3.1. Structural Characterization of Peptides in the Distillates from Various Rounds Soy Sauce-Flavored Baijiu

The amino acid sequences of peptides in the distillates from the first to seventh rounds of soy sauce-flavored Baijiu were identified using LC-MS in combination with de novo sequencing. A total of 46 peptides were identified in the first round of soy sauce-flavored Baijiu, with the identification results presented in

Table 1. In the second round, 35 peptides were identified (

Table 2), while 40 peptides were identified in the third round (

Table 3). In the fourth round, 19 peptides were detected (

Table 4), and 18 peptides were identified in the fifth round (

Table 5). The sixth round contained 19 peptides (

Table 6), and the seventh round contained 28 peptides (

Table 7).

Based on the confidence score, peak area, and retention time, representative peptide structures with high confidence, large peak areas, and short retention times were selected. The identified peptides from the first to seventh rounds include the following: Thr-Arg-His (TRH,

m/

z: 412.22), Tyr-His-Tyr (YHY,

m/

z: 481.20), Arg-Gln-Thr-Gln (RQTQ,

m/

z: 531.28), Pro-Leu-Asp-Leu-Thr-Ser-Phe-Val-Leu-His-Glu-Ala-Ile (PLDLTSFVLHEAI,

m/

z: 1453.78), Lys-His-Val-Ser (KHVS,

m/

z: 469.27), Leu-Pro-Gln-Arg-His-Arg-Met-Val-Tyr-Ser-Leu-Leu (LPQRHRMVYSLL,

m/

z: 1511.84), and Asn-Glu-Trp-His (NEWH,

m/

z: 584.23), which, to our best knowledge, has not been reported. These peptides were different from the oligopeptides found in other flavored Baijiu, which contain some amino acids related to biological activity, such as Gln-Gly-Val-Pro (QGVP) from sesame-flavored Baijiu [

6] and DRAR [

7] and AKRA [

8] in sesame-flavored Baijiu. It has been reported that hydrophobic amino acid residues frequently appear in oligopeptides derived from Baijiu related to its flavor. The total ion chromatograms for the first to seventh rounds and their corresponding mass spectra were shown in

Figure S1. Moreover, as shown in

Table S1, KHVS was detected in both the first and second rounds of soy sauce-flavored Baijiu, while NEWH was detected in both the first and third rounds.

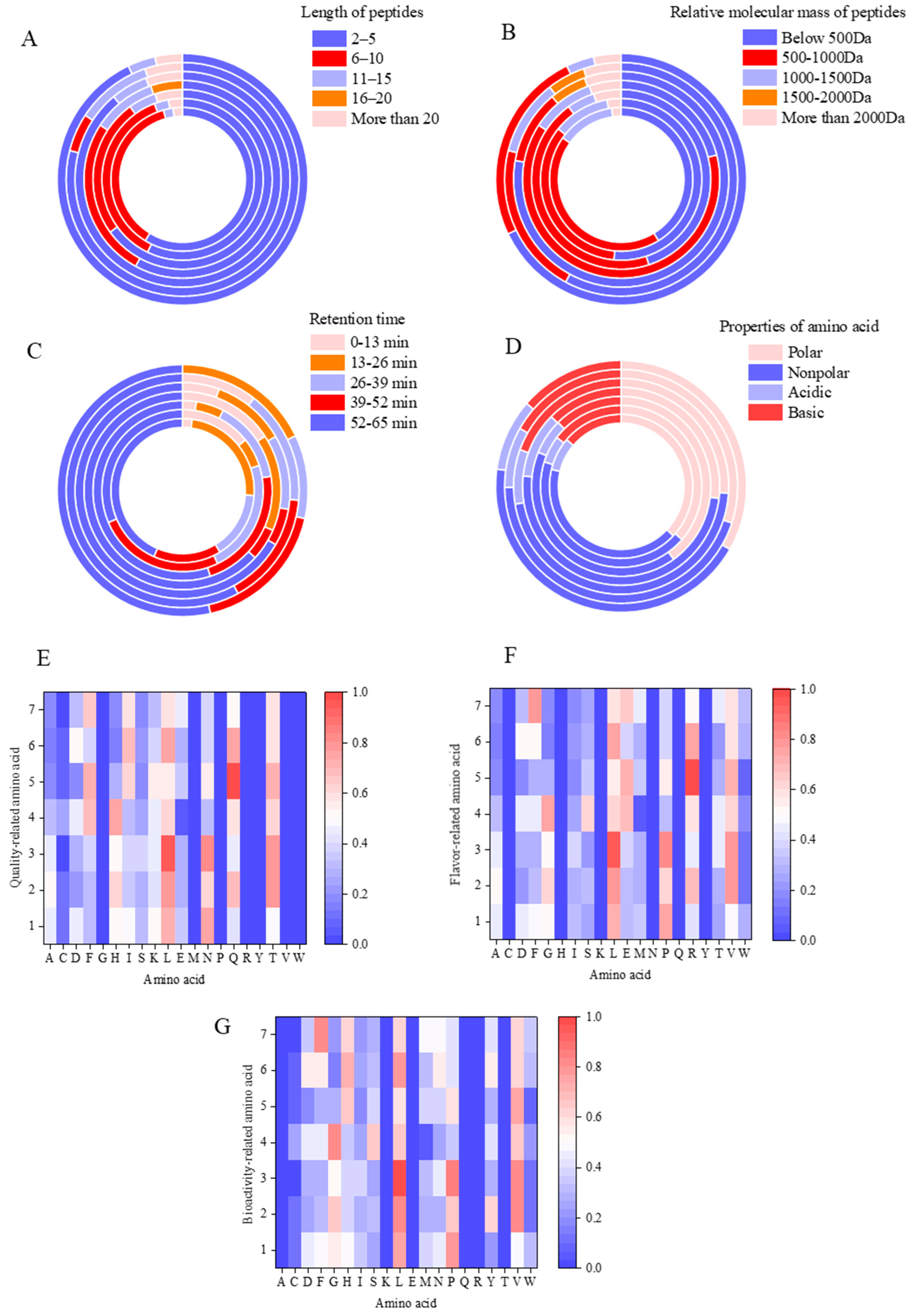

Based on the amino acid sequences of peptides collected from different rounds, it was observed that oligopeptides predominated in all rounds of soy sauce-flavored Baijiu. Peptides isolated from the first to fourth rounds primarily consisted of 2 to 10 amino acids, while peptides from the fifth to seventh rounds were mostly composed of 2 to 5 amino acids (

Figure 1A). The molecular weights of peptides from the first to third rounds generally fell below 1000 Da, while those from the fourth round ranged between 500 and 1000 Da. In contrast, peptides from the sixth and seventh rounds mostly had molecular weights below 500 Da (

Figure 1B). The retention times of peptides across all rounds were mainly between 52 and 65 min, with an increasing number of peptides detected as the analysis progressed (

Figure 1C). Furthermore, there was a higher prevalence of polar and basic amino acids in the peptides from the first to seventh rounds (

Figure 1D).

Specific amino acids, such as Ala, Gly, Leu, Glu, Lys, Pro, Arg, and Val, have been reported to positively influence the quality of liquor [

7,

8]. These amino acids, including Ala, Gly, Leu, Glu, Pro, Arg, Thr, and Val, are also associated with various taste profiles, such as sweet, sour, and bitter [

15]. Additionally, key amino acids with known biological activity, including Ala, Leu, Glu, Pro, Arg, Lys, Thr, and Val, have been identified in previous studies [

16,

17,

18]. As shown in

Figure 1E, among the amino acids influencing liquor quality, Lys, Leu, Pro, and Gly were found in relatively high proportions in the first round of soy sauce-flavored Baijiu. In the second round, Gly, Arg, Leu, Ala, Val, and Pro were more prevalent. Gly, Leu, Pro, and Val were commonly found in the third round, while Gly, Arg, Leu, Glu, and Val were more prominent in the fourth round. In the fifth round, His, Lys, Leu, Glu, Val, Pro, and Arg were more common. The sixth round showed a higher presence of His, Leu, Asp, Val, and Arg, while His, Leu, Glu, Val, and Arg were more prevalent in the seventh round.

Umami is a highly desirable taste, primarily induced via glutamic acid. In Baijiu, umami substances are mainly derived from amino acids, which are broken down from proteins and contribute to a pleasant, sweet taste. Increasing the amino acid content in liquor can enhance its quality. The type, content, and proportion of amino acids play a significant role in shaping the flavor of liquor. While many amino acids impart a primarily umami flavor, some also contribute bitter or salty notes. In Baijiu, these amino acids combine with other trace compounds to evolve, forming a distinctive, light, and elegant flavor profile characterized by a clean and delicate mouthfeel. This interaction enhances the overall harmony and fullness of the liquor’s body. Among the amino acids, Ala, Gly, Asp, Pro, Thr, and Ser are associated with sweetness, while Leu, Val, Pro, Arg, Try, Met, and Phe are linked to bitterness. As shown in

Figure 1F, among the flavor-related amino acids, Leu, Pro, and Gly were found in relatively high proportions in the first round of soy sauce-flavored Baijiu. In the second round, Gly, Arg, Leu, Ala, Val, and Pro were more prevalent. In the third round, Gly, Leu, Pro, Thr, and Val dominated. In the fourth round, Gly, Ser, Leu, Glu, Arg, Thr, and Val were more common. The fifth round was characterized by a higher presence of Leu, Glu, Val, Pro, and Arg. In the sixth round, Ala, Leu, Asp, Val, Arg, Try, and Phe were more prominent. Finally, in the seventh round, Met, Ala, Leu, Glu, Val, Arg, Thr, Try, and Phe were more abundant. Additionally, the first two rounds of liquor exhibited a sour and astringent taste, while the third round began to show a slight balance of sourness and sweetness. The sixth round was characterized by a subtle sweetness and bitterness, and the seventh round displayed a mild sour and bitter profile. The experimental results also revealed significant differences in the flavor amino acid composition across the first to seventh rounds of soy sauce-flavored Baijiu. This highlights the importance of exploring the different endogenous peptides that contribute to the distinct flavor profile of the liquor.

As shown in

Figure 1G, among the amino acids reported to have biological activity, Leu, Proline, Gly, and Try make up a relatively large proportion in the first round of soy sauce-flavored Baijiu. In the second round, Gly, Tyr, Leu, Ala, Val, and Pro were more prevalent. In the third round, Gly, Leu, Pro, and Val were more commonly found. The fourth round was characterized by a higher presence of Gly, Ser, Leu, Thr, and Val. In the fifth round, Leu, His, Val, Pro, and Arg were more abundant. The sixth round showed a greater proportion of His, Tyr, Ala, Leu, Asp, Val, Arg, Try, and Phe. Finally, in the seventh round, Met, Ala, Leu, His, Val, Try, and Phe were more prevalent. These findings indicated that there was a higher diversity of amino acids with biological activity in the different rounds of soy sauce-flavored Baijiu, with leucine being particularly abundant across all rounds.

3.2. Correlation Analysis of Peptides Derived from Different Distillation Rounds and Main Components

The main components in liquor are alcohols, esters, and acids [

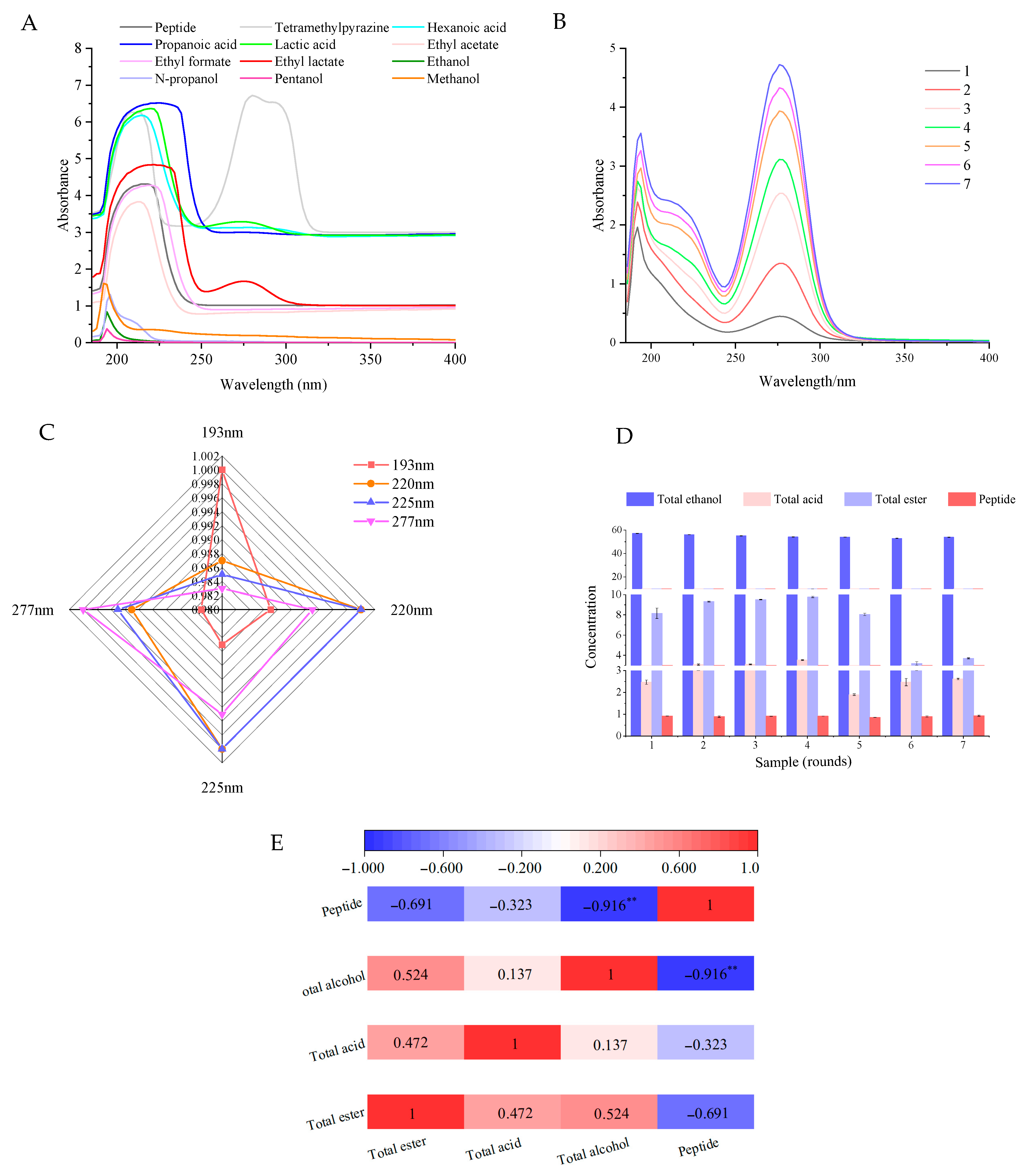

19]. Previous studies have performed full-wavelength scans of key flavor substances, such as alcohols, acids, and esters. As shown in

Figure 2A, alcohols (ethanol, methanol, n-butanol, and n-propanol) exhibit characteristic peaks within the 185–200 nm range, while acids and 2,3,5,6-tetramethylpyrazine display distinct peaks at 200–220 nm, 220–250 nm, and 250–300 nm, respectively [

20,

21,

22]. Peptide substances are known to exhibit characteristic peaks in the 200–220 nm range [

23], while esters typically show peaks between 250 and 300 nm.

Full-wavelength scanning of the different rounds of soy sauce-flavored Baijiu revealed significant differences in the absorption profiles across the 185–200 nm, 200–220 nm, 220–250 nm, and 250–300 nm regions (

Figure 2B). The correlation analysis of the peak intensities across these four wavelength segments for liquor samples from different rounds was presented in

Figure 2C. The maximum absorption values at 193 nm and 220 nm exhibited a strong positive correlation (r = 0.987), indicating a close relationship between these wavelengths. Similarly, absorption peaks at 225 nm (r = 0.985) and 277 nm (r = 0.983) showed a significant positive correlation. Additionally, the absorption peak at 225 nm was positively correlated with those at 220 nm (r = 1) and 277 nm (r = 0.995). A strong correlation was also observed between the absorption values at 220 nm and 277 nm (r = 0.993).

The contents of peptide, total acid, total ester, and ethanol in different rounds of soy sauce-flavored Baijiu were tested, and their correlations were analyzed. As shown in

Figure 2D, the total ester content in the first to fourth rounds of soy sauce-flavored Baijiu increased from 8.16 g/L to 9.77 g/L and then decreased to 3.19 g/L. The seventh round showed a slight increase to 3.70 g/L. The total acid content also increased from 2.47 g/L to 3.53 g/L in the first to fourth rounds and then decreased to 1.90 g/L in the fifth round, and increased to 2.47 g/L in the sixth and 2.62 g/L in the seventh rounds. The ethanol content showed an overall downward trend from 57.1% (

v/

v) to 52.9% (

v/

v), rising to 53.9% (

v/

v) in the seventh round. The peptide concentration in the different rounds of soy sauce-flavored Baijiu showed fluctuating changes. It first decreased in the first to seventh rounds, then increased, then decreased again, and finally increased in the seventh round to reach the maximum value of 0.93 mg/mL. In general, the peptide content in different rounds of soy sauce-flavored Baijiu did not differ significantly, but the content was highest in the first and seventh rounds.

As shown in

Figure 2E, the contents of total ester and total acid (r = 0.472) and alcohol (r = 0.524) were positively correlated with each other, while the contents of total ester and peptide were negatively correlated (r = −0.691). A positive correlation was observed between total acid content and alcohol content (r = 0.137), whereas a negative correlation was found between total acid content and peptide content (r = −0.323). There was a significant negative correlation between peptide content and ethanol content (r = −0.916,

p < 0.01). These results suggest that the correlation between peptide content and alcohol content is the strongest among the various components in the different rounds of soy sauce-flavored Baijiu. This may be attributed to the large differences in acidity, temperature, and microbial content in the fermented grains during different rounds of fermentation [

22,

23], which in turn affect various indices in distilled soy sauce-flavored Baijiu.

3.3. Interaction of Peptides Derived from Different Distillation Rounds and Main Components

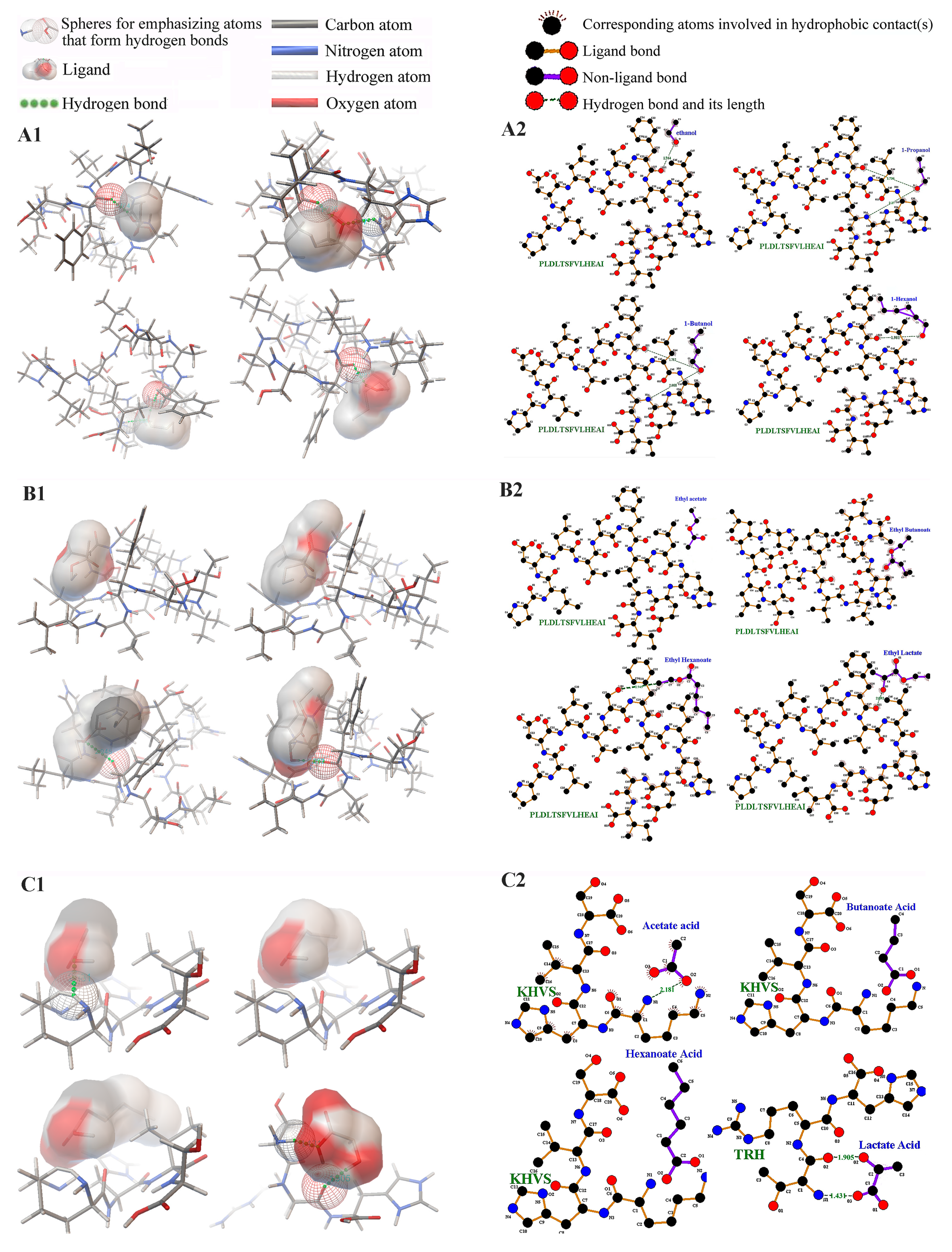

Seven representative peptides were selected as receptors, while flavor substances were used as ligands for a one-to-one molecular docking analysis. The results revealed that the torsion energy of each peptide remained constant when interacting with the same flavor substance (

Figure 3 and

Table S2). Based on these observations, the maximum and minimum binding energy values were highlighted for comparison. Among the findings, the peptide PLDLTSFVLHEAI exhibited the highest binding energy with alcohols and esters, while KHVS showed the strongest binding with acetic acid, butyric acid, and caproic acid, and TRH demonstrated the highest binding energy with lactic acid. The binding energy of alcohols with PLDLTSFVLHEAI ranged from −1.89 to −2.30 kcal/mol, while esters ranged from −2.31 to −2.65 kcal/mol. For acids, binding energy values ranged from −3.12 to −3.19 kcal/mol with KHVS or TRH.

The van der Waals, hydrogen bond, and desolvation energy (Vdw-Hb-Desolv energy) contributed favorably to binding (negative values), while electrostatic energy was generally conducive to binding but occasionally unfavorable (positive values). Torsion energy, however, consistently hindered binding. For alcohols and esters binding with PLDLTSFVLHEAI, the Vdw-Hb-Desolv energy ranged from −2.16 to −3.74 kcal/mol and −2.94 to −4.24 kcal/mol, respectively. For acids binding with KHVS or TRH, the Vdw-Hb-Desolv energy ranged from −0.97 to −2.34 kcal/mol, while the electrostatic energy ranged from −2.01 to −2.44 kcal/mol.

The electrostatic energy values for alcohols and esters binding with peptides were relatively small, ranging from −0.03 to −0.09 kcal/mol for alcohols and −0.02 to 0.04 kcal/mol for esters. Torsion energy tended to increase with the carbon chain length; for example, the torsion energy of butyric acid (0.89 kcal/mol) was higher than that of acetic acid (0.30 kcal/mol), and the torsion energy of ethyl butyrate (1.19 kcal/mol) exceeded that of butyric acid.

Interestingly, not all hydrogen bonds correlated with high Vdw-Hb-Desolv energy values. For instance, while PLDLTSFVLHEAI exhibited the highest Vdw-Hb-Desolv energy with ethyl butyrate, no hydrogen bond was formed in this case. On the other hand, PLDLTSFVLHEAI demonstrated the lowest binding energy with ethanol, and the binding energies of KHVS and TRH with acids were higher than with ethanol. This suggests that PLDLTSFVLHEAI may have a positive impact on flavor in high-alcohol liquors, while KHVS or TRH could enhance flavor in low-alcohol liquors.

The structural analysis further revealed specific hydrogen bond formations: Ala(H) or Phe(O) of PLDLTSFVLHEAI formed hydrogen bonds with alcohols, with bond lengths ranging from 1.736 Å to 2.088 Å. Similarly, Ser(O) and Phe(O) of PLDLTSFVLHEAI formed hydrogen bonds with ethyl butyrate and ethyl lactate, with bond lengths of 2.945 Å and 2.092 Å, respectively. Lys(H) of KHVS formed a hydrogen bond with ethyl acetate, with a bond length of 2.181 Å. Furthermore, Thr(H) or Arg(O) of TRH formed hydrogen bonds with ethyl lactate, with bond lengths of 1.431 Å and 1.905 Å, respectively.

These findings highlight the nuanced interactions between peptides and flavor substances, offering valuable insights into their roles in enhancing the sensory profiles of liquor.