Analyses of the Differences in Nutritional Quality and Volatile Aroma Compounds in Potato-Based Reconstituted Rice Produced from Different Potato Varieties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Determination of the Mineral Element and Amino Acid Contents

2.3. Determination of the Main Nutritional Indicators

2.4. Determination of Volatile Flavor Compounds

2.4.1. Sample Cooking and Pretreatment

2.4.2. GC-MS Parameters

2.5. Sensory Evaluation

2.6. Statistical Analysis

3. Results and Discussion

3.1. Differences in the Nutritional Composition of Potato-Based Reconstituted Rice Produced from Different Varieties

3.1.1. Main Mineral Elements and Amino Acids

3.1.2. Main Nutrients

3.2. Flavor Characteristics of Potato-Based Rice Produced from Different Potatoes

3.2.1. Changes in the Appearance of the Material and Quantitative Results for Main Volatile Compounds

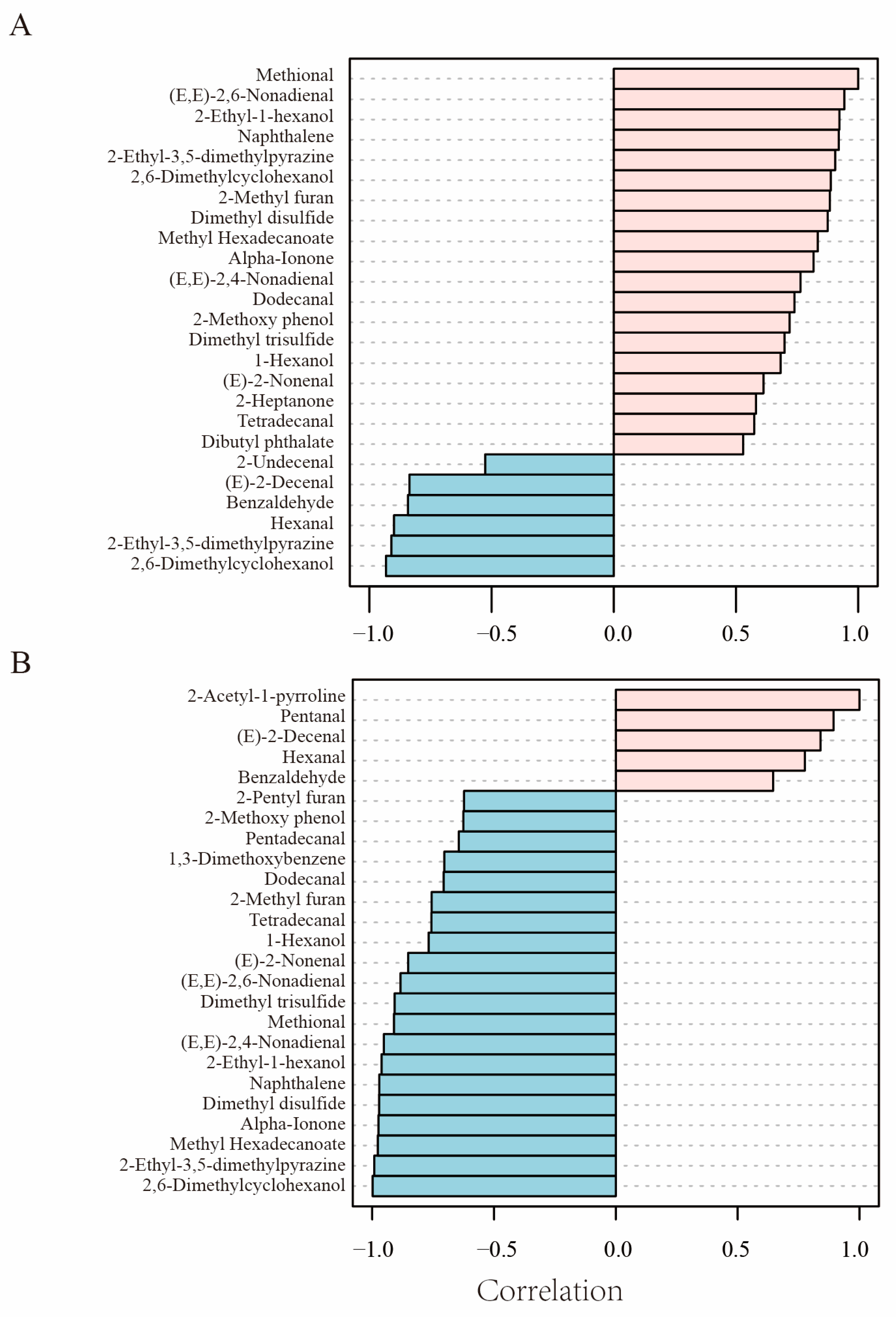

3.2.2. Results of the Screen of Key Compounds Using Orthogonal Partial Least Squares and Correlation Methods

3.2.3. Analyses of the OAVs and Aroma Characteristics of Different Varieties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Liu, H.; Zeng, F.; Yang, Y.; Xu, D.; Zhao, Y.-C.; Liu, X.; Kaur, L.; Liu, G.; Singh, J. Potato Processing Industry in China: Current Scenario, Future Trends and Global Impact. Potato Res. 2023, 66, 543–562. [Google Scholar] [CrossRef]

- Saha, S.; Roy, A. Whole Grain Rice Fortification as a Solution to Micronutrient Deficiency: Technologies and Need for More Viable Alternatives. Food Chem. 2020, 326, 127049. [Google Scholar] [CrossRef] [PubMed]

- Sumardiono, S.; Pudjihastuti, I.; Poerwoprajitno, A.R.; Suswadi, M.S. Physichocemical Properties of Analog Rice from Composite Flour: Cassava, Green Bean and Hanjeli. World Appl. Sci. J. 2014, 32, 1140–1146. [Google Scholar] [CrossRef]

- Lal, M.K.; Singh, B.; Sharma, S.; Singh, M.P.; Kumar, A. Glycemic Index of Starchy Crops and Factors Affecting Its Digestibility: A Review. Trends Food Sci. Technol. 2021, 111, 741–755. [Google Scholar] [CrossRef]

- Kumar, A.; Sahu, C.; Panda, P.A.; Biswal, M.; Sah, R.P.; Lal, M.K.; Baig, M.J.; Swain, P.; Behera, L.; Chattopadhyay, K.; et al. Phytic Acid Content May Affect Starch Digestibility and Glycemic Index Value of Rice (Oryza sativa L.). J. Sci. Food Agric. 2020, 100, 1598–1607. [Google Scholar] [CrossRef]

- Purwaningsih, S.; Santoso, J.; Handharyani, E.; Setiawati, N.P.; Deskawati, E. Artificial Rice from Gracillaria Sp. as Functional Food to Prevent Diabetes. IOP Conf. Ser. Earth Environ. Sci. 2020, 414, 012017. [Google Scholar] [CrossRef]

- Mahendradatta, M.; Rombe, T.E.; Rahman, A.N.F.; Langkong, J.; Tawali, A.B.; Nadhifa, D.G. Analog Rice Based on Sago and Corn with the Addition of Moringa Leaf (Moringa oleifera L.) Powder as a Nutritional Vehicle for Breastfeeding Women. Foods 2024, 14, 2780. [Google Scholar] [CrossRef]

- Saha, S.; Jha, S.; Tiwari, A.; Jayapalan, S.; Roy, A. Considerations for Improvising Fortified Extruded Rice Products. J. Food Sci. 2021, 86, 1180–1200. [Google Scholar] [CrossRef]

- Zhang, D.; Li, J.; Yao, D.; Wu, J.; Luo, Q.; Shen, H.; Hu, M.; Meng, F.; Zhang, Y.; Liu, X.; et al. Differences in Cooking Taste and Physicochemical Properties between Compound Nutritional Rice and Common Rice. Front. Nutr. 2024, 11, 1435977. [Google Scholar] [CrossRef]

- Damat, D.; Setyobudi, R.H.; Burlakovs, J.; Vincevica-Gaile, Z.; Siskawardani, D.D.; Anggriani, R.; Tain, A. Characterization Properties of Extruded Analog Rice Developed from Arrowroot Starch with Addition of Seaweed and Spices. Sarhad J. Agric. 2021, 37, 159–170. [Google Scholar] [CrossRef]

- Nadhifa, D.G.; Mahendradatta, M.; Poespitasari, A.; Bastian, F.; Adhnitasari, A.Y. Characterization of Analog Rice Produced from Various Carbohydrate Sources and Their Functional Components: A Review. Discov. Food 2025, 5, 190. [Google Scholar] [CrossRef]

- Ramadhan, W.; Purwaningsih, S.; Nafisah, S. Effects of Microwave Cooking on the Physicochemical and Sensory Properties of Seaweed-based Analogue Rice. Int. J. Food Sci. Technol. 2024, 59, 1770–1780. [Google Scholar] [CrossRef]

- Jiang, W.; Liang, W.X.; Pei, F.; Su, A.X.; Ma, G.X.; Fang, D.L.; Hu, Q.H.; Ma, N. Effects of Adding Pleurotus eryngii Powder on Quality Characteristics of Extruded Rice. Sci. Agric. Sin. 2024, 57, 779–796. [Google Scholar] [CrossRef]

- Olsson, K.; Svensson, R.; Roslund, C. Tuber Components Affecting Acrylamide Formation and Colour in Fried Potato: Variation by Variety, Year, Storage Temperature and Storage Time. J. Sci. Food Agric. 2004, 84, 447–458. [Google Scholar] [CrossRef]

- Zhang, Q.; Sun, Y.; Sun, Y.; Guo, C.; Zhu, J.; Niu, X.; Gao, M. Comparative Analysis of Physicochemical Properties, Sensory Characteristics, and Volatile Flavor Compounds in Five Types of Potato Chips. Front. Nutr. 2024, 11, 1525480. [Google Scholar] [CrossRef] [PubMed]

- GB 5009.5-2016; Determination of Protein in Foods. National Food Safety Standard, Standardization Administration of China: Beijing, China, 2016.

- GB 5009.9-2023; Determination of Starch in Foods. National Food Safety Standard, Standardization Administration of China: Beijing, China, 2023.

- GB 5009.3-2016; Determination of Moisture in Foods. National Food Safety Standard, Standardization Administration of China: Beijing, China, 2016.

- GB 5009.83-2016; Determination of Carotene in Foods. National Food Safety Standard, Standardization Administration of China: Beijing, China, 2016.

- GB 5009.268-2016; Determination of Multi-Elements in Foods. National Food Safety Standard, Standardization Administration of China: Beijing, China, 2016.

- GB 5009.124-2016; Determination of Amino Acids in Foods. National Food Safety Standard, Standardization Administration of China: Beijing, China, 2016.

- GB 5009.7-2016; Determination of Reducing Sugar in Foods. National Food Safety Standard, Standardization Administration of China: Beijing, China, 2016.

- GB 5009.88-2023; Determination of Dietary Fiber in Foods. National Food Safety Standard, Standardization Administration of China: Beijing, China, 2023.

- T/ZNZ 320-2025; Determination of Total Anthocyanins in Plant-Origin Food Agricultural Products. Zhejiang Agricultural Products Quality and Safety Association: Zhejiang, China, 2025.

- GB/T 15682-2008; Sensory Evaluation Method for Cooking and Eating Quality of Paddy Rice and Brown Rice. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2008.

- Bough, R. Profiling and Putative Aroma Biomarker Identification for Flavor in Potatoes Using a Trained Sensory Panel and HS-SPME GC-MS. Master’s Thesis, University of Idaho, Moscow, ID, USA, 2017. Available online: https://www.potatoslvrc.com/wp-content/uploads/2018/06/Bough_Raven_Thesis2.pdf (accessed on 20 October 2025).

- Van Gemert, L.J. Odour Thresholds: Compilations of Odour Threshold Values in Air, Water and Other Media, 2nd ed.; Oliemans Punter & Partners BV: Utrecht, The Netherlands, 2011. [Google Scholar]

- Farag, M.A.; Abib, B.; Qin, Z.; Ze, X.; Ali, S.E. Dietary Macrominerals: Updated Review of Their Role and Orchestration in Human Nutrition throughout the Life Cycle with Sex Differences. Curr. Res. Food Sci. 2023, 6, 100450. [Google Scholar] [CrossRef] [PubMed]

- Antunes, I.; Bexiga, R.; Pinto, C.; Roseiro, L.; Quaresma, M.A.G. Cow’s Milk in Human Nutrition and the Emergence of Plant-Based Milk Alternatives. Foods 2023, 12, 99. [Google Scholar] [CrossRef] [PubMed]

- Prentice, A.M.; Mendoza, Y.A.; Pereira, D.; Cerami, C.; Wegmuller, R.; Constable, A.; Spieldenner, J. Dietary Strategies for Improving Iron Status: Balancing Safety and Efficacy. Nutr. Rev. 2017, 75, 49–60. [Google Scholar] [CrossRef]

- Cai, C.; Liu, Y.; Xu, Y.; Zhang, J.; Wei, B.; Xu, C.; Wang, H. Mineral-Element-Chelating Activity of Food-Derived Peptides: Influencing Factors and Enhancement Strategies. Crit. Rev. Food Sci. Nutr. 2025, 65, 3241–3255. [Google Scholar] [CrossRef]

- Ajandouz, E.H.; Tchiakpe, L.S.; Ore, F.D.; Benajiba, A.; Puigserver, A. Effects of pH on Caramelization and Maillard Reaction Kinetics in Fructose-Lysine Model Systems. J. Food Sci. 2001, 66, 926–931. [Google Scholar] [CrossRef]

- Anderson, J.W.; Baird, P.; Davis, R.H.; Ferreri, S.; Knudtson, M.; Koraym, A.; Waters, V.; Williams, C.L. Health Benefits of Dietary Fiber. Nutr. Rev. 2009, 67, 188–205. [Google Scholar] [CrossRef]

- Tyl, C.; Bresciani, A.; Marti, A. Recent Progress on Improving the Quality of Bran-Enriched Extruded Snacks. Foods 2021, 10, 2024. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, J.; Zhang, X.; Li, Y.; Zhao, J.; Li, T.; Zhou, B.; Yang, H.; Qiao, L. Enrichment of Soybean Dietary Fiber and Protein Fortified Rice Grain by Dry Flour Extrusion Cooking: The Physicochemical, Pasting, Taste, Palatability, Cooking and Starch Digestibility Properties. RSC Adv. 2018, 8, 26682–26690. [Google Scholar] [CrossRef] [PubMed]

- Tang, G.; Qin, J.; Dolnikowski, G.G.; Russell, R.M.; Grusak, M.A. Golden Rice Is an Effective Source of Vitamin A. Am. J. Clin. Nutr. 2009, 89, 1776–1783. [Google Scholar] [CrossRef] [PubMed]

- Xie, F.; Zhang, W.; Lan, X.; Gong, S.; Wu, J.; Wang, Z. Physicochemical Properties and Structural Characteristics of Soluble Dietary Fibers from Yellow and Purple Fleshed Potatoes By-Product. Int. J. Food Prop. 2017, 20, S2939–S2949. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, Y.; Wang, R.; Sun, Y.; Li, X.; Liang, J. Effects of Adding Blueberry Residue Powder and Extrusion Processing on Nutritional Components, Antioxidant Activity and Volatile Organic Compounds of Indica Rice Flour. Biology 2022, 11, 1817. [Google Scholar] [CrossRef]

- Sailendra, N.V.; Aji, A.S.; Saloko, S.; Aprilia, V.; Djidin, R.T.S.; Rahmawati, S.; Khoirunnisah, F.M. The Effect of Rice Cooking Techniques on Sensory Evaluation and Stickiness Level of Rice from Analog Rice Made from Sorghum Flour, Mocaf, Glucomannan, and Moringa. Amerta Nutr. 2024, 8, 356–362. [Google Scholar] [CrossRef]

- Mahendradatta, M.; Assa, E.; Langkong, J.; Tawali, A.B.; Nadhifa, D.G. Development of Analog Rice Made from Cassava and Banana with the Addition of Katuk Leaf (Sauropus androgynous L. Merr.) and Soy Lecithin for Lactating Women. Foods 2024, 13, 1438. [Google Scholar] [CrossRef] [PubMed]

- Raigond, P.; Singh, B.; Dutt, S.; Kumar Chakrabarti, S. Potato: Nutrition and Food Security; Springer: Singapore, 2020; pp. 73–85. [Google Scholar] [CrossRef]

- Oruna-Concha, M.J.; Duckham, S.C.; Ames, J.M. Comparison of Volatile Compounds Isolated from the Skin and Flesh of Four Potato Cultivars after Baking. J. Agric. Food Chem. 2001, 49, 2414–2421. [Google Scholar] [CrossRef]

- Jansky, S.H. Potato Flavor. Am. J. Potato Res. 2010, 87, 209–217. [Google Scholar] [CrossRef]

- Hu, X.; Lu, L.; Guo, Z.; Zhu, Z. Volatile Compounds, Affecting Factors and Evaluation Methods for Rice Aroma: A Review. Trends Food Sci. Technol. 2020, 97, 136–146. [Google Scholar] [CrossRef]

- Zamora, R.; Gallardo, E.; Hidalgo, F.J. Strecker Degradation of Phenylalanine Initiated by 2,4-Decadienal or Methyl 13-Oxooctadeca-9,11-Dienoate in Model Systems. J. Agric. Food Chem. 2007, 55, 1308–1314. [Google Scholar] [CrossRef] [PubMed]

- Comandini, P.; Cerretani, L.; Blanda, G.; Bendini, A.; Toschi, T.G. Characterization of Potato Flavours: An Overview of Volatile Profiles and Analytical Procedures. In Potato V: Food 5 (Special Issue 1); Global Science Books: Ikenobe, Japan, 2011; pp. 1–14. Available online: http://globalsciencebooks.info/Online/GSBOnline/images/2011/FOOD_5(SI1)/FOOD_5(SI1)1-14o.pdf (accessed on 20 October 2025).

- Xiao, D.-R.; Liu, R.-S.; He, L.; Li, H.-M.; Tang, Y.-L.; Liang, X.-H.; Chen, T.; Tang, Y.-J. Aroma Improvement by Repeated Freeze-Thaw Treatment during Tuber Melanosporum Fermentation. Sci. Rep. 2015, 5, 17120. [Google Scholar] [CrossRef] [PubMed]

- Blanda, G.; Cerretani, L.; Comandini, P.; Toschi, T.G.; Lercker, G. Investigation of Off-Odour and off-Flavour Development in Boiled Potatoes. Food Chem. 2010, 118, 283–290. [Google Scholar] [CrossRef]

- McKenzie, M.; Corrigan, V. Potato Flavor. In Advances in Potato Chemistry and Technology, 2nd ed.; Singh, J., Kaur, L., Eds.; Academic Press: San Diego, CA, USA, 2016; pp. 339–368. [Google Scholar]

- Dresow, J.F.; Böhm, H. The Influence of Volatile Compounds of the Flavour of Raw, Boiled and Baked Potatoes: Impact of Agricultural Measures on the Volatile Components. Landbauforschung 2009, 59, 309–338. [Google Scholar]

- Thybo, A.K.; Christiansen, J.; Kaack, K.; Petersen, M.A. Effect of Cultivars, Wound Healing and Storage on Sensory Quality and Chemical Components in Pre-Peeled Potatoes. LWT Food Sci. Technol. 2006, 39, 166–176. [Google Scholar] [CrossRef]

- Morris, W.L.; Shepherd, T.; Verrall, S.R.; McNicol, J.W.; Taylor, M.A. Relationships between Volatile and Non-Volatile Metabolites and Attributes of Processed Potato Flavour. Phytochemistry 2010, 71, 1765–1773. [Google Scholar] [CrossRef]

- Schutte, L.; Teranishi, R. Precursors of Sulfur-containing Flavor Compounds. CRC Crit. Rev. Food Technol. 1974, 4, 457–505. [Google Scholar] [CrossRef]

- Simkin, A.J.; Schwartz, S.H.; Auldridge, M.; Taylor, M.G.; Klee, H.J. The Tomato Carotenoid Cleavage Dioxygenase 1 Genes Contribute to the Formation of the Flavor Volatiles β-Ionone, Pseudoionone, and Geranylacetone. Plant J. 2004, 40, 882–892. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, M.; Liang, S. Effect of overcooking on flavor compounds of potato. Food Sci. 2017, 38, 200–204. [Google Scholar] [CrossRef]

- Guo, L.; Chen, H.; Zhang, Y.; Yan, S.; Chen, X.; Gao, X. Starch granules and their size distribution in wheat: Biosynthesis, physicochemical properties and their effect on flour-based food systems. Comput. Struct. Biotechnol. J. 2023, 21, 4172–4186. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Liu, H.; Ma, Y.; Mai, S.; Li, C. Effects of extrusion on starch molecular degradation, order–disorder structural transition and digestibility—A review. Foods 2022, 11, 2538. [Google Scholar] [CrossRef] [PubMed]

- Mishra, A.; Mishra, H.N.; Srinivasa Rao, P. Preparation of rice analogues using extrusion technology. Int. J. Food Sci. Technol. 2012, 47, 1789–1797. [Google Scholar] [CrossRef]

- Kusmiandany, E.; Pratama, Y.; Pramono, Y.B. The Effect of Gatot (Fermented Dried Cassava) and Red Bean Ratio on Water Content and Organoleptic Characteristics of the “Gatotkaca” Analog Rice. J. Appl. Food Technol. 2019, 6, 9–11. [Google Scholar] [CrossRef]

| Compound | Reconstituted Rice | ||

|---|---|---|---|

| RBRR | YPRR | PPRR | |

| Mineral elements (mg/100 g) | |||

| Calcium | 67.90 ± 3.65 b | 114.00 ± 2.70 a | 74.20 ± 7.02 b |

| Potassium | 899.00 ± 79.36 b | 4360.00 ± 109.86 a | 4170.00 ± 134.78 a |

| Magnesium | 197.00 ± 8.08 b | 299.00 ± 8.16 a | 287.00 ± 5.33 a |

| Iron | 3.60 ± 0.15 b | 42.40 ± 2.46 a | 46.20 ± 4.53 a |

| Zinc | 12.70 ± 0.87 a | 7.12 ± 0.57 b | 7.98 ± 0.37 b |

| Amino acids (g/100 g) | |||

| Total amino acids | 5.130 ± 0.330 a | 5.640 ± 0.230 a | 4.850 ± 0.090 a |

| Histidine | 0.120 ± 0.001 a | 0.130 ± 0.002 a | 0.120 ± 0.007 a |

| Tyrosine | 0.022 ± 0.002 b | N.D. | 0.086 ± 0.006 a |

| Isoleucine | 0.220 ± 0.009 a | 0.210 ± 0.019 a | 0.150 ± 0.003 b |

| Valine | 0.320 ± 0.029 a | 0.300 ± 0.009 ab | 0.230 ± 0.003 b |

| Alanine | 0.330 ± 0.013 a | 0.380 ± 0.023 a | 0.360 ± 0.023 a |

| Arginine | 0.360 ± 0.025 a | 0.220 ± 0.009 b | 0.200 ± 0.008 b |

| Lysine | 0.190 ± 0.018 a | 0.210 ± 0.017 a | 0.190 ± 0.013 a |

| Serine | 0.290 ± 0.004 a | 0.270 ± 0.013 a | 0.250 ± 0.009 a |

| Glutamic acid | 1.130 ± 0.052 b | 1.380 ± 0.074 a | 1.110 ± 0.011 b |

| Glycine | 0.250 ± 0.007 a | 0.200 ± 0.023 ab | 0.190 ± 0.007 a |

| Methionine | 0.069 ± 0.004 b | 0.048 ± 0.001 c | 0.081 ± 0.001 a |

| Leucine | 0.540 ± 0.032 a | 0.640 ± 0.007 a | 0.560 ± 0.036 a |

| Phenylalanine | 0.270 ± 0.006 a | 0.270 ± 0.005 a | 0.270 ± 0.015 a |

| Threonine | 0.200 ± 0.016 a | 0.200 ± 0.007 a | 0.190 ± 0.006 a |

| Aspartic acid | 0.530 ± 0.001 b | 0.760 ± 0.048 a | 0.500 ± 0.017 b |

| Compound | Reconstituted Rice | ||

|---|---|---|---|

| RBRR | YPRR | PPRR | |

| Protein (g/100 g) | 3.41 ± 1.40 a | 3.63 ± 1.44 a | 3.38 ± 1.35 a |

| Starch (g/100 g) | 74.50 ± 5.60 a | 74.40 ± 4.20 a | 71.10 ± 1.90 a |

| Dry matter (g/100 g) | 86.80 ± 2.70 a | 88.00 ± 1.30 a | 86.90 ± 2.90 a |

| Reducing sugars (g/100 g) | 0.28 ± 0.01 c | 2.00 ± 0.10 a | 0.53 ± 0.01 b |

| Carotenoids (μg/100 g) | N.D. | 14.10 ± 0.80 a | N.D. |

| Anthocyanins (mg/100 g) | N.D. | N.D. | 45.00 ± 2.63 a |

| Dietary fiber (g/100 g) | N.D. | 3.92 ± 0.13 a | 3.44 ± 0.04 b |

| Compound | Odor Threshold (mg/kg) | OAV | Aroma Description | Aroma Classification | ||

|---|---|---|---|---|---|---|

| RBRR | PPRR | YPRR | ||||

| Alpha-Ionone | 0.0001 | 80 | 650 | 930 | Violet, berry | Fruity |

| (E,E)-2,6-Nonadienal | 0.0011 | 4.54 | 33.63 | 15.45 | Cucumber, green | Fruity |

| (E)-2-Decenal | 0.003 | 2 | 0.33 | 0.66 | Citrus peel, fatty | Fruity |

| Acetophenone | 0.05 | 0.28 | 0.12 | 0.64 | Orange blossom, cherry | Fruity |

| 2-Ethyl-3,5-dimethylpyrazine | 0.00001 | 2100 | 40,000 | 40,800 | Roasted nut, roasted coffee | Nutty |

| 2-Methyl furan | 0.0014 | 17.85 | 132.85 | 45 | Roasted coffee, caramel | Nutty |

| Dimethyl disulfide | 0.009 | 0.91 | 3.16 | 3.06 | Garlic, roasted potato | Potato-like |

| Dimethyl trisulfide | 0.007 | 0.54 | 1.23 | 2.05 | Cooked onion, roasted potato | Potato-like |

| Methional | 0.00006 | 0.01 | 6158.73 | 1952.38 | Boiled potato | Potato-like |

| 2-Acetyl-1-pyrroline | 0.00002 | 4300 | 0 | 0 | Toasty, rice-like | Cereal |

| Pentanal | 0.0014 | 630.71 | 302.85 | 385 | Bread, malt | Cereal |

| 1,3-Dimethoxybenzene | 0.0241 | 0.083 | 0.16 | 1.03 | Anise, herbal | Woody |

| Benzaldehyde | 0.01 | 116.8 | 60.9 | 98.3 | Cherry pit, roasted nut | Woody |

| (E)-2-Heptenal | 0.011 | 5.36 | 3.72 | 7.455 | Grassy, fatty | Green |

| Hexanal | 0.0067 | 1772.53 | 835.97 | 1253.88 | Grassy, unripe fruit | Green |

| 2-Ethyl-1-hexanol | 0.74 | 0.63 | 1.45 | 1.26 | Floral, slight green | Fatty |

| (E)-2-Nonenal | 0.0034 | 12.05 | 19.70 | 28.52 | Grassy, fatty | Fatty |

| (E,E)-2,4-Decadienal | 0.005 | 141.6 | 136.8 | 905.2 | Fried, nutty | Fatty |

| 2-Undecenal | 0.04 | 1.17 | 0.35 | 2.02 | Citrus, fatty | Fatty |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Z.; Li, K.; Zhang, Q.; Zeng, F.; Guo, H. Analyses of the Differences in Nutritional Quality and Volatile Aroma Compounds in Potato-Based Reconstituted Rice Produced from Different Potato Varieties. Foods 2025, 14, 3622. https://doi.org/10.3390/foods14213622

Guo Z, Li K, Zhang Q, Zeng F, Guo H. Analyses of the Differences in Nutritional Quality and Volatile Aroma Compounds in Potato-Based Reconstituted Rice Produced from Different Potato Varieties. Foods. 2025; 14(21):3622. https://doi.org/10.3390/foods14213622

Chicago/Turabian StyleGuo, Zongming, Kaifeng Li, Quanfeng Zhang, Fankui Zeng, and Huachun Guo. 2025. "Analyses of the Differences in Nutritional Quality and Volatile Aroma Compounds in Potato-Based Reconstituted Rice Produced from Different Potato Varieties" Foods 14, no. 21: 3622. https://doi.org/10.3390/foods14213622

APA StyleGuo, Z., Li, K., Zhang, Q., Zeng, F., & Guo, H. (2025). Analyses of the Differences in Nutritional Quality and Volatile Aroma Compounds in Potato-Based Reconstituted Rice Produced from Different Potato Varieties. Foods, 14(21), 3622. https://doi.org/10.3390/foods14213622