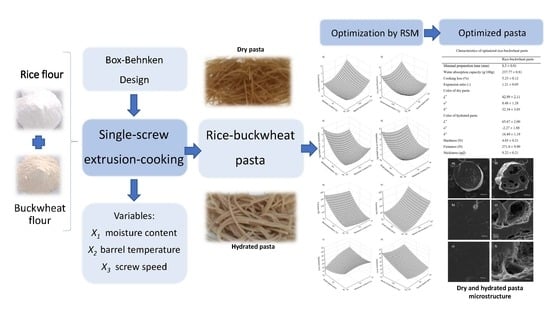

Rice-Buckwheat Gluten-Free Pasta: Effect of Processing Parameters on Quality Characteristics and Optimization of Extrusion-Cooking Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Pasta Processing

2.3. Design of Experiments

2.4. Optimization of Processing Parameters

2.5. Quality Evaluation of Gluten-Free Pasta

2.5.1. Chemical Composition

2.5.2. Minimal Preparation Time

2.5.3. Water Absorption Capacity and Cooking Loss

2.5.4. Texture Measurements

2.5.5. Expansion Ratio

2.5.6. Color

2.5.7. Sensory Evaluation

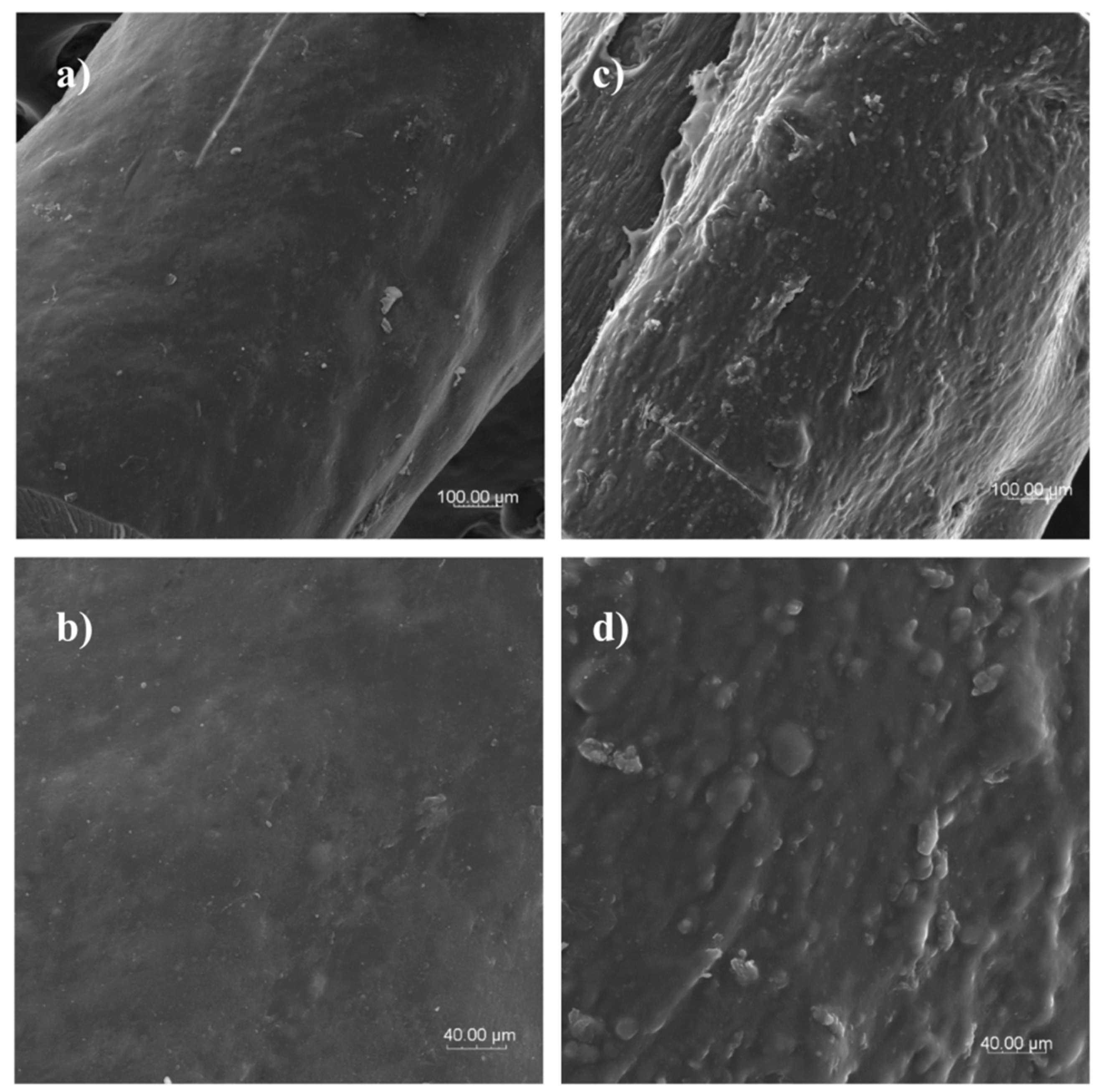

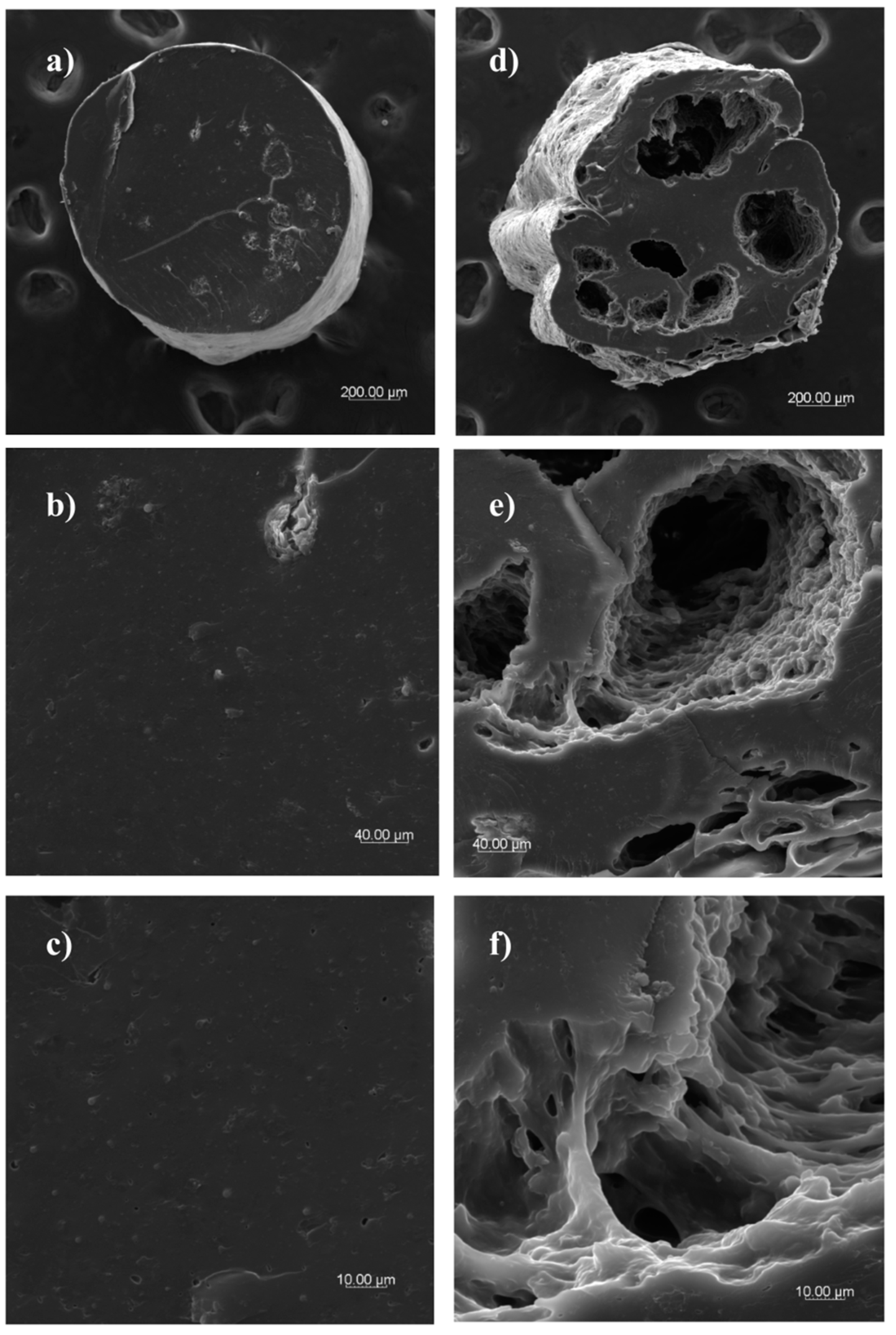

2.5.8. Microstructure

2.6. Statistical Analysis

3. Results and Discussion

3.1. Model Adequacy

3.2. Effect of Processing Parameters on Cooking Loss

3.3. Effect of Processing Parameters on Hardness, Firmness and Stickiness

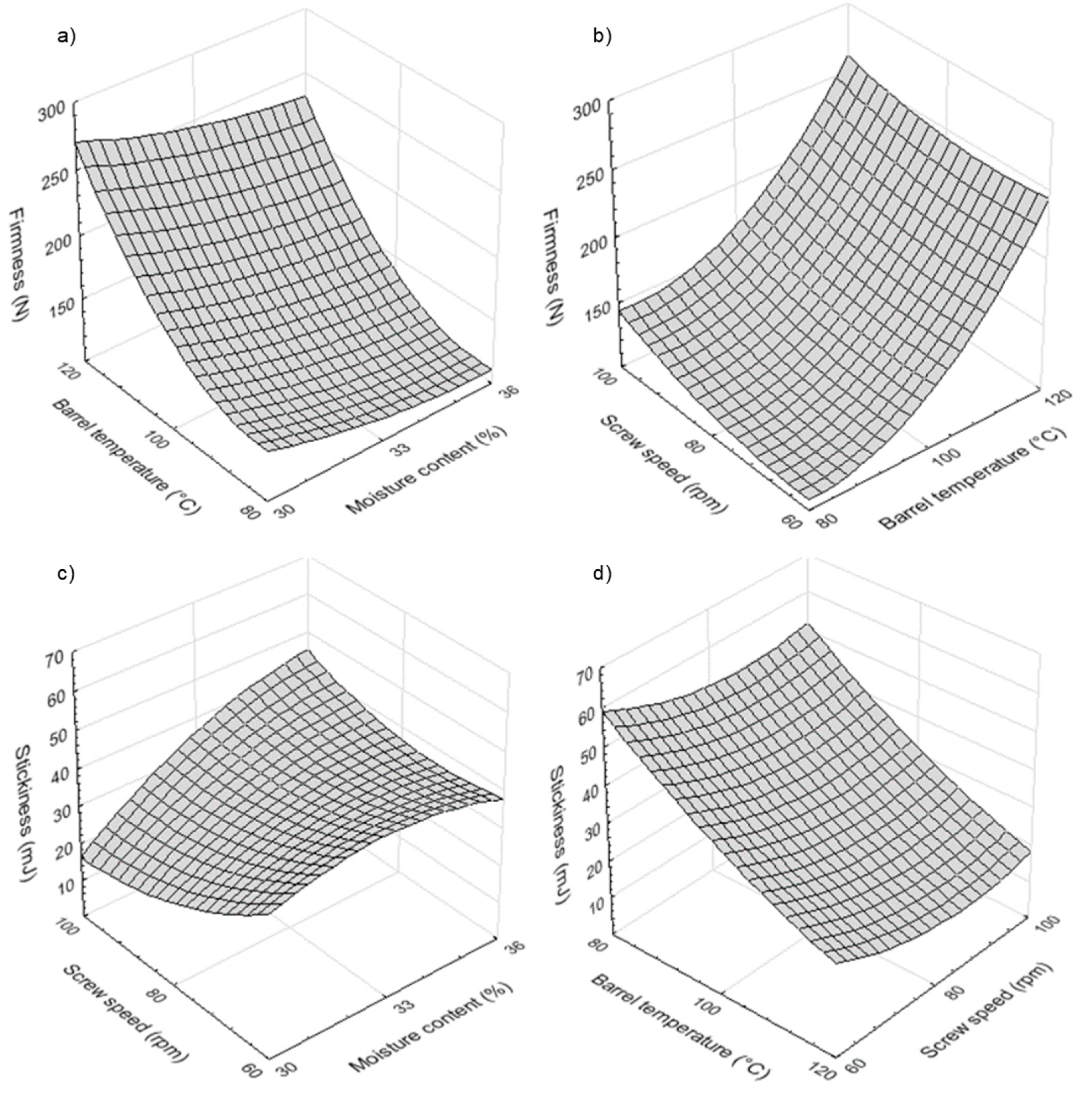

3.4. Optimal Parameters for Rice-Buckwheat Pasta-Making

3.5. Characteristics of Optimum Rice-Buckwheat Pasta

3.5.1. Chemical Composition

3.5.2. Cooking, Physical, and Textural Properties of Rice-Buckwheat Pasta

3.5.3. Sensory Attributes

3.5.4. Microstructure

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mercier, S.; Moresoli, C.; Mondor, M.; Villeneuve, S.; Marcos, B. A meta-analysis of enriched Pasta: What are the effects of enrichment and process specifications on the quality attributes of pasta? Compr. Rev. Food Sci. Food Saf. 2016, 15, 685–704. [Google Scholar] [CrossRef]

- Feillet, P.; Dexter, J.E. Quality requirements of durum wheat for semolina milling and pasta production. In Pasta and Noodle Technology; Kruger, J.E., Matsuo, R.R., Dick, J.W., Eds.; The American Association of Cereal Chemists: St. Paul, MN, USA, 1996; pp. 95–131. [Google Scholar]

- Gobbetti, M.; Pontonio, E.; Filannino, P.; Rizzello, C.G.; De Angelis, M.; Di Cagno, R. How to improve the gluten-free diet: The state of the art from a food science perspective. Food Res. Int. 2018, 110, 22–32. [Google Scholar] [CrossRef] [PubMed]

- Pellegrini, N.; Agostoni, C. Nutritional aspects of gluten-free products. J. Sci. Food Agric. 2015, 95, 2380–2385. [Google Scholar] [CrossRef] [PubMed]

- Giménez-Bastida, J.A.; Piskuła, M.; Zieliński, H. Recent advances in development of gluten-free buckwheat products. Trends Food Sci. Technol. 2015, 44, 58–65. [Google Scholar] [CrossRef]

- Biney, K.; Beta, T. Phenolic profile and carbohydrate digestibility of durum spaghetti enriched with buckwheat flour and bran. LWT-Food Sci. Technol. 2014, 57, 569–579. [Google Scholar] [CrossRef]

- Alamprese, C.; Casiraghi, E.; Pagani, M.A. Development of gluten-free fresh egg pasta analogues containing buckwheat. Eur. Food Res. Technol. 2007, 25, 205–213. [Google Scholar] [CrossRef]

- Schoenlechner, R.; Drausinger, J.; Ottenschlaeger, V.; Jurackova, K.; Berghofer, E. Functional properties of gluten-free pasta produced from amaranth, quinoa and buckwheat. Plant Foods Hum. Nutr. 2010, 65, 339–349. [Google Scholar] [CrossRef]

- Marti, A.; Pagani, M.A. What can play the role of gluten in gluten free-pasta? Trends Food Sci. Technol. 2013, 31, 63–71. [Google Scholar] [CrossRef]

- Wójtowicz, A. Precooked pasta. In Extrusion-Cooking Techniques. Applications, Theory and Sustainability; Mościcki, L., Ed.; Wiley: Weinheim, Germany, 2011; pp. 99–117. [Google Scholar]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N.; Olech, M.; Nowak, R.; Mitrus, M.; Oniszczuk, A. Gluten-free precooked rice-yellow pea pasta: Effect of extrusion-cooking conditions on phenolic acids composition, selected properties and microstructure. J. Food Sci. 2016, 81, 1070–1079. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Mościcki, L. Influence of extrusion-cooking parameters on some quality aspects of precooked pasta-like products. J. Food Sci. 2009, 74, 226–233. [Google Scholar] [CrossRef]

- Oniszczuk, A.; Kasprzak, K.; Wójtowicz, A.; Oniszczuk, T.; Olech, M. The impact of processing parameters on the content of phenolic compounds in new gluten-free precooked buckwheat pasta. Molecules 2019, 24, 1262. [Google Scholar] [CrossRef] [PubMed]

- Zieliński, H.; Michalska, A.; Piskuła, M.; Kozłowska, H. Antioxidants in thermally treated buckwheat groats. Mol. Nutr. Food Res. 2006, 50, 824–832. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, S.L.C.; Bruns, R.E.; Ferreira, H.S.; Matos, G.D.; David, J.M.; Brandão, G.C.; da Silva, E.G.P.; Portugal, L.A.; dos Reis, P.S.; Souza, A.S.; et al. Box-Behnken design: An alternative for the optimization of analytical methods. Anal. Chim. Acta 2007, 597, 179–186. [Google Scholar] [CrossRef] [PubMed]

- ACCC. AACC International Approved Methods of Analysis, 10th ed.; AACC International: St. Paul, MN, USA, 2000. [Google Scholar]

- William, H. Official Methods of Analysis of AOAC International, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Lisiecka, K.; Wójtowicz, A.; Dziki, D.; Gawlik-Dziki, U. The influence of Cistus incanus L. leaves on wheat pasta quality. J. Food Sci. Technol. 2019, 56, 4311–4322. [Google Scholar] [CrossRef] [PubMed]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventos, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Mościcki, L. Influence of legume type and addition level on quality characteristics, texture and microstructure of enriched precooked pasta. LWT-Food Sci. Technol. 2014, 59, 1175–1185. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N. Gluten-free precooked rice pasta enriched with legumes flours: Physical properties, texture, sensory attributes and microstructure. LWT-Food Sci. Technol. 2017, 75, 569–577. [Google Scholar] [CrossRef]

- Bustos, M.C.; Perez, G.T.; León, A.E. Sensory and nutritional attributes of fibre-enriched pasta. LWT-Food Sci. Technol. 2011, 44, 1429–1434. [Google Scholar] [CrossRef]

- Jalgaonkar, K.; Jha, S.K.; Mahawar, M.K.; Yadav, D.N. Pearl millet based pasta: Optimization of extrusion process through response surface methodology. J. Food Sci. Technol. 2019, 56, 1134–1144. [Google Scholar] [CrossRef]

- Galvez, F.C.F.; Resurreccion, A.V.A.; Ware, G.O. Process variables, gelatinized starch and moisture effects on physical properties of mungbean noodles. J. Food Sci. 1994, 59, 378–381. [Google Scholar] [CrossRef]

- Giménez, M.A.; González, R.J.; Wagner, J.; Torres, R.; Lobo, M.O.; Samman, N.C. Effect of extrusion conditions on physicochemical and sensorial properties of corn-broad beans (Vicia faba) spaghetti type pasta. Food Chem. 2013, 136, 538–545. [Google Scholar] [CrossRef] [PubMed]

- Rafiq, A.; Sharma, S.; Singh, B. Regression analysis of gluten-free pasta from brown rice for characterization and in vitro digestibility. J. Food Proc. Preserv. 2017, 41, e12830. [Google Scholar] [CrossRef]

- Wang, N.; Maximiuk, L.; Toews, R. Pea starch noodles: Effect of processing variables on characteristics and optimisation of twin-screw extrusion process. Food Chem. 2012, 133, 742–753. [Google Scholar] [CrossRef]

- Wójtowicz, A. Influence of process conditions on selected texture properties of precooked buckwheat pasta. Teka Kom. Motoryz. Energetyki Agric. 2012, 12, 315–322. [Google Scholar]

- Stojceska, V.; Ainsworth, P.; Plunkett, A.; İbanoğlu, S. The advantage of using extrusion processing for increasing dietary fibre level in gluten-free products. Food Chem. 2009, 121, 156–164. [Google Scholar] [CrossRef]

- Calvo-López, A.D.; Martínez-Bustos, F. Optimization of extrusion process of directly expanded snacks based on potato starch in a single step for the formation of type IV resistant starch. Plant Foods Hum. Nutr. 2017, 72, 243–249. [Google Scholar] [CrossRef]

- Sedej, I.; Sakač, M.; Mandić, M.; Mišan, A.; Tumbas, V.; Čanadanović-Brunet, J. Buckwheat (Fagopyrum esculentum Moench) grain and fractions: Antioxidant compounds and activities. J. Food Sci. 2012, 77, 954–959. [Google Scholar] [CrossRef]

- Carcea, M.; Narducci, V.; Turfani, V.; Giannini, V. Polyphenols in raw and cooked cereals/pseudocereals/legume pasta and couscous. Foods 2017, 6, 80. [Google Scholar] [CrossRef]

- De Pilli, T.; Derossi, A.; Talja, R.A.; Jouppila, K.; Severini, C. Starch-lipid complex formation during extrusion-cooking of model system (rice starch and oleic acid) and real food (rice starch and pistachio nut flour). Eur. Food Res. Technol. 2012, 234, 517–525. [Google Scholar] [CrossRef]

- Qian, J.; Rayas-Duarte, P.; Grant, L. Partial characterization of buckwheat (Fagopyrum esculentum) starch. Cereal Chem. 1998, 75, 365–373. [Google Scholar] [CrossRef]

- Kim, Y.; Wiesenborn, D.; Lorenzen, J.; Berglund, P. Suitability of edible bean and potato starches for starch noodles. Cereal Chem. 1996, 73, 302–307. [Google Scholar]

- Vallons, K.; Arendt, E.K. Effects of high pressure and temperature on buckwheat starch characteristics. Eur. Food Res. Technol. 2009, 230, 343–351. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Mościcki, L. Effect of wheat bran addition and screw speed on microstructure and textural characteristics of common wheat precooked pasta-like products. Pol. J. Food Nutr. Sci. 2011, 61, 101–107. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Mitrus, M.; Oniszczuk, T.; Mościcki, L.; Kręcisz, M.; Oniszczuk, A. Selected physical properties, texture and sensory characteristics of extruded breakfast cereals based on wholegrain wheat flour. Agric. Sci. Procedia 2015, 7, 301–308. [Google Scholar] [CrossRef]

- Petitot, M.; Boyer, L.; Minier, C.; Micard, V. Fortification of pasta with split pea and faba bean flours: Pasta processing and quality evaluation. Food Res. Int. 2010, 43, 634–641. [Google Scholar] [CrossRef]

- Bilgiçli, N. Some chemical and sensory properties of gluten-free noodle prepared with different legume, pseudocereal and cereal flour blends. J. Food Nutr. Res. 2013, 52, 251–255. [Google Scholar]

| Coded Values | Real Values | |||||

|---|---|---|---|---|---|---|

| Run | X1 | X2 | X3 | Moisture Content (%) | Barrel Temperature (°C) | Screw Speed (rpm) |

| 1 | –1 | –1 | 0 | 30 | 80 | 80 |

| 2 | +1 | –1 | 0 | 36 | 80 | 80 |

| 3 | –1 | +1 | 0 | 30 | 120 | 80 |

| 4 | +1 | +1 | 0 | 36 | 120 | 80 |

| 5 | –1 | 0 | –1 | 30 | 100 | 60 |

| 6 | +1 | 0 | –1 | 36 | 100 | 60 |

| 7 | –1 | 0 | +1 | 30 | 100 | 100 |

| 8 | +1 | 0 | +1 | 36 | 100 | 100 |

| 9 | 0 | –1 | –1 | 33 | 80 | 60 |

| 10 | 0 | +1 | –1 | 33 | 120 | 60 |

| 11 | 0 | −1 | +1 | 33 | 80 | 100 |

| 12 | 0 | +1 | +1 | 33 | 120 | 100 |

| 13 | 0 | 0 | 0 | 33 | 100 | 80 |

| 14 | 0 | 0 | 0 | 33 | 100 | 80 |

| 15 | 0 | 0 | 0 | 33 | 100 | 80 |

| Responses | Model | ||

|---|---|---|---|

| F-value | p-value | R2 | |

| Cooking loss (%) | 23.7806 | 0.0014* | 0.98 |

| Hardness (N) | 9.6248 | 0.0113* | 0.95 |

| Firmness (N) | 27.260 | 0.0010** | 0.98 |

| Stickiness (mJ) | 9.4727 | 0.0117* | 0.94 |

| Responses | Estimates of Regression Coefficients | ||

|---|---|---|---|

| Moisture content (%) | Barrel Temperature (°C) | Screw Speed (rpm) | |

| Cooking loss (%) | 0.3275 ** | −0.595 *** | ns |

| Hardness (N) | ns | 1.01375 ** | 1.055 ** |

| Firmness (N) | −16.6875 * | 63.3125 *** | 13.125 * |

| Stickiness (mJ) | 7.135 * | −16.9875 *** | ns |

| Samples | Protein (%) | Fat (%) | Ash (%) | Fiber (%) | TPC (mg GAE/g) |

|---|---|---|---|---|---|

| Rice flour | 7.72 ± 0.004 a | 2.30 ± 0.01 c | 1.37 ± 0.02 b | 1.31 ± 0.01 a | 0.04 ± 0.01 a |

| Buckwheat flour | 10.55 ± 0.01 c | 2.04 ± 0.01 b | 1.58 ± 0.01 c | 4.57 ± 0.01 b | 1.85 ± 0.20 b |

| Rice-buckwheat optimum pasta | 9.78 ± 0.01 b | 0.16 ± 0.01 a | 1.07 ± 0.01 a | 5.21 ± 0.01 c | 0.40 ± 0.02 a |

| Rice-Buckwheat Pasta | Rice Pasta [21] | |

|---|---|---|

| Minimal preparation time (min) | 8.5 ± 0.01 a | 8.0 ± 0.01 a |

| Water absorption capacity (g/100g) | 237.77 ± 0.81 b | 181.53 ± 6.68 a |

| Cooking loss (%) | 5.23 ± 0.12 b | 3.57 ± 0.30 a |

| Expansion ratio (-) | 1.21 ± 0.05 a | 1.55 ± 0.03 b |

| Color of dry pasta | ||

| L* | 42.99 ± 2.11 a | 72.29 ± 0.81 b |

| a* | 0.48 ± 1.28 b | −4.00 ± 0.33 a |

| b* | 32.34 ± 3.03 b | 29.25 ± 1.22 a |

| Color of hydrated pasta | ||

| L* | 65.67 ± 2.00 a | 79.07 ± 1.44 b |

| a* | −2.27 ± 1.88 b | −5.25 ± 0.63 a |

| b* | 16.49 ± 1.19 b | 13.71 ± 0.82 a |

| Hardness (N) | 4.05 ± 0.21 a | 12.12 ± 1.41 b |

| Firmness (N) | 271.0 ± 9.90 b | 199.5 ± 0.71 a |

| Stickiness (mJ) | 9.22 ± 0.21 b | 2.48 ± 0.13 a |

| Attributes | Rice-Buckwheat Pasta | Rice Pasta [21] |

|---|---|---|

| Appearance | 4.40 ± 0.63 a | 4.00 ± 1.13 a |

| Color | 4.00 ± 1.13 b | 3.27 ± 1.16 a |

| Flavor | 4.40 ± 0.99 b | 3.93 ± 1.03 a |

| Taste | 4.33 ± 0.72 a | 3.93 ± 1.03 a |

| Stickiness | 4.87 ± 0.35 b | 4.13 ± 0.92 a |

| Overall acceptability | 7.27 ± 1.28 b | 6.53 ± 1.51 a |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bouasla, A.; Wójtowicz, A. Rice-Buckwheat Gluten-Free Pasta: Effect of Processing Parameters on Quality Characteristics and Optimization of Extrusion-Cooking Process. Foods 2019, 8, 496. https://doi.org/10.3390/foods8100496

Bouasla A, Wójtowicz A. Rice-Buckwheat Gluten-Free Pasta: Effect of Processing Parameters on Quality Characteristics and Optimization of Extrusion-Cooking Process. Foods. 2019; 8(10):496. https://doi.org/10.3390/foods8100496

Chicago/Turabian StyleBouasla, Abdallah, and Agnieszka Wójtowicz. 2019. "Rice-Buckwheat Gluten-Free Pasta: Effect of Processing Parameters on Quality Characteristics and Optimization of Extrusion-Cooking Process" Foods 8, no. 10: 496. https://doi.org/10.3390/foods8100496

APA StyleBouasla, A., & Wójtowicz, A. (2019). Rice-Buckwheat Gluten-Free Pasta: Effect of Processing Parameters on Quality Characteristics and Optimization of Extrusion-Cooking Process. Foods, 8(10), 496. https://doi.org/10.3390/foods8100496