Author Contributions

Q.L. (First Author): Investigation, Methodology, Date Curation, Formal analysis, Writing—Original Draft. J.Q.: Investigation, Software. H.L.: Supervision, Writing—Review & Editing. J.L.: Supervision, Project administration. B.L. (Corresponding Author): Conceptualization, Project administration, Supervision, Writing—review & editing, Validation. S.Y.: Validation, Writing—Review & Editing. M.Y.: Validation, Writing—Review & Editing. Y.C.: Investigation, Methodology. All authors have read and agreed to the published version of the manuscript.

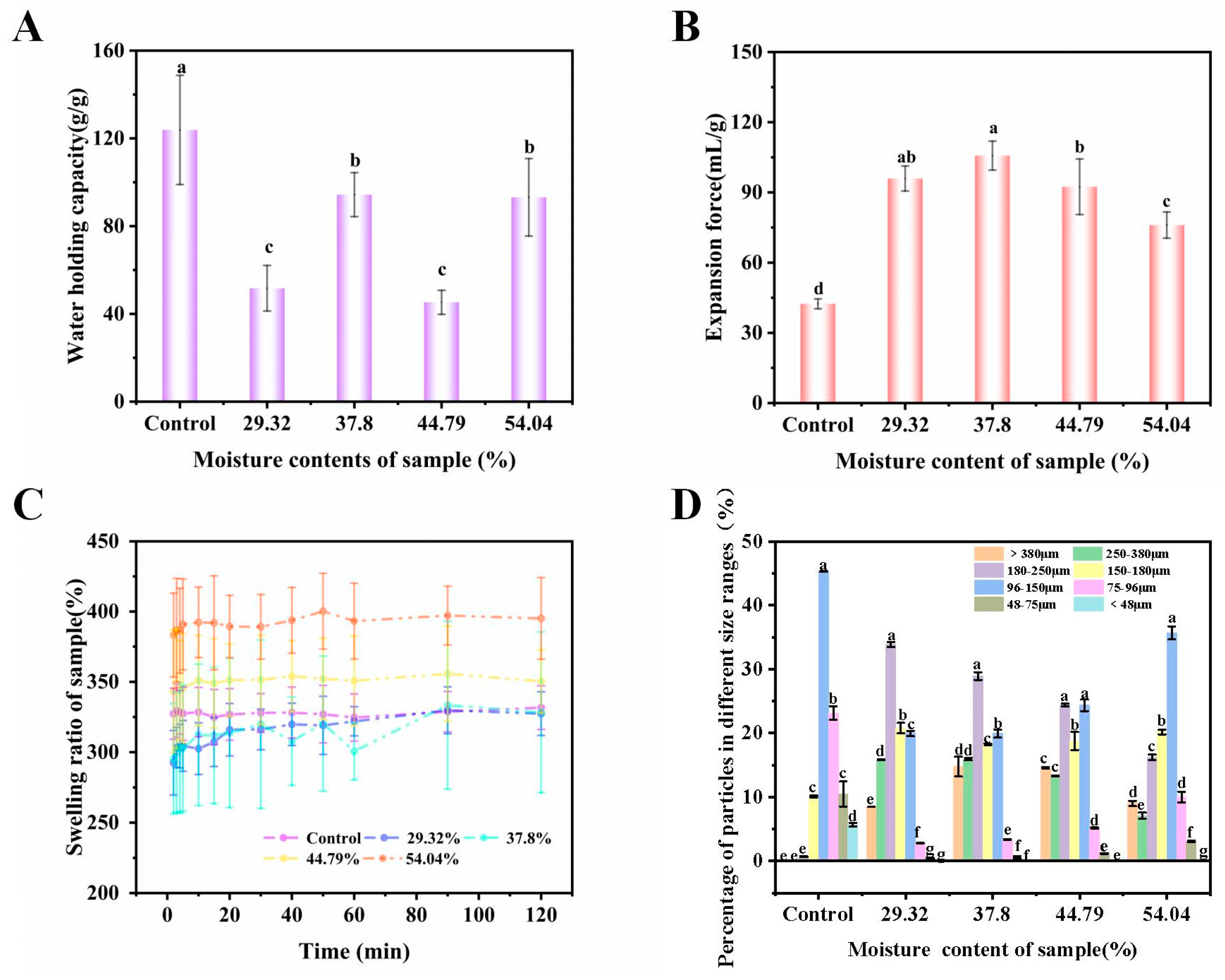

Figure 1.

Water-holding capacity (A), expansion force (B), dissolution curve (C), and particle size distribution (D) of konjac powders treated with different moisture contents (29.32–54.04%) (different letters a–g indicate significant differences between groups (p < 0.05)).

Figure 1.

Water-holding capacity (A), expansion force (B), dissolution curve (C), and particle size distribution (D) of konjac powders treated with different moisture contents (29.32–54.04%) (different letters a–g indicate significant differences between groups (p < 0.05)).

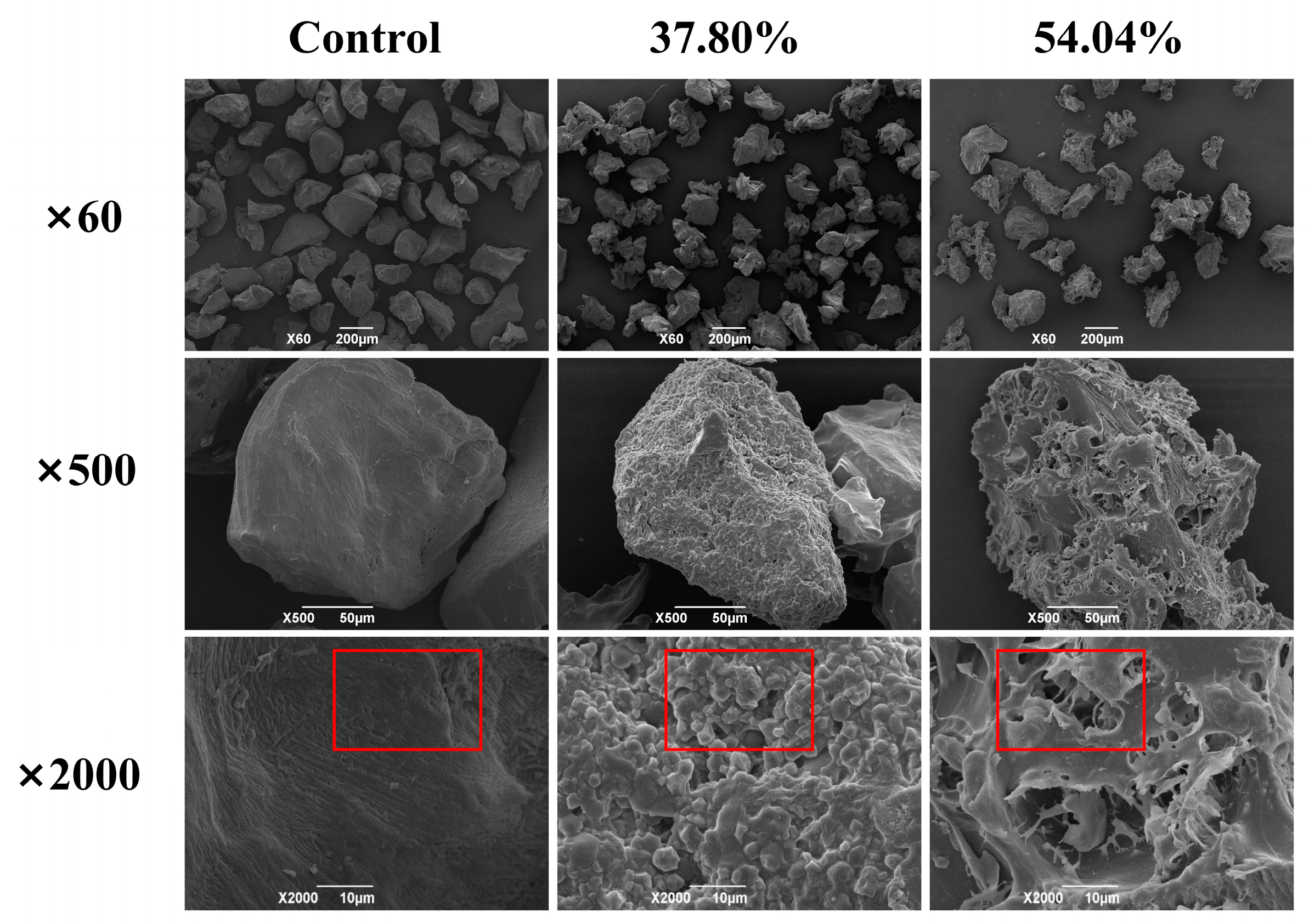

Figure 2.

Microscopic morphology of konjac powders treated with different moisture contents (37.80–54.04%).

Figure 2.

Microscopic morphology of konjac powders treated with different moisture contents (37.80–54.04%).

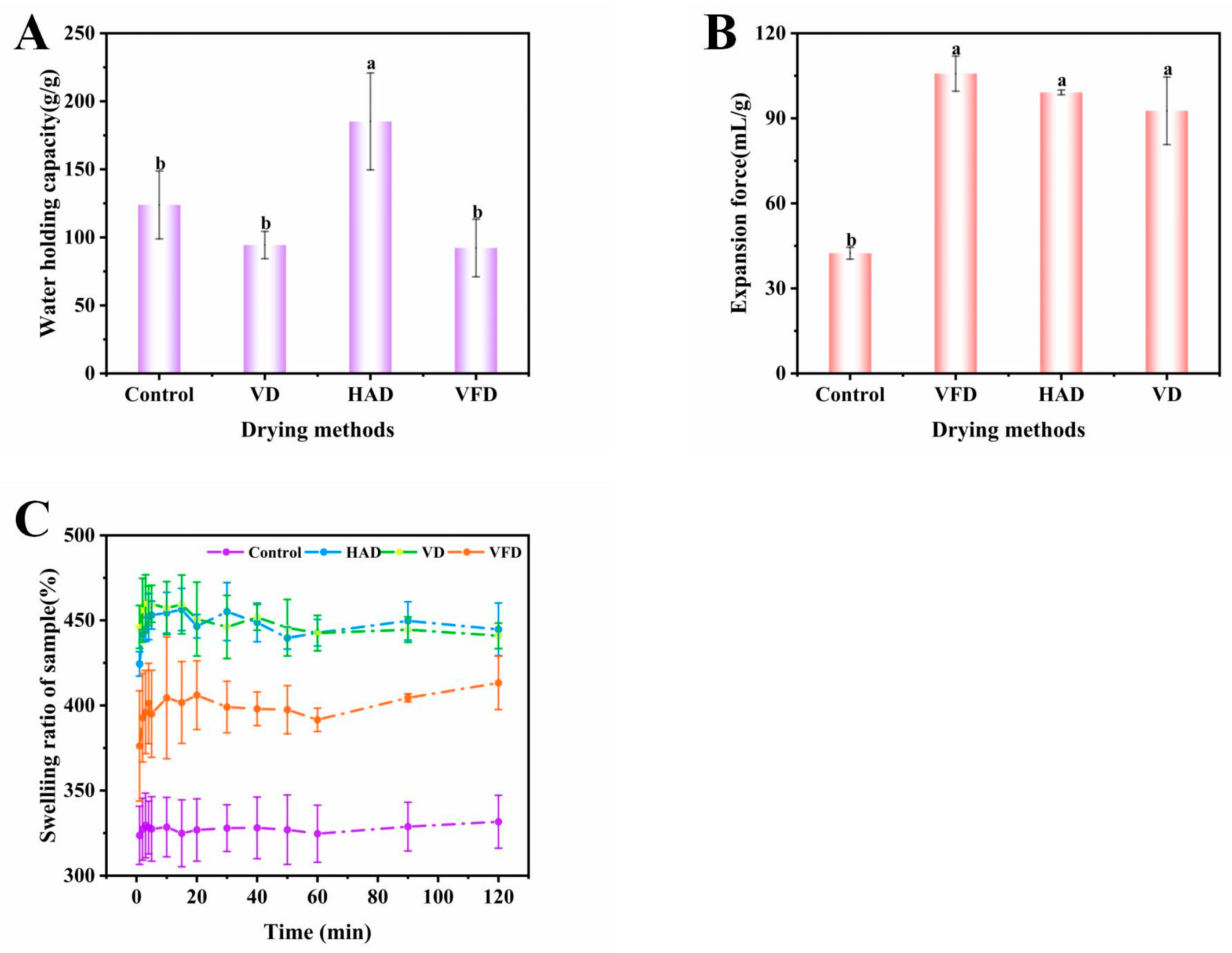

Figure 3.

Water-holding capacity (A), expansion force (B), and dissolution curve (C) of konjac powders treated with 37.80% moisture modification combined with three drying methods (different letters a,b indicate significant differences between groups (p < 0.05)).

Figure 3.

Water-holding capacity (A), expansion force (B), and dissolution curve (C) of konjac powders treated with 37.80% moisture modification combined with three drying methods (different letters a,b indicate significant differences between groups (p < 0.05)).

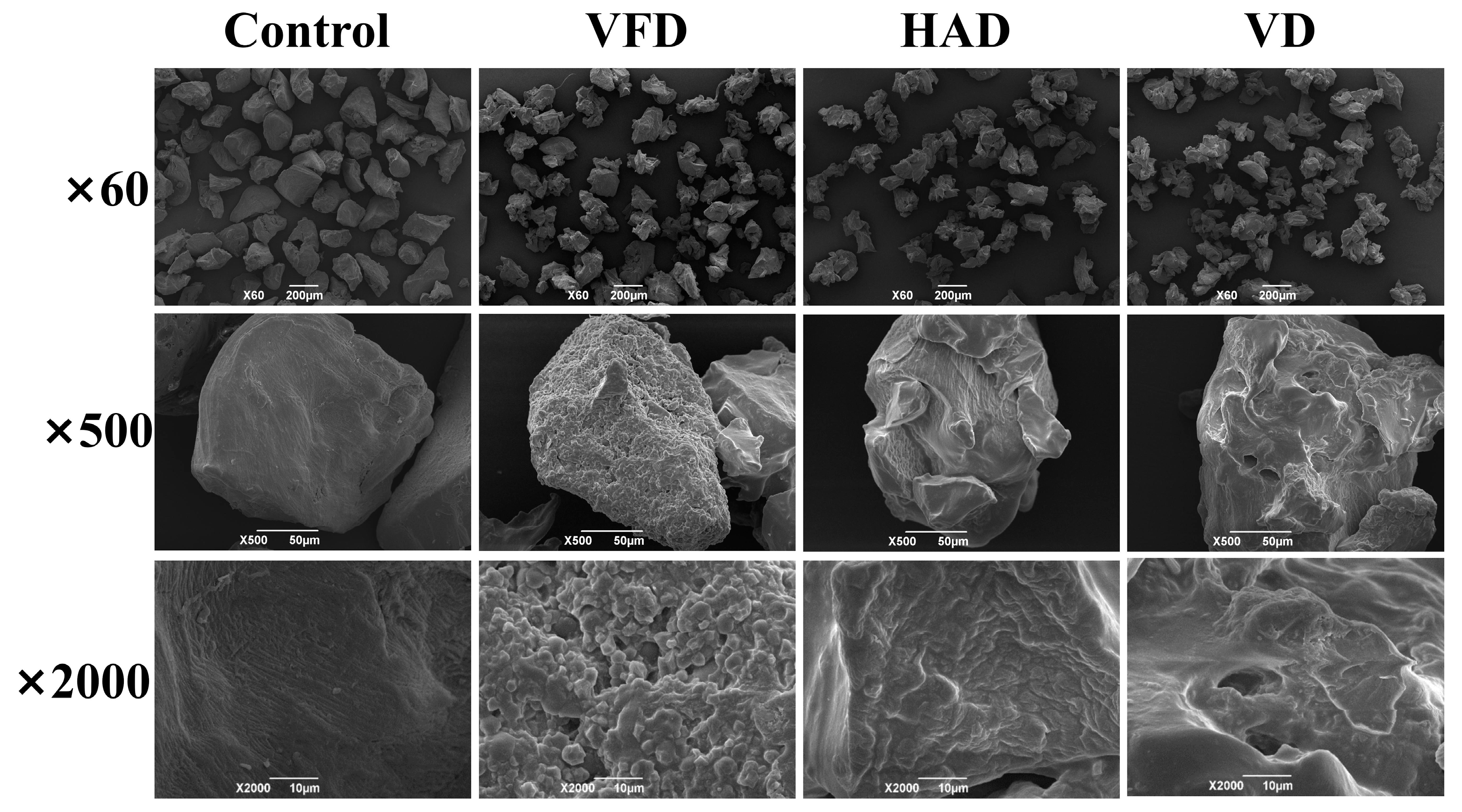

Figure 4.

Microscopic morphology of konjac powders treated with 37.80% moisture modification combined with three drying methods.

Figure 4.

Microscopic morphology of konjac powders treated with 37.80% moisture modification combined with three drying methods.

Figure 5.

Water-holding capacity (A), expansion force (B), and dissolution curves (C) of konjac powders treated with six combinations of drying methods at 37.80% moisture content (different letters a–c indicate significant differences between groups (p < 0.05)).

Figure 5.

Water-holding capacity (A), expansion force (B), and dissolution curves (C) of konjac powders treated with six combinations of drying methods at 37.80% moisture content (different letters a–c indicate significant differences between groups (p < 0.05)).

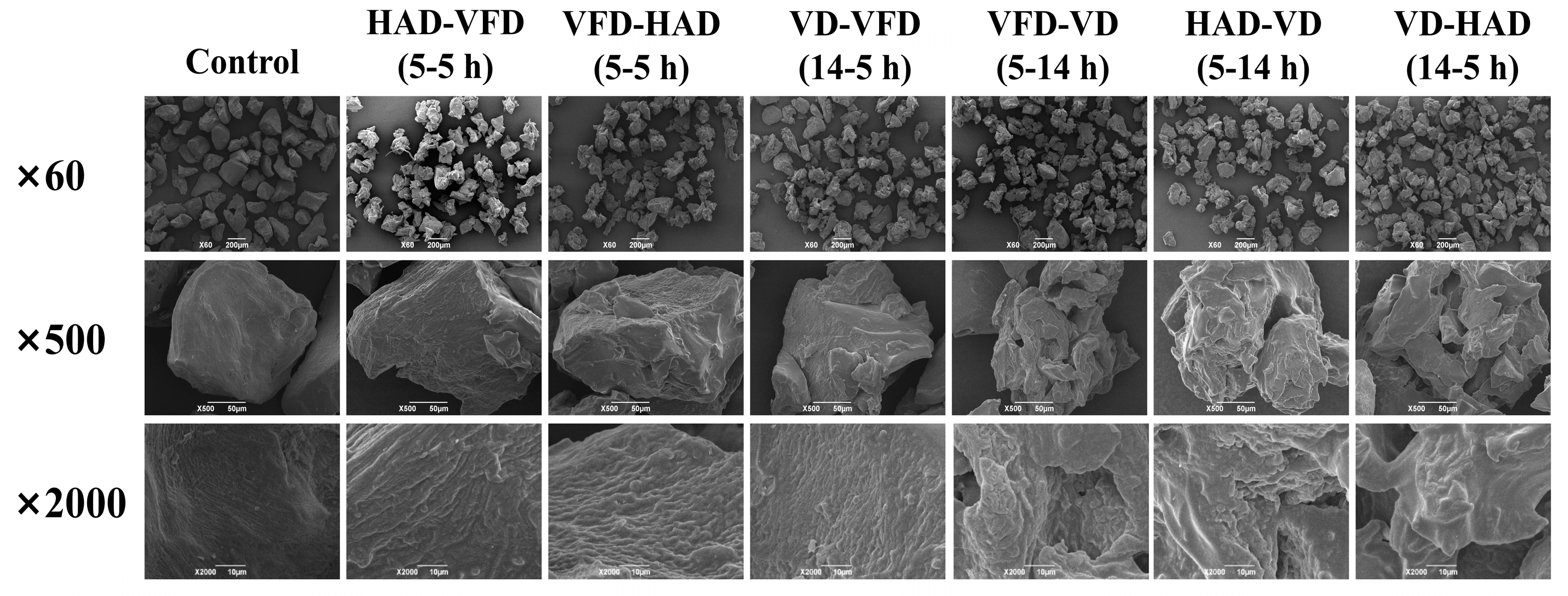

Figure 6.

Microscopic morphology of konjac powders treated with six combinations of drying methods at 37.80% moisture content.

Figure 6.

Microscopic morphology of konjac powders treated with six combinations of drying methods at 37.80% moisture content.

Figure 7.

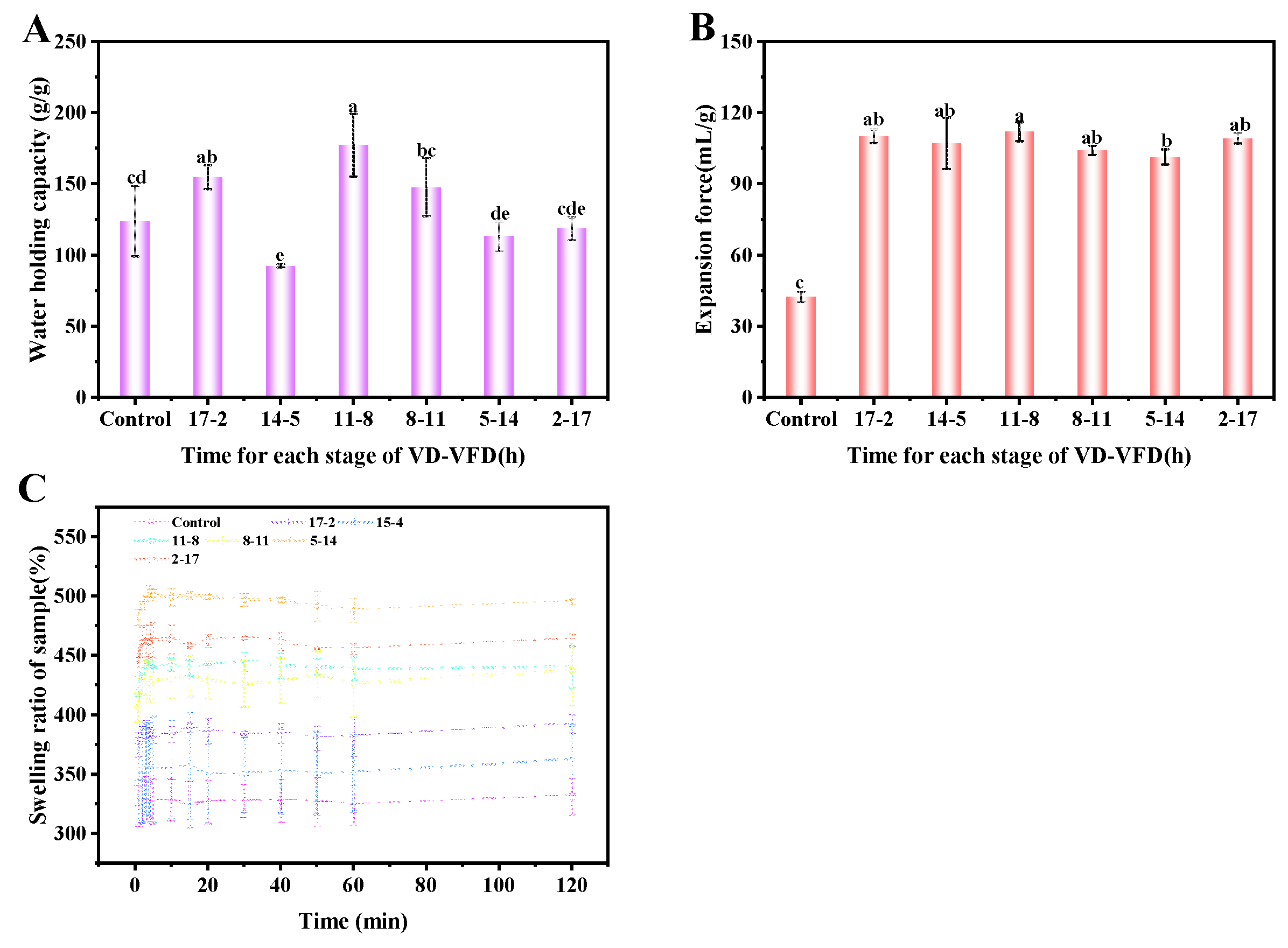

Water-holding capacity (A), expansion force (B), and dissolution curve (C) of konjac powders treated with VD-VFD at different moisture transition points (different letters a–e indicate significant differences between groups (p < 0.05)).

Figure 7.

Water-holding capacity (A), expansion force (B), and dissolution curve (C) of konjac powders treated with VD-VFD at different moisture transition points (different letters a–e indicate significant differences between groups (p < 0.05)).

Figure 8.

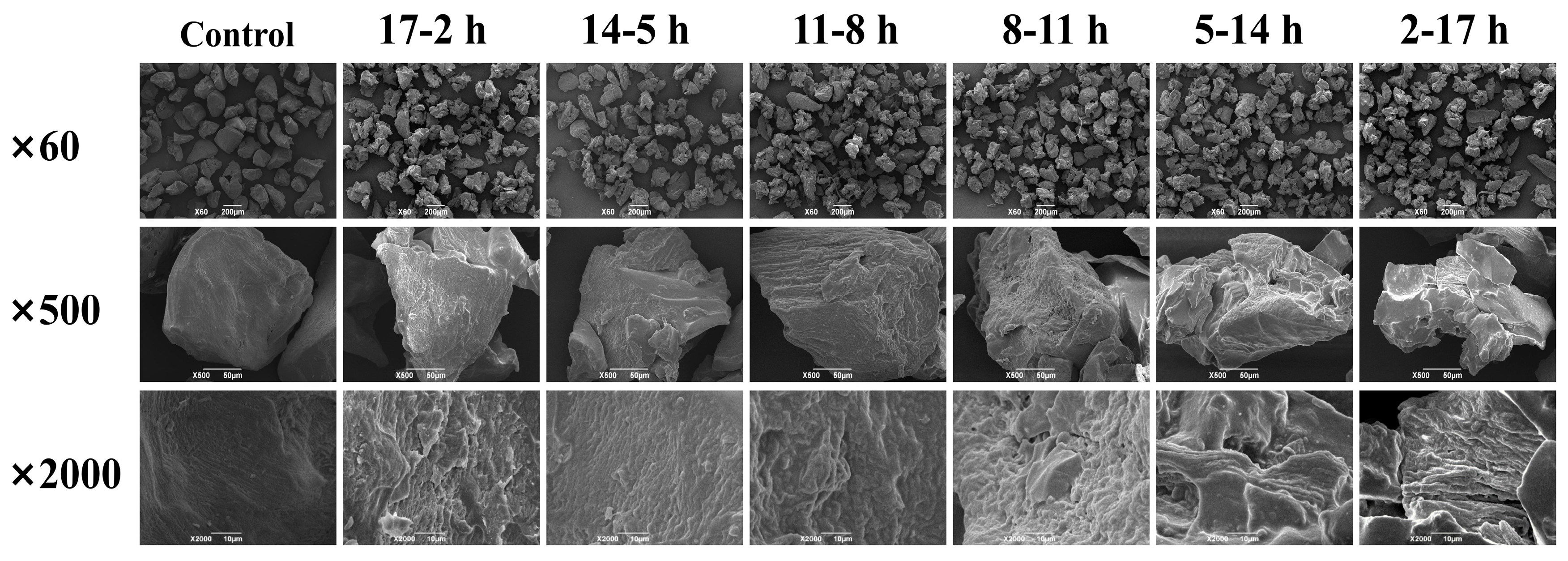

Microscopic morphology of konjac powders treated with VD-VFD at different moisture transition points.

Figure 8.

Microscopic morphology of konjac powders treated with VD-VFD at different moisture transition points.

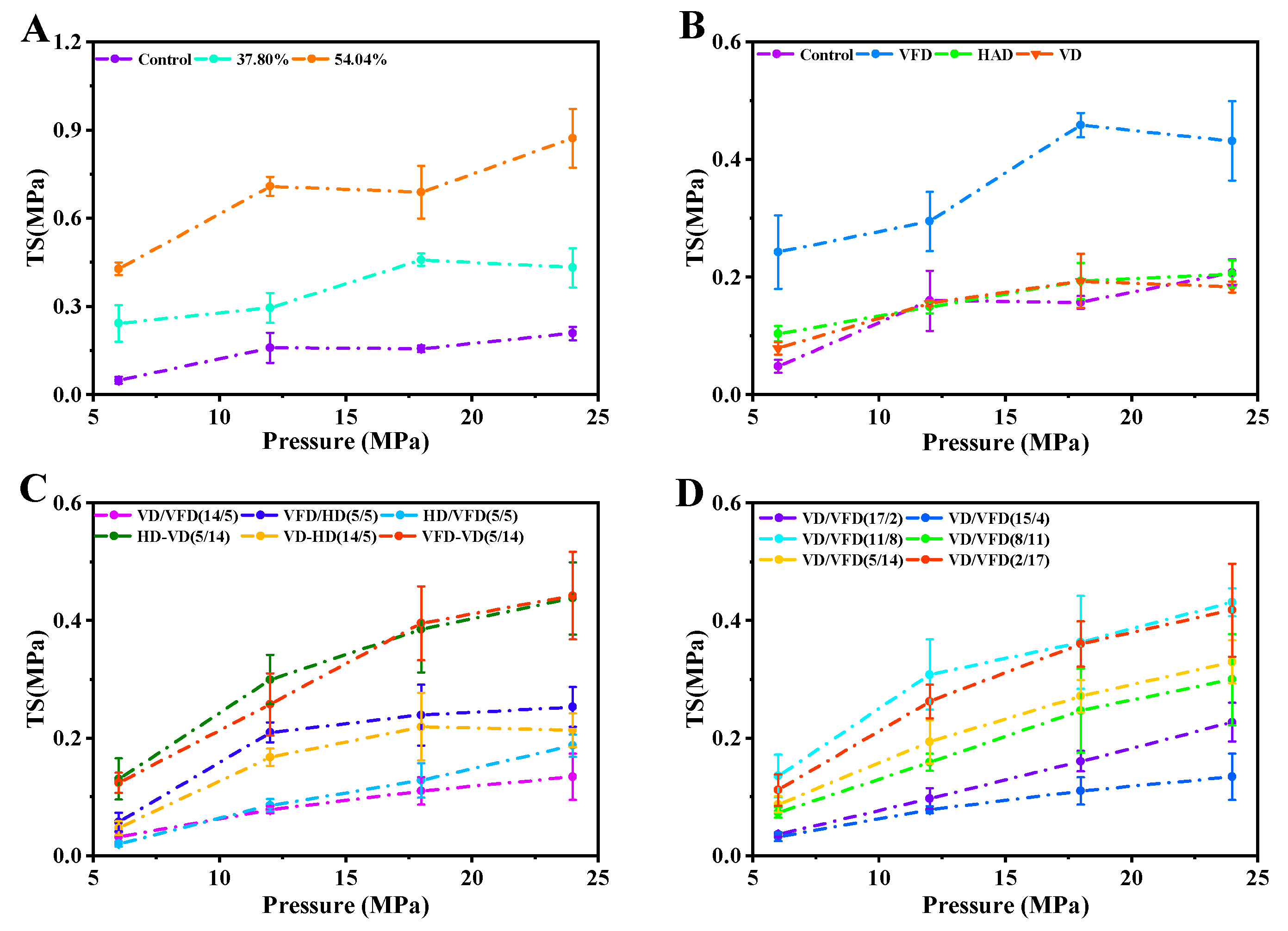

Figure 9.

TS–pressure change curves of tablets prepared from konjac powders with different moisture content treatments (29.32–54.04%) (A), 37.80% moisture modification combined with three drying treatments (B), six different combinations of drying methods at 37.80% moisture content (C), and different moisture transition points treatments (D).

Figure 9.

TS–pressure change curves of tablets prepared from konjac powders with different moisture content treatments (29.32–54.04%) (A), 37.80% moisture modification combined with three drying treatments (B), six different combinations of drying methods at 37.80% moisture content (C), and different moisture transition points treatments (D).

Table 1.

Drying parameters of different combined drying methods.

Table 1.

Drying parameters of different combined drying methods.

| Combined Drying Methods | Drying Temperature | Drying Time |

|---|

| VFD-VD (vacuum freeze-drying combined with vacuum drying) | −40–50 °C | 5 h–14 h |

| VD-VFD (vacuum drying combined with vacuum freeze-drying) | 50–−40 °C | 14 h–5 h |

| VD-HAD (vacuum drying combined with hot air drying) | 50–50 °C | 14 h–5 h |

| HAD-VD (hot air drying combined with vacuum drying) | 50–50 °C | 5 h–14 h |

| HAD-VFD (hot air drying combined with vacuum freeze-drying) | 50–−40 °C | 5 h–5 h |

| VFD-HAD (vacuum freeze-drying combined with hot air drying) | −40–50 °C | 5 h–5 h |

Table 2.

Criteria for weight variation according to the Chinese Pharmacopoeia.

Table 2.

Criteria for weight variation according to the Chinese Pharmacopoeia.

| Average Film Weight or Marked Film Weight | Weight Deviation Limits |

|---|

| Less than 0.3 g | ±7.5% |

| 0.3 g and above | ±5.0% |

Table 3.

Powder properties of konjac powders treated with different moisture contents (29.32–54.04%) (different letters a–d indicate significant differences between groups (p < 0.05)).

Table 3.

Powder properties of konjac powders treated with different moisture contents (29.32–54.04%) (different letters a–d indicate significant differences between groups (p < 0.05)).

| Sample | Bulk Density (g/cm3) | Tapped Density (g/cm3) | Hausner Index | Carr Index (%) | Angle of Repose (°) |

|---|

| Control | 0.64 ± 0.02 a | 0.72 ± 0.01 a | 1.13 ± 0.02 b | 11.68 ± 1.15 a | 31.94 ± 1.48 ab |

| 29.32% | 0.55 ± 0.00 b | 0.60 ± 0.00 b | 1.08 ± 0.07 c | 7.41 ± 0.00 b | 25.88 ± 3.22 b |

| 37.80% | 0.55 ± 0.14 b | 0.59 ± 0.02 b | 1.08 ± 0.00 c | 7.28 ± 0.19 b | 26.35 ± 4.29 b |

| 44.79% | 0.49 ± 0.12 c | 0.54 ± 0.00 c | 1.09 ± 0.03 c | 8.17 ± 2.13 b | 28.07 ± 1.51 b |

| 54.04% | 0.44 ± 0.01 d | 0.51 ± 0.01 d | 1.17 ± 0.15 a | 14.50 ± 0.30 a | 35.79 ± 6.50 a |

Table 4.

True density and porosity of konjac powders treated with different moisture contents (37.80–54.04%) (different letters a–c indicate significant differences between groups (p < 0.05)).

Table 4.

True density and porosity of konjac powders treated with different moisture contents (37.80–54.04%) (different letters a–c indicate significant differences between groups (p < 0.05)).

| Moisture Contents | Ρt (True Density) | ∈ (Porosity %) |

|---|

| Control | 1.628 ± 0.052 a | 59.181 ± 2.812 c |

| 37.80% | 1.732 ± 0.165 a | 68.631 ± 0.663 b |

| 54.04% | 1.827 ± 0.179 a | 75.539 ± 1.144 a |

Table 5.

Powder properties of konjac powders treated with 37.80% moisture modification combined with three drying methods (different letters a–c indicate significant differences between groups (p < 0.05)).

Table 5.

Powder properties of konjac powders treated with 37.80% moisture modification combined with three drying methods (different letters a–c indicate significant differences between groups (p < 0.05)).

| Drying Methods | Bulk Density (g/cm3) | Tapped Density (g/cm3) | Hausner Index | Carr Index (%) | Angle of Repose (°) |

|---|

| Control | 0.64 ± 0.02 a | 0.72 ± 0.01 a | 1.13 ± 0.02 c | 11.68 ± 1.15 b | 31.94 ± 1.48 a |

| VFD | 0.55 ± 0.14 a | 0.59 ± 0.02 b | 1.08 ± 0.00 c | 7.28 ± 0.19 c | 26.35 ± 4.29 a |

| HAD | 0.49 ± 0.01 b | 0.56 ± 0.01 c | 1.15 ± 0.00 ab | 12.90 ± 0.00 b | 31.94 ± 1.48 a |

| VD | 0.47 ± 0.01 b | 0.57 ± 0.01 bc | 1.20 ± 0.05 a | 18.75 ± 0.00 a | 26.35 ± 4.29 a |

Table 6.

True density and porosity of konjac powders treated with 37.80% moisture modification combined with three drying methods (different letters a–d indicate significant differences between groups (p < 0.05)).

Table 6.

True density and porosity of konjac powders treated with 37.80% moisture modification combined with three drying methods (different letters a–d indicate significant differences between groups (p < 0.05)).

| Drying Methods | Ρt (True Density) | ∈ (Porosity %) |

|---|

| Control | 1.628 ± 0.052 a | 59.181 ± 2.812 d |

| VFD | 1.732 ± 0.165 a | 68.631 ± 0.663 c |

| HAD | 1.722 ± 0.098 a | 71.577 ± 0.537 b |

| VD | 1.909 ± 0.307 a | 75.179 ± 0.456 a |

Table 7.

Powder properties of konjac powders treated with six combinations of drying methods at 37.80% moisture content (different letters a,b indicate significant differences between groups (p < 0.05)).

Table 7.

Powder properties of konjac powders treated with six combinations of drying methods at 37.80% moisture content (different letters a,b indicate significant differences between groups (p < 0.05)).

| Combined Drying Method | Individual Drying Times(h-h) | Bulk Density (g/cm3) | Tapped Density (g/cm3) | Hausner Index | Carr Index (%) | Angle of Repose (°) |

|---|

| Control | / | 0.64 ± 0.02 a | 0.72 ± 0.01 a | 1.13 ± 0.02 a | 11.68 ± 1.15 a | 31.94 ± 1.48 a |

| HAD-VFD | 5-5 | 0.52 ± 0.02 b | 0.59 ± 0.01 b | 1.13 ± 0.06 a | 11.39 ± 4.85 a | 31.32 ± 3.10 a |

| VFD-HAD | 5-5 | 0.50 ± 0.00 b | 0.54 ± 0.03 b | 1.10 ± 0.05 a | 8.82 ± 4.24 a | 31.19 ± 3.35 a |

| HAD-VD | 5-14 | 0.51 ± 0.02 b | 0.58 ± 0.02 b | 1.13 ± 0.02 a | 11.35 ± 1.76 a | 29.18 ± 6.83 a |

| VD-HAD | 14-5 | 0.51 ± 0.03 b | 0.56 ± 0.02 b | 1.10 ± 0.02 a | 9.06 ± 1.69 a | 30.93 ± 0.61 a |

| VD-VFD | 14-5 | 0.53 ± 0.01 b | 0.59 ± 0.01 b | 1.11 ± 0.05 a | 9.36 ± 3.84 a | 26.56 ± 4.69 a |

| VFD-VD | 5-14 | 0.52 ± 0.03 b | 0.58 ± 0.02 b | 1.10 ± 0.02 a | 9.25 ± 1.61 a | 32.33 ± 2.95 a |

Table 8.

True density and porosity of konjac powders treated with six combinations of drying methods at 37.80% moisture content (different letters a–c indicate significant differences between groups (p < 0.05)).

Table 8.

True density and porosity of konjac powders treated with six combinations of drying methods at 37.80% moisture content (different letters a–c indicate significant differences between groups (p < 0.05)).

| Combined Drying Methods | Individual Drying Times (h-h) | Ρt (True Density) | ∈ (Porosity %) |

|---|

| Control | / | 1.628 ± 0.000 ab | 59.181 ± 2.812 c |

| HAD-VFD | 5-5 | 1.559 ± 0.047 b | 66.801 ± 0.235 ab |

| VFD-HAD | 5-5 | 1.582 ± 0.004 b | 68.909 ± 0.088 b |

| HAD-VD | 5-14 | 1.560 ± 0.013 b | 67.176 ± 1.053 ab |

| VD-HAD | 14-5 | 1.543 ± 0.043 b | 67.394 ± 1.488 ab |

| VD-VFD | 14-5 | 1.955 ± 0.491 a | 72.054 ± 6.956 a |

| VFD-VD | 5-14 | 1.631 ± 0.200 ab | 67.311 ± 2.413 ab |

Table 9.

Powder properties of konjac powders treated with VD-VFD at different moisture transition points (controlled total drying time of 19 h; different letters a–d indicate significant differences between groups (p < 0.05)).

Table 9.

Powder properties of konjac powders treated with VD-VFD at different moisture transition points (controlled total drying time of 19 h; different letters a–d indicate significant differences between groups (p < 0.05)).

| Combined Drying Methods (Stage 1-Stage 2) | Individual Drying Times (h) | Bulk Density (g/cm3) | Tapped Density (g/cm3) | Hausner Index | Carr Index (%) | Angle of Repose (°) |

|---|

| Control | / | 0.64 ± 0.02 a | 0.72 ± 0.01 a | 1.13 ± 0.02 ab | 11.68 ± 1.15 bc | 31.94 ± 1.48 ab |

| VD-VFD | 17-2 | 0.50 ± 0.01 cd | 0.59 ± 0.03 bc | 1.19 ± 0.05 a | 15.95 ± 3.88 a | 35.65 ± 3.76 a |

| VD-VFD | 14-5 | 0.53 ± 0.01 bc | 0.59 ± 0.01 bc | 1.11 ± 0.05 b | 9.36 ± 3.84 c | 26.56 ± 4.69 b |

| VD-VFD | 11-8 | 0.48 ± 0.02 d | 0.56 ± 0.02 c | 1.16 ± 0.06 ab | 13.73 ± 4.27 b | 35.09 ± 0.59 a |

| VD-VFD | 8-11 | 0.51 ± 0.01 bcd | 0.58 ± 0.02 c | 1.14 ± 0.03 ab | 12.38 ± 2.07 bc | 33.50 ± 0.96 a |

| VD-VFD | 5-14 | 0.52 ± 0.00 bcd | 0.59 ± 0.01 bc | 1.13 ± 0.03 ab | 11.49 ± 1.99 bc | 33.12 ± 3.64 a |

| VD-VFD | 2-17 | 0.54 ± 0.01 b | 0.62 ± 0.01 b | 1.14 ± 0.03 ab | 12.04 ± 1.96 bc | 31.88 ± 2.93 ab |

Table 10.

True density and porosity of konjac powders treated with VD-VFD at different moisture transition points (controlled total drying time of 19 h; different letters a–d indicate significant differences between groups (p < 0.05)).

Table 10.

True density and porosity of konjac powders treated with VD-VFD at different moisture transition points (controlled total drying time of 19 h; different letters a–d indicate significant differences between groups (p < 0.05)).

| Combined Drying Methods (Stage 1-Stage 2) | Individual Drying Times (h) | Ρt (True Density) | ∈ (Porosity %) |

|---|

| Control | / | 1.628 ± 0.000 a | 59.181 ± 2.812 c |

| VD-VFD | 17-2 | 1.633 ± 0.044 a | 69.710 ± 0.290 a |

| VD-VFD | 14-5 | 1.723 ± 0.219 a | 69.259 ± 0.612 a |

| VD-VFD | 11-8 | 1.614 ± 0.032 a | 70.281 ± 1.428 a |

| VD-VFD | 8-11 | 1.377 ± 0.066 b | 63.262 ± 0.724 b |

| VD-VFD | 5-14 | 1.647 ± 0.016 a | 68.582 ± 0.006 a |

| VD-VFD | 2-17 | 1.258 ± 0.027 b | 56.866 ± 0.911 d |

Table 11.

Kawakita equation fitting parameters of konjac powders treated with different moisture contents (37.80–54.04%).

Table 11.

Kawakita equation fitting parameters of konjac powders treated with different moisture contents (37.80–54.04%).

| Moisture Contents | a | 1/b | ab | R2 |

|---|

| Control | 0.673 | 0.096 | 7.012 | 0.999 |

| 37.80% | 0.815 | 0.148 | 5.490 | 0.999 |

| 54.04% | 0.636 | 0.058 | 10.933 | 0.999 |

Table 12.

Kawakita equation fitting parameters of konjac powders treated with 37.80% moisture modification combined with three drying methods.

Table 12.

Kawakita equation fitting parameters of konjac powders treated with 37.80% moisture modification combined with three drying methods.

| Drying Methods | a | 1/b | ab | R2 |

|---|

| Control | 0.667 | 0.042 | 15.699 | 0.999 |

| VFD | 0.810 | 0.111 | 7.309 | 0.999 |

| HAD | 2.498 | 0.029 | 86.281 | 0.999 |

| VD | 2.549 | 0.097 | 26.364 | 0.999 |

Table 13.

Kawakita equation fitting parameters of konjac powders treated with six combinations of drying methods at 37.80% moisture content.

Table 13.

Kawakita equation fitting parameters of konjac powders treated with six combinations of drying methods at 37.80% moisture content.

| Combined Drying Methods | Individual Drying Times (h/h) | a | 1/b | ab | R2 |

|---|

| Control | / | 0.670 | 0.096 | 7.012 | 0.999 |

| HAD/VFD | 5/5 | 0.910 | 0.470 | 1.940 | 0.998 |

| VFD/HAD | 5/5 | 0.010 | 0.540 | 0.020 | 0.994 |

| HAD/VD | 5/14 | 0.540 | 0.480 | 1.130 | 0.994 |

| VD/HAD | 14/5 | 0.120 | 0.610 | 0.200 | 0.998 |

| VD/VFD | 14/5 | 0.450 | 0.510 | 0.880 | 0.999 |

| VFD/VD | 5/14 | 0.580 | 0.560 | 1.040 | 0.999 |

Table 14.

Kawakita equation fitting parameters for konjac powders treated with VD-VFD at different moisture transition points (total drying time of 19 h).

Table 14.

Kawakita equation fitting parameters for konjac powders treated with VD-VFD at different moisture transition points (total drying time of 19 h).

| Combined Drying Methods | Individual Drying Times (h/h) | a | 1/b | ab | R2 |

|---|

| VD/VFD | 17:2 | 0.667 | 0.580 | 1.160 | 0.999 |

| VD/VFD | 14:5 | 0.910 | 0.470 | 1.940 | 0.998 |

| VD/VFD | 11:8 | 0.657 | 0.510 | 1.290 | 0.999 |

| VD/VFD | 8:11 | 0.801 | 0.430 | 1.870 | 0.999 |

| VD/VFD | 5:14 | 0.334 | 0.570 | 0.580 | 0.999 |

| VD/VFD | 2:17 | 0.323 | 0.560 | 0.570 | 0.999 |

Table 15.

Quality of tablets prepared from untreated/treated konjac powders (different letters a,b indicate significant differences between groups (p < 0.05)).

Table 15.

Quality of tablets prepared from untreated/treated konjac powders (different letters a,b indicate significant differences between groups (p < 0.05)).

| Sample | Weight Variation | Hardness (N) | Brittleness (%) |

|---|

| Control | Does not meet the requirements | 29.52 ± 2.73 b | >1% with fragmented, lobes |

| 54.04% | Meet the requirements | 40.37 ± 3.00 a | 0.79% |