1. Introduction

The drying process is the removal of water or other liquids from gases, liquids, or solids. Most commonly, the term “drying” refers to the removal of water or other volatile substances from additives by thermal methods [

1]. The aim of drying is to reduce the volume and the weight to facilitate transportation, to sterilize the products, and to produce materials that provide the desired conditions.

In terms of energy saving, the major percentage of energy consumption in many industries is formed by the energy consumed for drying processes. With the usage of new technologies it is possible to save a considerable amount of energy. The main factor to be taken into consideration when selecting a drying process and a dryer is to use minimum energy and a maximum drying rate to obtain the product with the desired qualities [

2].

Microwaves are electromagnetic waves in the frequency range of 300 MHz to 300 GHz [

3]. The heating effect of the microwave can be explained as the ingestion of energy by a dielectric material and then an increase in the temperature as the result of the absorption of this material. There are two important mechanisms—Ionic polarization and dipole rotation—That explain the heat consumption in the microwave field [

4]. Electromagnetic energy in the systems of microwave heating is transformed into heat by the water molecules vibrating millions of times inside the direct substance. This vibration and the resulting energy ensure that the dampness in the material evaporates very rapidly [

5]. Therefore, the heat is transferred from the inside of the material to the outside, as opposed to conventional heating systems in microwave heating. In microwave drying, since it directly penetrates the heat and the material, the process is much faster and the duration is shorter than in conventional drying systems [

6]. Microwave drying is an alternative drying method that provides advantages such as high heat conduction to the inner parts of the dried material, cleaning, energy gain, easy process control, and a quick start and termination of the drying process [

7]. In this method, dielectric properties, mass of the material, specific heat, geometry, heat dissipation mechanism, power produced in the material, and the efficiency of the power produced in the microwave system are taken into consideration as the basic parameters [

5]. However, when used alone, the microwave drying method causes negative effects such as irregular heat distribution on the products, textural damage, high investment costs, and limited effect of the microwave rays on the products [

8]. In order to reduce these problems and provide faster and more efficient drying processes, it might be appropriate to consider the application of microwave and other drying methods together in the drying process of the food.

In order to design a suitable microwave dryer, drying kinetics data from experimental studies are necessary. However, it is impossible to investigate all the drying conditions just by experiments due to time and high cost. Therefore, drying models are developed for various of materials [

9]. Many studies have been carried out with these models on drying foods such as carrageenan [

10], cocoa [

11], apple and red bell paper [

12], plum [

13], rice [

14], prina (crude olive cake) [

15], carrot [

16], parsley leaves [

17], organic tomato [

18], and mushroom [

19]. In addition, the microwave-convective drying of food has been researched by many researchers in recent years. When the studies on drying included in the literature were examined, the process of drying was carried out by using microwave-vacuum [

20,

21,

22], microwave-hot air combination dryers [

23,

24,

25,

26], and microwave dryers [

27].

Air solar-collectors, also called solar-air heaters, are simple devices which are durable, lightweight, and suitable for volume heating without frost and corrosion problems. Solar air collectors can be easily used together with additional heaters in building heating and drying of the agricultural products. In addition, in medium- and low-temperature applications, the required hot air can be produced with solar air heaters.

Solar energy is one of the widely used renewable energy sources in drying. Drying of vegetables and fruits using renewable energy such as solar drying has less environmental impact. It is one of the oldest applications of solar energy to preserve food. The usage of solar energy in the drying is becoming an important and viable alternative. In this research, the black radish drying process was carried out using solar and microwave energy. Microwave energy was selected because the products can be brought to desired temperature levels in a shorter time compared to the conventional methods due to volumetric heating [

28]. For this reason, microwave technology provides faster heating than conventional methods, and the energy requirement is low while energy efficiency is high. Also, it is used as an alternative to conventional methods as it involves easy cleaning of equipment, occupies less space, is applicable to packaged foods, and preserves nutritional value [

29]. This design has been realized by taking these advantages into consideration. The main purpose of this research is to investigate the performance of the newly designed combined dryer in the food sector with low energy. In addition to this, another purpose is to compare the moisture content values obtained experimentally from the dried products with the estimated moisture content values using the seven different thin-layer drying methods used in this study to identify the model that best describes the experimental data.

2. Materials and Methods

2.1. Food Material and Drying System

A black radish (Raphanus sativus L. var. Niger) with approximately 85% ± 0.5% (wet base) (measured by drying at 105 °C in 24 h) moisture content was provided from a local market stored at 4 °C located in Tekirdağ City. The black radishes were peeled and sliced at 4 ± 0.3 mm, 6 ± 0.2 mm and 8 ± 0.2 mm thicknesses by the knife for the experiments. Different samples were used for each experiment.

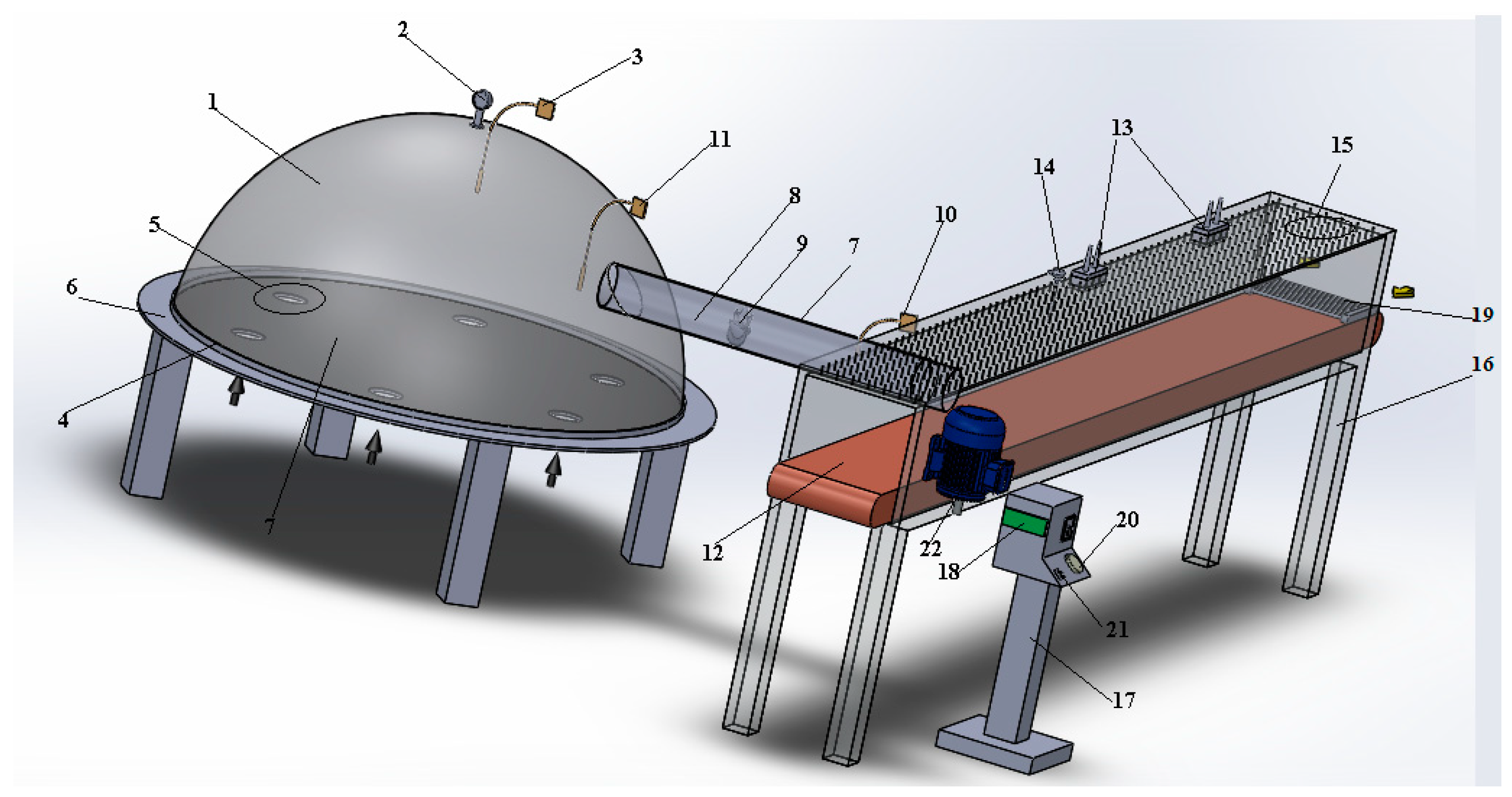

In the design and manufacture of the solar collector, basic parameters such as economic efficiency, easy accessibility of the collector’s materials, manufacturing possibilities, and thermal properties are taken into consideration. The experiment setup consists of a solar collector, a circulation fan, a drying chamber, two magnetrons, and one conveyor (

Figure 1) [

30].

It was made of acrylic material with a high thermal permeability and was designed as a sphere with a diameter of 1.5 m and a height of 0.6 m to take the sunlight straight from every possible directions. Thus, the heat of the air in the collector reached a high temperature in a short time and a short drying period was achieved, which is important in the food drying industry. In order to provide air circulation, the collector was placed at the stands with a height of 0.5 m and air inlet channels were opened to the bottom surface of the collector. The exhaust sheet metal placed on the bottom surface of the collector was painted with black enamel (α = 0.97) (ε = 0.97). In order to send warm air to the drying chamber, the carrier aluminum cylindrical channel (1 m × Ø0.2 m) was placed on the top surface of the collector where the temperature is the highest. Probes were used to measure the center and upper temperature values of the collector. The bottom part of the collector and the surrounding of the carrier channel are insulated to prevent heat losses. The intensity of the radiation on top of the collector was measured and recorded with a CEM DT-185 brand pyrometer during the drying process. A speed-adjustable fan (HCM-180 N, İstanbul, Turkey) with 35-W power was used inside the duct. The other end of the duct was connected to the drying chamber. An anemometer was connected to the duct outlet to measure the temperature probe and hot air velocity entering the drying chamber. The measured values were read out on the device and recorded. The drying chamber (3.5 × 0.4 × 0.4 m) is a conveyor system consisting of a Teflon belt. Two magnetrons which transmit microwave energy are connected to the inlet and outlet ends of the drying chamber. The setting of the microwave energy and conveyor speed was made from the control panel. The energy consumed during drying process was measured by an energy-measuring device connected to the system. In addition, a PT100 temperature gauge was used to measure the temperature in the drying chamber.

2.2. Experimental Procedure

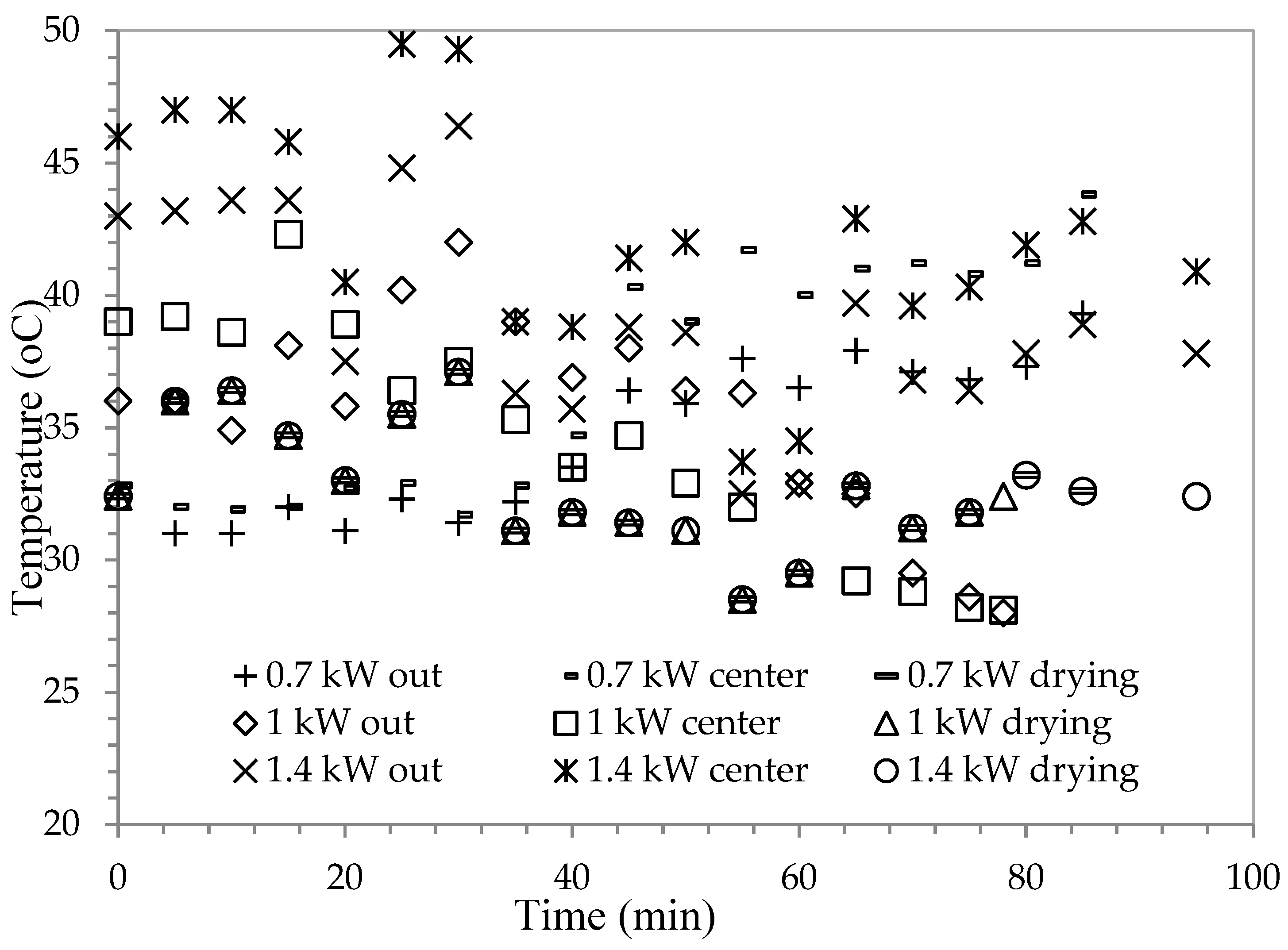

The experiments were held between 15 and 17 August in Tekirdağ City, Turkey. No pretreatment except peeling and slicing was applied to the radish before the drying experiments. After the slicing process, color parameters were measured with a colorimeter for fresh radish sample. Drying experiments were carried out with microwave power values of 0.7 kW, 1 kW, and 1.4 kW (at 2450 MHz) with a belt speed of 0.245 m/min. Weight loss values of the samples during drying were measured with the Presica XB 620 M (Precisa Instruments AG, Dietikon, Switzerland) brand precision scale of accuracy ± 0.001 g every 5 min. To determine the initial moisture value, the dry weight of the material was determined at 105 °C for 24 h. Initial sample weights ranged from 11 g to 13 g, depending on the slice thickness. The experiments were carried out according to the weather conditions. An outdoor environment where the sun was effective without shade was preferred. Prior to drying, conveyor speed and microwave power level were set on the control panel. At 11:30 h, when the air in the collector exposed to the sun reached to a constant temperature, the drying process was started. The microwave energy worked continuously throughout the drying during the experiments. Drying process lasted until 12% ± 0.5% (wet base) moisture level was reached. After drying, color parameters and energy consumption were measured and recorded. Each experiment was repeated three times in order to get the correct result.

2.3. Modeling of Drying

Different products and systems should be analyzed with different models which were created by using heat, mass and momentum transfer and material knowledge. Effectively, modeling the drying behavior is important for investigation of drying characteristics of samples. In this study, with the help of the nonlinear regression analysis method, the modeling of the moisture rate time variation curves obtained from the experimental results at different microwave power values was performed. The moisture ratio is defined as given in Equation (1).

The value of equilibrium moisture content (m

e) is relatively small compared to m, which represents the wet basis moisture content at any time, and initial moisture content (m

0), where the error implied in the simplification is negligible [

31]. Therefore, the equilibrium moisture content was assumed to be zero for microwave drying. Drying curves were obtained for the black radish. The experimental moisture ratio versus drying time data were fitted in seven thin-layer drying models, as shown in

Table 1.

In order to determine the most appropriate model, some statistical parameters need to be calculated. These are the

r2,

es, and

χ2 values. The correlation coefficient (

r2) is one of the criteria used in determining the curve fit. In addition to the correlation coefficient, the estimated standard error (

es) and chi-squared (

χ2) are the other parameters used in determining of the efficiency degree of regression fitness [

32]. To get the best fit of the experimental data, the coefficient of determination should be higher and the χ

2 and

es values should be lower. These parameters are defined as in Equations (2)–(4) [

19].

where MR

teo,i is the

ith predicted moisture ratio, MR

exp,i is the

ith experimental moisture ratio,

n0 is the number of observations, and

nc is the number of coefficients in the drying model.

2.4. Color Measurement

Color measurements for fresh and dried black radish samples were made using a colorimeter. Used parameters are L (brightness), a (redness/greenness), b (yellowness/blueness), and C (chroma) values. Chroma value and total color change (Δ

E) are calculated as given in Equations (5)–(6) [

33].

and

show dried product brightness, redness, and yellowness, respectively.

2.5. Solar Energy

The sun constant is the pre-atmosphere energy in direction of the radiation coming from the sun, perpendicular to the unit area at unit time, and the average distance between the sun-world is Isc = 1367 W/m2. The intensity of the radiation on top of the collector was measured and recorded with a CEM DT-185 brand pyrometer during the drying process.

The available solar energy inside the solar dryer (Q) could be calculated in terms of the solar radiation that penetrated the cover and the net surface area of the dryer as given below:

is the thermal power generated in the collector, which is obtained using Equations (7) and (8) [

34].

In Equation (8), Cp (=1005 J/kg °C) is the passing air-specific heat (J/kg °C), (kg/s) is the mass flow rate of the passing air (kg/s), and ∆ (°C) is the temperature difference between the input and output air from the collector.

The thermal efficiency (η) of the air solar collectors was calculated using Equation (9) [

35].

In this equation,

is the outlet temperature of the air from the collector,

is the inlet temperature of the air from the collector, I is the total solar radiation coming to the collector’s surface (W/m

2), and

is the collector’s surface area. The surface area of the air collector used in the experiments is 1.5136 m

2. The rate of the mass flow was calculated by Equation (10);

where ρ is the air density, V shows the speed of the air flow, and

shows the collector outlet’s cross-sectional area.

2.6. Statistical Analyses

The results of specific energy consumption and drying time depend on slice thickness and microwave power level were analyzed using analysis of variance (one-way ANOVA). The Tukey’s test was applied to determine if the differences were significant. All statistical analyses were performed with SPSS (PASW Statistics 18, SPSS Ltd, Hong Kong, China). Differences with p-values less than 0.05 were considered significant.

4. Conclusions

In this work, the drying operation for 0.7 kW power lasted between 70 and 82 min; for 1-kW power it lasted between 60 and 65 min; and for 1.4-kW power it lasted between 43 and 63 min depending on the slice thickness. The most suitable results for the required time of drying of the black radish slices until reaching 12 ± 0.5% (wet base) and for electrical energy consumption values were obtained using 1.4-kW microwave power, 0.245 m/min conveyor speed, and a 4-mm black radish slice thickness, at 0.980 kWh. Increasing microwave power for all slice thicknesses increased drying time and energy consumption values. Because of the high air temperature that was transferred to the drying tunnel, the trials that were performed for 1-kW power showed fast drying. That is why low consumption values were obtained. Also, specific energy consumption values were measured for 0.7-kW, 1-kW, and 1.4-kW microwave power levels at between 7.407 and 12.633 kWh/kg for 4 mm, between 4.894 and 10.449 kWh/kg for 6 mm, and between 3.671 and 11.863 kWh/kg for 8-mm slice thicknesses, respectively.

When color criteria were examined, the best results were obtained for 0.7-kW power drying operations with the 8-mm black radish slice compared to the other experiments, while taking in consideration (ΔL) and (ΔE) values.

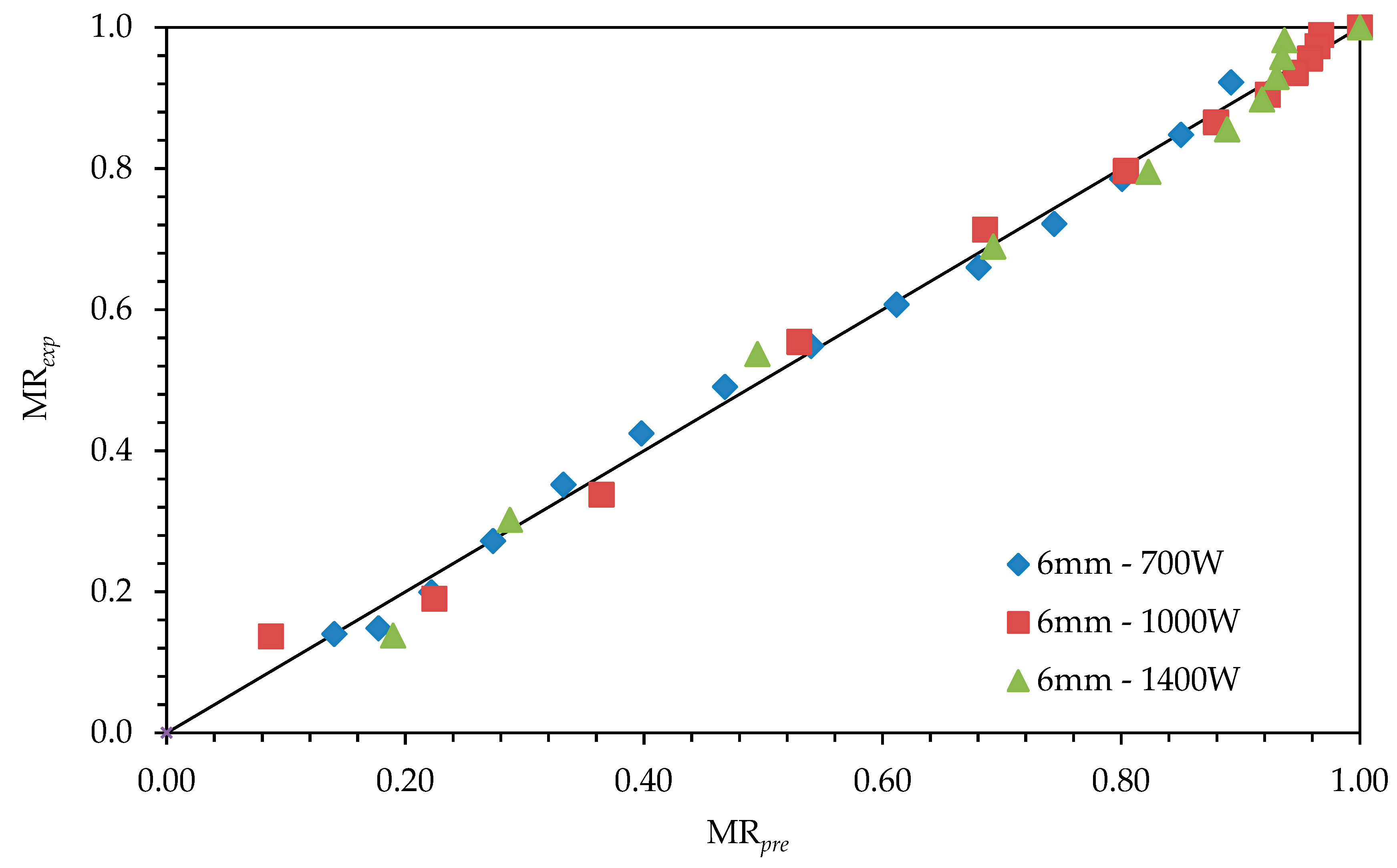

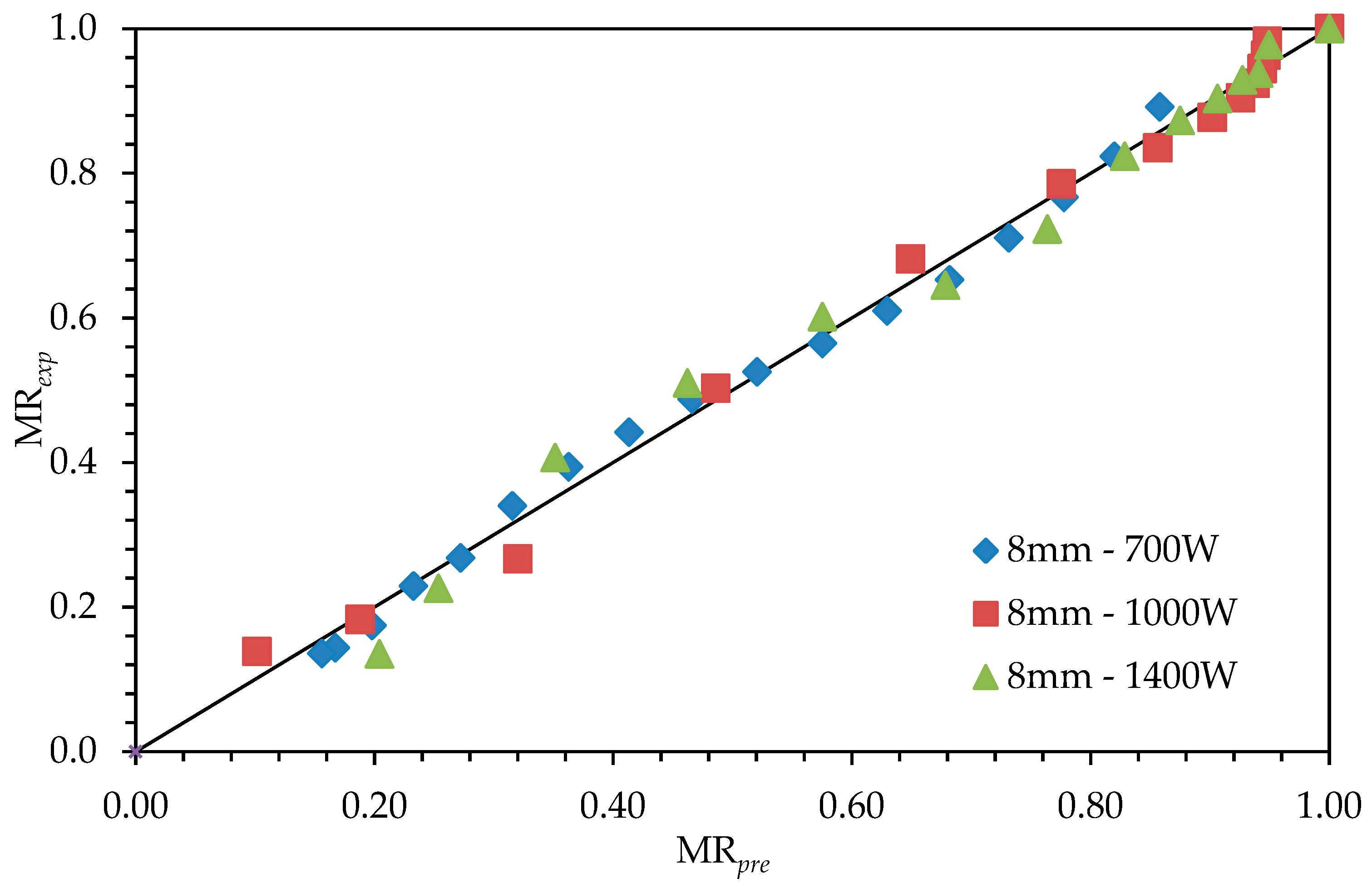

For predicting separable humidity rate, the “logistic” drying model was chosen as the most predictive drying kinetics model, with comparisons made depending on coefficients of the examined drying models, the highest r2 value based on microwave power, and slice thicknesses in the overall experimental conditions.

As a result, in the drying implementations with a microwave dryer with a conveyor it can be said that working with a low belt speed is possibly more beneficial for quality criteria, and in the conditions that the sun is effective, energy consumption values are lower. Also, it can be said that these methods are more feasible for drying of the fruits and vegetables where commercial issues, conservation of color, and the other quality parameters are important.