Valorization of Camelina Cake by Fractionation: Characterization of Nutritional and Functional Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Material

2.2. Methods

2.2.1. Proximate Composition

2.2.2. Amino Acid Profile

2.2.3. Fatty Acid Profile

2.2.4. Tocopherols

2.2.5. Antioxidative Potential

2.2.6. Color Measurements

2.2.7. Water and Oil Absorption Capacity

2.3. Statistical Analysis

3. Results

3.1. Yield of the Camelina Cake Fractions

3.2. Proximate Composition of Camelina Cake Fractions

3.3. Amino Acid Content of Camelina Cake Fractions

3.4. Fatty Acid Content of Camelina Seed Fractions

3.5. Tocopherol Content of Camelina Cake Fractions

3.6. Total Polyphenolic Content of Camelina Cake Fractions

3.7. Antioxidant Potential of Camelina Cake Fractions and Correlation Analysis

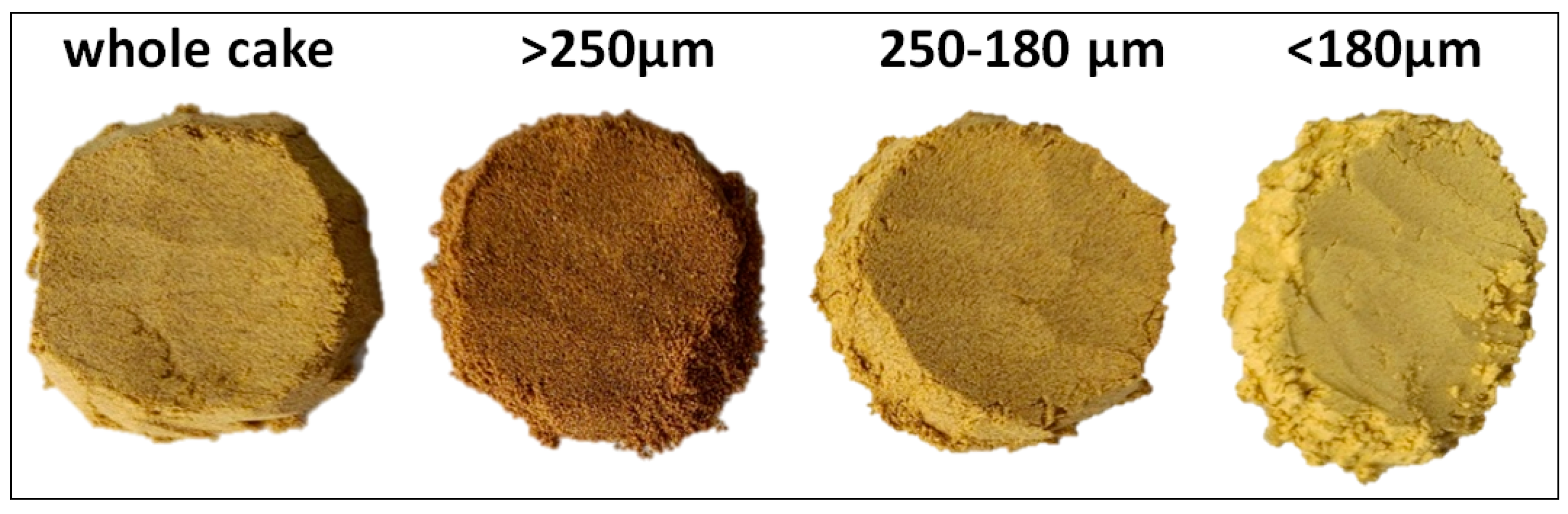

3.8. Color Properties of Camelina Cake Fractions

3.9. Water and Oil Absorption Properties of Camelina Cake Fractions

4. Discussion

4.1. Effect of Sieving on Proximate Composition

4.2. Effect of Sieving on Amino Acid Composition

4.3. Effect of Sieving on Fatty Acid Composition

4.4. Effect of Sieving on Tocopherol Content

4.5. Effect of Sieving on Phenolic Content and Antioxidative Potential

4.6. Effect of Sieving on Color Properties

4.7. Effect of Sieving on WAC and OAC

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FAME | fatty acid methyl esters |

| SFA | saturated fatty acids |

| MUFA | monounsaturated fatty acids |

| PUFA | polyunsaturated fatty acids |

| LA | linoleic acid |

| ALA | α-linolenic acid |

| EAA | essential amino acids |

| NEAA | non-essential amino acids |

| TAA | total amino acids |

| TPC | total polyphenolic content |

| IC50 | half-maximal inhibitory concentration |

| WAC | water absorption capacity |

| OAC | oil absorption capacity |

References

- Juodka, R.; Nainienè, R.; Juškienè, V.; Juška, R.; Leikus, R.; Kadžienè, G.; Stankevičinè, D. Camelina (Camelina sativa (L.) Crantz) as Feedstuffs in Meat Type Poultry Diet: A Source of Protein and n-3 Fatty Acids. Animals 2022, 12, 295. [Google Scholar] [CrossRef]

- Angelopoulou, F.; Roussis, I.; Kakabouki, I.; Mavroeidis, A.; Triantafyllidis, V.; Beslemes, D.; Kosma, C.; Stavropoulos, P.; Tsiplakou, E.; Bilalis, D. Influence of Organic Fertilization and Soil Tillage on the Yield and Quality of Cold-Pressed Camelina [Camelina sativa (L.) Crantz] Seed Cake: An Alternative Feed Ingredient. Appl. Sci. 2023, 13, 3759. [Google Scholar] [CrossRef]

- Smith, N.O. Crops for Industry and Energy in Europe; Office for Official Publications of the European Communities: Brussels, Belgium, 1997; ISBN 9282794156. [Google Scholar]

- Ilić, P.; Rakita, S.; Spasevski, N.; Đuragić, O.; Marjanović Jeromela, A.; Cvejić, S.; Zanetti, F. Nutritive Value of Serbian Camelina Genotypes as an Alternative Feed Ingredient. Food Feed Res. 2022, 49, 209–221. [Google Scholar] [CrossRef]

- Spasevski, N.; Peulić, T.; Banjac, V.; Čolović, R.; Pezo, L.; Rakita, S.; Puvaca, N.; Kokić, B.; Đuragić, O.; Basić, Z.N. Influence of Extruded Camelina Seed and Natural Colourants Addition in Laying Hens Diet on Eggs Yolk Colour and Fatty Acid Composition. J. Anim. Plant Sci. 2020, 30, 1347–1356. [Google Scholar] [CrossRef]

- Grahovac, N.; Aleksić, M.; Trajkovska, B.; Marjanović Jeromela, A.; Nakov, G. Extraction and Valorization of Oilseed Cakes for Value-Added Food Components-A Review for a Sustainable Foodstuff Production in a Case Process Approach. Foods 2025, 14, 2244. [Google Scholar] [CrossRef] [PubMed]

- Tavarini, S.; De Leo, M.; Matteo, R.; Lazzeri, L.; Braca, A.; Angelini, L.G. Flaxseed and Camelina Meals as Potential Sources of Health-Beneficial Compounds. Plants 2021, 10, 156. [Google Scholar] [CrossRef] [PubMed]

- Ermosh, L.G.; Prisuhina, N.V.; Koch, D.A.; Eremina, E.V. The use of oilseed cake for supplementation of bakery products. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Online Conference, March 2021; IOP Publishing: Bristol, UK, 2021; Volume 677, p. 022090. [Google Scholar]

- Łopusiewicz, Ł.; Kwiatkowski, P.; Drozłowska, E. Production and Characterization of Yogurt-Like Fermented Beverage Based on Camelina sativa L. Seed Press Cake. Appl. Sci. 2022, 12, 1085. [Google Scholar] [CrossRef]

- Li, X.; Mupondwa, E. Production and value-chain integration of Camelina sativa as a dedicated bioenergy feedstock in the Canadian prairies. In Proceedings of the 24th European Biomass Conference & Exhibition, Amsterdam, The Netherlands, 6–9 June 2016. [Google Scholar]

- Ryhänen, E.-L.; Perttilä, S.; Tupasela, T.; Valaja, J.; Eriksson, C.; Larkka, K. Effect of Camelina sativa Expeller Cake on Performance and Meat Quality of Broilers. J. Sci. Food Agric. 2007, 87, 1489–1494. [Google Scholar] [CrossRef]

- Orczewska-Dudek, S.; Pietras, M. The Effect of Dietary Camelina sativa Oil or Cake in the Diets of Broiler Chickens on Growth Performance, Fatty Acid Profile, and Sensory Quality of Meat. Animals 2019, 9, 734. [Google Scholar] [CrossRef]

- Taranu, I.; Gras, M.; Pistol, G.C.; Motiu, M.; Marin, D.E.; Lefter, N.; Ropota, M.; Habeanu, M. n-3 PUFA Rich Camelina Oil By-Products Improve the Systemic Metabolism and Spleen Cell Functions in Fattening Pigs. PLoS ONE 2014, 9, e110186. [Google Scholar] [CrossRef]

- Lawrence, R.D.; Anderson, J.L. Ruminal Degradation and Intestinal Digestibility of Camelina Meal and Carinata Meal Compared with Other Protein Sources. Prof. Anim. Sci. 2018, 34, 10–18. [Google Scholar] [CrossRef]

- Toma, S.; Dragomir, C.; Habeanu, M.; Ropota, M.; Cismileanu, A.; Grosu, H. Effects of Partial or Total Replacement of Sunflower Meal with Camelina Meal on Dairy Cows’ Milk Fatty Acids Profile. Arch. Zootech. 2015, 18, 85–94. [Google Scholar]

- Vujetić, J.; Spasevski, N.; Dragojlović, D. Processing Techniques of Removing Antinutrients from Oilseed Cakes as By-Products Intended for Animal Feeding. Food Feed Res. 2025, 52, 37–51. [Google Scholar] [CrossRef]

- Pojić, M.; Mišan, A.; Sakač, M.; Dapčević Hadnađev, T.; Šarić, B.; Milovanović, I.; Hadnađev, M. Characterization of Byproducts Originating from Hemp Oil Processing. J. Agric. Food Chem. 2014, 62, 12436–12442. [Google Scholar] [CrossRef]

- Bárta, J.; Bártová, V.; Jarošová, M.; Švajner, J.; Smetana, P.; Kadlec, J.; Filip, V.; Kyselka, J.; Berčíková, M.; Zdráhal, Z.; et al. Oilseed Cake Flour Composition, Functional Properties and Antioxidant Potential as Effects of Sieving and Species Differences. Foods 2021, 10, 2766. [Google Scholar] [CrossRef]

- Mejicanos, G.A.; Rogiewicz, A.; Nyachoti, C.M.; Slominski, B.A. Fractionation of Canola Meal Using Sieving Technology. Can. J. Anim. Sci. 2017, 97, 613–621. [Google Scholar] [CrossRef]

- Šuput, D.; Popović, S.; Hromiš, N.; Rakita, S.; Spasevski, N.; Lončar, B.; Erceg, T.; Knežević, V. The Influence of Oil Cake Granulation and Ultrasonic Pretreatment on the Properties of Biopolymer Films Based on Camelina sativa Oilseed Cake. Food Feed Res. 2023, 50, 61–75. [Google Scholar] [CrossRef]

- ISO 6496; Animal Feeding Stuffs—Determination of Moisture and Other Volatile Matter Content. International Organization for Standardization: Geneva, Switzerland, 1999.

- ISO 5983-1; Animal Feeding Stuffs—Determination of Nitrogen Content and Calculation of Crude Protein Content—Part 1: Kjeldahl Method. International Organization for Standardization: Geneva, Switzerland, 2005.

- ISO 5984; Animal Feeding Stuffs—Determination of Crude Ash. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 6492; Animal Feeding Stuffs—Determination of Fat Content. International Organization for Standardization: Geneva, Switzerland, 1999.

- AOCS. Official Methods and Recommended Practices of the AOCS; Official Method Ba 6-a05; The American Oil Chemists Society: Champaign, IL, USA, 2005. [Google Scholar]

- MSZ-08-1908; Determination of the Glucosinolate Content of Rapeseeds and Rapeseed Meals. Hungarian Standards Institution: Budapest, Hungary, 1989.

- Tomičić, Z.; Spasevski, N.; Popović, S.; Banjac, V.; Đuragić, O.; Tomičić, R. By-Products of the Oil Industry as Sources of Amino Acids in Feed. Food Feed Res. 2020, 47, 131–137. [Google Scholar] [CrossRef]

- SRPS EN 12822; Foodstuffs—Determination of Vitamin E by High Performance Liquid Chromatography—Measurement of α-, β-, γ- and δ-Tocopherol. Institute for Standardization of Serbia: Belgrade, Serbia, 2014.

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of Total Phenols and Other Oxidation Substrates and Antioxidants by Means of Folin–Ciocalteu Reagent. In Methods in Enzymology; Packer, L., Ed.; Academic Press: San Diego, CA, USA, 1999; Volume 299, pp. 152–178. [Google Scholar]

- Savić Gajić, I.; Savić, I.; Boškov, I.; Žerajić, S.; Markovic, I.; Gajić, D. Optimization of ultrasound-assisted extraction of phenolic compounds from black locust (Robiniae pseudoacaciae) flowers and comparison with conventional methods. Antioxidants 2019, 8, 248. [Google Scholar] [CrossRef]

- Kain, R.J.; Chenc, Z.; Abu-Kpawoh, J.C. Study on the Effects of Enzymatic Hydrolysis on the Physical, Functional and Chemical Properties of Peanut Protein Isolates Extracted from Defatted Heat Pressed Peanut Meal Flour (Arachis hypogaea L.). Pak. J. Nutr. 2009, 8, 818–825. [Google Scholar] [CrossRef]

- TIBCO Software Inc. Data Science Workbench; Version 14; Statistica 14; TIBCO Software Inc.: Palo Alto, CA, USA, 2020. [Google Scholar]

- Lolli, S.; Grilli, G.; Ferrari, L.; Battelli, G.; Pozzo, S.; Galasso, I.; Russo, R.; Brasca, M.; Reggiani, R.; Ferrante, V. Effect of Different Percentage of Camelina sativa Cake in Laying Hens Diet: Performance, Welfare, and Eggshell Quality. Animals 2020, 10, 1396. [Google Scholar] [CrossRef]

- Rakita, S.; Kokić, B.; Manoni, M.; Mazzoleni, S.; Lin, P.; Luciano, A.; Ottoboni, M.; Cheli, F.; Pinotti, L. Cold-Pressed Oilseed Cakes as Alternative and Sustainable Feed Ingredients: A Review. Foods 2023, 12, 432. [Google Scholar] [CrossRef]

- Hansen, J.Ø.; Skrede, A.; Mydland, L.T.; Øverland, M. Fractionation of rapeseed meal by milling, sieving and air classification—Effect on crude protein, amino acids and fiber content and digestibility. Anim. Feed Sci. Technol. 2017, 230, 143–153. [Google Scholar] [CrossRef]

- Bochkarev, B.; Egorova, E.; Poznyakovkiy, V. Reasons for the ways of using oilcakes in food industry. Foods Raw Mater. 2016, 4, 4–12. [Google Scholar] [CrossRef]

- Pekel, A.Y.; Kim, J.I.; Chapple, C.; Adeola, O. Nutritional characteristics of camelina meal for 3-week-old broiler chickens. Poult. Sci. 2015, 94, 371–378. [Google Scholar] [CrossRef]

- Banakar, P.S.; Anand Kumar, N.; Shashank, C.G. Physically effective fibre in ruminant nutrition: A review. J. Pharmacogn. Phytochem. 2018, 7, 303–308. [Google Scholar]

- Chuang, W.-Y.; Lin, L.-J.; Shih, H.-D.; Shy, Y.-M.; Chang, S.-C.; Lee, T.-T. The Potential Utilization of High-Fiber Agricultural By-Products as Monogastric Animal Feed and Feed Additives: A Review. Animals 2021, 11, 2098. [Google Scholar] [CrossRef]

- Mondor, M.; Hernández-Álvarez, A.J. Camelina sativa Composition, Attributes, and Applications: A Review. Eur. J. Lipid Sci. Technol. 2022, 124, 2100035. [Google Scholar] [CrossRef]

- Almeida, F.N.; Htoo, J.K.; Thomson, J.; Stein, H.H. Amino Acid Digestibility in Camelina Products Fed to Growing Pigs. Can. J. Anim. Sci. 2013, 93, 335–343. [Google Scholar] [CrossRef]

- Kahindi, R.K.; Woyengo, T.A.; Thacker, P.A.; Nyachoti, C.M. Energy and Amino Acid Digestibility of Camelina Cake Fed to Growing Pigs. Anim. Feed Sci. Technol. 2014, 193, 93–101. [Google Scholar] [CrossRef]

- Matthäus, B.; Angelini, L.G. Anti-Nutritive Constituents in Oilseed Crops from Italy. Ind. Crops Prod. 2005, 21, 89–99. [Google Scholar] [CrossRef]

- Egorova, T.A. Glucosinolates in Rape and Camelina: Composition, Concentrations, Toxicity and Anti-Nutritive Effects in Poultry, Methods of Neutralization—A Mini-Review. Sel’skokhozyaistvennaya Biol. 2023, 58, 1021–1034. [Google Scholar] [CrossRef]

- Russo, R.; Reggiani, R. Antinutritive Compounds in Twelve Camelina sativa Genotypes. Am. J. Plant Sci. 2012, 3, 1408–1412. [Google Scholar] [CrossRef]

- Kiarie, E.; Walsh, M.C.; He, L.; Velayudhan, D.E.; Yin, Y.L.; Nyachoti, C.M. Phytase Improved Digestible Protein, Phosphorous, and Energy Contents in Camelina Expellers Fed to Growing Pigs. J. Anim. Sci. 2016, 94, 215–218. [Google Scholar] [CrossRef]

- Bule, M.; Khan, F.; Nisar, M.F.; Niaz, K.; Nabavi, S.; Saeedi, M.; Sanches Silva, A. Tannins (Hydrolysable Tannins, Condensed Tannins, Phlorotannins, Flavono-Ellagitannins). Recent Adv. Nat. Prod. Anal. 2020, 132, 132–146. [Google Scholar]

- Colombini, S.; Broderick, G.A.; Galasso, I.; Martinelli, T.; Rapetti, L.; Russo, R.; Reggiani, R. Evaluation of Camelina sativa (L.) Crantz Meal as an Alternative Protein Source in Ruminant Rations. J. Sci. Food Agric. 2014, 94, 736–743. [Google Scholar] [CrossRef]

- Matthäus, B.; Zubr, J. Variability of Specific Components in Camelina sativa Oilseed Cakes. Ind. Crops Prod. 2000, 12, 9–18. [Google Scholar] [CrossRef]

- Kim, J.W.; Koo, B.; Nyachoti, C.M. Digestible, Metabolizable, and Net Energy of Camelina Cake Fed to Growing Pigs and Additivity of Energy in Mixed Diets. J. Anim. Sci. 2017, 95, 4037–4044. [Google Scholar] [CrossRef]

- Presto, M.H.; Lyberg, K.; Lindberg, J.E. Digestibility of Amino Acids in Organically Cultivated White-Flowering Faba Bean and Cake from Cold-Pressed Rapeseed, Linseed and Hemp Seed in Growing Pigs. Arch. Anim. Nutr. 2011, 65, 21–33. [Google Scholar] [CrossRef]

- Bailoni, L.; Bortolozzo, A.; Mantovani, R.; Simonetto, A.; Schiavon, S.; Bittante, G. Feeding Dairy Cows with Full Fat Extruded or Toasted Soybean Seeds as Replacement of Soybean Meal and Effects on Milk Yield, Fatty Acid Profile and CLA Content. Ital. J. Anim. Sci. 2004, 3, 243–258. [Google Scholar] [CrossRef]

- Altinoz, M.A.; Serdar, M.A.; Altinoz, S.M.; Eroglu, M.; Muhcu, M.; Kumru, P.; Ozpinar, A. ω9 Monounsaturated and Saturated Colostrum Fatty Acids May Benefit Newborns in General and Subtle Hypothyroid Stages. Nutrients 2025, 17, 2017. [Google Scholar] [CrossRef]

- Fan, G.; Li, Y.; Liu, Y.; Suo, X.; Jia, Y.; Yang, X. Gondoic acid alleviates LPS-induced Kupffer cells inflammation by inhibiting ROS production and PKCθ/ERK/STAT3 signaling pathway. Int. Immunopharmacol. 2022, 111, 109171. [Google Scholar] [CrossRef]

- Kurasiak-Popowska, D.; Graczyk, M.; Stuper-Szablewska, K. Winter camelina seeds as a raw material for the production of erucic acid-free oil. Foods Chem. 2020, 330, 127265. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No. 1870/2019 of 7 November 2019 Amending and Correcting Regulation (EC) No. 1881/2006 as Regards Maximum Levels of Erucic Acid and Hydrocyanic Acid in Certain Foodstuffs. Off. J. EU 2019, L289, 37–40. Available online: https://eur-lex.europa.eu/eli/reg/2019/1870/oj (accessed on 1 October 2024).

- Zárate, R.; El Jaber-Vazdekis, N.; Tejera, N.; Pérez, J.A.; Rodríguez, C. Significance of long chain polyunsaturated fatty acids in human health. Clin. Transl. Med. 2017, 6, 25. [Google Scholar] [CrossRef]

- Kokić, B.; Rakita, S.; Vujetić, J. Impact of Using Oilseed Industry Byproducts Rich in Linoleic and Alpha-Linolenic Acid in Ruminant Nutrition on Milk Production and Milk Fatty Acid Profile. Animals 2024, 14, 539. [Google Scholar] [CrossRef]

- Kakani, R.; Fowler, J.; Haq, A.U.; Murphy, E.J.; Rosenberger, T.A.; Berhow, M.; Bailey, C.A. Camelina meal increases egg n-3 fatty acid content without altering quality or production in laying hens. Lipids 2012, 47, 519–526. [Google Scholar] [CrossRef]

- Rakita, S.; Spasevski, N.; Savić, I.; Savić Gajić, I.; Lazarević, J.; Dragojlović, D.; Đuragić, O. Comparative Evaluation of Camelina Seed Oils Obtained by Cold-Pressing and Solvent Extraction. Foods 2024, 13, 3605. [Google Scholar] [CrossRef]

- Franke, S.; Fröhlich, K.; Werner, S.; Böhm, V.; Schöne, F. Analysis of carotenoids and vitamin E in selected oilseeds, press cakes and oils. Eur. J. Lipid Sci. Technol. 2010, 112, 1122–1129. [Google Scholar] [CrossRef]

- Es-Sai, B.; Wahnou, H.; Benayad, S.; Rabbaa, S.; Laaziouez, Y.; El Kebbaj, R.; Limami, Y.; Duval, R.E. Gamma-Tocopherol: A Comprehensive Review of Its Antioxidant, Anti-Inflammatory, and Anticancer Properties. Molecules 2025, 30, 653. [Google Scholar] [CrossRef]

- Kramar, A.; Laguta, I.; Anishchenko, V.; Stavinskaya, O.; Kuzema, P.; Smirnova, N.; Ivannikov, R.; Linnik, O. Comparative Study on Phenolic Content and Antioxidant/Reducing Properties of Extracts from Various Types of Camelina Plant Biomass. Waste Biomass Valor. 2025, 1, 4553–4566. [Google Scholar] [CrossRef]

- Piergiovanni, A.R.; Alberghini, B.; Zanetti, F.; Ponzoni, E.; Brambilla, I.M.; Galasso, I. The Effect of Year and Variety on the Nutritional Value of Camelina sativa Meal. Eur. Food Res. Technol. 2025, 251, 841–849. [Google Scholar] [CrossRef]

- Pozzo, S.; Piergiovanni, A.R.; Ponzoni, E.; Brambilla, I.M.; Galasso, I. Evaluation of Nutritional and Antinutritional Compounds in a Collection of Camelina sativa Varieties. J. Crop Improv. 2023, 37, 934–952. [Google Scholar] [CrossRef]

- Małajowicz, J.; Dziedzic, A.; Goleń, P.; Stepaniuk, T. Evaluation of Polyphenol Content and Lipoxygenase Activity in Selected Oil Cakes in Terms of Their Valorization. In Proceedings of the Biology and Life Sciences Forum, Online Conference, 18–20 October 2023. [Google Scholar]

- Drozłowska, E.; Starowicz, M.; Śmietana, N.; Krupa-Kozak, U.; Łopusiewicz, Ł. Spray-Drying Impact the Physicochemical Properties and Formation of Maillard Reaction Products Contributing to Antioxidant Activity of Camelina Press Cake Extract. Antioxidants 2023, 12, 919. [Google Scholar] [CrossRef]

- Molyneux, P. The Use of the Stable Free Radical Diphenylpicrylhydrazyl (DPPH) for Estimating Antioxidant Activity. Songklanakarin J. Sci. Technol. 2004, 26, 211–219. [Google Scholar]

- Laguta, I.; Stavinskaya, O.; Kuzema, P.; Anishchenko, V.; Ivannikov, R. Bio-Waste of Vegetable Oil Production as a Source of Natural Phenols with Antioxidant Properties. Biomass Convers. Biorefin. 2025, 15, 15385–15398. [Google Scholar] [CrossRef]

- Terpinc, P.; Polak, T.; Makuc, D.; Ulrih, N.P.; Abramovič, H. The Occurrence and Characterisation of Phenolic Compounds in Camelina sativa Seed, Cake and Oil. Food Chem. 2012, 131, 580–589. [Google Scholar] [CrossRef]

- Ahmad, Z.; Waraich, E.A.; Barutcular, C.; Alharby, H.; Bamagoos, A.; Kizilgeci, F.; Öztürk, F.; Hossain, A.; Bayoumi, Y.; El Sabagh, A. Enhancing Drought Tolerance in Camelina sativa L. and Canola (Brassica napus L.) through Application of Selenium. Pak. J. Bot. 2020, 52, 1927–1939. [Google Scholar] [CrossRef]

- Kurasiak-Popowska, D.; Ryńska, B.; Stuper-Szablewska, K. Analysis of Distribution of Selected Bioactive Compounds in Camelina sativa from Seeds to Pomace and Oil. Agronomy 2019, 9, 168. [Google Scholar] [CrossRef]

- Fabre, J.F.; Lacroux, E.; Gravé, G.; Mouloungui, Z. Extraction of Camelina Mucilage with Ultrasound and High Flow Rate Fluid Circulation. Ind. Crops Prod. 2020, 144, 112057. [Google Scholar] [CrossRef]

- Li, N.; Qi, G.; Sun, X.S.; Wang, D. Characterization of Gum Isolated from Camelina Seed. Ind. Crops Prod. 2016, 83, 268–274. [Google Scholar] [CrossRef]

- Alozie, Y.; Chinma, C. Proximate Composition, Physical and Sensory Properties of Cake Prepared from Wheat and Cocoyam Flour Blends. J. Food Res. 2015, 4, 5. [Google Scholar] [CrossRef]

- Ma, Z.; Boye, J.I.; Simpson, B.K.; Prasher, S.O.; Monpetit, D.; Malcolmson, L. Thermal Processing Effects on the Functional Properties and Microstructure of Lentil, Chickpea, and Pea Flours. Food Res. Int. 2011, 44, 2534–2544. [Google Scholar] [CrossRef]

- Čanak, P.; Jeromela, A.M.; Vujošević, B.; Kiprovski, B.; Mitrović, B.; Alberghini, B.; Facciolla, E.; Monti, A.; Zanetti, F. Is Drought Stress Tolerance Affected by Biotypes and Seed Size in the Emerging Oilseed Crop Camelina? Agronomy 2020, 10, 1856. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, N.; Sandhu, K.S. Preparation and Characterization of Protein Isolates from Different Lentil (Lens culinaris) Cultivars. J. Food Sci. Technol. 2007, 44, 327–329. [Google Scholar] [CrossRef]

- Rani, R.; Badwaik, L.S. Functional Properties of Oilseed Cakes and Defatted Meals of Mustard, Soybean and Flaxseed. Waste Biomass Valorization 2021, 12, 5639–5647. [Google Scholar] [CrossRef]

| Parameter | NS Zlatka | NS Slatka | ||||||

|---|---|---|---|---|---|---|---|---|

| Whole Cake | >250 µm | 250–180 µm | <180 µm | Whole Cake | >250 µm | 250–180 µm | <180 µm | |

| Moisture, % | 7.7 ± 0.04 b | 8.2 ± 0.07 c | 7.5 ± 0.01 b | 6.4 ± 0.12 a | 7.8± 0.06 b | 8.4 ± 0.11 d | 8.1 ± 0.04 c | 7.1 ± 0.01 a |

| Protein, % | 35.1 ± 0.02 b | 33.6 ± 0.07 a | 36.3 ± 0.01 c | 39.4 ± 0.08 d | 36.3 ± 0.15 c | 29.8 ± 0.06 a | 34.0 ± 0.01 b | 40.3 ± 0.11 d |

| Fat, % | 16.2 ± 0.04 b | 12.8 ± 0.11 a | 16.1 ± 0.34 b | 19.4 ± 0.01 c | 14.8 ± 0.06 c | 11.9 ± 0.17 a | 13.4 ± 0.14 b | 17.7 ± 0.08 d |

| Ash, % | 4.8 ± 0.02 a | 4.7 ± 0.01 a | 6.3 ± 1.16 a | 5.0 ± 0.04 a | 4.8 ± 0.06 a | 4.7 ± 0.05 a | 4.8 ± 0.00 a | 5.1 ± 0.08 b |

| Crude fiber, % | 9.3 ± 0.21 b | 13.0 ± 0.59 c | 10.1 ± 0.89 b | 5.9 ± 0.52 a | 8.8 ± 0.09 b | 15.3 ± 0.03 d | 11.0 ± 0.31 c | 6.8 ± 0.67 a |

| Glucosinolates, μmol/g | 21.9 ± 0.27 b | 19.8 ± 0.13 a | 21.3 ± 0.01 b | 24.3 ± 0.34 c | 24.9 ± 0.23 b | 21.1 ± 0.26 a | 24.2 ± 0.61 b | 27.4 ± 0.19 c |

| Condensed tannins, g/kg | 1.8 ± 0.02 b | 1.5 ± 0.06 b | 1.5 ± 0.40 b | 0.5 ± 0.13 a | 2.2 ± 0.07 b | 1.4 ± 0.55 ab | 2.1 ± 0.17 b | 0.9 ± 0.03 a |

| Phytic acid, g/kg | 30.7 ± 0.06 b | 17.6 ± 2.32 a | 31.1 ± 0.72 b | 41.1 ± 3.47 c | 33.1 ± 0.45 b | 20.6 ± 0.63 a | 33.6 ± 0.70 b | 38.4 ± 1.13 c |

| Amino Acids (g/100 g Sample) | NS Zlatka | NS Slatka | ||||||

|---|---|---|---|---|---|---|---|---|

| Whole Cake | >250 µm | 250–180 µm | <180 µm | Whole Cake | >250 µm | 250–180 µm | <180 µm | |

| Leucine | 2.34 ± 0.02 ab | 2.28 ± 0.09 a | 2.49 ± 0.06 b | 2.76 ± 0.08 c | 2.39 ± 0.03 c | 1.84 ± 0.05 a | 2.13 ± 0.06 b | 2.75 ± 0.06 d |

| Isoleucine | 1.36 ± 0.05 a | 1.27 ± 0.03 a | 1.53 ± 0.07 b | 1.62 ± 0.03 b | 1.47 ± 0.01 b | 1.18 ± 0.07 a | 1.25 ± 0.06 a | 1.64 ± 0.05 c |

| Lysine | 1.56 ± 0.04 a | 1.54 ± 0.05 a | 1.63 ± 0.06 ab | 1.75 ± 0.07 b | 1.62 ± 0.04 b | 1.43 ± 0.06 a | 1.54 ± 0.05 ab | 1.77 ± 0.05 c |

| Methionine | 0.65 ± 0.05 b | 0.43 ± 0.04 a | 0.57 ± 0.04 b | 0.64 ± 0.04 b | 0.65 ± 0.04 b | 0.34 ± 0.04 a | 0.66 ± 0.04 b | 0.73 ± 0.05 c |

| Threonine | 1.33 ± 0.05 ab | 1.28 ± 0.03 a | 1.35 ± 0.06 ab | 1.45 ± 0.04 b | 1.40 ± 0.01 ab | 1.27 ± 0.07 a | 1.35 ± 0.07 ab | 1.43 ± 0.06 c |

| Phenylalanine | 1.92 ± 0.05 b | 1.74 ± 0.07 a | 2.05 ± 0.05 b | 2.24 ± 0.08 c | 2.08 ± 0.03 c | 1.59 ± 0.06 a | 1.77 ± 0.06 b | 2.23 ± 0.03 d |

| Histidine | 1.07 ± 0.03 ab | 0.97 ± 0.06 a | 1.15 ± 0.04 bc | 1.20 ± 0.04 c | 1.16 ± 0.04 b | 0.85 ± 0.04 a | 0.940.06 a | 1.31 ± 0.05 c |

| Arginine | 3.09 ± 0.06 b | 2.84 ± 0.08 a | 3.13 ± 0.06 b | 3.52 ± 0.03 c | 3.23 ± 0.02 c | 2.52 ± 0.03 a | 2.93 ± 0.08 b | 3.51 ± 0.04 d |

| Valine | 1.51 ± 0.02 ab | 1.48 ± 0.03 a | 1.58 ± 0.03 b | 1.70 ± 0.05 c | 1.53 ± 0.03 b | 1.27 ± 0.02 a | 1.49 ± 0.05 b | 1.70 ± 0.03 c |

| EAA | 14.83 ± 0.05 b | 13.83 ± 0.28 a | 15.50 ± 0.01 c | 16.89 ± 0.09 d | 15.54 ± 0.03 c | 12.28 ± 0.03 a | 14.06 ± 0.07 b | 17.08 ± 0.10 d |

| Alanine | 1.29 ± 0.06 a | 1.28 ± 0.05 a | 1.37 ± 0.06 ab | 1.48 ± 0.03 b | 1.35 ± 0.03 b | 1.18 ± 0.02 a | 1.34 ± 0.05 b | 1.42 ± 0.04 b |

| Aspartic acid | 3.74 ± 0.04 ab | 3.66 ± 0.04 a | 3.86 ± 0.07 b | 4.22 ± 0.07 c | 3.67 ± 0.04 c | 3.26 ± 0.04 a | 3.54 ± 0.05 b | 4.14 ± 0.05 d |

| Glutamic acid | 5.70 ± 0.05 b | 5.51 ± 0.08 a | 5.75 ± 0.05 b | 6.16 ± 0.06 c | 5.33 ± 0.06 b | 4.69 ± 0.05 a | 5.41 ± 0.06 b | 6.14 ± 0.05 c |

| Glycine | 1.85 ± 0.20 a | 1.66 ± 0.06 a | 1.78 ± 0.03 a | 1.89 ± 0.05 a | 1.65 ± 0.04 ab | 1.51 ± 0.03 a | 1.69 ± 0.05 bc | 1.82 ± 0.07 c |

| Cystine | n.d | n.d | n.d | n.d | n.d | n.d | n.d | n.d |

| Proline | 2.46 ± 0.05 b | 2.13 ± 0.05 a | 2.52 ± 0.03 b | 2.84 ± 0.03 c | 2.62 ± 0.08 c | 2.01 ± 0.05 a | 2.34 ± 0.06 b | 2.95 ± 0.05 d |

| Serine | 2.17 ± 0.03 a | 2.14 ± 0.05 a | 2.25 ± 0.06 bc | 2.35 ± 0.08 c | 2.17 ± 0.04 b | 1.95 ± 0.05 a | 2.06 ± 0.06 ab | 2.30 ± 0.06 c |

| Tyrosine | 1.39 ± 0.02 ab | 1.35 ± 0.06 a | 1.42 ± 0.05 ab | 1.49 ± 0.06 b | 1.41 ± 0.10 b | 1.07 ± 0.09 a | 1.14 ± 0.06 a | 1.58 ± 0.06 b |

| NEAA | 18.59 ± 0.11 b | 17.73 ± 0.08 a | 18.96 ± 0.25 b | 20.44 ± 0.20 c | 18.24 ± 0.24 c | 15.69 ± 0.15 a | 17.49 ± 0.07 b | 19.86 ± 0.25 d |

| TAA | 33.42 ± 0.16 b | 31.56 ± 0.20 a | 34.46 ± 0.26 c | 37.33 ± 0.10 d | 33.88 ± 0.08 c | 27.86 ± 0.13 a | 31.72 ± 0.06 b | 37.42 ± 0.01 d |

| Fatty Acid (g/100 g) | NS Zlatka | NS Slatka | ||||||

|---|---|---|---|---|---|---|---|---|

| Whole Cake | >250 µm | 250–180 µm | <180 µm | Whole Cake | >250 µm | 250–180 µm | <180 µm | |

| C14:0 | 0.1 ± 0.01 | 0.1 ± 0.01 | 0.1 ± 0.00 | 0.1 ± 0.00 | 0.1 ± 0.01 | 0.1 ± 0.02 | 0.1 ± 0.00 | 0.1 ± 0.00 |

| C16:0 | 6.6 ± 0.01 a | 6.8 ± 0.00 b | 7.1 ± 0.04 c | 6.9 ± 0.07 b | 6.4 ± 0.02 a | 6.4 ± 0.04 a | 7.4 ± 0.01 b | 7.2 ± 0.22 b |

| C18:0 | 2.7 ± 0.02 | 2.7 ± 0.02 | 2.7 ± 0.03 | 2.7 ± 0.04 | 2.5 ± 0.01 | 2.5 ± 0.04 | 2.4 ± 0.02 | 2.6 ± 0.02 |

| C20:0 | 1.6 ± 0.03 | 1.6 ± 0.05 | 1.5 ± 0.03 | 1.6 ± 0.02 | 1.4 ± 0.04 ab | 1.5 ± 0.03 b | 1.3 ± 0.01 ab | 1.2 ± 0.01 a |

| SFA | 11.0 ± 0.00 a | 11.2 ± 0.04 b | 11.4 ± 0.04 c | 11.3 ± 0.08 bc | 10.4 ± 0.02 a | 10.4 ± 0.03 a | 11.2 ± 0.03 b | 11.1 ± 0.23 b |

| C16:1 | 0.2 ± 0.05 | 0.2 ± 0.06 | 0.2 ± 0.06 | 0.1 ± 0.00 | 0.2 ± 0.05 | 0.2 ± 0.05 | 0.2 ± 0.07 | 0.2 ± 0.04 |

| C18:1 n9 c | 13.8 ± 0.03 a | 13.8 ± 0.06 a | 14.9 ± 0.04 c | 14.3 ± 0.09 b | 13.8 ± 0.08 b | 13.6 ± 0.04 a | 15.1 ± 0.02 c | 15.9 ± 0.12 d |

| C20:1 n9 | 14.0 ± 0.77 | 14.1 ± 0.05 | 13.7 ± 0.46 | 14.4 ± 0.62 | 14.8 ± 0.02 c | 13.9 ± 0.50 ab | 13.6 ± 0.17 a | 14.6 ± 0.08 bc |

| MUFA | 31.2 ± 0.69 | 31.3 ± 0.13 | 31.7 ± 0.38 | 32.0 ± 0.48 | 31.8 ± 0.06 b | 30.8 ± 0.54 a | 31.4 ± 0.19 ab | 33.3 ± 0.00 c |

| C18:2 n6 c | 19.3 ± 0.01 a | 19.9 ± 0.06 b | 20.1 ± 0.05 c | 19.3 ± 0.09 a | 19.4 ± 0.14 a | 19.9 ± 0.07 b | 20.7 ± 0.03 d | 20.2 ± 0.11 c |

| C18:3 n3 | 35.0 ± 0.81 b | 34.0 ± 0.41 ab | 33.4 ± 0.39 a | 33.9 ± 0.39 ab | 34.9 ± 0.35 c | 35.4 ± 0.50 c | 33.6 ± 0.27 b | 32.4 ± 0.17 a |

| C20:2 n6 | 2.1 ± 0.00 | 2.1 ± 0.07 | 2.0 ± 0.00 | 2.0 ± 0.07 | 2.0 ± 0.03 b | 2.1 ± 0.05 b | 1.8 ± 0.02 a | 1.8 ± 0.12 a |

| C22:1 n9 | 3.3 ± 0.00 b | 3.3 ± 0.09 b | 3.0 ± 0.03 a | 3.2 ± 0.05 b | 3.0 ± 0.01 bc | 3.1 ± 0.04 c | 2.5 ± 0.07 a | 2.7 ± 0.24 ab |

| C20:3 n3 | 1.5 ± 0.13 | 1.5 ± 0.10 | 1.4 ± 0.09 | 1.5 ± 0.08 | 1.4 ± 0.10 | 1.4 ± 0.10 | 1.3 ± 0.01 | 1.3 ± 0.16 |

| PUFA | 57.8 ± 0.70 | 57.5 ± 0.18 | 56.9 ± 0.34 | 56.7 ± 0.40 | 57.7 ± 0.08 b | 58.8 ± 0.58 c | 57.4 ± 0.22 b | 55.6 ± 0.24 a |

| ω-3 PUFA | 36.5 ± 0.68 b | 35.5 ± 0.31 ab | 34.8 ± 0.30 a | 35.4 ± 0.31 ab | 36.3 ± 0.25 c | 36.8 ± 0.60 c | 34.8 ± 0.22 b | 33.7 ± 0.24 a |

| ω-6 PUFA | 21.4 ± 0.01 a | 22.0 ± 0.13 b | 22.1 ± 0.04 b | 21.4 ± 0.09 a | 21.4 ± 0.17 a | 22.0 ± 0.02 b | 22.6 ± 0.04 c | 22.0 ± 0.24 b |

| ω-6/ω-3 | 0.6 ± 0.01 | 0.6 ± 0.01 | 0.6 ± 0.00 | 0.6 ± 0.00 | 0.6 ± 0.01 a | 0.6 ± 0.01 a | 0.7 ± 0.01 b | 0.7 ± 0.01 b |

| Parameter, mg/kg | NS Zlatka | NS Slatka | ||||||

|---|---|---|---|---|---|---|---|---|

| Whole Cake | >250 µm | 250–180 µm | <180 µm | Whole Cake | >250 µm | 250–180 µm | <180 µm | |

| α-tocopherol | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

| β-tocopherol | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

| γ-tocopherol | 188.6 ± 1.84 a | 196.4 ± 3.54 a | 233.2 ± 4.95 b | 266.0 ± 12.30 c | 162.3 ± 11.10 b | 126.1 ± 8.13 a | 218.5 ± 8.06 c | 254.3 ± 5.80 d |

| Parameter | NS Zlatka | NS Slatka | ||||||

|---|---|---|---|---|---|---|---|---|

| Whole Cake | >250 µm | 250–180 µm | <180 µm | Whole Cake | >250 µm | 250–180 µm | <180 µm | |

| TPC (g GAE/100 g) | 0.58 ± 0.03 b | 0.52 ± 0.02 a | 0.55 ± 0.02 ab | 0.55 ± 0.04 ab | 0.51 ± 0.02 a | 0.53 ± 0.02 a | 0.51 ± 0.03 a | 0.52 ± 0.02 a |

| IC50 (μg/mL) | 80.3 ± 2.40 a | 108.2 ± 3.24 b | 91.9 ± 2.76 c | 122.4 ± 3.66 d | 123.4 ± 3.70 c | 83.4 ± 2.50 b | 101.9 ± 3.06 a | 104.9 ± 3.15 a |

| Parameter | NS Zlatka | NS Slatka | ||||||

|---|---|---|---|---|---|---|---|---|

| Whole Cake | >250 µm | 250–180 µm | <180 µm | Whole Cake | >250 µm | 250–180 µm | <180 µm | |

| L* | 70.5 ± 0.03 c | 50.9 ± 0.03 a | 69.0 ± 0.02 b | 78.1 ± 0.02 d | 69.9 ± 0.01 c | 51.2 ± 0.01 a | 61.9 ± 0.01 b | 76.8 ± 0.02 d |

| a* | 2.6 ± 0.03 b | 10.6 ± 0.01 d | 3.6 ± 0.02 c | −0.1 ± 0.02 a | 3.1 ± 0.02 b | 10.3 ± 0.02 d | 6.7 ± 0.03 c | 0.8 ± 0.02 a |

| b* | 28.4 ± 0.02 b | 26.7 ± 0.02 a | 29.5 ± 0.02 c | 31.0 ± 0.02 d | 28.2 ± 0.02 a | 27.5 ± 0.01 c | 28.6 ± 0.02 b | 31.3 ± 0.01 d |

| Parameter | NS Zlatka | NS Slatka | ||||||

|---|---|---|---|---|---|---|---|---|

| Whole Cake | >250 µm | 250–180 µm | <180 µm | Whole Cake | >250 µm | 250–180 µm | <180 µm | |

| WAC (g/g) | 9.31 c | 9.55 c | 8.48 b | 3.62 a | 8.85 b | 9.61 c | 8.36 b | 5.55 a |

| OAC (g/g) | 1.18 b | 1.34 b | 1.40 c | 0.99 a | 1.69 a | 1.48 a | 1.58 a | 1.64 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakita, S.; Spasevski, N.; Vidosavljević, S.; Tomičić, Z.; Savić, I.M.; Savić Gajić, I.M.; Đuragić, O.; Marjanović Jeromela, A. Valorization of Camelina Cake by Fractionation: Characterization of Nutritional and Functional Properties. Foods 2025, 14, 3437. https://doi.org/10.3390/foods14193437

Rakita S, Spasevski N, Vidosavljević S, Tomičić Z, Savić IM, Savić Gajić IM, Đuragić O, Marjanović Jeromela A. Valorization of Camelina Cake by Fractionation: Characterization of Nutritional and Functional Properties. Foods. 2025; 14(19):3437. https://doi.org/10.3390/foods14193437

Chicago/Turabian StyleRakita, Slađana, Nedeljka Spasevski, Strahinja Vidosavljević, Zorica Tomičić, Ivan M. Savić, Ivana M. Savić Gajić, Olivera Đuragić, and Ana Marjanović Jeromela. 2025. "Valorization of Camelina Cake by Fractionation: Characterization of Nutritional and Functional Properties" Foods 14, no. 19: 3437. https://doi.org/10.3390/foods14193437

APA StyleRakita, S., Spasevski, N., Vidosavljević, S., Tomičić, Z., Savić, I. M., Savić Gajić, I. M., Đuragić, O., & Marjanović Jeromela, A. (2025). Valorization of Camelina Cake by Fractionation: Characterization of Nutritional and Functional Properties. Foods, 14(19), 3437. https://doi.org/10.3390/foods14193437