Effect of Wheat Flour Integration with Blueberry Fruits on Rheological, Quality, Antioxidant, and Sensory Attributes of ‘French’ Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Location and Experimental Protocol

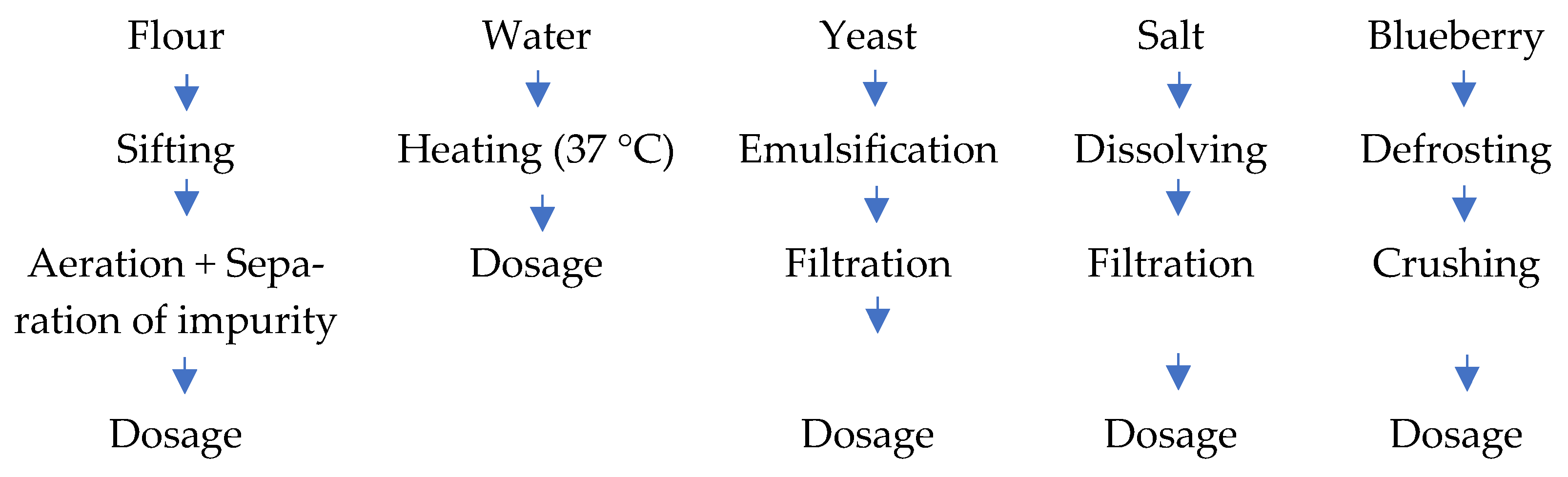

2.2. Preparation of the Raw and Auxiliary Materials

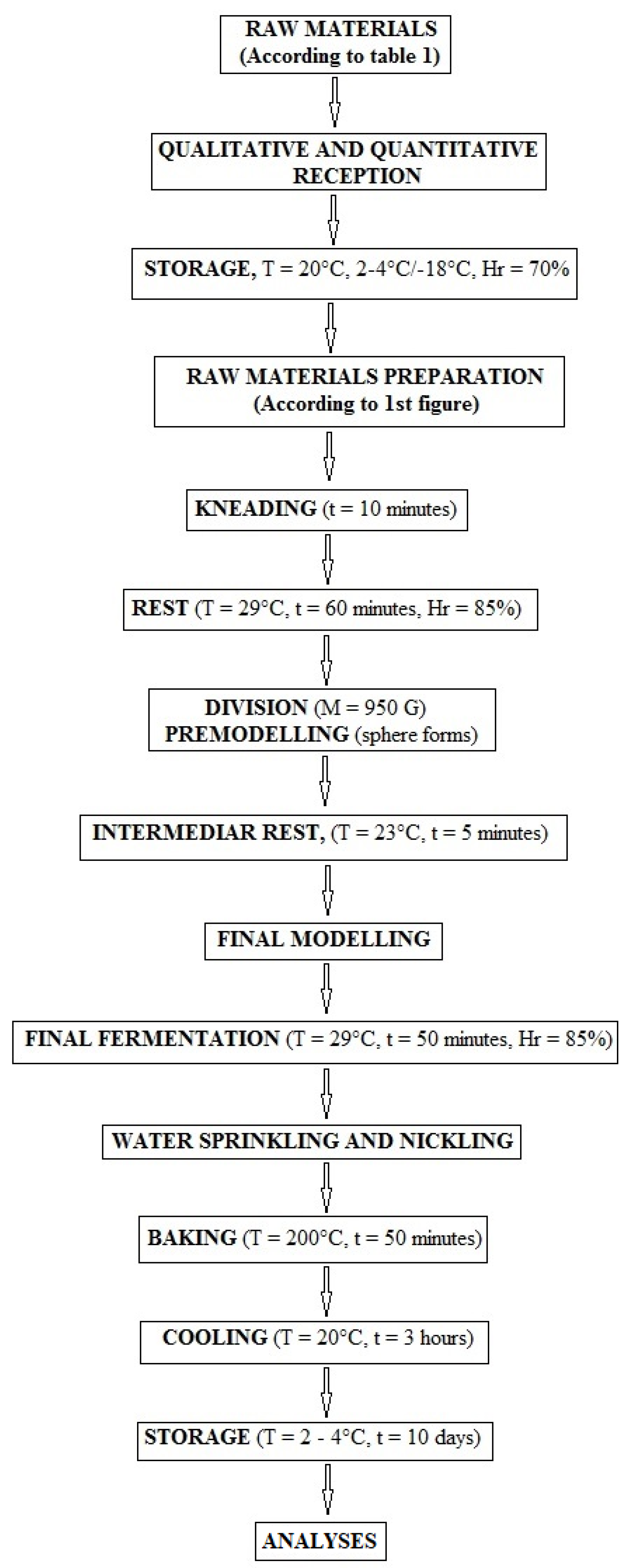

2.3. Bread Preparation

2.4. Determination of Bread Porosity and Rheological Properties

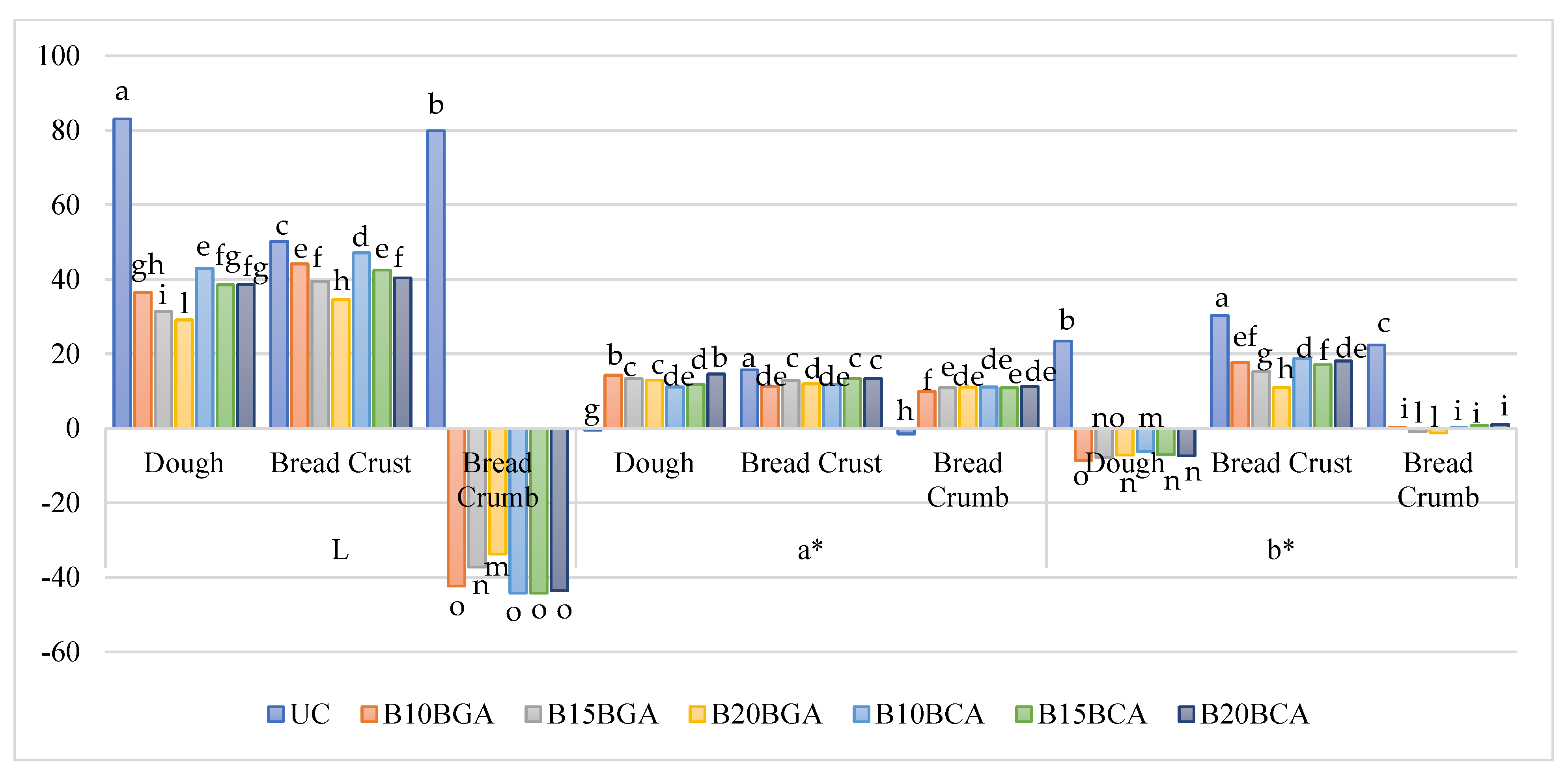

2.5. Determination of Quality and Color Parameters of Bread

2.6. Evaluation of the Phytochemical Profile

2.6.1. Extraction of Biologically Active Compounds

2.6.2. Determination of Vitamin C

2.6.3. Determination of Total Polyphenol Content

2.6.4. Determination of Flavonoid Content

2.6.5. Determination of Total Monomeric Anthocyanin Content

2.6.6. Determination of Antioxidant Activity by the DPPH-2,2-Diphenyl-1-Picrylhydrazyl Method

2.7. Sensory Evaluation of Bread Products

2.8. Statistical Analysis

3. Results and Discussion

3.1. Rheological and Quality Characteristics of Bread

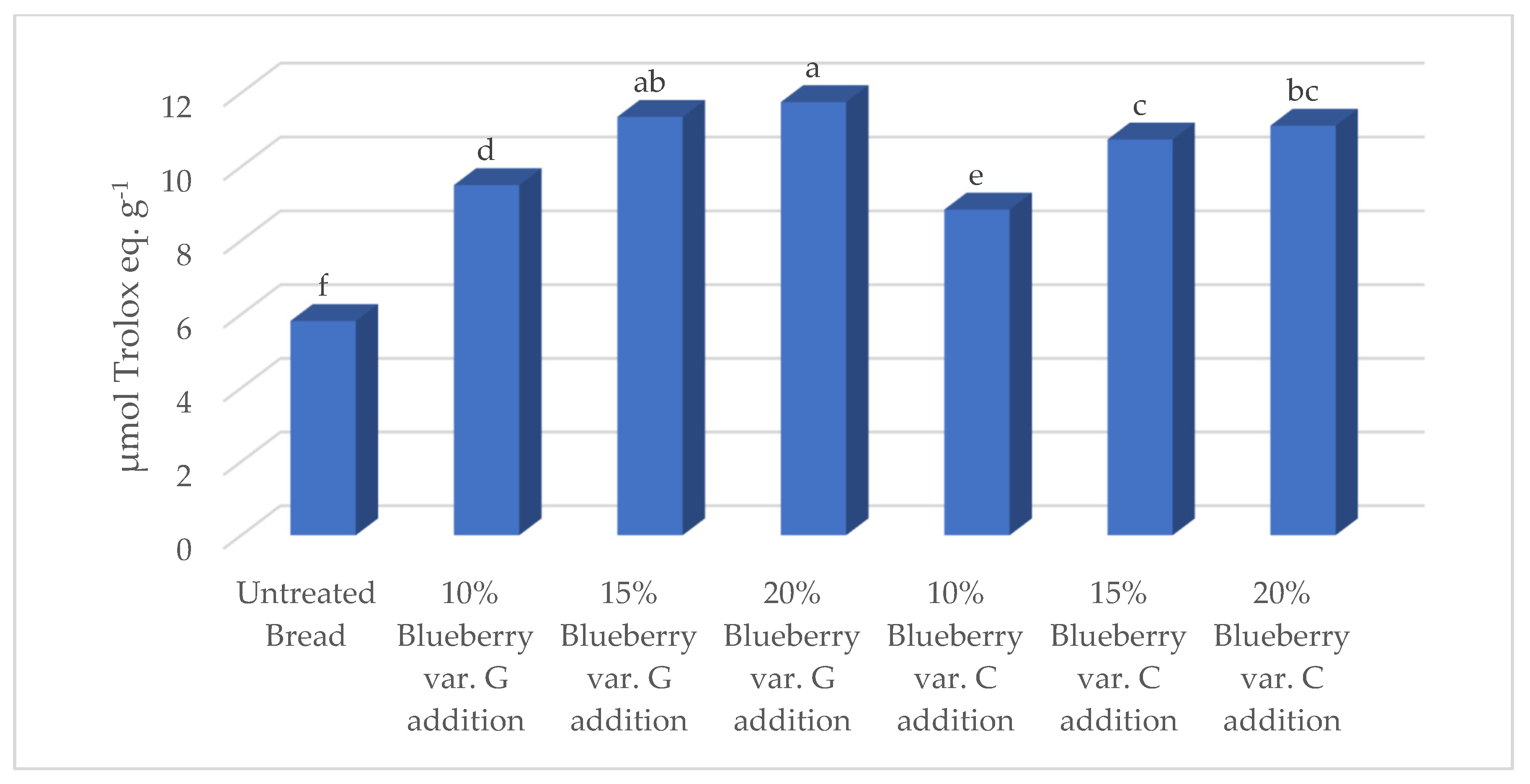

3.2. Antioxidant Compounds and Activity of Blueberry Fruit-Added Bread

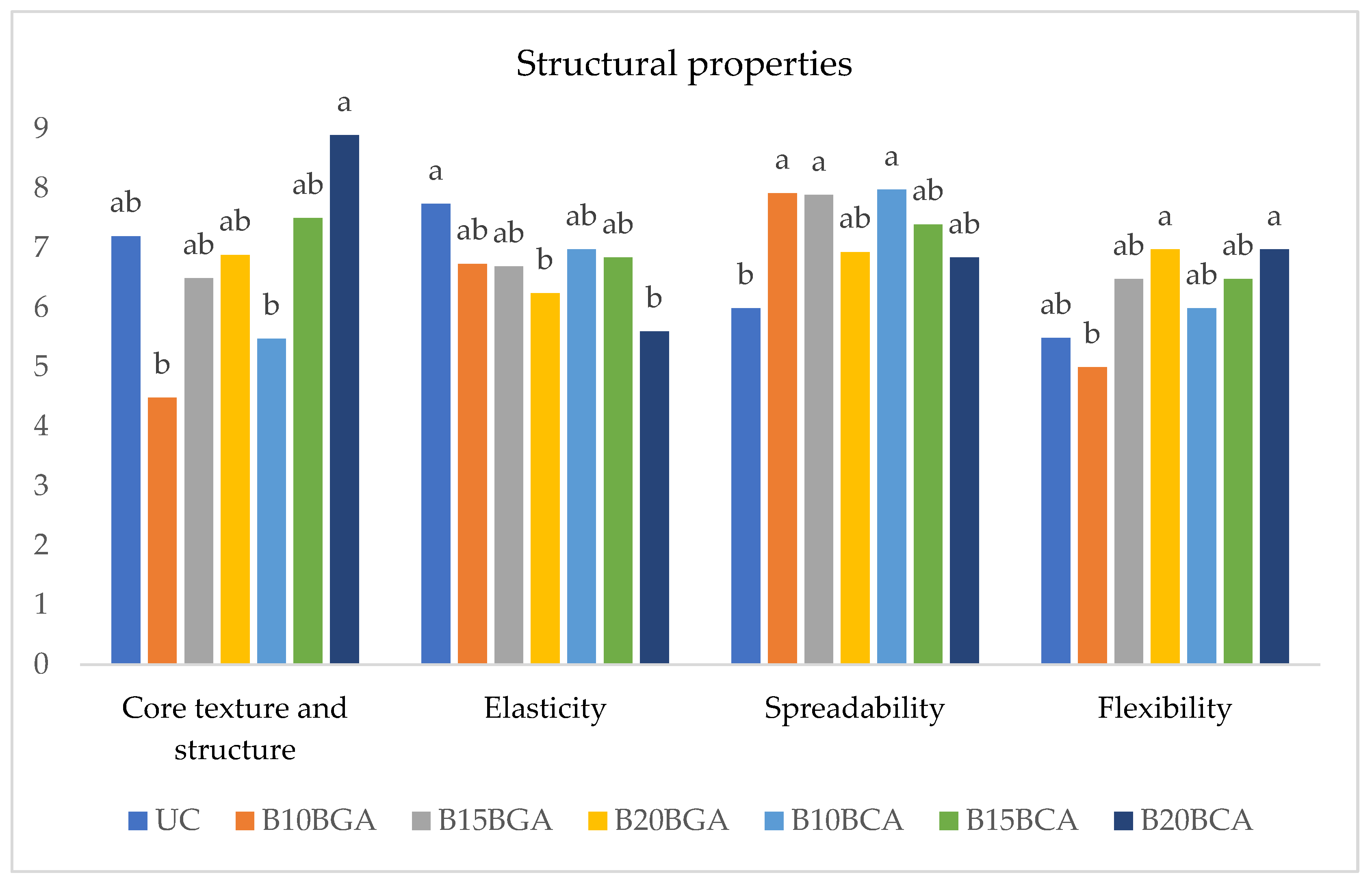

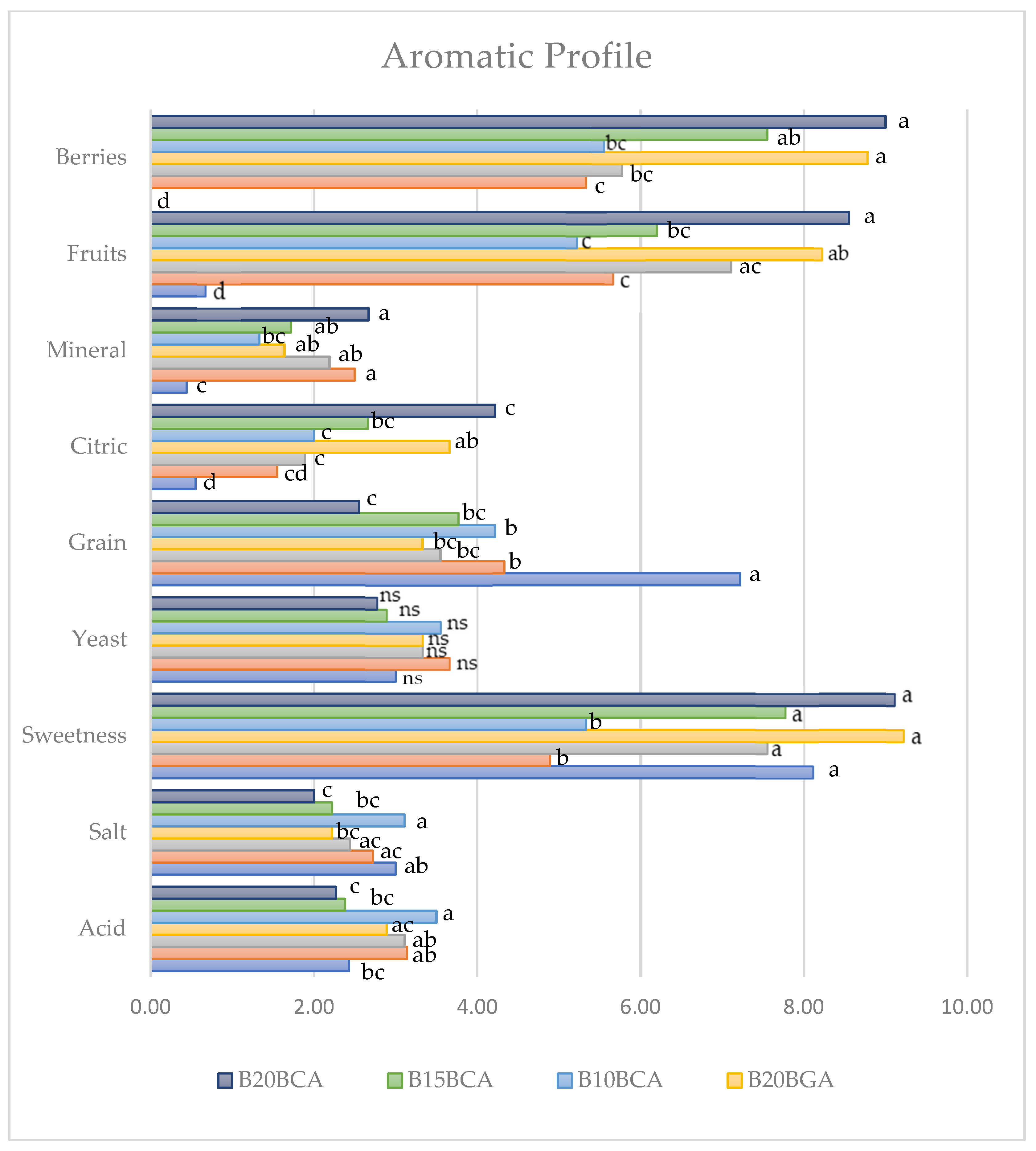

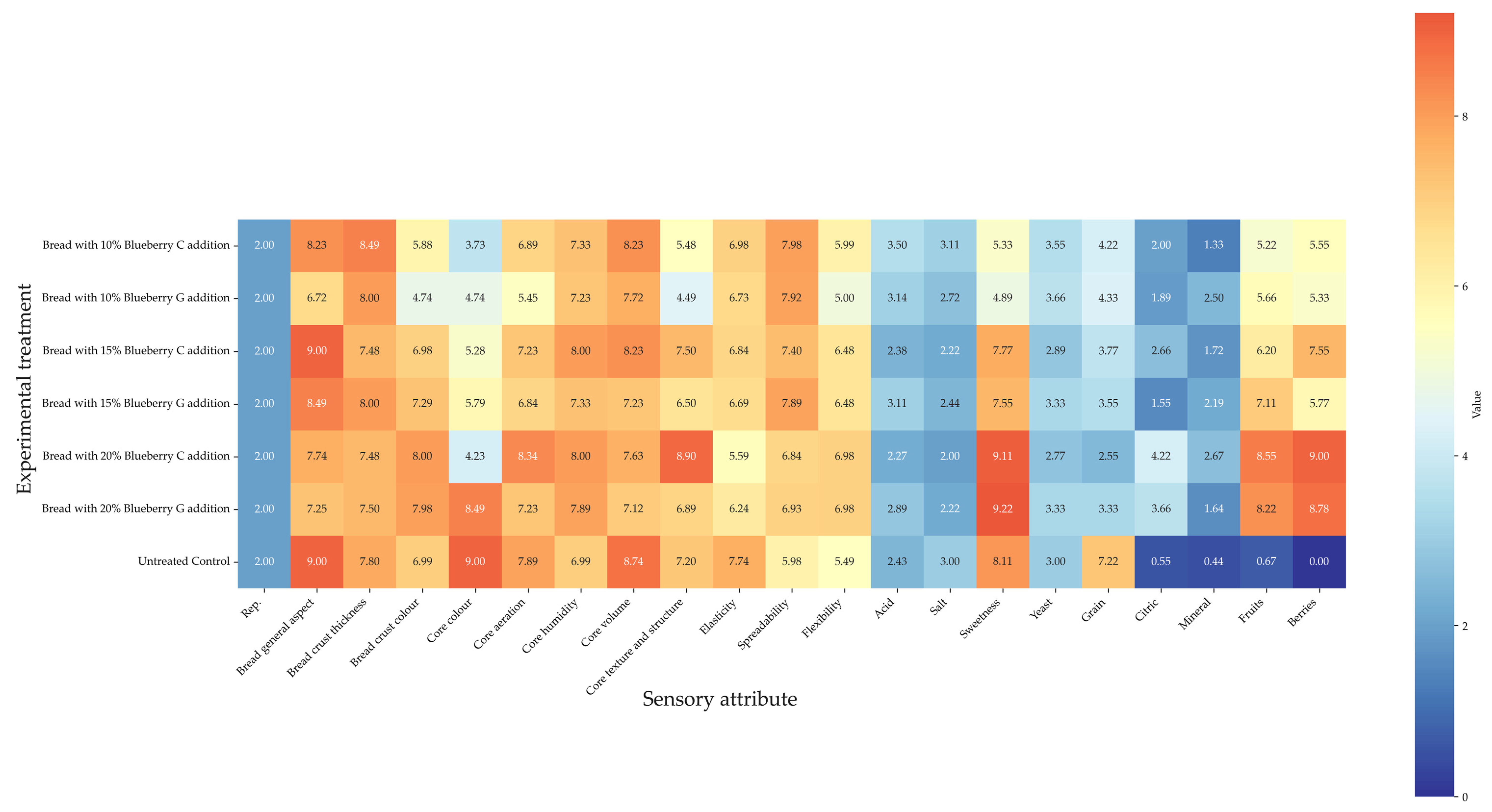

3.3. Sensory Features of Blueberry Fruit Added Bread

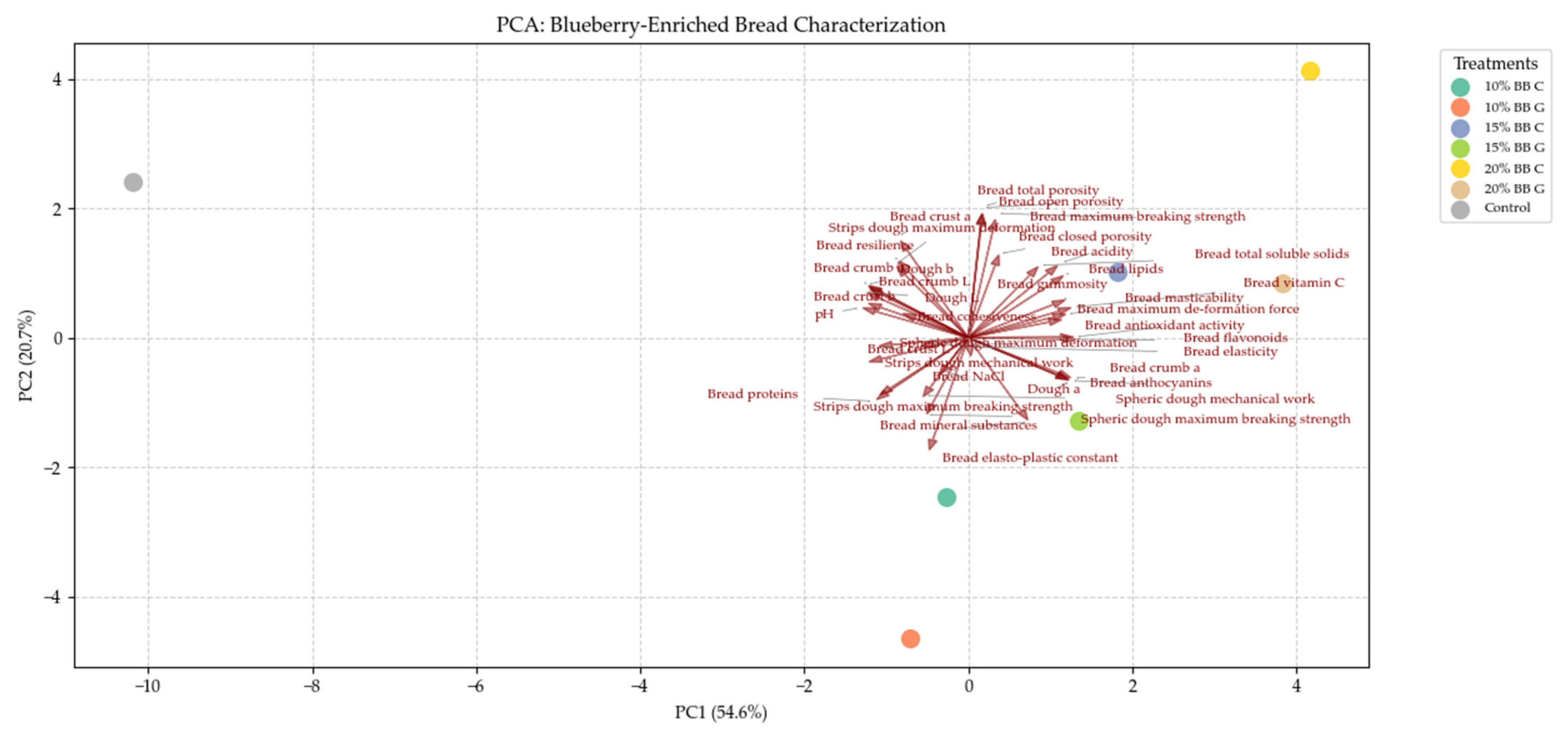

3.4. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gashi, N.; Hasani, E.; Salihu, S. Quality evaluation of muffins enriched with blueberry and cranberry powders. Int. J. Food Sci. 2024, 1, 7045401. [Google Scholar]

- Caleja, C.; Barros, L.; Antonio, A.L.; Oliveira, M.B.P.P.; Ferreira, I.C.F.R. A comparative study between natural and synthetic antioxidants: Evaluation of their performance after incorporation into biscuits. Food Chem. 2017, 2, 342–346. [Google Scholar] [CrossRef]

- Salehi, F.; Aghajanzadeh, S. Effect of dried fruits and vegetables powder on cakes quality: A review. Trends Food Sci. Technol. 2020, 95, 162–172. [Google Scholar]

- Bijlwan, M.; Bindu, N.; Deepak, S.; Ajay, S.; Vijay, K. Recent developments in dough based bakery products: A mini review. Pharma Innov. J. 2019, 8, 654–658. [Google Scholar]

- Stanciu, I.; Ungureanu, E.L.; Popa, B.E.E.; Geicu Cristea, M.; Draghici, M.; Mitelut, A.M.; Mustatea, G.; Popa, M.E. The experimental development of bread with enriched nutritional properties using organic Sea Buckthorn pomace. Appl. Sci. 2023, 13, 6513. [Google Scholar] [CrossRef]

- Sharma, M.; Shehzad, H.; Tatsiana, S.; Riina, A.; Rajeev, B. Valorization of sea buckthorn pomace to obtain bioactive carotenoids: An innovative approach of using green extraction techniques (ultrasonic and microwave-assisted extractions) synergized with green solvents (edible oils). Ind. Crops Prod. 2023, 175, 114257. [Google Scholar]

- Mickiewicz, B.; Britchenko, I. Main trends and development forecast of bread and bakery products market. VUZF Rev. 2022, 7, 113–123. [Google Scholar] [CrossRef]

- Psodorov, D.; Šimurina, O.; Runjaji-Antic, D.; Arsic, I.; Filipcev, B.; Bodroža-Solarov, M. New bakery products with the addition of medicinal herbs. In Proceedings of the 3rd International Congress “Flour-Bread 05” and 5th Croatian Congress of Cereal Technologists, Opatija, Croatia, 26–29 October 2005; pp. 177–181. [Google Scholar]

- Acun, S.; Gül, H. Effects of grape pomace and grape seed flours on cookie quality. Qual. Assur. Saf. Crops Foods 2014, 6, 81–88. [Google Scholar]

- Ungureanu, E.; Ungureanu, O.; Ulea, E.; Iacob, V.; Popa, V.I. On the biocide properties of some products based on natural aromatic compounds. Cell. Chem. Technol. 2008, 42, 381–386. [Google Scholar]

- Raba, D.N.; Radulov, I.; Alexa, E.; Poiana, M.A.; Misca, C.D.; Cocan, I.; Negrea, M.; Suster, G.; Dragomir, C. Insights into the development of pastry products based on spelt flour fortified with lingonberry powder. Agronomy 2023, 13, 2609. [Google Scholar] [CrossRef]

- Potter, R.; Stojceska, V.; Plunkett, A. The use of fruit powders in extruded snacks suitable for Children’s diets. LWT-Food Sci.Technol. 2013, 51, 537–544. [Google Scholar] [CrossRef]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2011, 124, 411–421. [Google Scholar] [CrossRef]

- Puvanenthiran, A.; Stevovitch-Rykner, C.; McCann, T.H.; Day, L. Synergistic effect of milk solids and carrot cell wall particles on the rheology and texture of yoghurt gels. Food Res. Int. 2014, 62, 701–708. [Google Scholar] [CrossRef]

- O’Shea, N.; Arendt, E.K.; Gallagher, E. Dietary fibre and phytochemical characteristics of fruit and vegetable by-products and their recent applications as novel ingredients in food products. Innov. Food Sci. Emerg. Technol. 2012, 16, 1–10. [Google Scholar] [CrossRef]

- Guijarro-Fuertes, M.; Andrade-Cuvi, M.J.; Bravo-Vasquez, J.; Ramos-Guerrero, L.; Vernaza, M.G. Andean Blueberry (Vaccinium floribundum) bread: Physicochemical properties and bioaccessibility of antioxidants. Food Sci. Technol. 2018, 39 (Suppl. S1), 56–62. [Google Scholar] [CrossRef]

- Salehi, F. Quality, physicochemical, and textural properties of dairy products containing fruits and vegetables: A review. Food Sci. Nutr. 2021, 9, 4666–4686. [Google Scholar] [CrossRef]

- Górnas, P.; Juhnevica-Radenkova, K.; Radenkovs, V.; Mišina, I.; Pugajeva, I.; Soliven, A.; Seglina, D. The impact of differentbaking conditions on the stability of the extractable polyphenols in muffins enriched by strawberry, sour cherry, raspberry or black currant pomace. LWT-Food Sci. Technol. 2016, 65, 946–953. [Google Scholar] [CrossRef]

- Mihaescu, G. Fructele. In Alimentatie, Bioterapie i Cosmetics; Ceres Publishing House: Bucuresti, Romania, 1994. [Google Scholar]

- Gafencu, A.M.; Florea, A.M.; Lipsa, F.D.; Ulea, E. Influence of crop species on soil microbial abundance and diversity. Sci. Pap. Ser. A Agron. 2023, 66, 75–80. [Google Scholar]

- Ordóñez-Díaz, J.L.; Pereira-Caro, G.; Cardeñosa, V.; Muriel, J.L.; Moreno-Rojas, J.M. Study of the Quality Attributes of Selected Blueberry (Vaccinium corymbosum L.) Varieties Grown under Different Irrigation Regimes and Cultivation Systems. Appl. Sci. 2020, 10, 8459. [Google Scholar] [CrossRef]

- AACC 74-10A; Measurement of Bread Firmness–Compression Test. Northwood Circle: Nacogdoches, TX, USA, 2003.

- Gavrilova, V.; Kajdžanoska, M.; Gjamovski, V.; Stefova, M. Separation, characterization and quantification of phenolic compounds in blueberries and red and black currants by HPLC-DAD-ESI-MSn. J. Agric. Food Chem. 2011, 59, 4009–4018. [Google Scholar] [CrossRef]

- Li, C.; Feng, J.; Huang, W.Y.; An, X.T. Composition of polyphenols and antioxidant activity of rabbiteye blueberry (Vaccinium ashei) in Nanjing. J. Agric. Food Chem. 2013, 61, 523–531. [Google Scholar] [PubMed]

- ISO 6820:1985; Wheat Flour and Rye Flour-General Guidance on the Drafting of Bread-Making Tests. International Organization for Standardization: Geneva, Switzerland, 1985.

- SR 91:2007; Romanian Standard for Bread, Confectionery and Bakery Specialties—Methods of Analysis. ASRO—Romanian Standards Association: Bucharest, Romania, 2007.

- AOAC International. Official Methods of Analysis, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Turturica, M. Kinetic Behaviour During Processing of Fruit Anthocyanins in Model and Food System. Ph.D. Thesis, University Dunarea de Jos of Galati, Galați, Romania, 2018. [Google Scholar]

- ISO 4121:2002; Sensory Analysis: Methodology: Evaluation of Food Product by Methods of Using Scales. International Organization for Standardization: Geneva, Switzerland, 2002.

- Elia, M. A procedure for sensory evaluation of bread: Protocol developed by a trained panel. J. Sens. Stud. 2011, 26, 269–277. [Google Scholar]

- Paravisini, L.; Snedonn, K.A.; Peterson, D.G. Comparison of the aroma profiles of intermediate wheatgrass and wheat bread crusts. Molecules 2019, 24, 2484. [Google Scholar] [CrossRef]

- Alfonsi, A.; Coles, D.; Hasle, C.; Koppel, J.; Ladikas, M.; Schmucker von Koch, J.; Schroeder, D.; Sprumont, D.; Verbeke, W.; Zaruk, D. Guidance Note: Ethics and Food-Related Research; European Commission Ethics Review Sector: Brussels, Belgium, 2012. [Google Scholar]

- Poiana, M.-A.; Alexa, E.; Radulov, I.; Raba, D.-N.; Cocan, I.; Negrea, M.; Misca, C.D.; Dragomir, C.; Dossa, S.; Suster, G. Strategies to Formulate Value-Added Pastry Products from Composite Flours Based on Spelt Flour and Grape Pomace Powder. Foods 2023, 12, 3239. [Google Scholar] [CrossRef]

- Plustea, L.; Negrea, M.; Cocan, I.; Radulov, I.; Tulcan, C.; Berbecea, A.; Popescu, I.; Obistioiu, D.; Hotea, I.; Suster, G.; et al. Lupin (Lupinus spp.)-Fortified Bread: A Sustainable, Nutritionally, Functionally, and Technologically Valuable Solution for Bakery. Foods 2022, 11, 2067. [Google Scholar] [CrossRef]

- Dossa, S.; Negrea, M.; Cocan, I.; Berbecea, A.; Obistioiu, D.; Dragomir, C.; Alexa, E.; Rivis, A. Nutritional, Physico-Chemical, Phytochemical, and Rheological Characteristics of Composite Flour Substituted by Baobab Pulp Flour (Adansonia digitata L.) for Bread Making. Foods 2023, 12, 2697. [Google Scholar] [CrossRef]

- Nakov, G.; Brandolini, A.; Hidalgo, A.; Ivanova, N.; Stamatovska, V.; Dimov, I. Effect of grape pomace powder addition on chemical, nutritional and technological properties of cakes. LWT-Food Sci. Technol. 2020, 134, 109950. [Google Scholar]

- Rosell, C.M.; Collar, C.; Haros, M. Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the Mixolab. Food Hydrocoll. 2007, 21, 452–462. [Google Scholar]

- Karnopp, A.R.; Figueroa, A.M.; Los, P.R.; Teles, J.C.; Simões, D.R.S.; Barana, A.C.; Kubiaki, F.T.; Oliveira, J.G.B.d.; Granato, D. Effects of whole-wheat flour and bordeaux grape pomace (Vitis labrusca L.) on the sensory, physicochemical and functional properties of cookies. Food Sci. Technol. 2015, 35, 750–756. [Google Scholar] [CrossRef]

- Okoye, J.I.; Obi, C.D. Nutrient composition and sensory properties of wheat-African bread fruit composite flour cookies. Sky J. Food Sci. 2017, 6, 027–032. [Google Scholar]

- Reis, L.C.R.D.; Facco, E.M.P.; Salvador, M.; Flôres, S.H.; Rios, A.D.O. Characterization of orange passion fruit peel flour and its use as an ingredient in bakery products. J. Culin. Sci. Technol. 2020, 18, 214–230. [Google Scholar]

- Morina, A.; Shehaj, A. Physico-chemical parameters and antioxidant activity of baked product fortified with fruit waste powder. J. Biol. Studies 2022, 5, 221–228. [Google Scholar]

- Troilo, M.; Difonzo, G.; Paradiso, V.M.; Pasqualone, A.; Caponio, F. Grape Pomace as Innovative Flour for the Formulation of Functional Muffins: How Particle Size Affects the Nutritional, Textural and Sensory Properties. Foods 2022, 11, 1799. [Google Scholar] [CrossRef] [PubMed]

- Sławińska, A.; Jabłońska-Ryś, E.; Waldemar, G. Physico-Chemical, Sensory, and Nutritional Properties of Shortbread Cookies Enriched with Agaricus bisporus and Pleurotus ostreatus Powders. Appl. Sci. 2024, 14, 1938. [Google Scholar] [CrossRef]

- Wang, J.; Chatzidimitriou, E.; Wood, L.; Hasanalieva, G.; Markelou, E.; Iversen, P.O.; Seal, C.; Baranski, M.; Vigar, V.; Ernst, L.; et al. Effect of wheat species (Triticum aestivum vs. T. spelta), farming system (organic vs. conventional) and flour type (wholegrain vs. white) on composition of wheat flour—Results of a retail survey in the UK and Germany—2. Antioxidant activity, and phenolic and mineral content. Food Chem. 2020, 6, 100091. [Google Scholar]

- Keriene, I.; Mankeviciene, A.; Bliznikas, S.; Jablonskyte-Rasce, D.; Maikštenienė, S.; Cesnuleviciene, R. Biologically active phenolic compounds in buckwheat, oats and winter spelt wheat. Zemdirb. Agric. 2015, 102, 289–296. [Google Scholar] [CrossRef]

- García-Lomillo, J.; González-SanJosé, M.L. Applications of wine pomace in the food industry: Approaches and functions. Compr. Rev. Food Sci. Food Saf. 2017, 16, 3–22. [Google Scholar]

- Mildner-Szkudlarz, S.; Bajerska, J.; Zawirska-Wojtasiak, R.; Górecka, D. White grape pomace as a source of dietary fibre and polyphenols and its effect on physical and nutraceutical characteristics of wheat biscuits. J. Sci. Food Agric. 2013, 93, 389–395. [Google Scholar] [CrossRef]

- Maner, S.; Sharma, A.K.; Banerjee, K. Wheat flour replacement by wine grape pomace powder positively affects physical, functional and sensory properties of cookies. Proc. Natl. Acad. Sci. India Sect. B Biol. Sci. 2017, 87, 109–113. [Google Scholar]

- Gaita, C.; Alexa, E.; Moigradean, D.; Conforti, F.; Poiana, M.A. Designing of high value-added pasta formulas by incorporation of grape pomace skins. Rom. Biotechnol. Lett. 2020, 25, 1607–1614. [Google Scholar]

- Seczyk, Ł.; Swieca, M.; Gawlik-Dziki, U. Changes of antioxidant potential of pasta fortified with parsley (Petroselinum crispum mill.) leaves in the light of protein-phenolics interactions. Acta Sci. Pol. Technol. Aliment. 2015, 14, 29–36. [Google Scholar] [CrossRef]

- Tournour, H.H.; Segundo, M.A.; Magalhaes, L.M.; Barreiros, L.; Queiroz, J.; Cunha, L.M. Valorization of grape pomace: Extraction of bioactive phenolics with antioxidant properties. Ind. Crops Prod. 2015, 74, 397–406. [Google Scholar] [CrossRef]

- Lau, K.Q.; Sabran, M.R.; Shafie, S.R. Utilization of vegetable and fruit by-products as functional ingredient and food. Front. Nutr. 2021, 8, 661693. [Google Scholar] [CrossRef] [PubMed]

- Ky, I.; Lorrain, B.; Kolbas, N.; Crozier, A.; Teissedre, P.-L. Wine by-Products: Phenolic Characterization and Antioxidant Activity Evaluation of Grapes and Grape Pomaces from Six Different French Grape Varieties. Molecules 2014, 19, 482–506. [Google Scholar] [CrossRef] [PubMed]

- Sturza, R.A.; Ghendov-Mosanu, A.A.; Deseatnicov, O.I.; Suhodol, N.F. Use of sea buckthorn fruits in the pastry manufacturing. Sci. Study Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2016, 17, 35–43. [Google Scholar]

- Ghendov-Mosanu, A.; Cristea, E.; Patras, A.; Sturza, R.; Padureanu, S.; Deseatnicova, O.; Turculet, N.; Boestean, O.; Niculaua, M. Potential Application of Hippophae rhamnoides in Wheat Bread Production. Molecules 2020, 25, 1272. [Google Scholar] [CrossRef]

- Muresan, E.A.; Chis, S.; Cerbu, C.G.; Man, S.; Pop, A.; Marc, R.; Muresan, V.; Muste, S. Development and characterization of biscuits based on sea buckthorn and blueberries by-products. J. Agroaliment. Process. Technol. 2019, 25, 59–63. [Google Scholar]

- Najjar, Z.; Kizhakkayil, J.; Shakoor, H.; Platat, C.; Stathopoulos, C.; Ranasinghe, M. Antioxidant Potential of Cookies Formulated with Date Seed Powder. Foods 2022, 11, 448. [Google Scholar] [CrossRef]

- Özcan, M.M.; Kandil, M.; Yılmaz, H. Comparison of the bioactive compounds, phytochemicals, nutrients and sensory properties of cookies prepared using wheat flour and mahaleb seed powders. Food Humanit. 2023, 1, 482–488. [Google Scholar] [CrossRef]

- Hussain, A.; Kausar, T.; Sehar, S.; Sarwar, A.; Ashraf, A.H.; Jamil, M.A.; Noreen, S.; Rafique, A.; Iftikhar, K.; Quddoos, M.Y. Determination of total phenolics, flavonoids, carotenoids, -carotene and dpph free radical scavenging activity of biscuits developed with different replacement levels of pumpkin (Cucurbita maxima) peel, flesh and seeds powders. Turk. J. Agric.-Food Sci. Technol. 2022, 10, 1506–1514. [Google Scholar] [CrossRef]

- Sumczynski, D.; Bubelova, Z.; Sneyd, J.; Erb-Weber, S.; Mlcek, J. Total phenolics, flavonoids, antioxidant activity, crude fibre and digestibility in non-traditional wheat flakes and muesli. Food Chem. 2015, 174, 319–325. [Google Scholar] [PubMed]

- Lou, W.; Zhou, K.; Li, B.; Nataliya, G. Rheological, pasting and sensory properties of biscuits supplemented with grape pomace powder. Food Sci. Technol. 2022, 42, e78421. [Google Scholar]

- Boff, J.M.; Strasburg, V.J.; Ferrari, G.T.; de Oliveira Schmidt, H.; Manfroi, V.; de Oliveira, V.R. Chemical, Technological, and Sensory Quality of Pasta and Bakery Products Made with the Addition of Grape Pomace Flour. Foods 2022, 11, 3812. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Brandón, M.; Lores, M.; Insam, H.; Domínguez, J. Strategies for recycling and valorization of grape marc. Crit. Rev. Biotechnol. 2019, 39, 437–450. [Google Scholar]

- Loncar, B.; Pezo, L.; Filipovic, V.; Nicetin, M.; Filipovic, J.; Pezo, M.; Šuput, D.; Acimovic, M. Physico-Chemical, Textural and Sensory Evaluation of Spelt Muffins Supplemented with Apple Powder Enriched with Sugar Beet Molasses. Foods 2022, 11, 1750. [Google Scholar] [CrossRef]

| Ingredients | UC | B10BGA | B15BGA | B20BGA | B10BCA | B15BCA | B20BCA |

|---|---|---|---|---|---|---|---|

| White flour (%) | 60 | 62 | 60 | 59 | 62 | 60 | 59 |

| Water (%) | 35 | 22 | 21 | 19.1 | 22 | 21 | 19.1 |

| Yeast (%) | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Blueberry (%) | - | 9.1 | 10.5 | 13 | 9.1 | 10.5 | 13 |

| Salt (%) | 1 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 |

| Sugar (%) | 1 | 3 | 4.5 | 5 | 4.5 | 4.5 | 5 |

| Treatment | Flat Spherical Dough–Bidimensional Elasticity | Flat Strips Dough–Unidimensional Elasticity | ||||

|---|---|---|---|---|---|---|

| MBS (N) | MDDS (mm) | MW (mJ) | MBS (N) | MDDS (mm) | MW (mJ) | |

| UC | 2.00 ± 0.05 ab | 47.32 ± 4.34 ab | 49.06 ± 3.21 b | 0.73 ± 0.03 a | 18.95 ± 1.41 a | 8.01 ± 0.38 a |

| B10BGA | 2.40 ± 0.95 a | 40.48 ± 8.89 c | 54.60 ± 9.20 a | 0.65 ± 0.09 b | 14.07 ± 1.08 bc | 5.25 ± 1.36 b |

| B15BGA | 2.30 ± 0.22 a | 43.46 ± 2.54 bc | 50.21 ± 7.42 ab | 0.63 ± 0.06 b | 14.24 ± 1.47 b | 5.24 ± 0.87 b |

| B20BGA | 1.72 ± 0.03 bc | 48.71 ± 7.68 a | 45.87 ± 7.00 b | 0.55 ± 0.05 c | 14.61 ± 2.86 b | 4.63 ± 1.87 b |

| B10BCA | 1.32 ± 0.19 cd | 26.98 ± 1.42 d | 20.41 ± 2.58 c | 0.60 ± 0.01 bc | 11.14 ± 1.44 c | 4.60 ± 0.17 b |

| B15BCA | 1.20 ± 0.10 d | 27.13 ± 5.18 d | 19.34 ± 1.22 c | 0.47 ± 0.06 d | 13.40 ± 0.10 b | 3.72 ± 0.90 c |

| B20BCA | 1.17 ± 0.10 d | 28.81 ± 1.30 d | 16.63 ± 2.70 c | 0.45 ± 0.05 d | 14.80 ± 1.35 b | 2.48 ± 0.56 d |

| Treatment | Total Porosity (%) | Open (%) | Closed (%) | Maximum Breaking Strength (N) | Elasto-Plastic Constant | Maximum Deformation Force (N) |

|---|---|---|---|---|---|---|

| UC | 48.7 ± 2.94 bc | 47.5 ± 3.28 b | 1.19 ± 0.12 bc | 12.1 ± 2.2 ac | 0.43 ± 0.02 a | 11.3 ± 0.7 c |

| B10BGA | 35.7 ± 1.72 e | 34.7 ± 2.05 d | 1.03 ± 0.14 cd | 8.6 ± 3.0 c | 0.54 ± 0.06 a | 15.3 ± 1.3 ab |

| B15BGA | 41.9 ± 2.14 d | 40.6 ± 2.26 c | 1.27 ± 0.08 ab | 10.9 ± 1.6 bc | 0.41 ± 0.03 bc | 17.6 ± 1.4 a |

| B20BGA | 44.7 ± 2.66 cd | 43.2 ± 2.17 c | 1.48 ± 0.18 a | 13.3 ± 1.4 ab | 0.36 ± 0.06 bc | 17.8 ± 2.4 a |

| B10BCA | 42.6 ± 1.64 d | 41.8 ± 1.70 c | 0.84 ± 0.16 d | 10.5 ± 1.9 bc | 0.47 ± 0.05 ab | 13.5 ± 0.8 bc |

| B15BCA | 52.3 ± 2.83 b | 51.3 ± 2.86 b | 1.02 ± 0.11 cd | 10.6 ± 0.8 bc | 0.45 ± 0.07 ac | 14.2 ± 1.3 bc |

| B20BCA | 57.3 ± 1.41 a | 55.9 ± 1.62 a | 1.38 ± 0.08 ab | 15.2 ± 1.6 a | 0.33 ± 0.02 c | 18.5 ± 2.4 a |

| Treatment | Firmness (N) | Elasticity | Resilience | Gumminess (N) | Chewiness (N) | Cohesiveness |

|---|---|---|---|---|---|---|

| UC | 5.63 ± 0.20 a | 0.95 ± 0.03 | 0.47 ± 0.05 a | 5.51 ± 0.46 b | 4.42 ± 1.10 c | 0.49 ± 0.01 |

| B10BGA | 5.45 ± 0.18 ab | 0.96 ± 0.02 | 0.40 ± 0.04 bc | 6.72 ± 0.57 ab | 6.45 ± 0.59 ab | 0.44 ± 0.01 |

| B15BGA | 5.30 ± 0.15ab | 0.93 ± 0.01 | 0.40 ± 0.09 bc | 7.25 ± 0.85 ab | 6.97 ± 0.89 ab | 0.43 ± 0.02 |

| B20BGA | 5.18 ± 0.13 b | 0.94 ± 0.01 | 0.38 ± 0.09 bc | 7.46 ± 0.30 a | 6.79 ± 0.36 ab | 0.41 ± 0.01 |

| B10BCA | 5.38 ± 0.16 ab | 0.96 ± 0.02 | 0.37 ± 0.04 c | 5.99 ± 0.20 ab | 5.15 ± 1.11 bc | 0.45 ± 0.02 |

| B15BCA | 5.16 ± 0.12 b | 0.98 ± 0.01 | 0.38 ± 0.01 bc | 7.18 ± 1.03 ab | 7.02 ± 1.15 ab | 0.50 ± 0.04 |

| B20BCA | 5.09 ± 0.16 b | 0.96 ± 0.01 | 0.43 ± 0.02 ab | 7.88 ± 0.98 a | 7.52 ± 0.93 a | 0.43 ± 0.01 |

| n.s. | n.s. |

| Treatment | Acidity (%) | pH | Proteins (%) | Lipids (%) | M.S. (%) | T.S.S. (%) | NaCl (%) |

|---|---|---|---|---|---|---|---|

| UC | 1.47 ± 0.12 d | 5.67 ± 0.01 a | 13.4 ± 0.6 | 0.18 ± 0.02 d | 1.12 ± 0.12 b | 12 ± 1 b | 1.17 ± 0.03 ab |

| B10BGA | 1.53 ± 0.12 cd | 4.87 ± 0.01 b | 13.4 ± 0.4 | 0.21 ± 0.03 cd | 1.37 ± 0.18 a | 12 ± 1 b | 1.29 ± 0.04 a |

| B15BGA | 1.87 ± 0.12 b | 4.84 ± 0.01 bc | 13.3 ± 0.5 | 0.25 ± 0.02 bc | 1.23 ± 0.04 ab | 13 ± 1 b | 1.13 ± 0.12 ab |

| B20BGA | 2.00 ± 0.10 ab | 4.76 ± 0.03 de | 13.2 ± 0.5 | 0.30 ± 0.03 ab | 1.26 ± 0.02 ab | 20 ± 1 a | 1.17 ± 0.10 ab |

| B10BCA | 1.67 ± 0.12 c | 4.83 ± 0.03 bc | 13.3 ± 0.6 | 0.22 ± 0.02 cd | 1.32 ± 0.05 ab | 13 ± 1 b | 0.91 ± 0.07 bc |

| B15BCA | 2.00 ± 0.10 ab | 4.80 ± 0.01 cd | 13.3 ± 0.5 | 0.27 ± 0.03 ab | 1.20 ± 0.14 ab | 13 ± 1 b | 0.91 ± 0.03 bc |

| B20BCA | 2.13 ± 0.12 a | 4.72 ± 0.02 e | 13.2 ± 0.4 | 0.31 ± 0.03 a | 1.29 ± 0.03 ab | 20 ± 1 a | 1.06 ± 0.02 bc |

| n.s. |

| Treatment | Color Components | ||

|---|---|---|---|

| L | a* | b* | |

| Blueberry var. fruit addition percentage | |||

| UC | 71.0 ± 15.7 a | 4.6 ± 8.4 e | 25.4 ± 3.9 a |

| B10BGA | 12.8 ± 41.5 c | 11.8 ± 2.0 c | 3.1 ± 11.6 d |

| B15BGA | 11.2 ± 36.5 de | 12.4 ± 1.1 b | 2.2 ± 10.3 e |

| B20BGA | 10.0 ± 32.9 e | 12.0 ± 0.9 bc | 0.9 ± 8.0 f |

| B10BCA | 15.3 ± 44.7 b | 11.3 ± 0.5 d | 4.3 ± 11.2 b |

| B15BCA | 11.8 ± 41.5 cd | 12.1 ± 1.2 bc | 3.6 ± 10.7 cd |

| B20BCA | 12.3 ± 42.4 cd | 13.1 ± 1.7 a | 3.9 ± 11.2 bc |

| Production stage | |||

| Dough | 42.9 ± 17.5 a | 11.1 ± 5.0 b | −3.0 ± 15.3 c |

| Bread Crust | 42.6 ± 5.0 a | 12.9 ± 1.4 a | 18.3 ± 5.7 a |

| Bread Crumb | −23.6 ± 43.5 b | 9.1 ± 4.5 c | 3.2 ± 12.1 b |

| Treatment | Vitamin C (mg 100 g−1) | Total Polyphenols (mg GAE g−1) | Flavonoids (mg CE g−1) | Total Anthocyanins (mg g−1) |

|---|---|---|---|---|

| UC | 0.0 ± 0.0 f | 0.63 ± 0.01 f | 0.37 ± 0.01 e | 0.0 ± 0.0 e |

| B10BGA | 14.1 ± 0.03 e | 0.84 ± 0.04 c | 0.70 ± 0.01 d | 85.3 ± 1.8 c |

| B15BGA | 28.1 ± 0.04 c | 1.05 ± 0.04 b | 0.83 ± 0.01 bc | 100.1 ± 0.5 b |

| B20BGA | 29.7 ± 0.18 b | 1.16 ± 0.01 a | 0.93 ± 0.01 a | 115.3 ± 2.8 a |

| B10BCA | 15.8 ± 0.08 d | 0.69 ± 0.02 e | 0.71 ± 0.01 d | 76.1 ± 3.1 d |

| B15BCA | 29.9 ± 0.06 b | 0.76 ± 0.04 d | 0.79 ± 0.01 c | 81.4 ± 4.3 c |

| B20BCA | 31.6 ± 0.06 a | 0.80 ± 0.02 cd | 0.86 ± 0.01 b | 85.3 ± 2.1 c |

| Treatment | General Aspect | Crust Thickness | Crust Color | Core Color | Core Aeration | Core Humidity | Core Volume |

|---|---|---|---|---|---|---|---|

| UC | 9.00 ± 0.00 a | 7.80 ± 1.04 ab | 6.99 ± 0.96 b | 9.00 ± 0.00 a | 7.89 ± 0.97 a | 6.99 ± 1.06 | 8.75 ± 0.44 |

| B10BGA | 6.72 ± 0.94 d | 8.00 ± 1.06 ab | 4.74 ± 0.92 d | 4.74 ± 0.42 b | 5.45 ± 0.82 b | 7.23 ± 1.14 | 7.73 ± 0.44 |

| B15BGA | 8.49 ± 0.88 ab | 8.00 ± 0.96 ab | 7.29 ± 0.59 ab | 5.79 ± 0.76 b | 6.84 ± 1.11 ab | 7.34 ± 1.29 | 7.23 ± 1.14 |

| B20BGA | 7.25 ± 0.83 cd | 7.50 ± 1.13 ab | 7.98 ± 0.88 a | 8.49 ± 0.88 a | 7.23 ± 1.01 ab | 7.89 ± 1.32 | 7.13 ± 1.01 |

| B10BCA | 8.24 ± 0.77 ab | 8.50 ± 0.88 a | 5.88 ± 1.05 c | 3.74 ± 1.09 b | 6.89 ± 0.79 ab | 7.34 ± 1.29 | 8.24 ± 0.77 |

| B15BCA | 9.00 ± 0.00 a | 7.49 ± 1.06 b | 6.98 ± 0.86 b | 5.28 ± 1.07 b | 7.23 ± 0.42 ab | 8.00 ± 1.37 | 8.24 ± 0.77 |

| B20BCA | 7.74 ± 0.83 bc | 7.49 ± 1.06 b | 8.00 ± 1.06 a | 4.23 ± 1.04 b | 8.34 ± 0.79 a | 8.00 ± 1.37 | 7.64 ± 1.09 |

| n.s. | n.s. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murariu, O.C.; Caruso, G.; Frunză, G.; Lipșa, F.D.; Ulea, E.; Tallarita, A.V.; Calistru, A.; Jităreanu, G. Effect of Wheat Flour Integration with Blueberry Fruits on Rheological, Quality, Antioxidant, and Sensory Attributes of ‘French’ Bread. Foods 2025, 14, 1189. https://doi.org/10.3390/foods14071189

Murariu OC, Caruso G, Frunză G, Lipșa FD, Ulea E, Tallarita AV, Calistru A, Jităreanu G. Effect of Wheat Flour Integration with Blueberry Fruits on Rheological, Quality, Antioxidant, and Sensory Attributes of ‘French’ Bread. Foods. 2025; 14(7):1189. https://doi.org/10.3390/foods14071189

Chicago/Turabian StyleMurariu, Otilia Cristina, Gianluca Caruso, Gabriela Frunză, Florin Daniel Lipșa, Eugen Ulea, Alessio Vincenzo Tallarita, Anca Calistru, and Gerard Jităreanu. 2025. "Effect of Wheat Flour Integration with Blueberry Fruits on Rheological, Quality, Antioxidant, and Sensory Attributes of ‘French’ Bread" Foods 14, no. 7: 1189. https://doi.org/10.3390/foods14071189

APA StyleMurariu, O. C., Caruso, G., Frunză, G., Lipșa, F. D., Ulea, E., Tallarita, A. V., Calistru, A., & Jităreanu, G. (2025). Effect of Wheat Flour Integration with Blueberry Fruits on Rheological, Quality, Antioxidant, and Sensory Attributes of ‘French’ Bread. Foods, 14(7), 1189. https://doi.org/10.3390/foods14071189