Impact of Hemp Flour on the Nutritional, Sensory and Functional Characteristics of Wheat and Whole Wheat Muffins

Abstract

1. Introduction

2. Materials and Methods

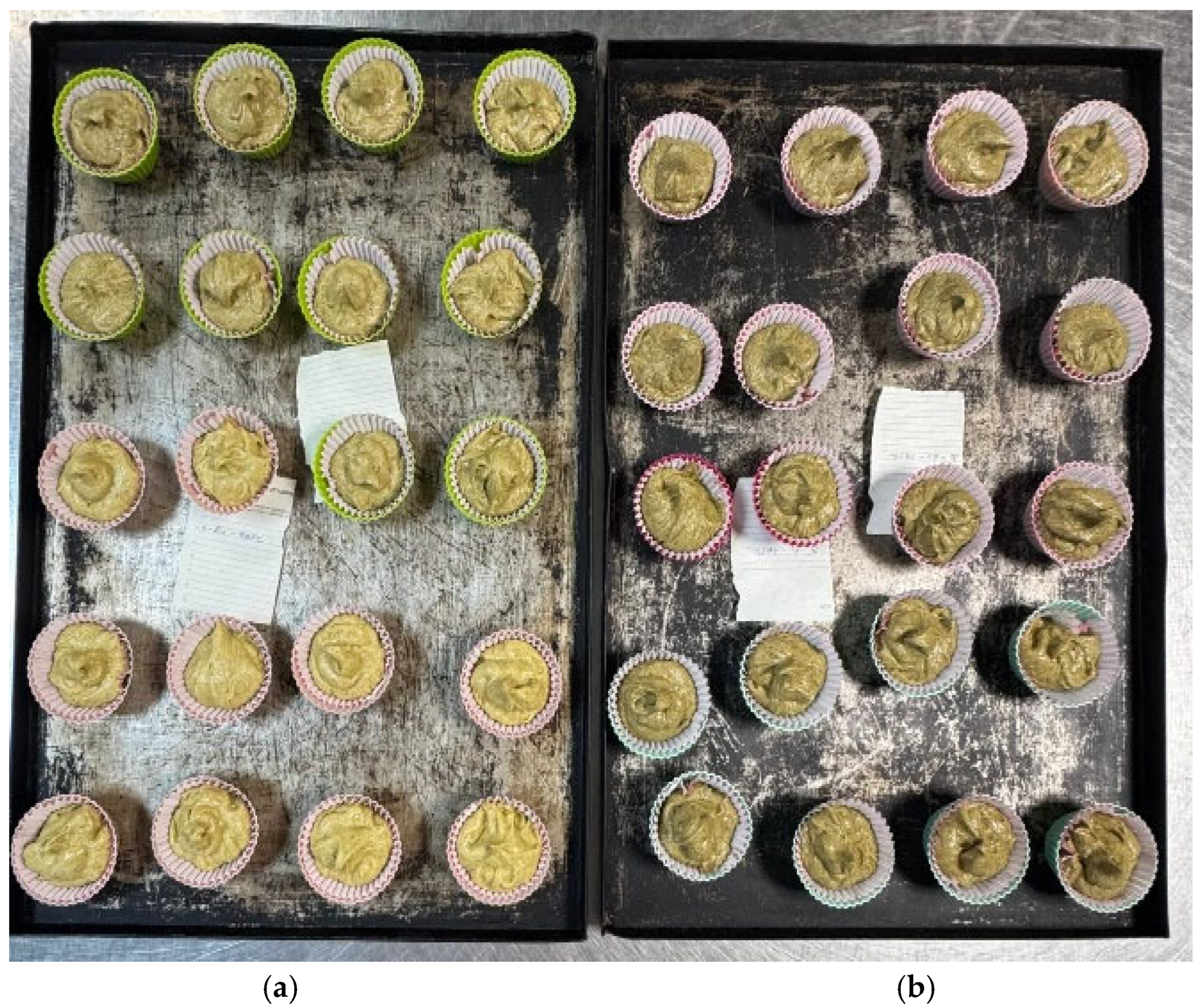

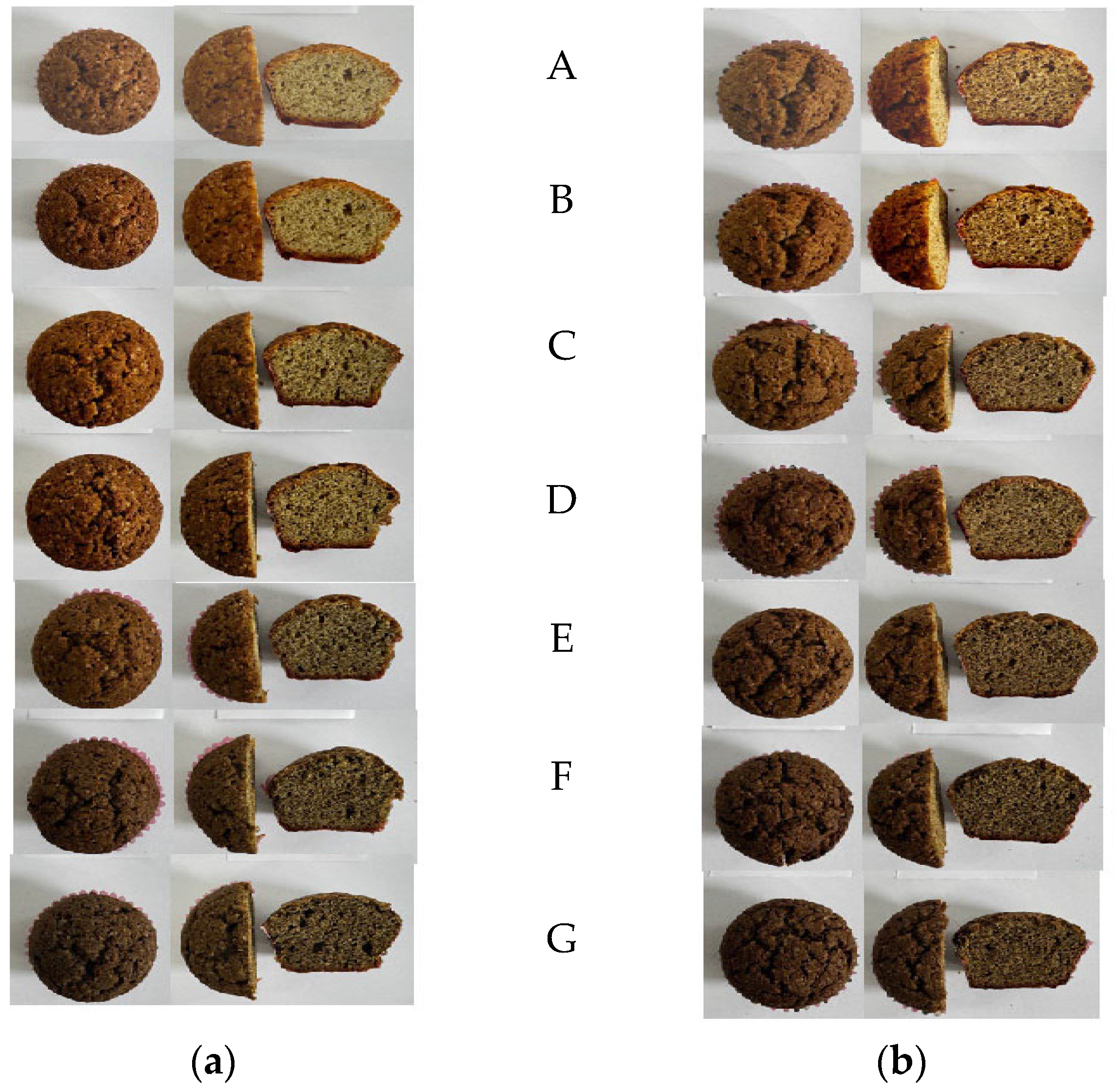

2.1. Preparation of Samples

2.2. Analyses Performed

2.2.1. Preferential (Hedonic) Sensory Analysis

2.2.2. Descriptive Sensory Analysis

2.2.3. Texture Analysis

2.2.4. Color Analysis

2.2.5. Microbiological Analysis

2.2.6. Physicochemical Analyses

2.3. Statistical Analysis

3. Results and Discussion

3.1. Sensory Analyses

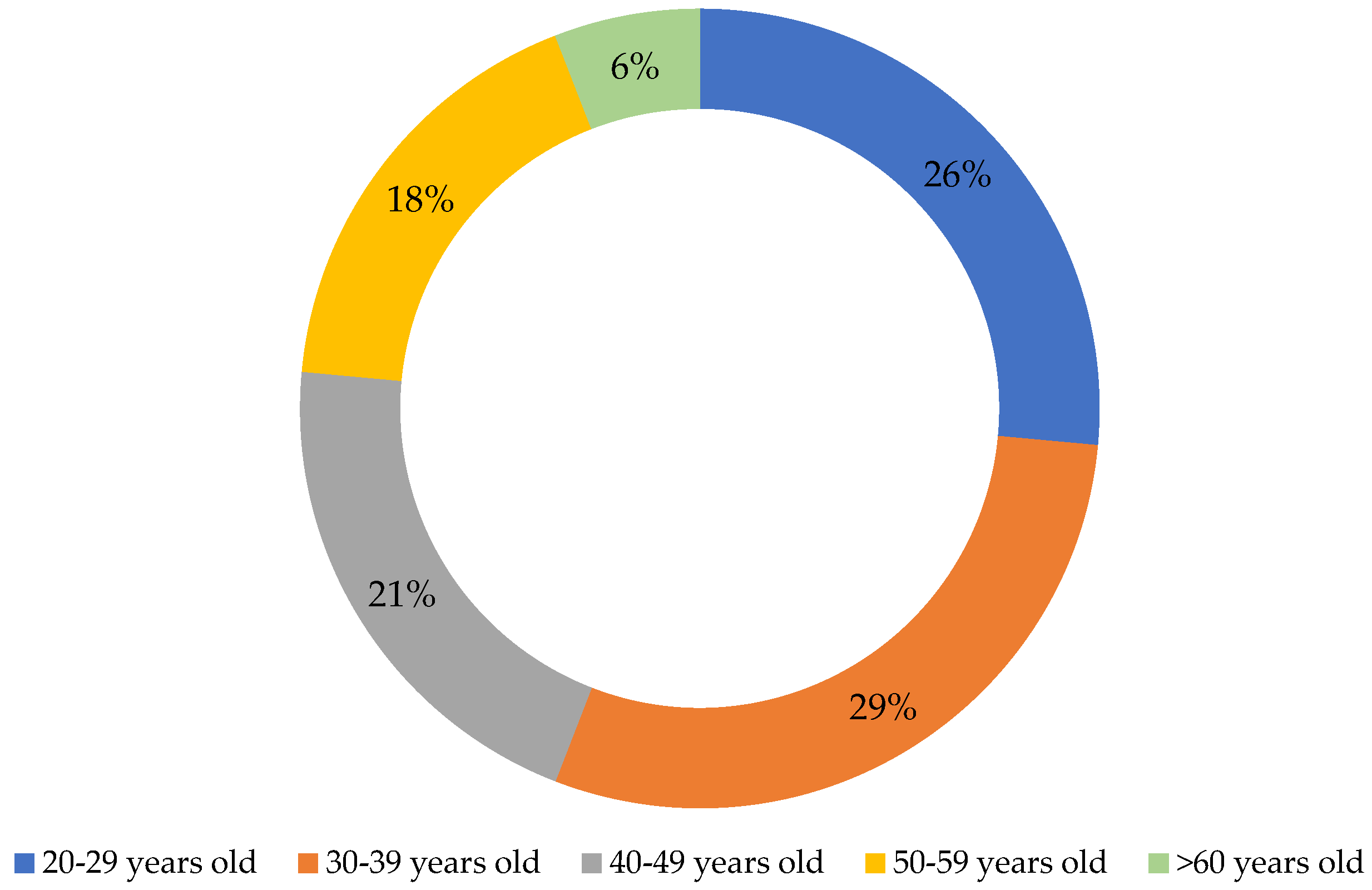

3.1.1. Preferential (Hedonic) Sensory Analysis

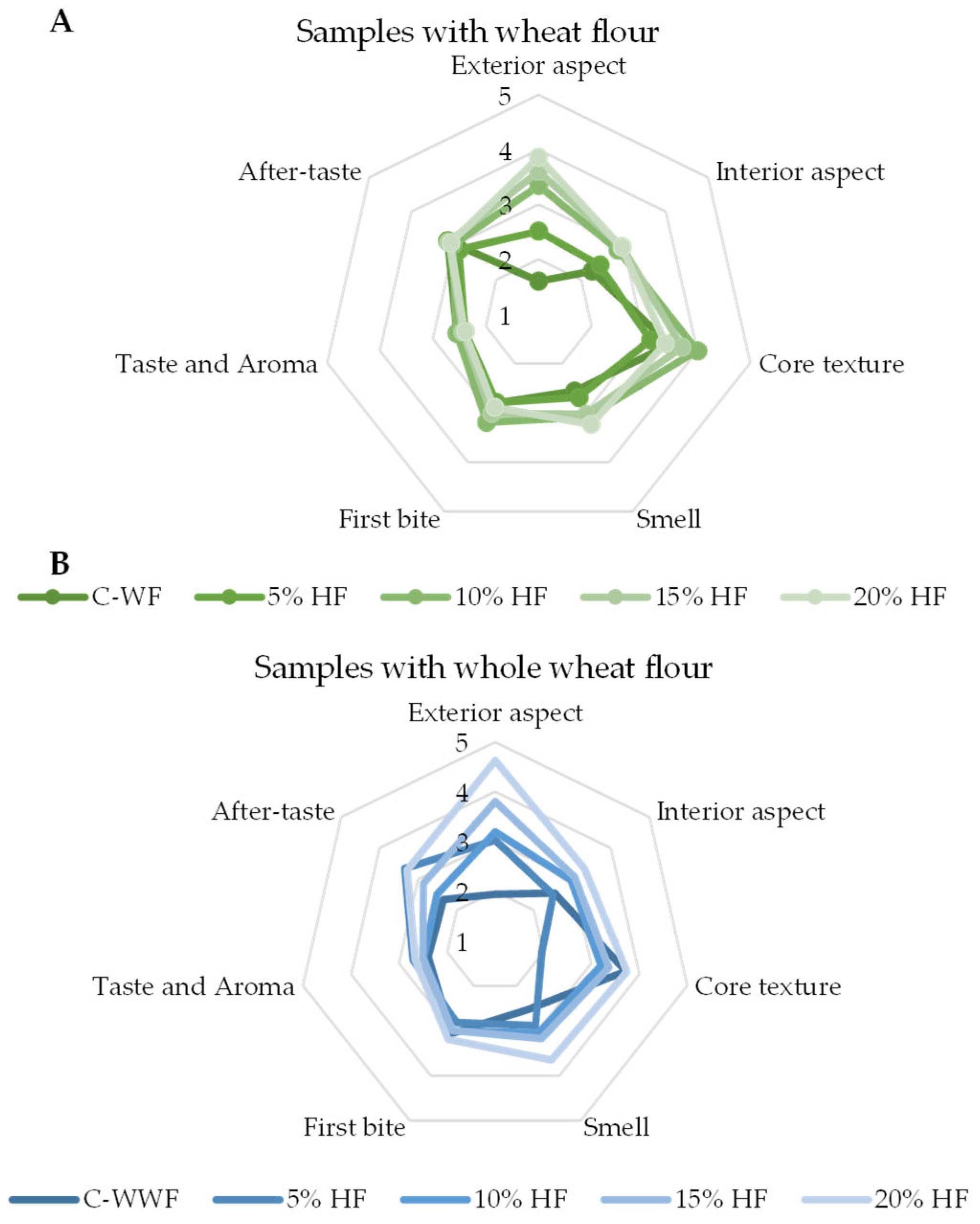

3.1.2. Descriptive Sensory Analysis

3.2. Physical Properties

3.2.1. Texture Measurements

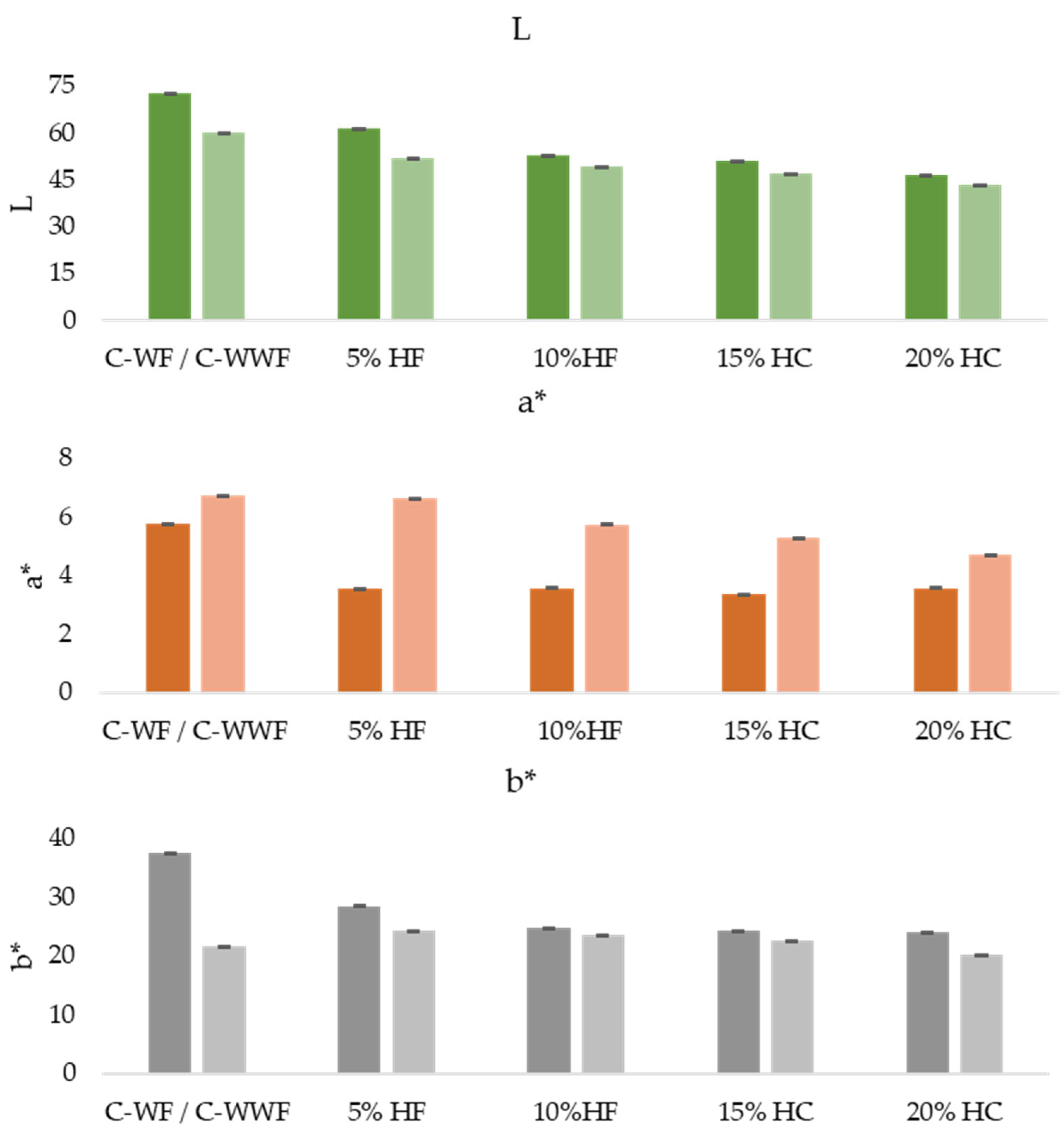

3.2.2. Color Measurements

3.3. Microbiology Analysis

3.4. Physicochemical Analyses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Crocq, M.-A. History of cannabis and the endocannabinoid system. Dialogues Clin. Neurosci. 2020, 22, 223–228. [Google Scholar] [CrossRef] [PubMed]

- Cvijic, A.; Bauer, B. History and medicinal properties of cannabis. Pharmacogn. Rev. 2024, 18, 159–164. [Google Scholar] [CrossRef]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The seed of industrial hemp (Cannabis sativa L.): Nutritional quality and potential functionality for human health and nutrition. Nutrients 2020, 12, 1935. [Google Scholar] [CrossRef] [PubMed]

- Iftikhar, A.; Zafar, U.; Ahmed, W.; Shabbir, M.A.; Sameen, A.; Sahar, A.; Bhat, Z.F.; Kowalczewski, P.L.; Jarzebski, M.; Aadil, R.M. Applications of Cannabis sativa L. in food and its therapeutic potential: From a prohibited drug to a nutritional supplement. Molecules 2021, 26, 7699. [Google Scholar] [CrossRef]

- Schanknecht, E.; Bachari, A.; Nassar, N.; Piva, T.; Mantri, N. Phytochemical constituents and derivatives of cannabis sativa; bridging the gap in melanoma treatment. Int. J. Mol. Sci. 2023, 24, 859. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Bai, M.; Song, H.; Yang, L.; Zhu, D.; Liu, H. Hemp (Cannabis sativa subsp. sativa) Chemical Composition and the Application of Hempseeds in Food Formulations. Plant Foods Hum. Nutr. 2022, 77, 355–365. [Google Scholar] [CrossRef]

- Fike, J. Industrial hemp: Renewed opportunities for an ancient crop. Crit. Rev. Plant Sci. 2016, 35, 406–424. [Google Scholar] [CrossRef]

- Rupasinghe, H.P.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial hemp (Cannabis sativa subsp. sativa) as an emerging source for value-added functional food ingredients and nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef]

- Naeem, M.Y.; Corbo, F.; Crupi, P.; Clodoveo, M.L. Hemp: An Alternative Source for Various Industries and an Emerging Tool for Functional Food and Pharmaceutical Sectors. Processes 2023, 11, 718. [Google Scholar] [CrossRef]

- Raihan, A.; Bijoy, T.R. A review of the industrial use and global sustainability of Cannabis sativa. Glob. Sust. Res. 2023, 2, 1–29. [Google Scholar] [CrossRef]

- Burton, R.A.; Andres, M.; Cole, M.; Cowley, J.M.; Augustin, M.A. Industrial hemp seed: From the field to value-added food ingredients. J. Cannabis Res. 2022, 4, 45. [Google Scholar] [CrossRef]

- Strzelczyk, M.; Lochynska, M.; Chudy, M. Systematics and Botanical Characteristics of Industrial Hemp Cannabis sativa L. J. Nat. Fibers. 2021, 19, 5804–5826. [Google Scholar] [CrossRef]

- Michels, M.; Brinkmann, A.; Mußhoff, O. Economic, ecological and social perspectives of industrial hemp cultivation in Germany: A qualitative analysis. J. Environ. Manag. 2025, 389, 126117. [Google Scholar] [CrossRef] [PubMed]

- Basak, M.; Broadway, M.; Lewis, J.; Starkey, H.; Bloomquist, M.; Peszlen, I.; Davis, J.; Lucia, L.A.; Pal, L. A critical review of industrial fiber hemp anatomy, agronomic practices, and valorization into sustainable bioproducts. BioResources 2025, 20, 5030–5070. [Google Scholar] [CrossRef]

- Hayit, F.; Balıkcı, E.; Yazıcı, L.; Beşcanlar, S. Investigation of the usability of hemp flour in the production of gluten-free cakes. J. Culin. Sci. Technol. 2024, 22, e2357282. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. Hemp (Cannabis sativa subsp. sativa) flour and protein preparation as natural nutritional and structure-forming agents in gluten-free starch bread. Food Chem. 2017, 223, 51–59. [Google Scholar] [CrossRef]

- Ramos-Sanchez, R.; Hayeard, J.; Henderson, D.; Duncan, G.D.; Russel, W.R.; Duncan, S.H.; Neacsu, M. Hemp Seed-Based Foods and Processing By-Products Are Sustainable Rich Sources of Nutrients and Plant Metabolites Supporting Dietary Biodiversity, Health, and Nutritional Needs. Foods 2025, 14, 875. [Google Scholar] [CrossRef]

- Svec, I.; Hruskova, M. Properties and nutritional value of wheat bread enriched by hemp products. Potravin 2015, 9, 304–308. [Google Scholar] [CrossRef]

- Lukin, A.; Bitiutskikh, K. On potential use of hemp flour in bread production. Bull. Transilv. Univ. Bras. Ser. II 2017, 10, 117–123. [Google Scholar]

- Kowalski, S.; Mikulec, A.; Litwinek, D.; Mickowska, B.; Skotnicka, M.; Oacz, J.; Karwowska, K.; Wiweocka-Gurgul, A.; Sabat, R.; Platta, A. The influence of fermentation technology on the functional and sensory properties of hemp bread. Molecules. 2024, 29, 5455. [Google Scholar] [CrossRef]

- Del Vecchio, L.; Chiodetti, M.; Cirlini, M.; Ricci, S.; Di Fazio, A.; Caligiani, A.; Carini, E. Hemp flour in breadmaking: Circularity and opportunities for bread quality and stability during storage. Eur. Food Res. Technol. 2025, 251, 1047–1060. [Google Scholar] [CrossRef]

- Ertaș, N.; Aslan, M. Antioxidant and physicochemical properties of cookies containing raw and roasted hemp flour. Acta Sci. Pol. Technol. Aliment. 2020, 19, 177–184. [Google Scholar] [CrossRef]

- Capcanari, T.; Covaliov, E.; Negoiță, C.; Siminiuc, S.; Chirsanova, A.; Reșitca, V.; Țurcanu, D. Hemp seed cake as a source of proteins, minerals, and polyphenols and its impact on the nutritional, sensorial and technological quality of bread. Foods 2023, 12, 4327. [Google Scholar] [CrossRef]

- Mikulek, A.; Kowalski, S.; Sabat, R.; Skoczylas, L.; Tabaszewska, M.; Wywrocka-Gurul, A. Hemp flour as a valuable component for enriching physicochemical and antioxidant properties of wheat flour. LWT Food Sci. Technol. 2019, 102, 164–172. [Google Scholar] [CrossRef]

- Merlino, M.; Tripodi, G.; Cincotta, F.; Prestia, O.; Miller, A.; Gattuso, A.; Verzera, A.; Condurso, C. Technological, nutritional, and sensory characteristics of gnocchi enriched with hemp seed flour. Foods. 2022, 11, 2783. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Baek, I.; Jang, Y.; Said, N.S.; Lee, W.Y. Effects on physicochemical, nutritional, and quality attributes of fortified vegan muffins incorporated with hempseed as an alternative protein source. Foods. 2025, 14, 601. [Google Scholar] [CrossRef] [PubMed]

- El-Sohaimy, S.A.; Sitohy, M.; El-Masry, R. Chickpea protein isolation, characterization and application in muffin enrichement. Int. J. Food Stud. 2021, 10, S157–S171. [Google Scholar] [CrossRef]

- Alvarez, M.D.; Herranz, B.; Fuentes, R.; Cuesta, F.J.; Canet, W. Replacement of wheat flour by chickpea flour in muffin batter: Effect on rheological properties. J. Food Process Eng. 2016, 40, e12372. [Google Scholar] [CrossRef]

- Lee, J.H.; Shim, Y.Y.; Reaney, M.J.T.; Yoon, J.A. The impacts of standardized flaxseed meal (XanFlax) on the physicochemical, textural and sensory properties of muffins. Foods 2023, 12, 4085. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, T.; Su, C.; Li, Q.; Yu, X. Fortification of Chinese steamed bread with flaxseed flour and evaluation of its physicochemical and sensory properties. Food Chem. X. 2022, 13, 100267. [Google Scholar] [CrossRef]

- Wichchukit, S.; O’Mahony, M. The 9-point hedonic scale and hedonic ranking in food science: Some reappraisals and alternatives. J. Sci. Food Agric. 2014, 95, 2167–2178. [Google Scholar] [CrossRef] [PubMed]

- Peryam, D.R.; Pilgrim, F.J. Hedonic scale method of measuring food preferences. Food Technol. 1957, 11, 9–14. [Google Scholar]

- Lawless, H.T.; Heymann, H. Sensory evaluation of food: Principles and practices. In Sensory Evaluation of Food, 2nd ed.; Springer: New York, NY, USA, 2010; pp. 1–596. [Google Scholar]

- Stone, H.; Bleibaum, R.; Thomas, H.A. Sensory Evaluation Practices, 4th ed.; Academic Press: San Diego, CA, USA, 2012; pp. 1–448. [Google Scholar]

- Meilgaard, M.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, 4th ed.; CRC Press: Boca Raton, FL, USA, 2007; pp. 1–464. [Google Scholar]

- Marques, C.; Correia, E.; Dinis, L.-T.; Vilela, A. An overview of sensory characterization techniques: From classical descriptive analysis to the emergence of novel profiling methods. Foods 2022, 11, 255. [Google Scholar] [CrossRef]

- Bourne, M.C. Food Texture and Viscosity: Concept and Measurement, 2nd ed.; Academic Press: San Diego, CA, USA, 2002. [Google Scholar]

- Gámbaro, A.; Fiszman, S.M.; Giménez, A.; Varela, P.; Salvador, A. Consumer acceptability compared with sensoy and instrumental parameters of texture in breaded chicken breast products. J. Texture Stud. 2006, 37, 501–514. [Google Scholar] [CrossRef]

- Trinh, K.T.; Glasgow, S. On the Texture Profile Analysis Test. In Proceedings of the Food Science Conference, Massey University, Palmerston North, New Zealand, 25–27 September 2012. [Google Scholar]

- Commission Internationale de l’Éclairage (CIE). Colorimetry, 2nd ed.; CIE Publication No. 15.2; CIE: Vienna, Austria, 1986. [Google Scholar]

- Maskan, M. Kinetics of colou change of kiwifruits during hot air and microwave drying. J. Food Eng. 2001, 48, 169–175. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.-J. Colour measurement and analysis in fresh and processed foods: A review. Food Bioproc. Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- ISO 21527-2:2008; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Yeasts and Moulds—Part 2: Colony Count Technique in Products with Water Activity ≤0.95. ISO: Geneva, Switzerland, 2008.

- ISO 21528-2:2004; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Detection and Enumeration of Enterobacteriaceae—Part 2: Colony-Count Method. ISO: Geneva, Switzerland, 2004.

- ISO 712:2009; Cereals and Cereal Products—Determination of Moisture Content—Reference Method. ISO: Geneva, Switzerland, 2009.

- Vartolomei, N.; Turtoi, M. The influence of the addition of rosehip powder to wheat flour on the dough farinographic properties and bread physico-chemical characteristics. Appl. Sci. 2021, 11, 12035. [Google Scholar] [CrossRef]

- ISO 2171:2007; Cereals, Pulses and by-Products—Determination of Ash Yield by Incineration. German version DIN EN ISO 2171:2010; ISO: Geneva, Switzerland, 2007.

- ISO 6865:2000; Animal Feeding Stuffs—Determination of Crude Fibre Content—Method with Intermediate Filtration. ISO: Geneva, Switzerland, 2000.

- ISO 20483:2013; Cereals and Cereal Products—Determination of the Nitrogen Content and Calculation of the Crude Protein Content—Kjeldahl Method. ISO: Geneva, Switzerland, 2013.

- Romanian Standards Association (ASRO). SR 91:2007—Cereals and Derived Products—Determination of Total Sugars by Fehling-Lane-Eynon; ASRO: Bucharest, Romania, 2007. [Google Scholar]

- Stanciu, I.; Ungureanu, E.L.; Popa, E.E.; Geicu-Cristea, M.; Drăghici, M.; Miteluț, A.C.; Mustatea, G.; Popa, M.E. The experimental development of bread with enriched nutritional properties using organic sea buckthorn pomace. Appl. Sci. 2023, 13, 6513. [Google Scholar] [CrossRef]

- ISO 11085:2015; Cereals, Cereal-Based Products and Animal Feeding Stuffs—Determination of Crude Fat an Total Fat Content by the Randall Extraction Method. ISO: Geneva, Switzerland, 2015.

- Rusu, I.E.; Marc (Vlaic), R.A.; Mureșan, C.C.; Mureșan, A.E.; Mureșan, V.; Pop, C.R.; Chiș, M.S.; Man, S.M.; Filip, M.R.; Onica, B.-M.; et al. Hemp (Cannabis sativa L.) flour-based wheat bread as fortified bakery product. Plants 2021, 10, 1558. [Google Scholar] [CrossRef]

| Sample | Flour % | Sugar (%) | Butter (%) | Eggs (%) | Baking Soda (%) | Flavor (%) | ||

|---|---|---|---|---|---|---|---|---|

| Wheat | Whole Wheat | Hemp | ||||||

| C–WF 1 | 30.44 | - | - | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 5% HF 3 | 28.92 | - | 1.52 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 10% HF | 27.40 | - | 3.04 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 15% HF | 25.88 | - | 4.57 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 20% HF | 24.35 | - | 6.09 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 30% HF | 21.31 | - | 9.13 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 40% HF | 18.26 | - | 12.18 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| C–WWF 2 | - | 30.44 | - | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 5% HF | - | 28.92 | 1.52 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 10% HF | - | 27.40 | 3.04 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 15% HF | - | 25.88 | 4.57 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 20% HF | - | 24.35 | 6.09 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 30% HF | - | 21.31 | 9.13 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| 40% HF | - | 18.26 | 12.18 | 22.83 | 22.83 | 22.83 | 0.76 | 0.30 |

| Samples | Choices | Estimated Preference % | |||||

|---|---|---|---|---|---|---|---|

| Code | WF % | HF % | First | Second | Third | Fourth | |

| 426 | 95 | 5 | 9 | 7 | 7 | 5 | 82.35 |

| 951 | 90 | 10 | 7 | 10 | 3 | 5 | 73.53 |

| 159 | 85 | 15 | 10 | 5 | 5 | 7 | 79.41 |

| 684 | 80 | 20 | 3 | 4 | 11 | 9 | 79.41 |

| 357 | 70 | 30 | 2 | 2 | 5 | 4 | 38.24 |

| 753 | 60 | 40 | 3 | 6 | 3 | 4 | 47.06 |

| Code | WWF % | HF % | First | Second | Third | Fourth | |

| 351 | 95 | 5 | 12 | 10 | 5 | 1 | 82.35 |

| 934 | 90 | 10 | 11 | 5 | 6 | 3 | 73.53 |

| 671 | 85 | 15 | 3 | 8 | 12 | 5 | 82.35 |

| 248 | 80 | 20 | 1 | 5 | 9 | 12 | 79.41 |

| 349 | 70 | 30 | 2 | 4 | 2 | 9 | 50.00 |

| 761 | 60 | 40 | 5 | 2 | 0 | 4 | 32.35 |

| Samples | Attribute | ||||||

|---|---|---|---|---|---|---|---|

| Exterior Aspect | Interior Aspect | Core Texture | Smell | First Bite | Taste and Aroma | After-Taste | |

| C–WF 1 | 1.6 ± 0.6 b | 2.3 ± 1.2 b | 3.5 ± 1.2 b | 2.6 ± 1.5 b | 2.8 ± 1.4 b | 2.5 ± 1.4 b | 3.1 ± 1.3 b |

| 5% HF 3 | 2.5 ± 0.6 b | 2.4 ± 1.1 b | 3.1 ± 1.0 b | 2.7 ± 1.3 b | 2.8 ± 1.2 b | 2.4 ± 1.3 b | 2.9 ± 1.1 b |

| 10% HF | 3.3 ± 0.7 a,b | 2.9 ± 1.2 a,b | 4.0 ± 1.0 a,b | 3.1 ± 1.2 a,b | 3.2 ± 1.2 a,b | 2.5 ± 1.2 b | 3.0 ± 1.1 b |

| 15% HF | 3.6 ± 0.7 a,b | 3.0 ± 1.1 a,b | 3.7 ± 1.0 a,b | 3.0 ± 1.2 a,b | 3.0 ± 1.1 a,b | 2.4 ± 1.2 b | 3.1 ± 1.1 b |

| 20% HF | 3.9 ± 0.8 a | 3.0 ± 1.2 a,b | 3.4 ± 1.0 a,b | 3.2 ± 1.3 a | 2.9 ± 1.3 a,b | 2.4 ± 1.3 b | 3.1 ± 1.3 b |

| C–WWF 2 | 1.9 ± 0.7 b | 2.5 ± 1.3 b | 3.7 ± 0.8 b | 2.5 ± 1.3 b | 3.1 ± 1.2 b | 2.4 ± 1.2 b | 2.3 ± 1.0 b |

| 5% HF | 3.0 ± 0.7 a,b | 2.5 ± 1.1 b | 2.0 ± 1.0 b | 2.9 ± 1.4 b | 2.8 ± 1.3 b | 2.7 ± 1.5 b | 3.3 ± 1.4 a,b |

| 10% HF | 3.2 ± 0.6 a,b | 3.0 ± 1.0 a,b | 3.2 ± 1.0 a,b | 3.0 ± 1.2 a,b | 3.0 ± 1.1 a,b | 2.5 ± 1.2 b | 2.5 ± 1.0 b |

| 15% HF | 3.8 ± 0.7 a,b | 3.1 ± 1.0 a,b | 3.4 ± 0.9 a,b | 3.2 ± 1.4 a,b | 3.0 ± 1.2 a,b | 2.5 ± 1.2 b | 2.9 ± 0.9 a,b |

| 20% HF | 4.6 ± 0.6 a | 3.3 ± 1.3 a,b | 3.7 ± 1.1 a | 3.6 ± 1.2 a | 3.2 ± 1.3 a,b | 2.7 ± 1.4 b | 3.3 ± 1.3 a |

| Sample | Firmness (N) | Cohesiveness | Elasticity | Gumminess |

|---|---|---|---|---|

| C–WF 1 | 6.29 ± 1.47 | 0.2 ± 0.13 | 1.62 ± 0.38 | 1.84 ± 1.15 |

| 5% HF 3 | 4.08 ± 0.19 | 0.12 ± 0.08 | 1.56 ± 0.14 | 0.74 ± 0.50 |

| 10% HF | 7.81 ± 1.36 | 0.18 ± 0.18 | 1.55 ± 0.93 | 1.72 ± 1.82 |

| 15% HF | 5.06 ± 0.37 | 0.06 ± 0.07 | 1.20 ± 0.38 | 0.50 ± 0.63 |

| 20% HF | 5.04 ± 0.06 | −0.01 ± 0.22 | 2.42 ± 0.30 | −1.53 ± 2.93 |

| C–WWF 2 | 5.28 ± 1.95 | −0.67 | 3.52 | −8.67 |

| 5% HF | 4.10 ± 0.50 | 0.22 ± 0.03 | 1.63 ± 0.024 | 1.44 ± 0.24 |

| 10% HF | 7.89 ± 1.28 | 0.14 ± 0.05 | 1.95 ± 0.12 | 2.19 ± 0.96 |

| 15% HF | 6.87 ± 0.56 | 0.15 ± 0.02 | 2.04 ± 0.32 | 2.12 ± 0.14 |

| 20% HF | 8.05 ± 2.70 | 0.13 ± 0.02 | 1.94 ± 0.93 | 2.36 ± 1.37 |

| Sample | Yeast and Molds (CFU/g) | Enterobacteriaceae (CFU/g) |

|---|---|---|

| C–WF 1 | <10 | <10 |

| 5% HF 3 | <10 | <10 |

| 10% HF | <10 | <10 |

| 15% HF | <10 | <10 |

| 20% HF | <10 | <10 |

| C–WWF 2 | <10 | <10 |

| 5% HF | <10 | <10 |

| 10% HF | <10 | <10 |

| 15% HF | <10 | <10 |

| 20% HF | <10 | <10 |

| Sample | Moisture % | Ash % | Crude Fiber % | Protein % | Fat % | Sugar % |

|---|---|---|---|---|---|---|

| C–WF 1 | 17.59 ± 0.014 a | 0.95 ± 0.028 c | 2.79 ± 0.099 e | 6.89 ± 0.028 c | 27.41 ± 0.014 | 32.05 ± 0.007 b |

| 5% HF 3 | 14.58 ± 0.014 b | 1.10 ± 0.064 c | 3.98 ± 0.191 d | 8.07 ± 0.085 d | 26.08 ± 0.219 | 39.95 b |

| 10% HF | 14.10 ± 0.014 b | 1.25 ± 0.021 b | 5.45 ± 0.233 c | 8.59 ± 0.021 b | 26.24 ± 0.191 | 31.40 ± 0.014 b |

| 15% HF | 14.62 b | 1.35 ± 0.042 b | 4.64 ± 0.269 c | 8.68 ± 0.078 b | 26.18 ± 0.014 | 29.07 ± 0.007 c |

| 20% HF | 14.45 ± 0.007 c | 1.44 ± 0.071 a | 5.87 ± 0.099 b | 9.26 ± 0.049 b | 26.09 ± 0.049 | 29.07 c |

| C–WWF 2 | 12.88 ± 0.007 a | 1.35 ± 0.014 b | 3.64 ± 0.304 d | 8.82 ± 0.007 b | 26.66 ± 0.042 | 31.07 ± 0.007 b |

| 5% HF | 13.80 b | 1.38 ± 0.014 b | 4.38 ± 0.019 c | 9.29 ± 0.042 a | 26.28 ± 0.014 | 27.76 c |

| 10% HF | 12.78 ± 0.007 b | 1.42 ± 0.035 b | 5.66 ± 0.453 c | 9.54 a | 26.62 ± 0.071 | 30.40 ± 0.007 b |

| 15% HF | 13.10 ± 0.014 b | 1.59 ± 0.014 a | 7.00 ± 0.247 a | 9.81 ± 0.021 a | 26.55 ± 0.028 | 32.33 ± 0.071 a |

| 20% HF | 10.76 ± 0.007 c | 1.67 ± 0.007 a | 7.59 ± 0.057 a | 9.95 ± 0.028 a | 27.02 ± 0.049 | 30.73 ± 0.007 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mocanu, A.-L.; Dobre, A.A.; Stroe, C.-A.; Poteraș, C.-B.; Ungureanu, E.-L.; Mustatea, G.; Criveanu-Stamatie, G.D.; Cucu, Ș.E.; Bobea, S.A.; Florea, C.; et al. Impact of Hemp Flour on the Nutritional, Sensory and Functional Characteristics of Wheat and Whole Wheat Muffins. Foods 2025, 14, 3578. https://doi.org/10.3390/foods14203578

Mocanu A-L, Dobre AA, Stroe C-A, Poteraș C-B, Ungureanu E-L, Mustatea G, Criveanu-Stamatie GD, Cucu ȘE, Bobea SA, Florea C, et al. Impact of Hemp Flour on the Nutritional, Sensory and Functional Characteristics of Wheat and Whole Wheat Muffins. Foods. 2025; 14(20):3578. https://doi.org/10.3390/foods14203578

Chicago/Turabian StyleMocanu, Andreea-Lavinia, Alina Alexandra Dobre, Corina-Alexandra Stroe, Cătălina-Beatrice Poteraș, Elena-Loredana Ungureanu, Gabriel Mustatea, Gabriela Daniela Criveanu-Stamatie, Șerban Eugen Cucu, Sabina Andreea Bobea, Cristian Florea, and et al. 2025. "Impact of Hemp Flour on the Nutritional, Sensory and Functional Characteristics of Wheat and Whole Wheat Muffins" Foods 14, no. 20: 3578. https://doi.org/10.3390/foods14203578

APA StyleMocanu, A.-L., Dobre, A. A., Stroe, C.-A., Poteraș, C.-B., Ungureanu, E.-L., Mustatea, G., Criveanu-Stamatie, G. D., Cucu, Ș. E., Bobea, S. A., Florea, C., Nicolcioiu, M.-B., & Stan, R. (2025). Impact of Hemp Flour on the Nutritional, Sensory and Functional Characteristics of Wheat and Whole Wheat Muffins. Foods, 14(20), 3578. https://doi.org/10.3390/foods14203578