Design and Research of a New Cold Storage: The Phase-Temperature Storage (PTS) to Reduce Evaporator Frosting

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Experimental Materials

2.1.2. Experimental Instruments and Equipment

2.2. Methods

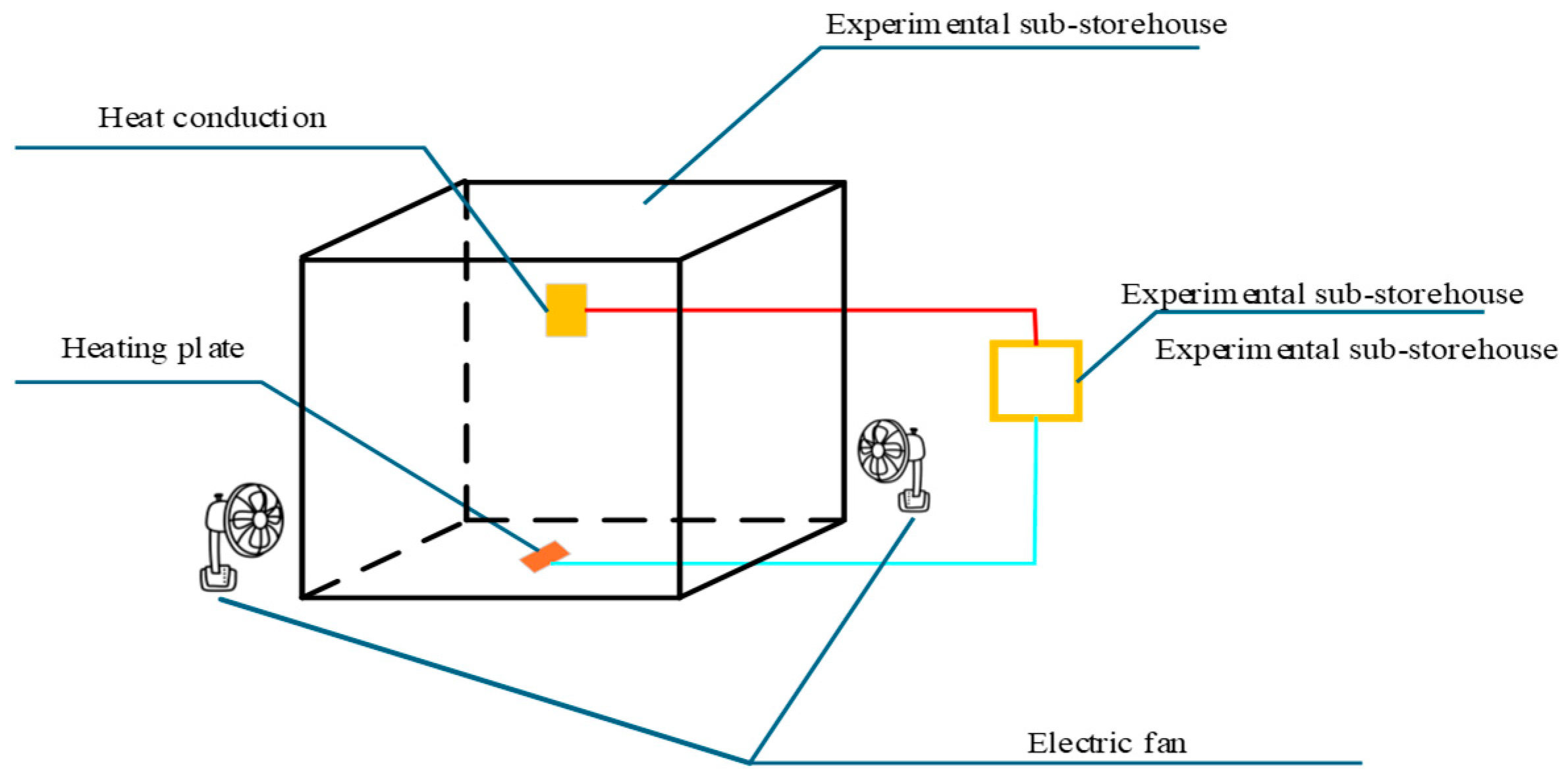

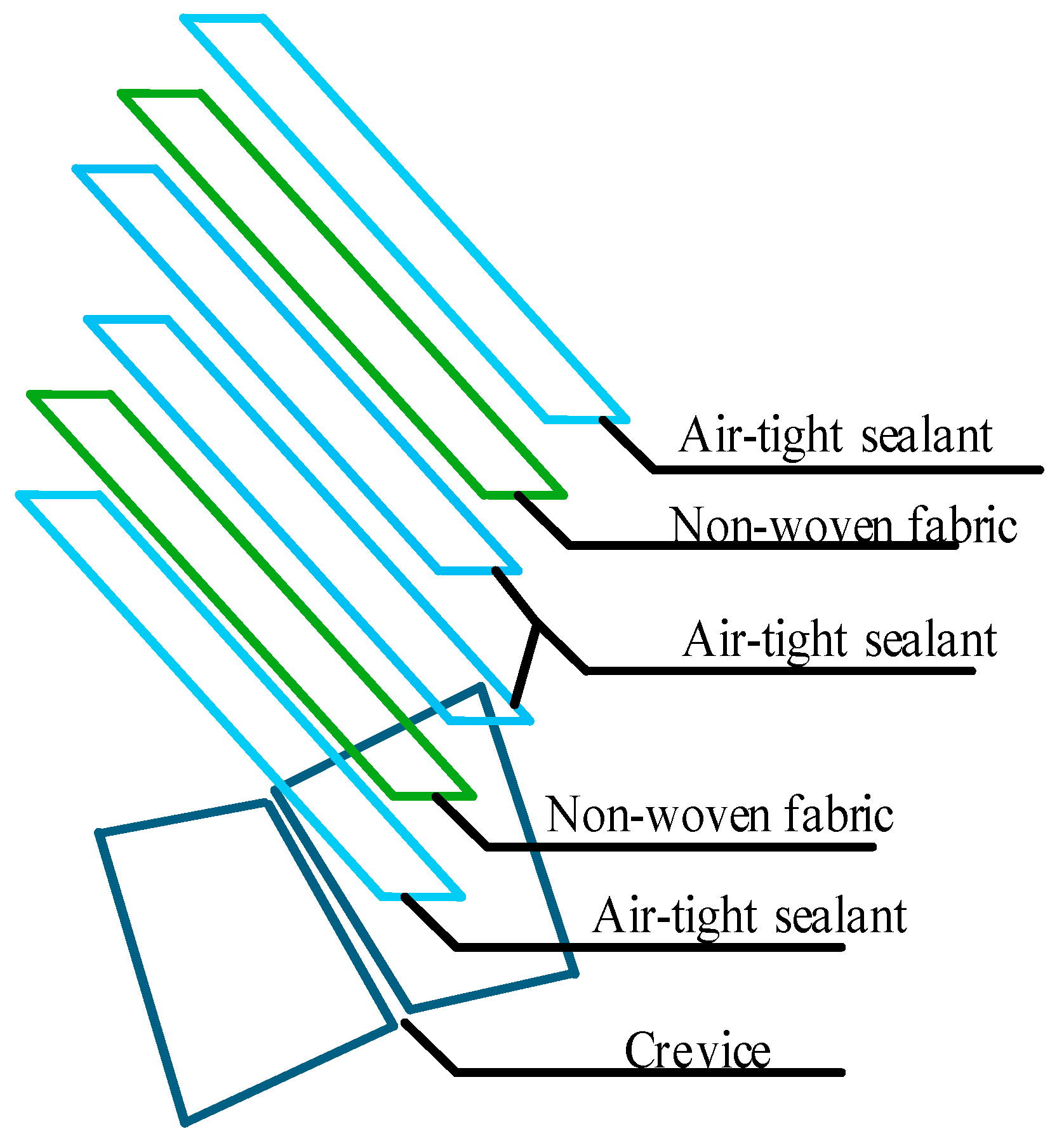

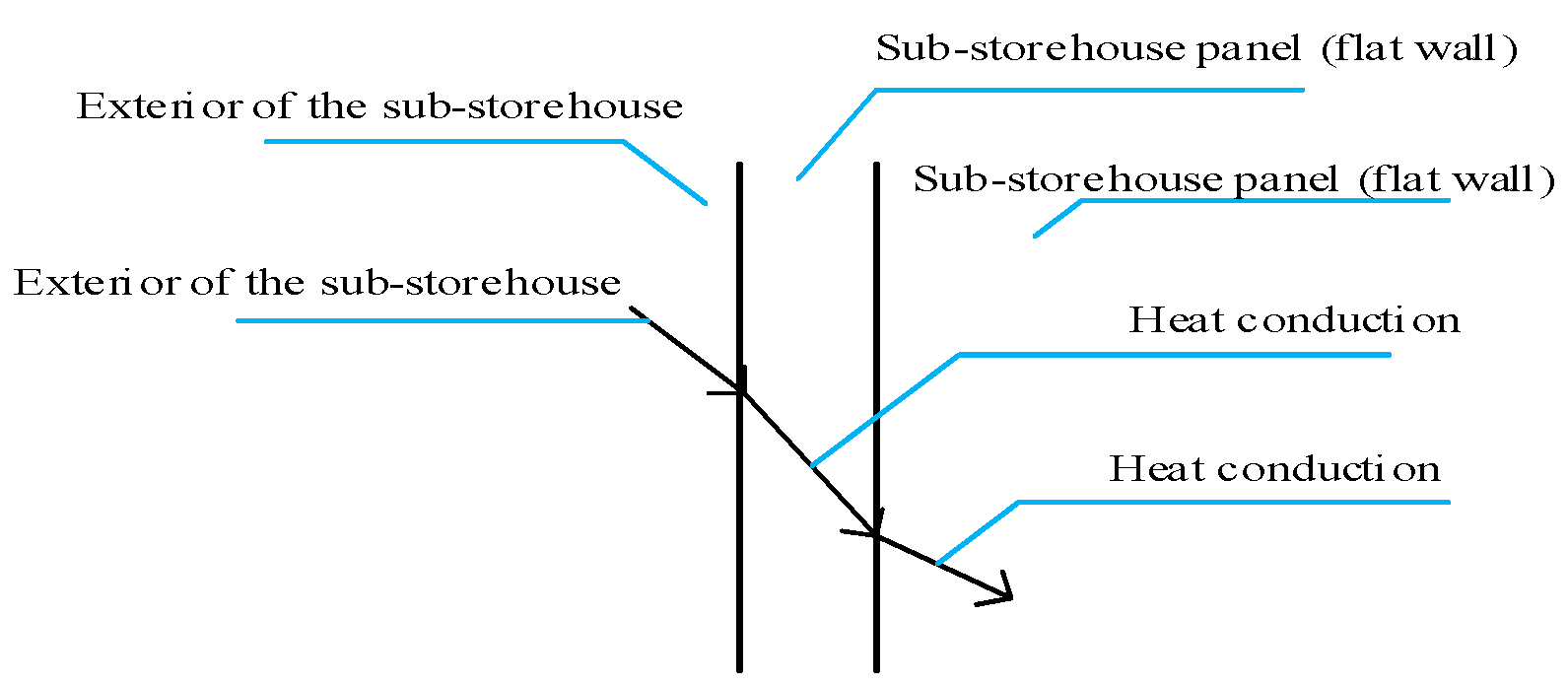

2.2.1. Determination of the Sub-Storehouse Material for Phase-Temperature Storage

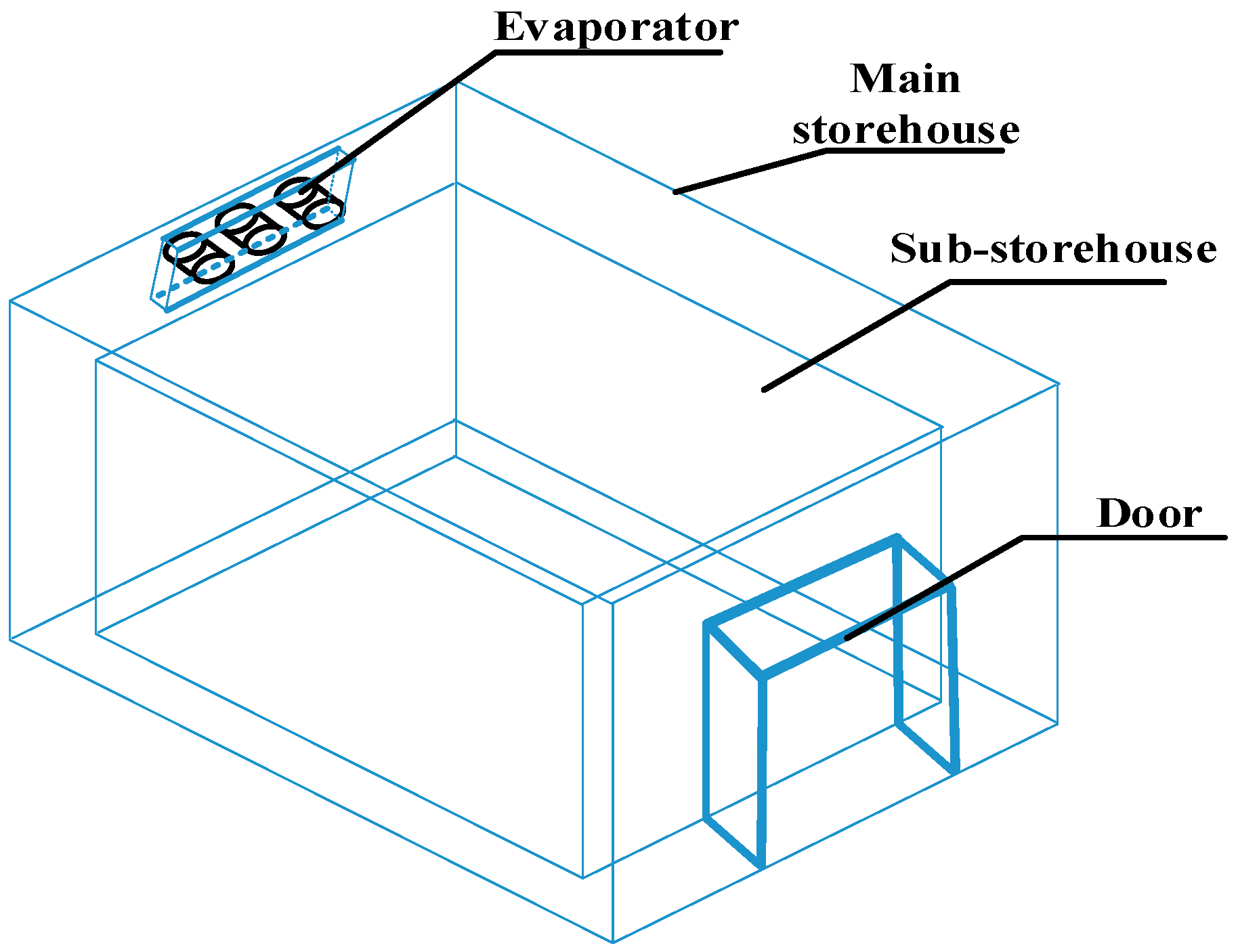

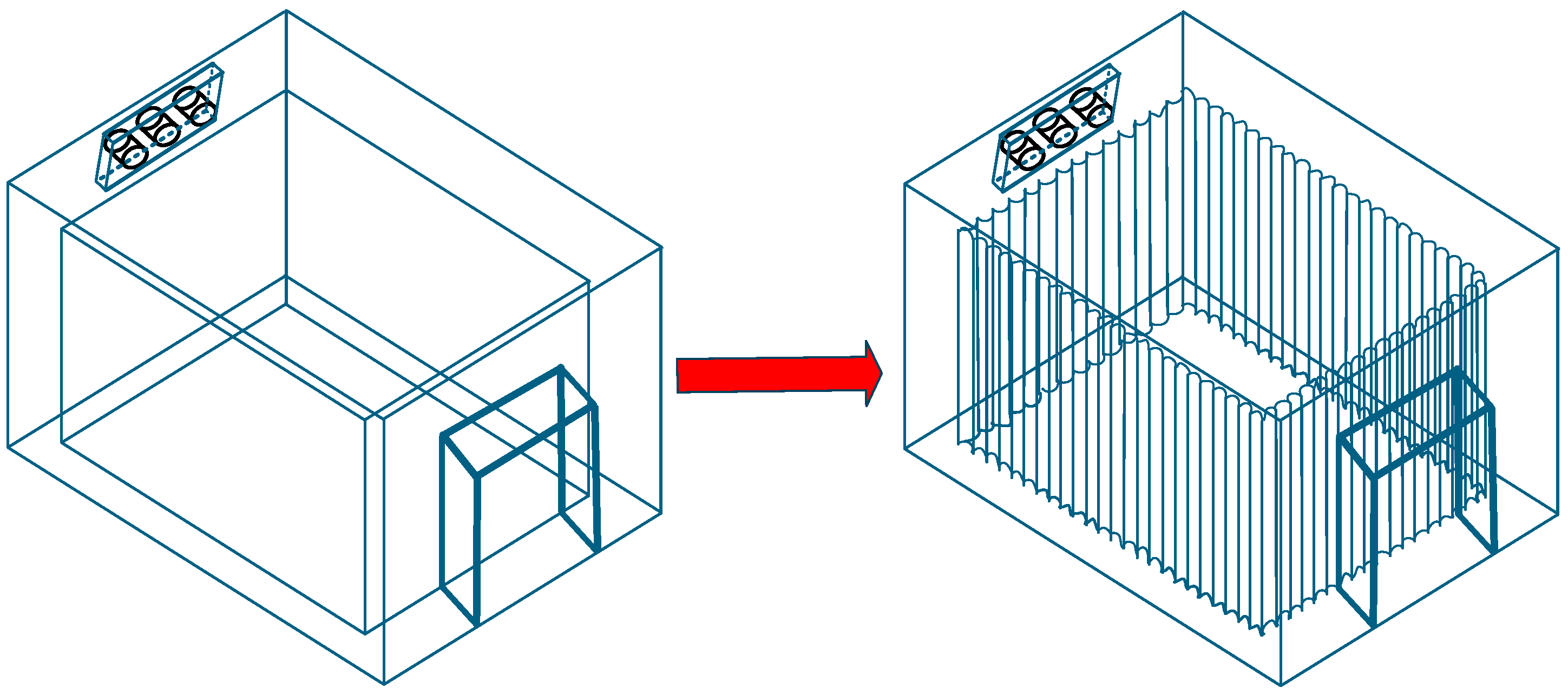

2.2.2. Simulation of the Temperature Field Within the Phase Temperature Storage and Optimization of the Sub-Storehouse Structure

2.3. Mathematical Model

- 1.

- Standard model

- 2.

- Mass Conservation Equation

- 3.

- Momentum Conservation Equations

- 4.

- Energy Conservation Equation

2.3.1. Boundary Conditions

2.3.2. Defrosting Experiment Design

Determination of Defrosting Energy Consumption

Determination of Defrosting Heat Recovery

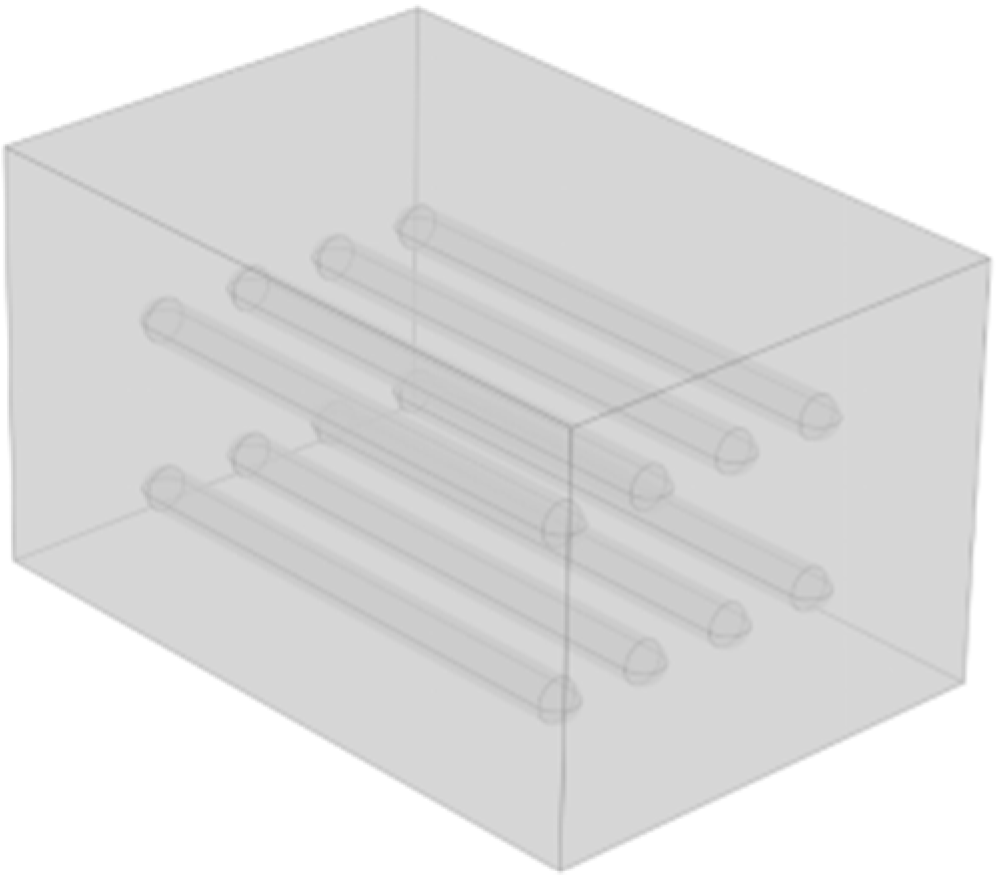

2.3.3. Simulation Analysis of Goods Stored in Sub-Storehouse

2.3.4. Design of the Freshness Preservation Experiment

Measurement of Apple Respiration Intensity

Measurement of Apple Weight Loss Rate

Measurement of Apple Hardness

Measurement of Soluble Solid Content (TSS) in Apples

Experimental Data Processing

3. Results

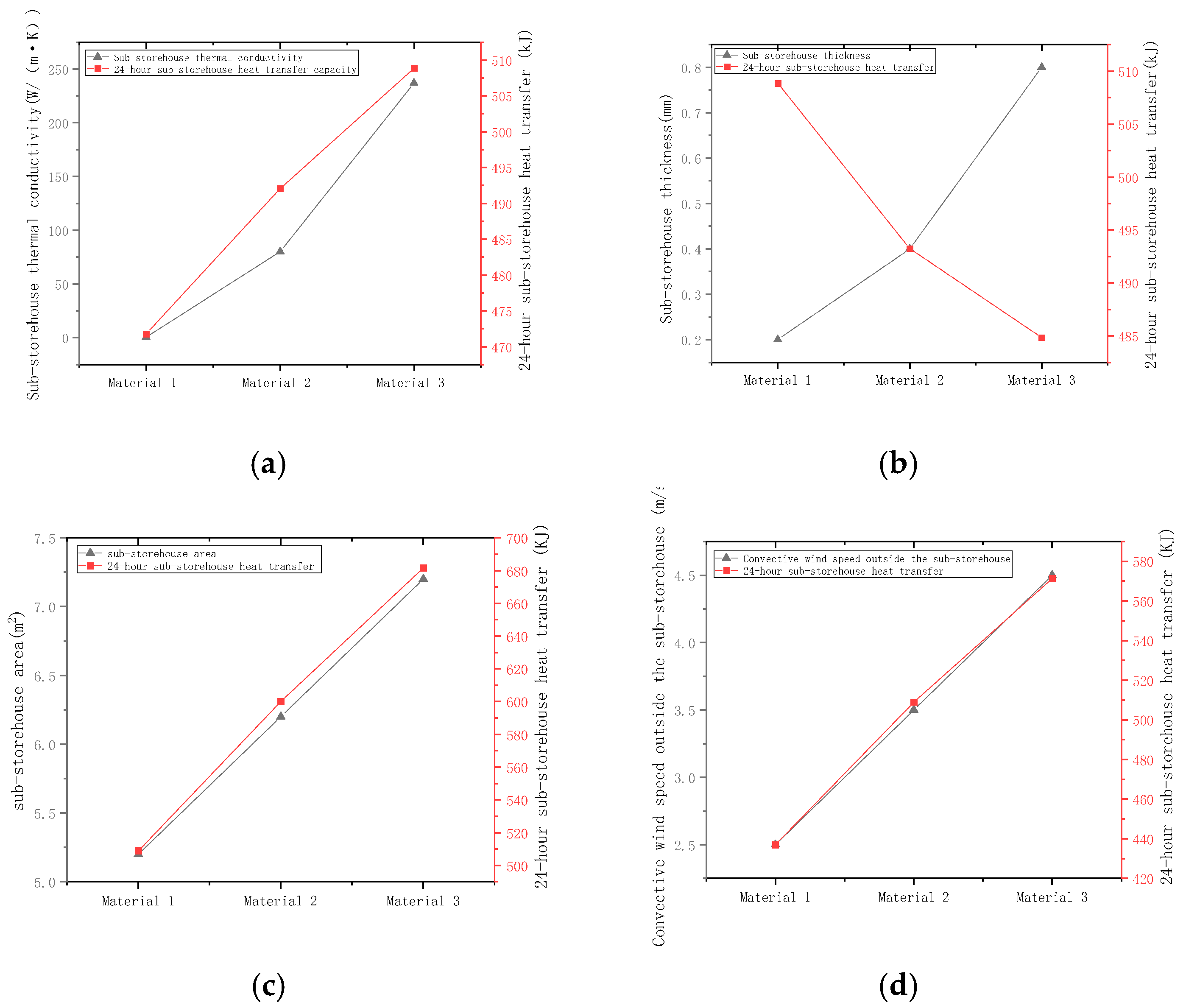

3.1. Determination of Sub-Storehouse Body for Phase-Temperature Storage

- (a)

- Selection of Sub-storehouse Body Materials

- (b)

- Determination of Sub-storehouse Wall Thickness

- (c)

- Determination of sub-storehouse Heat Transfer Area

- (d)

- Effect of Convection Velocity

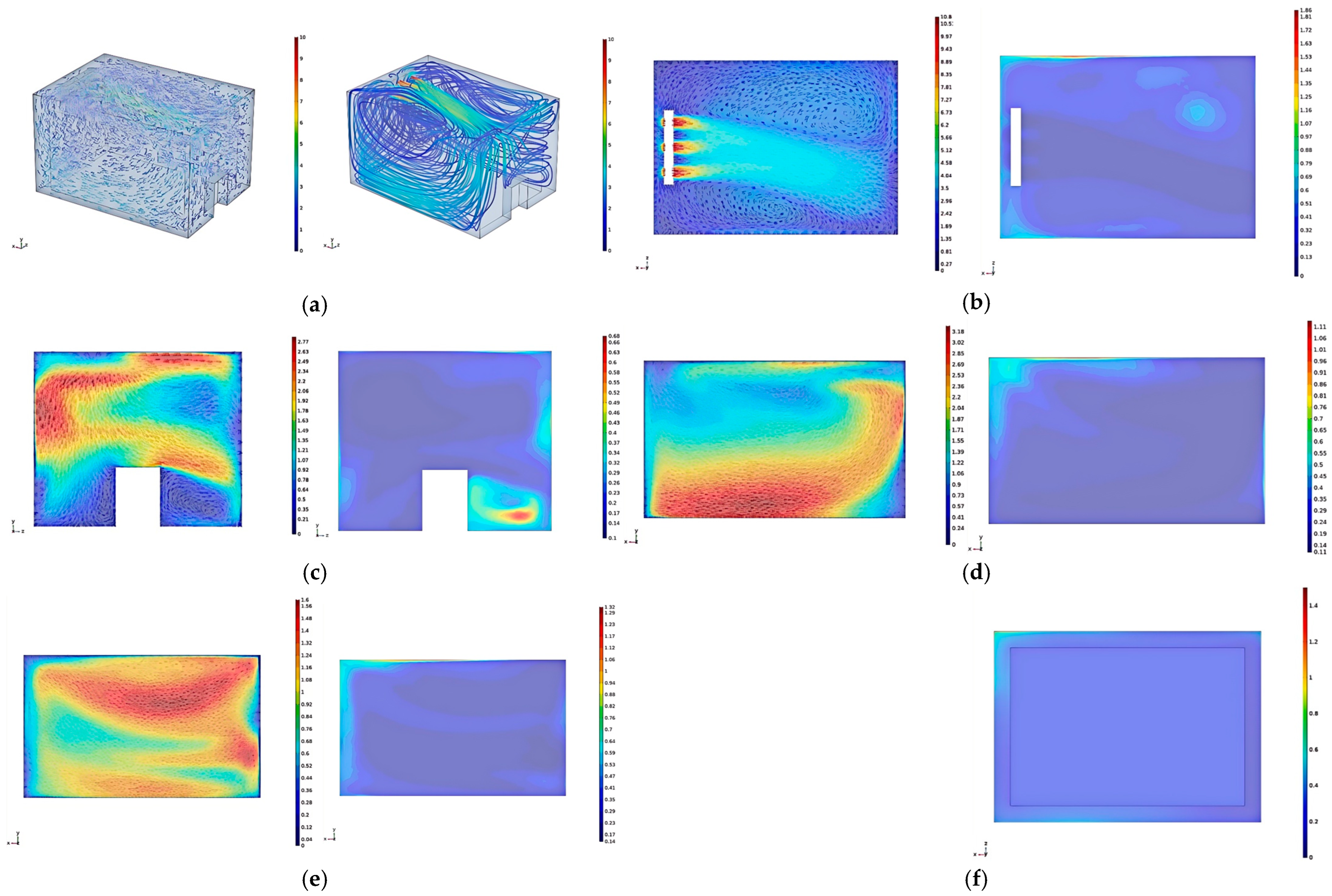

3.2. Simulation of Temperature Field in Phase Temperature Storage and Optimization of Sub-Storehouse Structure

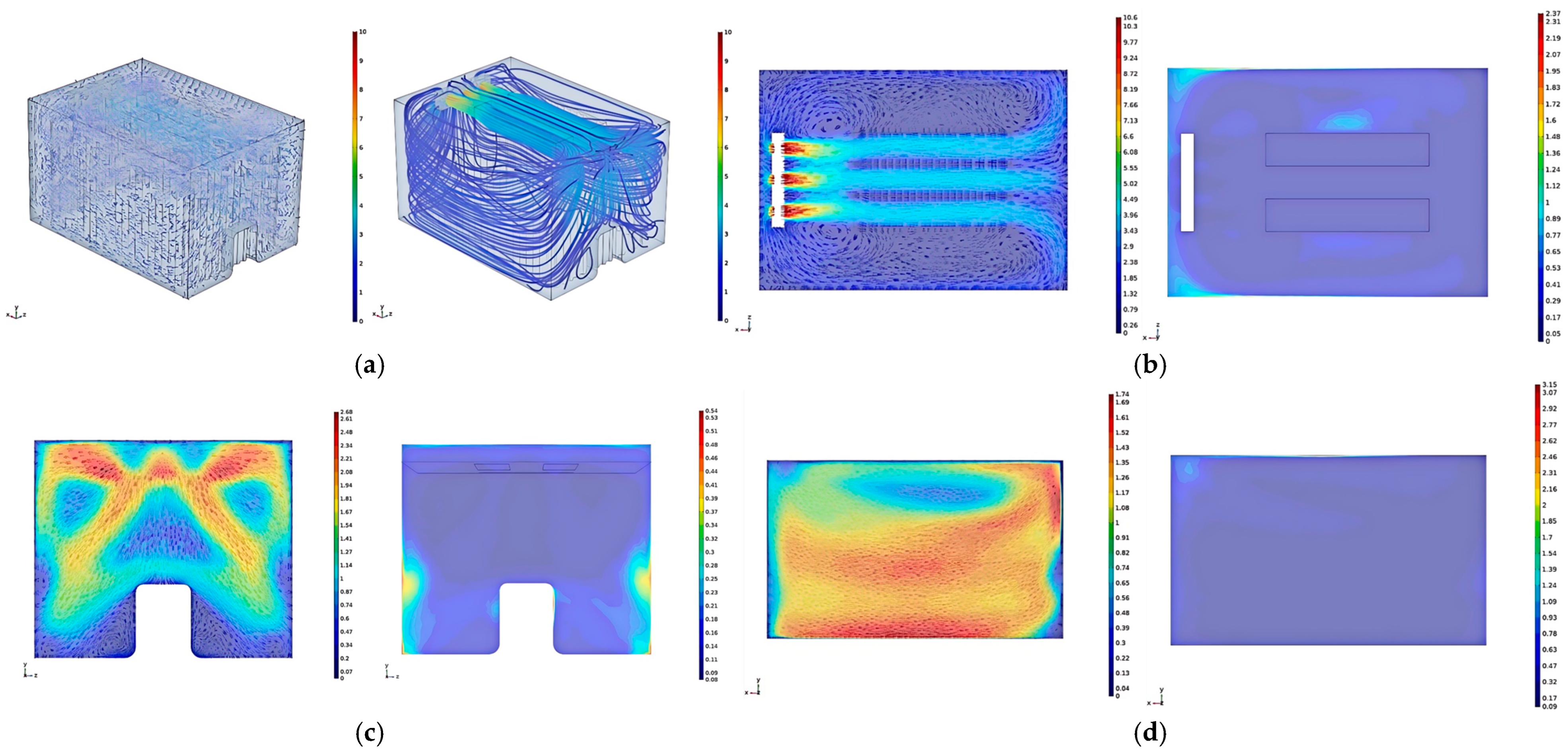

3.2.1. Analysis of Flow Field and Temperature Field Simulation Results

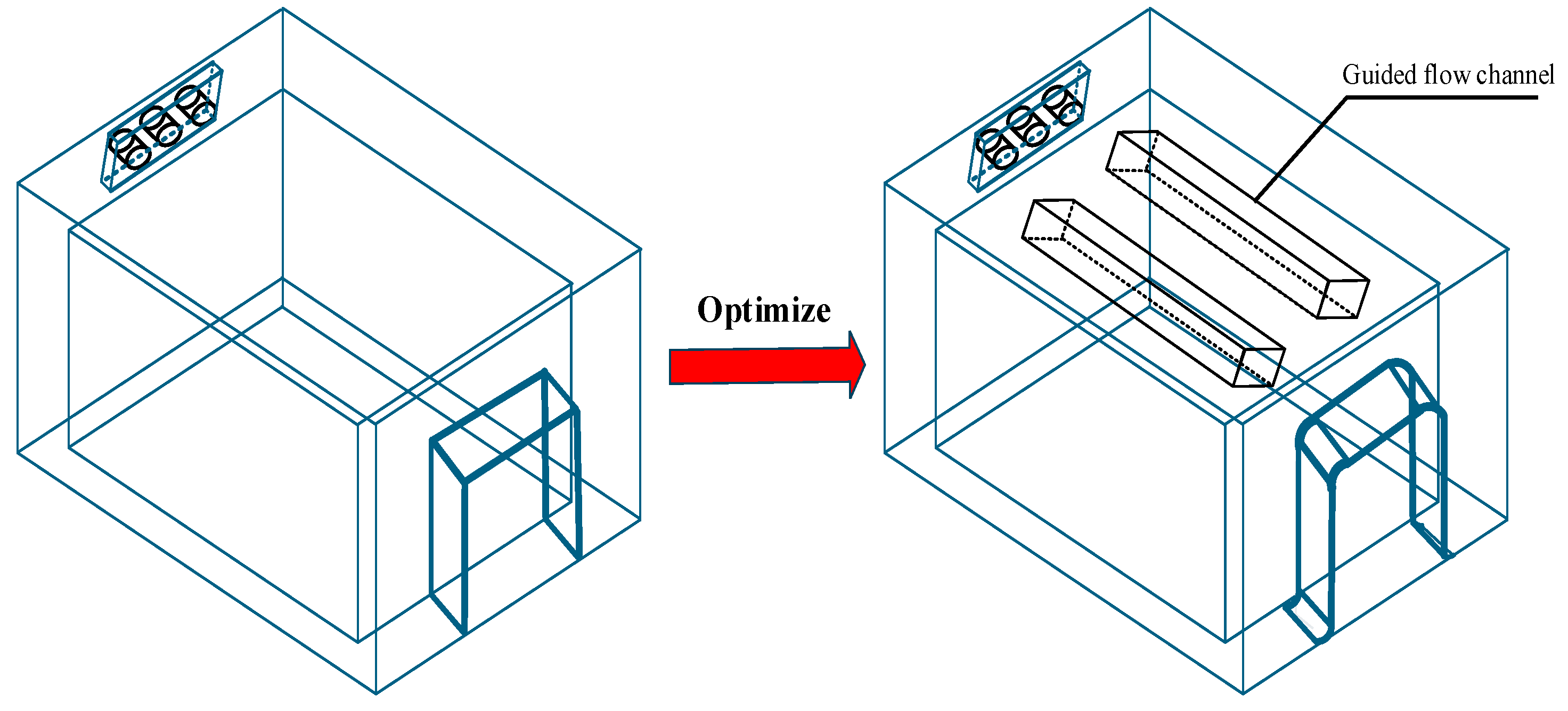

3.2.2. Optimization of the Sub-Storehouse Structure in Phase Temperature Storage

3.3. Analysis of Defrosting Experiment Results

3.3.1. Comparison of Defrosting Energy Consumption

3.3.2. Study of Defrosting Waste Heat

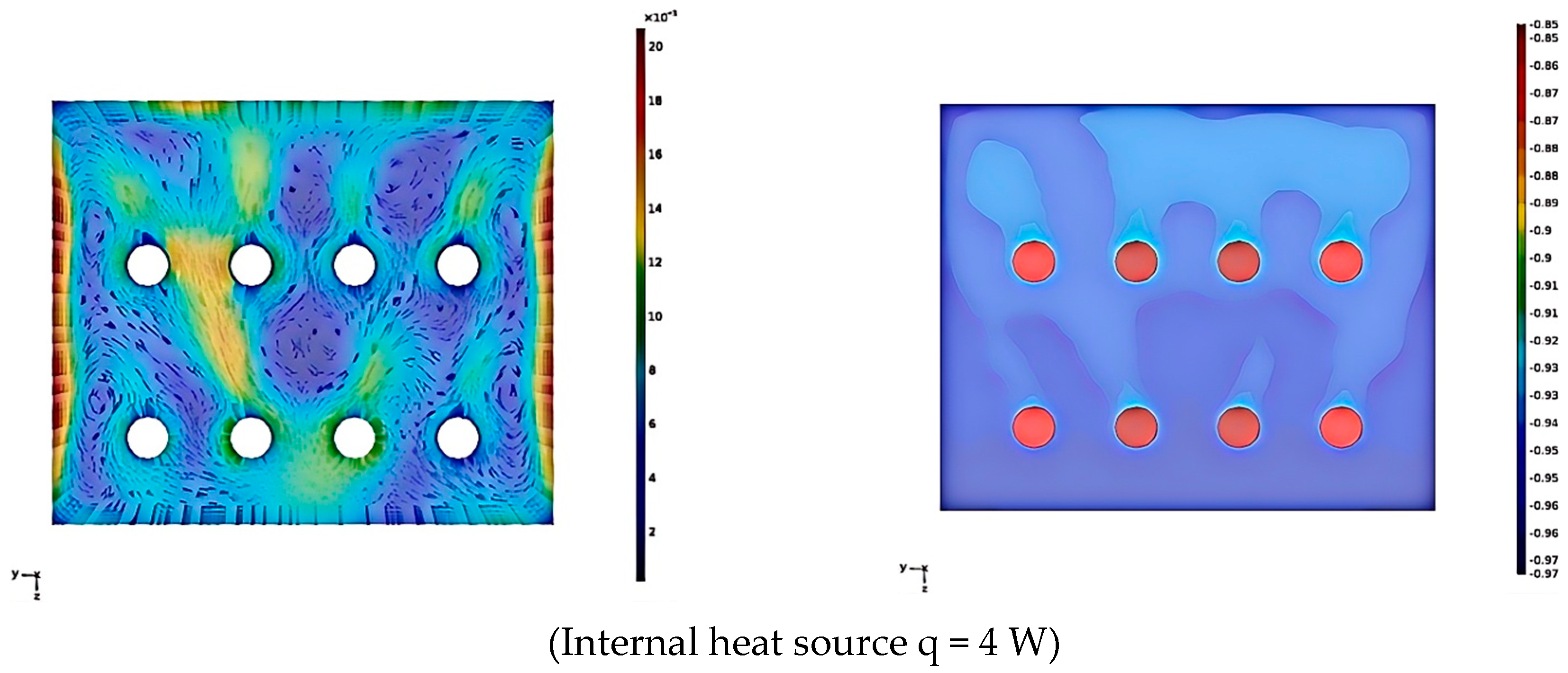

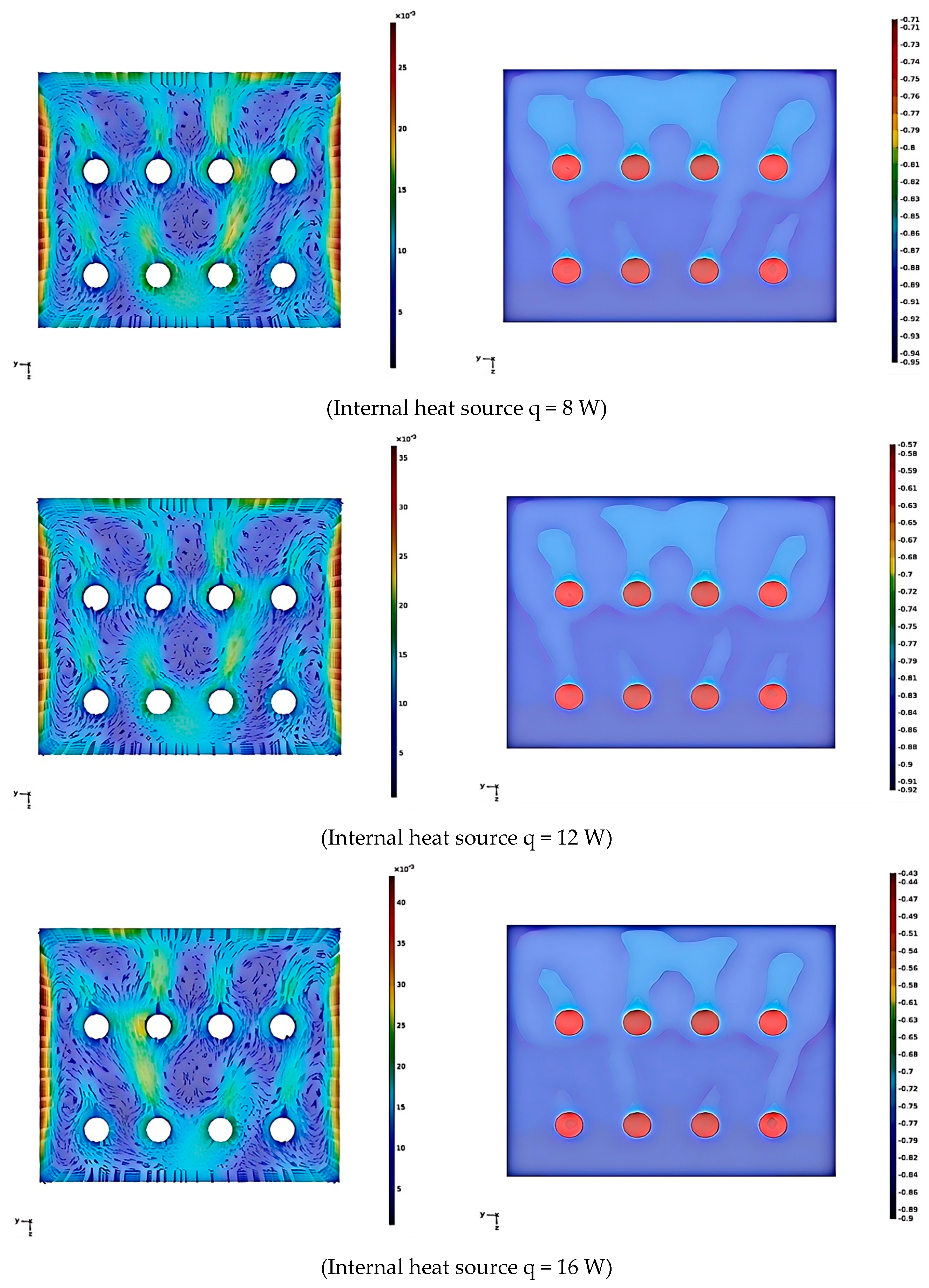

3.4. Results of Simulation Analysis of Goods Stored in Sub-Storehouse

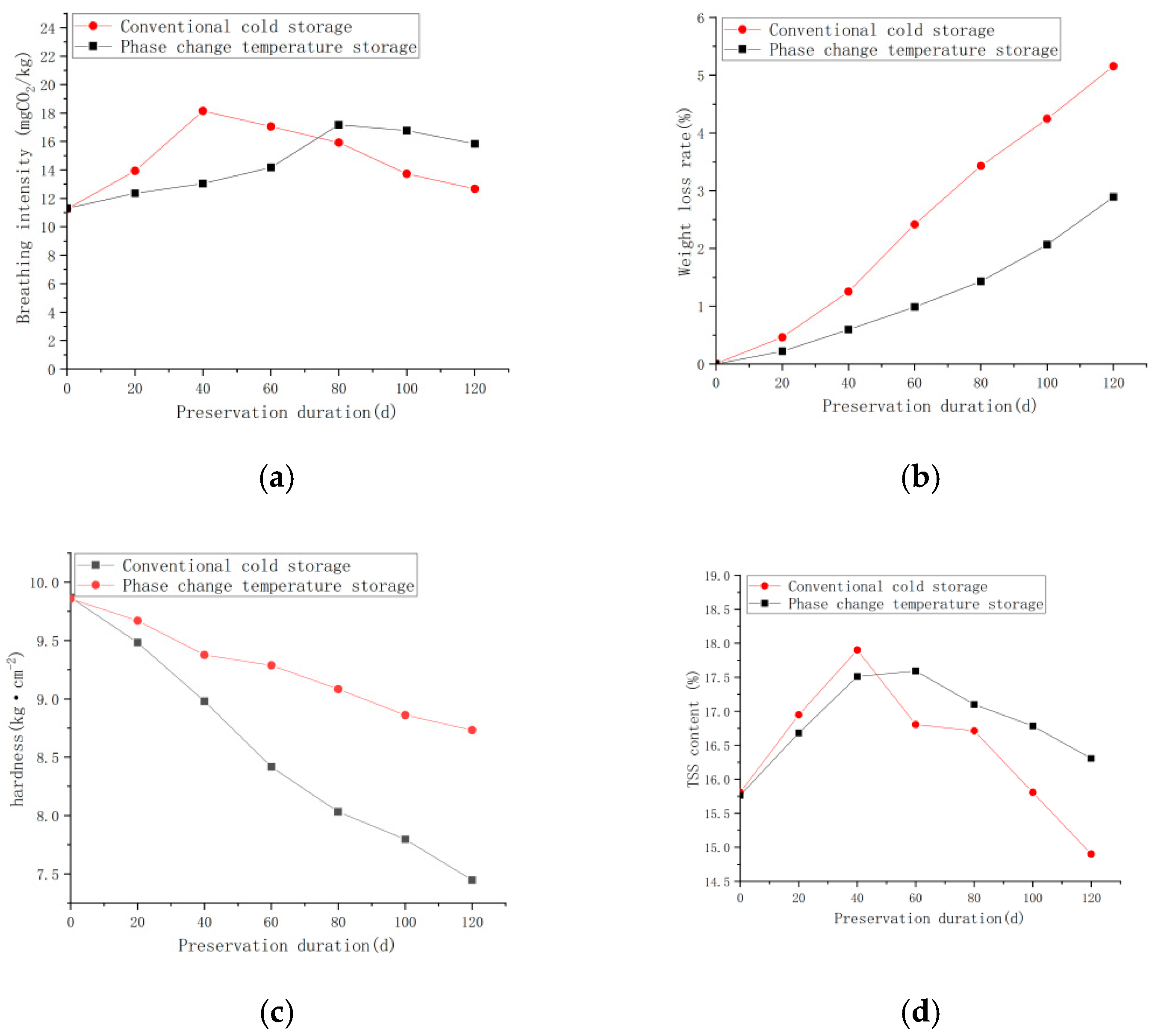

3.5. Comparison of Preservation Effects Between Phase-Temperature Storage and Conventional Cold Storage

3.5.1. Impact of Different Storage Environments on Apple Respiration Rate

3.5.2. Impact of Different Storage Environments on Apple Weight Loss Rate

3.5.3. Impact of Different Storage Environments on Apple Firmness

3.5.4. Impact of Different Storage Environments on Apple Total Soluble Solids (TSS) Content

4. Conclusions

- Experimental results demonstrated that the thermal conductivity of the sub-storehouse material exhibits a strong correlation with the storage area and airflow velocity. Conversely, the thickness and type of material were found to exert a relatively minor influence on thermal performance;

- The top jacket layer of the sub-storehouse was equipped with an innovative guided flow channel. Additionally, the storage door geometry was modified from an angular to a curved configuration, a marked improvement in airflow distribution uniformity within the jacket layer. Vortex formation at the door was significantly mitigated, and the internal temperature of the sub-storehouse decreased by 0.14 °C. These results provide compelling evidence of enhanced heat transfer performance in the optimized PTS structure;

- Under the same external conditions, an energy savings of over 96% for the PTS compared to conventional cold storage. Besides this, the PTS, owing to its unique structural design, achieved a reduction in overall energy consumption of approximately 70.5 kwh when considering both defrosting system operation and heat recovery;

- Software is used to simulate the heat transfer of the walls and goods by convection as the intensity of the internal heat source increases and the cargo temperature rises, resulting in greater temperature non-uniformity and enhanced flow velocities. Despite these variations, the overall flow velocity remains relatively low, and the temperature distribution remains largely uniform, thereby maintaining optimal storage conditions for goods;

- Apples stored in the PTS exhibit superior quality characteristics compared to those in conventional cold storage. Specifically, PTS-stored apples demonstrated higher firmness and TSS content, coupled with lower weight loss rates and respiration intensity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Makule, E.; Dimoso, N.; Tassou, S.A. Precooling and cold storage methods for fruits and vegetables in Sub-Saharan Africa-A review. Horticulturae 2022, 8, 776. [Google Scholar] [CrossRef]

- María, C.V.; Manuel, J.S.; Alberto, M.; Santiago, R.M.; Cristina, P.; María, G.C. Synergism of defatted soybean meal extract and modified atmosphere packaging to preserve the quality of figs (Ficus carica L.). Postharvest Biol. Technol. 2016, 111, 264–273. [Google Scholar]

- Zou, J.; Chen, J.; Tang, N.; Gao, Y.; Hong, M.; Wei, W.; Cao, H.; Jian, W.; Li, N.; Deng, W.; et al. Transcriptome analysis of aroma volatile metabolism change in tomato (Solanum lycopersicum) fruit under different storage temperatures and 1-MCP treatment. Postharvest Biol. Technol. 2018, 135, 57–67. [Google Scholar]

- Chen, L.; Pan, Y.; Li, H.; Liu, Z.; Jia, X.; Li, W.; Jia, H.; Li, X. Constant temperature during postharvest storage delays fruit ripening and enhances the antioxidant capacity of mature green tomato. Food Process. Preserv. 2020, 44, e14831. [Google Scholar] [CrossRef]

- Deng, S.; Han, Y.; Gao, T.; Ye, K.; Liu, J. Effect of temperature fluctuation during frozen storage on beef quality. J. Food Process. Preserv. 2021, 45, e15043. [Google Scholar] [CrossRef]

- Chen, L.; Pan, Y.; Jia, X.; Wang, X.; Yuan, J.; Li, X. Constant storage temperature delays firmness decreasing and pectin solubilisation of apple during post-harvest storage. J. Food Process. Preserv. 2021, 45, e15655. [Google Scholar]

- Xin, Y.; Liu, Z.; Zhang, Y.; Shi, X.; Chen, F.; Liu, K. Effect of temperature fluctuation on colour change and softening of postharvest sweet cherry. J. RSC Adv. 2021, 11, 22969–22982. [Google Scholar] [CrossRef]

- Göransson, M.; Nilsson, F.; Jevinger, Å. Temperature performance and food shelf-life accuracy in cold food supply chains-Insights from multiple field studies. Food Control 2018, 86, 332–341. [Google Scholar]

- Sonawane, C.; Alrubaie, A.J.; Panchal, H.; Chamkha, A.J.; Jaber, M.M.; Oza, A.D.; Zahmatkesh, S.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Investigation on the impact of different absorber materials in solar still using CFD simulation-economic and environmental analysis. Water 2022, 14, 3031. [Google Scholar] [CrossRef]

- Temirel, M.; Hu, H.; Shabgard, H.; Boettcher, P.; McCarthy, M.; Sun, Y. Solidification of additive-enhanced phase change materials in spherical enclosures with convective cooling. Appl. Therm. Eng. 2017, 111, 134–142. [Google Scholar] [CrossRef]

- Hedayat, M.; Sheikholeslami, M.; Shafee, A.; Nguyen-Thoi, T.; Henda, M.B.; Tlili, I.; Li, Z. Investigation of nanofluid conduction heat transfer within a triplex tube considering solidification. J. Mol. Liq. 2019, 290, 111–232. [Google Scholar] [CrossRef]

- Leong, K.Y.; Hasbi, S.; Ku Ahmad, K.Z.; Mat Jali, N.; Ong, H.C.; Md Din, M.F. Thermal properties evaluation of paraffin wax enhanced with carbon nanotubes as latent heat thermal energy storage. J. Energy Storage 2022, 52, 105027. [Google Scholar] [CrossRef]

- Wu, X.; Wang, C.; Wang, Y.; Zhu, Y. Experimental study of thermo-physical properties and application of paraffin-carbon nanotubes composite phase change materials. Int. J. Heat Mass Transf. 2019, 140, 671–677. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.; Guo, W.; Chen, F.; Chen, H. Thermophysical Properties of Cool Storage of Paraffin-based Composite Phase Change Materials Filled with Carbon Nanotubes. J. Refrig. 2014, 35, 110–113. [Google Scholar]

- Umate, T.B.; Sawarkar, P.D. Numerical investigations of temperature distribution in refrigerated vehicles with flow-guided phase change cold storage materials. J. Energy Storage 2025, 114, 115770. [Google Scholar] [CrossRef]

- Sparks, L.L. Cryogenic Foam Insulations: Polyurethane and Polystyrene, Nonmetallic Materials and Composites at Low Temperatures; Springer: Boston, MA, USA, 1979; pp. 165–205. [Google Scholar]

- Barrios, M.; Van Sciver, S.W. Thermal conductivity of rigid foam insulations for aerospace vehicles. Cryogenics 2013, 55–56, 12–19. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, L.; Hu, X. A symmetry-based hybrid model of computational fluid dynamics and machine learning for cold storage temperature management. Symmetry 2025, 17, 539. [Google Scholar] [CrossRef]

- Li, D.; Chen, Z. Experimental study on instantaneously shedding frozen water droplets from cold vertical surface by ultrasonic vibration. Exp. Therm. Fluid Sci. 2014, 53, 17–25. [Google Scholar] [CrossRef]

- Cho, H.; Kim, Y.; Jang, I. Performance of a showcase refrigeration system with multi-evaporator during on–off cycling and hot-gas bypass defrost. Energy 2005, 30, 1915–1930. [Google Scholar] [CrossRef]

- Adetunji, C.O.; Wike, N.Y.; Ogundolie, F.A.; Olaniyan, O.T.; Adetunji, J.B.; Akinbo, O.; Inobeme, A.; Adetuyi, B.O.; Dauda, W.P. Evaporative Coolers for the Postharvest Management of Fruits and Vegetables. Health Benefits Derived from Fruits and Vegetables Stored Using Evaporative Coolers; Elsevier Inc.: Amsterdam, The Netherlands, 2023; pp. 87–100. [Google Scholar]

- Qin, H.; Li, W.; Dong, B.; Zhao, Z.; Zhu, W. Experimental study of the characteristic of frosting on low-temperature air cooler. Exp. Therm. Fluid Sci. 2014, 55, 106–114. [Google Scholar]

- Chen, H.; Thomas, L.; Besant, R.W. Fan supplied heat exchanger fin performance under frosting conditions. Refigeration 2003, 26, 140–149. [Google Scholar] [CrossRef]

- Staby, G. Commercial Cooling of Fruits, Vegetables and Flowers. HortTechnology 2000, 10, 399a. [Google Scholar] [CrossRef]

- Uharek, S.; Baratchi, S.; Zhu, J.Y.; Alshehri, M.A.; Mitchell, A.; Rebner, K.; Karnutsch, C.; Khoshmanesh, K. Water jacket systems for temperature control of Petri dish cell culture chambers. J. Appl. Sci. 2019, 9, 621. [Google Scholar] [CrossRef]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 130–135. [Google Scholar]

- Bekele, B. Review on factors affecting postharvest quality of fruits. J. Plant Sci. Res. 2018, 5, 180. [Google Scholar]

- Brasil, I.M. postharvest quality of fruits and vegetables: An overview. In Preharvest Modulation of Postharvest Fruit and Vegetable Quality; Academic Press: New York, NY, USA, 2018; pp. 1–40. [Google Scholar]

- Feng, L.; Chang, K.; Zhao, Y.; Chen, X. Dual characterization method of temperature uniformity and fluctuation for refrigerator: Experiment, methodology, and improvement. J. Alex. Eng. J. 2024, 87, 300–307. [Google Scholar]

- Mahdi, Q.S.; Hadi, H.M.; Publication, I. Experimental and numerical investigation of airflow and temperature distribution in a prototype cold storage. Iraq. IJMET 2014, 5, 123. [Google Scholar]

- Budiyanto, M.A.; Imamudien, O.; Alhamid, M.I.; Shinoda, T. Design and analysis of a 20-feet modular cold storage system. Therm. Sci. Eng. Prog. 2024, 50, 102587. [Google Scholar] [CrossRef]

- Hu, W.; Jiang, Y.; Qu, M.; Long, N.; Yang, Y.; Deng, S. An experimental study on the operating performance of a novel reverse-cycle hot gas defrosting method for air source heat pumps. Appl. Therm. Eng. 2010, 31, 363–369. [Google Scholar]

- Penazzi, L.; Jannot, Y.; Meulemans, J.; Farges, O.; Schick, V. Influence of radiation heat transfer on parallel hot-wire thermal conductivity measurements of semi-transparent materials at high temperature. Int. J. Therm. Sci. 2022, 179, 107690. [Google Scholar] [CrossRef]

- Schouten, M.A.; Tappi, S.; Glicerina, V.; Rocculi, P.; Angeloni, S.; Cortese, M.; Caprioli, S.; Vittori, S.; Romani, S. Formation of acrylamide in biscuits during baking under different heat transfer conditions. LWT 2022, 153, 112541. [Google Scholar] [CrossRef]

- Ruelland, E.; Zachowski, A. How plants sense temperature. Environ. Exp. Bot. 2010, 69, 225–232. [Google Scholar] [CrossRef]

- Holman, J.P. Heat Transfer, 10th ed.; Department of Mechanical Engineering Southern Methodist University: Dallas, TX, USA, 2010; pp. 6–7. [Google Scholar]

- Zhang, J.Q. Optimization analysis of high temperature workwear based on one-dimensional multilayer flat wall heat transfer process. J. Phys. Conf. Ser. 2019, 1300, 012025. [Google Scholar] [CrossRef]

- Mancin, S.; Zilio, C.; Diani, A.; Rossetto, L. Material and height effects on the heat transfer performance of metal foams cooled by air in forced convection. In Proceedings of the Conference Proceedings, AIP, Potsdam, Germany, 17–22 June 2012; pp. 231–236. [Google Scholar]

- Liu, C.; Tao, S.; Yang, S.; Wu, W.; Chen, S. Analysis on the influence of the exchange area on the heat exchange efficiency during far-infrared convection combination grain drying process. In Proceedings of the International Conference on Smart Grid and Electrical Automation (ICSGEA), Changsha, China, 27–28 May 2017. [Google Scholar]

- Scheffler, T.B.; Leao, A.J. Fabrication of polymer film heat transfer elements for energy efficient multi-effect distillation. J. Desalination 2008, 222, 696–710. [Google Scholar] [CrossRef]

- Ni, B.; Watanabe, T.; Phillpot, S.R. Thermal transport in polyethylene and at polyethylene–diamond interfaces investigatedusing molecular dynamics simulation. J. Phys. Condens. Matter. 2009, 21, 084219. [Google Scholar] [CrossRef] [PubMed]

- Niu, J.L.; Zhang, L.Z. Effects of wall thickness on the heat and moisture transfers in desiccant wheels for air dehumidification and enthalpy recovery. Int. Commun. Heat Mass Transf. 2002, 29, 255–268. [Google Scholar] [CrossRef]

- He, Y.; Li, X.; Ge, L.; Qian, Q.; Hu, W. Cross-plane thermal conductivity of thin films characterized by Flash DSC measurement. Thermochim. Acta 2019, 677, 21–25. [Google Scholar] [CrossRef]

- Söylemez, M.S. On the optimum heat exchanger sizing for heat recovery. Energy Convers. Manag. 2000, 41, 1419–1427. [Google Scholar] [CrossRef]

- Ding, K.; Calautit, J.K.; Jimenez-Bescos, C. Significance of external wind conditions on the convective heat transfer coefficients (CHTC) and energy performance in multi-zone high-rise buildings. Energy Build. 2024, 320, 114570. [Google Scholar] [CrossRef]

- Palyvos, J.A. A survey of wind convection coefficient correlations for building envelope energy systems’ modeling. Appl. Therm. Eng. 2008, 28, 801–808. [Google Scholar] [CrossRef]

- Li, B.; Guo, J.; Xia, J.; Wei, X.; Shen, H.; Cao, Y.; Lu, H.; Lü, E. Temperature distribution in insulated temperature-controlled container by numerical simulation. Energies 2020, 13, 4765. [Google Scholar] [CrossRef]

- Jaydeep, B.; Bharat, V. Temperature and velocity distribution in apple cold storage by CFD simulation. Int. J. Sci. Dev. Res. 2016, 1, 511–517. [Google Scholar]

- Zargar, O.A.; Liao, Y.A.; Hu, M.H.; Lin, T.; Shih, Y.C.; Hu, S.C.; Leggett, G. Design of an innovative flow isolation device (FID) as an air flow barrier to control the temperature of large storage areas in cold room applications. Int. J. Thermofluids 2024, 23, 100778. [Google Scholar] [CrossRef]

- Chen, M.; Zhao, J.; Zhang, Z.; Gu, C.; Wang, X. Influencing factors of thermal performance of small-size vaccine cold storage: An experiment-based parametric study. J. Energy Storage 2022, 51, 104496. [Google Scholar] [CrossRef]

- Dong, J.; Deng, S.; Jiang, Y.; Xia, L.; Yao, Y. An experimental study on defrosting heat supplies and energy consumptions during a reverse cycle defrost operation for an air source heat pump. J. Appl. Therm. Eng. 2012, 37, 380–387. [Google Scholar] [CrossRef]

- Qu, M.; Li, T.; Deng, S.; Fan, Y.; Li, Z. Improving defrosting performance of cascade air source heat pump using thermal energy storage based reverse cycle defrosting method. Appl. Therm. Eng. 2017, 121, 728–736. [Google Scholar] [CrossRef]

- Ye, Z.; Wang, Y.; Yin, X.; Song, Y.; Cao, F. Comparison between reverse cycle and hot gas bypass defrosting methods in a transcritical CO2 heat pump water heater. Appl. Therm. Eng. 2021, 196, 117356. [Google Scholar] [CrossRef]

- Jang, J.Y.; Bae, H.H.; Lee, S.J.; Ha, M.Y. Continuous heating of an air-source heat pump during defrosting and improvement of energy efficiency. Appl. Energy 2013, 110, 9–16. [Google Scholar] [CrossRef]

- Melo, C.; Knabben, F.T.; Pereira, P.V. An experimental study on defrost heaters applied to frost-free household refrigerators. Appl. Therm. Eng. 2013, 51, 239–245. [Google Scholar] [CrossRef]

- Alexander, L.D.; Jakhar, S.; Dasgupta, M.S. Influence of pallet height on energy consumption and cooling effectiveness in an apple cold storage. Sci. Rep. 2025, 15, 11534. [Google Scholar] [CrossRef]

- Li, H.; Yin, Y.; Affandi Fahrizal, Y.; Zhong, C.; Schouten Rob, E.; Woltering Ernst, J. High CO2 Reduces Spoilage Caused by Botrytis cinerea in Strawberry Without Impairing Fruit Quality. Front. Plant Sci. 2022, 13, 842317. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, P.; Niu, T.; He, D.; Wang, M.; Yang, H.; Zhao, X. Soluble solid content and firmness index assessment and maturity discrimination of Malus micromalus Makino based on near-infrared hyperspectral imaging. Food Chem. 2022, 370, 131013. [Google Scholar] [CrossRef] [PubMed]

| Name | Apple | Cucumber | Kiwi Fruit | Orange | Banana | Onion | Eggplant |

|---|---|---|---|---|---|---|---|

| Freezing Point (°C) | ~3–3.8 | ~2.5–2.7 | ~3.3–3.7 | ~1.5–1.6 | 2~.2–2.7 | ~1.8–2.0 | ~2.2–2.8 |

| Cold Storage Operation Time (h) | Defrosting Unit Energy Consumption (kWh) | Melting Water Volume (kg) | Melting Heat Absorption Q (kJ) | Melting Heat Absorption Energy Consumption (kWh) | Defrosting Waste Heat (kWh) | Defrosting Energy Consumption Utilization Rate |

|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | 0 | |

| 12 | 2.448 | 1.426 | 530.743 | 0.149 | 2.302 | 6.09% |

| 24 | 5.264 | 2.907 | 1081.986 | 0.299 | 4.964 | 5.68% |

| 36 | 7.956 | 4.419 | 1644.618 | 0.457 | 7.499 | 5.74% |

| 48 | 10.649 | 5.876 | 2186.750 | 0.608 | 10.041 | 5.71% |

| 60 | 13.219 | 7.399 | 2753.937 | 0.765 | 12.455 | 5.79% |

| 72 | 15.425 | 8.899 | 3312.014 | 0.921 | 14.503 | 5.97% |

| 84 | 17.871 | 10.349 | 3851.869 | 1.071 | 16.800 | 5.99% |

| 96 | 20.319 | 11.812 | 4396.278 | 1.222 | 19.097 | 6.01% |

| 108 | 22.277 | 13.232 | 4924.742 | 1.369 | 20.908 | 6.15% |

| 120 | 24.603 | 14.701 | 5471.429 | 1.520 | 23.083 | 6.18% |

| 132 | 28.275 | 16.304 | 6068.229 | 1.686 | 26.590 | 5.96% |

| 144 | 30.968 | 17.608 | 6553.415 | 1.820 | 29.148 | 5.88% |

| 156 | 34.028 | 19.003 | 7072.768 | 1.965 | 32.063 | 5.77% |

| 168 | 36.359 | 20.588 | 7662.737 | 2.128 | 34.231 | 5.85% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, L.; Zheng, Y.; Jiang, Y.; Li, W.; Li, L.; Liu, B.; Li, B.; Li, X. Design and Research of a New Cold Storage: The Phase-Temperature Storage (PTS) to Reduce Evaporator Frosting. Foods 2025, 14, 1592. https://doi.org/10.3390/foods14091592

Duan L, Zheng Y, Jiang Y, Li W, Li L, Liu B, Li B, Li X. Design and Research of a New Cold Storage: The Phase-Temperature Storage (PTS) to Reduce Evaporator Frosting. Foods. 2025; 14(9):1592. https://doi.org/10.3390/foods14091592

Chicago/Turabian StyleDuan, Lihua, Yanli Zheng, Yunbin Jiang, Wenhan Li, Limei Li, Bin Liu, Bin Li, and Xihong Li. 2025. "Design and Research of a New Cold Storage: The Phase-Temperature Storage (PTS) to Reduce Evaporator Frosting" Foods 14, no. 9: 1592. https://doi.org/10.3390/foods14091592

APA StyleDuan, L., Zheng, Y., Jiang, Y., Li, W., Li, L., Liu, B., Li, B., & Li, X. (2025). Design and Research of a New Cold Storage: The Phase-Temperature Storage (PTS) to Reduce Evaporator Frosting. Foods, 14(9), 1592. https://doi.org/10.3390/foods14091592