Assessment of Quality and Environmental Impact of Artisanal Fresh Pasta Fortified with Agri-Food By-Products

Abstract

1. Introduction

2. Materials and Methods

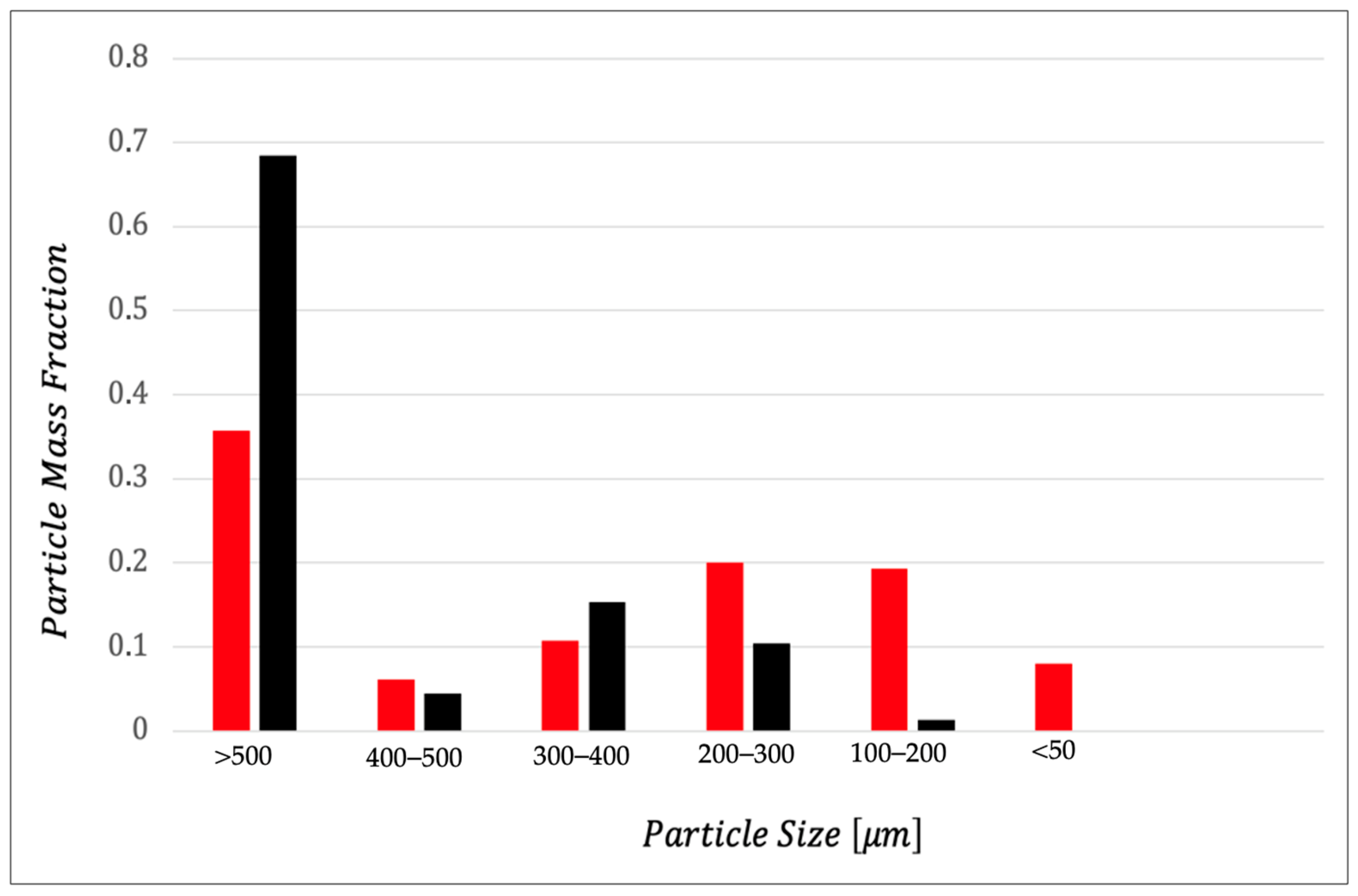

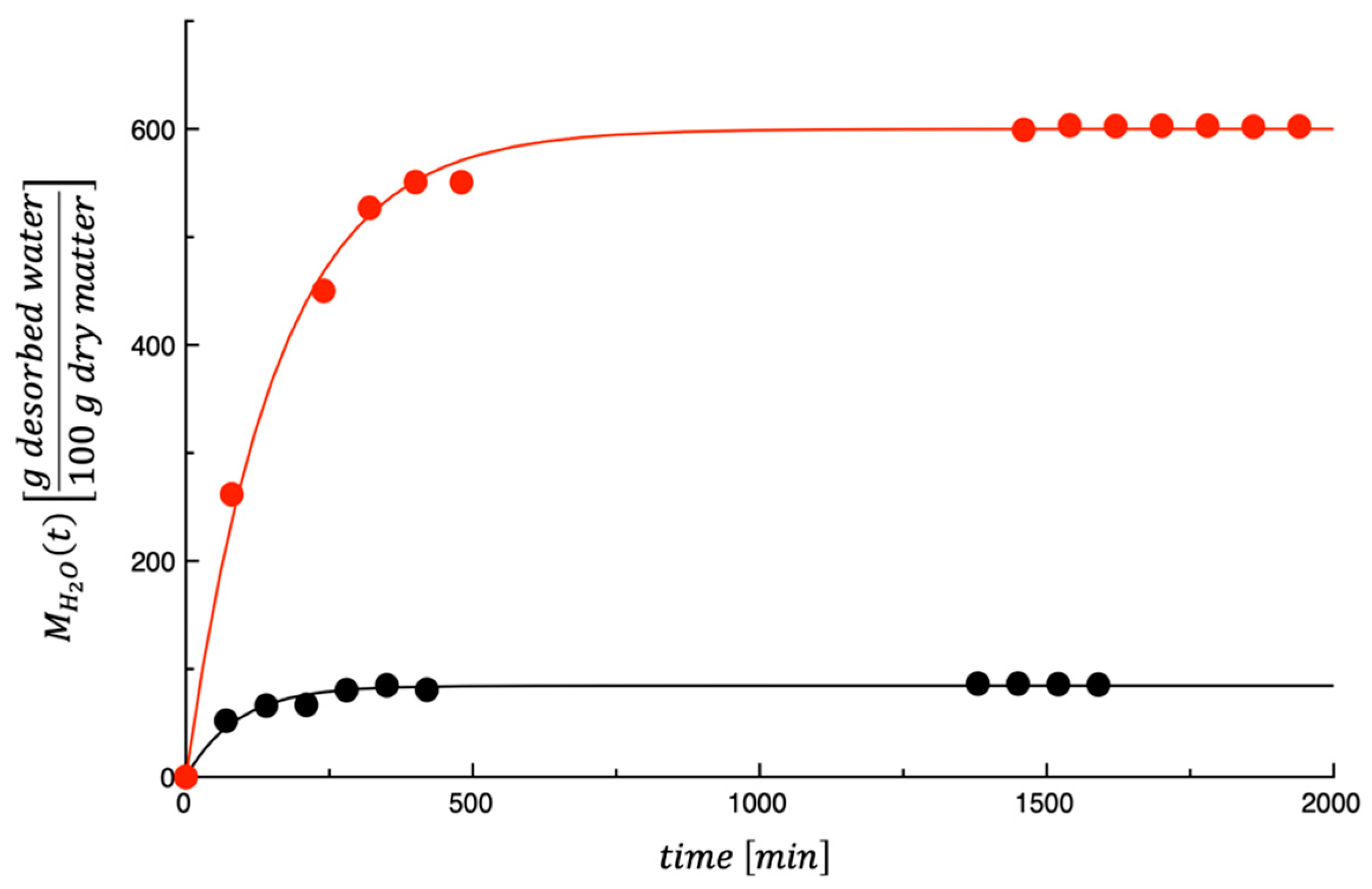

2.1. Raw Material Processing and Dehydration

2.2. Pasta Production

2.3. Sensory Analysis

2.4. Technological Analyses

2.5. Chemical Analyses

2.6. Fiber Content

2.7. Energy Consumption for the By-Product Dehydration Process

2.8. Environmental Impact Measurement

2.9. Global Quality Index Calculation

2.10. Statistical Analysis

3. Results and Discussion

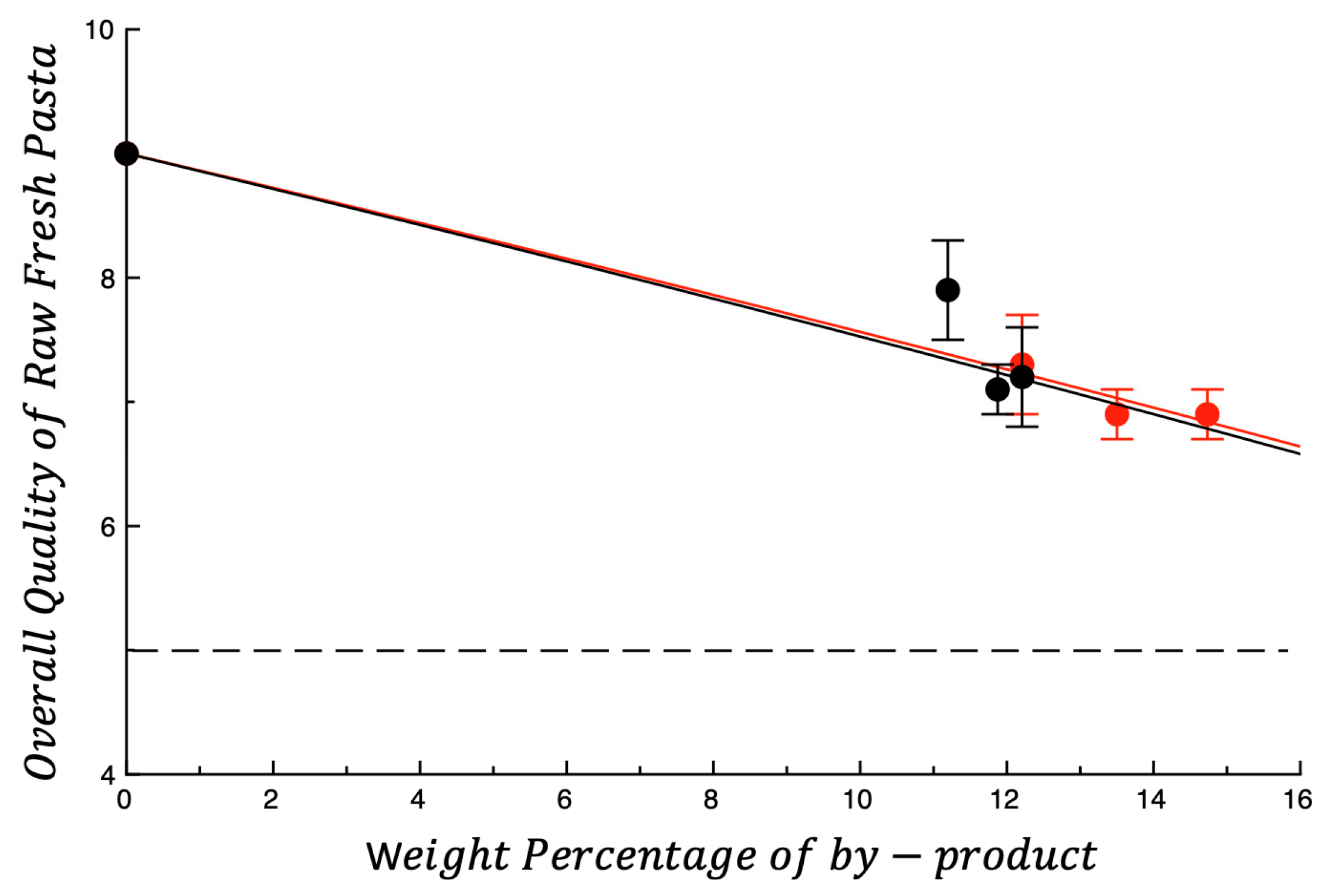

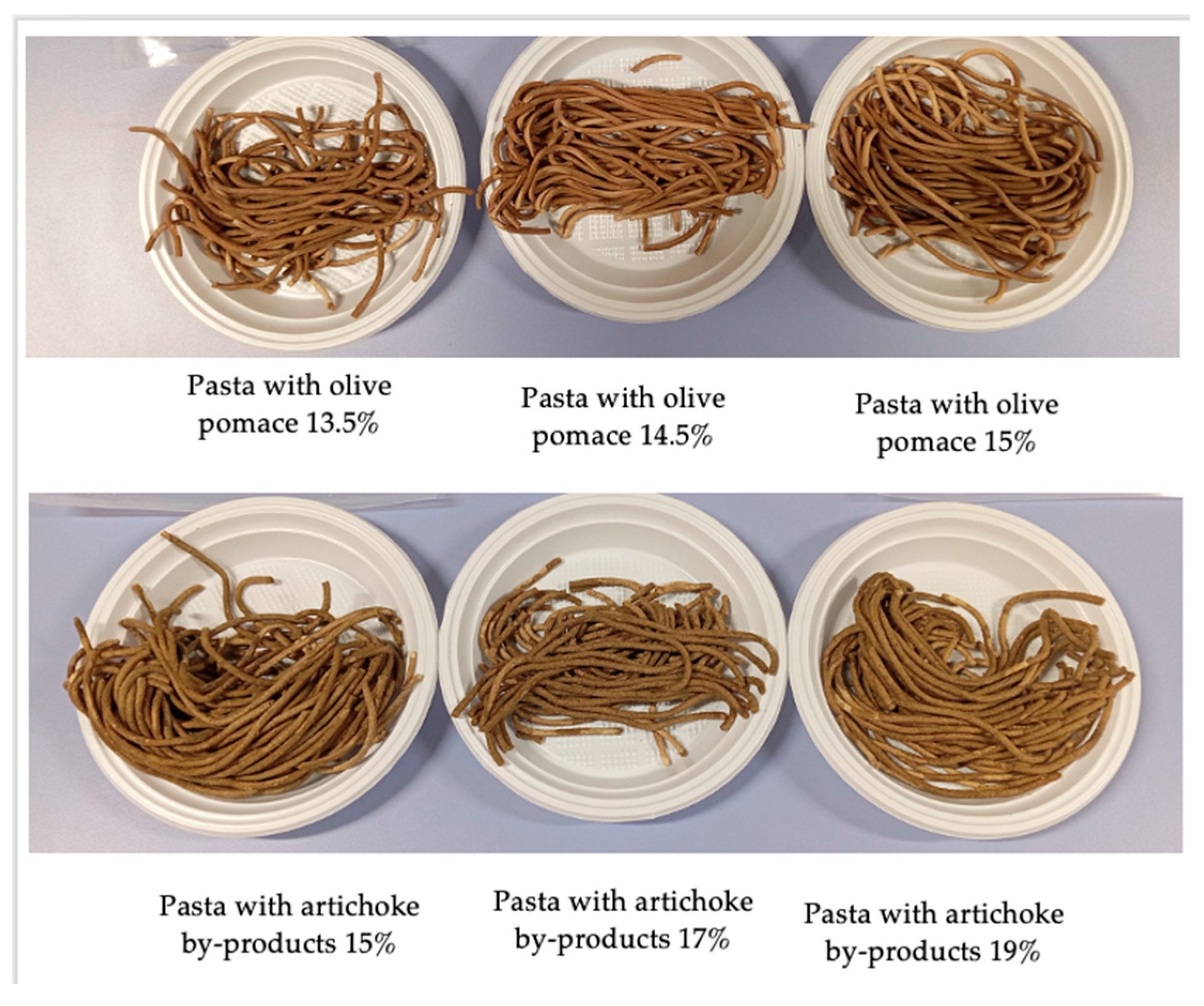

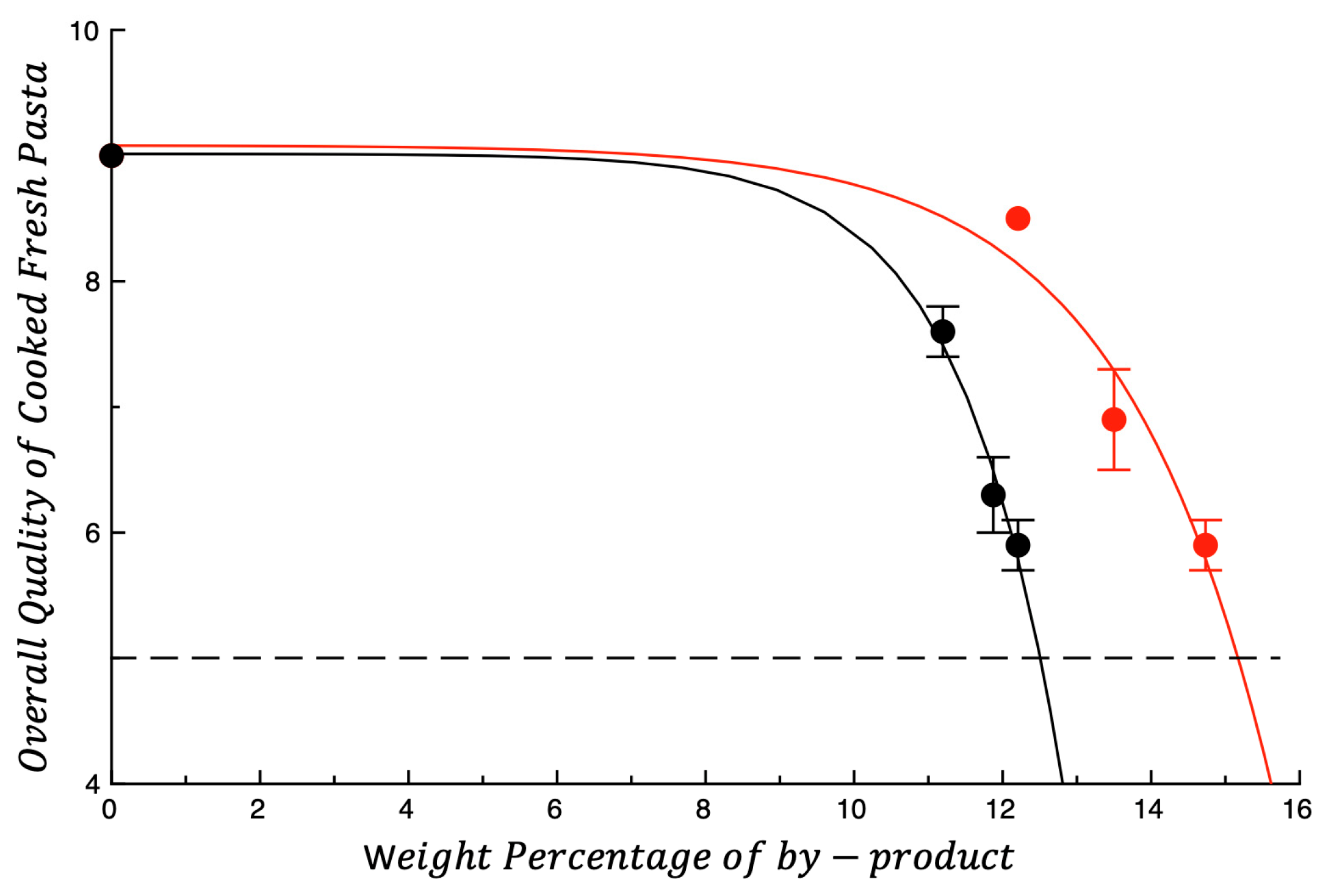

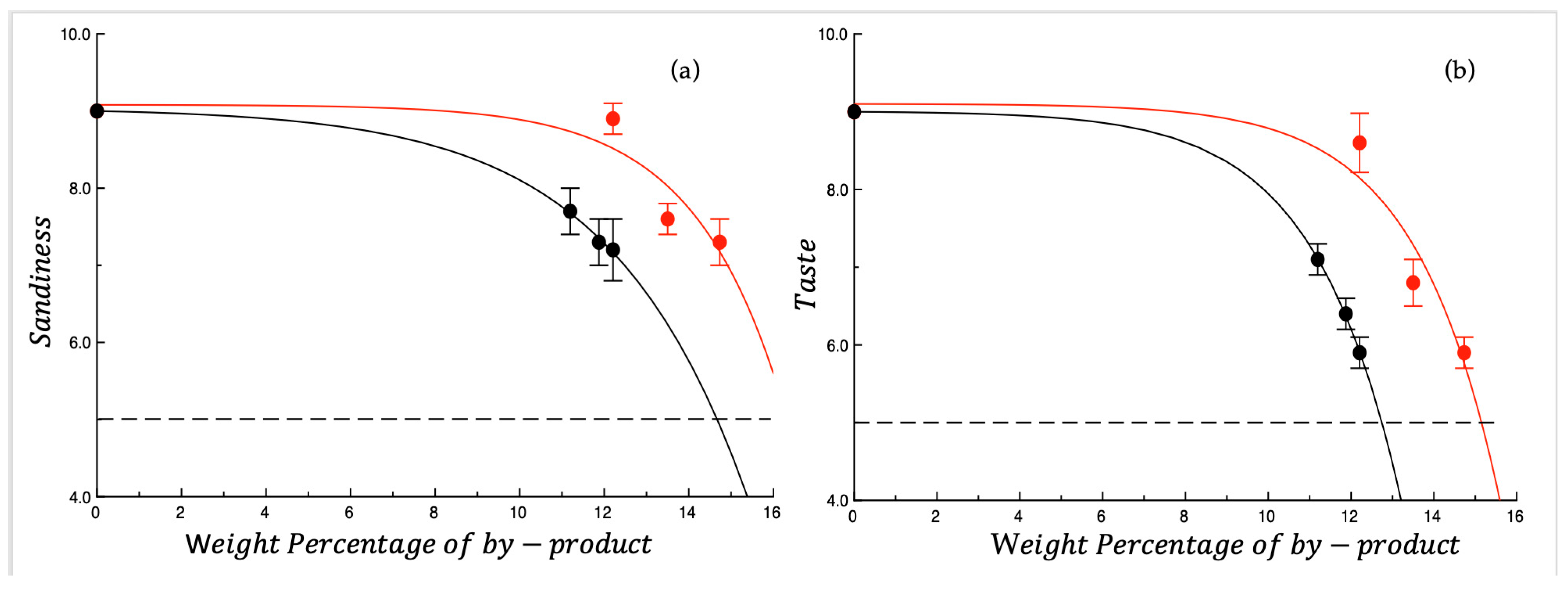

3.1. Effect of Fortification on Sensory Quality of Fresh Pasta

3.2. Effect of Fortification on Technological Quality of Fresh Pasta

3.3. Effect of Fortification on Nutritional Quality of Fresh Pasta

3.4. Energy Consumption of By-Product Dehydration Process

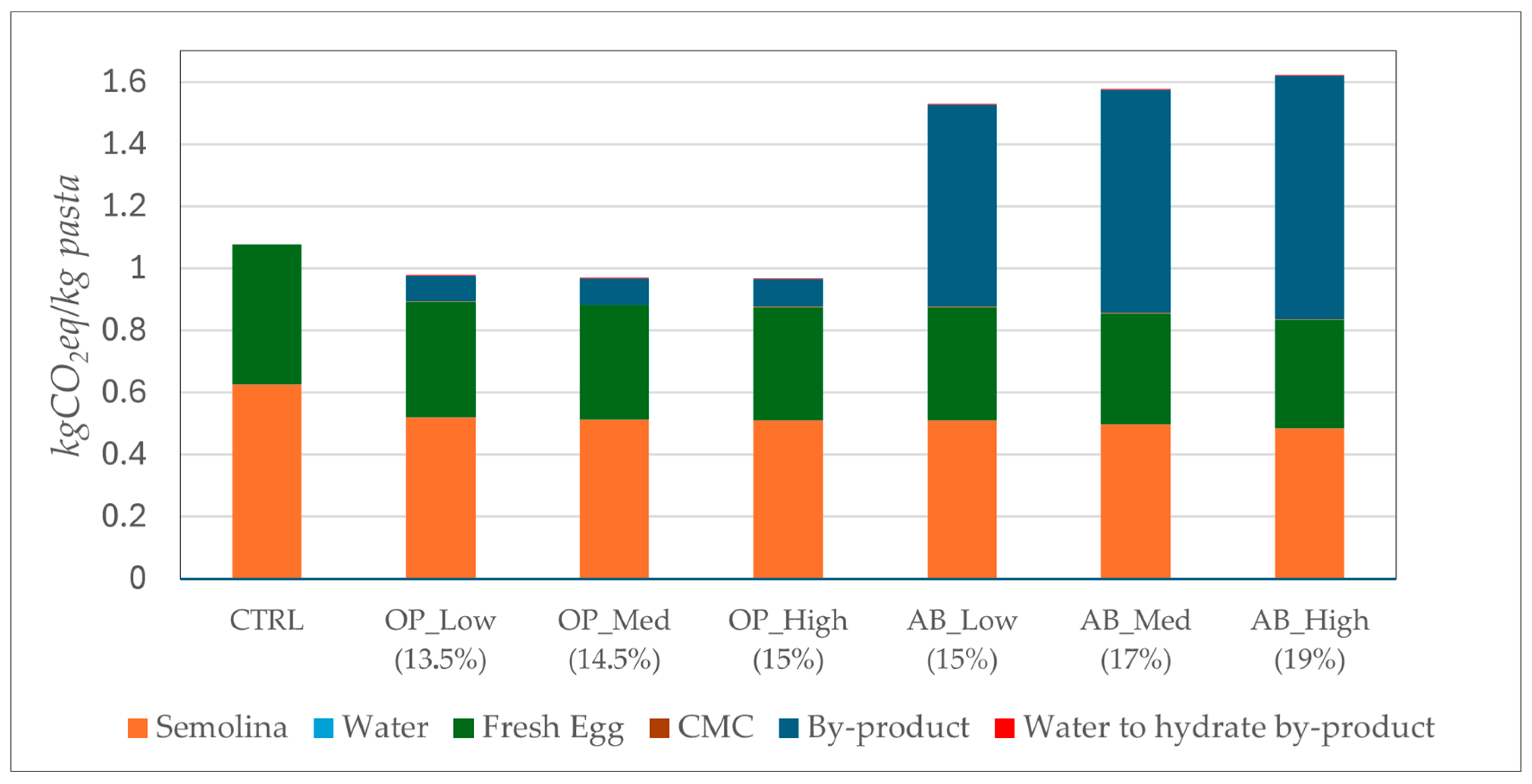

3.5. Environmental Impact

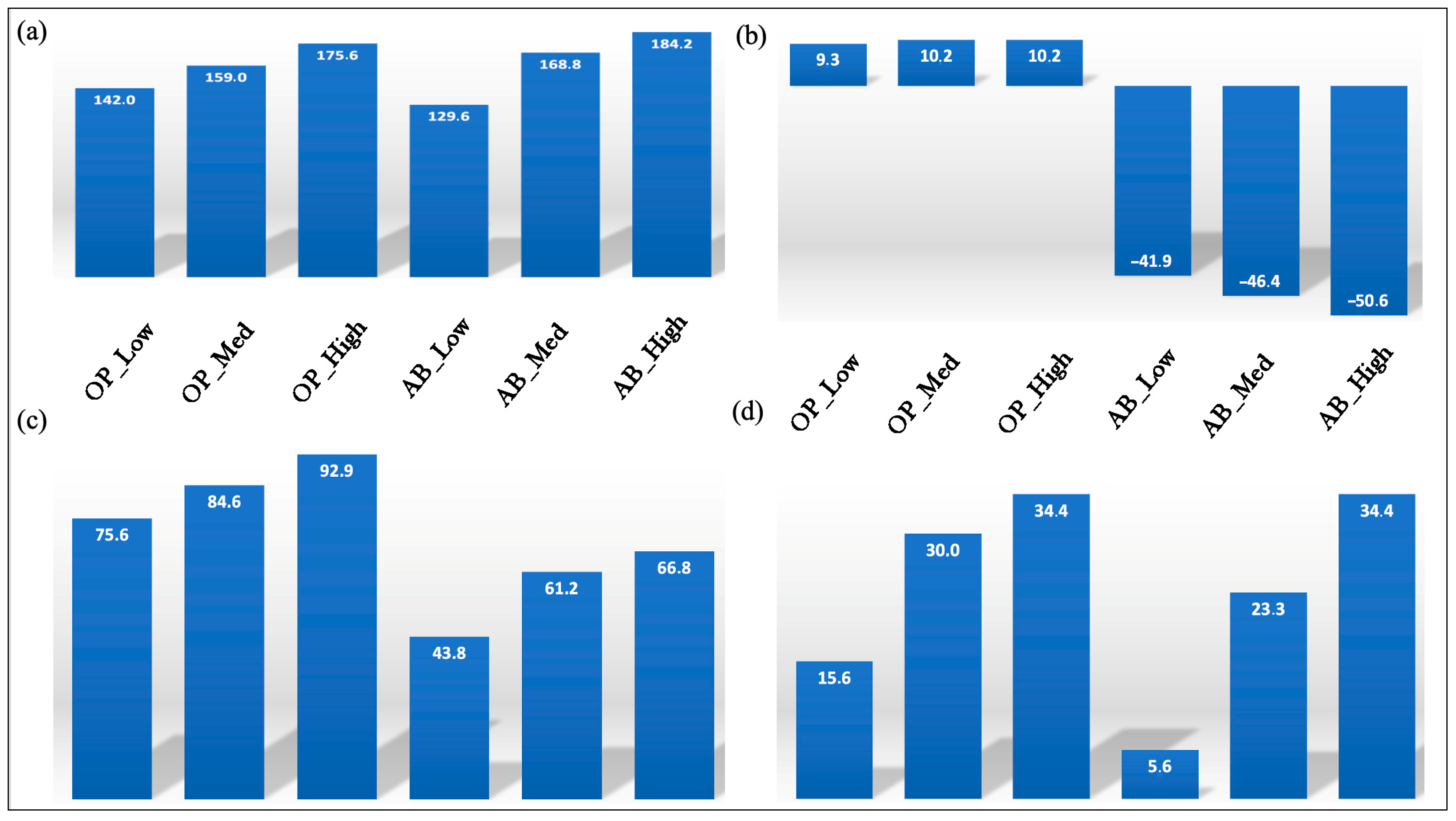

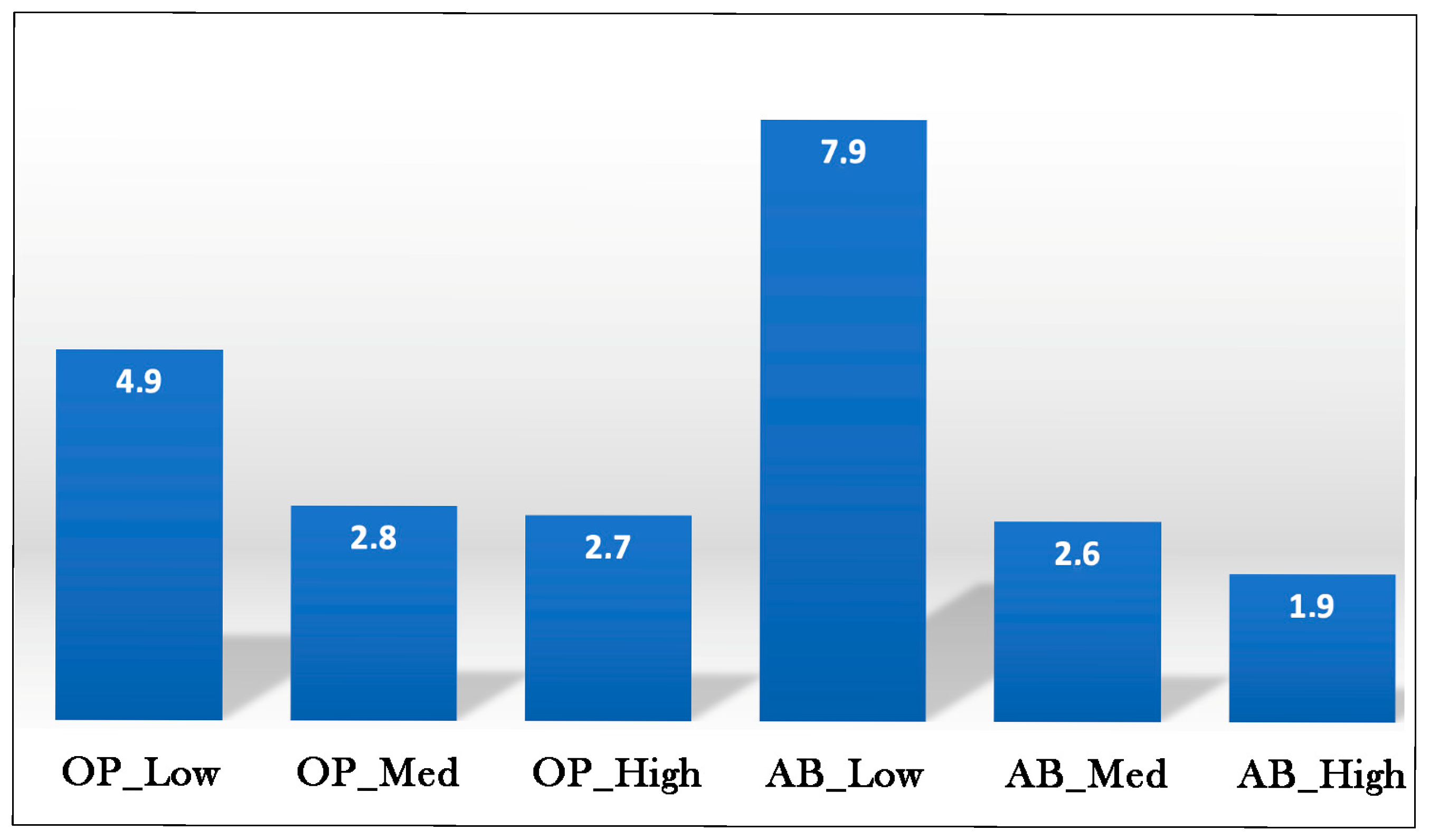

3.6. Global Quality Index

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thevarajah, B.; Nimarshana, P.H.V.; Sandeepa, G.D.S.; Boopathy, R.; Ariyadasa, T.U. Upcycling food processing industrial wastes in Spirulina cultivation: A perspective on the advancement of Sustainable Development Goal 12. Trends Food Sci. Technol. 2024, 149, 104537. [Google Scholar] [CrossRef]

- Masiala, A.; Vingadassalon, A.S.; Lemoyne, E.; Pejcz, A.; Wojciechowicz-Budzisz, R.; Olędzki, J.; Harasym, S. Sustainable Valorization of Breadfruit (Artocarpus altilis leaves) as a Pasta Ingredient. Sustainability 2024, 16, 11030. [Google Scholar] [CrossRef]

- Xu, M.; Yang, M.; Sun, H.; Gao, M.; Wang, Q.; Wu, C. Bioconversion of biowaste into renewable energy and resources: A sustainable strategy. Environ. Res. 2022, 214, 113929. [Google Scholar] [CrossRef] [PubMed]

- Sagar, N.A.; Pareek, S.; Sharma, S.; Yahia, E.M.; Lobo, M.G. Fruit and vegetable waste: Bioactive compounds, their extraction, and possible utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef]

- Okuthe, G. Valorizing fruit and vegetable waste: The untapped potential for entrepreneurship in sub-Saharan Africa—A systematic review. Recycling 2024, 9, 40. [Google Scholar] [CrossRef]

- Majerska, J.; Michalska, A.; Figiel, A. A review of new directions in managing fruit and vegetable processing by-products. Trends Food Sci. Technol. 2019, 88, 207–219. [Google Scholar] [CrossRef]

- Reguengo, L.M.; Salgaço, M.K.; Sivieri, K.; Marostica Júnior, M.R. Agro-industrial by-products: Valuable sources of bioactive compounds. Food Res. Int. 2022, 152, 110871. [Google Scholar] [CrossRef]

- López-Salas, L.; Borrás-Linares, I.; Quintin, D.; García-Gomez, P.; Giménez-Martínez, R.; Segura-Carretero, A.; Lozano-Sánchez, J. Artichoke by-products as natural source of phenolic food ingredient. Appl. Sci. 2021, 11, 3788. [Google Scholar] [CrossRef]

- F.A.O.S.T.A.T. Food and Agriculture Organization of the United Nations. Crops Statistics. 2023. Available online: http://www.fao.org (accessed on 20 May 2025).

- Tortosa-Díaz, L.; Saura-Martínez, J.; Taboada-Rodríguez, A.; Martínez-Hernández, G.B.; López-Gómez, A.; Marín-Iniesta, F. Influence of Industrial Processing of Artichoke and By-Products on The Bioactive and Nutritional Compounds. Food Eng. Rev. 2025, 17, 384–407. [Google Scholar] [CrossRef]

- Amoriello, T.; Mellara, F.; Ruggeri, S.; Ciorba, R.; Ceccarelli, D.; Ciccoritti, R. Artichoke by-products valorization for phenols-enriched fresh egg pasta: A sustainable food design project. Sustainability 2022, 14, 14778. [Google Scholar] [CrossRef]

- Quintero Ruiz, N.A.; Paolucci, M.; Siano, F.; Mamone, G.; Picariello, G.; Puppo, M.C.; Cascone, G.; Volpe, M.G. Characterization of soluble and insoluble fibers in artichoke by-products by ATR-FTIR spectroscopy coupled with chemometrics. Int. J. Food Prop. 2021, 24, 1693–1704. [Google Scholar] [CrossRef]

- Cannas, M.; Conte, P.; Urgeghe, P.P.; Piga, A.; Alañón, M.E.; Del Caro, A. Artichoke by-products: Promising ingredients for breadstick fortification. LWT 2024, 202, 116307. [Google Scholar] [CrossRef]

- Borsini, A.A.; Llavata, B.; Umaña, M.; Cárcel, J.A. Artichoke by products as a source of antioxidant and fiber: How it can be affected by drying temperature. Foods 2021, 10, 459. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Fernández, M.; Irigoyen, A.; de los Angeles Vargas-Alvarez, M.; Ludwig, I.A.; De Pena, M.P.; Cid, C. Influence of culinary process on free and bound (poly) phenolic compounds and antioxidant capacity of artichokes. Int. J. Gastron. Food Sci. 2021, 25, 100389. [Google Scholar] [CrossRef]

- Claus, T.; Maruyama, S.A.; Palombini, S.V.; Montanher, P.F.; Bonafé, E.G.; de Oliveira Santos Junior, O.; Matsushita, M.; Visentainer, J.V. Chemical characterization and use of artichoke parts for protection from oxidative stress in canola oil. LWT Food Sci. Technol. 2015, 61, 346–351. [Google Scholar] [CrossRef]

- Larrosa, M.; Llorach, R.; Espín, J.C.; Tomás-Barberán, F.A. Increase of antioxidant activity of tomato juice upon functionalisation with vegetable byproduct extracts. LWT 2002, 35, 532–542. [Google Scholar] [CrossRef]

- Umaña, M.; Wawrzyniak, P.; Rosselló, C.; Llavata, B.; Simal, S. Evaluation of the addition of artichoke by-products to O/W emulsions for oil microencapsulation by spray drying. LWT 2021, 151, 112146. [Google Scholar] [CrossRef]

- Bravo Bolívar, M.S.; Pasini, F.; Marzocchi, S.; Ravagli, C.; Tedeschi, P. Future perspective and technological innovation in cheese making using artichoke (Cynara scolymus) as vegetable rennet: A review. Foods 2023, 12, 3032. [Google Scholar] [CrossRef]

- Boubaker, M.; Omri, A.E.; Blecker, C.; Bouzouita, N. Fibre concentrates from artichoke (Cynara scolymus L.) stem by-products: Characterization and application as a bakery product ingredient. Food Sci. Technol. Int. 2016, 22, 759–768. [Google Scholar] [CrossRef]

- Canale, M.; Spina, A.; Summo, C.; Strano, M.C.; Bizzini, M.; Allegra, M.; Sanfilippo, R.; Amenta, M.; Pasqualone, A. Waste from artichoke processing industry: Reuse in bread-making and evaluation of the physico-chemical characteristics of the final product. Plants 2022, 11, 3409. [Google Scholar] [CrossRef]

- Ribeiro, T.B.; Oliveira, A.L.; Costa, C.; Nunes, J.; Vicente, A.A.; Pintado, M. Total and sustainable valorisation of olive pomace using a fractionation approach. Appl. Sci. 2020, 10, 6785. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; Gonzálvez, J.; Garcıa, D.; Cegarra, J. Agrochemical characterization of “alperujo”, a solid by-product of the two-phase centrifugation method for olive oil extraction. Bioresour. Technol. 2004, 91, 195–200. [Google Scholar] [CrossRef] [PubMed]

- Gullon, P.; Gullon, B.; Astray, G.; Carpena, M.; Fraga-Corral, M.; Prieto, M.A.; Simal-Gandara, J. Valorization of by-products from olive oil industry and added-value applications for innovative functional foods. Food Res. Int. 2020, 137, 109683. [Google Scholar] [CrossRef] [PubMed]

- Abd-ElGhany, M.E.; Ammar, M.S.; Hegazy, A.E. Use of olive waste cake extract as a natural antioxidant for improving the stability of heated sunflower oil. World Appl. Sci. J. 2010, 11, 106–113. [Google Scholar]

- Di Nunzio, M.; Picone, G.; Pasini, F.; Chiarello, E.; Caboni, M.F.; Capozzi, F.; Gianotti, A.; Bordoni, A. Olive oil by-product as functional ingredient in bakery products. Influence of processing and evaluation of biological effects. Food Res. Int. 2020, 131, 108940. [Google Scholar] [CrossRef]

- Simonato, B.; Trevisan, S.; Tolve, R.; Favati, F.; Pasini, G. Pasta fortification with olive pomace: Effects on the technological characteristics and nutritional properties. LWT 2019, 114, 108368. [Google Scholar] [CrossRef]

- Aliakbarian, B.; Casale, M.; Paini, M.; Casazza, A.A.; Lanteri, S.; Perego, P. Production of a novel fermented milk fortified with natural antioxidants and its analysis by NIR spectroscopy. LWT 2015, 62, 376–383. [Google Scholar] [CrossRef]

- Muíño, I.; Díaz, M.T.; Apeleo, E.; Pérez-Santaescolástica, C.; Rivas-Cañedo, A.; Pérez, C.; Cañeque, V.; Lauzurica, S.; de la Fuente, J. Valorization of an extract from olive oil waste as a natural antioxidant for reducing meat waste resulting from oxidative processes. J. Clean. Prod. 2017, 140, 924–932. [Google Scholar] [CrossRef]

- Sucu, E.; Akbay, K.C.; Şengül, Ö.; Yavuz, M.T.; Ak, İ. Effects of stoned olive pomace on carcass characteristics and meat quality of lambs. Turk. J. Vet. Anim. Sci. 2018, 42, 533–542. [Google Scholar] [CrossRef]

- Perito, M.A.; Di Fonzo, A.; Sansone, M.; Russo, C. Consumer acceptance of food obtained from olive by-products: A survey of Italian consumers. Br. Food J. 2020, 122, 212–226. [Google Scholar] [CrossRef]

- Conte, A.; Lordi, A.; Del Nobile, M.A. Dehydration of tomato peels and seeds as affected by the temperature. Int. J. Food Sci. Technol. 2024, 59, 7325–7333. [Google Scholar] [CrossRef]

- Martín-Esparza, M.E.; Raigón, M.D.; García-Martínez, M.D.; Albors, A. Role of hydrocolloids in the structure, cooking, and nutritional properties of fiber-enriched, fresh egg pasta based on tiger nut flour and durum wheat semolina. Foods 2021, 10, 2510. [Google Scholar] [CrossRef] [PubMed]

- AACC. Approved Methods of the American Association of Cereal Chemists, (Method 66-50), 10th ed.; AACC/Eagan Press: St. Paul, MN, USA, 2000; Volume 1. [Google Scholar]

- Panza, O.; Conte, A.; Del Nobile, M.A. Recycling of fig peels to enhance the quality of handmade pasta. LWT 2022, 168, 113872. [Google Scholar] [CrossRef]

- Natrella, G.; Miccolis, M.; Caponio, G.R.; Di Michele, A.; Zago, L.; Di Mattia, C.; Difonzo, G. Physicochemical and Nutritional Properties of Functional Fresh Pasta with Free and Microencapsulated Olive Pomace Extract. Food Front. 2025, 6, 2035–2051. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- AOAC 985.29-1986; Total Dietary Fiber in Foods. Enzymatic-Gravimetric Method. AOAC International: Rockville, MA, USA, 2003.

- Le Rose, A.; Panza, O.; Caro, D.; Conte, A.; Del Nobile, M.A. Cheesecake Customized Using Juice and By-Products from Prickly Pears: A Case Study of Recycling and Environmental Impact Evaluation. Foods 2025, 14, 1159. [Google Scholar] [CrossRef]

- Panza, O.; Del Nobile, M.A.; Conte, A. The optimization of the dehydration temperature of peels from prickly pears. Foods 2025, 14, 811. [Google Scholar] [CrossRef]

- EN ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- EN ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Arzoumanidis, I.; D’Eusanio, M.; Raggi, A.; Petti, L. Functional unit definition criteria in life cycle assessment and social life cycle assessment: A discussion. In Perspectives on Social LCA: Contributions from the 6th International Conference; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–10. [Google Scholar]

- Environdec. Environmental Product Declaration: Pasta di Semola Agnesi. 2022. Available online: https://api.environdec.com/api/v1/EPDLibrary/Files/f53689a9-89dc-405c-9b45-08da3d5507cb/Data (accessed on 4 July 2025).

- Leinonen, I.; Williams, A.G.; Wiseman, J.; Guy, J.; Kyriazakis, I. Predicting the environmental impacts of chicken systems in the United Kingdom through a life cycle assessment: Broiler production systems. Poult. Sci. 2012, 91, 8–25. [Google Scholar] [CrossRef]

- Guillaume, A.; Hubatová-Vacková, A.; Kočí, V. Environmental impacts of egg production from a life cycle perspective. Agriculture 2022, 12, 355. [Google Scholar] [CrossRef]

- Ecoinvent. Ecoinvent Database Version 3. 2024. Available online: https://ecoinvent.org/database/ (accessed on 4 July 2025).

- Caro, D. Carbon Footprint. In Encyclopedia of Ecology; Elsevier: Amsterdam, The Netherlands, 2019; Volume 4, pp. 252–257. [Google Scholar]

- Lordi, A.; Caro, D.; Le Rose, A.; Del Nobile, M.A.; Conte, A. Quality and environmental impact of meat burgers fortified with tomato by-products. LWT 2025, 229, 118182. [Google Scholar] [CrossRef]

- Zhou, Y.; Dhital, S.; Zhao, C.; Ye, F.; Chen, J.; Zhao, G. Dietary fiber-gluten protein interaction in wheat flour dough: Analysis, consequences and proposed mechanisms. Food Hydrocoll. 2021, 111, 10620. [Google Scholar] [CrossRef]

- Minarovičová, L.; Lauková, M.; Kohajdová, Z.; Karovičová, J.; Dobrovická, D.; Kuchtová, V. Qualitative Properties of Pasta Enriched with Celery Root and Sugar Beet By-Products. Czech J. Food Sci. 2018, 36, 66–72. [Google Scholar] [CrossRef]

- Romano, A.; Ferranti, P.; Gallo, V.; Masi, P. New ingredients and alternatives to durum wheat semolina for a high quality dried pasta. Curr. Opin. Food Sci. 2021, 41, 249–259. [Google Scholar] [CrossRef]

- Li, M.; Yue, Q.; Liu, C.; Zheng, X.; Hong, J.; Wang, N.; Bian, K. Interaction between gliadin/glutenin and starch granules in dough during mixing. LWT 2021, 148, 111624. [Google Scholar] [CrossRef]

- Cecchi, L.; Schuster, N.; Flynn, D.; Bechtel, R.; Bellumori, M.; Innocenti, M.; Mulinacci, N.; Guinard, J.X. Sensory profiling and consumer acceptance of pasta, bread, and granola bar fortified with dried olive pomace (pâté): A byproduct from virgin olive oil production. J. Food Sci. 2019, 84, 2995–3008. [Google Scholar] [CrossRef]

- Difonzo, G.; Troilo, M.; Squeo, G.; Pasqualone, A.; Caponio, F. Functional compounds from olive pomace to obtain high-added value foods—A review. J. Sci. Food Agric. 2021, 101, 15–26. [Google Scholar] [CrossRef]

- Troilo, M.; Difonzo, G.; Paradiso, V.M.; Pasqualone, A.; Caponio, F. Grape pomace as innovative flour for the formulation of functional muffins: How particle size affects the nutritional, textural and sensory properties. Foods 2022, 11, 1799. [Google Scholar] [CrossRef]

- Jahanbakhshi, R.; Ansari, S. Physicochemical properties of sponge cake fortified by olive stone powder. J. Food Qual. 2020, 1493638. [Google Scholar] [CrossRef]

- Ferreira, D.M.; Oliveira, B.C.; Barbosa, C.; Costa, A.S.; Nunes, M.A.; Oliveira, M.B.P.; Alves, R.C. Pasta Incorporating Olive Pomace: Impact on Nutritional Composition and Consumer Acceptance of a Prototype. Foods 2024, 13, 2933. [Google Scholar] [CrossRef]

- Shiau, S.-Y.; Wu, T.-T.; Liu, Y.-L. Effect of the Amount and Particle Size of Wheat Fiber on Textural and Rheological Properties of Raw, Dried and Cooked Noodles. J. Food Qual. 2012, 35, 207–216. [Google Scholar] [CrossRef]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, nutritional and sensory properties of pasta fortified with agro-industrial by-products: A review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Tolve, R.; Pasini, G.; Vignale, F.; Favati, F.; Simonato, B. Effect of grape pomace addition on the technological, sensory, and nutritional properties of durum wheat pasta. Foods 2020, 9, 354. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Huang, J.; Mei, X.; Sui, Y.; Li, S.; Zhu, Z. Noncovalent conjugates of anthocyanins to wheat gluten: Unraveling their microstructure and physicochemical properties. Foods 2024, 13, 220. [Google Scholar] [CrossRef] [PubMed]

- Bavaro, A.R.; De Bellis, P.; Linsalata, V.; Rucci, S.; Predieri, S.; Cianciabella, M.; Tamburino, R.; Cardinali, A. Valorization of Artichoke Bracts in Pasta Enrichment: Impact on Nutritional, Technological, Antioxidant, and Sensorial Properties. Antioxidants 2025, 14, 475. [Google Scholar] [CrossRef]

- Michalak-Majewska, M.; Teterycz, D.; Muszyński, S.; Radzki, W.; Sykut-Domańska, E. Influence of onion skin powder on nutritional and quality attributes of wheat pasta. PLoS ONE 2020, 15, e0227942. [Google Scholar]

- Koca, I.; Tekguler, B.; Yilmaz, V.A.; Hasbay, I.; Koca, A.F. The use of grape, pomegranate and rosehip seed flours in Turkish noodle (erişte) production. J. Food Process. Preserv. 2018, 42, e13343. [Google Scholar]

- Shallan, M.A.; Ali, M.A.; Meshrf, W.A.; Marrez, D.A. In vitro antimicrobial, antioxidant and anticancer activities of globe artichoke (Cynara cardunculus var. scolymus L.) bracts and receptacles ethanolic extract. Biocatal. Agric. Biotechnol. 2020, 29, 101774. [Google Scholar] [CrossRef]

- Ayuso, P.; Quizhpe, J.; Rosell, M.D.L.A.; Peñalver, R.; Nieto, G. Bioactive compounds, health benefits and food applications of artichoke (Cynara scolymus L.) and artichoke by-products: A review. Appl. Sci. 2024, 14, 4940. [Google Scholar] [CrossRef]

- Loschi, F.; Zengin, G.; Zancato, M.; Ferrarese, I.; De Zordi, N.; Dall’Acqua, S.; Sut, S. Valorization of olive pomace from Veneto region: Oven-dried material for food, nutraceutical, and cosmetic application of the OLIVARE project. Process Biochem. 2024, 137, 153–163. [Google Scholar]

- Zicari, G.; Carraro, E.; Bonetta, S. The Regulation (EC) N. 1924/2006 of the European Parliament and of the Council of the 20 December 2006 on nutrition and health claims made no foods. Prog. Nutr. 2007, 9, 264–273. [Google Scholar]

- Baker, P.W.; Višnjevec, A.M.; Peeters, K.; Schwarzkopf, M.; Charlton, A. Valorization of waste olive pomace: Laboratory and pilot scale processing to extract dietary fibre. Clean. Circ. Bioeconomy 2023, 5, 100045. [Google Scholar]

- Balli, D.; Cecchi, L.; Innocenti, M.; Bellumori, M.; Mulinacci, N. Food by-products valorization: Grape pomace and olive pomace (pâté) as sources of phenolic compounds and fiber for enrichment of tagliatelle pasta. Food Chem. 2021, 355, 129642. [Google Scholar] [CrossRef]

- Buonocore, G.G.; Del Nobile, M.A.; Di Martino, C.; Gambacorta, G.; La Notte, E.; Nicolais, L. Modeling the water transport properties of casein-based edible coating. J. Food Eng. 2003, 60, 99–106. [Google Scholar] [CrossRef]

- Gómez-García, R.; Campos, D.A.; Aguilar, C.N.; Madureira, A.R.; Pintado, M. Valorization of food agro-industrial by-products: From the past to the present and perspectives. J. Environ. Manag. 2021, 299, 113571. [Google Scholar] [CrossRef]

OP = olive pomace;

OP = olive pomace;  AB = artichoke by-products.

AB = artichoke by-products.

OP = olive pomace;

OP = olive pomace;  AB = artichoke by-products.

AB = artichoke by-products.

| Samples | Semolina (g) | Distilled Water (g) | Fresh Egg (g) | CMC (g) | By-Product (g) | Water to Hydrate By-Product (g) |

|---|---|---|---|---|---|---|

| CTRL | 1035 | 270 | 195 | 0 | 0 | 0 |

| AB_Med | 1035 | 270 | 195 | 0.77 | 225 | 117 |

| AB_Low | 1035 | 270 | 195 | 0.80 | 255 | 133 |

| AB_High | 1035 | 270 | 195 | 0.83 | 285 | 148 |

| OP_Low | 1035 | 270 | 195 | 0.75 | 202 | 105 |

| OP_Med | 1035 | 270 | 195 | 0.76 | 217 | 113 |

| OP_High | 1035 | 270 | 195 | 0.77 | 225 | 117 |

| Samples | OCT (min) | Cooking Loss (%) | Swelling Index (g Water/g Dry Pasta) | Water Absorption (%) |

|---|---|---|---|---|

| AB_High | 13 | 4.54 ± 0.11 a | 1.84 ± 0.01 a | 65.47 ± 1.47 a |

| AB_Med | 12 | 4.33 ± 0.15 a | 1.82 ± 0.01 a | 63.05 ± 2.14 a |

| AB_Low | 11.30 | 4.32 ± 0.13 a | 1.81 ± 0.01 a | 59.87 ± 1.80 a,b |

| OP_High | 11.30 | 3.26 ± 0.09 b | 1.65 ± 0.09 b | 53.72 ± 4.23 b,c |

| OP_Med | 11.30 | 3.09 ± 0.05 b | 1.64 ± 0.08 b | 52.31 ± 0.91 c |

| OP_Low | 11 | 3.03 ± 0.24 b | 1.62 ± 0.01 b | 51.63 ± 0.47 c |

| CTRL | 9.30 | 2.37 ± 0.12 c | 1.55 ± 0.03 b | 50.44 ± 3.97 c |

| Powder Samples | Total Phenols (mg GAE/g dw) | Total Flavonoids (mg QE/g dw) | Antioxidant Activity (mg TE/g dw) | TDF (g/100 g) |

|---|---|---|---|---|

| OP | 38.38 ± 5.56 a | 35.64 ± 2.77 b | 30.48 ± 6.68 a | 59.6 ± 3.4 a |

| AB | 36.88 ± 3.50 a | 54.69 ± 4.25 a | 31.07 ± 3.01 a | 43.0 ± 2.4 b |

| Samples | Total Phenols (mg GAE/g dw) | Total Flavonoids (mg QE/g dw) | Antioxidant Activity (mg TE/g dw) | TDF (g/100 g) |

|---|---|---|---|---|

| CTRL | 1.76 ± 0.08 b | 1.39 ± 0.13 c | 0.88 ± 0.06 d | 3.10 ± 0.18 c |

| OP_Low | 2.76 ± 0.24 a | 2.07 ± 0.30 b | 1.20 ± 0.16 c | 10.60 ± 0.61 a |

| OP_Med | 2.99 ± 0.11 a | 2.57 ± 0.13 a,b | 1.24 ± 0.07 c | 11.50 ± 0.66 a |

| OP_High | 3.03 ± 0.03 a | 2.58 ± 0.20 a,b | 1.36 ± 0.07 c | 12.10± 0.70 a |

| AB_Low | 3.01 ± 0.25 a | 2.64 ± 0.50 a | 1.56 ± 0.08 b | 8.60 ± 0.50 b |

| AB_Med | 3.06 ± 0.28 a | 2.75 ± 0.32 a | 1.73 ± 0.08 a | 10.40 ± 0.60 a |

| AB_High | 3.17 ± 0.46 a | 2.80 ± 0.33 a | 1.77 ± 0.05 a | 11.20 ± 0.65 a |

| Parameters | OP | AB |

|---|---|---|

| 3.41 × 10−6 | 8.89 × 10−6 | |

| 0.938 | 3.79 | |

| 84.45 | 599.97 | |

| 1.49 × 10−2 | 1.44 × 10−2 | |

| 5.28 × 10−1 | 1.46 × 10−1 | |

| 6000 | 6000 | |

| Dehydration Kinetic | 4.11 | 1.66 |

| Energy Consumption | 3.14 | 1.73 |

| 1.83 × 10−3 | 1.34 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayub, M.; Le Rose, A.; Panza, O.; Caro, D.; Del Nobile, M.A.; Conte, A. Assessment of Quality and Environmental Impact of Artisanal Fresh Pasta Fortified with Agri-Food By-Products. Foods 2025, 14, 3379. https://doi.org/10.3390/foods14193379

Ayub M, Le Rose A, Panza O, Caro D, Del Nobile MA, Conte A. Assessment of Quality and Environmental Impact of Artisanal Fresh Pasta Fortified with Agri-Food By-Products. Foods. 2025; 14(19):3379. https://doi.org/10.3390/foods14193379

Chicago/Turabian StyleAyub, Manazza, Alessia Le Rose, Olimpia Panza, Dario Caro, Matteo Alessandro Del Nobile, and Amalia Conte. 2025. "Assessment of Quality and Environmental Impact of Artisanal Fresh Pasta Fortified with Agri-Food By-Products" Foods 14, no. 19: 3379. https://doi.org/10.3390/foods14193379

APA StyleAyub, M., Le Rose, A., Panza, O., Caro, D., Del Nobile, M. A., & Conte, A. (2025). Assessment of Quality and Environmental Impact of Artisanal Fresh Pasta Fortified with Agri-Food By-Products. Foods, 14(19), 3379. https://doi.org/10.3390/foods14193379