Impacts of Chitosan Coating on Shelf Life and Quality of Ready-to-Cook Beef Seekh Kabab During Refrigeration Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Raw Material Collection

2.3. Chitosan Coating Preparation

2.4. Seekh Kabab Preparation

2.5. Evaluation of Antimicrobial Activity of Chitosan Coating

2.6. Analysis of Seekh Kabab Samples

2.6.1. Determination of Proximate Analysis

2.6.2. pH

2.6.3. Color

2.6.4. Lipid Oxidation

2.6.5. Protein Oxidation

2.6.6. Total Volatile Basic Nitrogen (TVB-N)

2.6.7. Microbiological Analysis

2.7. Sensory Properties of Cooked Seekh Kabab

2.8. Statistical Analysis

3. Results and Discussion

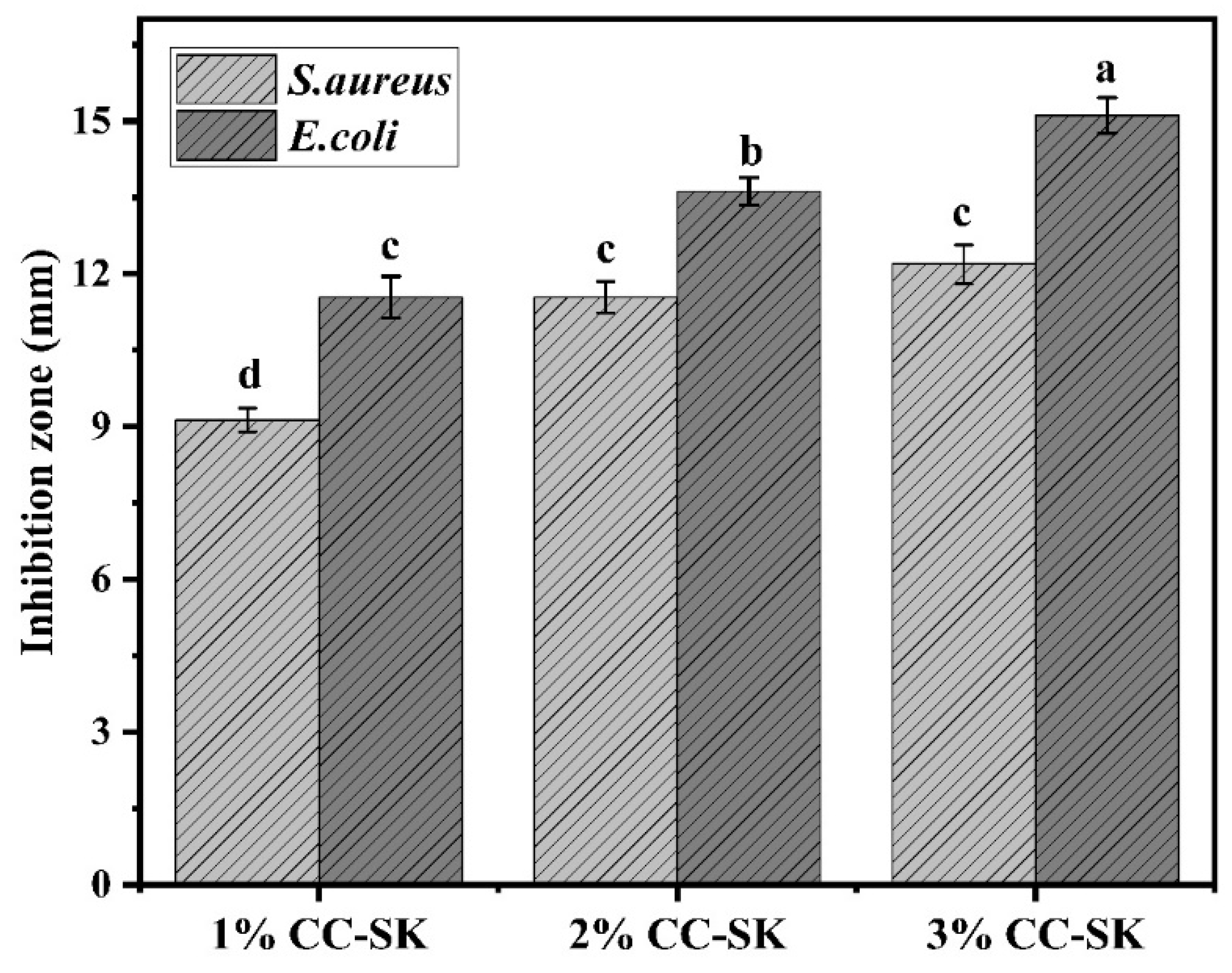

3.1. Antimicrobial Activity of Chitosan Coating

3.2. Proximate Analysis

3.3. Change in pH of Seekh Kabab

3.4. Chromaticity and Color Determination of Seekh Kabab

3.5. Secondary Lipid Oxidation in Seekh Kabab

3.6. Protein Oxidation of Seekh Kabab

3.7. Total Viable Basic Nitrogen Composition of Seekh Kabab

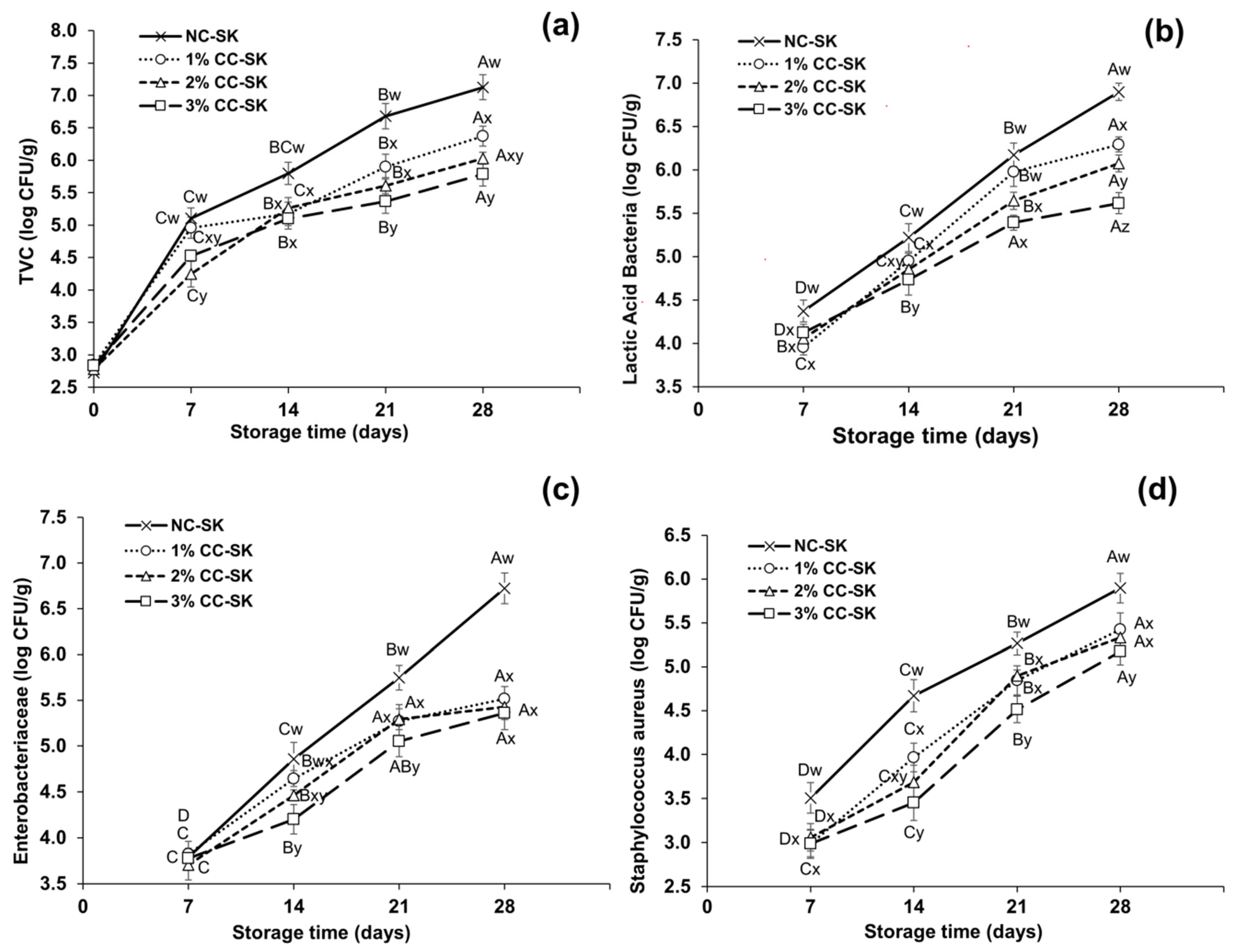

3.8. Microbial Composition of Seekh Kabab

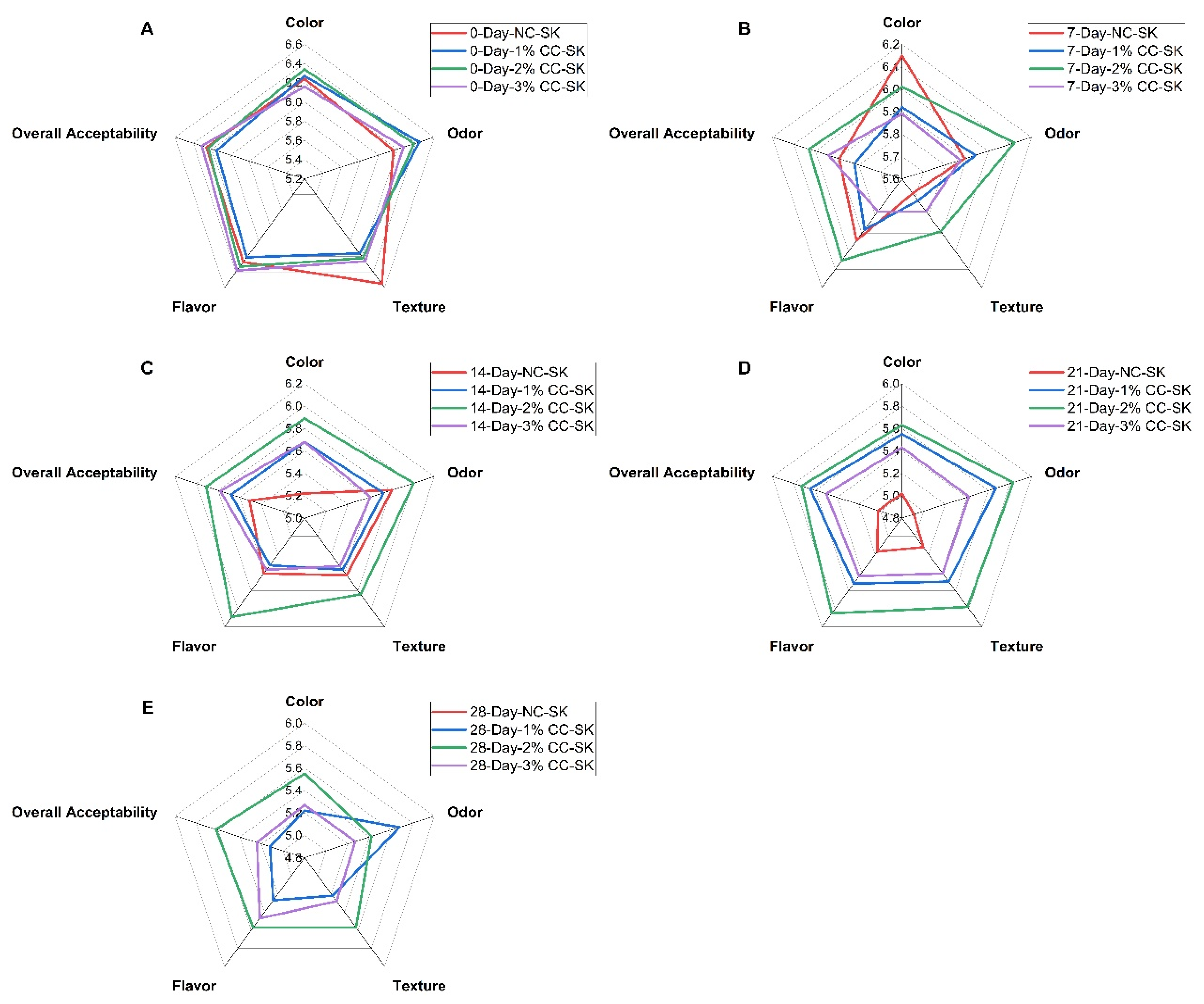

3.9. Sensory Attributes

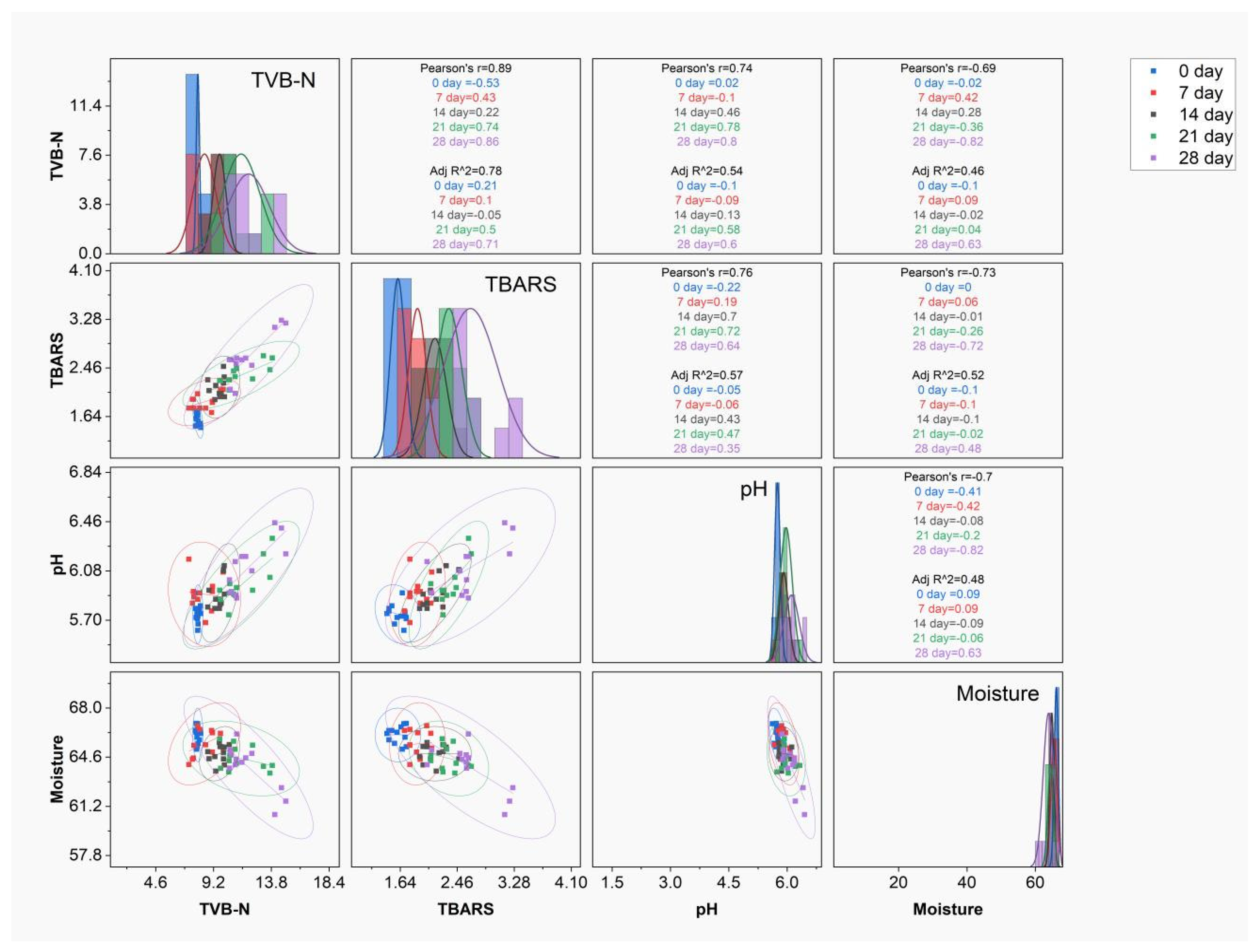

3.10. Correlation Analyses on Effect of Storage Time

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhandare, Y.; Gadekar, S. Ethnic Meat Products/Indian Subcontinent. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2024; pp. 451–472. [Google Scholar]

- Kebab Shop Market, Industry Analysis, Size, Share, Growth, Trends, and Forecast. 2024. Available online: https://dataintelo.com/report/kebab-shop-market (accessed on 19 October 2025).

- Mishra, V.; Tarafdar, A.; Talukder, S.; Mendiratta, S.K.; Agrawal, R.K.; Jaiswal, R.K.; Bomminayuni, G.P. Enhancing the Shelf Life of Chevon Kabab Using Chitosan Edible Film and Cinnamomum zeylanicum Essential Oil. J. Food Sci. Technol. 2023, 60, 1814. [Google Scholar] [CrossRef]

- Fernandes, R.P.P.; Trindade, M.A.; Lorenzo, J.M.; Munekata, P.E.S.; de Melo, M.P. Effects of Oregano Extract on Oxidative, Microbiological and Sensory Stability of Sheep Burgers Packed in Modified Atmosphere. Food Control 2016, 63, 65–75. [Google Scholar] [CrossRef]

- Garavito, J.; Moncayo-Martinez, D.; Castellanos, D. Evaluation of Antimicrobial Coatings on Preservation Cold Storage. Foods 2020, 9, 1203. [Google Scholar] [CrossRef]

- Hussain, Z.; Li, X.; Ijaz, M.; Xiao, X.; Hou, C.; Zheng, X.; Ren, C.; Zhang, D. Effect of Chinese Cinnamon Powder on the Quality and Storage Properties of Ground Lamb Meat during Refrigerated Storage. Food Sci. Anim. Resour. 2020, 40, 311–322. [Google Scholar] [CrossRef] [PubMed]

- Fernando, S.S.; Jo, C.; Mudannayake, D.C.; Jayasena, D.D. An Overview of the Potential Application of Chitosan in Meat and Meat Products. Carbohydr. Polym. 2024, 324, 121477. [Google Scholar] [CrossRef]

- Rajoka, M.S.R.; Zhao, L.; Mehwish, H.M.; Wu, Y.; Mahmood, S. Chitosan and Its Derivatives: Synthesis, Bio-Technological Applications, and Future Challenges. Appl. Microbiol. Biotechnol. 2019, 103, 1557–1571. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-Tebar, N.; Pérez-Álvarez, J.A.; Fernández-López, J.; Viuda-Martos, M. Chitosan Edible Films and Coatings with Added Bioactive Compounds: Antibacterial and Antioxidant Properties and Their Application to Food Products: A Review. Polymers 2023, 15, 396. [Google Scholar] [CrossRef]

- Tsitsos, A.; Economou, V.; Chouliara, E.; Koutouzidou, G.; Arsenos, G.; Ambrosiadis, I. Effect of Chitosan and Alginate-Based Edible Membranes with Oregano Essential Oil and Olive Oil on the Microbiological, Physicochemical and Organoleptic Characteristics of Mutton. Microorganisms 2023, 11, 507. [Google Scholar] [CrossRef]

- Zhang, X.; Ismail, B.B.; Cheng, H.; Jin, T.Z.; Qian, M.; Arabi, S.A.; Liu, D.; Guo, M. Emerging Chitosan–Essential Oil Films and Coatings for Food Preservation—A Review of Advances and Applications. Carbohydr. Polym. 2021, 273, 118616. [Google Scholar] [CrossRef]

- Liu, T.; Li, J.; Tang, Q.; Qiu, P.; Gou, D.; Zhao, J. Chitosan-Based Materials: An Overview of Potential Applications in Food Packaging. Foods 2022, 11, 1490. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Lu, J.; Wu, J.; Luo, Y. Applications and Functionalities of Chitosan in Seafood Preservation: A Review. Food Chem. 2021, 359, 129871. [Google Scholar] [CrossRef]

- Coma, V. Bioactive Packaging Technologies for Extended Shelf Life of Meat-Based Products. Meat Sci. 2008, 78, 90–103. [Google Scholar] [CrossRef]

- Bhat, Z.F.; Pathak, V.; Fayaz, H. Effect of Refrigerated Storage on the Quality Characteristics of Microwave-Cooked Chicken Seekh Kababs Extended with Different Non-Meat Proteins. J. Food Sci. Technol. 2013, 50, 926–933. [Google Scholar] [CrossRef] [PubMed]

- Moller, A.; Ahrens, K.; Hjernø, K.; Petersen, M.A.; Christensen, M. Effect of a Carrageenan/Chitosan Coating with Allyl Isothiocyanate on Microbial Spoilage and Quality of Chicken Breast. Poult. Sci. 2023, 102, 102442. [Google Scholar] [CrossRef]

- Zhang, H.; He, P.; Kang, H.; Li, X. Antioxidant and Antimicrobial Effects of Edible Coating Based on Chitosan and Bamboo Vinegar in Ready-to-Cook Pork Chops. LWT 2018, 93, 470–476. [Google Scholar] [CrossRef]

- Dong, C.; Wang, B.; Li, F.; Zhong, Q.; Xia, X.; Kong, B. Effects of Edible Chitosan Coating on Harbin Red Sausage Storage Stability at Room Temperature. Meat Sci. 2020, 159, 107919. [Google Scholar] [CrossRef] [PubMed]

- Ashraf, J.; Ismail, N.; Tufail, T.; Zhang, J.; Awais, M.; Zhang, Q.; Ahmed, Z.; Qi, Y.; Liu, S.; Xu, B. Fabrication of Novel Pullulan/Carboxymethyl Chitosan-Based Edible Film Incorporated with Ultrasonically Equipped Aqueous Zein/Turmeric Essential Oil Nanoemulsion for Effective Preservation of Mango Fruits. Int. J. Biol. Macromol. 2025, 294, 139330. [Google Scholar] [CrossRef]

- Hussain, Z.; Ijaz, M.; Zhang, Y.; Bai, Y.; Hou, C.; Li, X.; Zhang, D. Combined Effect of Cinnamon Bark Oil and Packaging Methods on Quality of Fresh Lamb Meat Patties during Storage at 4 °C. Foods 2023, 12, 2916. [Google Scholar] [CrossRef] [PubMed]

- Ijaz, M.; Li, X.; Zhang, D.; Hussain, Z.; Ren, C.; Bai, Y.; Zheng, X. Association between Meat Color of DFD Beef and Other Quality Attributes. Meat Sci. 2020, 161, 107954. [Google Scholar] [CrossRef] [PubMed]

- Woldemariam, K.Y.; Wang, Z.; Cai, M.; Li, M.; Jiang, W.; Hu, Z.; Li, J.; Tang, W.; Jiao, Y.; Liu, Y.; et al. Lipid Hydrolysis, Oxidation, and Fatty Acid Formation Pathway Mapping of Synergistically Fermented Sausage and Characterization of Lipid Mediating Genes. J. Agric. Food Chem. 2024, 72, 17536–17548. [Google Scholar] [CrossRef]

- Rodríguez-Carpena, J.-G.; Morcuende, D.; Estévez, M. Avocado By-Products as Inhibitors of Color Deterioration and Lipid and Protein Oxidation in Raw Porcine Patties Subjected to Chilled Storage. Meat Sci. 2011, 89, 166–173. [Google Scholar] [CrossRef] [PubMed]

- Hussain, Z.; Li, X.; Zhang, D.; Hou, C.; Ijaz, M.; Bai, Y.; Xiao, X.; Zheng, X. Influence of Adding Cinnamon Bark Oil on Meat Quality of Ground Lamb during Storage at 4 °C. Meat Sci. 2021, 171, 108269. [Google Scholar] [CrossRef]

- Kanatt, S.R.; Rao, M.S.; Chawla, S.P.; Sharma, A. Effects of Chitosan Coating on Shelf-Life of Ready-to-Cook Meat Products during Chilled Storage. LWT 2013, 53, 321–326. [Google Scholar] [CrossRef]

- Yu, J.; Xu, S.; Goksen, G.; Yi, C.; Shao, P. Chitosan Films Plasticized with Choline-Based Deep Eutectic Solvents: UV Shielding, Antioxidant, and Antibacterial Properties. Food Hydrocoll. 2023, 135, 108196. [Google Scholar] [CrossRef]

- Zhang, L.; Li, K.; Yu, D.; Regenstein, J.M.; Dong, J.; Chen, W.; Xia, W. Chitosan/Zein Bilayer Films with One-Way Water Barrier Characteristic: Physical, Structural and Thermal Properties. Int. J. Biol. Macromol. 2022, 200, 378–387. [Google Scholar] [CrossRef]

- Safari, R.; Yaghoubi, M.; Marcinkowska-Lesiak, M.; Paya, H.; Sun, X.; Rastgoo, A.; Rafie, M.; Kazem, A. The Effects of Double Gelatin Containing Chitosan Nanoparticles–Calcium Alginate Coatings on the Stability of Chicken Breast Meat. Food Sci. Nutr. 2023, 11, 7673–7685. [Google Scholar] [CrossRef]

- Elsabee, M.Z.; Abdou, E.S. Chitosan-Based Edible Films and Coatings: A Review. Mater. Sci. Eng. 2013, 33, 1819–1841. [Google Scholar] [CrossRef]

- Pabast, M.; Shariatifar, N.; Beikzadeh, S.; Jahed, G. Effects of Chitosan Coatings Incorporating with Free or Nano-Encapsulated Satureja Plant Essential Oil on Quality Characteristics of Lamb Meat. Food Contr. 2018, 91, 185–192. [Google Scholar] [CrossRef]

- Mancini, S.; Preziuso, G.; Dal Bosco, A.; Roscini, V.; Szendrő, Z.; Fratini, F.; Paci, G. Effect of Turmeric Powder (Curcuma longa L.) and Ascorbic Acid on Physical Characteristics and Oxidative Status of Fresh and Stored Rabbit Burgers. Meat Sci. 2015, 110, 93–100. [Google Scholar] [CrossRef]

- Farina, P.; Ascrizzi, R.; Bedini, S.; Castagna, A.; Flamini, G.; Macaluso, M.; Petruccelli, R.; Donato, R.; Rosi, R.; Menicagli, E.; et al. Chitosan and essential oils combined for beef meat protection against oviposition, water loss, lipid peroxidation, and colour changes. Foods 2022, 11, 3994. [Google Scholar] [CrossRef]

- Fernández-Eslava, B.; Alonso, D.; Alonso-Alvarez, C. An Age-Related Decline in the Expression of a Red Carotenoid-Based Ornament in Wild Birds. Evolution 2021, 75, 3142–3153. [Google Scholar] [CrossRef]

- Zhao, X.; Liang, Z.; Wang, Z.; Zhang, P.; Fang, Z. Effect of Natural Colorants on the Quality Attributes of Pea Protein-Based Meat Patties. Food Biosci. 2024, 59, 103976. [Google Scholar] [CrossRef]

- Paparella, A.; Mazzarrino, G.; Chaves-López, C.; Rossi, C.; Sacchetti, G.; Guerrieri, O.; Serio, A. Chitosan Boosts the Antimicrobial Activity of Origanum vulgare Essential Oil in Modified Atmosphere Packaged Pork. Food Microbiol. 2016, 59, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Xu, M.; Gao, X.; Zhang, Z. Influence of Chitosan/Lycopene on Myoglobin and Meat Quality of Beef during Storage. Coatings 2024, 14, 1445. [Google Scholar] [CrossRef]

- Chaijan, M. Lipid and Myoglobin Oxidations in Muscle Foods. Songklanakarin J. Sci. Technol. 2008, 30, 47–53. [Google Scholar]

- Alirezalu, K.; Pirouzi, S.; Yaghoubi, M.; Karimi-Dehkordi, M.; Jafarzadeh, S.; Mousavi Khaneghah, A. Packaging of Beef Fillet with Active Chitosan Film Incorporated with ε-Polylysine: An Assessment of Quality Indices and Shelf Life. Meat Sci. 2021, 176, 108475. [Google Scholar] [CrossRef]

- Wang, Y.; Domínguez, R.; Lorenzo, J.M.; Bohrer, B.M. The Relationship between Lipid Content in Ground Beef Patties with Rate of Discoloration and Lipid Oxidation during Simulated Retail Display. Foods 2021, 10, 1982. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Lipid Oxidation in Meat and Meat Products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef]

- Aydemir, M.E.; Arslan, A.; Takım, K.; Kılıç Altun, S.; Yılmaz, M.A.; Çakır, O. Inhibitory Effect of Paliurus spina-christi Mill., Celtis tournefortii L., and Nigella sativa L. on Nε–(Carboxymethyl) Lysine in Meatballs. Meat Sci. 2024, 207, 109362. [Google Scholar] [CrossRef]

- Xu, M.; Liu, Q.; Ni, X.; Chen, C.; Deng, X.; Fang, Y.; Wang, X.; Shen, Q.; Yu, R. Lipidomics Reveals the Effect of Hot-Air Drying on the Quality Characteristics and Lipid Oxidation of Tai Lake Whitebait (Neosalanx taihuensis Chen). LWT 2024, 197, 115942. [Google Scholar] [CrossRef]

- Hu, H.; Yong, H.; Zong, S.; Jin, C.; Liu, J. Effect of Chitosan/Starch Aldehyde-Catechin Conjugate Composite Coating on the Quality and Shelf Life of Fresh Pork Loins. J. Sci. Food Agric. 2022, 102, 5238–5249. [Google Scholar] [CrossRef]

- de Lima, A.F.; Leite, R.H.L.; Pereira, M.W.F.; Silva, M.R.L.; de Araújo, T.L.A.C.; de Lima Júnior, D.M.; Gomes, M.N.B.; Lima, P.O. Chitosan Coating with Rosemary Extract Increases Shelf Life and Reduces Water Losses from Beef. Foods 2024, 13, 1353. [Google Scholar] [CrossRef]

- Yuan, G.; Chen, X.; Li, D. Chitosan Films and Coatings Containing Essential Oils: The Antioxidant and Antimicrobial Activity, and Application in Food Systems. Food Res. Int. 2016, 89, 117–128. [Google Scholar] [CrossRef]

- Yarahmadi, A.; Dousti, B.; Karami-Khorramabadi, M.; Afkhami, H. Materials Based on Biodegradable Polymers Chitosan/Gelatin: A Review of Potential Applications. Front. Bioeng. Biotechnol. 2024, 12, 1397668. [Google Scholar] [CrossRef]

- Guo, C.; Wang, S.; Jia, X.; Pan, J.; Dong, X.; Li, S. Changes in Novel Biomarkers for Protein Oxidation in Pork Patties under Different Cooking Methods. Foods 2024, 28, 1034. [Google Scholar] [CrossRef] [PubMed]

- Stadtman, E.R.; Levine, R.L. Free Radical-Mediated Oxidation of Free Amino Acids and Amino Acid Residues in Proteins. Amino Acids 2003, 25, 207–218. [Google Scholar] [CrossRef] [PubMed]

- Duran, A.; Kahve, H.I. The Effect of Chitosan Coating and Vacuum Packaging on the Microbiological and Chemical Properties of Beef. Meat Sci. 2020, 162, 107961. [Google Scholar] [CrossRef]

- Chen, X.; Chen, W.; Lu, X.; Mao, Y.; Luo, X.; Liu, G.; Zhu, L.; Zhang, Y. Effect of Chitosan Coating Incorporated with Oregano or Cinnamon Essential Oil on the Bacterial Diversity and Shelf Life of Roast Duck in Modified Atmosphere Packaging. Food Res. Int. 2021, 147, 110491. [Google Scholar] [CrossRef]

- Bekhit, A.E.D.A.; Holman, B.W.B.; Giteru, S.G.; Hopkins, D.L. Total Volatile Basic Nitrogen (TVB-N) and Its Role in Meat Spoilage: A Review. Trends Food Sci. Technol. 2021, 109, 280–302. [Google Scholar] [CrossRef]

- Arslan, B.; Soyer, A. Effects of Chitosan as a Surface Fungus Inhibitor on Microbiological, Physicochemical, Oxidative and Sensory Characteristics of Dry Fermented Sausages. Meat Sci. 2018, 145, 107–113. [Google Scholar] [CrossRef]

- Kong, Y.W.; Feng, M.Q.; Sun, J. Effects of Lactobacillus plantarum CD101 and Staphylococcus simulans NJ201 on Proteolytic Changes and Bioactivities (Antioxidant and Antihypertensive Activities) in Fermented Pork Sausage. LWT 2020, 133, 109985. [Google Scholar] [CrossRef]

- Hosseinnejad, M.; Jafari, S.M. Evaluation of Different Factors Affecting Antimicrobial Properties of Chitosan. Int. J. Biol. Macromol. 2016, 85, 467–475. [Google Scholar] [CrossRef]

- Suman, S.P.; Mancini, R.A.; Joseph, P.; Ramanathan, R.; Konda, M.K.R.; Dady, G.; Yin, S. Chitosan Inhibits Premature Browning in Ground Beef. Meat Sci. 2011, 88, 512–516. [Google Scholar] [CrossRef] [PubMed]

- Giatrakou, V.; Ntzimani, A.; Savvaidis, I.N. Effect of Chitosan and Thyme Oil on a Ready-to-Cook Chicken Product. Food Microbiol. 2010, 27, 132–136. [Google Scholar] [CrossRef]

- Torri, L.; Piochi, M. Sensory methods and electronic nose as innovative tools for the evaluation of the aroma transfer properties of food plastic bags. Food Res. Int. 2016, 85, 235–243. [Google Scholar] [CrossRef]

- Ke, C.L.; Deng, F.S.; Chuang, C.Y.; Lin, C.H. Antimicrobial Actions and Applications of Chitosan. Polymers 2021, 13, 904. [Google Scholar] [CrossRef] [PubMed]

- Ngo, D.H.; Kim, S.K. Antioxidant Effects of Chitin, Chitosan, and Their Derivatives. Adv. Food Nutr. Res. 2014, 73, 15–31. [Google Scholar] [CrossRef]

- Shin, D.M.; Kim, Y.J.; Yune, J.H.; Kim, D.H.; Kwon, H.C.; Sohn, H.; Han, S.G.; Han, J.H.; Lim, S.J.; Han, S.G. Effects of Chitosan and Duck Fat-Based Emulsion Coatings on the Quality Characteristics of Chicken Meat during Storage. Foods 2022, 11, 245. [Google Scholar] [CrossRef] [PubMed]

| Ingredients | For 1 kg of Seekh Kabab |

|---|---|

| 800 g |

| 200 g |

| 20 g |

| 350 g |

| 12 g |

| 20 g |

| 6 g |

| 2.5 g |

| 2.7 g |

| 2.5 g |

| 5 g |

| 1.5 g |

| 0.5 g |

| 3 g |

| Parameters | Treatments | Storage Time (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Ash (%) | NC-SK | 2.26 ± 0.14 A | 2.20 ± 0.09 ABw | 2.13 ± 0.16 ABw | 2.11 ± 0.11 ABw | 2.02 ± 0.11 Bw |

| 1% CC-SK | 2.20 ± 0.04 A | 2.06 ± 0.15 Awx | 2.05 ± 0.07 Awx | 1.96 ± 0.10 Awx | 2.09 ± 0.19 Aw | |

| 2% CC-SK | 2.17 ± 0.11 A | 1.97 ± 0.11 Bx | 1.91 ± 0.16 BCx | 1.89 ± 0.14 Cx | 1.89 ± 0.23 Cwx | |

| 3% CC-SK | 2.25 ± 0.09 A | 2.14 ± 0.15 ABwx | 1.98 ± 0.35 Bwx | 1.98 ± 0.50 Bwx | 1.94 ± 0.18 Bwx | |

| Moisture (%) | NC-SK | 65.89 ± 0.65 A | 64.74 ± 0.59 ABx | 64.78 ± 0.41 ABw | 63.82 ± 0.39 By | 61.55 ± 0.74 Cx |

| 1% CC-SK | 66.68 ± 0.25 A | 66.51 ± 0.26 Aw | 65.46 ± 0.14 Bw | 65.42 ± 0.27 Bw | 64.54 ± 0.30 Cw | |

| 2% CC-SK | 65.55 ± 0.24 A | 65.40 ± 0.46 Awx | 64.06 ± 0.42 Bx | 64.11 ± 0.26 Bwx | 64.25 ± 0.51 Bw | |

| 3% CC-SK | 66.43 ± 0.46 A | 65.44 ± 1.01 Awx | 64.21 ± 0.34 Bx | 64.71 ± 0.85 Bwx | 64.84 ± 0.91 Bw | |

| Fat (%) | NC-SK | 15.02 ± 0.58 A | 14.53 ± 0.33 ABw | 13.89 ± 0.27 B | 13.21 ± 0.3 Cx | 12.85 ± 0.36 Cx |

| 1% CC-SK | 15.17 ± 0.55 A | 14.51 ± 0.50 ABwx | 14.06 ± 0.31 B | 13.75 ± 0.62 BCw | 13.30 ± 0.14 Cw | |

| 2% CC-SK | 14.96 ± 0.17 A | 14.69 ± 0.17 ABx | 14.19 ± 0.18 BC | 13.63 ± 0.18 CDw | 13.48 ± 0.18 Dw | |

| 3% CC-SK | 15.22 ± 0.12 A | 14.79 ± 0.25 ABwx | 14.29 ± 0.45 B | 13.95 ± 0.38 Cw | 13.66 ± 0.10 Cw | |

| Protein (%) | NC-SK | 18.22 ± 0.42 A | 17.39 ± 0.89 ABx | 16.70 ± 0.67 Bx | 15.82 ± 0.43 CDy | 15.44 ± 0.56 Dy |

| 1% CC-SK | 18.37 ± 0.36 A | 17.83 ± 0.48 ABwx | 16.91 ± 0.44 Bwx | 16.51 ± 0.47 BCx | 15.90 ± 0.17 Cxy | |

| 2% CC-SK | 17.91 ± 1.25 A | 17.56 ± 0.85 ABx | 17.05 ± 0.67 Bw | 16.93 ± 0.20 Bw | 16.14 ± 0.60 Cwx | |

| 3% CC-SK | 18.10 ± 0.37 A | 18.03 ± 0.25 Aw | 17.50 ± 0.24 ABw | 17.02 ± 0.46 Bw | 16.71 ± 0.37 BCw | |

| Parameters | Treatments | Storage Time (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| pH | NC-SK | 5.80 ± 0.04 D | 6.03 ± 0.03 Cw | 6.09 ± 0.16 BCw | 6.18 ± 0.03 Bw | 6.37 ± 0.07 Aw |

| 1% CC-SK | 5.75 ± 0.03 C | 5.88 ± 0.03 Bx | 5.84 ± 0.04 Bxy | 5.89 ± 0.06 Bx | 6.16 ± 0.05 Ax | |

| 2% CC-SK | 5.70 ± 0.04 B | 5.90 ± 0.05 Awx | 5.90 ± 0.06 Ax | 5.91 ± 0.04 Ax | 5.98 ± 0.07 Ay | |

| 3% CC-SK | 5.72 ± 0.09 C | 5.77 ± 0.05 BCy | 5.81 ± 0.05 ABy | 5.86 ± 0.08 ABx | 5.92 ± 0.08 Ay | |

| L* (lightness) | NC-SK | 43.08 ± 0.75 C | 44.02 ± 0.83 C | 44.44 ± 0.81 Cy | 46.71 ± 0.57 By | 48.26 ± 0.61 Ay |

| 1% CC-SK | 44.11 ± 1.10 CD | 45.02 ± 1.48 C | 45.76 ± 0.64 Cxy | 47.52 ± 1.85 Bwx | 49.12 ± 1.28 Awx | |

| 2% CC-SK | 43.97 ± 0.60 C | 44.63 ± 0.39 C | 46.60 ± 1.12 Bwx | 49.29 ± 0.26 Aw | 50.11 ± 0.13 Awx | |

| 3% CC-SK | 44.12 ± 1.03 C | 45.47 ± 1.11 C | 47.54 ± 0.34 BCw | 48.06 ± 0.85 Bwx | 51.43 ± 0.91 Aw | |

| a* (redness) | NC-SK | 7.91 ± 0.66 A | 7.52 ± 0.46 A | 6.04 ± 0.35 B | 5.75 ± 0.62 Cx | 5.65 ± 0.66 Cx |

| 1% CC-SK | 8.01 ± 0.14 A | 7.86 ± 0.62 AB | 6.85 ± 0.51 B | 5.85 ± 0.50 Cx | 5.75 ± 0.55 Cwx | |

| 2% CC-SK | 8.05 ± 0.27 A | 7.73 ± 0.74 AB | 6.14 ± 0.45 B | 6.19 ± 0.23 Bw | 6.11 ± 0.17 Bw | |

| 3% CC-SK | 7.89 ± 0.10 A | 7.51 ± 0.34 AB | 6.08 ± 0.51 B | 6.17 ± 0.65 Cw | 5.89 ± 0.25 Cwx | |

| b* (yellowness) | NC-SK | 18.22 ± 1.13 B | 18.75 ± 0.62 Bwx | 19.04 ± 1.21 AB | 21.18 ± 0.71 Aw | 21.78 ± 0.92 Aw |

| 1% CC-SK | 18.07 ± 1.14 B | 19.01 ± 0.37 Bw | 18.93 ± 0.73 B | 20.12 ± 0.98 Awx | 20.89 ± 0.73 Awx | |

| 2% CC-SK | 18.43 ± 1.14 B | 18.54 ± 0.86 Bx | 18.87 ± 1.30 B | 19.68 ± 0.67 Ax | 20.14 ± 0.69 Ax | |

| 3% CC-SK | 19.04 ± 0.76 AB | 19.24 ± 0.22 ABw | 18.98 ± 0.51 AB | 20.13 ± 0.65 Awx | 20.08 ± 0.25 Ax | |

| Parameters | Treatments | Storage Time (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| TBARS (mg MDA/kg) | NC-SK | 1.57 ± 0.11 D | 1.91 ± 0.08 Cw | 2.32 ± 0.14 Bw | 2.57 ± 0.12 Bw | 3.20 ± 0.04 Aw |

| 1% CC-SK | 1.62 ± 0.12 D | 1.96 ± 0.17 Cw | 2.08 ± 0.15 Cx | 2.33 ± 0.08 Bx | 2.57 ± 0.08 Axy | |

| 2% CC-SK | 1.59 ± 0.12 D | 1.86 ± 0.08 Cx | 2.06 ± 0.13 Cx | 2.26 ± 0.18 Ax | 2.21 ± 0.25 Ay | |

| 3% CC-SK | 1.64 ± 0.04 D | 1.80 ± 0.11 Cx | 2.07 ± 0.17 Bx | 2.19 ± 0.10 Bx | 2.61 ± 0.19 Ax | |

| Carbonyl content (nmol/mg protein) | NC-SK | 2.23 ± 0.09 E | 2.81 ± 0.18 Dw | 3.22 ± 0.16 Cw | 3.65 ± 0.16 Bw | 3.96 ± 0.13 Aw |

| 1% CC-SK | 2.26 ± 0.17 D | 2.73 ± 0.13 Cwx | 2.98 ± 0.09 BCx | 3.11 ± 0.11 Bx | 3.62 ± 0.11 Ax | |

| 2% CC-SK | 2.30 ± 0.12 D | 2.61 ± 0.08 Cx | 2.81 ± 0.07 BCy | 3.06 ± 0.12 Ax | 3.42 ± 0.15 Ay | |

| 3% CC-SK | 2.28 ± 0.04 D | 2.66 ± 0.13 BCx | 2.87 ± 0.12 By | 3.16 ± 0.15 Axy | 3.34 ± 0.14 Ay | |

| TVBN (mg/100 g) | NC-SK | 7.96 ± 0.20 D | 8.73 ± 0.03 Dw | 10.01 ± 0.04 Cw | 13.58 ± 0.13 Bw | 14.55 ± 0.12 Aw |

| 1% CC-SK | 7.86 ± 0.09 C | 8.64 ± 0.18 Cw | 9.96 ± 0.43 Bwx | 11.35 ± 0.43 Ax | 11.84 ± 0.46 Ax | |

| 2% CC-SK | 7.99 ± 0.30 C | 8.12 ± 0.41 BCx | 9.43 ± 0.27 Bwx | 10.42 ± 0.23 Ay | 10.83 ± 0.35 Ay | |

| 3% CC-SK | 8.00 ± 0.13 C | 8.32 ± 0.29 BCx | 9.29 ± 0.53 By | 10.21 ± 0.44 Ay | 10.73 ± 0.26 Ay | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, Z.; Ijaz, M.; Li, M.; Woldemariam, K.Y.; Wang, Z.; Liu, D.; Wu, C.; Li, X.; Zheng, Q.; Zhang, D. Impacts of Chitosan Coating on Shelf Life and Quality of Ready-to-Cook Beef Seekh Kabab During Refrigeration Storage. Foods 2025, 14, 3844. https://doi.org/10.3390/foods14223844

Hussain Z, Ijaz M, Li M, Woldemariam KY, Wang Z, Liu D, Wu C, Li X, Zheng Q, Zhang D. Impacts of Chitosan Coating on Shelf Life and Quality of Ready-to-Cook Beef Seekh Kabab During Refrigeration Storage. Foods. 2025; 14(22):3844. https://doi.org/10.3390/foods14223844

Chicago/Turabian StyleHussain, Zubair, Muawuz Ijaz, Min Li, Kalekristos Yohannes Woldemariam, Zhiying Wang, Dongmin Liu, Chao Wu, Xin Li, Qiankun Zheng, and Dequan Zhang. 2025. "Impacts of Chitosan Coating on Shelf Life and Quality of Ready-to-Cook Beef Seekh Kabab During Refrigeration Storage" Foods 14, no. 22: 3844. https://doi.org/10.3390/foods14223844

APA StyleHussain, Z., Ijaz, M., Li, M., Woldemariam, K. Y., Wang, Z., Liu, D., Wu, C., Li, X., Zheng, Q., & Zhang, D. (2025). Impacts of Chitosan Coating on Shelf Life and Quality of Ready-to-Cook Beef Seekh Kabab During Refrigeration Storage. Foods, 14(22), 3844. https://doi.org/10.3390/foods14223844