The Effects of Malting and Extrusion on the Functional and Physical Properties of Extrudates from Malted Brown Rice and Pigeon Pea Flour Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Acquisition of Raw Materials

2.2. Malting of Brown Rice and Pigeon Pea

2.3. Designing Formulations Using Response Surface Methodology

2.4. Determination of Physical Properties

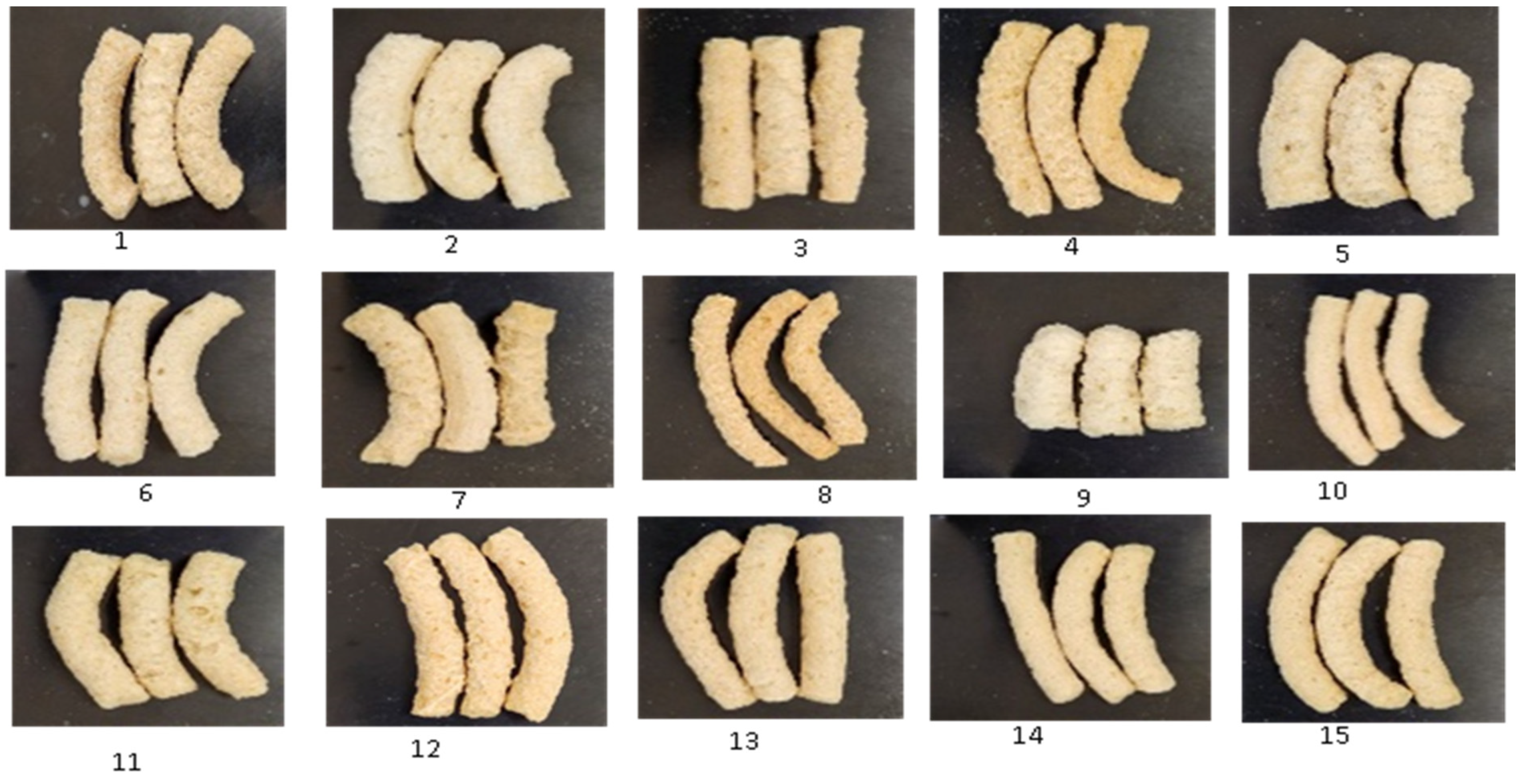

2.4.1. Photographic (Longitudinal Section) Image of the Extrudates

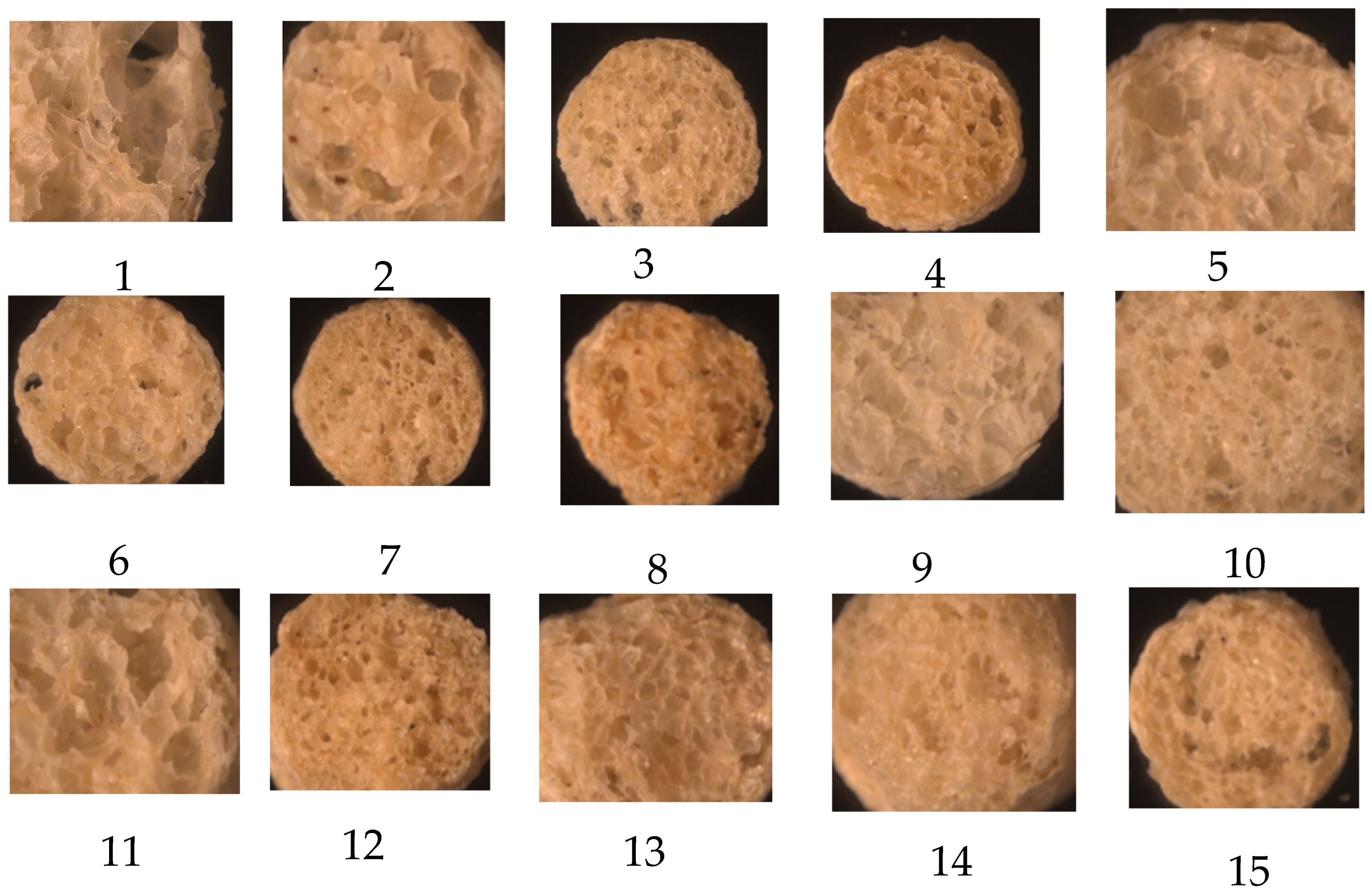

2.4.2. Development of 2-D Slice Microscopic Expanded Product

2.4.3. Sectional Expansion Index

2.4.4. Determination of Color Characteristics

2.5. Determination of Functional Properties of the Extrudates

2.5.1. Bulk Density (BD)

2.5.2. Viscosity Measurement of the Extrudates

2.5.3. Swelling Capacity

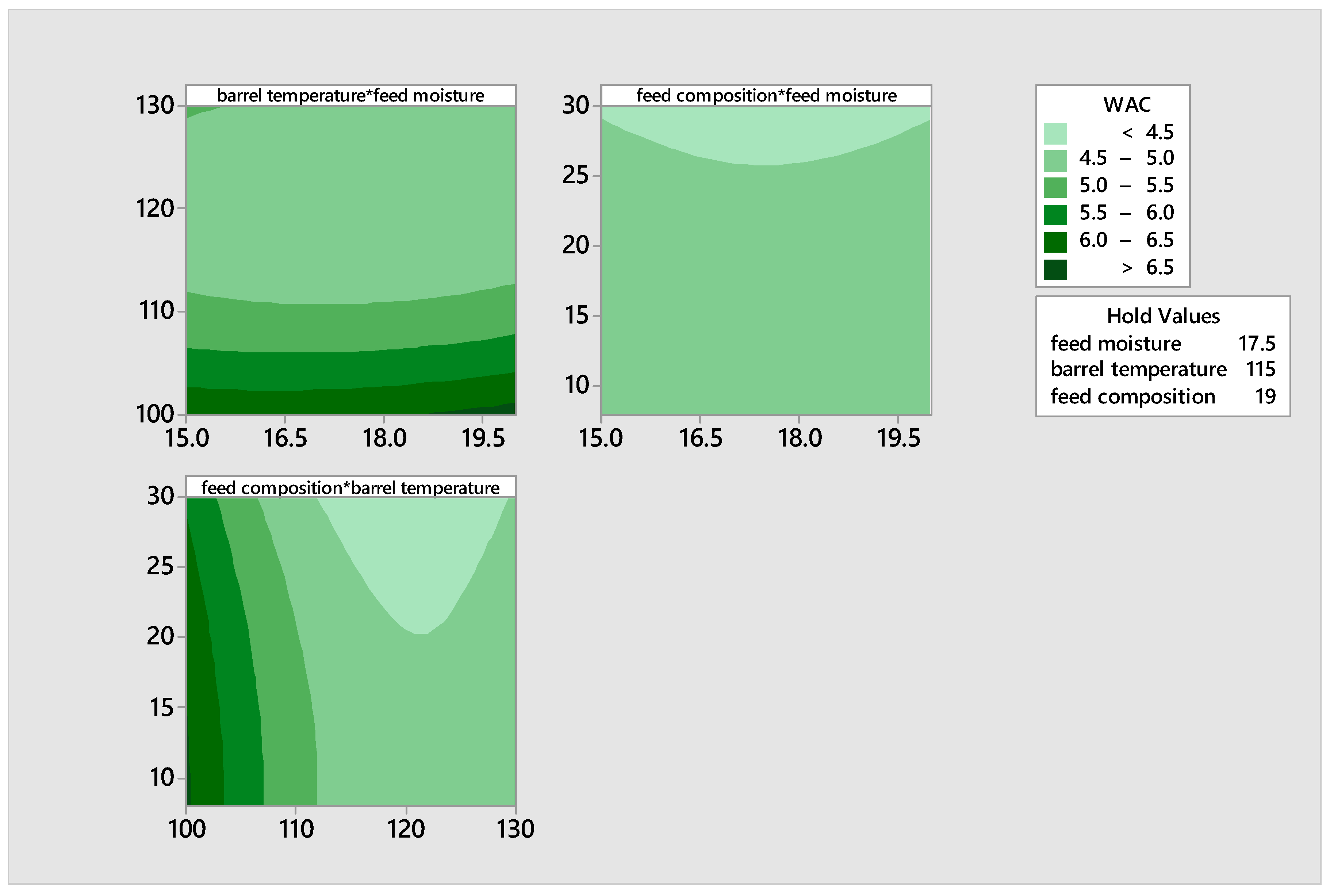

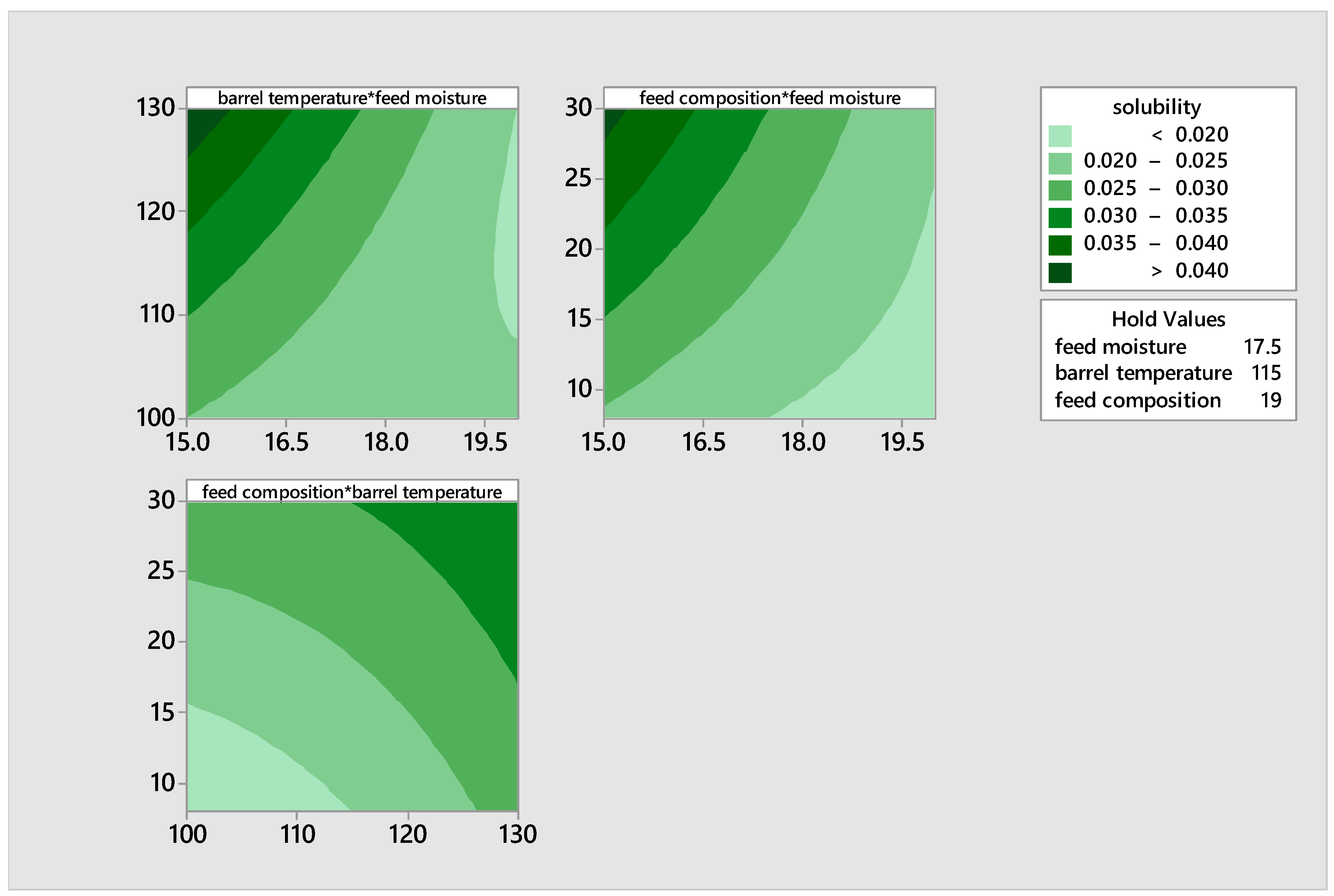

2.5.4. Water Absorption Capacity (WAC) and Solubility Index

2.5.5. Optimization of the Responses

2.6. Statistical Analysis

3. Results and Discussion

3.1. Effects of Malting and Extrusion Variables on the Physical Properties of Rice–Pigeon Pea Extrudates

3.1.1. Appearance

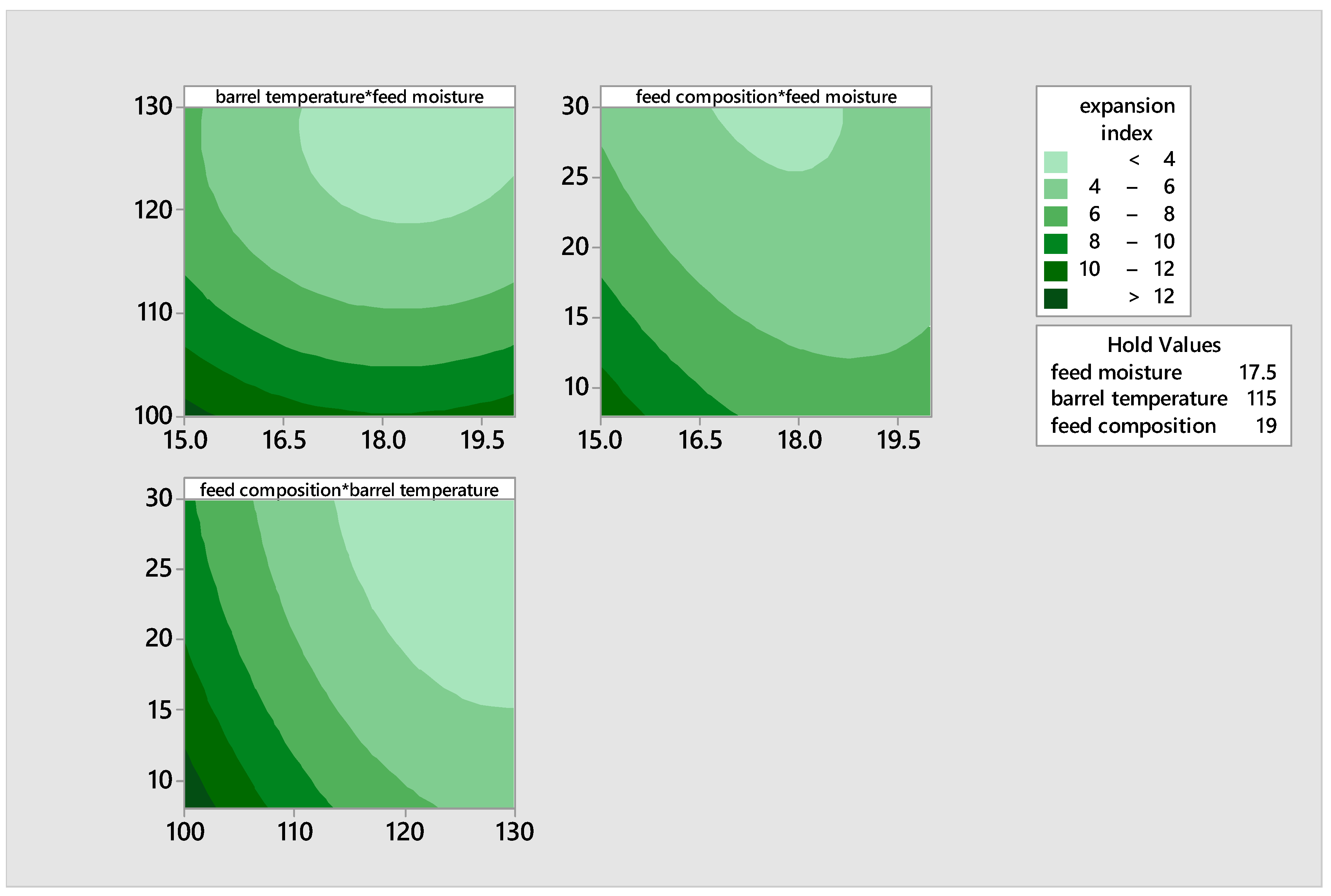

3.1.2. Expansion Index (EI)

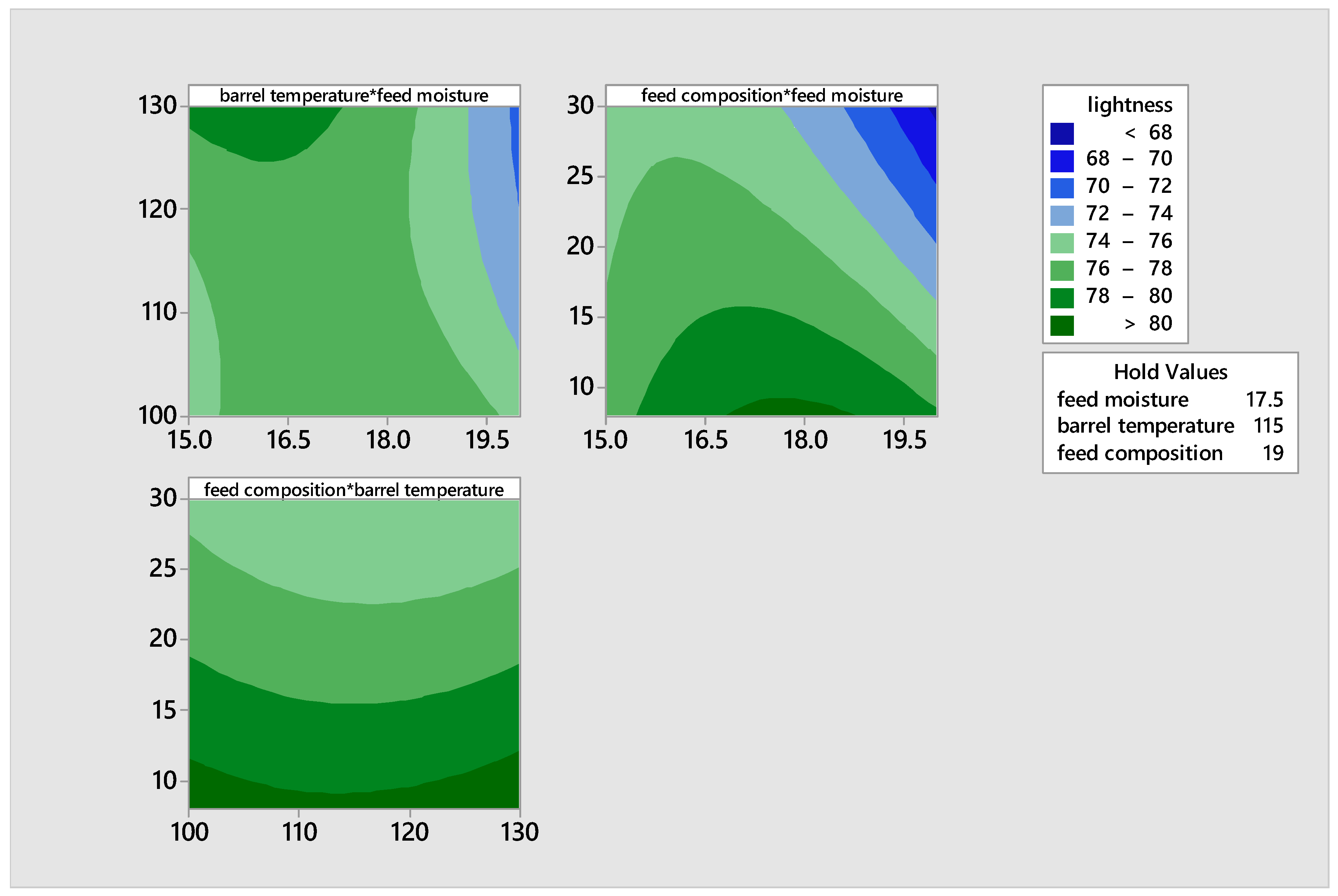

3.1.3. Color Characteristics of the Extrudates

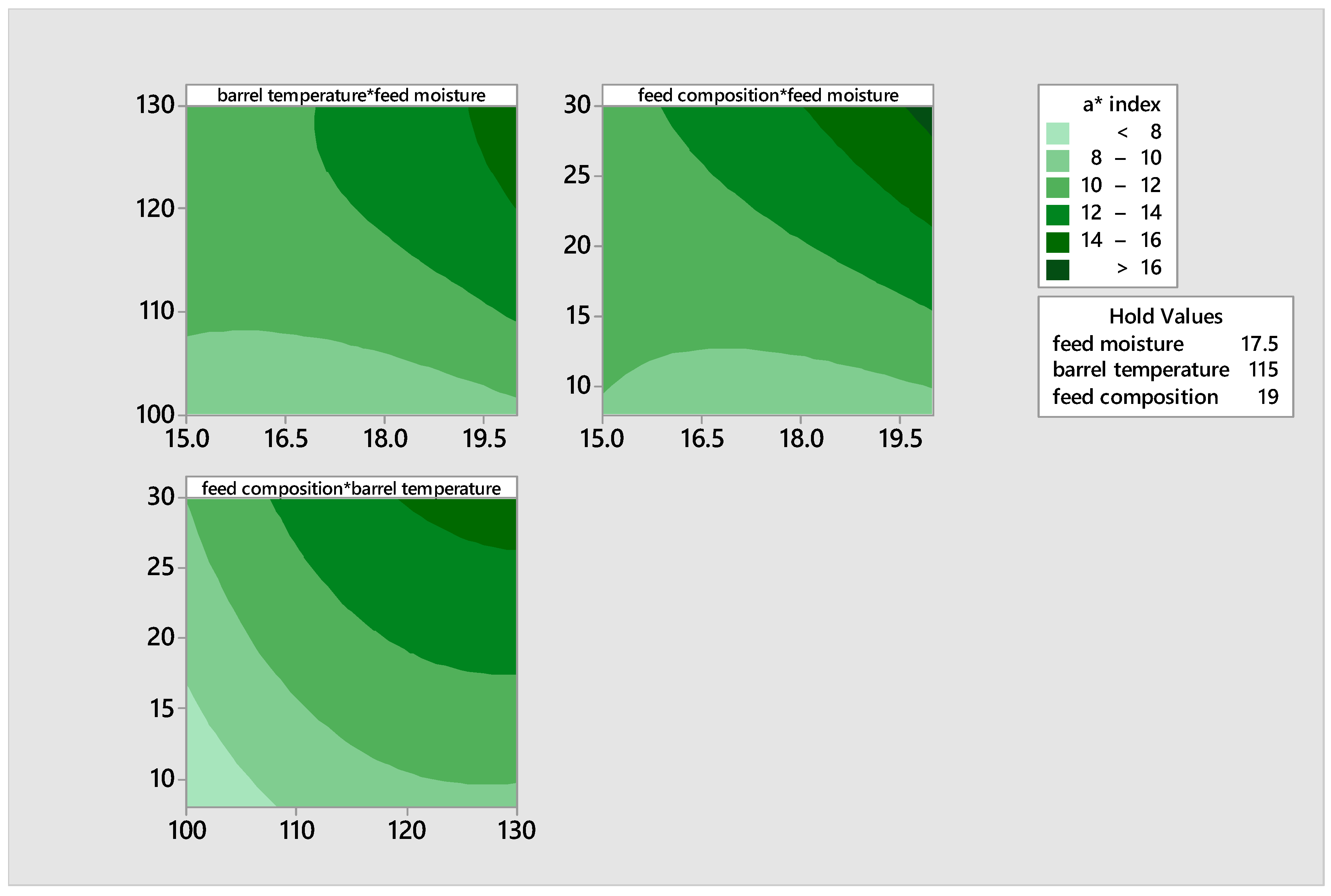

3.1.4. Responses of the a* Color Index

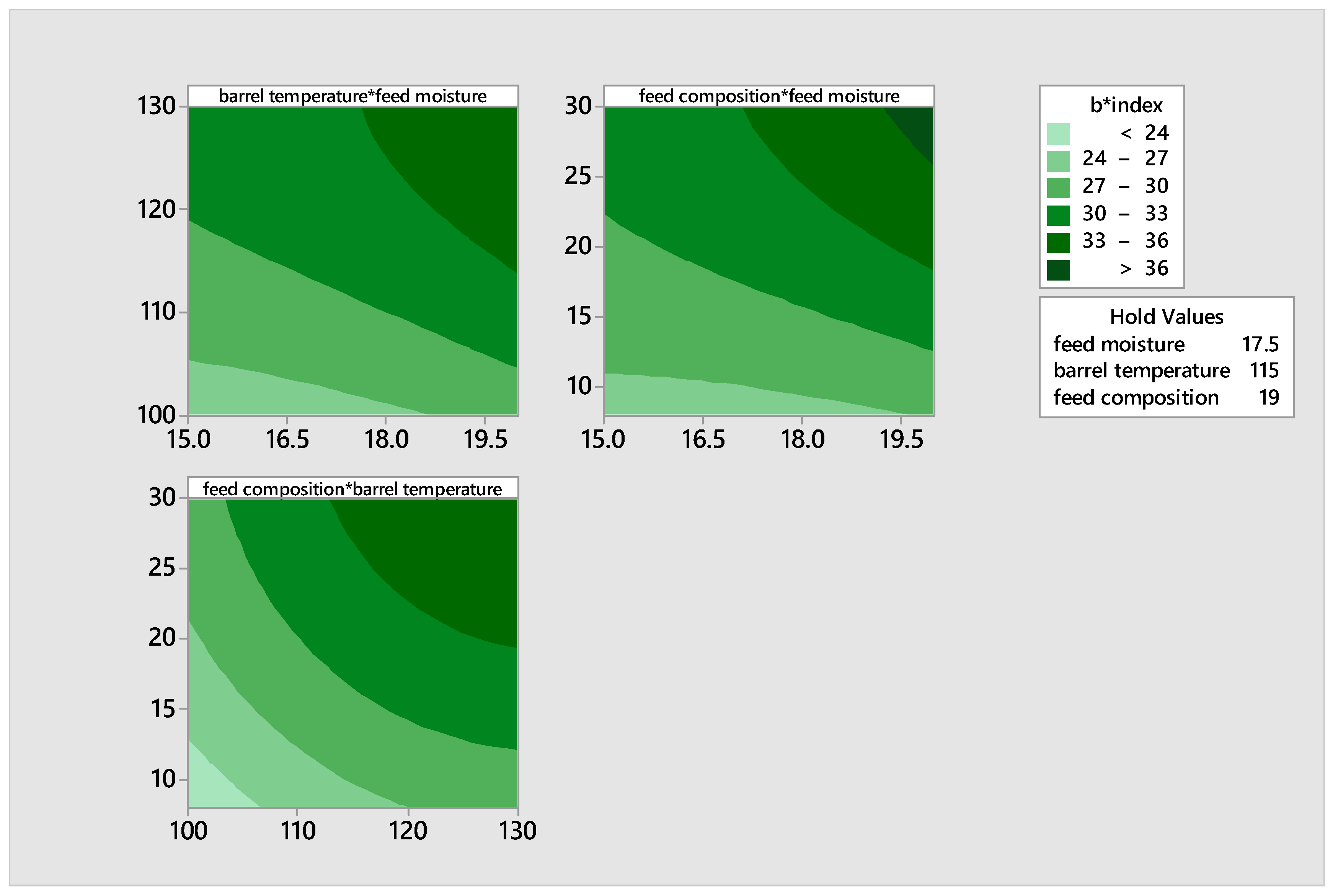

3.1.5. Responses of the b* Color Index

3.1.6. Changes in Color and Whiteness Index

3.2. Effects of Malting and Extrusion Variables on the Functional Properties of Rice–Pigeon Pea Extrudates

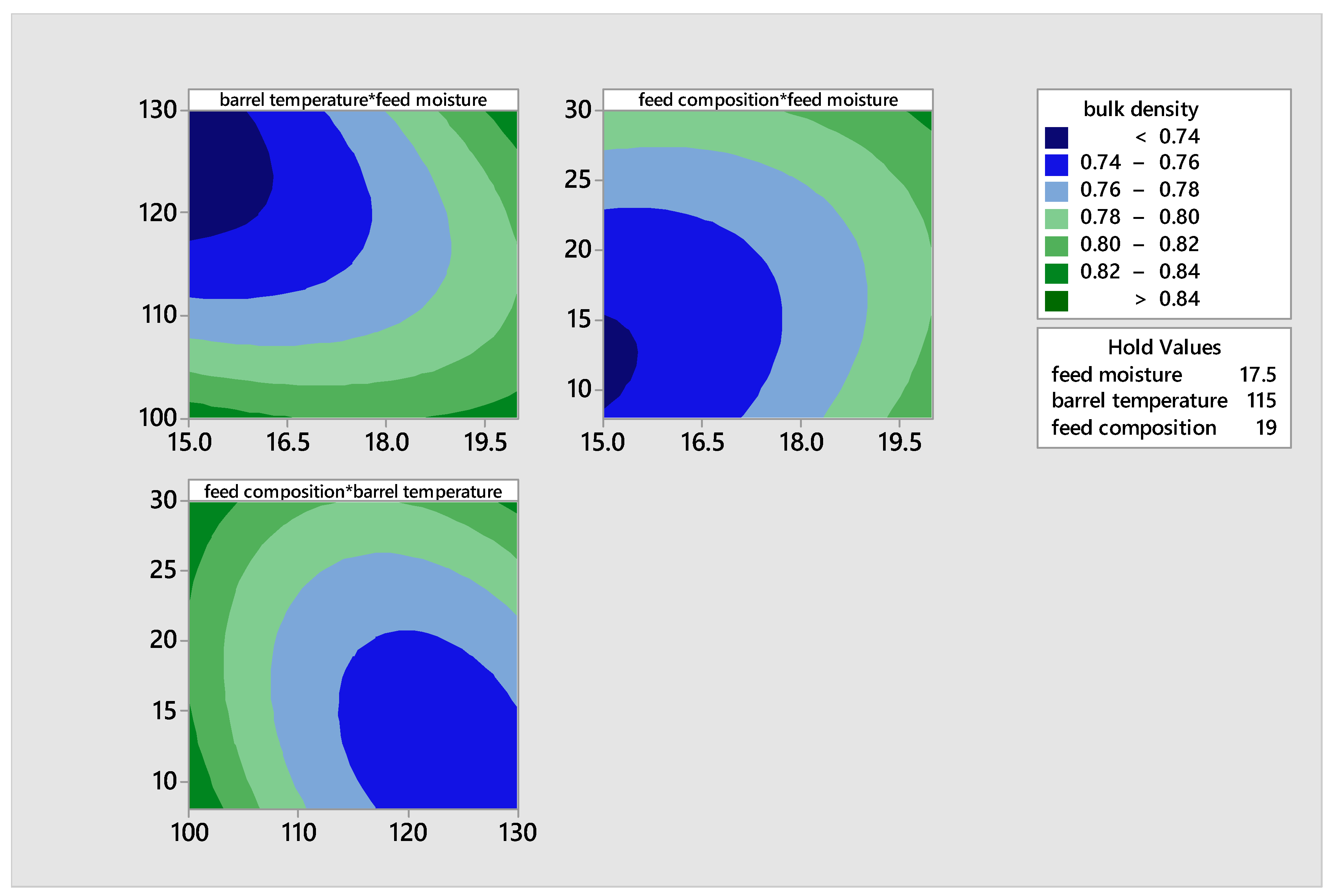

Bulk Density of the Extrudates

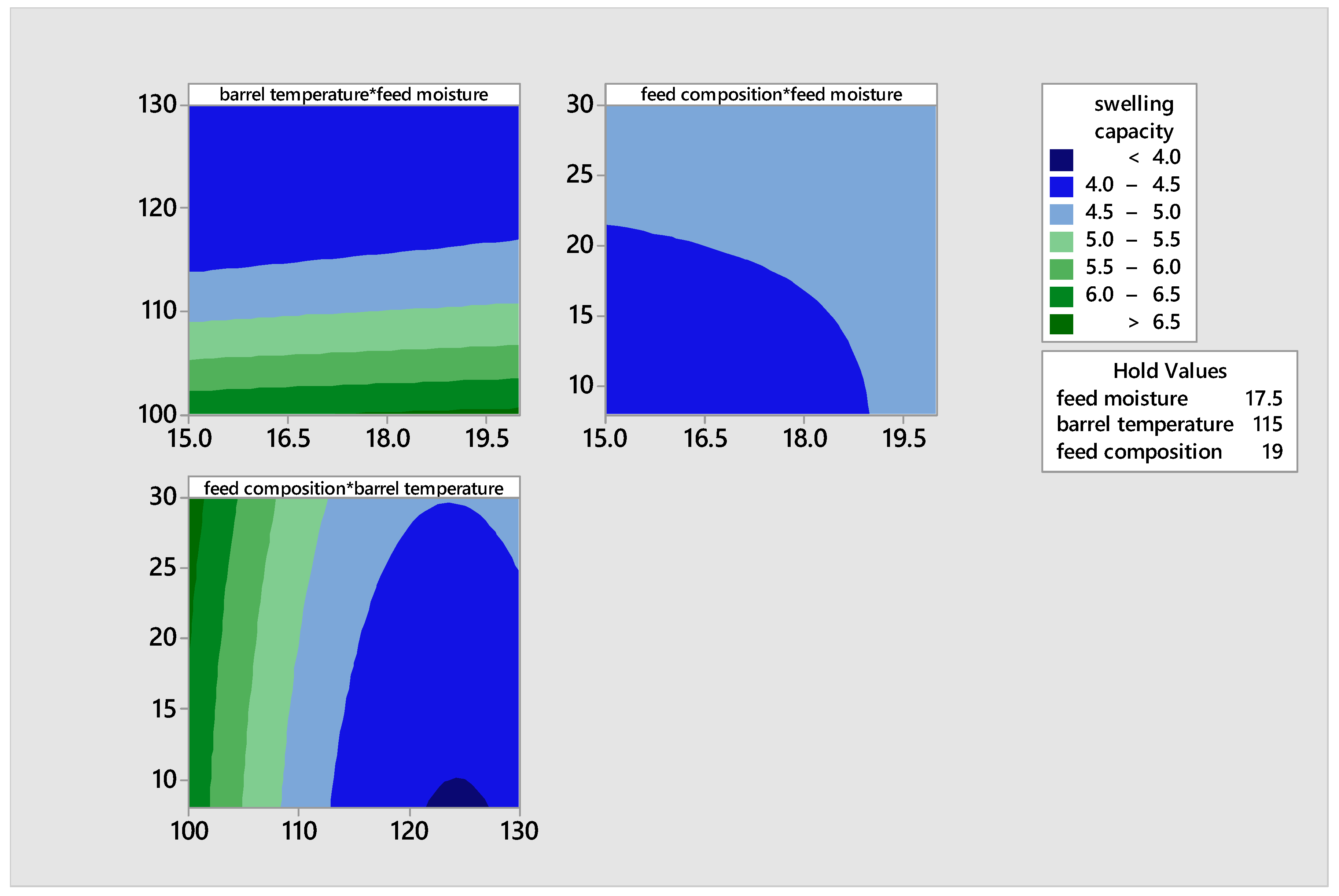

3.3. Swelling Capacity

3.4. Water Absorption Capacity (WAC)

3.5. Solubility

3.6. Viscosity

3.7. Analysis of Variance of the Functional Properties of the Developed Quadratic Model for Germinated Brown Rice–Pigeon Pea Blend

3.8. Optimization of the Responses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jabeen, R.; Hussain, S.Z.; Jan, N.; Fatima, T.; Naik, H.R.; Jabeen, A. Comparative study of brown rice and malted brown rice for nutritional composition, in vitro starch digestibility, bioactive compounds, antioxidant activity and microstructural properties. Cereal Chem. 2023, 100, 434–444. [Google Scholar] [CrossRef]

- Nkhata, S.G.; Ayua, E.; Kamau, E.H.; Shingiro, J.-B. Fermentation and malting improve nutritional value of cereals and legumes through activation of endogenous enzymes. Food Sci. Nutr. 2018, 6, 2446–2458. [Google Scholar] [CrossRef]

- Uppal, V.; Bains, K. Effect of malting periods and hydrothermal treatments on in vitro protein and starch digestibility of malted legumes. J. Food Sci. Technol. 2012, 49, 184–191. [Google Scholar] [CrossRef] [PubMed]

- Moongngarm, A.; Saetung, N. Comparison of chemical compositions and bioactive compounds of malted rough rice and brown rice. Food Chem. 2010, 122, 782–788. [Google Scholar] [CrossRef]

- Ojha, P.; Adhikari, R.; Karki, R.; Mishra, A.; Subedi, U.; Karki, T.B. Malting and fermentation effects on antinutritional components and functional characteristics of sorghum flour. Food Sci. Nutr. 2018, 6, 47–53. [Google Scholar] [CrossRef]

- Zhang, G.; Xu, Z.; Gao, Y.; Huang, X.; Zou, Y.; Yang, T. Effects of Malting on the Nutritional Properties, Phenolic Profiles, and Antioxidant Activities of Buckwheat. J. Food Sci. 2015, 80, H1111–H1119. [Google Scholar] [CrossRef]

- Zilic, S.; Delic, N.; Basic, Z.; Ignjatovic-Micic, D.; Jankovic, M.; Vancetovic, J. Effects of alkaline cooking and sprouting on bioactive compounds, their bioavailability and relation to antioxidant capacity of maize flour. J. Food Nutr. Res. 2015, 54, 155–164. [Google Scholar]

- Avezum, L.; Rondet, E.; Mestres, C.; Achir, N.; Madode, Y.; Gibert, O.; Lefevre, C.; Hemery, Y.; Verdeil, J.-L.; Rajjou, L. Improving the nutritional quality of pulses via malting. Food Rev. Int. 2022, 39, 6011–6044. [Google Scholar] [CrossRef]

- Erba, D.; Angelino, D.; Marti, A.; Manini, F.; Faoro, F.; Morreale, F.; Pellegrini, N.; Casiraghi, M.C. Effect of sprouting on nutritional quality of pulses. Int. J. Food Sci. Nutr. 2019, 70, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Gharachorloo, M.; Ghiassi Tarzi, B.; Baharinia, M. The Effect of Malting on Phenolic Compounds and Antioxidant Activity of Pulses. J. Am. Oil Chem. Soc. 2013, 90, 407–411. [Google Scholar] [CrossRef]

- López-Martínez, L.X.; Leyva-López, N.; Gutiérrez-Grijalva, E.P.; Heredia, J.B. Effect of cooking and malting on bioactive compounds in pulses and their health benefits. J. Funct. Foods 2017, 38, 624–634. [Google Scholar] [CrossRef]

- Cáceres, P.J.; Peñas, E.; Martinez-Villaluenga, C.; Amigo, L.; Frias, J. Enhancement of biologically active compounds in malted brown rice and the effect of sun-drying. J. Cereal Sci. 2017, 73, 1–9. [Google Scholar] [CrossRef]

- Uchegbu, N.N.; Ishiwu, C.N. Malted Pigeon Pea (Cajanus cajan): A novel diet for lowering oxidative stress and hyperglycemia. Food Sci. Nutr. 2016, 4, 772–777. [Google Scholar] [CrossRef]

- Kuraz Abebe, B. The Dietary Use of Pigeon Pea for Human and Animal Diets. Sci. World J. 2022, 2022, 1–12. [Google Scholar] [CrossRef]

- George, T.T.; Obilana, A.O.; Oyeyinka, S.A. The prospects of African yam bean: Past and future importance. Heliyon 2020, 6, e05458. [Google Scholar] [CrossRef]

- Uchegbu, N.N.; Okoli, E.C.; Onwurafor, E.U. Antioxidant Properties of Steamed Paste (Moin-Moin) Made from Sprouted Pigeon Pea Flour as Influenced by Heat Treatment. Am. J. Food Technol. 2017, 13, 42–47. [Google Scholar] [CrossRef][Green Version]

- Dalbhagat, C.G.; Mahato, D.K.; Mishra, H.N. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: A review. Trends Food Sci. Technol. 2019, 85, 226–240. [Google Scholar] [CrossRef]

- Adeleye, O.O.; Awodiran, S.T.; Ajayi, A.O.; Ogunmoyela, T.F. Influence of extrusion cooking on physicochemical properties and starch digestion kinetics of Sphenostylis stenocarpa, Cajanus cajan, and Vigna subterranean grains. PLoS ONE 2020, 15, e0242697. [Google Scholar] [CrossRef] [PubMed]

- Kamau, E.H.; Nkhata, S.G.; Ayua, E.O. Extrusion and nixtamalization conditions influence the magnitude of change in the nutrients and bioactive components of cereals and legumes. Food Sci. Nutr. 2020, 8, 1753–1765. [Google Scholar] [CrossRef] [PubMed]

- Wójtowicz, A.; Mościcki, L. Influence of Extrusion-Cooking Parameters on Some Quality Aspects of Precooked Pasta-Like Products. J. Food Sci. 2009, 74, E226–E233. [Google Scholar] [CrossRef]

- Brennan, M.A.; Merts, I.; Monro, J.; Woolnough, J.; Brennan, C.S. Impact of Guar and Wheat Bran on the Physical and Nutritional Quality of Extruded Breakfast Cereals. Starch-Stärke 2008, 60, 248–256. [Google Scholar] [CrossRef]

- Martin, A.; Schmidt, V.; Osen, R.; Bez, J.; Ortner, E.; Mittermaier, S. Texture, sensory properties and functionality of extruded snacks from pulses and pseudocereal proteins. J. Sci. Food Agric. 2022, 102, 5011–5021. [Google Scholar] [CrossRef]

- Gajula, H.; Liu, S.; Alavi, S.; Herald, T.; Madl, R.; Bean, S.R.; Tilley, M. Pre-Cooked Fiber-Enriched Wheat Flour Obtained by Extrusion: Rheological and Functional Properties. Int. J. Food Prop. 2009, 12, 27–44. [Google Scholar] [CrossRef]

- Wang, S.; Nosworthy, M.G.; House, J.D.; Niefer, S.-H.; Nickerson, M.T. Effect of barrel temperature and feed moisture on protein quality in pre-cooked Kabuli chickpea, sorghum, and maize flours. Food Sci. Technol. Int. 2020, 26, 265–274. [Google Scholar] [CrossRef]

- Forsido, S.F.; Welelaw, E.; Belachew, T.; Hensel, O. Effects of storage temperature and packaging material on physico-chemical, microbial and sensory properties and shelf life of extruded composite baby food flour. Heliyon 2021, 7, e06821. [Google Scholar] [CrossRef] [PubMed]

- Samard, S.; Maung, T.-T.; Gu, B.-Y.; Kim, M.-H.; Ryu, G.-H. Influences of extrusion parameters on physicochemical properties of textured vegetable proteins and its meatless burger patty. Food Sci. Biotechnol. 2021, 30, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Li, S.; Zhang, B.; Drago, S.R.; Zhang, J. Relationships between the gelatinization of starches and the textural properties of extruded texturized soybean protein-starch systems. J. Food Eng. 2016, 174, 29–36. [Google Scholar] [CrossRef]

- Banki, N.M.; Salihu, A.; Muhammad, A.; Bala, S.M. Optimization and characterization of rice–pigeon pea flour blend using extrusion cooking process. Legume Sci. 2021, 3, e73. [Google Scholar] [CrossRef]

- Patil, S.B.; Khan, M.K. Malted brown rice as a value added rice product: A review. J. Food Sci. Technol. 2011, 48, 661–667. [Google Scholar] [CrossRef]

- Danbaba, N.; Idakwo, N.I.; Yahaya, P.; Mamudu, B.; Aliyu, U. Chapter Advances in Rice Postharvest Loss Reduction Strategies in Africa through Low Grade Broken Rice Fractions and Husk Value Addition. In Recent Advances in Rice Research; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Patil, R.T.; Berrios, D.J.J.; Tang, J.; Pan, J.; Swanson, B. Physical Characteristics of Food Extrudates—A Review. In Proceedings of the An ASAE Meeting Presentation, Tampa, FL, USA, 17–20 July 2005. [Google Scholar]

- Danbaba, N.; Nkama, I.; Badau, M.H.; Idakwo, P.Y. Predictive modeling and optimization of extrusion cooking process for color characteristics and consumer acceptability of fortified rice snacks. IOSR J. Environ. Sci. Toxicol. Food Technol. (IOSR-JESTFT) 2019, 13, 33–43. [Google Scholar]

- Okaka, J.C.; Potter, N.N. Functional and storage properties of cowpea powder-wheat flour blends in breadmaking. J. Food Sci. 1977, 42, 828–833. [Google Scholar] [CrossRef]

- Gandhi, A.P.; Srivastava, J. Studies on the Production of Protein Isolates from Defatted Sesame Seed (Sesamum indicum) flour and their nutritional profile. ASEAN Food J. 2007, 14, 175–180. [Google Scholar]

- Yousf, N.; Nazir, F.; Salim, R.; Ahsan, H.; Sirwal, A.A. Water solubility index and water absorption index of extruded product from rice and carrot blend. J. Pharmacogn. Phytochem. 2017, 6, 2165–2168. [Google Scholar]

- Anuar, N.; Mohd Adnan, A.F.; Saat, N.; Aziz, N.; Mat Taha, R. Optimization of Extraction Parameters by Using Response Surface Methodology, Purification, and Identification of Anthocyanin Pigments inMelastoma malabathricumFruit. Sci. World J. 2013, 2013, 810547. [Google Scholar] [CrossRef] [PubMed]

- Gupta, K.; Mansi, V.; Payal, J.; Monika, J. Process optimization for producing cowpea added instant kheer mix using response surface methodology. J. Nutr. Health Food Eng. 2014, 1, 00030. [Google Scholar] [CrossRef][Green Version]

- Danbaba, N.N.; Nkama, I.; Badau, M.H. Use of Response Surface Methodology (RSM) for Composite Blends of Low Grade Broken Rice Fractions and Full-fat Soybean Flour by a Twin-screw Extrusion Cooking Process. Int. J. Food Stud. 2019, 8, 14–29. [Google Scholar] [CrossRef]

- Nwabueze, T.U.; Iwe, M.O.; Akobundu, E.N.T. Physical characteristics and acceptability of extruded african breadfruit-based snacks. J. Food Qual. 2007, 31, 142–155. [Google Scholar] [CrossRef]

- Azuka, C.E.; Okafor, G.; Asoiro, F.; Marshall, L.J.; Holmes, M.; Boesch, C. Effect of germination and extrusion on the physical properties of extruded germinated brown rice and pigeon pea flour blends. In AAB Early Career Professional Skills and Science Workshop University of Leicester 18th–19th December 23; University of Leicester College Court: Leicester, UK; p. 22.

- Hagenimana, A.; Ding, X.; Fang, T. Evaluation of rice flour modified by extrusion cooking. J. Cereal Sci. 2006, 43, 38–46. [Google Scholar] [CrossRef]

- Yu, L.; Ramaswamy, H.S.; Boye, J. Protein rich extruded products prepared from soy protein isolate-corn flour blends. LWT—Food Sci. Technol. 2013, 50, 279–289. [Google Scholar] [CrossRef]

- Devi, N.L.; Shobha, S.; Tang, X.; Shaur, S.A.; Dogan, H.; Alavi, S. Development of protein-Rich Sorghum-Based Expanded Snacks Using Extrusion Technology. Int. J. Food Prop. 2013, 16, 263–276. [Google Scholar] [CrossRef]

- Moraru, C.I.; Kokini, J.L. Nucleation and Expansion During Extrusion and Microwave Heating of Cereal Foods. Compr. Rev. Food Sci. Food Saf. 2003, 2, 147–165. [Google Scholar] [CrossRef] [PubMed]

- Singha, P.; Singh, S.K.; Muthukumarappan, K.; Krishnan, P. Physicochemical and nutritional properties of extrudates from food grade distiller’s dried grains, garbanzo flour, and corn grits. Food Sci. Nutr. 2018, 6, 1914–1926. [Google Scholar] [CrossRef] [PubMed]

- Nath, A.; Chattopadhyay, P.K. Optimization of oven toasting for improving crispness and other quality attributes of ready to eat potato-soy snack using response surface methodology. J. Food Eng. 2007, 80, 1282–1292. [Google Scholar] [CrossRef]

- Gutkoski, L.C.; El-Dash, A.A. Plant Foods for Human Nutrition. Plant Foods Hum. Nutr. 1999, 54, 315–325. [Google Scholar] [CrossRef] [PubMed]

- Altan, A.; McCarthy, K.L.; Maskan, M. Evaluation of snack foods from barley–tomato pomace blends by extrusion processing. J. Food Eng. 2008, 84, 231–242. [Google Scholar] [CrossRef]

- Ding, Q.B.; Ainsworth, P.; Plunkett, A.; Tucker, G.; Marson, H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J. Food Eng. 2006, 73, 142–148. [Google Scholar] [CrossRef]

- Azuka, C.E.; Onwuchekwa, A.; Okafor, G.; Marshall, L.J.; Holmes, M.; Boesch, C. Effect of malting and extrusion on the functional properties of extrudates from flour blends of malted brown rice and pigeon pea. In Proceedings of the 10th Regional Food Science and Technology Summit (ReFoSTS) of NIFST East Central Chapter, Awka, Nigeria, 7 June 2024; pp. 74–77. [Google Scholar]

- Kristiawan, M.; Della Valle, G.; Berzin, F. Extrusion Simulation for the Design of Cereal and Legume Foods. Foods 2022, 11, 1780. [Google Scholar] [CrossRef] [PubMed]

| Runs | Independent Variables in Coded Form | Independent Variables in Their Natural Form | ||||

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X1 | X2 | X3 | |

| 1 | −1 | −1 | 0 | 15 | 100 | 19 |

| 2 | 1 | −1 | 0 | 20 | 100 | 19 |

| 3 | −1 | 1 | 0 | 15 | 130 | 19 |

| 4 | 1 | 1 | 0 | 20 | 130 | 19 |

| 5 | −1 | 0 | −1 | 15 | 115 | 8 |

| 6 | 1 | 0 | −1 | 20 | 115 | 8 |

| 7 | −1 | 0 | 1 | 15 | 115 | 30 |

| 8 | 1 | 0 | 1 | 20 | 115 | 30 |

| 9 | 0 | −1 | −1 | 17.5 | 100 | 8 |

| 10 | 0 | 1 | −1 | 17.5 | 130 | 8 |

| 11 | 0 | −1 | 1 | 17.5 | 100 | 30 |

| 12 | 0 | 1 | 1 | 17.5 | 130 | 30 |

| 13 | 0 | 0 | 0 | 17.5 | 115 | 19 |

| 14 | 0 | 0 | 0 | 17.5 | 115 | 19 |

| 15 | 0 | 0 | 0 | 17.5 | 115 | 19 |

| Run | Germinated Brown Rice Flour (GBRF) | Non-Germinated Brown Rice Flour (BRF) | Germinated Pigeon Pea Flour (PPF) |

|---|---|---|---|

| 1 | 546.75 | 668.25 | 285 |

| 2 | 546.75 | 668.25 | 285 |

| 3 | 546.75 | 668.25 | 285 |

| 4 | 546.75 | 668.25 | 285 |

| 5 | 621 | 759 | 120 |

| 6 | 621 | 759 | 120 |

| 7 | 472.5 | 577.5 | 450 |

| 8 | 472.5 | 577.5 | 450 |

| 9 | 621 | 759 | 120 |

| 10 | 621 | 759 | 120 |

| 11 | 472.5 | 577.5 | 450 |

| 12 | 472.5 | 577.5 | 450 |

| 13 | 546.75 | 668.25 | 285 |

| 14 | 546.75 | 668.25 | 285 |

| 15 | 546.75 | 668.25 | 285 |

| Runs | Design Points (X1, X2,, X3) | Moisture Content (%) | Expansion Index | Lightness | a* | b* | Whiteness Index | Change in Color |

|---|---|---|---|---|---|---|---|---|

| 1 | (15, 100, 19) | 8.79 ± 0.00 | 12.46 ± 0.71 | 73.74 ± 0.70 | 8.71 ± 0.25 | 24.85 ± 0.46 | 63.67 ± 9.59 | 34.47 |

| 2 | 20, 100, 19) | 10.00 ± 0.00 | 12.33 ± 1.96 | 74.23 ± 1.34 | 9.45 ± 0.33 | 27.96 ± 0.99 | 63.72 ± 9.87 | 36.66 |

| 3 | (15, 130, 19) | 7.40 ± 0.28 | 5.17 ± 0.52 | 79.65 ± 0.07 | 11.24 ± 0.11 | 31.05 ± 0.19 | 63.90 ± 10.15 | 36.84 |

| 4 | (20, 130, 19) | 9.80 ± 0.00 | 3.92 ± 0.26 | 72.81 ± 0.62 | 14.70 ± 0.37 | 36.23 ± 0.53 | 64.08 ± 10.46 | 45.47 |

| 5 | (15, 115, 8) | 8.30 ± 0.13 | 12.94 ± 1.54 | 77.63 ± 0.45 | 9.00 ± 0.15 | 25.17 ± 0.34 | 64.91 ± 10.33 | 32.43 |

| 6 | (20, 115, 8) | 9.60 ± 0.00 | 7.26 ± 0.81 | 78.84 ± 0.45 | 8.70 ± 0.03 | 26.32 ± 0.16 | 64.90 ± 10.73 | 32.59 |

| 7 | (15, 115, 30) | 6.80 ± 0.85 | 5.56 ± 0.50 | 74.87 ± 0.40 | 12.08 ± 0.36 | 31.62 ± 0.71 | 64.88 ± 11.18 | 39.91 |

| 8 | (20, 115, 30) | 9.20 ± 0.28 | 3.5 ± 0.36 | 66.83 ± 2.84 | 17.48 ± 0.79 | 37.95 ± 0.72 | 65.52 ± 11.47 | 50.99 |

| 9 | (17.5, 100, 8) | 7.90 ± 0.14 | 12.06 ± 1.42 | 81.71 ± 0.53 | 6.95 ± 0.20 | 22.77 ± 0.48 | 67.40 ± 10.21 | 27.75 |

| 10 | (17.5, 130, 8) | 8.20 ± 0.84 | 5.24 ± 0.42 | 79.62 ± 0.20 | 10.28 ± 0.03 | 28.36 ± 0.51 | 67.12 ± 10.74 | 34.33 |

| 11 | (17.5, 100, 30) | 8.10 ± 0.14 | 8.71 ± 0.82 | 77.35 ± 0.84 | 9.25 ± 0.15 | 28.16 ± 0.35 | 67.56 ± 11.34 | 35.01 |

| 12 | (17.5, 130, 30) | 7.80 ± 0.28 | 4.24 ± 0.20 | 74.16 ± 0.44 | 14.05 ± 0.23 | 34.65 ± 0.51 | 68.26 ± 11.99 | 43.31 |

| 13 | (17.5, 115, 19) | 8.30 ± 0.14 | 4.85 ± 0.31 | 77.94 ± 0.29 | 11.39 ± 0.18 | 31.01 ± 0.25 | 70.54 ± 11.42 | 37.65 |

| 14 | (17.5, 115, 19) | 8.00 ± 0.28 | 4.98 ± 0.09 | 76.80 ± 0.96 | 11.29 ± 0.11 | 30.62 ± 0.15 | 72.59 ± 11.46 | 37.87 |

| 15 | (17.5, 115, 19) | 8.10 ± 0.14 | 4.96 ± 0.21 | 76.21 ± 0.72 | 11.55 ± 0.45 | 30.96 ± 0.87 | 75.75 ± 10.61 | 38.52 |

| 16 | GBRF | 12.29 ± 0.14 | 89.20 ± 0.38 | 2.31 ± 0.15 | 12.56 ± 0.35 | 81.25 ± 4.33 | 14.41 | |

| 17 | BRF | 10.50 ± 0.42 | 91.11 ± 0.32 | 2.78 ± 0.12 | 11.89 ± 0.28 | 80.24 ± 5.14 | 13.11 | |

| 18 | PPF | 6.70 ± 0.14 | 88.43 ± 1.72 | 4.60 ± 0.13 | 20.96 ± 0.94 | 75.58 ± 0.78 | 22.70 |

| Source | Expansion Index p-Value | Moisture p-Value | Lightness p-Value | a* p-Value | b* p-Value |

|---|---|---|---|---|---|

| Model | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| X1 (feed moisture) | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| X2 (barrel temperature) | 0.000 | 0.063 | 0.744 | 0.000 | 0.000 |

| X3 (feed composition) | 0.000 | 0.018 | 0.000 | 0.000 | 0.000 |

| X12 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| X22 | 0.000 | 0.207 | 0.054 | 0.000 | 0.084 |

| X32 | 0.000 | 0.039 | 0.466 | 0.235 | 0.000 |

| X1X2 | 0.092 | 0.051 | 0.000 | 0.001 | 0.048 |

| X1X3 | 0.000 | 0.071 | 0.000 | 0.000 | 0.000 |

| X2X3 | 0.000 | 0.312 | 0.527 | 0.068 | 0.380 |

| Lack of fit | 0.000 | 0.026 | 0.000 | 0.000 | 0.000 |

| Coefficient of variation (%) | 8.47 | 3.03 | 0.99 | 2.14 | 1.6 |

| Coefficient of determination (R2) | 87.03% | 86.55% | 86.53% | 94.94% | 96.53% |

| Adjusted R2 | 86.49% | 80.50% | 83.06% | 93.63% | 95.64% |

| Runs | Design Points (X1, X2, X3) | Bulk Density | Swelling Cap (%) | WAC (%) | Solubility |

|---|---|---|---|---|---|

| 1 | (15, 100, 19) | 0.83 ± 0.00 | 6.45 ± 0.07 | 6.64 ± 0.02 | 0.03 ± 0.01 |

| 2 | 20, 100, 19) | 0.83 ± 0.00 | 6.50 ± 0.14 | 6.82 ± 0.10 | 0.02 ± 0.00 |

| 3 | (15, 130, 19) | 0.72 ± 0.00 | 4.30 ± 0.14 | 4.95 ± 0.08 | 0.05 ± 0.01 |

| 4 | (20, 130, 19) | 0.83 ± 0.00 | 4.40 ± 0.14 | 4.58 ± 0.01 | 0.02 ± 0.00 |

| 5 | (15, 115, 8) | 0.75 ± 0.00 | 4.05 ± 0.07 | 4.79 ± 0.01 | 0.02 ± 0.00 |

| 6 | (20, 115, 8) | 0.82 ± 0.00 | 4.80 ± 0.00 | 4.90 ± 0.05 | 0.02 ± 0.01 |

| 7 | (15, 115, 30) | 0.79 ± 0.00 | 4.70 ± 0.00 | 4.49 ± 0.05 | 0.05 ± 0.01 |

| 8 | (20, 115, 30) | 0.82 ± 0.02 | 4.69 ± 0.14 | 4.58 ± 0.04 | 0.03 ± 0.01 |

| 9 | (17.5, 100, 8) | 0.83 ± 0.00 | 6.28 ± 0.11 | 6.47 ± 0.26 | 0.02 ± 0.00 |

| 10 | (17.5, 130, 8) | 0.75 ± 0.06 | 3.95 ± 0.07 | 5.08 ± 0.06 | 0.03 ± 0.00 |

| 11 | (17.5, 100, 30) | 0.84 ± 0.01 | 6.90 ± 0.00 | 5.67 ± 0.17 | 0.03 ± 0.01 |

| 12 | (17.5, 130, 30) | 0.83 ± 0.00 | 4.75 ± 0.07 | 4.66 ± 0.04 | 0.03 ± 0.00 |

| 13 | (17.5, 115, 19) | 0.75 ± 0.03 | 4.58 ± 0.03 | 4.74 ± 0.06 | 0.02 ± 0.00 |

| 14 | (17.5, 115, 19) | 0.76 ± 0.01 | 4.38 ± 0.01 | 4.75 ± 0.24 | 0.03 ± 0.00 |

| 15 | (17.5, 115, 19) | 0.77 ± 0.00 | 4.59 ± 0.16 | 4.60 ± 0.11 | 0.03 ± 0.01 |

| Sample | t (s) | Temperature °C | Force (N) | Share Stress (Pa) | Share Rate (s−1) | Viscosity (Pa·s) |

|---|---|---|---|---|---|---|

| Run1 at 25% Conc. | 22.3 | 25.01 | 0.6186 | 71.47 | 0.1 | 714.7 |

| 42.41 | 25.01 | 0.5862 | 83.41 | 0.2155 | 387.1 | |

| 62.52 | 25.01 | 0.5595 | 101.2 | 0.4642 | 218.1 | |

| 83.23 | 25.01 | 0.5215 | 123.1 | 1 | 123.1 | |

| 104.7 | 25.01 | 0.468 | 145.6 | 2.155 | 67.58 | |

| 125.8 | 25.01 | 0.4181 | 165.2 | 4.642 | 35.59 | |

| 146 | 25.01 | 0.3836 | 191.8 | 10 | 19.18 | |

| 208.3 | 25.01 | 0.2322 | 215.2 | 21.55 | 9.988 | |

| 245.5 | 25.01 | 0.1742 | 205.8 | 46.42 | 4.434 | |

| 364.8 | 25.02 | 0.09375 | 90.43 | 100 | 0.9043 | |

| Run 6 at 25% Conc. | 100.8 | 25.01 | 0.8894 | 33.96 | 0.1 | 339.5 |

| 125.4 | 25 | 0.677 | 35.01 | 0.2155 | 162.5 | |

| 145.8 | 25 | 0.5126 | 38.98 | 0.4642 | 83.99 | |

| 165.9 | 25 | 0.3856 | 46.43 | 1 | 46.43 | |

| 186 | 25 | 0.3179 | 60.73 | 2.155 | 28.19 | |

| 232.5 | 25 | 0.1235 | 64.31 | 4.642 | 13.85 | |

| 412.6 | 25 | 0.03763 | 62.28 | 10 | 6.227 | |

| 592.6 | 25.01 | −0.07939 | 71.74 | 21.55 | 3.33 | |

| 612.7 | 25.01 | −0.08936 | 88.3 | 46.42 | 1.902 | |

| 716.6 | 25.01 | 0.07892 | 87.46 | 100 | 0.8746 | |

| Run 12 at 25% Conc. | 63.7 | 25 | 0.6088 | 25.81 | 0.1 | 258.1 |

| 83.81 | 25 | 0.468 | 27.19 | 0.2155 | 126.2 | |

| 103.9 | 25.01 | 0.3483 | 30.21 | 0.4642 | 65.07 | |

| 124 | 25.01 | 0.2613 | 35.79 | 1 | 35.78 | |

| 144.1 | 25.01 | 0.2005 | 44.51 | 2.155 | 20.66 | |

| 168.9 | 25.01 | 0.1366 | 54.48 | 4.642 | 11.74 | |

| 199.1 | 25.01 | 0.07035 | 65.66 | 10 | 6.566 | |

| 219.2 | 25.01 | 0.03252 | 77.28 | 21.55 | 3.587 | |

| 239.3 | 25.01 | 2.17 × 10−3 | 82.51 | 46.42 | 1.778 | |

| 259.4 | 25 | −0.03595 | 86.38 | 100 | 0.8637 |

| Source | Bulk Density (g/mL) p-Value | Swelling Cap p-Value | WAC p-Value | Solubility p-Value |

|---|---|---|---|---|

| Model | 0.000 | 0.000 | 0.000 | 0.000 |

| X1 (feed moisture) | 0.000 | 0.000 | 0.000 | 0.000 |

| X2 (barrel temperature) | 0.000 | 0.000 | 0.000 | 0.063 |

| X3 (feed composition) | 0.000 | 0.000 | 0.000 | 0.018 |

| X12 | 0.050 | 0.000 | 0.050 | 0.000 |

| X22 | 0.000 | 0.000 | 0.000 | 0.207 |

| X32 | 0.002 | 0.000 | 0.002 | 0.039 |

| X1X2 | 0.000 | 0.092 | 0.000 | 0.051 |

| X1X3 | 0.064 | 0.000 | 0.064 | 0.071 |

| X2X3 | 0.007 | 0.000 | 0.007 | 0.312 |

| Lack of fit | 0.639 | 0.000 | 0.639 | 0.026 |

| Coefficient of variation (%) | 1.09 | 8.47 | 1.09 | 3.03 |

| Coefficient of determination (R2) | 88.98% | 87.03% | 88.98% | 86.55% |

| Adjusted R2 | 84.02% | 86.49% | 84.02% | 80.50% |

| Coefficient | Expansion Index | Lightness | a* | b* | Bulk Density | Swelling Cap | WAC | Solubility |

|---|---|---|---|---|---|---|---|---|

| Constant | ||||||||

| Linear | ||||||||

| X1 | ||||||||

| X2 | ||||||||

| X3 | ||||||||

| Quadratic | ||||||||

| X12 | ||||||||

| X22 | ||||||||

| X32 | ||||||||

| Interaction | ||||||||

| X12 | ||||||||

| X13 | ||||||||

| X23 | ||||||||

| R2 (%) | ||||||||

| R2adj (%) |

| Variables | Goal | Lower Limit | Upper Limit | Importance | Optimum Level |

|---|---|---|---|---|---|

| Independent Variables | |||||

| Moisture content (% w.b) | In range | 15 | 20 | 3 | 15 |

| Barrel Temperature (°C) | In range | 100 | 130 | 3 | 130 |

| Feed composition (%) | In range | 8 | 30 | 3 | 30 |

| Response Variables | |||||

| Physical properties | |||||

| Bulk density | Minimum | 0.72 | 0.84 | 3 | 0.80 |

| Expansion index | Maximum | 3.51 | 12.94 | 5 | 5.00 |

| b* | Maximum | 22.77 | 37.95 | 5 | 32.43 |

| a* | Minimum | 6.95 | 17.48 | 1 | 12.11 |

| Lightness | Maximum | 66.83 | 81.71 | 5 | 77.78 |

| Functional Properties | |||||

| Water absorption capacity | Maximum | 4.49 | 6.82 | 5 | 4.82 |

| Swelling capacity | Maximum | 3.95 | 6.90 | 5 | 4.73 |

| Solubility | Maximum | 0.01 | 0.04 | 5 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azuka, C.; Onwuchekwa, A.; Nwosu, A.; Holmes, M.; Boesch, C.; Okafor, G. The Effects of Malting and Extrusion on the Functional and Physical Properties of Extrudates from Malted Brown Rice and Pigeon Pea Flour Blends. Foods 2025, 14, 422. https://doi.org/10.3390/foods14030422

Azuka C, Onwuchekwa A, Nwosu A, Holmes M, Boesch C, Okafor G. The Effects of Malting and Extrusion on the Functional and Physical Properties of Extrudates from Malted Brown Rice and Pigeon Pea Flour Blends. Foods. 2025; 14(3):422. https://doi.org/10.3390/foods14030422

Chicago/Turabian StyleAzuka, Chinenye, Amarachi Onwuchekwa, Adaora Nwosu, Mel Holmes, Christine Boesch, and Gabriel Okafor. 2025. "The Effects of Malting and Extrusion on the Functional and Physical Properties of Extrudates from Malted Brown Rice and Pigeon Pea Flour Blends" Foods 14, no. 3: 422. https://doi.org/10.3390/foods14030422

APA StyleAzuka, C., Onwuchekwa, A., Nwosu, A., Holmes, M., Boesch, C., & Okafor, G. (2025). The Effects of Malting and Extrusion on the Functional and Physical Properties of Extrudates from Malted Brown Rice and Pigeon Pea Flour Blends. Foods, 14(3), 422. https://doi.org/10.3390/foods14030422