Determination of the Sensory Characteristics of Traditional and Novel Fortified Blended Foods Used in Supplementary Feeding Programs

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.1.1. Novel Extruded Fortified Blended Foods

2.1.2. Current Non-Extruded Fortified Blended Food

2.2. Sample Preparation

2.3. Descriptive Sensory Analysis

2.4. Data Analysis

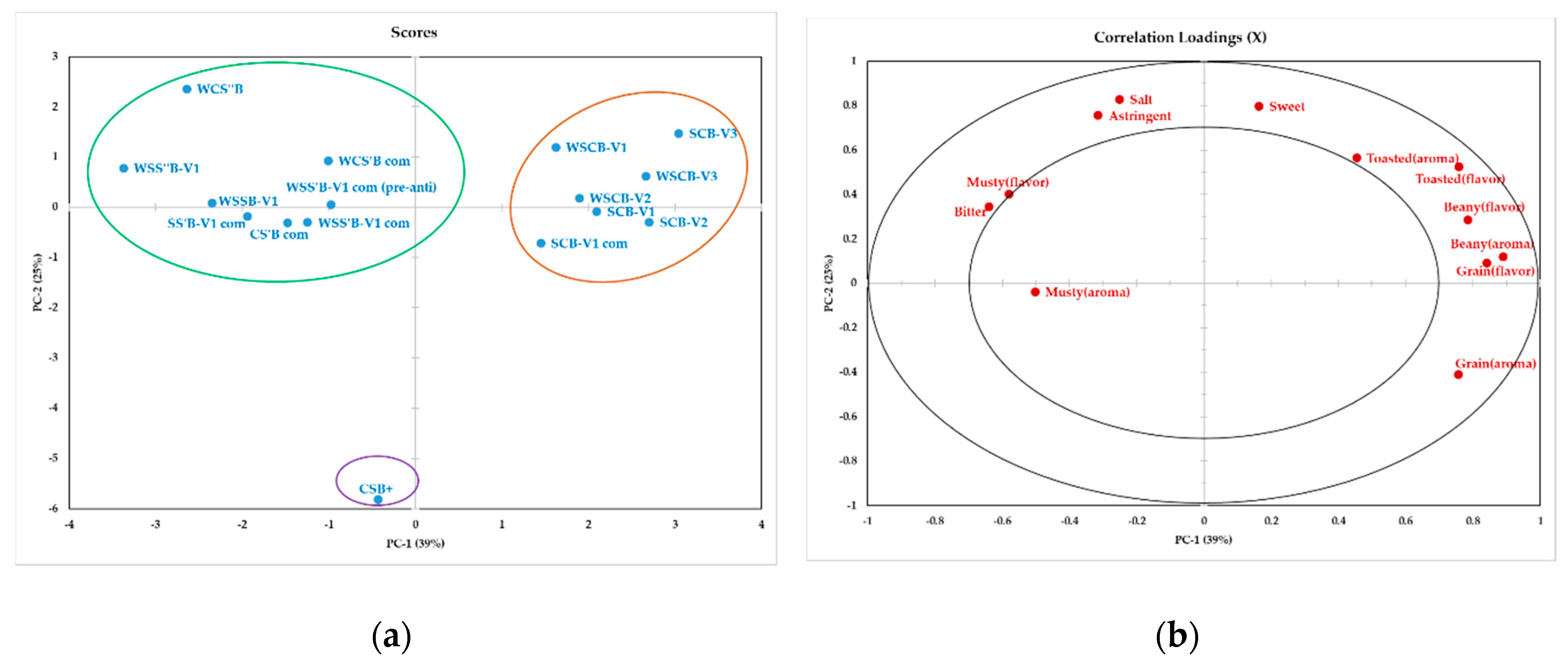

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hill, R.V.; Smith, L.C.; Wiesmann, D.M.; Frankenberger, T.; Gulati, K.; Quabili, W.; Yohannes, Y. The World’s Most Deprived: Characteristics and Causes of Extreme Poverty and Hunger; International Food Policy Research Institute: Washington, DC, USA, 2007; Volume 43. [Google Scholar]

- FAO; IFAD; WFP. The State of Food Insecurity in the World 2015. Meeting the 2015 International Hunger Targets: Taking Stock of Uneven Progress; Food and Agriculture Organization Publications: Rome, Italy, 2015. [Google Scholar]

- Perez-Exposito, A.B.; Klein, B.P. Impact of fortified blended food aid products on nutritional status of infants and young children in developing countries. Nutr. Rev. 2009, 67, 706–718. [Google Scholar] [CrossRef] [PubMed]

- De Pee, S.; Bloem, M.W. Current and potential role of specially formulated foods and food supplements for preventing malnutrition among 6-to 23-month-old children and for treating moderate malnutrition among 6-to 59-month-old children. Food Nutr. Bull. 2009, 30, S434. [Google Scholar] [CrossRef] [PubMed]

- Fleige, L.E.; Moore, W.R.; Garlick, P.J.; Murphy, S.P.; Turner, E.H.; Dunn, M.L.; Van Lengerich, B.; Orthoefer, F.T.; Schaefer, S.E. Recommendations for optimization of fortified and blended food aid products from the United States. Nutr. Rev. 2010, 68, 290–315. [Google Scholar] [CrossRef] [PubMed]

- Webb, P.; Rogers, B.; Rosenberg, I.; Schlossman, N.; Wanke, C.; Bagriansky, J.; Sadler, K.; Johnson, Q.; Tilahun, J.; Reese Masterson, A. Delivering Improved Nutrition: Recommendations for Changes to US Food Aid Products and Programs; Tufts University: Boston, MA, USA, 2011. [Google Scholar]

- Black, C.T.; Pahulu, H.F.; Dunn, M.L. Effect of preparation method on viscosity and energy density of fortified humanitarian food-aid commodities. Int. J. Food Sci. Nutr. 2009, 60, 219–228. [Google Scholar] [CrossRef] [PubMed]

- Ozcan, S.; Jackson, D.S. Functionality behavior of raw and extruded corn starch mixtures. Cereal Chem. 2005, 82, 223–227. [Google Scholar] [CrossRef]

- Hoppe, C.; Andersen, G.S.; Jacobsen, S.; Molgaard, C.; Friis, H.; Sangild, P.T.; Michaelsen, K.F. The use of whey or skimmed milk powder in fortified blended foods for vulnerable groups. J. Nutr. 2008, 138, 145S–161S. [Google Scholar] [CrossRef] [PubMed]

- USAID. Corn Commodity Fact Sheet. Available online: https://www.usaid.gov/what-we-do/agriculture-and-food-security/food-assistance/resources/corn-commodity-fact-sheet (accessed on 13 January 2017).

- Tenenbaum, D.J. Food vs. fuel: Diversion of crops could cause more hunger. Environ. Health Perspect. 2008, 116, A254–A257. [Google Scholar] [CrossRef] [PubMed]

- Dicko, M.H.; Gruppen, H.; Traoré, A.S.; Voragen, A.G.; Van Berkel, W.J. Review: Sorghum grain as human food in Africa: Relevance of starch content and amylase activities. Afr. J. Biotechnol. 2006, 5, 384–395. [Google Scholar]

- Mahasukhonthachat, K.; Sopade, P.; Gidley, M. Kinetics of starch digestion and functional properties of twin-screw extruded sorghum. J. Cereal Sci. 2010, 51, 392–401. [Google Scholar] [CrossRef]

- Uzogara, S.; Ofuya, Z. Processing and utilization of cowpeas in developing countries: A review. J. Food Process. Preserv. 1992, 16, 105–147. [Google Scholar] [CrossRef]

- Anglani, C. Sorghum for human food—A review. Plant Foods Hum. Nutr. 1998, 52, 85–95. [Google Scholar] [CrossRef] [PubMed]

- Chanadang, S.; Chambers, E.I.; Kayanda, R.; Alavi, S.; Msuya, W. Novel fortified blended foods: Preference testing with infants and young children in Tanzania and descriptive sensory analysis. J. Food Sci. 2018, 83, 2343–2350. [Google Scholar] [CrossRef] [PubMed]

- Chanadang, S.; Chambers, E.I. Sensory shelf life estimation of novel fortified blended foods under accelerated and real-time storage conditions. J. Food Sci. 2019, 84. in press. [Google Scholar]

- Delimont, N.M.; Chanadang, S.; Joseph, M.V.; Rockler, B.E.; Guo, Q.; Regier, G.K.; Mulford, M.R.; Kayanda, R.; Range, M.; Mziray, Z.; et al. The MFFAPP Tanzania efficacy study protocol: Newly formulated, extruded fortified-blended foods for food aid. Curr. Dev. Nutr. 2017, 1, e000315. [Google Scholar] [CrossRef] [PubMed][Green Version]

- USDA. USDA Commodity Requirements. Corn-Soy Blend for Use in Export Programs. Available online: https://www.fsa.usda.gov/Internet/FSA_File/csb13_110507.pdf (accessed on 10 January 2017).

- Chanadang, S.; Chambers, E.I.; Alavi, S. Tolerance Testing for Cooked Porridge made from a Sorghum Based Fortified Blended Food. J. Food Sci. 2016, 81, S1210–S1221. [Google Scholar] [CrossRef] [PubMed]

- Moussa, M.; Qin, X.; Chen, L.F.; Campanella, O.H.; Hamaker, B.R. High- quality instant sorghum porridge flours for the West African market using continuous processor cooking. Int. J. Food Sci. Technol. 2011, 46, 2344–2350. [Google Scholar] [CrossRef]

- Rowe, J.P.; Brodegard, W.C.; Pike, O.A.; Steele, F.M.; Dunn, M.L. Storage, preparation, and usage of fortified food aid among Guatemalan, Ugandan, and Malawian beneficiaries: A field study report. Food Nutr. Bull. 2008, 29, 213–220. [Google Scholar] [CrossRef] [PubMed]

- Mouquet, C.; Greffeuille, V.; Treche, S. Characterization of the consistency of gruels consumed by infants in developing countries: Assessment of the Bostwick consistometer and comparison with viscosity measurements and sensory perception. Int. J. Food Sci. Nutr. 2006, 57, 459–469. [Google Scholar] [CrossRef] [PubMed]

- Bredie, W.L.; Mottram, D.S.; Guy, R.C. Aroma volatiles generated during extrusion cooking of maize flour. J. Agric. Food Chem. 1998, 46, 1479–1487. [Google Scholar] [CrossRef]

- Bredie, W.L.; Mottram, D.S.; Guy, R.C. Effect of temperature and pH on the generation of flavor volatiles in extrusion cooking of wheat flour. J. Agric. Food Chem. 2002, 50, 1118–1125. [Google Scholar] [CrossRef]

- Parker, J.K.; Hassell, G.M.; Mottram, D.S.; Guy, R.C. Sensory and instrumental analyses of volatiles generated during the extrusion cooking of oat flours. J. Agric. Food Chem. 2000, 48, 3497–3506. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, A.; Tsuda, Y.; Hirata, N.; Kubota, K.; Kitamura, K. Aroma constituents of soybean [Glycine max (L.) Merril] milk lacking lipoxygenase isoenzymes. J. Agric. Food Chem. 1995, 43, 2449–2452. [Google Scholar] [CrossRef]

- Sessa, D.J. Biochemical aspects of lipid-derived flavors in legumes. J. Agric. Food Chem. 1979, 27, 234–239. [Google Scholar] [CrossRef]

- Vara-Ubol, S.; Chambers, E.; Chambers, D.H. Sensory characteristics of chemical compounds potentially associated with beany aroma in foods. J. Sens. Stud. 2004, 19, 15–26. [Google Scholar] [CrossRef]

- Brannan, G.; Setser, C.; Kemp, K.; Seib, P.; Roozeboom, K. Sensory characteristics of grain sorghum hybrids with potential for use in human food. Cereal Chem. 2001, 78, 693–700. [Google Scholar] [CrossRef]

- Anyango, J.O.; de Kock, H.L.; Taylor, J.R. Evaluation of the functional quality of cowpea-fortified traditional African sorghum foods using instrumental and descriptive sensory analysis. Food Sci. Technol. 2011, 44, 2126–2133. [Google Scholar] [CrossRef]

- Iuel-Brockdorf, A.; Draebel, T.A.; Ritz, C.; Fabiansen, C.; Cichon, B.; Christensen, V.B.; Yameogo, C.; Oummani, R.; Briend, A.; Michaelsen, K.F.; et al. Evaluation of the acceptability of improved supplementary foods for the treatment of moderate acute malnutrition in Burkina Faso using a mixed method approach. Appetite 2016, 99, 34–45. [Google Scholar] [CrossRef] [PubMed]

- Gilbertson, T.A.; Baquero, A.F.; Spray-Watson, K.J. Water taste: the importance of osmotic sensing in the oral cavity. J. Water Health 2006, 4, 35–40. [Google Scholar] [CrossRef] [PubMed]

- Teillet, E.; Schlich, P.; Urbano, C.; Cordelle, S.; Guichard, E. Sensory methodologies and the taste of water. Food Qual. Prefer. 2010, 21, 967–976. [Google Scholar] [CrossRef]

- Drewnowski, A.; Gomez-Carneros, C. Bitter taste, phytonutrients, and the consumer: A review. Am. J. Clin. Nutr. 2000, 72, 1424–1435. [Google Scholar] [CrossRef]

- Rackis, J.; Sessa, D.; Honig, D. Flavor problems of vegetable food proteins. J. Am. Oil Chem. Soc. 1979, 56, 262–271. [Google Scholar] [CrossRef]

- Kobue-Lekalake, R.I.; Taylor, J.; De Kock, H.L. Effects of phenolics in sorghum grain on its bitterness, astringency and other sensory properties. J. Sci. Food Agric. 2007, 87, 1940–1948. [Google Scholar] [CrossRef]

- Chambers, E.I.; Maughan, C.; Padmanabhan, N.; Alavi, S.; Adedeji, A. Sensory analysis of 20% solids fortified blended porridge. Br. Food J. 2019, 121, 633–641. [Google Scholar] [CrossRef]

- Joseph, M.V. Extrusion, Physico-Chemical Characterization and Nutritional Evaluation of Sorghum-Based High Protein, Micronutrient Fortified Blended Foods (Chapter 3—Characterization of Physico-Chemical Properties of High Protein Extrudates from Binary Blends of Cereal and Legume Flours). Ph.D. Thesis, Kansas State University, Manhattan, KS, USA, 2016. [Google Scholar]

- Feng, Y.; Lee, Y. Effect of Specific Mechanical Energy on In-Vitro Digestion and Physical Properties of Extruded Rice-Based Snacks. Food Nutr. Sci. 2014, 5, 1818–1827. [Google Scholar]

| Treatment | Product Code 1 | Cereal | Legume | |||

|---|---|---|---|---|---|---|

| Cereal Type | Variety | Milling Type | ||||

| 1 | Sorghum-Cowpea blend | SCB-V1 com | Sorghum-Decorticated | White-Fontanelle 4525 | Commercial | Cowpea |

| 2 | SCB-V1 | Sorghum-Decorticated | White-Fontanelle 4525 | Pilot | Cowpea | |

| 3 | SCB-V2 | Sorghum-Decorticated | White-738Y | Pilot | Cowpea | |

| 4 | SCB-V3 | Sorghum-Decorticated | Red-217X Burgundy | Pilot | Cowpea | |

| 5 | WSCB-V1 | Sorghum-Whole | White-Fontanelle 4525 | Pilot | Cowpea | |

| 6 | WSCB-V2 | Sorghum-Whole | White-738Y | Pilot | Cowpea | |

| 7 | WSCB-V3 | Sorghum-Whole | Red-217X Burgundy | Pilot | Cowpea | |

| 8 | Sorghum-Soy blend | SS’B-V1 com | Sorghum-Decorticated | White-Fontanelle 4525 | Commercial | Soybean—High Fat |

| 9 | WSSB-V1 | Sorghum-Whole | White-Fontanelle 4525 | Pilot | Soybean—Low Fat | |

| 10 | WSS’B-V1 com | Sorghum-Whole | White-Fontanelle 4525 | Commercial | Soybean—High Fat | |

| 11 | WSS’B-V1 com (pre-anti) | Sorghum-Whole | White-Fontanelle 4525 | Commercial | Soybean—High Fat | |

| 12 | WSS’’B-V1 | Sorghum-Whole | White-Fontanelle 4525 | Pilot | Soybean—Full Fat | |

| 13 | Corn-Soy blend | CS’B com | Corn-Degermed | Commercial | Soybean—High Fat | |

| 14 | WCS’B com | Corn-Whole | Commercial | Soybean—High Fat | ||

| 15 | WCS’’B | Corn-Whole | Pilot | Soybean—Full Fat | ||

| Ingredients (%) | Extruded FBFs 1 | Non-Extruded FBF | ||

|---|---|---|---|---|

| Sorghum-Cowpea Blends (SCB) | Sorghum-Soy Blends (SSB) | Corn-Soy Blends (CSB) | Corn Soy Blend Plus (CSB+) | |

| Sorghum flour | 24.7 | 47.6 | ||

| Cowpea flour | 38.6 | |||

| Corn flour | 48.1 | |||

| Corn (White or Yellow) | 78.5 | |||

| Whole soybeans | 20.0 | |||

| Soy flour | 15.7 | 15.2 | ||

| Sugar | 15.0 | 15.0 | 15.0 | |

| Whey Protein Concentrate (WPC80) | 9.5 | 9.5 | 9.5 | |

| Soybean oil | 9.0 | 9.0 | 9.0 | |

| Vitamin & Mineral Premix | 3.1 | 3.1 | 3.1 | |

| Antioxidant 2 | 0.1 | 0.1 | 0.1 | |

| Vitamin/Mineral | 0.2 | |||

| Tri-Calcium Phosphate | 1.2 | |||

| Potassium Chloride | 0.2 | |||

| Attribute | Definition | Reference $ |

|---|---|---|

| Aroma | ||

| Overall Grain * | A general term used to describe the aromatics which includes musty, dusty, slightly brown, slightly sweet and is associated with harvested grains and dry grain stems. | Cereal Mix(dry) = 7.5. Preparation: Mix ½ cup of each General Mills Rice Chex, Wheaties and Quaker Quick Oats. Put in a blender and “pulse” blend into small particles. Serve 2 Tablespoon in a 12 oz brandy snifter, covered with a watch glass. |

| Toasted * | A moderately browned/baked impression. | Crushed Post Shredded wheat = 2.5. Preparation: Crush ¼ cup of Shredded wheat and served in a 12 oz brandy snifter, covered with a watch glass. |

| Crushed General Mills Cheerios = 7.0. Preparation: Crush ¼ cup of Cheerios and serve in a 12 oz brandy snifter, covered with a watch glass. | ||

| Beany | Aromatic characteristic of beans and bean products, includes musty/earthy, musty/dusty, sour aromatics, bitter aromatics, starchy and green/pea pod, nutty or brown. | Cooked Soy Bean = 4.0. Preparation: Soak ½ cup of soy bean overnight and boil the bean 2.5 h. Serve 1 table spoon of cooked soy bean in a 12 oz brandy snifter, covered with a watch glass. |

| Bush Pinto Beans (canned) = 7.0. Preparation: Drain beans and rinse with de-ionized water Place one table spoon in a 12 oz brandy snifter, covered with a watch glass. | ||

| Musty Overall * | A combination of one or more aromatic impressions characterized to some degree as being somewhat dry, dusty, damp, earthy, stale, sour, or moldy. If identifiable, attribute will be listed. | 1,2,4Trimethoxybenzene 50,000 ppm = 4.0. Preparation: Dip an Orlandi Perfumer Strip #27995 2.2 cm (second marking line) into solution and place dipped end up in a Fisherbrand Disposable Borosilicate Glass Tubes with Threaded End (15 × 150 mm) cap. |

| Rancid | A somewhat heavy aromatic characteristic of old, oxidized, decomposing fat and oil. The aromatics may include painty, varnish, or fishy. | Microwaved Wesson vegetable oil (4 min at high) = 2.5. Preparation: Microwave 1 ½ cups oil on high power for 4 min. Let cool and serve ¼ cup in a 12 oz brandy snifter covered with a watch glass. |

| Microwaved Wesson vegetable oil (5 min at high) = 5.0. Preparation: Microwave 1 ½ cups oil on high power for 5 min. Let cool and serve ¼ cup in a 12 oz brandy snifter covered with a watch glass. | ||

| Painty | The aromatic associated with rancid oil and fat, typically in the late stages of rancidity. | Microwaved Wesson vegetable oil (4 min at high) = 2.5. Preparation: Microwave 1 ½ cups oil on high power for 4 min. Let cool and pour into 1 oz cups. Serve covered. |

| Microwaved Wesson vegetable oil (5 min at high) = 4.5. Preparation: Microwave 1 ½ cups oil on high power for 5 min. Let cool and pour into 1 oz cups. | ||

| Flavor | ||

| Overall Grain * | A general term used to describe the light dusty/musty aromatics associated with grains such as corn, wheat, bran, rice, oats and soybean. | Cereal Mix (dry) = 8.0. Preparation: Mix ½ cup of each General Mills Rice Chex, Wheaties and Quaker Quick Oats. Put in a blender and “pulse” blend into small particles. Serve in 1 oz cup. |

| Toasted * | A moderately browned/baked impression. | Post Shredded Wheat (Spoon size) = 3.5. Preparation: Serve in 3.25 oz cup.General Mills Cheerios = 7.0. Preparation: Serve in 3.25 oz cup. |

| Beany | Aromatic characteristic of beans and bean products, includes musty/earthy, musty/dusty, sour aromatics, bitter aromatics, starchy and green/pea pod, nutty or brown. | Cooked Soy Bean = 4.0. Preparation: Soak ½ cup of soy bean overnight and boil the bean 2.5 h. Serve in 1 oz cup. |

| Bush Pinto Beans (canned) = 7.5. Preparation: Drain beans and rinse with de-ionized water Serve in 1 oz cup. | ||

| Musty * | Aromatics associated with wet grain and damp earth. | Cooked American Beauty elbow macaroni = 5.0. Preparation: Bring 3 cups water to a rapid boil. Add 1 cup pasta and stir, returning to a rapid boil. Cook 6 min, stirring occasionally. Drain and place into 3.25 oz cups. |

| Rancid | A somewhat heavy aromatic characteristic of old, oxidized, decomposing fat and oil. The aromatics may include painty, varnish, or fishy. | Microwaved Wesson vegetable oil (4 min at high) = 3.0. Preparation: Microwave 1 ½ cups oil on high power for 4 min. Let cool and serve in 1 oz cup. |

| Microwaved Wesson vegetable oil (5 min at high) = 5.0. Preparation: Microwave 1 ½ cups oil on high power for 5 min. Let cool and serve in 1 oz cup. | ||

| Painty | The aromatic associated with rancid oil and fat, typically in the late stages of rancidity. | Microwaved Wesson vegetable oil (4 min at high) = 0.0. Preparation: Microwave 1 ½ cups oil on high power for 4 min. Let cool and serve in 1 oz cup. |

| Microwaved Wesson vegetable oil (5 min at high) = 3.0. Preparation: Microwave 1 ½ cups oil on high power for 5 min. Let cool and serve in 1 oz cup. | ||

| Sweet * | A fundamental taste factor of which sucrose is typical. | 2% Sucrose Solution = 2.0 |

| 4% Sucrose Solution = 4.0 | ||

| Salt * | Fundamental taste factor of which sodium chloride is typical. | 0.15% Sodium Chloride Solution = 1.5 |

| 0.20% Sodium Chloride Solution = 2.5 | ||

| Bitter * | The fundamental taste factor associated with a caffeine solution. | 0.01% Caffeine Solution = 2.0 |

| 0.02% Caffeine Solution = 3.5 | ||

| 0.035% Caffeine Solution = 5.0 | ||

| 0.05% Caffeine Solution = 6.5 | ||

| Astringent * | The drying, puckering sensation on the tongue and other mouth surfaces. | 0.050% alum solution = 2.5 |

| 0.100% alum solution = 5.0 |

| Treatment 2 | Overall Grain (a) 3 | Toasted (a) | Beany (a) | Musty Overall (a) | Overall Grain (f) | Toasted (f) | Beany (f) | Musty (f) | Sweet (f) | Salt (f) | Astringent (f) | Bitter (f) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SCB-V1 com | 7.14 (0.07) | 3.53 ab4 (0.18) | 3.28 abc (0.19) | 3.36 (0.16) | 7.36 (0.07) | 2.97 abc (0.20) | 3.58 bcd (0.15) | 4.47 (0.15) | 2.11 a (0.16) | 1.42 ab (0.15) | 2.64 (0.17) | 2.89 d (0.18) |

| SCB-V1 | 7.17 (0.07) | 3.89 ab (0.29) | 3.28 abc (0.24) | 3.11 (0.21) | 7.36 (0.10) | 3.28 abc (0.27) | 3.64 bc (0.24) | 4.36 (0.22) | 2.03 a (0.15) | 1.39 ab (0.15) | 2.81 (0.25) | 3.17 bcd (0.18) |

| SCB-V2 | 7.25 (0.08) | 4.47 a (0.23) | 3.19 abc (0.13) | 3.17 (0.18) | 7.42 (0.09) | 3.22abc (0.16) | 3.64bc (0.16) | 4.33 (0.21) | 2.00 a (0.19) | 1.31 ab (0.14) | 2.81 (0.15) | 3.08 cd (0.20) |

| SCB-V3 | 7.22 (0.07) | 4.53 a (0.30) | 3.36 ab (0.19) | 2.94 (0.19) | 7.36 (0.09) | 3.75 a (0.31) | 4.19 ab (0.14) | 4.69 (0.22) | 1.97 a (0.12) | 1.58 a (0.20) | 2.68 (0.19) | 3.31 bcd (0.13) |

| WSCB-V1 | 7.11 (0.08) | 4.28 ab (0.18) | 3.25 abc (0.19) | 3.19 (0.18) | 7.39 (0.08) | 3.50 ab (0.23) | 3.50 bcde (0.17) | 4.58 (0.23) | 2.00 a (0.10) | 1.58a (0.15) | 2.78 (0.18) | 3.28 bcd (0.20) |

| WSCB-V2 | 7.22 (0.07) | 3.83 ab (0.24) | 3.14 abc (0.18) | 3.06 (0.18) | 7.44 (0.08) | 3.11 abc (0.23) | 3.64 bc (0.18) | 4.75 (0.22) | 2.03 a (0.12) | 1.50 ab (0.16) | 2.72 (0.19) | 2.97 d (0.19) |

| WSCB-V3 | 7.19 (0.07) | 3.67 ab (0.23) | 3.89 a (0.17) | 3.44 (0.21) | 7.33 (0.08) | 3.33 abc (0.27) | 4.44 a (0.19) | 4.39 (0.24) | 2.06 a (0.14) | 1.47 ab (0.20) | 2.83 (0.23) | 3.36 bcd (0.20) |

| SS’B-V1 com | 6.92 (0.10) | 3.56 ab (0.21) | 2.72 bc (0.21) | 3.47 (0.22) | 7.17 (0.07) | 2.75 abc (0.11) | 3.19 cde (0.10) | 4.75 (0.18) | 1.89 a (0.14) | 1.31 ab (0.13) | 2.97 (0.19) | 3.31 bcd (0.17) |

| WSSB-V1 | 6.92 (0.06) | 2.97 b (0.14) | 2.69 bc (0.21) | 3.19 (0.20) | 7.19 (0.08) | 2.36 c (0.13) | 3.39 cde (0.21) | 4.94 (0.25) | 1.97a (0.17) | 1.58 a (0.18) | 2.75 (0.13) | 3.47 bcd (0.14) |

| WSS’B-V1 com | 7.03 (0.16) | 3.72 ab (0.21) | 2.61 bc (0.16) | 3.22 (0.18) | 7.14 (0.17) | 2.69 bc (0.14) | 3.11 cde (0.15) | 4.69 (0.21) | 2.17 a (0.18) | 1.44 ab (0.18) | 2.67 (0.17) | 3.22 bcd (0.18) |

| WSS’B-V1 com (pre-anti) | 7.06 (0.08) | 3.58 ab (0.19) | 2.75 bc (0.18) | 3.36 (0.13) | 7.19 (0.06) | 3.00 abc (0.16) | 3.28 cde (0.16) | 4.72 (0.18) | 1.94 a (0.15) | 1.44 ab (0.15) | 2.86 (0.18) | 3.31 bcd (0.21) |

| WSS’’B-V1 | 7.00 (0.07) | 3.00 b (0.17) | 2.56 c (0.18) | 3.75 (0.20) | 7.25 (0.09) | 2.50 bc (0.16) | 3.17 cde (0.18) | 4.94 (0.21) | 1.86 a (0.08) | 1.64 a (0.18) | 3.06 (0.19) | 3.81 abc (0.19) |

| CS’B com | 6.94 (0.09) | 3.89 ab (0.22) | 2.64 bc (0.11) | 3.28 (0.18) | 7.19 (0.12) | 2.53 bc (0.14) | 3.03cde (0.14) | 4.42 (0.27) | 2.03 a (0.17) | 1.47 ab (0.17) | 2.72 (0.23) | 3.58 bcd (0.17) |

| WCS’B com | 7.08 (0.14) | 4.22 ab (0.24) | 2.58 bc (0.16) | 3.22 (0.19) | 7.17 (0.11) | 3.19 abc (0.19) | 2.89 de (0.10) | 4.50 (0.19) | 2.11 a (0.19) | 1.67 a (0.19) | 2.67 (0.22) | 3.89 ab (0.20) |

| WCS’’B | 7.03 (0.10) | 4.50 a (0.24) | 2.64 bc (0.18) | 3.17 (0.14) | 7.06 (0.07) | 3.03 abc (0.14) | 2.89 de (0.17) | 4.75 (0.23) | 1.89 a (0.21) | 1.69 a (0.21) | 3.08 (0.18) | 4.53 a (0.20) |

| CSB+ | 7.33 (0.11) | 2.97 b (0.20) | 2.75 bc (0.19) | 3.22 (0.15) | 7.17 (0.11) | 2.36 c (0.10) | 2.83 e (0.15) | 4.36 (0.18) | 0.86 b (0.13) | 1.14 b (0.13) | 2.28 (0.14) | 3.39 cde (0.18) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chanadang, S.; Chambers IV, E. Determination of the Sensory Characteristics of Traditional and Novel Fortified Blended Foods Used in Supplementary Feeding Programs. Foods 2019, 8, 261. https://doi.org/10.3390/foods8070261

Chanadang S, Chambers IV E. Determination of the Sensory Characteristics of Traditional and Novel Fortified Blended Foods Used in Supplementary Feeding Programs. Foods. 2019; 8(7):261. https://doi.org/10.3390/foods8070261

Chicago/Turabian StyleChanadang, Sirichat, and Edgar Chambers IV. 2019. "Determination of the Sensory Characteristics of Traditional and Novel Fortified Blended Foods Used in Supplementary Feeding Programs" Foods 8, no. 7: 261. https://doi.org/10.3390/foods8070261

APA StyleChanadang, S., & Chambers IV, E. (2019). Determination of the Sensory Characteristics of Traditional and Novel Fortified Blended Foods Used in Supplementary Feeding Programs. Foods, 8(7), 261. https://doi.org/10.3390/foods8070261