Effects of Mechanical Damage for Different Type of Threshing Patterns on Wheat Storage Quality Traits

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Research Methods

2.2.1. Experiment for Counting Mold Colonies of Wheat Grains

2.2.2. Experiment for Testing Wheat Seed Vigor

2.2.3. Experiment for Testing Dry Basis 1000 Grain Weight

2.2.4. Experiment for Testing Germination Characteristics

2.2.5. Experiment for Testing Fatty Acid Value

2.3. Statistical Analysis of Data

3. Results

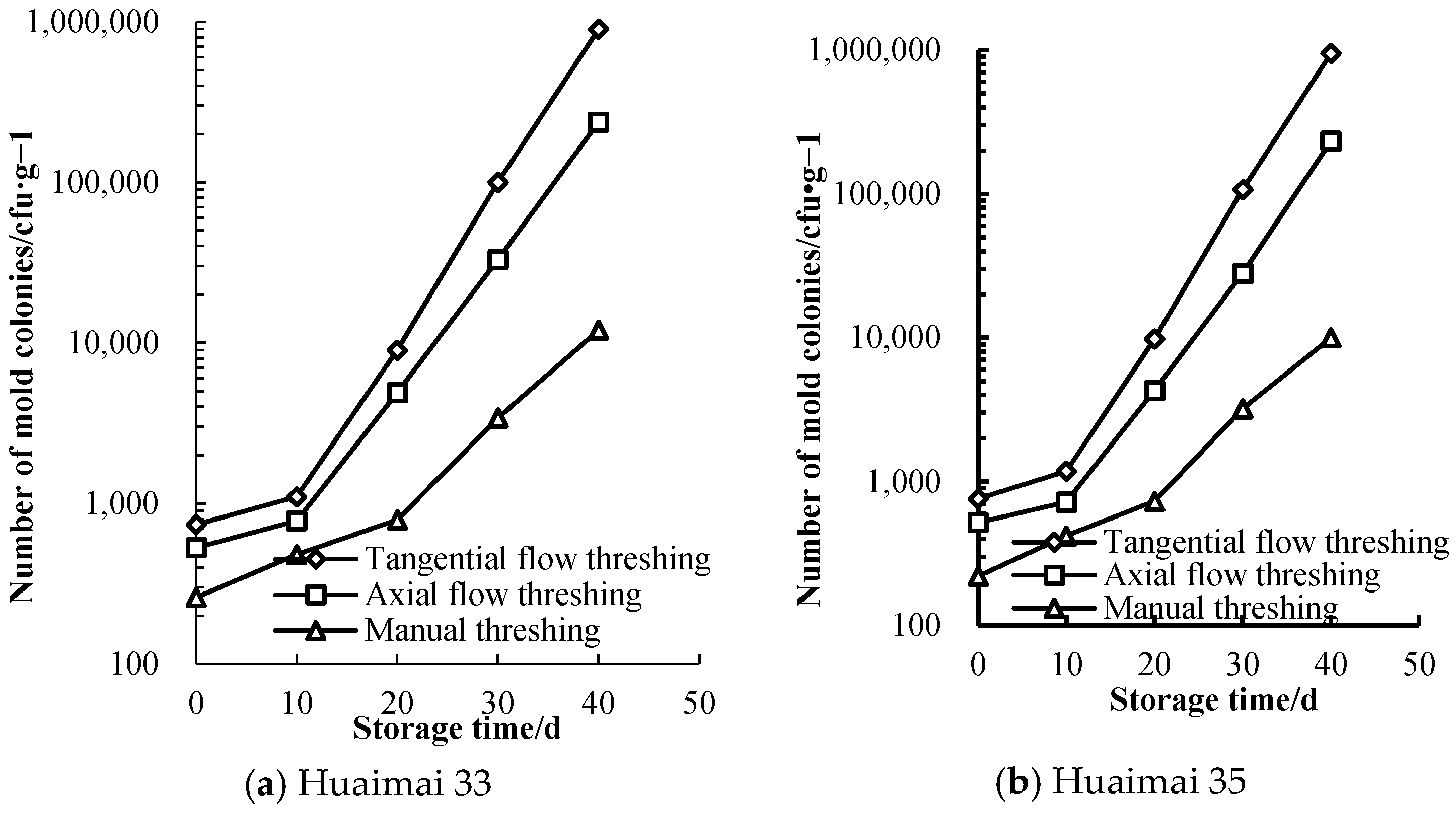

3.1. Characteristics of Mold Colonies of Wheat Grains

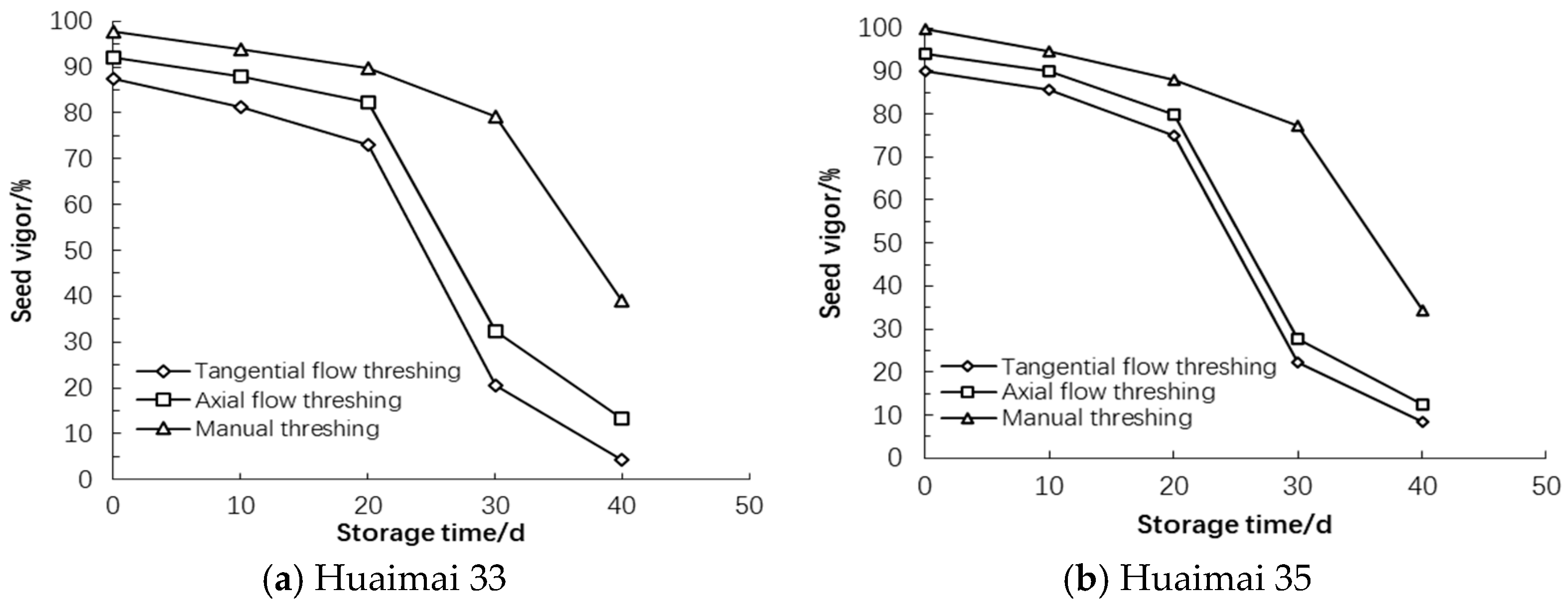

3.2. Characteristics of Wheat Seed Vigor

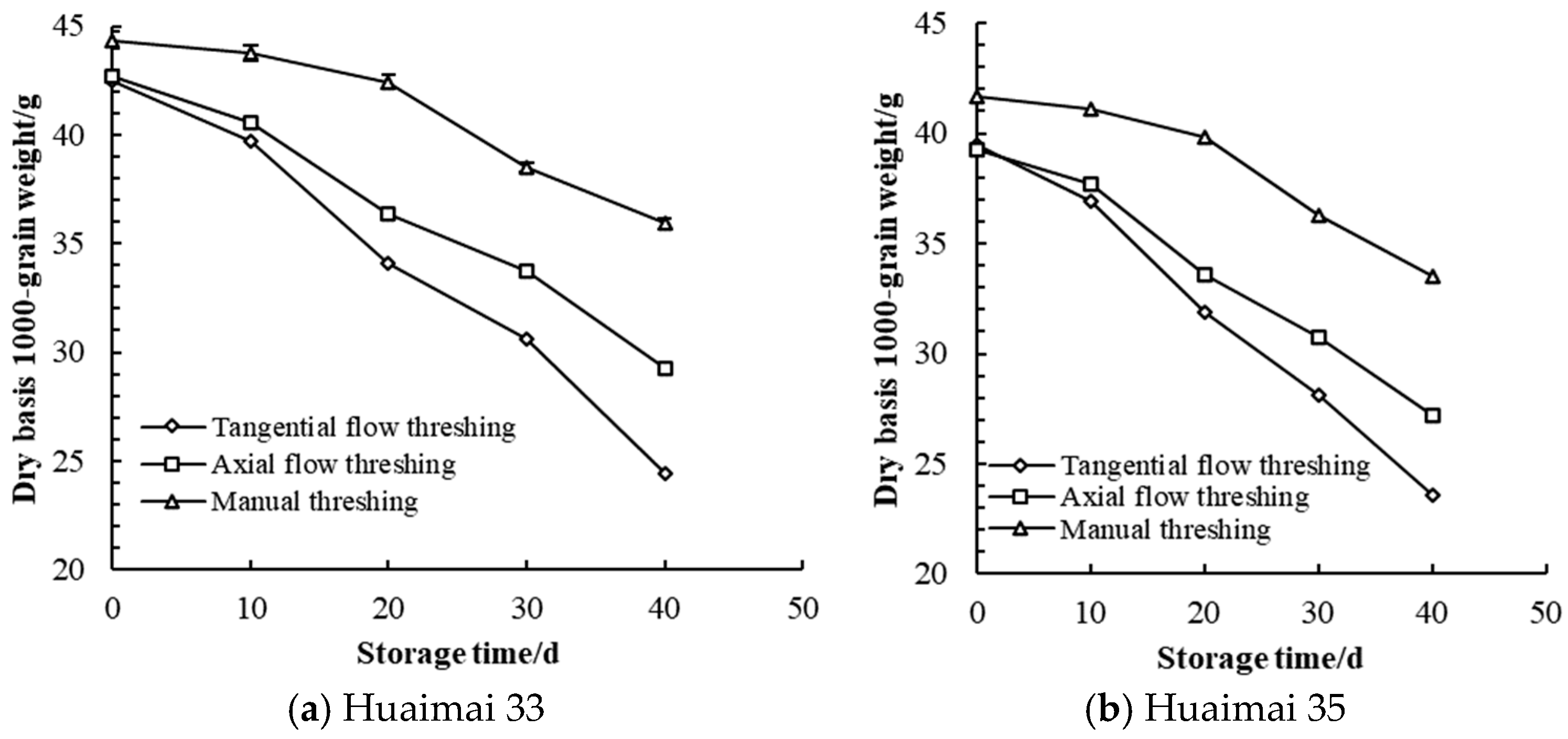

3.3. Characteristics of Wheat Dry Basis 1000 Grain Weight

3.4. Germination Characteristics

3.5. Characteristics of the Fatty Acid Value in Wheat Grains

3.6. Analysis of Correlation Between Wheat Storage Quality Traits and Mold Colonies of Wheat Grains

3.6.1. Analysis of Correlation Between Seed Vigor and Mold Colonies of Wheat Grains

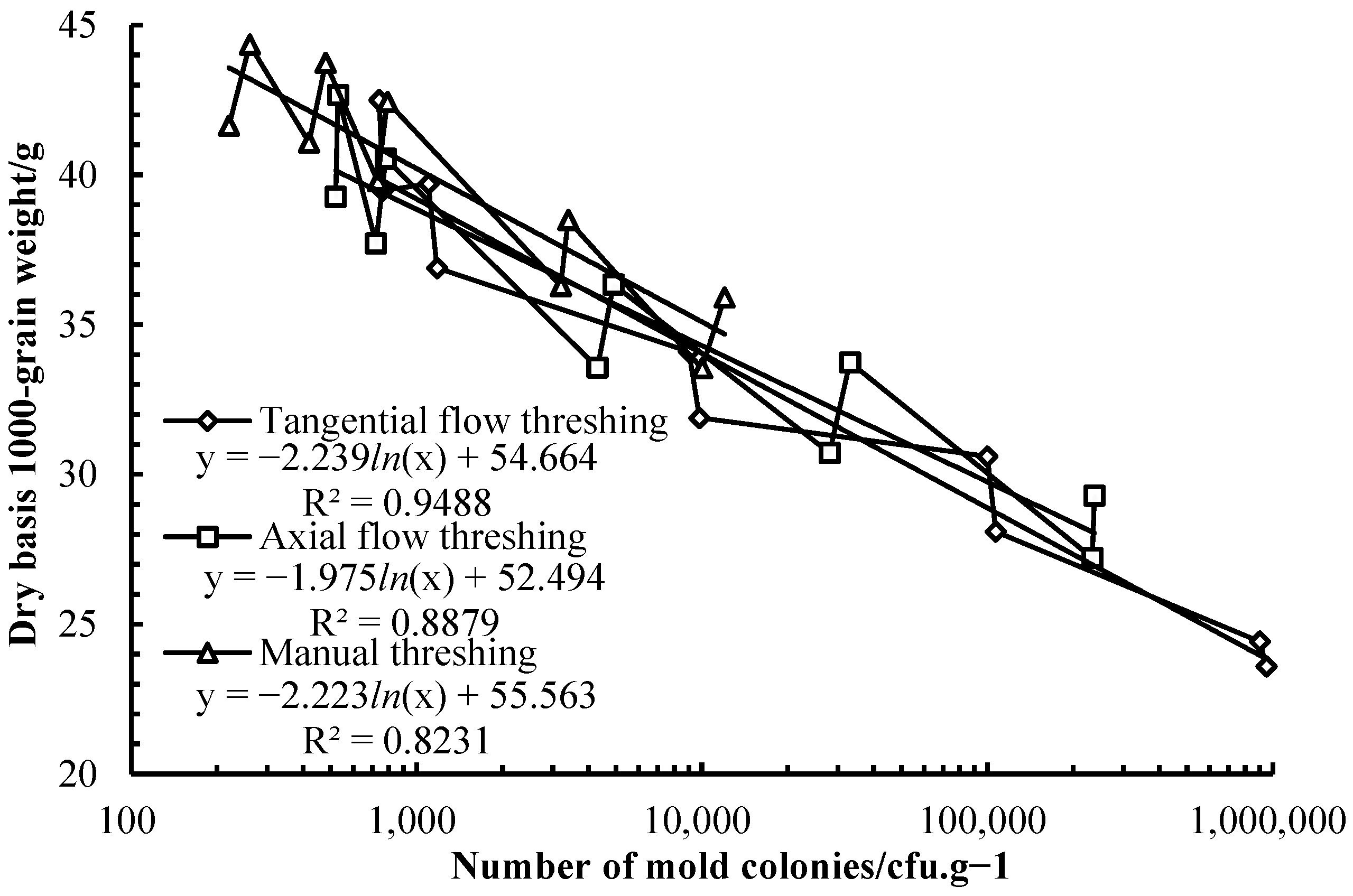

3.6.2. Analysis of Correlation Between the Dry Basis 1000 Grain Weight and Mold Colonies of Wheat Grains

3.6.3. Correlation Analysis Between Germination Characteristics Indexes and Mold Colonies of Wheat Grains

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shiju, M. A review on the effect of fungi on the wheat grain under post-harvest storage ecology. Food Environ. Saf.—J. Fac. Food Eng. 2010, 9, 87–96. [Google Scholar]

- Zhao, Y.J.; Han, X.X.; Guo, W.; Zhang, J.; Zheng, X.L.; Tian, J.Z. Study on influence of mildewing on wheat quality. J. Henan Univ. Technol. (Nat. Sci. Ed.) 2013, 34, 43–46. [Google Scholar]

- Wang, R.L.; Kong, X.G. Study on the changes and relativity of husked rice physiological activities under controlled atmosphere storage conditions. J. Henan Univ. Technol. (Nat. Sci. Ed.) 2011, 32, 5–9. [Google Scholar]

- Sun, H.; Jiang, W.L.; Nei, L. Changes of physiological activity and quality of wheat during storage. Cereals Oils Food Sci. Technol. 2011, 19, 1–3. [Google Scholar]

- Schmidt, M.; Horstmann, S.; De Colli, L.; Danaher, M.; Speer, K.; Zannini, E.; Arendt, E.K. Impact of fungal contamination of wheat on grain quality criteria. J. Cereal Sci. 2016, 69, 95–103. [Google Scholar] [CrossRef]

- Qi, Z.; Zhou, X.; Tian, L.; Zhang, H.; Lei, Y.; Tang, F. Assessment of wheat grain quality in China during harvest and storage using a mycobiome approach. Food Secur. 2024, 16, 1619–1632. [Google Scholar] [CrossRef]

- Xu, H.Y. The Effect of Temperature Fluctuation on Stored-Wheat Safe Moisture Content and Microbial Activity; Henan University of Technology: Zhengzhou, China, 2013. [Google Scholar]

- Wei, X. The Studies on Activity Characteristics of Fungus on Different Varieties of Wheat in the Process of Storage; Henan University of Technology: Zhengzhou, China, 2012. [Google Scholar]

- Adriana, L.; Zoe, M.; Mario, D.; Colin, W.; Severino, S.P. Distribution of microbial contamination within cereal grains. J. Food Eng. 2006, 72, 332–338. [Google Scholar]

- Sabina, M.T.; Renata, H.B.; Patrícia, Z.; Fábio, d.S.G.; Benedito, C. Fungal diversity and natural occurrence of deoxynivalenol and zearalenone in freshly harvested wheat grains from Brazil. Food Chem. 2016, 196, 445–450. [Google Scholar]

- Senatore, M.T.; Prodi, A.; Tini, F.; Balmas, V.; Infantino, A.; Onofri, A.; Cappelletti, E.; Oufensou, S.; Sulyok, M.; Covarelli, L.; et al. Different diagnostic approaches for the characterization of the fungal community and Fusarium species complex composition of Italian durum wheat grain and correlation with secondary metabolite accumulation. J. Sci. Food Agric. 2023, 103, 4503–4521. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Pei, F.; Fang, Y.; Li, P.; Xia, J.; Sun, L.; Zou, Y.Y.; Shen, F.; Hu, Q.H. Interactions among Fungal Community, Fusarium Mycotoxins, and Components of Harvested Wheat under Simulated Storage Conditions. J. Agric. Food Chem. 2019, 67, 8411–8418. [Google Scholar] [CrossRef]

- Wang, R.H.; Li, M.M.; Jin, R.; Liu, Y.X.; Guan, E.Q.; Mohamed, S.R.; Bian, K. Interactions among the composition changes in fungal communities and the main mycotoxins in simulated stored wheat grains. J. Sci. Food Agric. 2024, 104, 373–382. [Google Scholar] [CrossRef]

- Qi, Z.H.; Tian, L.; Zhang, H.Y.; Zhou, X.; Lei, Y.Q.; Tang, F. Mycobiome mediates the interaction between environmental factors and mycotoxin contamination in wheat grains. Sci. Total Environ. 2024, 928, 172494. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.L.; Liu, L.L.; Guo, Y.P.; He, X.; Lu, Q. Effects of deterioration and mildewing on the quality of wheat seeds with different moisture contents during storage. RSC Adv. 2020, 10, 14581–14594. [Google Scholar] [CrossRef]

- Chen, Z.; Wassgren, C.; Kingsly Ambrose, R.P. A review of grain kernel damage: Mechanisms, modeling, and testing procedures. Trans. ASABE 2020, 63, 455–475. [Google Scholar] [CrossRef]

- Derevjanko, D.; Holovach, I.; Bulgakov, V.; Kuvachev, V.; Olt, J. Theoretical and experimental research into impact of threshing tools in combine grain harvesters on quality of cereal crop seeds. Agron. Res. 2020, 18, 393–403. [Google Scholar]

- Xu, L.Z.; Li, Y.M.; Ma, Z.; Zhao, Z.; Wang, C.H. Theoretical analysis and finite element simulation of a rice kernel obliquely impacted by a threshing tooth. Biosyst. Eng. 2013, 114, 146–156. [Google Scholar]

- Lachuga, Y.F.; Bur’yanov, A.I.; Pakhomov, V.I.; Chervyakov, I.V. Adaptation of threshing devices to physical and mechanical characteristics of harvested crops. Russ. Agric. Sci. 2020, 46, 198–201. [Google Scholar] [CrossRef]

- Gu, R.L.; Huang, R.; Jia, G.Y.; Yuan, Z.P.; Ren, L.S.; Li, L.; Wang, J.H. Effect of mechanical threshing on damage and vigor of maize seed threshed at different moisture contents. J. Integr. Agric. 2019, 18, 1571–1578. [Google Scholar] [CrossRef]

- Li, Y.N.; Chen, J.S.; Ding, Q.S.; Ding, W.M. Effects of axial flow and tangential flow mechanical threshing on rice damage and processing quality. Trans. Chin. Soc. Agric. Eng. 2017, 33, 41–48. [Google Scholar]

- Li, L.; Li, Y.N.; Chen, Y.L.; Ding, Q.S.; He, R.Y. Study on storage quality of japonica rice by different mechanical threshing and its relevance. Sci. Technol. Food Ind. 2020, 41, 299–304. [Google Scholar]

- Neme, K.; Mohammed, A. Mycotoxin occurrence in grains and the role of postharvest management as a mitigation strategies. A review. Food Control 2017, 78, 412–425. [Google Scholar] [CrossRef]

- Masek, J.; Kumhala, F.; Novak, P.; Fic, T. Influence of different threshing system design on grain damage. In Proceedings of the 15th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 25–27 May 2016; pp. 756–761. [Google Scholar]

- Wei, L.J. The Design of Plot Wheat Breeding Threshing Machine and Research on It’s Low Damage Characteristics; Gansu Agricultural University: Lanzhou, China, 2016. [Google Scholar]

- Javad, K.; Feizollah, S.; Jafar, M.; Mehdi, N.; Mohammad, H.K. Evaluation and modeling of physical and physiological damage to wheat seeds under successive impact loadings: Mathematical and neural networks modeling. Crop Sci. 2008, 48, 1532–1544. [Google Scholar]

- Som, B.; Pao, S.; late Hourn, S.; Yim, S.; Sareth, C.; Makara, O.; Chao, S.; Nob, L.; Hel, S.; Yong, R.; et al. Fissured grain and head rice yield of crops harvested manually or by combine at different ripening stages in Cambodia. Plant Prod. Sci. 2019, 22, 88–97. [Google Scholar] [CrossRef]

- Warzecha, T.; Zieliński, A.; Skrzypek, E.; Wójtowicz, T.; Moś, M. Effect of mechanical damage on vigor, physiological parameters, and susceptibility of oat (Avena sativa) to Fusarium culmorum infection. Phytoparasitica 2012, 40, 29–36. [Google Scholar] [CrossRef]

- GB 4789.15-2016 [s]; National Food Safety Standard-Microbiological Examination of Food-Count of Molds and Yeasts. Standards Press of China: Beijing, China, 2016.

- Bi, X.H.; Dai, X.W. Seed Science; China Agriculture Press: Beijing, China, 2011; p. 70. [Google Scholar]

- GB/T 5519-2018 [S]; Grains and Pulses-Determination of the Mass of 1000 Grains. Standards Press of China: Beijing, China, 2018.

- GB/T3543.4-1995 [S]; Rules for Agricultural Seed Testing-Germination Test. Standards Press of China: Beijing, China, 1995.

- GB 5510-2011 [S]; Inspection of Grain and Oils-Determination of Fat Acidity Value of Grain and Oilseeds. Standards Press of China: Beijing, China, 2011.

- Wan, Z.M.; Wu, L. The wheat quality deterioration in different storage temperature. Cereals Oils Food Sci. Technol. 2005, 13, 6–7. [Google Scholar]

- Xu, Z.F.; Zhang, H.Y.; Zhang, D.Y. Wheat Quality and Its Improvement; Meteorological Press: Beijing, China, 2000; pp. 43–45. [Google Scholar]

- Ma, H.; Zhang, L.J.; Liu, C. Fatty acid value as an index of wheat storage quality control. Food Process. 2013, 38, 73–74. [Google Scholar]

- Tian, P.P.; Lv, Y.Y.; Yuan, W.J.; Zhang, S.B.; Hu, Y.S. Effect of artificial aging on wheat quality deterioration during storage. J. Stored Prod. Res. 2019, 80, 50–56. [Google Scholar] [CrossRef]

- Guo, L.L. The change law on fatty acid value of stored wheat flour. Grain Storage 2006, 35, 46–48. [Google Scholar]

- Garcia-Cela, E.; Kiaitsi, E.; Sulyok, M.; Medina, A.; Magan, N. Fusarium graminearum in stored wheat: Use of CO2 production to quantify dry matter losses and relate this to relative risks of zearalenone contamination under interacting environmental conditions. Toxins 2018, 10, 86. [Google Scholar] [CrossRef]

- Zhang, S.B.; Lv, Y.Y.; Wang, Y.L.; Jia, F.; Wang, J.S.; Hu, Y.S. Physiochemical changes in wheat of different hardnesses during storage. J. Stored Prod. Res. 2017, 72, 161–165. [Google Scholar] [CrossRef]

| Cultivar | Threshing Methods | Germination Potential | Germination Rate | Aberrations | Mold Colonies in Seedling Root |

|---|---|---|---|---|---|

| Huaimai 33 | TFT (before storage) | 81.00 ± 2.65 c | 81.67 ± 2.08 c | 16.67 ± 1.53 a | 32.67 ± 4.04 a |

| TFT (after storage) | 3.33 ± 0.58 c | 4.00 ± 0.00 c | 95.67 ± 0.58 a | 99.33 ± 0.58 a | |

| AFT (before storage) | 86.67 ± 2.31 b | 87.33 ± 3.06 b | 11.00 ± 4.00 b | 26.33 ± 1.58 b | |

| AFT (after storage) | 12.00 ± 0.00 b | 13.67 ± 0.58 b | 86.67 ± 0.58 b | 89.67 ± 0.58 b | |

| Manual threshing (before storage) | 97.00 ± 2.00 a | 97.67 ± 1.53 a | 1.00 ± 1.00 c | 14.00 ± 2.00 c | |

| Manual threshing (after storage) | 34.00 ± 0.00 a | 35.00 ± 1.00 a | 64.67 ± 0.58 c | 75.67 ± 0.58 c | |

| Huaimai 35 | TFT (before storage) | 82.33 ± 1.53 c | 82.33 ± 1.53 c | 17.00 ± 1.00 a | 32.33 ± 2.89 a |

| TFT (after storage) | 7.33 ± 1.53 c | 8.00 ± 1.73 c | 91.67 ± 1.53 a | 98.33 ± 0.58 a | |

| AFT (before storage) | 89.00 ± 1.00 b | 89.33 ± 1.15 b | 10.33 ± 1.53 b | 23.33 ± 3.06 b | |

| AFT (after storage) | 11.67 ± 0.58 b | 12.00 ± 0.00 b | 87.33 ± 0.58 b | 90.33 ± 0.58 b | |

| Manual threshing (before storage) | 98.67 ± 0.58 a | 98.67 ± 0.58 a | 1.33 ± 0.58 c | 12.33 ± 0.58 c | |

| Manual threshing (after storage) | 30.33 ± 0.58 a | 31.33 ± 1.16 a | 69.00 ± 1.00 c | 74.67 ± 0.58 c |

| Cultivar | Storage Time (d) | TFT | AFT | Manual Threshing |

|---|---|---|---|---|

| Huaimai 33 | 0 | 19.2 | 19.2 | 17.9 |

| 10 | 25.9 | 23.2 | 19.3 | |

| 20 | 55.0 | 50.9 | 37.8 | |

| 30 | 91.4 | 88.4 | 51.3 | |

| 40 | 86.9 | 85.4 | 85.2 | |

| Huaimai 35 | 0 | 15.4 | 15.4 | 14.1 |

| 10 | 22.0 | 20.6 | 19.3 | |

| 20 | 48.5 | 44.4 | 36.5 | |

| 30 | 96.7 | 92.5 | 42.2 | |

| 40 | 88.3 | 82.7 | 89.2 |

| Wheat Germination Characteristics Indexes Before Storage | Correlation Coefficient | Wheat Germination Characteristics Indexes After Storage | Correlation Coefficient |

|---|---|---|---|

| Germination potential | −0.964 ** | Germination potential | −0.825 ** |

| Germination rate | −0.965 ** | Germination rate | −0.829 ** |

| Aberrations | 0.962 ** | Aberrations | 0.826 ** |

| Mold colonies in seedling root | 0.962 ** | Mold colonies in seedling root | 0.904 ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Li, Y.; Chen, Y.; Ding, Q.; He, R.; Liu, Y. Effects of Mechanical Damage for Different Type of Threshing Patterns on Wheat Storage Quality Traits. Foods 2025, 14, 1577. https://doi.org/10.3390/foods14091577

Li L, Li Y, Chen Y, Ding Q, He R, Liu Y. Effects of Mechanical Damage for Different Type of Threshing Patterns on Wheat Storage Quality Traits. Foods. 2025; 14(9):1577. https://doi.org/10.3390/foods14091577

Chicago/Turabian StyleLi, Ling, Yinian Li, Yulun Chen, Qishuo Ding, Ruiyin He, and Yingying Liu. 2025. "Effects of Mechanical Damage for Different Type of Threshing Patterns on Wheat Storage Quality Traits" Foods 14, no. 9: 1577. https://doi.org/10.3390/foods14091577

APA StyleLi, L., Li, Y., Chen, Y., Ding, Q., He, R., & Liu, Y. (2025). Effects of Mechanical Damage for Different Type of Threshing Patterns on Wheat Storage Quality Traits. Foods, 14(9), 1577. https://doi.org/10.3390/foods14091577