Study of the Impact of Operating Parameters and the Addition of Fat on the Physicochemical and Texture Properties of Extruded Snacks

Abstract

1. Introduction

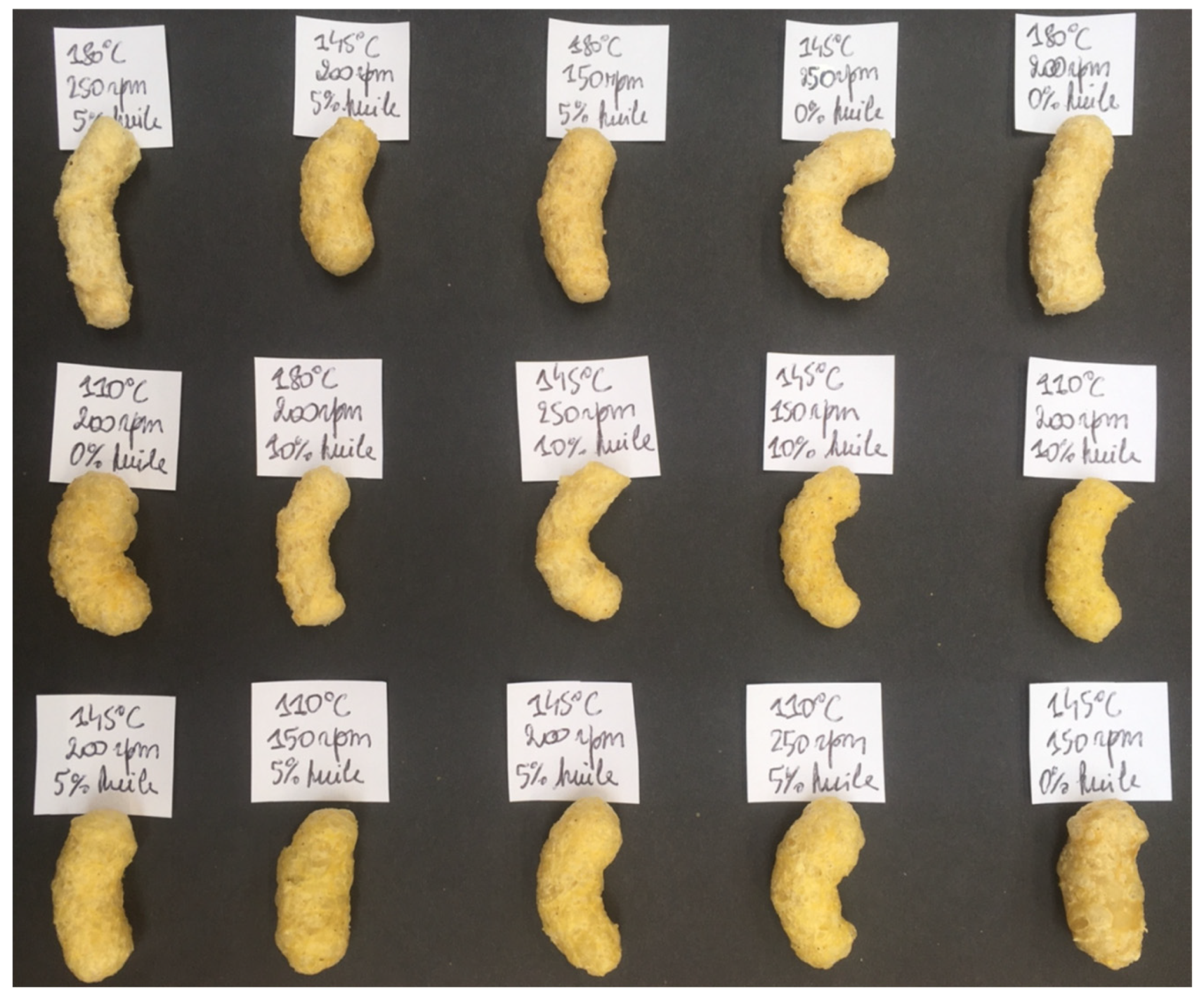

2. Materials and Methods

2.1. Material and Sample Preparation

2.2. Extrusion

2.3. Specific Mechanical Energy (SME)

2.4. Sample Characterization

2.4.1. Textural Properties

Expansion

Bulk Density

Hardness and Crispness

2.4.2. Physicochemical Properties

Water Activity (aw)

Dry Matter (DM)

Water Absorption Index (WAI) and Water Solubility Index (WSI)

X-Ray Diffraction (XRD)

2.5. Response Surface Methodology (RSM)

3. Results and Discussion

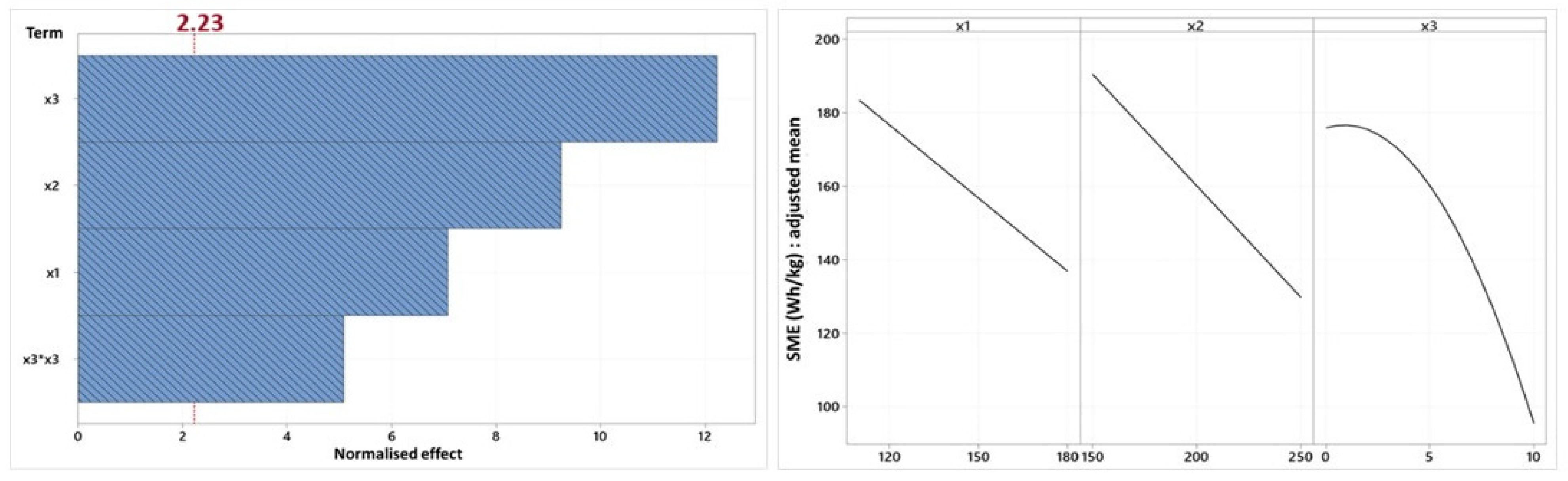

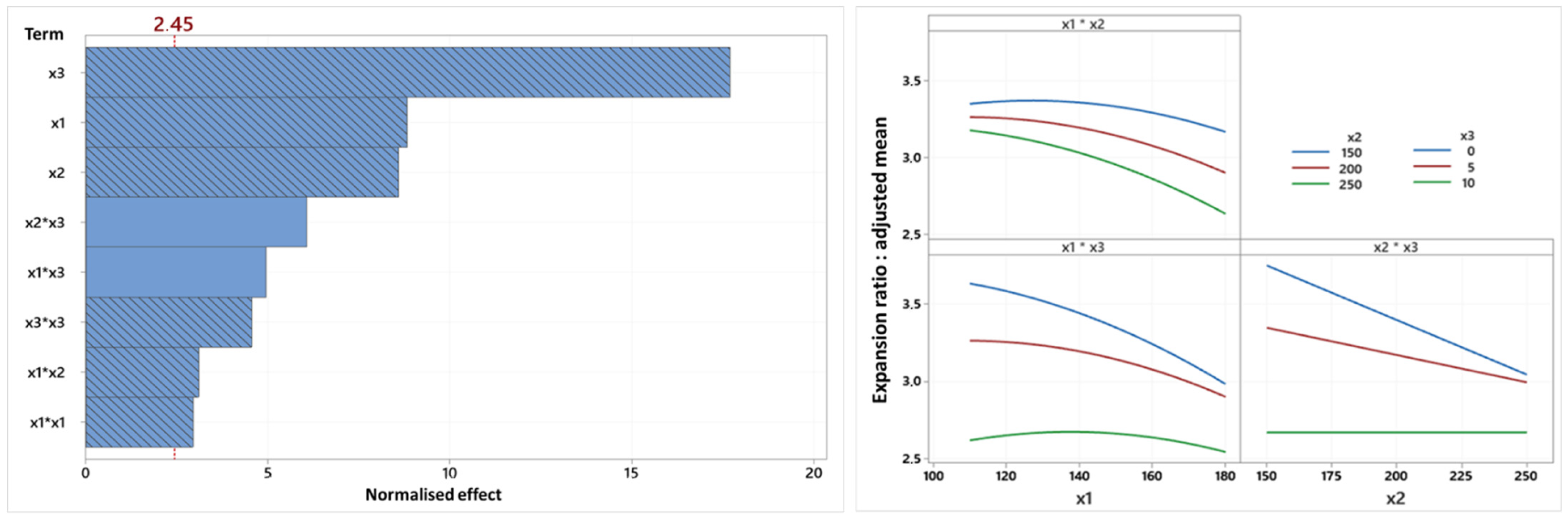

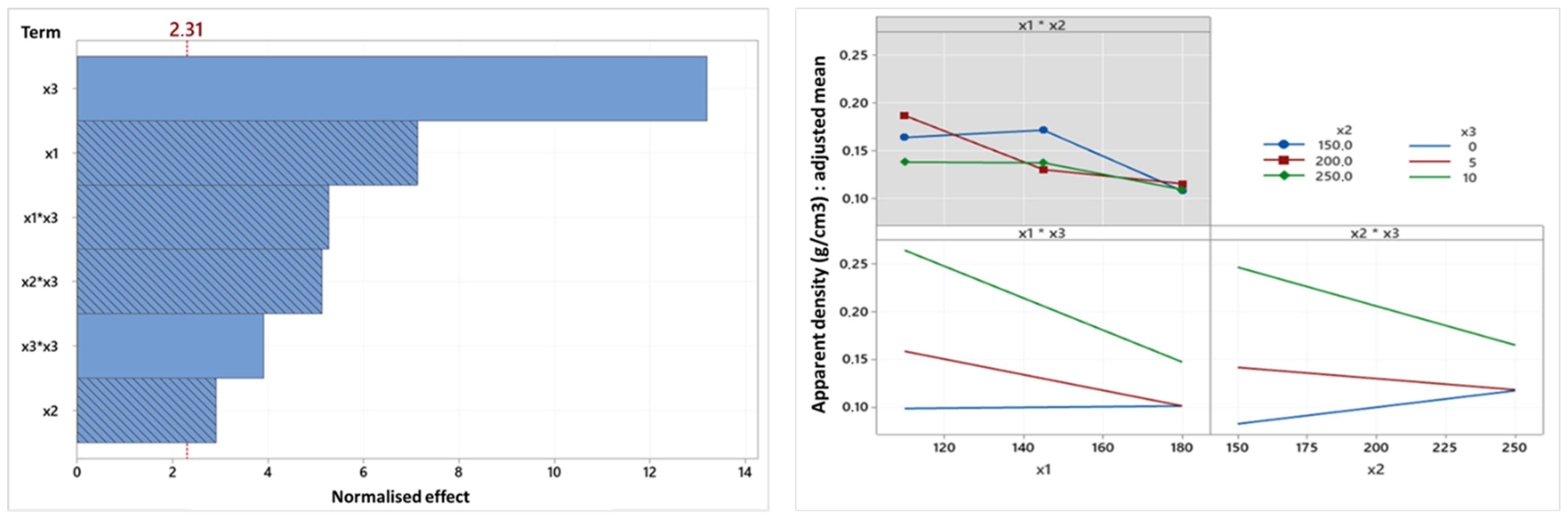

3.1. Prediction Models

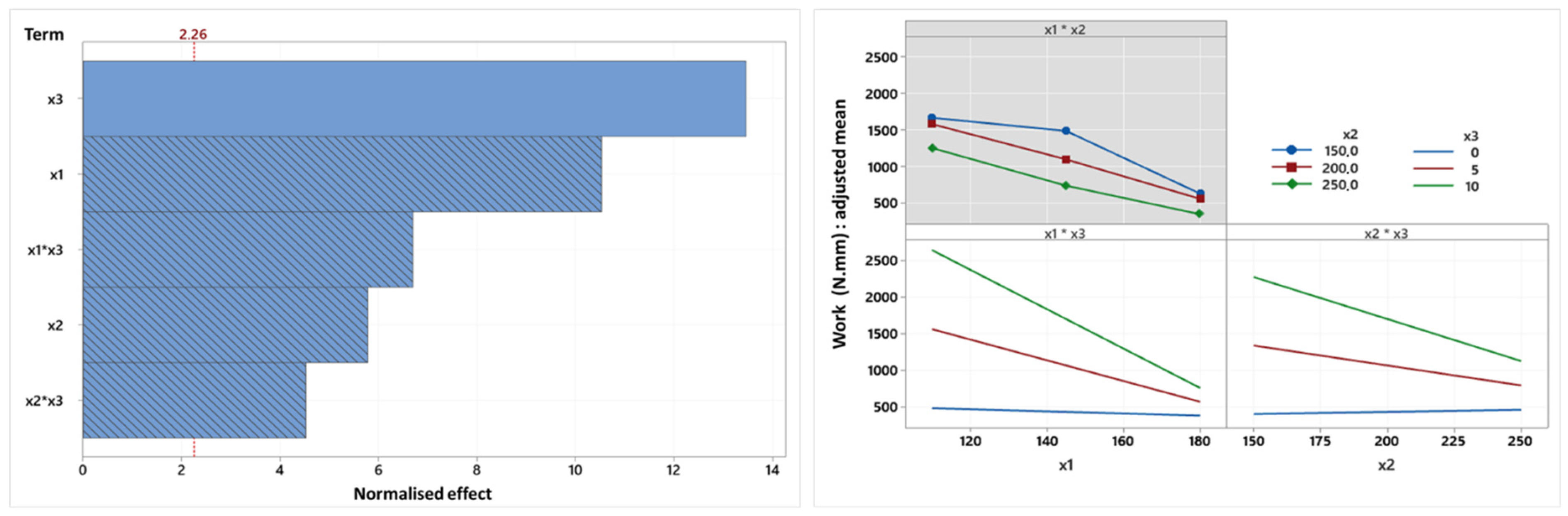

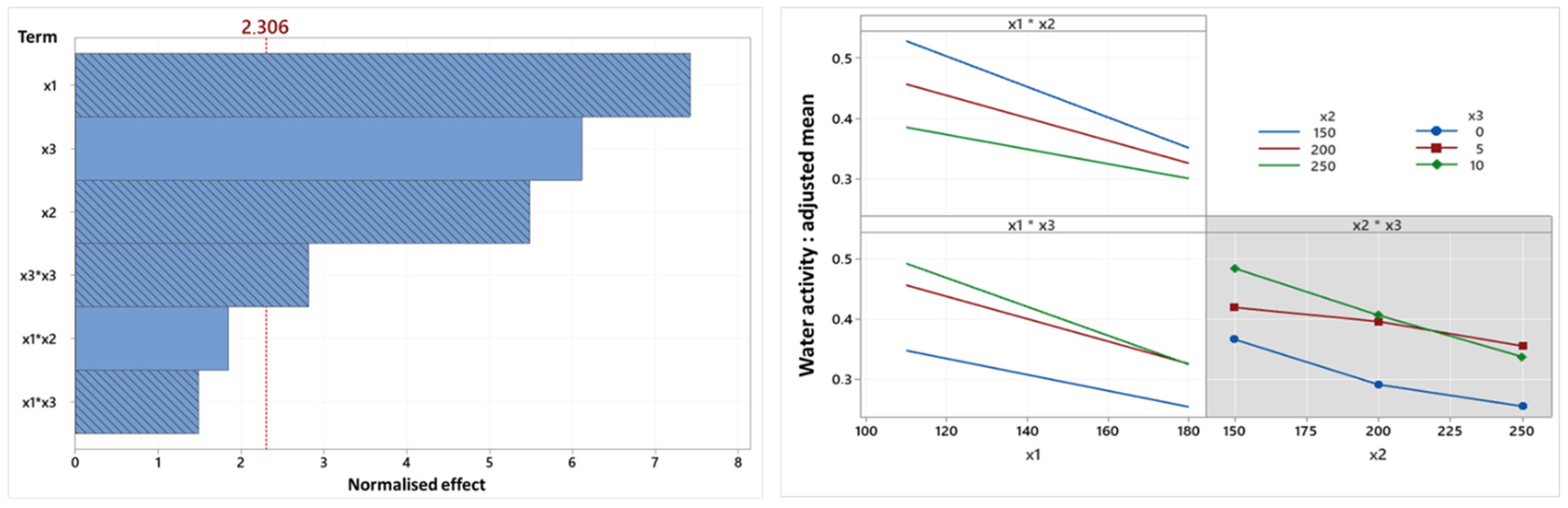

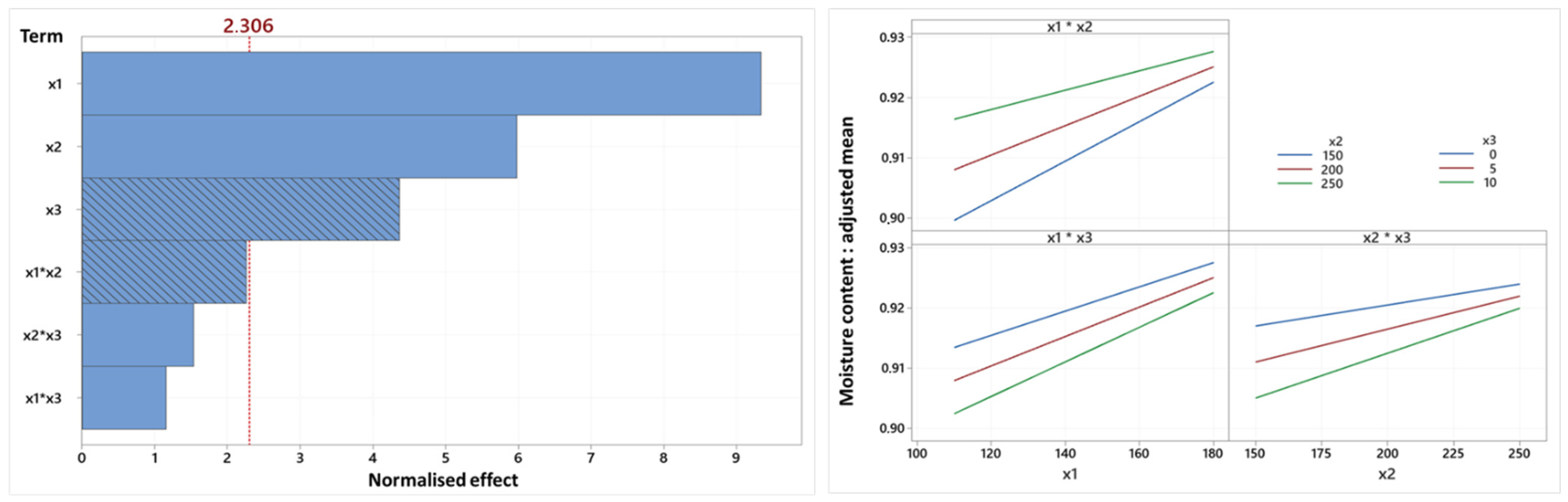

3.2. Impact of Operating Parameters and Oil Content on the Properties of Extruded Snacks

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hegazy, H.S.; El-Fath, A.; El-Bedawey, A.; Rahma, E.-S.H.; Gaafar, A.M. Effect of Extrusion Process on Nutritional, Functional Properties and Antioxidant Activity of Germinated Chickpea Incorporated Corn Extrudates. Am. J. Food Sci. Nutr. Res. 2017, 4, 59–66. [Google Scholar]

- Pasqualone, A.; Costantini, M.; Coldea, T.E.; Summo, C. Use of Legumes in Extrusion Cooking: A Review. Foods 2020, 9, 958. [Google Scholar] [CrossRef] [PubMed]

- Brennan, M.A.; Derbyshire, E.; Tiwari, B.K.; Brennan, C.S. Ready-to-Eat Snack Products: The Role of Extrusion Technology in Developing Consumer Acceptable and Nutritious Snacks. Int. J. Food Sci. Technol. 2013, 48, 893–902. [Google Scholar] [CrossRef]

- Nor, N.M.; Carr, A.; Hardacre, A.; Brennan, C.S. The Development of Expanded Snack Product Made from Pumpkin Flour-Corn Grits: Effect of Extrusion Conditions and Formulations on Physical Characteristics and Microstructure. Foods 2013, 2, 160–169. [Google Scholar] [CrossRef]

- Pankyamma, V.; Basu, S.; Bhadran, S.S.; Chouksey, M.K.; Gudipati, V. Fish Oil-Fortified Extruded Snacks: Evaluation of Physical Properties and Oxidative Stability by Response Surface Methodology. J. Food Process. Eng. 2014, 37, 349–361. [Google Scholar] [CrossRef]

- Offiah, V.; Kontogiorgos, V.; Falade, K.O. Extrusion Processing of Raw Food Materials and By-Products: A Review. Crit. Rev. Food Sci. Nutr. 2019, 59, 2979–2998. [Google Scholar] [CrossRef]

- Bresciani, A.; Giordano, D.; Vanara, F.; Blandino, M.; Marti, A. The Effect of the Amylose Content and Milling Fractions on the Physico-Chemical Features of Co-Extruded Snacks from Corn. Food Chem. 2021, 343, 128503. [Google Scholar] [CrossRef]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and Extruded Products: Changes in Quality Attributes as Affected by Extrusion Process Parameters: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef]

- Adekola, K.A. Engineering Review Food Extrusion Technology and Its Applications. J. Food Sci. Eng. 2016, 6, 149–168. [Google Scholar] [CrossRef][Green Version]

- Chokshi, R.; Zia, H. Hot-Melt Extrusion Technique: A Review. Iran. J. Pharm. Res. 2004, 3, 3–16. [Google Scholar]

- Singh, S.; Gamlath, S.; Wakeling, L. Nutritional Aspects of Food Extrusion: A Review. Int. J. Food Sci. Technol. 2007, 42, 916–929. [Google Scholar] [CrossRef]

- Sharma, R.; Kumar, R.; Srivastava, T.; Saxena, D.C. Textural and Microstructural Properties of Extruded Snack Prepared from Rice Flour, Corn Flour and Deoiled Rice Bran by Twin Screw Extrusion. Intern. J. Comput. Appl. ICAET 2015, 1, 33–38. [Google Scholar]

- Moisio, T.; Forssell, P.; Partanen, R.; Damerau, A.; Hill, S.E. Reorganisation of Starch, Proteins and Lipids in Extrusion of Oats. J. Cereal Sci. 2015, 64, 48–55. [Google Scholar] [CrossRef]

- Falk, A.; Fuhrmann, A.; Jacke, K.; Schmitt, J.J. Influence of Oil on Extrusion Cooking Process of Maize Semolina in a Twin Screw Extruder. Adv. J. Food Sci. Technol. 2017, 13, 100–103. [Google Scholar] [CrossRef]

- Gujral, H.S.; Singh, N.; Singh, B. Extrusion Behaviour of Grits from Flint and Sweet Corn. Food Chem. 2001, 74, 303–308. [Google Scholar] [CrossRef]

- Pastor-Cavada, E.; Drago, S.R.; González, R.J.; Juan, R.; Pastor, J.E.; Alaiz, M.; Vioque, J. Effects of the Addition of Wild Legumes (Lathyrus annuus and Lathyrus clymenum) on the Physical and Nutritional Properties of Extruded Products Based on Whole Corn and Brown Rice. Food Chem. 2011, 128, 961–967. [Google Scholar] [CrossRef]

- Christofides, V.; Ainsworth, P.; Ìbanoǧlu, Ş.; Gomes, F. Physical Evaluation of a Maize-Based Extruded Snack with Curry Powder. Nahrung/Food. 2004, 48, 61–64. [Google Scholar] [CrossRef]

- Rodríguez-Miranda, J.; Ruiz-López, I.I.; Herman-Lara, E.; Martínez-Sánchez, C.E.; Delgado-Licon, E.; Vivar-Vera, M.A. Development of Extruded Snacks Using Taro (Colocasia esculenta) and Nixtamalized Maize (Zea mays) Flour Blends. LWT—Food Sci. Technol. 2011, 44, 673–680. [Google Scholar] [CrossRef]

- O’Shea, N.; Arendt, E.; Gallagher, E. Enhancing an Extruded Puffed Snack by Optimising Die Head Temperature, Screw Speed and Apple Pomace Inclusion. Food Bioprocess Technol. 2014, 7, 1767–1782. [Google Scholar] [CrossRef]

- Malumba, P.; Janas, S.; Deroanne, C.; Masimango, T.; Béra, F. Structure de l’Amidon de Maïs et Principaux Phénomènes Impliqués Dans Sa Modification Thermique. Biotechnol. Agron. Soc. Environ. 2011, 15, 315–326. [Google Scholar]

- Bhattacharya, S. Extrusion Technology and Glass Transition. In Non-Equilibrium States and Glass Transitions in Foods: Processing Effects and Product-Specific Implications; Bhandari, B., Roos, Y.H., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 137–152. [Google Scholar] [CrossRef]

- Bisharat, G.I.; Oikonomopoulou, V.P.; Panagiotou, N.M.; Krokida, M.K.; Maroulis, Z.B. Effect of Extrusion Conditions on the Structural Properties of Corn Extrudates Enriched with Dehydrated Vegetables. Food Res. Int. 2013, 53, 1–14. [Google Scholar] [CrossRef]

- Steel, C.; Vernaza Leoro, M.G.; Schmiele, M.; Eduardo, R.; Kil, Y. Thermoplastic Extrusion in Food Processing. Thermoplast. Elastomers. 2012, 265, 290. [Google Scholar] [CrossRef]

- Guha, M.; Ali, S.Z.; Bhattacharya, S. Twin-Screw Extrusion of Rice Flour Without a Die: Effect of Barrel Temperature and Screw Speed on Extrusion and Extrudate Characteristics. J. Food Eng. 1997, 32, 251–267. [Google Scholar] [CrossRef]

- Robin, F.; Schuchmann, H.P.; Palzer, S. Dietary Fiber in Extruded Cereals: Limitations and Opportunities. Trends Food Sci. Technol. 2012, 28, 23–32. [Google Scholar] [CrossRef]

- Kaisangsri, N.; Kowalski, R.J.; Wijesekara, I.; Kerdchoechuen, O.; Laohakunjit, N.; Ganjyal, G.M. Carrot Pomace Enhances the Expansion and Nutritional Quality of Corn Starch Extrudates. LWT—Food Sci. Technol. 2016, 68, 391–399. [Google Scholar] [CrossRef]

- Cortés, R.N.F.; Guzmán, I.V.; Martínez-Bustos, F. Effects of Some Extrusion Variables on Physicochemical Characteristics of Extruded Corn Starch-Passion Fruit Pulp (Passiflora edulis) Snacks. Plant Foods Hum. Nutr. 2014, 69, 365–371. [Google Scholar] [CrossRef]

- Fernández-Gutiérrez, J.A.; Martín-Martínez, E.S.; Martínez-Bustos, F.; Cruz-Orea, A. Physicochemical Properties of Casein-Starch Interaction Obtained by Extrusion Process. Starch/Staerke 2004, 56, 190–198. [Google Scholar] [CrossRef]

- Chaudhary, D.P.; Kumar, D.; Verma, R.P.S.; Langyan, S.; Sangwan, S. Maize Malting: Retrospect and Prospect, 1st ed.; Chaudhary, D.P., Kumar, S., Langyan, S., Eds.; Springer: New Delhi, India, 2014. [Google Scholar] [CrossRef]

- Chao, C.; Yu, J.; Wang, S.; Copeland, L.; Wang, S. Mechanisms Underlying the Formation of Complexes between Maize Starch and Lipids. J. Agric. Food Chem. 2018, 66, 272–278. [Google Scholar] [CrossRef]

- Thachil, M.T.; Chouksey, M.K.; Gudipati, V. Amylose-Lipid Complex Formation during Extrusion Cooking: Effect of Added Lipid Type and Amylose Level on Corn-Based Puffed Snacks. Int. J. Food Sci. Technol. 2013, 49, 309–316. [Google Scholar] [CrossRef]

- Panyoo, A.E.; Emmambux, M.N. Amylose–Lipid Complex Production and Potential Health Benefits: A Mini-Review. Starch/Staerke 2017, 69, 1600203. [Google Scholar] [CrossRef]

- Ilo, S.; Schoenlechner, R.; Berghofe, E. Role of Lipids in the Extrusion Cooking Processes. Grasas y Aceites 2000, 51, 97–110. [Google Scholar] [CrossRef]

- Ye, J.; Hu, X.; Luo, S.; Liu, W.; Chen, J.; Zeng, Z.; Liu, C. Properties of Starch after Extrusion: A Review. Starch/Staerke 2018, 70, 1700110. [Google Scholar] [CrossRef]

- Selani, M.M.; Brazaca, S.G.C.; Dos Santos Dias, C.T.; Ratnayake, W.S.; Flores, R.A.; Bianchini, A. Characterisation and Potential Application of Pineapple Pomace in an Extruded Product for Fibre Enhancement. Food Chem. 2014, 163, 23–30. [Google Scholar] [CrossRef] [PubMed]

- Navale, S.A.; Swami, S.B.; Thakor, N.J. Extrusion Cooking Technology for Foods: A Review. J. Ready Eat Food 2015, 2, 66–80. [Google Scholar]

- Ramos Diaz, J.M. Use of Amaranth, Quinoa, Kañiwa and Lupine for the Development of Gluten-Free Extruded Snacks; University of Helsinki: Helsinki, Finland, 2015. [Google Scholar]

- Singh, B.; Rachna; Hussain, S.Z.; Sharma, S. Response Surface Analysis and Process Optimization of Twin Screw Extrusion Cooking of Potato-Based Snacks. J. Food Process. Preserv. 2015, 39, 270–281. [Google Scholar] [CrossRef]

- Dogan, H.; Kokini, J.L. Psychophysical Markers for Crispness and Influence of Phase Behavior and Structure. J. Texture Stud. 2007, 38, 324–354. [Google Scholar] [CrossRef]

- Oliveira, L.C.; Barros, J.H.T.; Rosell, C.M.; Steel, C.J. Physical and Thermal Properties and X-Ray Diffraction of Corn Flour Systems as Affected by Whole Grain Wheat Flour and Extrusion Conditions. Starch/Staerke 2017, 69, 1600299. [Google Scholar] [CrossRef]

- Ding, Q.B.; Ainsworth, P.; Tucker, G.; Marson, H. The Effect of Extrusion Conditions on the Physicochemical Properties and Sensory Characteristics of Rice-Based Expanded Snacks. J. Food Eng. 2005, 66, 283–289. [Google Scholar] [CrossRef]

- Anderson, R.A.; Conway, H.F.; Peplinski, A.J. Gelatinization of Corn Grits by Roll Cooking, Extrusion Cooking and Steaming. Starch—Stärke 1970, 22, 130–135. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Zhang, R.; Zhong, Y.; Luo, Y.; Xu, S.; Liu, J.; Xue, J.; Guo, D. Effects of Extrusion Treatment on Physicochemical Properties and in Vitro Digestion of Pregelatinized High Amylose Maize Flour. J. Cereal Sci. 2016, 68, 108–115. [Google Scholar] [CrossRef]

- Kaur, A.; Kaur, S.; Singh, M.; Singh, N.; Shevkani, K.; Singh, B. Effect of Banana Flour, Screw Speed and Temperature on Extrusion Behaviour of Corn Extrudates. J. Food Sci. Technol. 2015, 52, 4276–4285. [Google Scholar] [CrossRef]

- Singh, J.P.; Kaur, A.; Shevkani, K.; Singh, N.; Singh, B. Physicochemical Characterisation of Corn Extrudates Prepared with Varying Levels of Beetroot (Beta vulgaris) at Different Extrusion Temperatures. Int. J. Food Sci. Technol. 2016, 51, 911–919. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N.; Rattan, B.; Singh, J.P.; Kaur, A.; Singh, B. Effect of Chickpea and Spinach on Extrusion Behavior of Corn Grit. J. Food Sci. Technol. 2019, 56, 2257–2266. [Google Scholar] [CrossRef]

- Raphaelides, S.N.; Arsenoudi, K.; Exarhopoulos, S.; Xu, Z.M. Effect of Processing History on the Functional and Structural Characteristics of Starch-Fatty Acid Extrudates. Food Res. Int. 2010, 43, 329–341. [Google Scholar] [CrossRef]

- Zhu, L.J.; Shukri, R.; De Mesa-Stonestreet, N.J.; Alavi, S.; Dogan, H.; Shi, Y.C. Mechanical and Microstructural Properties of Soy Protein—High Amylose Corn Starch Extrudates in Relation to Physiochemical Changes of Starch during Extrusion. J. Food Eng. 2010, 100, 232–238. [Google Scholar] [CrossRef]

- Pansawat, N.; Jangchud, K.; Jangchud, A.; Wuttijumnong, P.; Saalia, F.K.; Eitenmiller, R.R.; Phillips, R.D. Effects of Extrusion Conditions on Secondary Extrusion Variables and Physical Properties of Fish, Rice-Based Snacks. LWT—Food Sci. Technol. 2008, 41, 632–641. [Google Scholar] [CrossRef]

- Joshi, S.M.R.; Bera, M.B.; Panesar, P.S. Extrusion Cooking of Maize/Spirulina Mixture: Factors Affecting Expanded Product Characteristics and Sensory Quality. J. Food Process. Preserv. 2014, 38, 655–664. [Google Scholar] [CrossRef]

| Components | Maize Flour | |

|---|---|---|

| Average [% DM] | SD [% DM] | |

| Starch | 72.47 | 1.02 |

| Total fiber | 16.03 | 0.85 |

| • Insoluble fiber | 13.15 | 0.78 |

| • Soluble fiber | 2.88 | 0.32 |

| Proteins | 7.06 | 0.07 |

| Fat | 4.06 | 0.08 |

| Ash | 1.22 | 0.01 |

| Total | 100.85 | |

| Water | 13.17 | 0.02 |

| Independent Factors | Encoded Levels | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| Temperature [°C] | 110 | 145 | 180 |

| Screw speed [rpm] | 150 | 200 | 250 |

| Oil content [%] | 0 | 5 | 10 |

| N° | Experimental Design Independent Variables | Secondary Extrusion Variable | Textural Properties | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Texturometry | |||||||||||||||

| x1 | x2 | x3 | SME [Wh/kg] | Expansion | Bulk Density [g/cm3] | Hardness [N] | Work [N.mm] | Count Peaks Positive | N Average Drop Off [N] | Linear Distance | |||||

| Thresholds: 0.05 N | Thresholds: 0.3 N | Thresholds: 0.1 N | Thresholds: 0.05 N | Thresholds: 0.3 N | Thresholds: 0.1 N | ||||||||||

| Temperature [°C] | Screw Speed [rpm] | Oil Content [%] | |||||||||||||

| 1 | 180 | 250 | 5 | 106.5 | 2.59 ± 0.19 | 0.109 ± 0.019 | 58.4 ± 10.4 | 356 ± 60 | 302 ± 80 | 85 ± 39 | 15 ± 10 | 0.33 ± 0.08 | 0.88 ± 0.24 | 2.70 ± 1.30 | 279 ± 62 |

| 2 | 145 | 200 | 5 | 163.9 | 3.20 ± 0.11 | 0.122 ± 0.010 | 160.8 ± 27.0 | 988 ± 216 | 218 ± 74 | 104 ± 40 | 45 ± 13 | 1.51 ± 0.57 | 2.98 ± 1.09 | 5.97 ± 2.27 | 757 ± 134 |

| 3 | 180 | 150 | 5 | 172.1 | 3.14 ± 0.11 | 0.108 ± 0.008 | 105.7 ± 16.1 | 637 ± 132 | 261 ± 62 | 123 ± 32 | 50 ± 16 | 0.96 ± 0.27 | 1.87 ± 0.49 | 3.76 ± 0.81 | 597 ± 116 |

| 4 | 145 | 250 | 0 | 147.5 | 3.04 ± 0.09 | 0.115 ± 0.010 | 68.8 ± 12.5 | 397 ± 96 | 192 ± 45 | 88 ± 19 | 37 ± 11 | 0.92 ± 0.22 | 1.82 ± 0.42 | 3.55 ± 0.81 | 419 ± 80 |

| 5 | 180 | 200 | 0 | 155.7 | 3.03 ± 0.14 | 0.090 ± 0.009 | 67.9 ± 12.4 | 392 ± 96 | 177 ± 33 | 81 ± 17 | 33 ± 8 | 0.88 ± 0.22 | 1.73 ± 0.39 | 3.44 ± 0.68 | 383 ± 77 |

| 6 | 110 | 200 | 0 | 196.7 | 3.60 ± 0.18 | 0.102 ± 0.012 | 81.8 ± 11.4 | 518 ± 87 | 204 ± 18 | 124 ± 12 | 70 ± 9 | 1.89 ± 0.29 | 2.99 ± 0.41 | 4.91 ± 0.67 | 847 ± 116 |

| 7 | 180 | 200 | 10 | 68.2 | 2.56 ± 0.10 | 0.140 ± 0.011 | 131.9 ± 26.9 | 739 ± 185 | 249 ± 78 | 86 ± 38 | 25 ± 13 | 0.55 ± 0.21 | 1.35 ± 0.53 | 3.10 ± 1.25 | 402 ± 98 |

| 8 | 145 | 250 | 10 | 79.7 | 2.70 ± 0.12 | 0.159 ± 0.017 | 188.0 ± 27.3 | 1094 ± 226 | 233 ± 82 | 93 ± 36 | 36 ± 13 | 0.97 ± 0.44 | 2.15 ± 0.78 | 4.48 ± 1.46 | 600 ± 108 |

| 9 | 145 | 150 | 10 | 116.9 | 2.69 ± 0.09 | 0.251 ± 0.017 | 406.5 ± 60.1 | 2442 ± 488 | 277 ± 90 | 160 ± 69 | 70 ± 43 | 1.01 ± 0.36 | 1.68 ± 0.52 | 3.27 ± 1.14 | 957 ± 233 |

| 10 | 110 | 200 | 10 | 116.9 | 2.55 ± 0.13 | 0.271 ± 0.031 | 466.9 ± 67.2 | 2651 ± 783 | 303 ± 87 | 202 ± 63 | 95 ± 37 | 1.12 ± 0.30 | 1.59 ± 0.33 | 2.80 ± 0.57 | 1148 ± 214 |

| 11 | 145 | 200 | 5 | 155.7 | 3.12 ± 0.10 | 0.130 ± 0.010 | 173.4 ± 19.7 | 1096 ± 188 | 215 ± 75 | 107 ± 38 | 49 ± 12 | 1.48 ± 0.44 | 2.75 ± 0.74 | 5.15 ± 1.30 | 747 ± 103 |

| 12 | 110 | 150 | 5 | 229.5 | 3.40 ± 0.19 | 0.164 ± 0.020 | 245.7 ± 35.6 | 1670 ± 353 | 119 ± 49 | 69 ± 27 | 37 ± 8 | 2.35 ± 0.88 | 3.89 ± 1.34 | 6.40 ± 1.89 | 750 ± 129 |

| 13 | 145 | 200 | 5 | 147.5 | 3.17 ± 0.09 | 0.138 ± 0.012 | 196.7 ± 25.2 | 1226 ± 206 | 167 ± 69 | 86 ± 31 | 43 ± 15 | 1.54 ± 0.58 | 2.71 ± 0.84 | 4.70 ± 1.34 | 661 ± 132 |

| 14 | 110 | 250 | 5 | 145.3 | 3.22 ± 0.12 | 0.138 ± 0.012 | 189.0 ± 19.0 | 1258 ± 184 | 176 ± 53 | 94 ± 22 | 52 ± 15 | 2.22 ± 0.64 | 3.93 ± 0.95 | 6.55 ± 1.39 | 913 ± 114 |

| 15 | 145 | 150 | 0 | 203.4 | 3.73 ± 0.22 | 0.092 ± 0.013 | 90.1 ± 16.7 | 539 ± 127 | 225 ± 29 | 139 ± 17 | 79 ± 13 | 1.89 ± 0.39 | 2.96 ± 0.53 | 4.76 ± 0.86 | 931 ± 172 |

| N° | Experimental Design Independent Variables | Physicochemical Properties | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | Water Activity | Dry Matter | WAI [g/g] | WSI [%] | X-Ray Diffraction: Peak Area at 2θ Angle: | |||||||

| Temperature [°C] | Screw Speed [rpm] | Oil Content [%] | ±6.8° | ±7.4° | ±11.9° | ±13.2° | ±18.1° | ±19.7° | ±22.4° | |||||

| 1 | 180 | 250 | 5 | 0.32 ± 0.01 | 0.928 ± 0.002 | 3.69 ± 0.25 | 30.6 ± 5.5 | 0.497 | 0.000 | 0.346 | 0.953 | 1.111 | 0.000 | 0.000 |

| 2 | 145 | 200 | 5 | 0.37 ± 0.00 | 0.920 ± 0.002 | 4.25 ± 0.26 | 27.7 ± 3.1 | 0.491 | 0.000 | 0.549 | 0.905 | 1.705 | 0.000 | 0.633 |

| 3 | 180 | 150 | 5 | 0.34 ± 0.00 | 0.925 ± 0.001 | 4.27 ± 0.58 | 29.1 ± 6.3 | 0.656 | 0.000 | 0.550 | 0.911 | 2.268 | 0.000 | 0.000 |

| 4 | 145 | 250 | 0 | 0.26 ± 0.00 | 0.925 ± 0.001 | 3.53 ± 0.10 | 43.3 ± 1.3 | 0.442 | 0.000 | 0.376 | 0.815 | 1.252 | 0.000 | 0.000 |

| 5 | 180 | 200 | 0 | 0.24 ± 0.00 | 0.927 ± 0.000 | 3.13 ± 0.78 | 47.3 ± 9.4 | 0.503 | 0.000 | 0.349 | 0.964 | 1.211 | 0.000 | 0.000 |

| 6 | 110 | 200 | 0 | 0.35 ± 0.00 | 0.915 ± 0.001 | 4.12 ± 0.69 | 37.4 ± 8.1 | 0.769 | 0.000 | 0.551 | 1.216 | 2.209 | 0.000 | 0.000 |

| 7 | 180 | 200 | 10 | 0.31 ± 0.00 | 0.922 ± 0.001 | 4.08 ± 0.12 | 33.8 ± 3.4 | 0.336 | 0.000 | 0.237 | 0.428 | 1.062 | 0.000 | 0.000 |

| 8 | 145 | 250 | 10 | 0.34 ± 0.00 | 0.921 ± 0.000 | 3.49 ± 5.02 | 33.2 ± 2.3 | 0.376 | 0.000 | 0.271 | 0.549 | 1.010 | 0.000 | 0.000 |

| 9 | 145 | 150 | 10 | 0.48 ± 0.01 | 0.904 ± 0.001 | 5.02 ± 0.17 | 22.3 ± 0.6 | 0.000 | 0.000 | 0.000 | 0.929 | 0.646 | 2.547 | 0.561 |

| 10 | 110 | 200 | 10 | 0.50 ± 0.00 | 0.913 ± 0.000 | 4.57 ± 0.23 | 22.9 ± 1.4 | 0.000 | 0.239 | 0.000 | 1.479 | 0.310 | 2.430 | 0.705 |

| 11 | 145 | 200 | 5 | 0.41 ± 0.01 | 0.900 ± 0.001 | 4.26 ±0.10 | 28.3 ± 2.1 | 0.586 | 0.000 | 0.456 | 0.886 | 1.452 | 0.000 | 0.326 |

| 12 | 110 | 150 | 5 | 0.50 ± 0.00 | 0.913 ± 0.000 | 4.66 ± 0.08 | 22.7 ± 0.6 | 0.00 | 0.303 | 0.000 | 1.765 | 0.538 | 3.316 | 0.570 |

| 13 | 145 | 200 | 5 | 0.42 ± 0.00 | 0.915 ± 0.000 | 4.41 ± 0.09 | 28.5 ± 0.8 | 0.333 | 0.000 | 0.279 | 1.014 | 1.353 | 0.000 | 0.000 |

| 14 | 110 | 250 | 5 | 0.39 ± 0.00 | 0.916 ± 0.001 | 4.20 ± 0.13 | 27.0 ± 1.7 | 0.442 | 0.000 | 0.354 | 1.300 | 1.211 | 0.713 | 0.000 |

| 15 | 145 | 150 | 0 | 0.37 ± 0.00 | 0.945 ± 0.001 | 5.16 ± 0.05 | 24.4 ± 0.5 | 0.708 | 0.000 | 0.613 | 1.341 | 2.389 | 0.000 | 0.000 |

| Terms of the Model | SME [Wh/kg] | Expansion | Bulk Density [g/cm3] | Hardness [N] | ||||

|---|---|---|---|---|---|---|---|---|

| Coefficients | p-Values | Coefficients | p-Values | Coefficients | p-Values | Coefficients | p-Values | |

| Constant | 393.5 | 0.000 | 3.128 | 0.000 | 524 | 0.000 | 1.07 | 0.000 |

| x1 | −0.6638 | 0.000 | 2.204 × 10−3 | 0.000 | −1.43 | 0.000 | −3.96 × 10−3 | 0.000 |

| x2 | −0.6070 | 0.000 | 4 × 10−4 | 0.000 | 0.58 | 0.000 | −2.87 × 10−3 | 0.001 |

| x3 | 1.74 | 0.000 | −0.2783 | 0.000 | 738.3 | 0.000 | 4.06 × 10−2 | 0.000 |

| x12 | - | - | −7.3 × 10−5 | 0.026 | - | - | - | - |

| x22 | - | - | - | - | - | - | - | - |

| x32 | −0.977 | 0.000 | −5.5 × 10−3 | 0.004 | - | - | −1.449 × 10−3 | 0.078 (*) |

| x1*x2 | - | - | −5.1 × 10−5 | 0.021 | - | - | 1.3 × 10−6 | - |

| x1*x3 | - | - | 8.23 × 10−4 | 0.003 | −2.552 | 0.000 | −1.06 × 10−4 | 0.000 |

| x2*x3 | - | - | 7.06 × 10−4 | 0.001 | −1.206 | 0.001 | - | 0.004 |

| R2 adjusted | 95.64% | 97.54% | 95.49% | 95.65% | ||||

| R2 predicted | 92.67% | 90.55% | 89.17% | 90.82% | ||||

| Terms of the Model | Work [N.mm] | Water Activity | Dry Matter (%) | |||||

| Coefficients | p-values | Coefficients | p-values | Coefficients | p-values | |||

| Constant | 524 | 0.000 | 1.07 | 0.000 | 0.829 | 0.000 | ||

| x1 | −1.43 | 0.000 | −3.96 × 10−3 | 0.000 | 5.35 × 10−4 | 0.000 | ||

| x2 | 0.58 | 0.000 | −2.87 × 10−3 | 0.001 | 3.12 × 10−4 | 0.000 | ||

| x3 | 738.3 | 0.000 | 4.06 × 10−2 | 0.000 | −3.63 × 10−3 | 0.002 | ||

| x12 | - | - | - | - | - | - | ||

| x22 | - | - | - | - | - | - | ||

| x32 | - | - | −1.449 × 10−3 | 0.023 | - | - | ||

| x1*x2 | - | - | 1.3 × 10−6 | 0.102 (*) | −2 × 10−6 | 0.054 (*) | ||

| x1*x3 | −2.552 | 0.000 | −1.06 × 10−4 | 0.175 (*) | 9 × 10−6 | 0.280 (*) | ||

| x2*x3 | −1.206 | 0.001 | - | - | 8 × 10−6 | 0.163 (*) | ||

| R2 adjusted | 96.50% | 90.28% | 91.18% | |||||

| R2 predicted | 93.27% | 77.20% | 86.80% | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jacquet, N.; Plompteux, A.; Brostaux, Y.; Malumba, P.; Danthine, S.; Blecker, C. Study of the Impact of Operating Parameters and the Addition of Fat on the Physicochemical and Texture Properties of Extruded Snacks. Foods 2025, 14, 1307. https://doi.org/10.3390/foods14081307

Jacquet N, Plompteux A, Brostaux Y, Malumba P, Danthine S, Blecker C. Study of the Impact of Operating Parameters and the Addition of Fat on the Physicochemical and Texture Properties of Extruded Snacks. Foods. 2025; 14(8):1307. https://doi.org/10.3390/foods14081307

Chicago/Turabian StyleJacquet, Nicolas, Armande Plompteux, Yves Brostaux, Paul Malumba, Sabine Danthine, and Christophe Blecker. 2025. "Study of the Impact of Operating Parameters and the Addition of Fat on the Physicochemical and Texture Properties of Extruded Snacks" Foods 14, no. 8: 1307. https://doi.org/10.3390/foods14081307

APA StyleJacquet, N., Plompteux, A., Brostaux, Y., Malumba, P., Danthine, S., & Blecker, C. (2025). Study of the Impact of Operating Parameters and the Addition of Fat on the Physicochemical and Texture Properties of Extruded Snacks. Foods, 14(8), 1307. https://doi.org/10.3390/foods14081307