Enhancing Quality and Processing Efficiency of Germinated Buckwheat Tea Through Hot Air-Assisted Radio Frequency Roasting

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of GB Tea

2.3. HARF Roasting of GB Tea

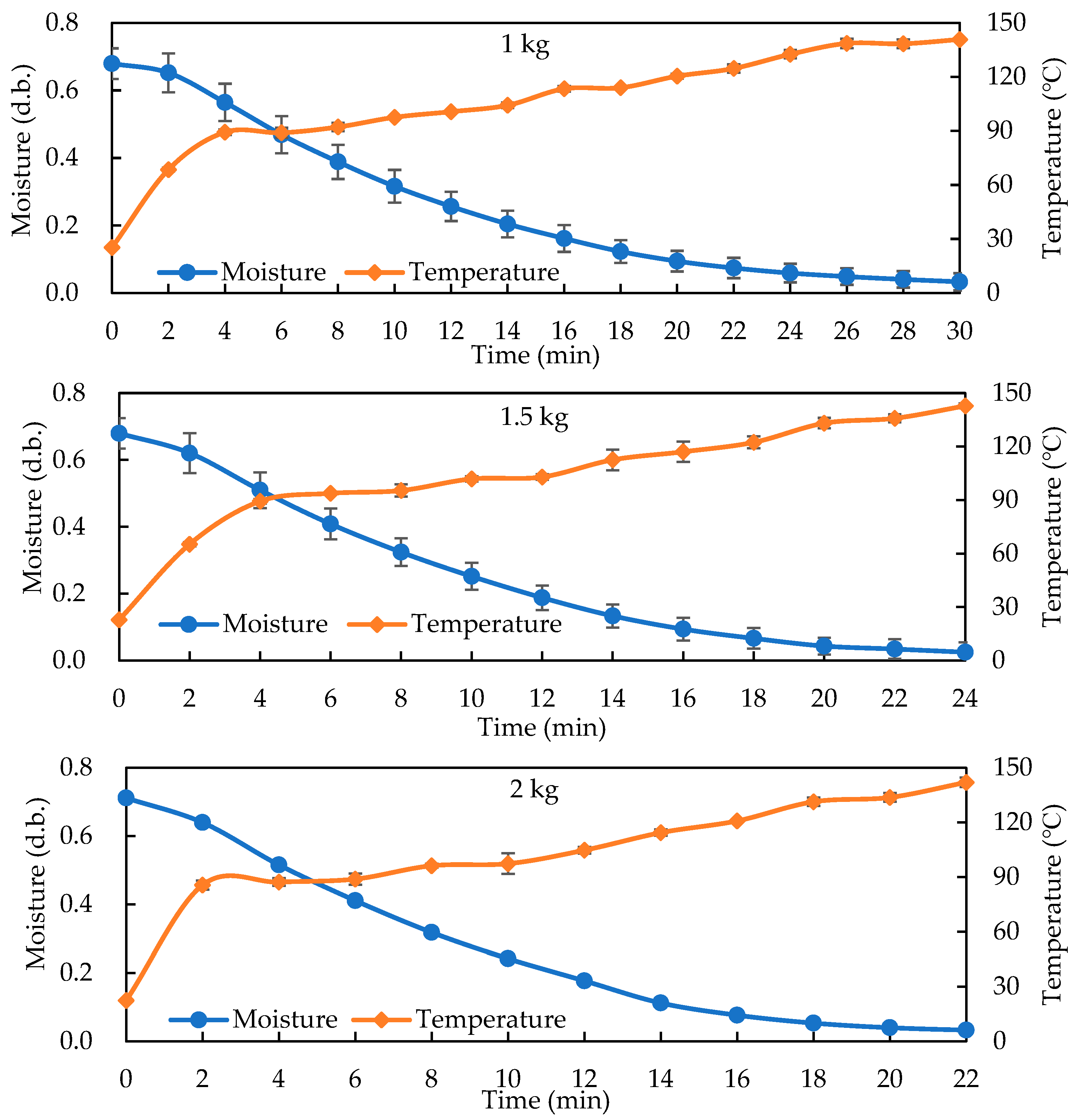

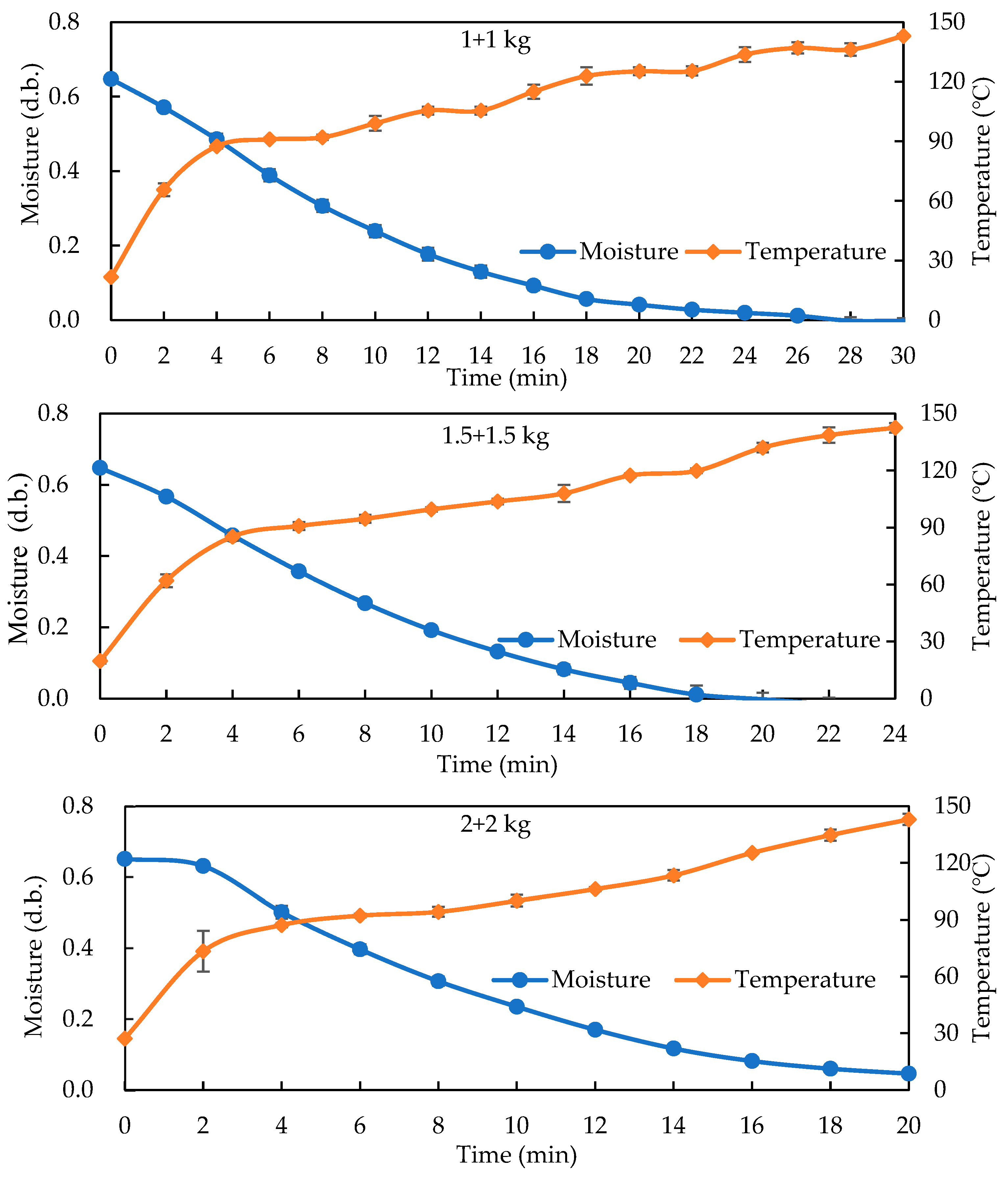

2.4. Temperature and Moisture Changes During HARF Drying

2.5. Energy Consumption During RF Drying and Roasting

2.6. Cyclone Oven Roasting of GB Tea

2.7. Color Analysis of GB Tea

2.8. Nine-Point Hedonic Sensory Evaluation

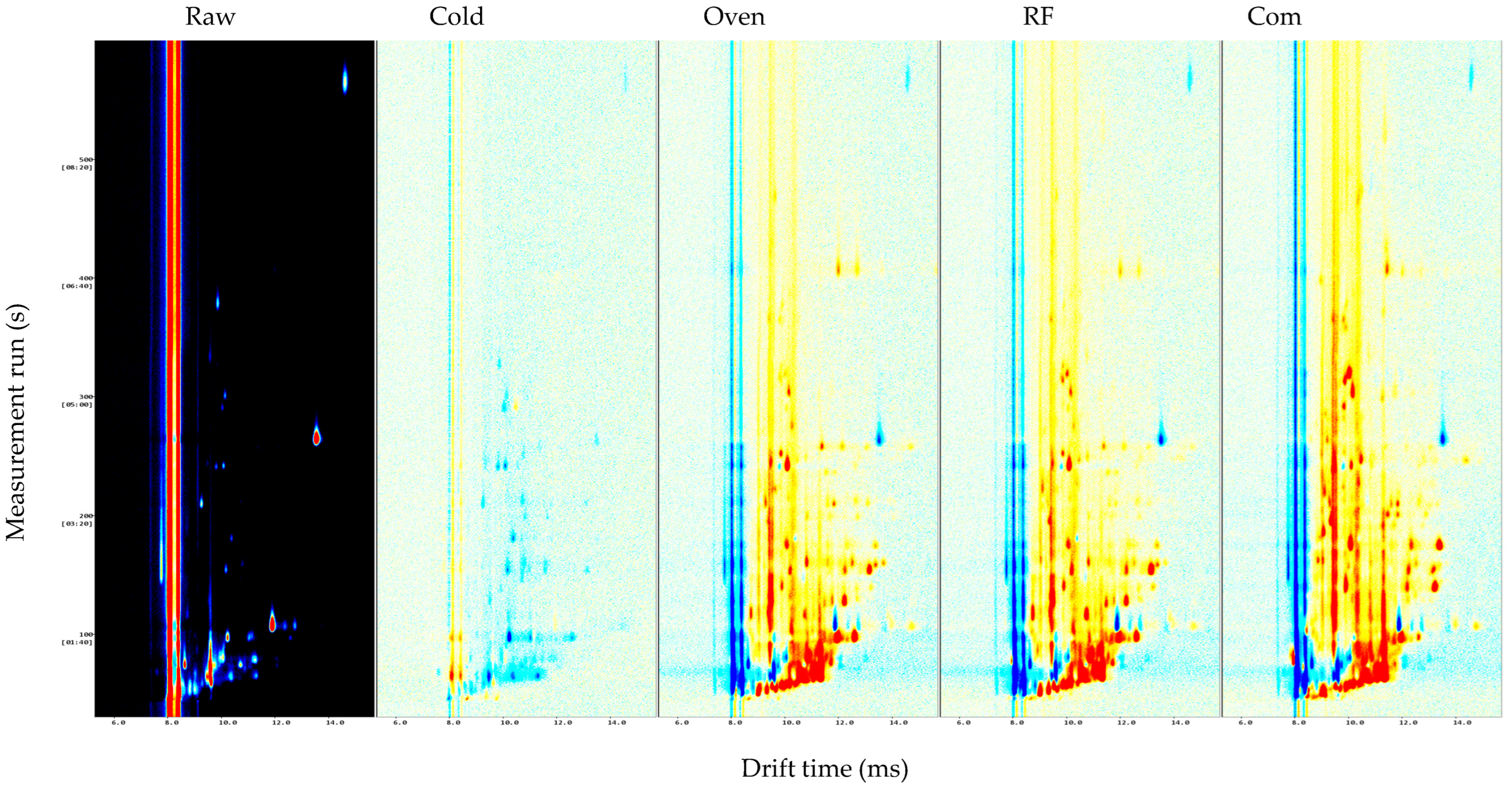

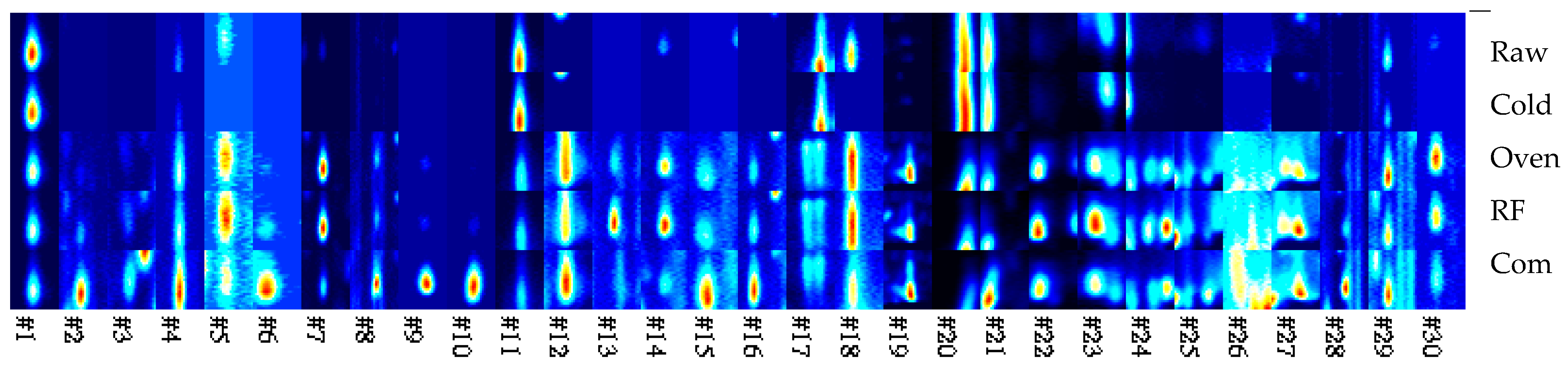

2.9. GC-IMS Analysis of Volatiles

2.10. Statistical Analysis

3. Results and Discussion

3.1. The 10 kW RF Roasting of GB Tea

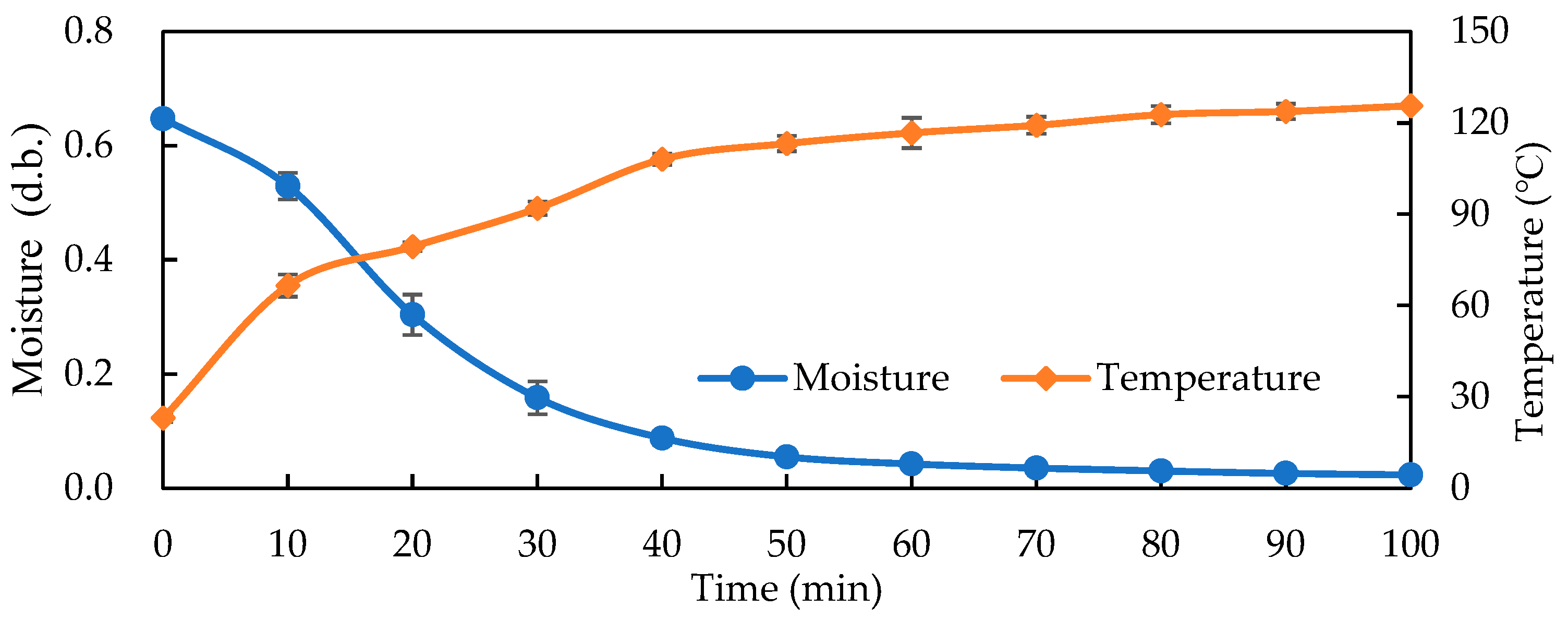

3.2. Sensory Evaluation and Aroma Analysis of GB Tea

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.; Wang, Y.; Chen, J.; Zhang, L.; Liu, H. Effects of radio frequency assisted hot air drying on germinated wheat: Drying kinetics and quality attributes. J. Food Eng. 2021, 285, 110104. [Google Scholar] [CrossRef]

- Kawatra, N.; Jha, G.; Dubey, A. Effect of selected elicitors on phytochemical content and antioxidant activity of buckwheat (Fagopyrum esculentum) sprouts obtained from seeds cultivated using the hydroponics technology. Int. J. Food Sci. Technol. 2023, 58, 3252–3263. [Google Scholar] [CrossRef]

- Zhang, Y.; Pandiselvam, R.; Zhu, H.; Su, D.; Wang, H.; Ai, Z.; Kothakota, A.; Khaneghah, A.M.; Liu, Y. Impact of radio frequency treatment on textural properties of food products: An updated review. Trends Food Sci. Technol. 2022, 124, 154–166. [Google Scholar] [CrossRef]

- Ling, B.; Cheng, T.; Wang, S. Recent developments in applications of radio frequency heating for improving safety and quality of food grains and their products: A review. Crit. Rev. Food Sci. Nutr. 2020, 60, 2622–2642. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Zhong, M.; Feng, L.; Huo, Y.; Pan, L. Evaluation of flavor characteristics in tartary buckwheat (Fagopyrum tataricum) by E-nose, GC-IMS, and HS-SPME-GC-MS: Influence of different roasting temperatures. LWT 2024, 191, 115672. [Google Scholar] [CrossRef]

- Ma, C.; Nie, H.; Liu, L.-X.; Wang, F.-R.; Chen, Y.; Zhang, W.; Liu, Y.-G. Gas chromatography–ion mobility spectrometry (GC-IMS) technique and its recent applications in grain research. J. Sci. Food Agric. 2024, 104, 9093–9101. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Cao, M.; Wang, X.; Guo, S.; Ding, Z.; Kang, Y.; Hu, L.; Xiong, L.; Pei, J.; Ma, Y.; et al. The combined analysis of GC-IMS and GC-MS reveals the differences in volatile flavor compounds between yak and cattle-yak meat. Foods 2024, 13, 2364. [Google Scholar] [CrossRef] [PubMed]

- Parastar, H.; Weller, P. Towards greener volatilomics: Is GC-IMS the new Swiss army knife of gas phase analysis? TrAC Trends Anal. Chem. 2024, 170, 117438. [Google Scholar] [CrossRef]

- Tsou, S.-F.; Hsu, H.-Y.; Chen, S.-D. Effects of different pretreatments on the GABA content of germinated brown rice. Appl. Sci. 2024, 14, 5771. [Google Scholar] [CrossRef]

- Castro-Alba, V.; Lazarte, C.E.; Perez-Rea, D.; Sandberg, A.S.; Carlsson, N.G.; Almgren, A.; Bergenståhl, B.; Granfeldt, Y. Effect of fermentation and dry roasting on the nutritional quality and sensory attributes of quinoa. Food Sci. Nutr. 2019, 7, 3902–3911. [Google Scholar] [CrossRef] [PubMed]

- Ryu, J.Y.; Choi, Y.; Hong, K.H.; Chung, Y.S.; Cho, S.K. Effect of roasting and brewing on the antioxidant and antiproliferative activities of tartary buckwheat. Foods 2020, 9, 1331. [Google Scholar] [CrossRef] [PubMed]

- Teseme, W.B.; Weldeselassie, H.W. Review on the study of dielectric properties of food materials. Am. J. Eng. Technol. Manag. 2020, 5, 76–83. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, S. Recent developments in radio frequency drying of food and agricultural products: A review. Dry. Technol. 2019, 37, 271–286. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Yen, Y.-F.; Chen, S.-D. Effects of radio frequency heating on the stability and antioxidant properties of rice bran. Foods 2021, 10, 810. [Google Scholar] [CrossRef] [PubMed]

- Chitsuthipakorn, K.; Thanapornpoonpong, S.N. Quality of milled rice from large-scale dried paddy rice by hot air combined with radio frequency heating. Processes 2021, 9, 2277. [Google Scholar] [CrossRef]

- Xu, J.; Yang, G.; Li, R.; Xu, Y.; Lin, B.; Wang, S. Effects of radio frequency heating on microbial populations and physicochemical properties of buckwheat. Int. J. Food Microbiol. 2022, 363, 109500. [Google Scholar] [CrossRef] [PubMed]

- Schlörmann, W.; Zetzmann, S.; Wiege, B.; Haase, N.U.; Greiling, A.; Lorkowski, S.; Dawczynski, C.; Glei, M. Impact of different roasting conditions on sensory properties and health-related compounds of oat products. Food Chem. 2020, 307, 125548. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zhang, M.; Mujumdar, A.S.; Sun, J. Characterization of volatile compounds in roasted grains by HS-GC-IMS. Foods 2022, 11, 2921. [Google Scholar] [CrossRef]

- Peng, S.; Li, Y.; Yang, X.; Liu, X. Influence of germination and roasting on the characteristic aroma of quinoa: HS-GC-IMS and HS-SPME-GC-MS analysis. J. Food Compos. Anal. 2024, 125, 105776. [Google Scholar] [CrossRef]

- Zieliński, H.; Michalska, A.; Piskuła, M.K.; Kozłowska, H. Changes in protein quality and antioxidant properties of buckwheat seeds and groats induced by roasting. J. Agric. Food Chem. 2009, 57, 4771–4776. [Google Scholar] [CrossRef] [PubMed]

| RF Loading Capacity (kg) | Average Current (A) | * Time (min) | Total Energy Consumption (kWh) | Energy (kWh/kg) |

|---|---|---|---|---|

| 1 kg | 16.73 | 30 | 3.19 | 3.19 |

| 1.5 kg | 18.54 | 24 | 2.82 | 1.88 |

| 2 kg | 20.96 | 22 | 2.92 | 1.46 |

| 1 + 1 kg | 19.27 | 30 | 3.68 | 1.84 |

| 1.5 +1.5 kg | 23.14 | 24 | 3.54 | 1.18 |

| 2 + 2 kg | 27.25 | 20 | 3.48 | 0.87 |

| 1 kg Oven | 38.06 | 100 | 15.91 | 15.91 |

| Treatment | L * | a * | b * | ΔE |

|---|---|---|---|---|

| N | 25.99 ± 2.57 b | 3.04 ± 0.50 b | 5.77 ± 1.00 c | 0 |

| RF | 18.57 ± 2.57 d | 3.51 ± 0.51 b | 6.12 ± 1.73 c | 7.44 |

| Oven | 22.96 ± 2.15 c | 4.18 ± 0.37 a | 7.88 ± 1.10 b | 3.86 |

| Commercial | 34.21 ± 1.98 a | 3.04 ± 0.50 a | 16.41 ± 1.22 a | 13.45 |

| Item | GO140 | GRF140 | Commercial |

|---|---|---|---|

| Color | 6.29 ± 1.56 a | 6.00 ± 1.67 b | 5.49 ± 2.07 bc |

| Smell | 5.62 ± 1.67 b | 6.85 ± 1.54 a | 5.16 ± 1.74 b |

| Taste | 5.58 ± 2.08 a | 6.22 ± 1.65 a | 5.02 ± 2.04 b |

| Overall | 6.05 ± 1.08 b | 6.40 ± 1.56 a | 5.42± 1.84 bc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, H.-Y.; Hsiao, J.-M.; Chen, S.-D. Enhancing Quality and Processing Efficiency of Germinated Buckwheat Tea Through Hot Air-Assisted Radio Frequency Roasting. Foods 2025, 14, 3596. https://doi.org/10.3390/foods14213596

Lai H-Y, Hsiao J-M, Chen S-D. Enhancing Quality and Processing Efficiency of Germinated Buckwheat Tea Through Hot Air-Assisted Radio Frequency Roasting. Foods. 2025; 14(21):3596. https://doi.org/10.3390/foods14213596

Chicago/Turabian StyleLai, Hsiang-Yu, Jui-Min Hsiao, and Su-Der Chen. 2025. "Enhancing Quality and Processing Efficiency of Germinated Buckwheat Tea Through Hot Air-Assisted Radio Frequency Roasting" Foods 14, no. 21: 3596. https://doi.org/10.3390/foods14213596

APA StyleLai, H.-Y., Hsiao, J.-M., & Chen, S.-D. (2025). Enhancing Quality and Processing Efficiency of Germinated Buckwheat Tea Through Hot Air-Assisted Radio Frequency Roasting. Foods, 14(21), 3596. https://doi.org/10.3390/foods14213596