.S.; McClements, D.J.; Weiss, J.; Decker, E. Factors influencing the chemical stability of carotenoids in foods. Crit. Rev. Food Sci. Nutr. 2010, 50, 515–532. [Google Scholar] [CrossRef] [PubMed]

- McClements, D.J. Crystals and crystallization in oil-in-water emulsions: Implications for emulsion-based delivery systems. Adv. Colloid. Interface Sci. 2012, 174, 1–30. [Google Scholar] [CrossRef] [PubMed]

- Köhn, S.; Kolbe, H.; Korger, M.; Köpsel, C.; Mayer, B.; Auweter, H.; Lüddecke, E.; Bettermann, H.; Martin, H. Aggregation and Interface Behaviour of Carotenoids. In Carotenoids Volume 4: Natural Functions; Britton, G., Liaaen-Jensen, S., Pfander, H., Eds.; Birkhäuser Basel: Basel, Switzerland, 2008; pp. 53–98. [Google Scholar]

- Schweiggert, R.; Mezger, D.; Schimpf, F.; Steingass, C.B.; Carle, R. Influence of chromoplast morphology on carotenoid bioaccessibility of carrot, mango, papaya, and tomato. Food Chem. 2012, 135, 2736–2742. [Google Scholar] [CrossRef] [PubMed]

- Kläui, H.; Bauernfeind, J.C. Carotenoids as food colors. In Carotenoids as Colorants and Vitamin a Precursors; Bauernfeind, C.J., Ed.; Academic Press: San Diego, CA, USA, 1981; pp. 47–317. [Google Scholar]

- Knockaert, G.; Lemmens, L.; Buggenhout, S.V.; Hendrickx, M.; Loey, A. Changes in β-carotene bioaccessibility and concentration during processing of carrot puree. Food Chem. 2012, 133, 60–67. [Google Scholar] [CrossRef]

- Marx, M.; Stuparic, M.; Schieber, A.; Carle, R. Effects of thermal processing on trans–cis-isomerization of β-carotene in carrot juices and carotene-containing preparations. Food Chem. 2003, 83, 609–617. [Google Scholar] [CrossRef]

- Hempel, J.; Müller-Maatsch, J.; Carle, R.; Schweiggert, R.M. Non-destructive approach for the characterization of the in situ carotenoid deposition in gac fruit aril. J. Food Compos. Anal. 2018, 65, 16–22. [Google Scholar] [CrossRef]

- Gaier, K.; Angerhofer, A.; Wolf, H.C. The lowest excited electronic singlet states of all-trans β-carotene single crystals. Chem. Phys. Lett. 1991, 187, 103–109. [Google Scholar] [CrossRef]

- Simonyi, M.; Bikadi, Z.; Zsila, F.; Deli, J. Supramolecular Exciton Chirality of Carotenoid Aggregates. Chem. Inform. 2004, 35. [Google Scholar] [CrossRef]

- Sadler, G.; Davis, J.; Dezman, D. Rapid Extraction of Lycopene and β-Carotene from Reconstituted Tomato Paste and Pink Grapefruit Homogenates. J. Food Sci. 1990, 55, 1460–1461. [Google Scholar] [CrossRef]

- Rodriguez-Amaya, D.B. Quantitative analysis, in vitro assessment of bioavailability and antioxidant activity of food carotenoids—A review. J. Food Compos. Anal. 2010, 23, 726–740. [Google Scholar] [CrossRef]

- Wagner, L.A.; Warthesen, J. Stability of Spray-Dried Encapsulated Carrot Carotenes. J. Food Sci. 1995, 60, 1048–1053. [Google Scholar] [CrossRef]

- Hedges, L.V. Distribution Theory for Glass’s Estimator of Effect size and Related Estimators. J. Educ. Stat. 1981, 6, 107–128. [Google Scholar] [CrossRef]

- Gianfrancesco, A.; Turchiuli, C.; Dumoulin, E. Powder agglomeration during the spray-drying process: Measurements of air properties. Dairy Sci. Technol. 2008, 88, 53–64. [Google Scholar] [CrossRef]

- Vicente, J.; Pinto, J.; Menezes, J.; Gaspar, F. Fundamental analysis of particle formation in spray drying. Powder Technol. 2013, 247, 1–7. [Google Scholar] [CrossRef]

- Desobry, S.A.; Netto, F.M.; Labuza, T.P. Preservation of beta-carotene from carrots. Crit. Rev. Food Sci. Nutr. 1998, 38, 381–396. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Li, F.; Li, Z.; McClements, D.J.; Xiao, H. Encapsulation of carotenoids in emulsion-based delivery systems: Enhancement of β-carotene water-dispersibility and chemical stability. Food Hydrocoll. 2017, 69, 49–55. [Google Scholar] [CrossRef]

- Sharma, K.D.; Karki, S.; Thakur, N.S.; Attri, S. Chemical composition, functional properties and processing of carrot—A review. J. Food Sci. Technol. 2012, 49, 22–32. [Google Scholar] [CrossRef] [PubMed]

- Stefanovich, A.F.; Karel, M. Kinetic of beta-carotene degradation at temperatures typical of air drying of foods. J. Food Process Pres. 1982, 6, 227–242. [Google Scholar] [CrossRef]

- Serfert, Y.; Drusch, S.; Schmidt-Hansberg, B.; Kind, M.; Schwarz, K. Process engineering parameters and type of n-octenylsuccinate-derivatised starch affect oxidative stability of microencapsulated long chain polyunsaturated fatty acids’. J. Food Eng. 2009, 95, 386–392. [Google Scholar] [CrossRef]

- Adamkiewicz, P.; Sujak, A.; Gruszecki, W.I. Spectroscopic study on formation of aggregated structures by carotenoids: Role of water. J. Mol. Struct. 2013, 1046, 44–51. [Google Scholar] [CrossRef]

- Harnkarnsujarit, N.; Charoenrein, S.; Roos, Y.; Porosity, H. Water Activity Effects on Stability of Crystalline β-Carotene in Freeze-Dried Solids. J. Food Sci. 2012, 77, E313–E320. [Google Scholar] [CrossRef] [PubMed]

- Anwar, S.H.; Kunz, B. The influence of drying methods on the stabilization of fish oil microcapsules: Comparison of spray granulation, spray drying, and freeze drying. J. Food Eng. 2011, 105, 367–378. [Google Scholar] [CrossRef]

- Soottitantawat, A.; Bigeard, F.; Yoshii, H.; Furuta, T.; Ohkawara, M.; Linko, P. Influence of emulsion and powder size on the stability of encapsulated d-limonene by spray drying. Innov. Food Sci. Emerg. Technol. 2005, 6, 107–114. [Google Scholar] [CrossRef]

- Vhangani, L.; Van, N.; Wyk, J. Antioxidant activity of Maillard reaction products (MRPs) derived from fructose–lysine and ribose–lysine model systems. Food Chem. 2013, 137, 92–98. [Google Scholar] [CrossRef] [PubMed]

- Janiszewska-Turak, E. Carotenoids microencapsulation by spray drying method and supercritical micronization. Food Res. Int. 2017, 99, 891–901. [Google Scholar] [CrossRef] [PubMed]

- Soukoulis, C.; Bohn, T. A Comprehensive Overview on the Micro- and Nano-technological Encapsulation Advances for Enhancing the Chemical Stability and Bioavailability of Carotenoids. Crit. Rev. Food Sci. Nutr. 2015. [Google Scholar] [CrossRef] [PubMed]

- Jafari, S.M.; Assadpoor, E.; He, Y.; Bhandari, B. Encapsulation Efficiency of Food Flavours and Oils during Spray Drying. Dry. Technol. 2008, 26, 816–835. [Google Scholar] [CrossRef]

- Krishnan, S.; Bhosale, R.; Singhal, R. Microencapsulation of cardamom oleoresin: Evaluation of blends of gum arabic, maltodextrin and a modified starch as wall materials. Carbohydr. Polym. 2005, 61, 95–102. [Google Scholar] [CrossRef]

- Munoz-Ibanez, M.; Nuzzo, M.; Turchiuli, C.; Bergenståhl, B.; Dumoulin, E.; Millqvist-Fureby, A. The microstructure and component distribution in spray-dried emulsion particles. Food Struct. 2016, 8, 16–24. [Google Scholar] [CrossRef]

- Kang, Y.; Lee, Y.; Kim, Y.K.; Chang, Y.H. Characterization and storage stability of chlorophylls microencapsulated in different combination of gum Arabic and maltodextrin. Food Chem. 2019, 272, 337–346. [Google Scholar] [CrossRef]

- Velasco, J.; Dobarganes, M.C.; Márquez-Ruiz, G. Oxidation of free and encapsulated oil fractions in dried microencapsulated fish oils. Grasas Aceites 2000, 51, 6. [Google Scholar] [CrossRef]

- Velasco, J.; Marmesat, S.; Dobarganes, C.; Márquez-Ruiz, G. Heterogeneous Aspects of Lipid Oxidation in Dried Microencapsulated Oils. J. Agric. Food Chem. 2006, 54, 1722–1729. [Google Scholar] [CrossRef] [PubMed]

- Berdahl, D.R.; Nahas, R.I.; Barren, J.P. Synthetic and natural antioxidant additives in food stabilization: Current applications and future research. In Oxidation in Foods and Beverages and Antioxidant Applications; MCClements, D.J., Decker, E.A., Eds.; Woodhead Publishing: Sawston, England, 2010; pp. 272–320. [Google Scholar]

- Baik, M.Y.; Suhendro, E.L.; Nawar, W.W.; McClements, D.J.; Decker, E.A.; Chinachoti, P. Effects of antioxidants and humidity on the oxidative stability of microencapsulated fish oil. J. Am. Oil Chem. Soc. 2004, 81, 355–360. [Google Scholar] [CrossRef]

- Barden, L.; Decker, E.A. Lipid Oxidation in Low-moisture Food: A Review. Crit. Rev. Food Sci. 2016, 56, 2467–2482. [Google Scholar] [CrossRef] [PubMed]

| Sample Code | Toc 1 | SA 2 | MD 3 | OSA 4 | GA 5 |

|---|---|---|---|---|---|

| (µg/g DM) | (µg/g DM) | (g/g DM) | (g/g DM) | (g/g DM) | |

| SD-Ref a/FD b/SD-no-HPH b/SD-E a | - | - | 0.5 | - | - |

| SD 50% GA b | - | - | 0.25 | - | 0.25 |

| SD 100% GA b | - | - | - | - | 0.5 |

| SD 50% OSA b | - | - | 0.25 | 0.25 | - |

| SD 100% OSA b | - | - | - | - | 0.5 |

| SD-Toc-low c | 250 | - | 0.5 | - | - |

| SD-SA-low c | 500 | 0.5 | - | - | |

| SD-Toc-high b | 2500 | - | 0.5 | - | - |

| SD-SA-high b | 5000 | 0.5 | - | - | |

| SD-Toc-SA-low b | 250 | 500 | 0.5 | - | - |

| SD-Toc-SA-high c | 2500 | 5000 | 0.49 | - | - |

| Sample Code | CRec (%) | SC (%) | CRet (%) |

|---|---|---|---|

| SD-Ref | 99.4 ± 0.8 e | 29.2 ± 1.3 e,d | 44.9 ± 0.8 c |

| FD | 98.9 ± 1.3 c,d,e | 26.3 ± 3.9 d,e | 12.3 ± 2.1 a |

| SD-no-HPH | 98.3 ± 0.4 c,d | 32.9 ± 0.8 f | 38.1 ± 0.5 b |

| SD-E | 97.1 ± 0.5 a,b | 14.1 ± 2.5 a | 66.0 ± 5.4 h |

| SD 50% GA | 98.8 ± 0.7 d,e | 23.6 ± 1.0 c,d | 52.6 ± 1.2 d |

| SD 100% GA | 95.9 ± 0.8 a | 19.6 ± 0.6 b,c | 60.1 ± 1.3 e |

| SD 50% OSA | 99.4 ± 0.5 e | 16.3 ± 0.6 a,b | 54.6 ± 1.2 d |

| SD 100% OSA | 98.0 ± 0.5 b,c,d | 12.2 ± 0.1 a | 61.6 ± 1.3 e |

| Sample Code | CRec (%) | SC (%) | CRet (%) |

|---|---|---|---|

| SD-Ref 1 | 99.4 ± 0.8 c | 29.2 ± 1.3 c,d | 44.9 ± 0.8 a |

| SD-Toc-low | 97.8 ± 0.2 a,b | 25.4 ± 0.6 a | 52.5 ± 0.5 c |

| SD-SA-low | 96.8 ± 0.5 a,b | 26.5 ± 0.8 a,b | 49.7 ± 0.6 b |

| SD-Toc-high | 97.2 ± 1.0 a | 28.5 ± 1.0 b,c | 59.8 ± 1.8 e |

| SD-SA-high | 97.7 ± 0.5 a,b | 25.1 ± 0.7 c | 54.1 ± 1.9 c,d |

| SD-Toc-SA-low | 98.8 ± 1.2 b,c | 28.2 ± 2.0 b,c | 49.3 ± 0.4 b |

| SD-Toc-SA-high | 97.8 ± 1.4 a,b | 30.1 ± 0.3 d | 60.2 ± 1.3 e |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haas, K.; Robben, P.; Kiesslich, A.; Volkert, M.; Jaeger, H. Stabilization of Crystalline Carotenoids in Carrot Concentrate Powders: Effects of Drying Technology, Carrier Material, and Antioxidants. Foods 2019, 8, 285. https://doi.org/10.3390/foods8080285

Haas K, Robben P, Kiesslich A, Volkert M, Jaeger H. Stabilization of Crystalline Carotenoids in Carrot Concentrate Powders: Effects of Drying Technology, Carrier Material, and Antioxidants. Foods. 2019; 8(8):285. https://doi.org/10.3390/foods8080285

Chicago/Turabian StyleHaas, Klara, Paul Robben, Anke Kiesslich, Marcus Volkert, and Henry Jaeger. 2019. "Stabilization of Crystalline Carotenoids in Carrot Concentrate Powders: Effects of Drying Technology, Carrier Material, and Antioxidants" Foods 8, no. 8: 285. https://doi.org/10.3390/foods8080285

APA StyleHaas, K., Robben, P., Kiesslich, A., Volkert, M., & Jaeger, H. (2019). Stabilization of Crystalline Carotenoids in Carrot Concentrate Powders: Effects of Drying Technology, Carrier Material, and Antioxidants. Foods, 8(8), 285. https://doi.org/10.3390/foods8080285