Advances in Starch-Based Nanocomposites for Functional Food Systems: Harnessing AI and Nuclear Magnetic Resonance Technologies for Tailored Stability and Bioactivity

Abstract

1. Introduction

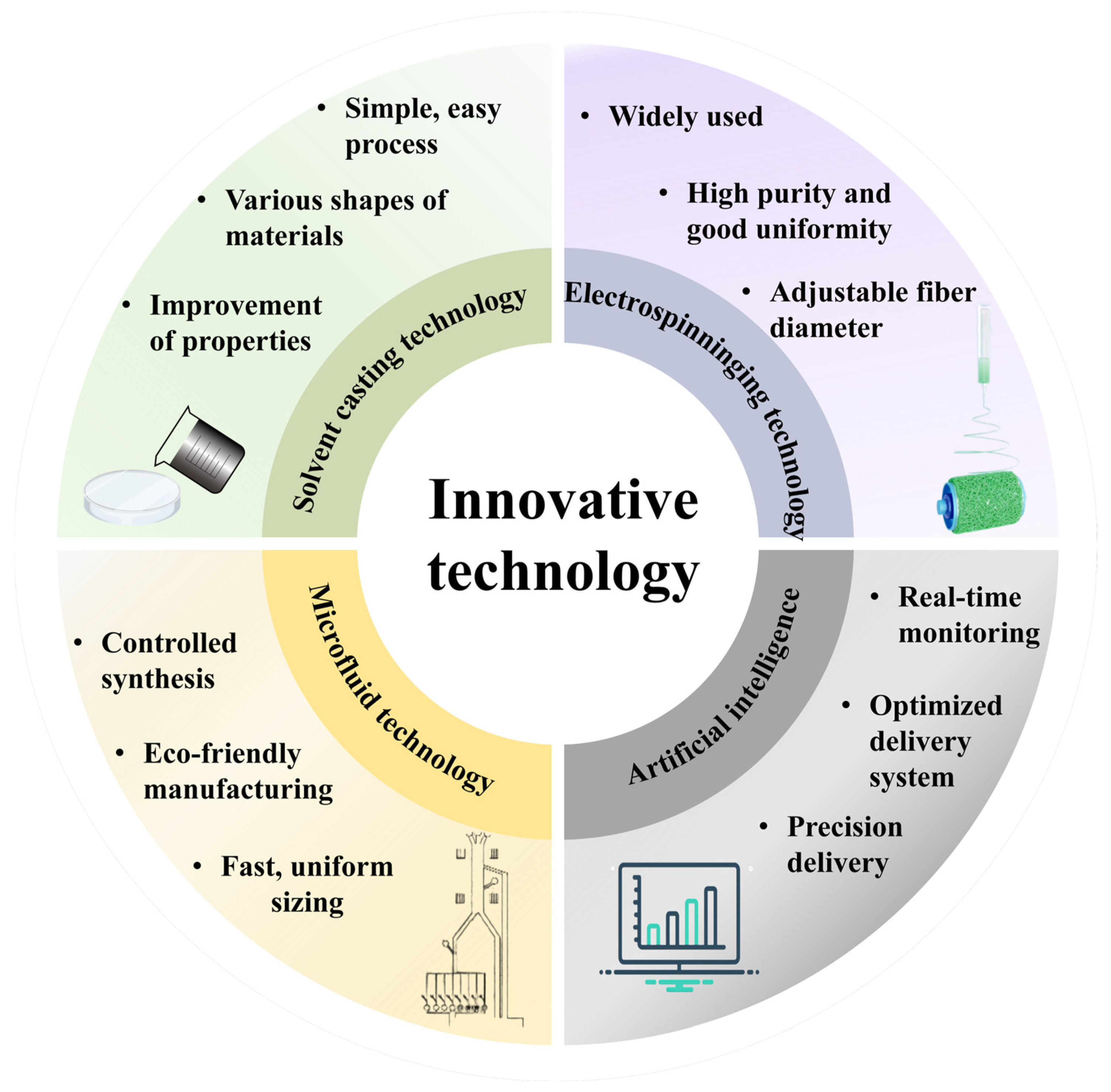

2. Innovative Fabrication Techniques for SNCs

2.1. Comparison Between Traditional and Innovative Methods

| Fabrication Technique | Advantages | Limitations | Refs | |

|---|---|---|---|---|

| Traditional technology | Self-assembly method | Structural controllability, convenience and environmental friendliness, wide applicability | Complex influencing factors, template dependence, limitations of physical field regulation | [20] |

| Cross-linking method | Good biocompatibility, biodegradability | High equipment requirements, applicability restriction, non-uniform particle size, may introduce toxic substances | [21] | |

| Precipitation method | Easy to operate, short reaction time, low cost, wide applicability | Low purity, large particle radius, agglomeration, organic solvent residue | [22,23] | |

| Mechanical method | Wide applicability, scale of production, efficient and convenient, small and uniform size | High equipment requirements, high energy consumption, easily mixed with impurities | [24] | |

| Innovative technology | Microfluidic technology | Controllable particle size and morphology, short preparation time, high yield, precise control of reaction conditions, less reagent needed | High equipment cost and maintenance cost, challenges of large-scale production, technical challenge | [25] |

| Electrostatic spinning technology | Adjustable fineness, high production efficiency, diversification of fiber material, easy to control, wide applicability | Industrialization application challenge, high cost, complex influencing factors | [26] | |

| Solvent casting technology | Simple operation, high porosity, controllable pore structure, wide applicability | Solvent selection restriction, possible solvent residue, environmental and health issues, high equipment cost | [27] |

2.2. Application of AI in SNCs Design and Optimization

2.2.1. Model Prediction and Rapid Analysis

2.2.2. Industrial Production

3. Application of NMR in SNCs

3.1. Structural Analysis of SNCs Using NMR

3.2. Non-Destructive Analysis of SNCs Using NMR

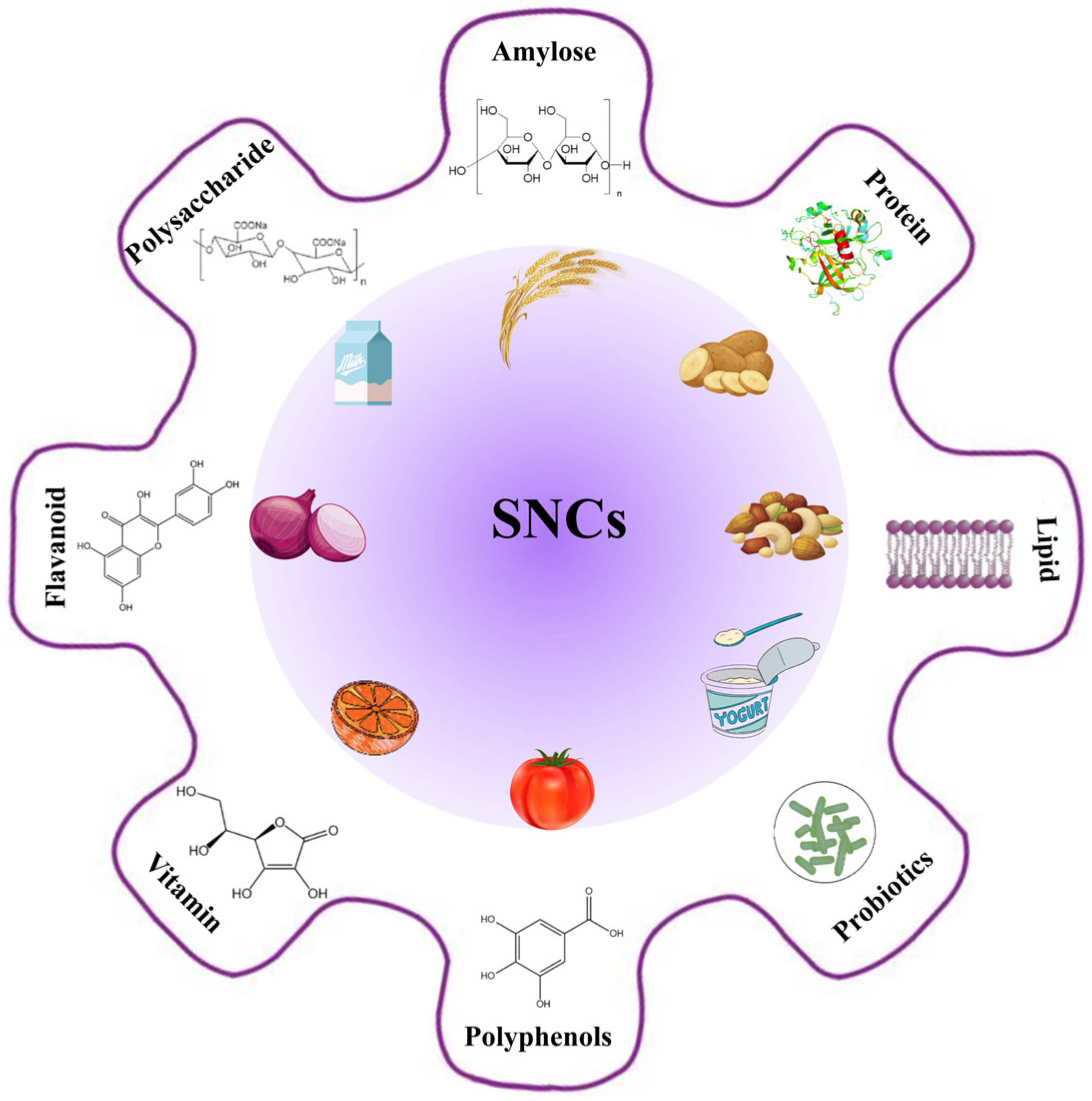

4. Mechanistic Insights into Bioactivity of SNCs

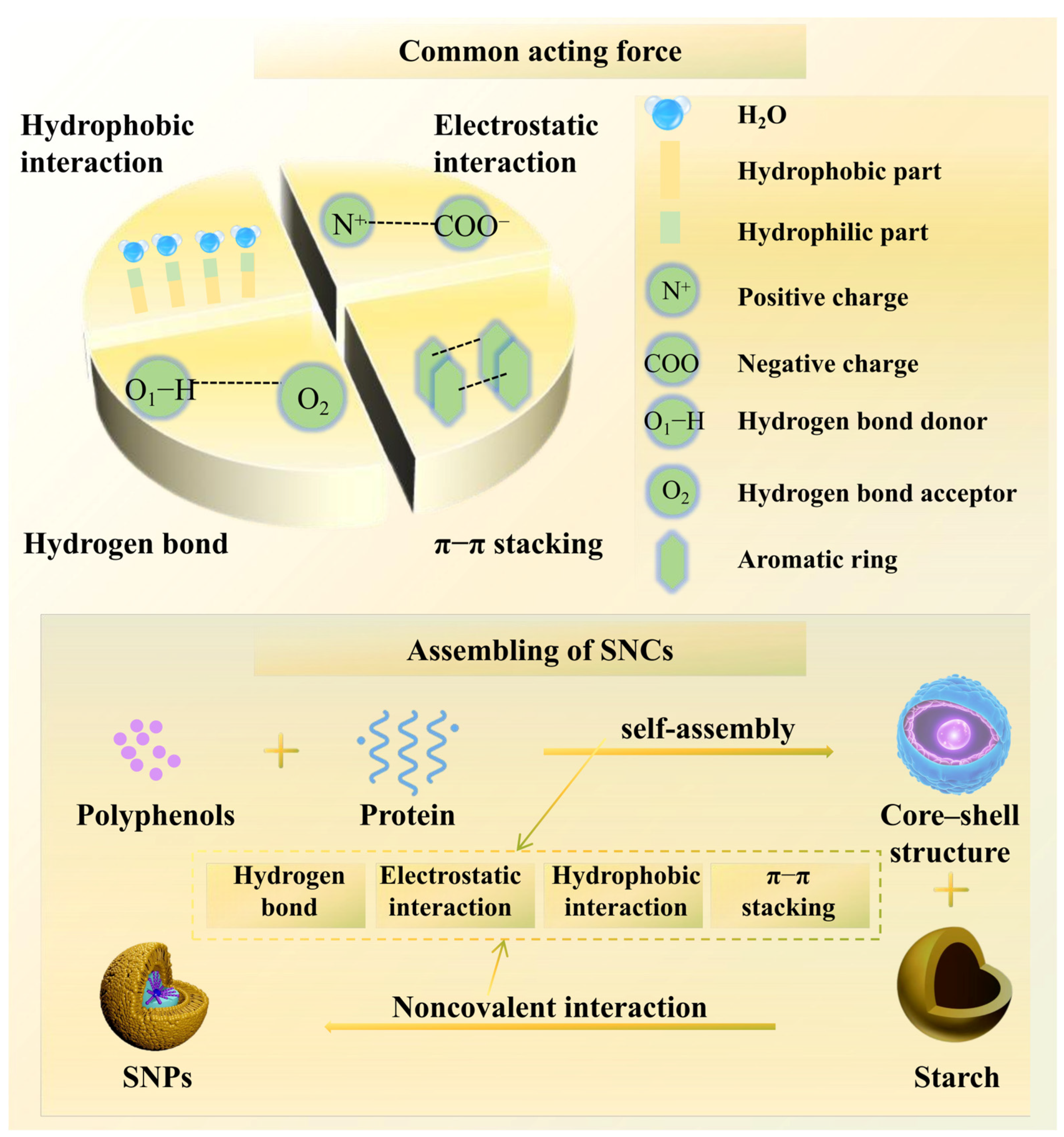

4.1. Molecular Mechanisms of Interaction in SNCs Systems

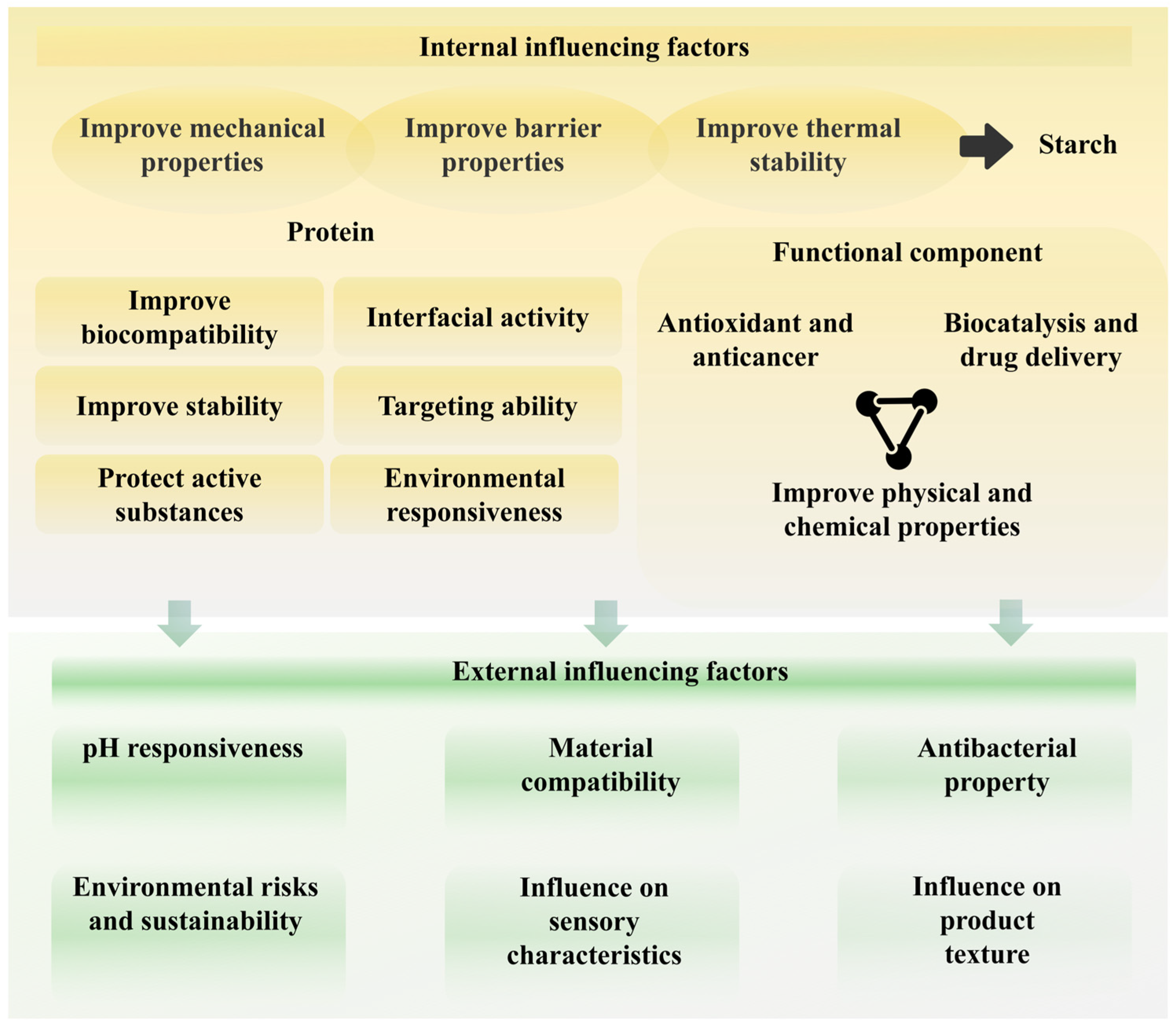

4.2. Factors Influencing the Bioactivity of SNCs

4.2.1. Intrinsic Factors

Plant Source

Particle Morphology and Size

Composition Selection

4.2.2. Extrinsic Factors

pH Responsiveness

Environmental Impact and Sustainability

Biocompatibility and Toxicity

4.3. AI-Driven Innovations in SNCs Stability and Food Applications

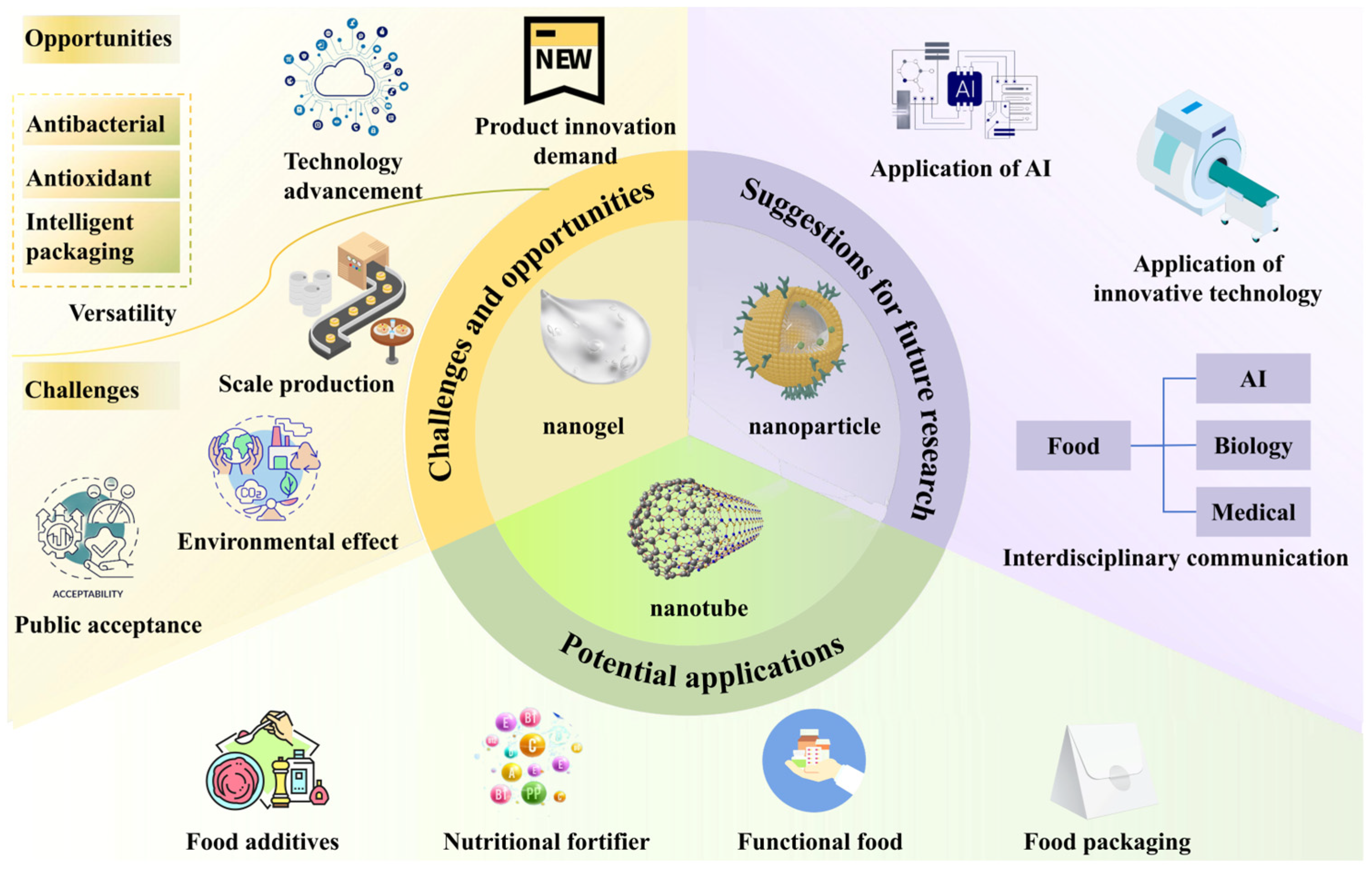

5. Potential Applications of SNCs in Advanced Functional Foods

5.1. Enhancing Nutritional Value and Functional Properties of SNCs

5.1.1. Food Packaging

5.1.2. Fat Substitutes

5.2. AI Applications in SNCs Design and Consumer-Driven Innovations

5.2.1. Leveraging Data Mining for Consumer-Centric Innovation

5.2.2. Transformative Potential of ML in SNCs Optimization

6. Future Perspectives and Research Directions

6.1. Opportunities for SNCs Development

6.2. Challenges in Commercializing SNCs

6.2.1. Scale Production

6.2.2. Regulatory Landscape

6.2.3. Environmental Impact

6.2.4. Comparative Analysis with Alternative Nanocomposites

6.3. Future Research Directions

6.3.1. Interdisciplinary Communication

6.3.2. Application of AI and NMR

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barbhuiya, R.I.; Wroblewski, C.; Ravikumar, S.P.; Kaur, G.; Routray, W.; Subramanian, J.; Elsayed, A.; Singh, A. Upcycling of industrial pea starch by rapid spray nanoprecipitation to develop plant-derived oil encapsulated starch nanoparticles for potential agricultural applications. Carbohydr. Polym. 2024, 346, 122618. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ding, L.; Di, H.; Kirkensgaard, J.J.K.; Khakimov, B.; Sun, B.; Pang, C.; Chen, J.; Blennow, A. Green preparation of small-sized starch nanoparticles using nanoprecipitation. Food Hydrocoll. 2024, 153, 109974. [Google Scholar] [CrossRef]

- Pei, J.J.; Yan, Y.; Jayaraman, S.; Rajagopal, P.; Natarajan, P.M.; Umapathy, V.R.; Gopathy, S.; Roy, J.R.; Sadagopan, J.C.; Thalamati, D.; et al. A review on advancements in the applicatiotarch-based nanomn of saterials in biomedicine: Precision drug delivery and cancer therapy. Int. J. Biol. Macromol. 2024, 265, 130746. [Google Scholar] [CrossRef] [PubMed]

- Lei, W.; Qi, M.; Tan, P.; Yang, S.; Fan, L.; Li, H.; Gao, Z. Impact of polyphenol-loaded edible starch nanomaterials on antioxidant capacity and gut microbiota. Int. J. Biol. Macromol. 2024, 265, 130979. [Google Scholar] [CrossRef] [PubMed]

- Gong, Y.; Xiao, S.; Yao, Z.; Deng, H.; Chen, X.; Yang, T. Factors and modification techniques enhancing starch gel structure and their applications in foods: A review. Food Chem. X 2024, 24, 102045. [Google Scholar] [CrossRef]

- Cao, R.; Li, J.; Ding, H.; Zhao, T.; Guo, Z.; Li, Y.; Sun, X.; Wang, F.; Qiu, J. Synergistic approaches of AI and NMR in enhancing food component analysis: A comprehensive review. Trends Food Sci. Technol. 2024, 156, 104852. [Google Scholar] [CrossRef]

- Song, B.; Wang, F.; Zhu, Q.; Xie, L.; Peng, L. Investigations of the interactions between ZnO nanorods and H2 with 17O NMR spectroscopy. Chem. Commun. 2024, 60, 14121–14124. [Google Scholar] [CrossRef]

- Yang, L.; Wang, H.; Leng, D.; Fang, S.; Yang, Y.; Du, Y. Machine learning applications in nanomaterials: Recent advances and future perspectives. Chem. Eng. J. 2024, 500, 156687. [Google Scholar] [CrossRef]

- Mishra, B.; Panda, J.; Mishra, A.K.; Nath, P.C.; Nayak, P.K.; Mahapatra, U.; Sharma, M.; Chopra, H.; Mohanta, Y.K.; Sridhar, K. Recent advances in sustainable biopolymer-based nanocomposites for smart food packaging: A review. Int. J. Biol. Macromol. 2024, 279, 135583. [Google Scholar] [CrossRef]

- Chowdhury, S.; Kar, K.; Mazumder, R. Exploration of different strategies of nanoencapsulation of bioactive compounds and their ensuing approaches. Future J. Pharm. Sci. 2024, 10, 72. [Google Scholar] [CrossRef]

- Mehraji, S.; DeVoe, D.L. Microfluidic synthesis of lipid-based nanoparticles for drug delivery: Recent advances and opportunities. Lab Chip 2024, 24, 1154–1174. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; He, R.; Chai, J.; Qi, X.; Xue, Q.; Bi, X.; Yu, J.; Sun, Z.; Xia, L.; Wang, K. Synthesis Strategies for High Entropy Nanoparticles. Adv. Mater. 2024, 37, 2412337. [Google Scholar] [CrossRef] [PubMed]

- Tadele, D.T.; Islam, M.S.; Mekonnen, T.H. Zein-Based Nanoparticles and Nanofibers: Co-Encapsulation, Characterization, and Application in Food and Biomedicine. Trends Food Sci. Technol. 2024, 155, 104809. [Google Scholar] [CrossRef]

- Chen, R.; Wang, L.; Ji, D.; Luo, M.; Zhnag, Z.; Zhao, G.; Chang, X.; Zhu, Y. Highly stretchable, conductive, and self-adhesive starch-based hydrogel for high-performance flexible electronic devices. Carbohydr. Polym. 2025, 352, 123220. [Google Scholar] [CrossRef]

- Yang, Q.; Hu, X.; Bao, Q.; Zhao, Y.; Zhang, S.; Li, S.; Li, T. Preparation of starch nanoparticles by jet cavitation and enzymatic hydrolysis and their application in starch films. LWT 2023, 185, 115138. [Google Scholar] [CrossRef]

- Cao, P.; Wu, G.; Yao, Z.; Wang, Z.; Li, E.; Yu, S.; Liu, Q.; Gilbert, R.G.; Li, S. Effects of amylose and amylopectin molecular structures on starch electrospinning. Carbohydr. Polym. 2022, 296, 119959. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Min, T.; Zhao, Y.; Cheng, C.; Yin, H.; Yue, J. The developments and trends of electrospinning active food packaging: A review and bibliometrics analysis. Food Control 2024, 160, 110291. [Google Scholar] [CrossRef]

- Huang, X.; Zhao, F.; Teng, Z.; Li, Y.; Zhang, C.; Liu, X.; Li, S.; Xie, F. Electrospinning of emulsions stabilized by octenylsuccinylated starch and pullulan. Food Hydrocoll. 2025, 158, 110482. [Google Scholar] [CrossRef]

- Lv, H.; Xu, H.; Xu, E.; Jin, Z.; Zhao, H.; Yuan, C.; Zhao, M.; Wu, Z.; He, D.; Cui, B. Improving structural and functional properties of starch-catechin-based green nanofiber mats for active food packaging by electrospinning and crosslinking techniques. Int. J. Biol. Macromol. 2024, 267, 131460. [Google Scholar] [CrossRef]

- Zhong, C.; Luo, S.; Xiong, R.; Liu, C.; Ye, J. A new green self-assembly strategy for preparing curcumin-loaded starch nanoparticles based on natural deep eutectic solvent: Development, characterization and stability. Food Hydrocoll. 2024, 151, 109878. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, L.; Qu, L.; Zhang, R.; Qin, Z.; Zhang, H.; Wei, J.; Xu, J.; Hou, Z. Cross-linked poly (ester urethane)/starch composite films with high starch content as sustainable food-packaging materials: Influence of cross-link density. Int. J. Biol. Macromol. 2024, 256, 128441. [Google Scholar] [CrossRef]

- Saremi, A.; Mirkazemi, S.M.; Sazvar, A.; Rezaie, H. Controlling magnetic and surface properties of cobalt ferrite nanoparticles: A comparison of co-precipitation and solvothermal synthesis methods. Solid State Sci. 2024, 148, 107432. [Google Scholar] [CrossRef]

- Bhavesh, G.; Hariharan, P.; Dhinasekaran, D. Comparative study on the synthesis and characterization of Gd2Zr2O7 nanoparticles by mechanical milling and Co-precipitation techniques. Ceram. Int. 2024, 50, 27476–27485. [Google Scholar] [CrossRef]

- García-Guzmán, L.; Velazquez, G.; Arzate-Vázquez, I.; Castaño-Rivera, P.; Guerra-Valle, M.; Castaño, J.; Guadarrama-Lezama, A.Y. Preparation of Nanocomposite Biopolymer Films from Commelina coelestis Willd Starch and Their Nanostructures as a Potential Replacement for Single-Use Polymers. Foods 2024, 13, 4129. [Google Scholar] [CrossRef] [PubMed]

- Garavito, J.; Peña-Venegas, C.P.; Castellanos, D.A. Production of Starch-Based Flexible Food Packaging in Developing Countries: Analysis of the Processes, Challenges, and Requirements. Foods 2024, 13, 4096. [Google Scholar] [CrossRef]

- Fonseca, L.M.; da Cruz, E.P.; Crizel, R.L.; Jansen-Alves, C.; Dias, A.R.G.; Zavareze, E.R. New advances of electrospun starch fibers, encapsulation, and food applications: A review. Trends Food Sci. Technol. 2024, 147, 104467. [Google Scholar] [CrossRef]

- Garuti, G.L.; Freitas, R.R.M.; Lima, V.H.; Carmo, K.P.; Pádua, F.A.; Botaro, V.R. Nanocellulose reinforced starch biocomposite films via tape-casting technique. Polímeros 2024, 34, e20240004. [Google Scholar] [CrossRef]

- Madani, M.; Lacivita, V.; Shin, Y.; Tarakanova, A. Accelerating materials property prediction via a hybrid Transformer Graph framework that leverages four body interactions. Npj Comput. Mater. 2025, 11, 15. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Ouyang, Z.; Zhang, Y.; Lu, Y.; Wei, C.; Tu, Y.; He, B. Research progress on the artificial intelligence applications in food safety and quality management. Trends Food Sci. Technol. 2024, 156, 104855. [Google Scholar] [CrossRef]

- Liu, Z.; Huo, Y.; Chen, Q.; Zhan, S.; Li, Q.; Zhao, Q.; Cui, L.; Liu, J. Predicting the glass transition temperature of polymer based on generative adversarial networks and automated machine learning. Mater. Genome Eng. Adv. 2024, 2, e78. [Google Scholar] [CrossRef]

- Dubrovsky, I.; Dmitrenko, A.; Dmitrenko, A.; Serov, N.; Vinogradov, V. Unveiling the Potential of AI for Nanomaterial Morphology Prediction. arXiv 2024, arXiv:2406.02591. [Google Scholar]

- Vargo, E.; Dahl, J.C.; Evans, K.M.; Khan, T.; Alivisatos, P.; Xu, T. Using Machine Learning to Predict and Understand Complex Self-Assembly Behaviors of a Multicomponent Nanocomposite. Adv. Mater. 2022, 34, 2203168. [Google Scholar] [CrossRef] [PubMed]

- Mottafegh, A.; Joo, J.U.; Na, G.S.; Sharma, V.; Kim, D.P. AI-assisted autonomous manufacturing of tailored drug-loaded nanoparticles by multi-step continuous-flow platform. Chem. Eng. J. 2024, 500, 157454. [Google Scholar] [CrossRef]

- Du, S.; Huang, Z.; Jin, L.; Wan, X. Recent Progress in Data-Driven Intelligent Modeling and Optimization Algorithms for Industrial Processes. Algorithms 2024, 17, 569. [Google Scholar] [CrossRef]

- Cao, R.; Liu, X.; Liu, Y.; Zhai, X.; Cao, T.; Wang, A.; Qiu, J. Applications of nuclear magnetic resonance spectroscopy to the evaluation of complex food constituents. Food Chem. 2021, 342, 128258. [Google Scholar] [CrossRef]

- Cao, R.; Kobayashi, Y.; Nonaka, A.; Miyata, Y.; Tanaka, K.; Tanaka, T.; Matsui, T. NMR spectroscopic and quantum mechanical analyses of enhanced solubilization of hesperidin by theasinensin A. Pharm. Res. 2015, 32, 2301–2309. [Google Scholar] [CrossRef]

- Cao, R.; Liu, X.; Zhai, X.; Wang, L.; Zhou, Z. Preparation, investigation and storage application of thymol–chitooligosaccharide complex with enhanced antioxidant and antibacterial properties. J. Sci. Food Agric. 2022, 102, 1561–1568. [Google Scholar] [CrossRef] [PubMed]

- Ziani, I.; Bouakline, H.; El Guerraf, A.; El Bachiri, A.; Fauconnier, M.L.; Sher, F. Integrating AI and advanced spectroscopic techniques for precision food safety and quality control. Trends Food Sci. Technol. 2024, 156, 104850. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, Z.; Chen, R.; Wang, Z.; Zhnag, S.; Chen, J. Probing molecular interactions of amylose-morin complex and their effect on antioxidant capacity by 2D solid-state NMR spectroscopy. Food Chem. 2023, 415, 135693. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Duan, Z.; Zheng, L.; Yang, Y.; Zheng, X.; Xiao, D.; Ai, B.; Wang, M.; Sheng, Z. Digestive enzyme corona formed in simulated gastrointestinal tract and its impact on EGCG release from banana resistant starch nanoparticles. Food Hydrocoll. 2024, 146, 109267. [Google Scholar] [CrossRef]

- Dong, Y.; Li, Z.; Kong, H.; Ban, X.; Gu, Z.; Hong, Y.; Cheng, L.; Li, C. Correlation analysis of starch molecular structure and film properties via rearrangements of glycosidic linkages by 1,4-α-glucan branching enzyme. Carbohydr. Polym. 2025, 348, 122908. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Qin, X.; Du, Y.; Shan, Z.; Shi, C.; Huang, K.; Wang, J.; Zhi, K. Dual-modified starch nanoparticles containing aromatic systems with highly efficient encapsulation of curcumin and their antibacterial applications. Food Res. Int. 2022, 162, 111926. [Google Scholar] [CrossRef]

- Yan, X.; Diao, M.; Yu, Y.; Gao, F.; Wang, E.; Wang, Z.; Zhang, T.; Zhao, P. Characterization of resistant starch nanoparticles prepared via debranching and nanoprecipitation. Food Chem. 2022, 369, 130824. [Google Scholar] [CrossRef] [PubMed]

- Shin, H.Y.; Kim, J.H.; Kim, J.Y. Effect of fatty acid chain length on physicochemical properties of starch nanocomposites obtained via nanoprecipitation. Int. J. Biol. Macromol. 2023, 230, 123415. [Google Scholar] [CrossRef]

- Meng, F.; Tian, S.; Chen, Y.; Liu, Z. Preparation and physicochemical properties of OSA modified Cyperus esculentus starch nanoparticles. Int. J. Biol. Macromol. 2025, 292, 140045. [Google Scholar] [CrossRef]

- Shi, T.; Dai, T.; Zhang, T.; Ma, X.; Wang, X. NMR spectroscopy combined with chemometrics for quality assessment of common vegetable oils: A review. Trends Food Sci. Technol. 2025, 157, 104889. [Google Scholar] [CrossRef]

- Dev, R.; Aroor, M.S.; Gupta, M. Recent Advancements in Metabolomics: Applications and Insights into Functional Beverages. Curr. Food Sci. Technol. Rep. 2025, 3, 6. [Google Scholar] [CrossRef]

- Yudhistira, B.; Husnayain, N.; Punthi, F.; Gavahian, M.; Chang, C.K.; Hsieh, C.W. Progress in the application of emerging technology for the improvement of starch-based active packaging properties: A review. ACS Food Sci. Technol. 2024, 4, 1997–2012. [Google Scholar] [CrossRef]

- Akhila, V.; Badwaik, L.S. Recent advancement in improvement of properties of polysaccharides and proteins based packaging film with added nanoparticles: A review. Int. J. Biol. Macromol. 2022, 203, 515–525. [Google Scholar]

- Irmukhametova, G.; Azzam, K.M.A.; Mun, G.A.; Bekbayeva, L.; Dinara, Z.; Yermukhambetova, B.B.; Nechipurenko, V.; Efremov, S.A.; El-Sayed, N.; Samy, M. Obtaining and Characterization of Biodegradable Polymer Blends Based on Polyvinyl Alcohol, Starch, and Chitosan. Polymers 2025, 17, 479. [Google Scholar] [CrossRef]

- Guo, Y.; Ma, C.; Xu, Y.; Du, L.; Yang, X. Food gels based on polysaccharide and protein: Preparation, formation mechanisms, and delivery of bioactive substances. Gels 2024, 10, 735. [Google Scholar] [CrossRef] [PubMed]

- Su, C.; Xia, T.; Li, D.; Wang, L.; Wang, Y. Hybrid biodegradable materials from starch and hydrocolloid: Fabrication, properties and applications of starch-hydrocolloid film, gel and bead. Crit. Rev. Food Sci. Nutr. 2024, 64, 12841–12859. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Gu, J.; Yang, K.; Bu, T.; Natallia, K.; Zhang, Z.; Wu, W. Mechanism of hydrocolloids effect on buckwheat starch gels from interaction and structural perspectives: A comparative study. Int. J. Biol. Macromol. 2025, 284, 137886. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Ji, H.; Wang, Z.; Wang, W.; Wang, X.; Chen, Z. Effects of different charged polysaccharides on the gelation properties and in vitro digestibility of potato protein gel: Insight into underlying mechanisms. Food Hydrocoll. 2025, 164, 111187. [Google Scholar] [CrossRef]

- Wang, A.; Breakwell, C.; Foglia, F.; Tan, R.; Lovell, L.; Wei, X.; Wong, T.; Meng, N.; Li, H.; Seel, A.; et al. Selective ion transport through hydrated micropores in polymer membranes. Nature 2024, 635, 353–358. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zhang, X.; He, F.; Liu, K.; Xia, N.; Wu, Q.; Kong, F. Starch-based self-assembled three-dimensional network nanostructure materials for sustainable cascade adsorption. Int. J. Biol. Macromol. 2024, 277, 134355. [Google Scholar] [CrossRef]

- Xu, H.; Ma, Q.; Qiu, C.; Wang, J.; Jin, Z.; Hu, Y. Encapsulation and controlled delivery of curcumin by self-assembled cyclodextrin succinate/chitosan nanoparticles. Food Hydrocoll. 2024, 157, 110465. [Google Scholar] [CrossRef]

- Qiu, Z.; Chen, L.; Liu, Z.; Zheng, B. Rational mutual interactions in starch-lipid-chlorogenic acid ternary systems enable formation of ordered starch structure for anti-digestibility during hot-extrusion 3D printing: Based on the nonlinear rheology and molecular simulation. Food Chem. 2025, 465, 141997. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Zhang, M.; Gao, T.; Chen, L.; Liu, Y.; Huang, Y.; Teng, F.; Li, Y. Assembly of soy protein-corn starch composite gels by thermal induction: Structure, and properties. Food Chem. 2024, 434, 137433. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; He, J.; Chen, Q.; Zhou, J.; Xie, F.; Cai, J. Advancements in starch-based nanomaterials for functional delivery and food packaging: A comprehensive review and future directions. J. Future Foods 2025, 5, 443–454. [Google Scholar] [CrossRef]

- Zhang, W.; Roy, S.; Ezati, P.; Da-Peng, W.; Jong-Whan, R. Tannic acid: A green crosslinker for biopolymer-based food packaging films. Trends Food Sci. Technol. 2023, 136, 11–23. [Google Scholar] [CrossRef]

- Xie, F.; Feng, X.; Wang, Z.; Zhang, D.; Chen, Q.; He, Z.; He, S.; Wang, X.; Wu, Y.; Cai, J. Bioinspired starch nanofibrous films with tunable hydrophobicity and water adhesion via tannic acid-interfacial self-assembly for food packaging. Chem. Eng. J. 2024, 496, 154113. [Google Scholar] [CrossRef]

- Nazrin, A.; Ilyas, R.A.; Rajeshkumar, L.; Hazrati, K.Z.; Jamal, T.; Mahardika, M.; Aisyah, H.A.; Atiqah, A.; Radzi, A.M. Lignocellulosic fiber-reinforced starch thermoplastic composites for food packaging application: A review of properties and food packaging abetted with safety aspects. Food Packag. Shelf Life 2025, 47, 101431. [Google Scholar] [CrossRef]

- Ramos, G.V.C.; Ramírez-López, S.; Pinho, S.C.; Ditchfield, C.; Moraes, I.C.F. Starch-Based Pickering Emulsions for Bioactive Compound Encapsulation: Production, Properties, and Applications. Processes 2025, 13, 342. [Google Scholar] [CrossRef]

- Himat, A.S.; Vasanthan, T.; Kharraz, E.; Ullah, A. Harnessing Glucan Branching Enzymes for Amylose-Based Starch Nanoparticle Formation: A Novel Bottom-up Approach. Food Hydrocoll. 2025, 164, 111182. [Google Scholar] [CrossRef]

- Nambiar, R.B.; Perumal, A.B.; Sadiku, E.R. Advances in Nanocomposites: Preparation, Characterization, Properties, and Applications. Molecules 2024, 29, 5924. [Google Scholar] [CrossRef] [PubMed]

- Dacanal, G.C. Particle size and morphology in food science and technology: A review. Int. J. Food Sci. Technol. 2024, 59, 6821–6833. [Google Scholar] [CrossRef]

- Apostolidis, E.; Gerogianni, A.; Anagnostaki, E.; Paximada, P.; Mandala, I. Assembly of spherical-shaped resistant starch nanoparticles to the oil droplet surface promotes the formation of stable oil in water Pickering emulsions. Food Hydrocoll. 2024, 151, 109775. [Google Scholar] [CrossRef]

- Yang, J.; Sun, Y.; Mu, H.; Li, X.; Wang, Y.; Xu, X.; Sun, Q. The formation of protein coronas and the interaction of soy protein isolate and whey protein isolate with starch nanoparticles. Int. J. Biol. Macromol. 2024, 282, 137451. [Google Scholar] [CrossRef]

- Lv, H.; Wang, C.; Xu, E.; Jin, Z.; Zhao, H.; Yuan, C.; Zhao, M.; Yu, B.; Wu, Z.; He, D.; et al. Preparation of starch-based oral fast-disintegrating nanofiber mats for astaxanthin encapsulation and delivery via emulsion electrospinning. Int. J. Biol. Macromol. 2025, 289, 136466. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, R.; Cai, Z.; Wu, F.; Hu, Y.; Huang, C.; Hu, K.; Chen, Y. Preparation and properties of pH-sensitive cationic starch nanoparticles. Food Chem. 2024, 437, 137916. [Google Scholar] [CrossRef] [PubMed]

- Bora, A.; Sarmah, D.; Rather, M.A.; Mandal, M.; Karak, N. Nanocomposite of starch, gelatin and itaconic acid-based biodegradable hydrogel and ZnO/cellulose nanofiber: A pH-sensitive sustained drug delivery vehicle. Int. J. Biol. Macromol. 2024, 256, 128253. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Yang, X.; Lu, Y.; Qiu, Y.; Zeng, Q. Review of the Synthesis and Degradation Mechanisms of Some Biodegradable Polymers in Natural Environments. Polymers 2024, 17, 66. [Google Scholar] [CrossRef] [PubMed]

- Dejene, B.K.; Birilie, A.A.; Yizengaw, M.A.; Getahun, S.A. Thermoplastic starch-ZnO nanocomposites: A comprehensive review of their applications in functional food packaging. Int. J. Biol. Macromol. 2024, 282, 137099. [Google Scholar] [CrossRef]

- Mei, S.; Roopashree, R.; Altalbawy, F.M.A.; Hamid, A.; Ahmed, H.H.; Naser, B.K.; Rizaev, J.; AbdulHussein, A.H.; Saud, A.; Hammoodi, H.A.; et al. Synthesis, characterization, and applications of starch-based nano drug delivery systems for breast cancer therapy: A review. Int. J. Biol. Macromol. 2024, 280, 136058. [Google Scholar] [CrossRef] [PubMed]

- Dhayal, A.; Kumar, H.; Mangla, B.; Singh, D. Harnessing the power of carbohydrates: Chitosan and starch-based nanocomposites for sustainable developments. Inorg. Chem. Commun. 2024, 171, 113597. [Google Scholar] [CrossRef]

- Griesemer, S.D.; Xia, Y.; Wolverton, C. Accelerating the prediction of stable materials with machine learning. Nat. Comput. Sci. 2023, 3, 934–945. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Li, C.; Feng, J.; Li, T.; Zhou, D.; Wu, C.; Fan, G. Insights into formation and stability mechanism of V7-type short amylose-resveratrol complex using molecular dynamics simulation and molecular docking. Int. J. Biol. Macromol. 2024, 265, 130930. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Zhang, S.; Piao, C.; Xu, F.; Zhang, Y.; Wang, X.; Zhang, J.; Zhao, C.; You, S.G.; Zhang, Y. Investigation of the formation mechanism of the pepper starch-piperine complex. Int. J. Biol. Macromol. 2024, 268, 131777. [Google Scholar] [CrossRef]

- Li, M.; Ma, S. A review of healthy role of dietary fiber in modulating chronic diseases. Food Res. Int. 2024, 191, 114682. [Google Scholar] [CrossRef] [PubMed]

- Gressler, S.; Hipfinger, C.; Part, F.; Pavlicek, A.; Zafiu, C.; Giese, B. A systematic review of nanocarriers used in medicine and beyond—Definition and categorization framework. J. Nanobiotechnology 2025, 23, 90. [Google Scholar] [CrossRef] [PubMed]

- Shoukat, L.; Javed, S.; Afzaal, M.; Akhter, N.; Shah, Y.A. Starch-based encapsulation to enhance probiotic viability in simulated digestion conditions. Int. J. Biol. Macromol. 2024, 283, 137606. [Google Scholar] [CrossRef]

- Li, H.; Song, J.; Liu, C.; Wang, X.; Liu, Y.; Han, M.; Liang, J.; Gao, Z. Corn starch/β-Cyclodextrin composite nanoparticles for encapsulation of tea polyphenol and development of oral targeted delivery systems with pH-responsive properties. Food Hydrocoll. 2024, 151, 109823. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, K.; Chi, C.; Chen, L.; Li, X. Preparation, stability and controlled release properties of starch-based micelles for oral delivery of hydrophobic bioactive molecules. Int. J. Biol. Macromol. 2024, 262, 130241. [Google Scholar] [CrossRef]

- Sethi, S.; Mahajan, P.; Thakur, S.; Sharma, N.; Singh, N.; Kumar, A.; Kaur, A.; Kaith, B.S. Design and evaluation of fluorescent chitosan-starch hydrogel for drug delivery and sensing applications. Int. J. Biol. Macromol. 2024, 274, 133486. [Google Scholar]

- Wang, W.; Liu, W.; Wu, J.; Liu, M.; Wang, Y.; Liu, H.; Liu, J. Preparation and characterization of particle-filled microgels by chemical cross-linking based on zein and carboxymethyl starch for delivering the quercetin. Carbohydr. Polym. 2024, 323, 121375. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Wang, Y.; Wei, A.; Peng, K.; Huang, R.; Wang, Z.; Ma, X.; Tian, Q.; Chen, Y. Polyelectrolyte composite hydrogels based on a derivative of functional dietary fiber for long-term gastric retention and drug delivery. Compos. Part B Eng. 2024, 272, 111194. [Google Scholar] [CrossRef]

- Chen, C.; Wang, Z.; Fu, H.; Yu, G.; Luo, X.; Zhu, K. Enhanced bioavailability of curcumin amorphous nanocomposite prepared by a green process using modified starch. Int. J. Biol. Macromol. 2024, 270, 132210. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Zhao, W.; Zou, Q.; Wang, L. Amphiphilic hydroxyethyl starch-based nanoparticles carrying linoleic acid modified berberine inhibit the expression of krasv12 oncogene in zebrafish. Biomed. Pharmacother. 2024, 176, 116798. [Google Scholar] [CrossRef] [PubMed]

- Priyanka, S.; Namasivayam, S.K.R.; Kennedy, J.F.; Moovendhan, M. Starch-chitosan-Taro mucilage nanocomposite active food packaging film doped with zinc oxide nanoparticles–Fabrication, mechanical properties, anti-bacterial activity and eco toxicity assessment. Int. J. Biol. Macromol. 2024, 277, 134319. [Google Scholar] [CrossRef]

- Hashem, A.H.; El-Naggar, M.E.; Abdelaziz, A.M.; Abdelbary, S.; Hassan, Y.R.; Hasanin, M.S. Bio-based antimicrobial food packaging films based on hydroxypropyl starch/polyvinyl alcohol loaded with the biosynthesized zinc oxide nanoparticles. Int. J. Biol. Macromol. 2023, 249, 126011. [Google Scholar] [CrossRef]

- Li, X.; Zhang, X.; Lv, J.; Zhang, X.; Li, Y.; Han, X.; Zhang, W. Development of starch-based films reinforced with curcumin-loaded nanocomplexes: Characterization and application in the preservation of blueberries. Int. J. Biol. Macromol. 2024, 264, 130464. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Wang, L.; Ma, C.; Xu, M.; Guan, X.; Lin, F.; Jiang, T.; Chen, X.; Bu, N.; Duan, J.; et al. Konjac glucomannan/xanthan gum film embedding soy protein isolate–tannic acid–iron complexes for blueberry preservation. Food Hydrocoll. 2024, 163, 111040. [Google Scholar] [CrossRef]

- Sreekanth, K.; Sharath, K.P.; CD, M.D.; Mathew, D.; Radhakrishnan, E.K. Microbial load reduction in stored raw beef meat using chitosan/starch-based active packaging films incorporated with cellulose nanofibers and cinnamon essential oil. Meat Sci. 2024, 216, 109552. [Google Scholar]

- Kaur, M.; Sharma, S.; Kalia, A.; Jawandha, S.K. Maize starch-PVA nanocomposite biodegradable antimicrobial packaging films for enhancement of shelf-life of Agaricus bisporus. Sustain. Mater. Technol. 2024, 41, e01114. [Google Scholar] [CrossRef]

- Dutta, D.; Sit, N. Preparation and characterization of potato starch-based composite films reinforced by modified banana fibers and its application in packaging of grapes. Int. J. Biol. Macromol. 2024, 254, 127791. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Ji, R.; Xu, J.; Yang, X.; An, Q.; Zhang, X.; Zhang, W. Preparation and characterization of highly stable pH-sensitive multifunctional films based on co-pigment-anthocyanin conjugate system for pork monitoring and preservation. Food Hydrocoll. 2025, 164, 111151. [Google Scholar] [CrossRef]

- Li, N.; Jiang, D.; Zhou, Z.; Lu, Y.; Zhong, L.; Law, W.C.; Tang, C.Y. Development of carboxymethyl cellulose/starch films enriched with ZnO-NPs and anthocyanins for antimicrobial and pH-indicating food packaging. Int. J. Biol. Macromol. 2024, 282, 136814. [Google Scholar] [CrossRef] [PubMed]

- Othman, S.H.; Shapi’i, R.A.; Ronzi, N.D.A. Starch biopolymer films containing chitosan nanoparticles: A review. Carbohydr. Polym. 2024, 329, 121735. [Google Scholar] [CrossRef]

- Sganzerla, W.G.; Rosa, G.B.; Ferreira, A.L.A.; Rosa, C.G.; Beling, P.C. Xavier, L.O.; Hansen, C.M.; Ferrareze, J.P.; Nunes, M.R.; Barreto, P.L.M.; et al. Bioactive food packaging based on starch, citric pectin and functionalized with Acca sellowiana waste by-product: Characterization and application in the postharvest conservation of apple. Int. J. Biol. Macromol. 2020, 147, 295–303. [Google Scholar]

- Gamage, A.; Thiviya, P.; Mani, S.; Ponnusamy, P.G.; Manamperi, A.; Evon, P.; Merah, O.; Madhujith, T. Environmental properties and applications of biodegradable starch-based nanocomposites. Polymers 2022, 14, 4578. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, L.; McClements, D.J.; Yang, T.; Zhang, Z.; Ren, F.; Miao, F.; Tian, Y.; Jin, Z. Starch-based biodegradable packaging materials: A review of their preparation, characterization and diverse applications in the food industry. Trends Food Sci. Technol. 2021, 114, 70–82. [Google Scholar] [CrossRef]

- Miao, W.; McClements, D.J.; Zhang, Z.; Liu, Q.; Ji, H.; Wang, J.; Jin, Z.; Li, G.; Jiang, L.; Wen, J. Fabrication and characterization of emulsion-template oleogels assembled from octenyl succinic anhydride starch/chitosan electrostatic complexes. Food Hydrocoll. 2024, 151, 109882. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, H.; Ren, Y.; Sun, M.; Zhang, T.; Li, H.; Liu, X. Functionality and application of emulsion gels in fat replacement strategies for dairy products. Trends Food Sci. Technol. 2024, 152, 104673. [Google Scholar] [CrossRef]

- Lin, Q.; Jiang, L.; Li, X.; Sang, S.; Ji, H.; Jin, Z.; Qiu, C. Starch based fat replacers in food system: Modification, structured design, and application. Food Biosci. 2024, 59, 104149. [Google Scholar] [CrossRef]

- Chen, Y.; She, Y.; Zhang, R.; Wang, J.; Zhang, X.; Gou, X. Use of starch-based fat replacers in foods as a strategy to reduce dietary intake of fat and risk of metabolic diseases. Food Sci. Nutr. 2020, 8, 16–22. [Google Scholar] [CrossRef]

- Chen, M.F. Consumer food choice motives and willingness to try plant-based meat: Moderating effect of meat attachment. Br. Food J. 2024, 126, 1301–1324. [Google Scholar] [CrossRef]

- Boateng, D.; Li, X.; Zhu, Y.; Zhang, H.; Wu, M.; Liu, J.; Kang, Y.; Zeng, H.; Han, L. Recent advances in flexible hydrogel sensors: Enhancing data processing and machine learning for intelligent perception. Biosens. Bioelectron. 2024, 261, 116499. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Song, P.; Li, G.; Han, Y.; Ren, X.; Bai, L.; Su, J. AI energized hydrogel design, optimization and application in biomedicine. Mater. Today Bio 2024, 25, 101014. [Google Scholar] [CrossRef]

- Boateng, D.; Li, X.; Wu, W.; Yang, A.; Gul, A.; Kang, Y.; Yang, L.; Liu, G.; Zeng, H.; Zhang, H.; et al. Air-Writing Recognition Enabled by a Flexible Dual-Network Hydrogel-Based Sensor and Machine Learning. ACS Appl. Mater. Interfaces 2024, 16, 54555–54565. [Google Scholar] [CrossRef]

- Joshi, T.; Sehgal, H.; Puri, S.; Karnika; Mahapatra, T.; Joshi, M.; Deepa, P.R.; Sharma, P.K. ML-based technologies in sustainable agro-food production and beyond: Tapping the (semi) arid landscape for bioactives-based product development. J. Agric. Food Res. 2024, 18, 101350. [Google Scholar] [CrossRef]

- Guida, C.; Aguiar, A.C.; Magalhães, A.E.R.; Soares, M.G.; Cunha, R.L. Impact of ultrasound process on cassava starch nanoparticles and Pickering emulsions stability. Food Res. Int. 2024, 192, 114810. [Google Scholar] [CrossRef] [PubMed]

- EFSA Scientific Committee; More, S.; Bampidis, V.; Benford, D.; Bragard, C.; Halldorsson, T.; Hernández-Jerez, A.; Bennekou, S.H.; Koutsoumanis, K.; Lambré, C.; et al. Guidance on risk assessment of nanomaterials to be applied in the food and feed chain: Human and animal health. EFSA J. 2021, 19, e06768. [Google Scholar]

- Subhan, M.A.; Subhan, T. Nanomaterial’s Safety Regulations in Food and Drug Industry. In Handbook of Green and Sustainable Nanotechnology: Fundamentals, Developments and Applications; Springer International Publishing: Cham, Switzerland, 2023; pp. 641–657. [Google Scholar]

- O’Brien Laramy, M.; Foley, D.A.; Pak, R.H.; Lewis, J.A.; McKinney, E.; Egan, P.M.; Yerabolu, R.; Dane, E.; Dirat, O.; Gorka, L.S.; et al. Chemistry, manufacturing and controls strategies for using novel excipients in lipid nanoparticles. Nat. Nanotechnol. 2025. online ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, Z.; Jafari, S.M. Regulatory principles on food nanoparticles legislated by Asian and Oceanian countries. In Safety and Regulatory Issues of Nanoencapsulated Food Ingredients; Academic Press: Cambridge, MA, USA, 2021; pp. 201–238. [Google Scholar]

- Parrella, J.A.; Leggette, H.R.; Lu, P.; Wingenbach, G.; Baker, M.; Murano, E. Nanofood insights: A survey of US consumers’ attitudes toward the use of nanotechnology in food processing. Appetite 2024, 201, 107613. [Google Scholar] [CrossRef] [PubMed]

- Downer, S.; Berkowitz, S.A.; Harlan, T.S.; Olstad, D.L.; Mozaffarian, D. Food is medicine: Actions to integrate food and nutrition into healthcare. BMJ 2020, 369, m2482. [Google Scholar] [CrossRef] [PubMed]

- Lv, Y.; Zhang, Y.; Xu, Y. Understanding and technological approach of acid hydrolysis processing for lignocellulose biorefinery: Panorama and perspectives. Biomass Bioenergy 2024, 183, 107133. [Google Scholar] [CrossRef]

- Zhu, Y.; Du, C.; Jiang, F.; Hu, W.; Yu, X.; Du, S.K. Pickering emulsions stabilized by starch nanocrystals prepared from various crystalline starches by ultrasonic assisted acetic acid: Stability and delivery of curcumin. Int. J. Biol. Macromol. 2024, 267, 131217. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Masood, A.; Ali, K.; Farid, N.; Bashir, A.; Dar, M.S. Green synthesis of silver, starch, and zinc oxide mediated nanoparticles with probiotics and plant extracts, their characterization and anti-bacterial activity. Microb. Pathog. 2024, 196, 107012. [Google Scholar] [CrossRef] [PubMed]

- Nestlé. Nestlé and ETH Zurich Establish Research Program to Reduce Carbon Footprint of Agricultural Raw Materials; Nestlé Global: Vevey, Switzerland, 2021. [Google Scholar]

- Zatsu, V.; Shine, A.E.; Tharakan, J.M.; Peter, D.; Ranganathan, T.V.; Alotaibi, S.S.; Mugabi, R.; Muhsinah, A.B.; Waseem, M.; Nayik, G.A. Revolutionizing the food industry: The transformative power of artificial intelligence—A review. Food Chem. X 2024, 24, 101867. [Google Scholar] [CrossRef] [PubMed]

- Van Duynhoven, J.; Voda, A.; Witek, M.; As, H.H. Time-domain NMR applied to food products. In Annual Reports on NMR Spectroscopy; Academic Press: Cambridge, MA, USA, 2010; Volume 69, pp. 145–197. [Google Scholar]

| Application | Compounds | Advantages | References |

|---|---|---|---|

| Delivery | Corn starch/lactobacillus rhamnosus | Enhancement of stability and vitality of probiotics. | [82] |

| Corn starch/β-cyclodextrin/tea polyphenols | Improvement of stability and bioavailability of tea polyphenols. | [83] | |

| Amphiphilic starch synthesized by stearic acid and lauric acid | Stability improvement of hydrophobic molecules, and bioavailability enhancement in gastrointestinal tract. | [84] | |

| Chitosan/starch | A potential candidate for drug release control and fluorescence sensing applications. | [85] | |

| Zein/carboxymethyl starch/quercetin | Improvement of stability, bioavailability, and targeted delivery ability of quercetin. | [86] | |

| Carboxymethylation resistant starch/chitosan | Accomplishment of in situ gelation in stomach, biocompatibility, degradation resistance, and sustained drug release. | [87] | |

| Octenyl succinic anhydride-modified starch/curcumin | Remarkable improvement in solubility, stability, and bioavailability of curcumin. | [88] | |

| Amphiphilic hydroxyethyl starch/linoleic acid-modified berberine | Improvement in anti-cancer activity of modified berberine, and excellent ability to inhibit the expression of oncogene in zebrafish model. | [89] | |

| Packaging | Starch/chitosan/taro mucus embedded with zinc oxide nanoparticles | Excellent mechanical properties, antibacterial activity, and biocompatibility. | [90] |

| Films based on hydroxypropyl starch/polyvinyl alcohol loaded with zinc oxide nanoparticles | Excellent antibacterial properties, mechanical stability, and biodegradability. | [91] | |

| Corn starch/curcumin-loaded nanocomplexes | Improvement in postharvest quality and shelf life of blueberries. | [92] | |

| Konjac glucomannan/xanthan gum/soy protein isolate/tannic acid/iron | Excellent mechanical properties, barrier properties, and antibacterial and antioxidant activities. | [93] | |

| Corn starch/chitosan/cellulose nanofibers/cinnamon essential oil | Excellent mechanical, physical, and chemical properties, and significantly reduced bacterial load in beef packed with this film. | [94] | |

| Maize starch/polyvinyl alcohol/nano-clay/essential oil | Excellent antibacterial performance and oxidation resistance, degradable and environmentally friendly. | [95] | |

| Potato starch/modified banana fibers | Excellent mechanical properties, thermal stability, non-toxicity, and biodegradability, and effective extension of grape shelf life. | [96] | |

| Potato starch/carrageenan/co-pigment/anthocyanin | High stability, pH sensitivity, excellent optical, mechanical, and barrier properties, and remarkable antioxidant and antibacterial abilities. | [97] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Wang, Z.; Ye, J.; Li, Y.; Wang, L.; Cao, R. Advances in Starch-Based Nanocomposites for Functional Food Systems: Harnessing AI and Nuclear Magnetic Resonance Technologies for Tailored Stability and Bioactivity. Foods 2025, 14, 773. https://doi.org/10.3390/foods14050773

Sun Y, Wang Z, Ye J, Li Y, Wang L, Cao R. Advances in Starch-Based Nanocomposites for Functional Food Systems: Harnessing AI and Nuclear Magnetic Resonance Technologies for Tailored Stability and Bioactivity. Foods. 2025; 14(5):773. https://doi.org/10.3390/foods14050773

Chicago/Turabian StyleSun, Yue, Ziyu Wang, Jian Ye, Yinta Li, Lili Wang, and Ruge Cao. 2025. "Advances in Starch-Based Nanocomposites for Functional Food Systems: Harnessing AI and Nuclear Magnetic Resonance Technologies for Tailored Stability and Bioactivity" Foods 14, no. 5: 773. https://doi.org/10.3390/foods14050773

APA StyleSun, Y., Wang, Z., Ye, J., Li, Y., Wang, L., & Cao, R. (2025). Advances in Starch-Based Nanocomposites for Functional Food Systems: Harnessing AI and Nuclear Magnetic Resonance Technologies for Tailored Stability and Bioactivity. Foods, 14(5), 773. https://doi.org/10.3390/foods14050773