Impact of Ultrasonic Time and Marinating Temperature on the Physicochemical Properties of Guinea Pig Meat (Cavia porcellus)

Abstract

1. Introduction

2. Materials and Methods

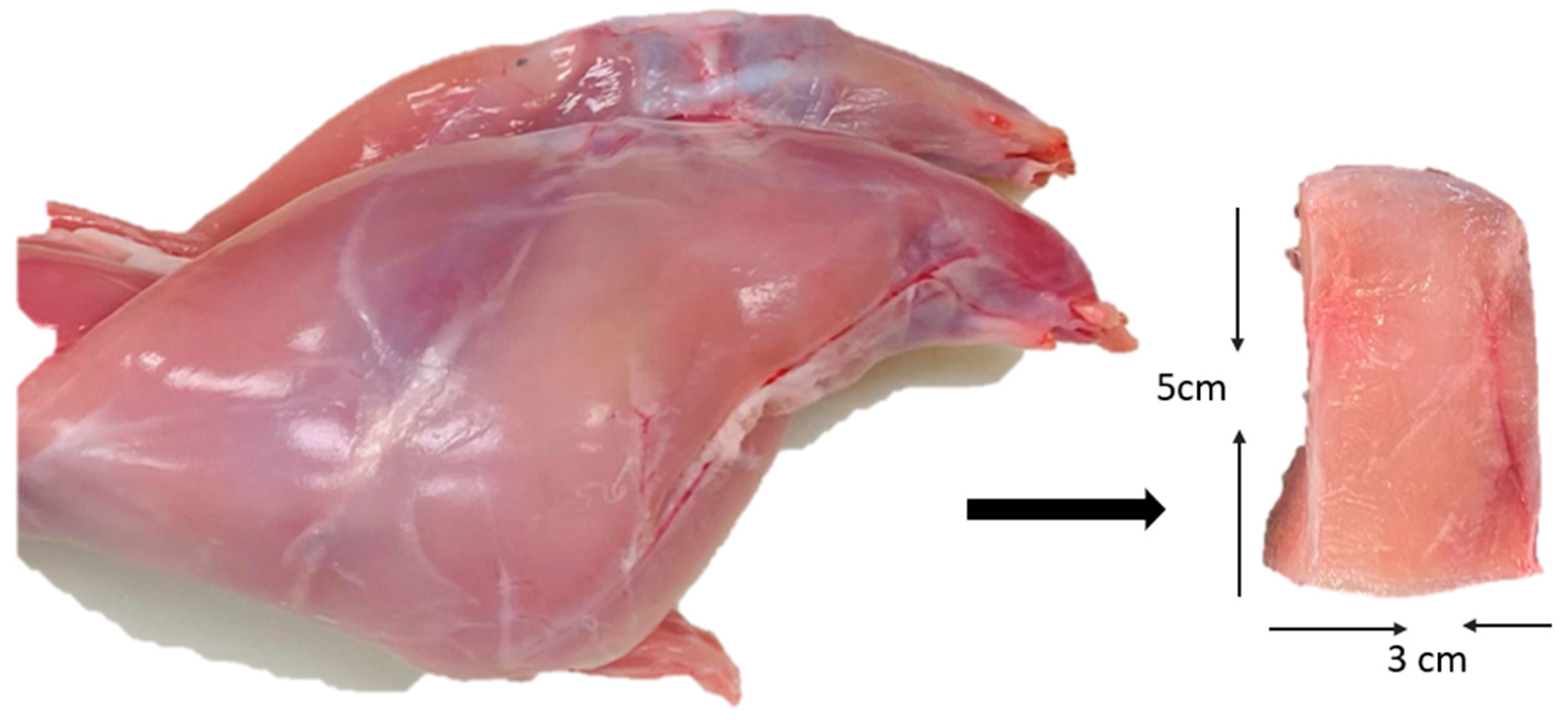

2.1. Materials

2.2. Experimental Conditions

2.3. Quality Attributes of Guinea Pig (Cavia porcellus) Meat

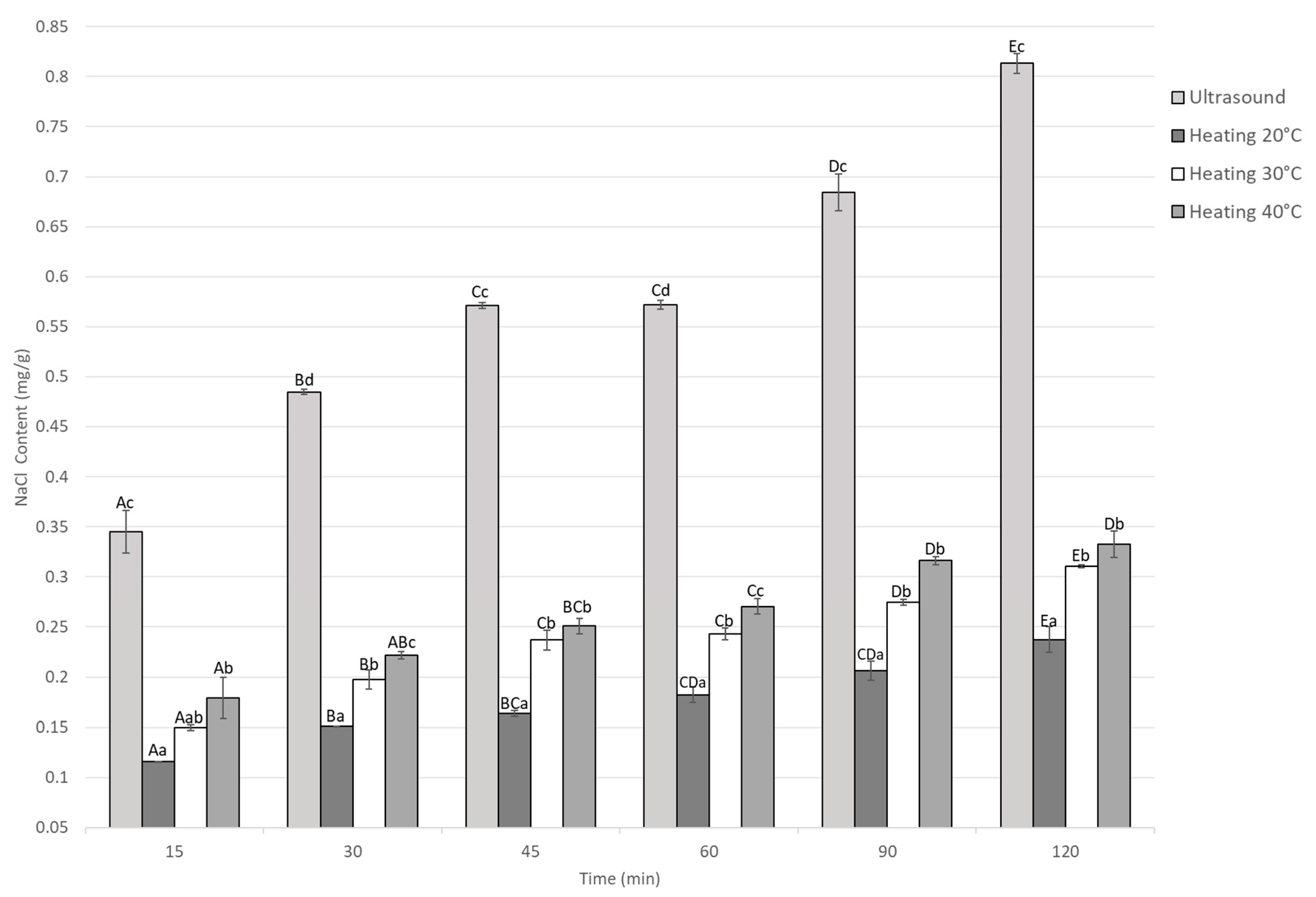

2.3.1. NaCl Content

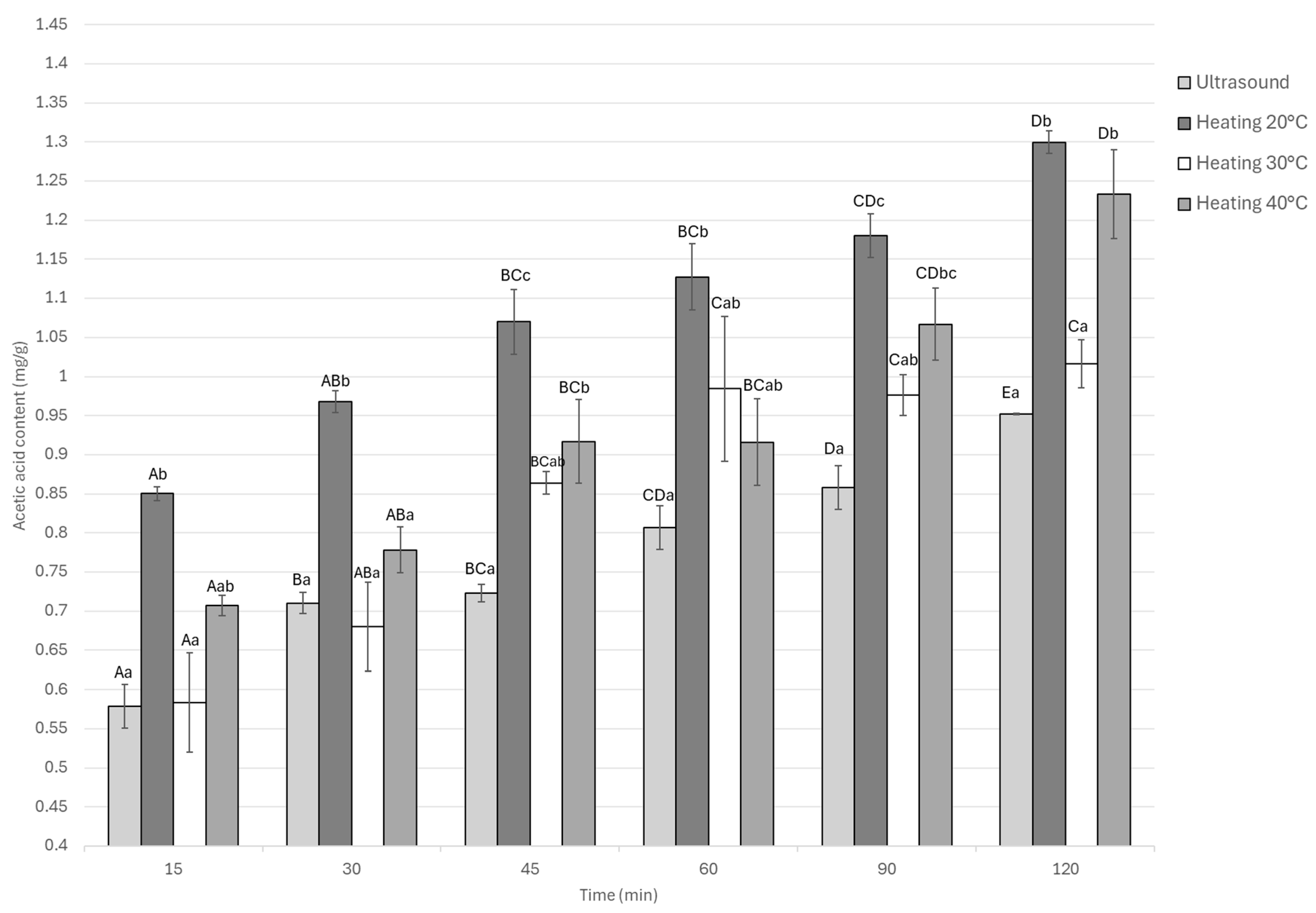

2.3.2. Acetic Acid Content

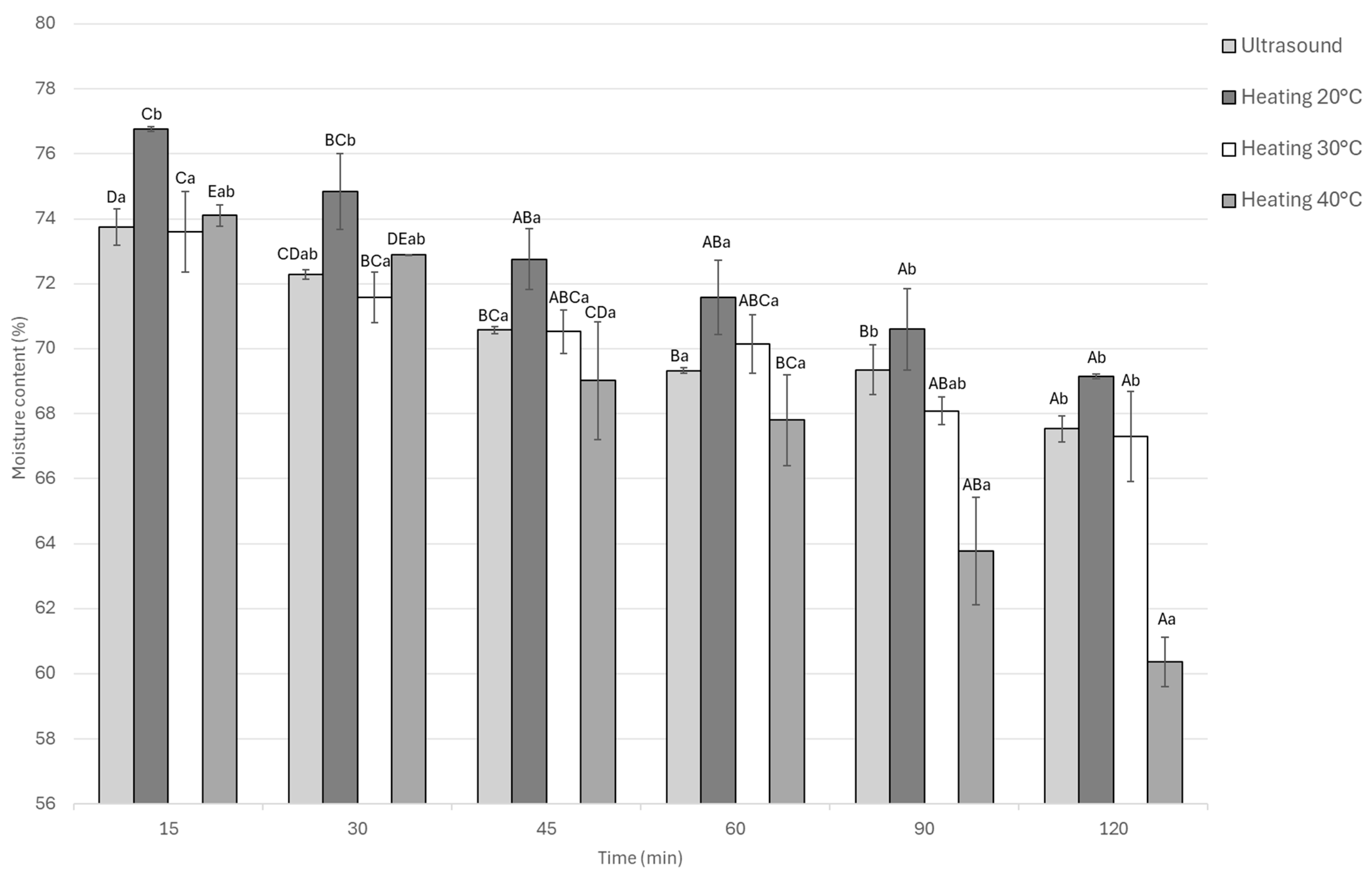

2.3.3. Moisture Content

2.3.4. Marination Weight Loss

2.3.5. Cooking Loss

2.3.6. Water Holding Capacity

2.3.7. Texture

2.3.8. pH

2.3.9. Color Determination

2.4. Statistical Analysis

3. Results

3.1. Physicochemical Parameters of Guinea Pig (Cavia porcellus) Meat

3.1.1. NaCl Content

3.1.2. Acetic Acid Content

3.1.3. Moisture Content

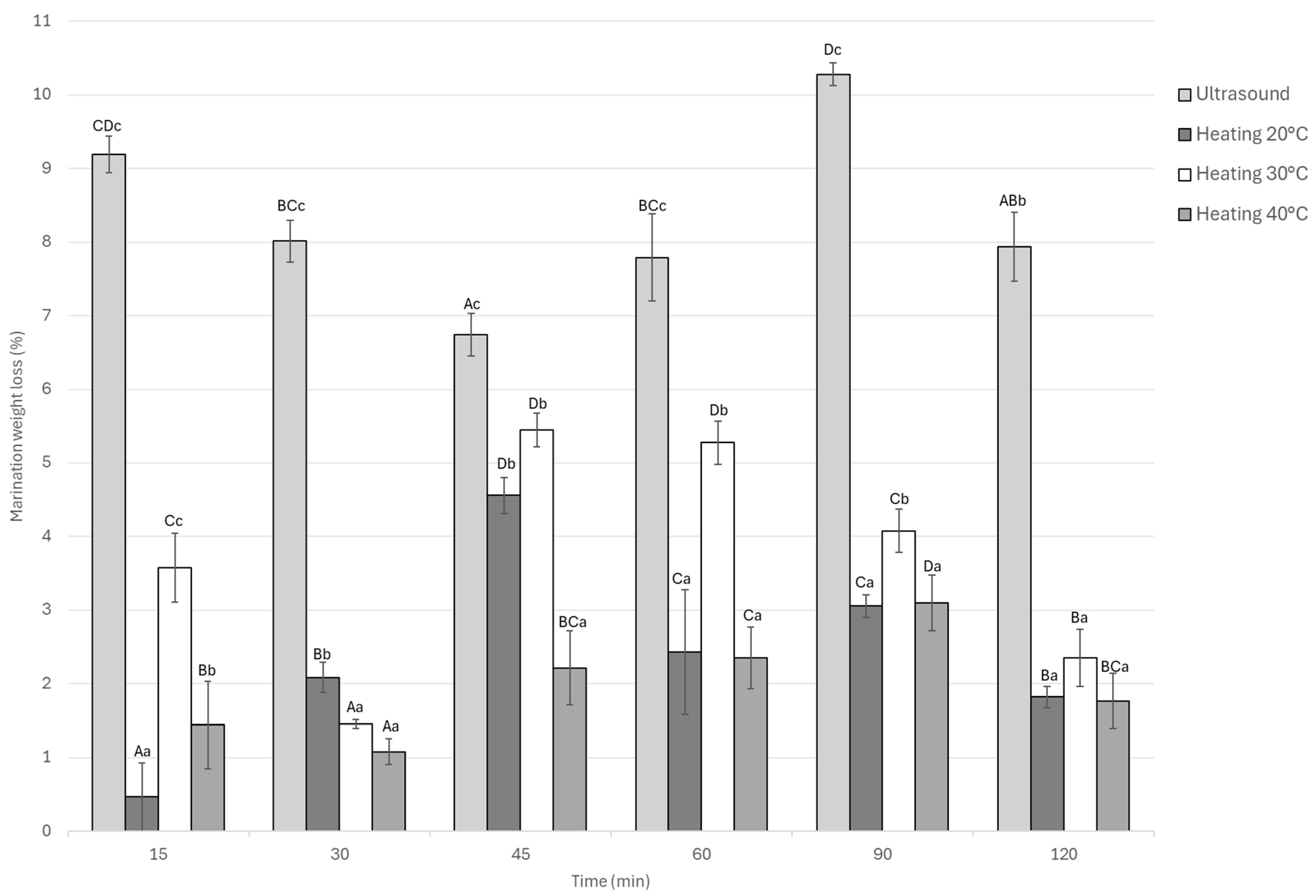

3.1.4. Marination Weight Loss

3.1.5. Cooking Loss

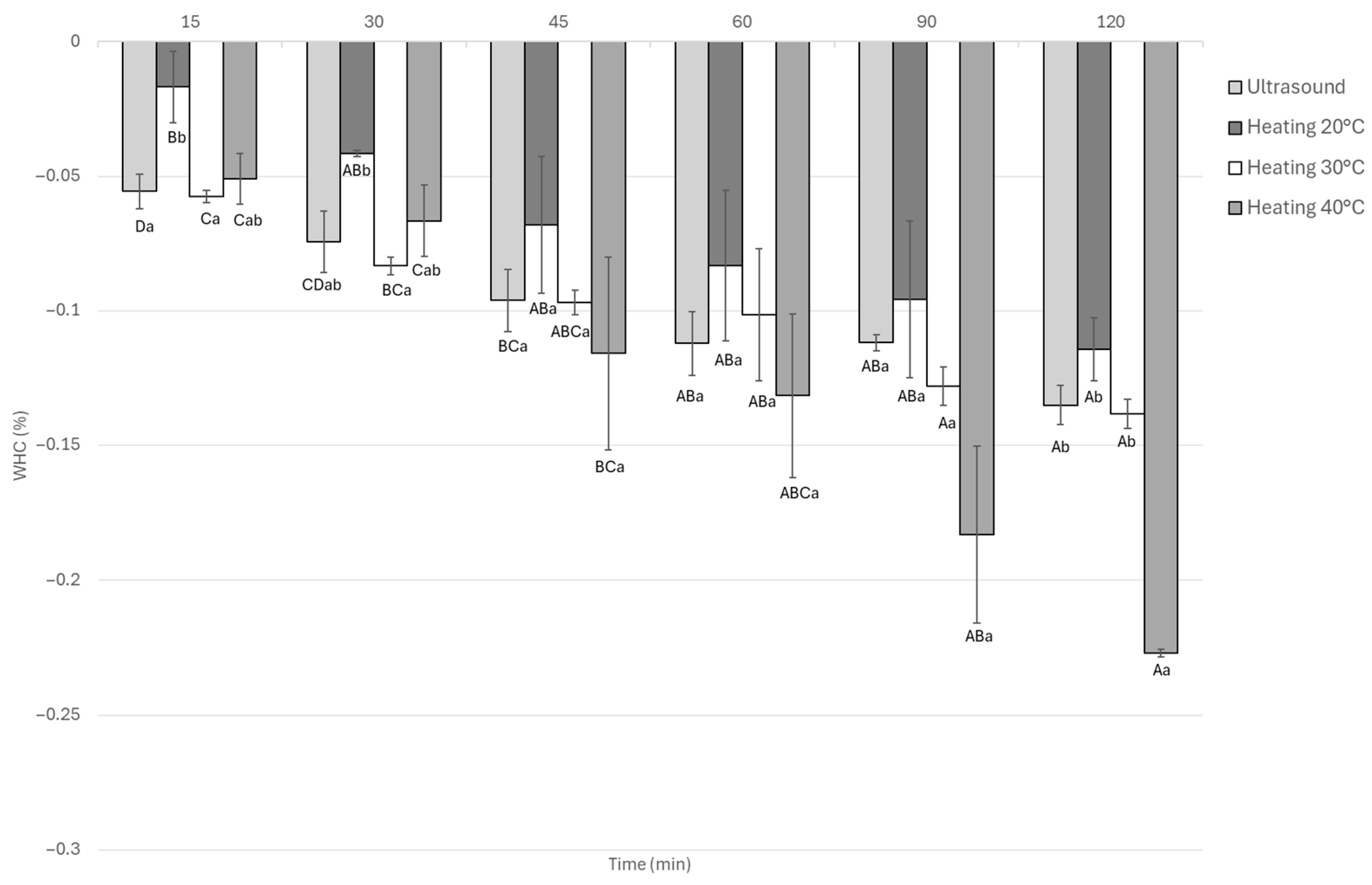

3.1.6. Water Holding Capacity

3.2. Effect of Treatments on Quality Properties of Guinea Pig (Cavia porcellus) Meat

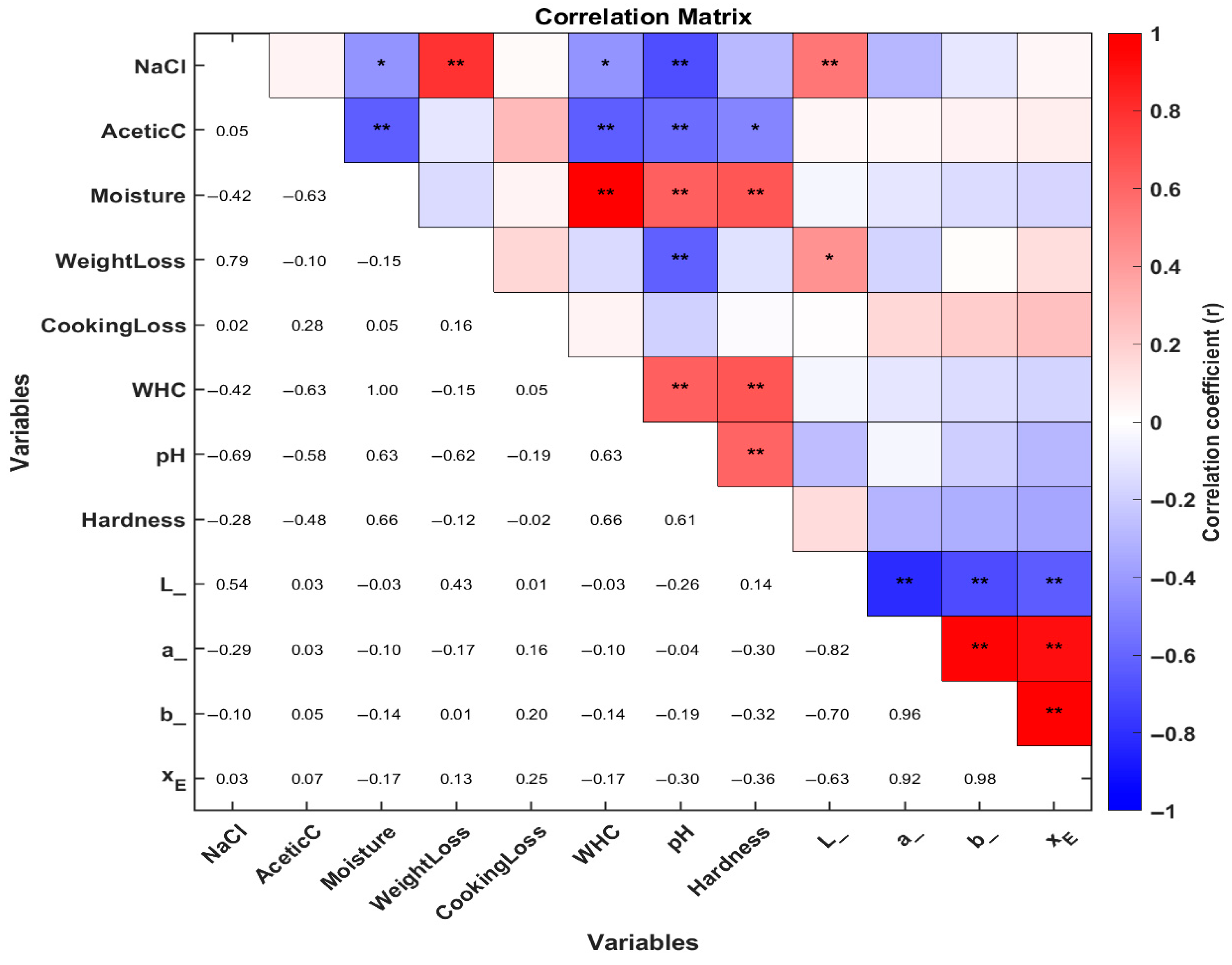

3.3. Correlation Analysis of Marinating Physicochemical Properties Guinea Pig (Cavia porcellus) Meat

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sánchez-Macías, D.; Barba-Maggi, L.; Morales-delaNuez, A.; Palmay-Paredes, J. Guinea Pig for Meat Production: A Systematic Review of Factors Affecting the Production, Carcass and Meat Quality. Meat Sci. 2018, 143, 165–176. [Google Scholar] [CrossRef]

- Donoso, G.; Galecio, J.S.; Fuentes-Quisaguano, O.G.; Pairis-Garcia, M. Guinea Pig Meat Production in South America: Reviewing Existing Practices, Welfare Challenges, and Opportunities. Anim. Welf. 2025, 34, e29. [Google Scholar] [CrossRef]

- Nurmalia Sentono, D.; Aphrodita, A.; Fitria, L. Comparison of Microscopic Meat Quality Parameters in Guinea Pig [Cavia Porcellus (Linnaeus, 1758)], Broiler Chicken, and Local Catfish as Protein Source. BIO Web Conf. 2024, 94, 06005. [Google Scholar] [CrossRef]

- Çimen, N.; Unal, K.; Alp, H. Effects of Ultrasound-Assisted Marination on Spent Hen Meats: Microstructure, Textural and Technological Properties. Food Biosci. 2024, 61, 104563. [Google Scholar] [CrossRef]

- Gómez-Salazar, J.A.; Ochoa-Montes, D.A.; Cerón-García, A.; Ozuna, C.; Sosa-Morales, M.E. Effect of Acid Marination Assisted by Power Ultrasound on the Quality of Rabbit Meat. J. Food Qual. 2018, 2018, 5754930. [Google Scholar] [CrossRef]

- Vidal, N.P.; Manful, C.; Pham, T.H.; Wheeler, E.; Stewart, P.; Keough, D.; Thomas, R. Novel Unfiltered Beer-Based Marinades to Improve the Nutritional Quality, Safety, and Sensory Perception of Grilled Ruminant Meats. Food Chem. 2020, 302, 125326. [Google Scholar] [CrossRef]

- Zheng, H.; Li, L.; Huang, C.; Liu, S.; Chen, X.; Wang, X.; Hu, P. Evaluation of Ultrasound-Assisted Tomato Sour Soup Marination on Beef: Insights into Physicochemical, Sensory, Microstructural, and Flavour Characteristics. Ultrason. Sonochem. 2024, 110, 107028. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, C.; Guo, Y.; Zhang, C.; Guo, X.; Bouhile, Y.; Ma, H. Ultrasonic-Assisted Flowing Water Thawing of Frozen Beef with Different Frequency Modes: Effects on Thawing Efficiency, Quality Characteristics and Microstructure. Food Res. Int. 2022, 157, 111484. [Google Scholar] [CrossRef] [PubMed]

- Visy, A.; Jónás, G.; Szakos, D.; Horváth-Mezőfi, Z.; Hidas, K.I.; Barkó, A.; Friedrich, L. Evaluation of Ultrasound and Microbubbles Effect on Pork Meat during Brining Process. Ultrason. Sonochem. 2021, 75, 105589. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, M.; Yang, C. Application of Ultrasound Technology in Processing of Ready-to-Eat Fresh Food: A Review. Ultrason. Sonochem. 2020, 63, 104953. [Google Scholar] [CrossRef] [PubMed]

- Jin, G.; Liu, Y.; Zhang, Y.; Li, C.; He, L.; Zhang, Y.; Wang, Y.; Cao, J. Underlying Formation Mechanisms of Ultrasound-Assisted Brined Porcine Meat: The Role of Physicochemical Modification, Myofiber Fragmentation and Histological Organization. Ultrason. Sonochem. 2023, 94, 106318. [Google Scholar] [CrossRef]

- Brasil, C.C.B.; Barin, J.S.; Jacob-Lopes, E.; Menezes, C.R.; Zepka, L.Q.; Wagner, R.; Campagnol, P.C.B.; Cichoski, A.J. Single Step Non-Thermal Cleaning/Sanitation of Knives Used in Meat Industry with Ultrasound. Food Res. Int. 2017, 91, 133–139. [Google Scholar] [CrossRef] [PubMed]

- Bai, H.; Li, L.; Wu, Y.; Chen, S.; Zhao, Y.; Cai, Q.; Wang, Y. Ultrasound Improves the Low-Sodium Salt Curing of Sea Bass: Insights into the Effects of Ultrasound on Texture, Microstructure, and Flavor Characteristics. Ultrason. Sonochem. 2023, 100, 106597. [Google Scholar] [CrossRef] [PubMed]

- Inguglia, E.S.; Zhang, Z.; Burgess, C.; Kerry, J.P.; Tiwari, B.K. Influence of Extrinsic Operational Parameters on Salt Diffusion during Ultrasound Assisted Meat Curing. Ultrasonics 2018, 83, 164–170. [Google Scholar] [CrossRef]

- Kim, T.-K.; Hwang, K.-E.; Kim, Y.-B.; Jeon, K.-H.; Leem, K.-H.; Choi, Y.-S. Effects of Pre-Cooking Methods on Quality Characteristics of Reheated Marinated Pork Loin. Korean J. Food Sci. Anim. Resour. 2018, 38, 970–980. [Google Scholar] [CrossRef]

- Gómez-Salazar, J.A.; Galván-Navarro, A.; Lorenzo, J.M.; Sosa-Morales, M.E. Ultrasound Effect on Salt Reduction in Meat Products: A Review. Curr. Opin. Food Sci. 2021, 38, 71–78. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, X.; Guo, Y.; Chen, Z.; Ma, H. Evaluation of Ultrasonic-Assisted Pickling with Different Frequencies on NaCl Transport, Impedance Properties, and Microstructure in Pork. Food Chem. 2024, 430, 137003. [Google Scholar] [CrossRef]

- Abdel-Naeem, H.H.S.; Sallam, K.I.; Zaki, H.M.B.A. Effect of Different Cooking Methods of Rabbit Meat on Topographical Changes, Physicochemical Characteristics, Fatty Acids Profile, Microbial Quality and Sensory Attributes. Meat Sci. 2021, 181, 108612. [Google Scholar] [CrossRef]

- Ardicli, S.; Ardicli, O.; Ustuner, H. Unraveling the Complexities of Beef Marination: Effect of Marinating Time, Marination Treatments, and Breed. Foods 2024, 13, 2979. [Google Scholar] [CrossRef] [PubMed]

- Zawani, C.; Nor-Khaizura, M.; Mahyudin, N.; Ismail-Fitry, M.; Nirmal, N. Microbiological and Sensorial Quality of Beef Meat (Longissimus Dorsi) Marinated with Cinnamon Extract and Stored at Various Temperatures. Foods 2022, 11, 3971. [Google Scholar] [CrossRef]

- Tang, T.; Zhang, M.; Lim Law, C.; Mujumdar, A.S. Novel Strategies for Controlling Nitrite Content in Prepared Dishes: Current Status, Potential Benefits, Limitations and Future Challenges. Food Res. Int. 2023, 170, 112984. [Google Scholar] [CrossRef]

- Gómez, I.; Ibañez, F.C.; Beriain, M.J. Physicochemical and Sensory Properties of Sous Vide Meat and Meat Analog Products Marinated and Cooked at Different Temperature-Time Combinations. Int. J. Food Prop. 2019, 22, 1693–1708. [Google Scholar] [CrossRef]

- Gamage, H.G.C.L.; Mutucumarana, R.K.; Andrew, M.S. Effect of Marination Method and Holding Time on Physicochemical and Sensory Characteristics of Broiler Meat. J. Agric. Sci. 2017, 12, 172–184. [Google Scholar] [CrossRef]

- Guo, L.; Hong, C.; Wang, W.; Zhang, X.; Chen, J.; Chen, Z.; Ashokkumar, M.; Ma, H. Evaluation of Low-Temperature Ultrasonic Marination of Pork Meat at Various Frequencies on Physicochemical Properties, Myoglobin Levels, and Volatile Compounds. Meat Sci. 2024, 217, 109606. [Google Scholar] [CrossRef]

- AOAC International. Methods of Analysis of AOAC International; AOAC International: Rockville, MD, USA, 2000; Volume 18. [Google Scholar]

- Goli, T.; Ricci, J.; Bohuon, P.; Marchesseau, S.; Collignan, A. Influence of Sodium Chloride and PH during Acidic Marination on Water Retention and Mechanical Properties of Turkey Breast Meat. Meat Sci. 2014, 96, 1133–1140. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Feng, T.; Shen, Y.; Xia, S. Saltiness Perception Enhancement of Fish Meat Treated by Microwave: The Significance of Conformational Characteristics, Water and Sodium Mobility. Food Chem. 2021, 347, 129033. [Google Scholar] [CrossRef] [PubMed]

- Echeverria, L.; da Silva, C.; Danesi, E.D.G.; Porciuncula, B.D.A.; Bolanho Barros, B.C. Characterization of Okara and Rice Bran and Their Application as Fat Substitutes in Chicken Nugget Formulations. LWT 2022, 161, 113383. [Google Scholar] [CrossRef]

- World Health Organization. WHO Global Report on Sodium Intake Reduction; World Health Organization: Geneva, Switzerland, 2023; ISBN 9240069984. [Google Scholar]

- Fraqueza, M.J.; Alfaia, C.M.; Rodrigues, S.S.; Teixeira, A. Strategies to Reduce Salt Content: PDO and PGI Meat Products Case. Foods 2024, 13, 2681. [Google Scholar] [CrossRef]

- Yao, Y.; Han, R.; Li, F.; Tang, J.; Jiao, Y. Mass Transfer Enhancement of Tuna Brining with Different NaCl Concentrations Assisted by Ultrasound. Ultrason. Sonochem. 2022, 85, 105989. [Google Scholar] [CrossRef]

- Bampi, M.; Domschke, N.N.; Schmidt, F.C.; Laurindo, J.B. Influence of Vacuum Application, Acid Addition and Partial Replacement of NaCl by KCl on the Mass Transfer during Salting of Beef Cuts. LWT 2016, 74, 26–33. [Google Scholar] [CrossRef]

- Ojha, K.S.; Keenan, D.F.; Bright, A.; Kerry, J.P.; Tiwari, B.K. Ultrasound Assisted Diffusion of Sodium Salt Replacer and Effect on Physicochemical Properties of Pork Meat. Int. J. Food Sci. Technol. 2016, 51, 37–45. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, J.; Zhou, L.; Wang, L.; Zhang, W. Influence of Ultrasound-Assisted Tumbling on NaCl Transport and the Quality of Pork. Ultrason. Sonochem. 2021, 79, 105759. [Google Scholar] [CrossRef]

- Tomaszewska-Gras, J.; Konieczny, P. Effect of Marination on the Thermodynamic Properties of Chicken Muscle Proteins Studied by DSC. Czech J. Food Sci. 2012, 30, 302–308. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, H.; Mei, J.; Xie, J.; Shao, C. Advances in Application of Ultrasound in Meat Tenderization: A Review. Front. Sustain. Food Syst. 2022, 6, 969503. [Google Scholar] [CrossRef]

- Shi, H.; Ali Khan, I.; Zhang, R.; Zou, Y.; Xu, W.; Wang, D. Evaluation of Ultrasound-Assisted L-Histidine Marination on Beef M. Semitendinosus: Insight into Meat Quality and Actomyosin Properties. Ultrason. Sonochem. 2022, 85, 105987. [Google Scholar] [CrossRef]

- Ale Enriquez, F.; Ahring, B.K. Strategies to Overcome Mass Transfer Limitations of Hydrogen during Anaerobic Gaseous Fermentations: A Comprehensive Review. Bioresour. Technol. 2023, 377, 128948. [Google Scholar] [CrossRef]

- Deng, Y.; Zhao, Y. Effect of Pulsed Vacuum and Ultrasound Osmopretreatments on Glass Transition Temperature, Texture, Microstructure and Calcium Penetration of Dried Apples (Fuji). LWT-Food Sci. Technol. 2008, 41, 1575–1585. [Google Scholar] [CrossRef]

- Topuz, O.K. Effects of Marinating Time, Acetic Acid and Salt Concentrations on the Quality of Little Tunny Fish (Euthynnus alletteratus) Fillet. J. Food Process. Preserv. 2016, 40, 1154–1163. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, X.; Hong, C.; Liu, N.; Ouyang, N.; Chen, J.; Ashokkumar, M.; Ma, H. Application of Ultrasound Treatment in Pork Marination: Effects on Moisture Migration and Microstructure. Food Chem. 2024, 447, 138950. [Google Scholar] [CrossRef] [PubMed]

- Xiong, G.; Fu, X.; Pan, D.; Qi, J.; Xu, X.; Jiang, X. Influence of Ultrasound-Assisted Sodium Bicarbonate Marination on the Curing Efficiency of Chicken Breast Meat. Ultrason. Sonochem. 2020, 60, 104808. [Google Scholar] [CrossRef] [PubMed]

- Ge, Q.; Guo, S.; Chen, S.; Wu, Y.; Jia, Z.; Kang, Z.; Xiong, G.; Yu, H.; Wu, M.; Liu, R. A Comparative Study of Vacuum Tumbling and Immersion Marination on Quality, Microstructure, and Protein Changes of Xueshan Chicken. Front. Nutr. 2022, 9, 1064521. [Google Scholar] [CrossRef]

- Warner, R.D. The Eating Quality of Meat: IV—Water Holding Capacity and Juiciness. In Lawrie’s Meat Science; Elsevier: Amsterdam, The Netherlands, 2023; pp. 457–508. [Google Scholar]

- Son, Y.-M.; Lee, E.-Y.; Alam, A.N.; Samad, A.; Hossain, M.J.; Hwang, Y.-H.; Seo, J.-K.; Kim, C.-B.; Choi, J.-H.; Joo, S.-T. The Application of High-Intensity Ultrasound on Wet-Dry Combined Aged Pork Loin Induces Physicochemical and Oxidative Alterations. Food Sci. Anim. Resour. 2024, 44, 899–911. [Google Scholar] [CrossRef]

- Alarcon-Rojo, A.D.; Janacua, H.; Rodriguez, J.C.; Paniwnyk, L.; Mason, T.J. Power Ultrasound in Meat Processing. Meat Sci. 2015, 107, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Carrillo-Lopez, L.M.; Robledo, D.; Martínez, V.; Huerta-Jimenez, M.; Titulaer, M.; Alarcon-Rojo, A.D.; Chavez-Martinez, A.; Luna-Rodriguez, L.; Garcia-Flores, L.R. Post-Mortem Ultrasound and Freezing of Rabbit Meat: Effects on the Physicochemical Quality and Weight Loss. Ultrason. Sonochem. 2021, 79, 105766. [Google Scholar] [CrossRef]

- Latoch, A.; Czarniecka-Skubina, E.; Moczkowska-Wyrwisz, M. Marinades Based on Natural Ingredients as a Way to Improve the Quality and Shelf Life of Meat: A Review. Foods 2023, 12, 3638. [Google Scholar] [CrossRef]

- Babikova, J.; Hoeche, U.; Boyd, J.; Noci, F. Nutritional, Physical, Microbiological, and Sensory Properties of Marinated Irish Sprat. Int. J. Gastron. Food Sci. 2020, 22, 100277. [Google Scholar] [CrossRef]

- Sengun, I.Y.; Yildiz Turp, G.; Cicek, S.N.; Avci, T.; Ozturk, B.; Kilic, G. Assessment of the Effect of Marination with Organic Fruit Vinegars on Safety and Quality of Beef. Int. J. Food Microbiol. 2021, 336, 108904. [Google Scholar] [CrossRef] [PubMed]

- Istrati, D.; Simion Ciuciu, A.; Vizireanu, C.; Ionescu, A.; Carballo, J. Impact of Spices and Wine-Based Marinades on Tenderness, Fragmentation of Myofibrillar Proteins and Color Stability in Bovine Biceps Femoris Muscle. J. Texture Stud. 2015, 46, 455–466. [Google Scholar] [CrossRef]

- Wang, X.; Muhoza, B.; Wang, X.; Feng, T.; Xia, S.; Zhang, X. Comparison between Microwave and Traditional Water Bath Cooking on Saltiness Perception, Water Distribution and Microstructure of Grass Crap Meat. Food Res. Int. 2019, 125, 108521. [Google Scholar] [CrossRef]

- Ramanathan, R.; Suman, S.P.; Faustman, C. Biomolecular Interactions Governing Fresh Meat Color in Post-Mortem Skeletal Muscle: A Review. J. Agric. Food. Chem. 2020, 68, 12779–12787. [Google Scholar] [CrossRef]

- Pakula, C.; Stamminger, R. Measuring Changes in Internal Meat Colour, Colour Lightness and Colour Opacity as Predictors of Cooking Time. Meat Sci. 2012, 90, 721–727. [Google Scholar] [CrossRef] [PubMed]

| pH | Hardness (N) | L* | a* | b* | ΔE | ||

| Control | 5.79 ± 0.07 a | 3.27 ± 0.11 a | 47.83 ± 1.02 a | 5.14 ± 0.56 a | 6.97 ± 0.47 e | 0 ± 0 | |

| US | 15 | 4.48 ± 0.04 b | 2.75 ± 0.11 b | 52.62 ± 0.74 b | 2.8 ± 0.2 b | 11.63 ± 0.02 b | 7.09 ± 0.58 c |

| 30 | 4.05 ± 0.04 d | 1.12 ± 0.06 c | 59.34 ± 0.29 c | 3.29 ± 0.16 b | 10.23 ± 0.15 c | 12.11 ± 0.33 b | |

| 45 | 4.23 ± 0.04 c | 0.74 ± 0.02 d | 50.62 ± 1.12 ab | 2.97 ± 0.32 b | 13.01 ± 0.68 a | 7.06 ± 0.76 c | |

| 60 | 3.94 ± 0.05 e | 0.76 ± 0.04 d | 58.2 ± 0.68 c | 2.94 ± 0.07 b | 10.4 ± 0.1 c | 11.14 ± 0.65 b | |

| 90 | 3.76 ± 0.01 e | 0.76 ± 0.07 d | 60.8 ± 2.31 cd | 0.64 ± 0.07 c | 9.04 ± 0.14 d | 13.9 ± 2.18 ab | |

| 120 | 3.91 ± 0.01 f | 0.8 ± 0.04 d | 62.96 ± 1.47 d | 1.32 ± 0.08 c | 8.92 ± 0.06 d | 15.73 ± 1.41 a | |

| pH | Hardness (N) | L* | a* | b* | ΔE | ||

| Control | 5.79 ± 0.07 a | 3.27 ± 0.11 a | 47.83 ± 1.02 c | 5.14 ± 0.56 ab | 6.97 ± 0.47 a | 0 ± 0 | |

| 20 °C | 15 | 4.78 ± 0.03 b | 3.31 ± 0.05 a | 44.91 ± 0.48 b | 6.47 ± 0.16 b | 7.38 ± 0.09 ab | 3.24 ± 0.58 a |

| 30 | 4.55 ± 0.05 b | 1.18 ± 0.06 bc | 41.4 ± 0.16 a | 4.43 ± 0.23 a | 8.66 ± 0.31 bc | 6.69 ± 0.33 c | |

| 45 | 4.43 ± 0.02 c | 0.77 ± 0.05 e | 53.39 ± 0.39 d | 4.59 ± 0.84 a | 8.32 ± 0.16 abc | 7.79 ± 0.75 bc | |

| 60 | 4.28 ± 0.03 d | 1.05 ± 0.02 cd | 55.30 ± 0.51 d | 3.61 ± 0.09 a | 11.07 ± 0.38 e | 8.67 ± 0.65 d | |

| 90 | 4.17 ± 0.03 d | 1.33 ± 0.07 b | 49.79 ± 2.31 c | 4.50 ± 1.10 a | 10.37 ± 1.26 de | 4.55 ± 2.18 ab | |

| 120 | 4.21 ± 0.01 d | 0.88 ± 0.04 de | 54.18 ± 0.49 d | 3.63 ± 0.06 a | 9.53 ± 0.09 cd | 7.01 ± 1.41 c | |

| pH | Hardness (N) | L* | a* | b* | ΔE | ||

| Control | 5.79 ± 0.07 a | 3.27 ± 0.11 a | 47.83 ± 1.02 a | 5.14 ± 0.56 a | 6.97 ± 0.47 ab | 0 ± 0 | |

| 30 °C | 15 | 4.78 ± 0.03 b | 3.31 ± 0.05 a | 48.76 ± 1.06 a | 6.77 ± 1.23 ab | 7.81 ± 1.38 a | 2.55 ± 1.03 a |

| 30 | 4.55 ± 0.05 b | 1.18 ± 0.06 b | 37.93 ± 0.08 b | 5.09 ± 0.12 abc | 6.11 ± 0.16 b | 7.05 ± 0.19 d | |

| 45 | 4.43 ± 0.02 c | 0.77 ± 0.05 c | 21.09 ± 0.12 c | 4.53 ± 0.12 abc | 5.52 ± 0.51 b | 6.62 ± 0.44 cd | |

| 60 | 4.28 ± 0.03 d | 0.65 ± 0.02 c | 19.23 ± 0.59 c | 3.16 ± 0.05 bc | 3.47 ± 0.51 c | 5.46 ± 0.50 bc | |

| 90 | 4.17 ± 0.03 d | 0.83 ± 0.07 bc | 16.41 ± 1.22 c | 3.11 ± 0.08 bc | 3.26 ± 0.26 c | 5.01 ± 0.03 b | |

| 120 | 4.21 ± 0.01 d | 0.88 ± 0.04 bc | 17.14 ± 0.07 c | 3.35 ± 0.53 bc | 2.07 ± 0.18 c | 6.63 ± 0.01 cd | |

| pH | Hardness (N) | L* | a* | b* | ΔE | ||

| Control | 5.79 ± 0.07 a | 3.27 ± 0.11 a | 47.83 ± 1.02 a | 5.14 ± 0.56 a | 6.97 ± 0.47 ab | 0 ± 0 | |

| 40 °C | 15 | 4.82 ± 0.04 b | 1.33 ± 0.09 b | 44.43 ± 0.68 ab | 6.06 ± 0.25 cd | 6.39 ± 0.17 b | 3.57 ± 0.72 bc |

| 30 | 4.59 ± 0.01 c | 0.32 ± 0.02 c | 46.05 ± 0.99 ab | 6.44 ± 0.27 d | 6.95 ± 0.22 b | 2.25 ± 0.90 abc | |

| 45 | 4.52 ± 0.01 c | 0.40 ± 0.02 c | 46.63 ± 1.90 abc | 4.54 ± 0.51 b | 6.99 ± 0.80 b | 2.16 ± 0.46 ab | |

| 60 | 4.34 ± 0.02 d | 0.57 ± 0.04 c | 47.21 ± 0.66 abc | 6.56 ± 0.18 d | 7.59 ± 0.29 bc | 1.77 ± 0.05 a | |

| 90 | 4.28 ± 0.03 d | 0.55 ± 0.04 c | 45.54 ± 0.67 ab | 3.31 ± 0.27 a | 4.39 ± 0.30 a | 3.94 ± 0.39 c | |

| 120 | 4.27 ± 0.02 d | 0.48 ± 0.04 c | 49.11 ± 1.7 c | 6.86 ± 0.15 d | 8.61 ± 0.57 c | 2.80 ± 0.82 abc | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arteaga-Cabrera, E.; Escobar-Escobar, L.; Osorio-Mora, O.; Gómez-Salazar, J.A. Impact of Ultrasonic Time and Marinating Temperature on the Physicochemical Properties of Guinea Pig Meat (Cavia porcellus). Foods 2025, 14, 3887. https://doi.org/10.3390/foods14223887

Arteaga-Cabrera E, Escobar-Escobar L, Osorio-Mora O, Gómez-Salazar JA. Impact of Ultrasonic Time and Marinating Temperature on the Physicochemical Properties of Guinea Pig Meat (Cavia porcellus). Foods. 2025; 14(22):3887. https://doi.org/10.3390/foods14223887

Chicago/Turabian StyleArteaga-Cabrera, Esteban, Lina Escobar-Escobar, Oswaldo Osorio-Mora, and Julián Andrés Gómez-Salazar. 2025. "Impact of Ultrasonic Time and Marinating Temperature on the Physicochemical Properties of Guinea Pig Meat (Cavia porcellus)" Foods 14, no. 22: 3887. https://doi.org/10.3390/foods14223887

APA StyleArteaga-Cabrera, E., Escobar-Escobar, L., Osorio-Mora, O., & Gómez-Salazar, J. A. (2025). Impact of Ultrasonic Time and Marinating Temperature on the Physicochemical Properties of Guinea Pig Meat (Cavia porcellus). Foods, 14(22), 3887. https://doi.org/10.3390/foods14223887