Investigation of Quality Enhancement Mechanisms in Tenobe Somen Noodles During Storage and Maturation

Abstract

1. Introduction

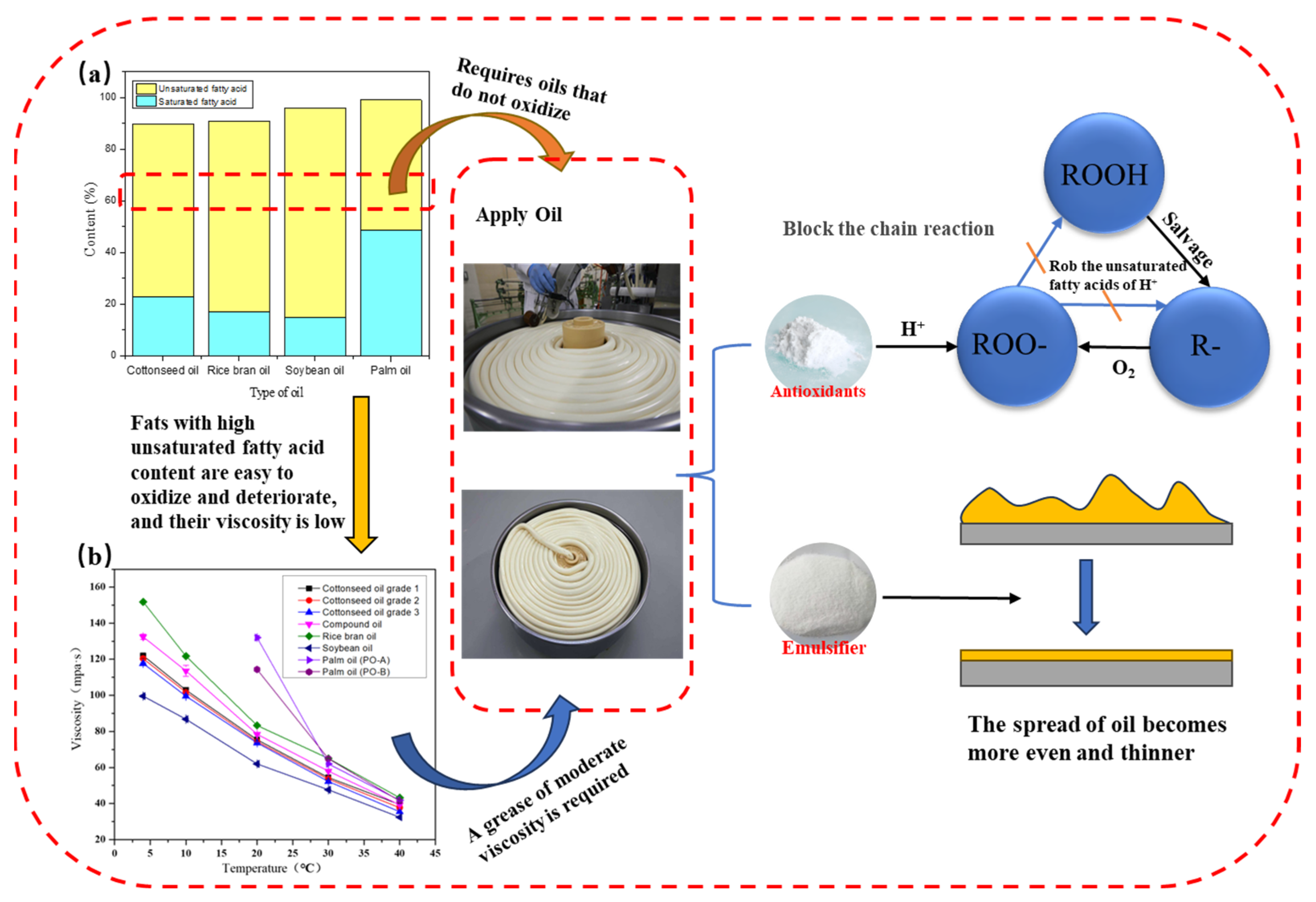

2. Optimizing Anti-Stick Oil Selection in Tenobe Somen Noodle Production

2.1. Stability of Different Oils

| Types of Oil | Palmitic Acid (%) | Stearic Acid (%) | Oleic Acid (%) | Linoleic Acid (%) | Linolenic Acid (%) | Other Fatty Acid Components (%) | References |

|---|---|---|---|---|---|---|---|

| Cottonseed oil | 20.80 | 2.10 | 16.10 | 50.70 | / | 10.30 | [33] |

| Rice bran oil | 14.97 | 1.93 | 40.85 | 31.42 | 1.65 | 9.18 | [34] |

| Soybean oil | 10.67 | 3.98 | 22.75 | 51.45 | 7.07 | 4.08 | [35] |

| Palm oil | 45.00 | 3.50 | 40.50 | 10.00 | / | 1.00 | [36] |

| Peanut oil | 12.60 | 5.14 | 42.24 | 31.37 | 0.11 | 8.54 | [37] |

| Rapeseed oil | 4.82 | 4.91 | 48.68 | 17.92 | 8.67 | 15.00 | [38] |

| Sesame oil | 7.86 | 5.25 | 39.10 | 45.50 | 0.26 | 2.03 | [39] |

| Corn oil | 13.76 | 2.21 | 29.67 | 51.70 | 1.02 | 1.64 | [40] |

| Tea seed oil | 11.92 | 2.95 | 83.19 | 0.08 | 0.45 | 1.41 | [41] |

| Olive oil | 13.50 | 4.46 | 72.71 | 6.07 | 0.72 | 2.54 | [42] |

| Sunflower oil | 7.97 | 4.87 | 22.54 | 62.18 | 0.20 | 2.24 | [43] |

2.2. Viscosity of Different Oils

2.3. Oil Adhesion on Noodle Surfaces

3. Quality Changes of Tenobe Somen Noodles During the Aging Period

3.1. Changes in the Basic Properties of Tenobe Somen Noodles During Maturation

3.2. Changes in Cooking Properties of Tenobe Somen Noodles During Maturation

3.3. Changes in the Edible Quality of Tenobe Somen Noodles During Maturation

4. Chemical Changes in Tenobe Somen Noodles During the Maturation Process

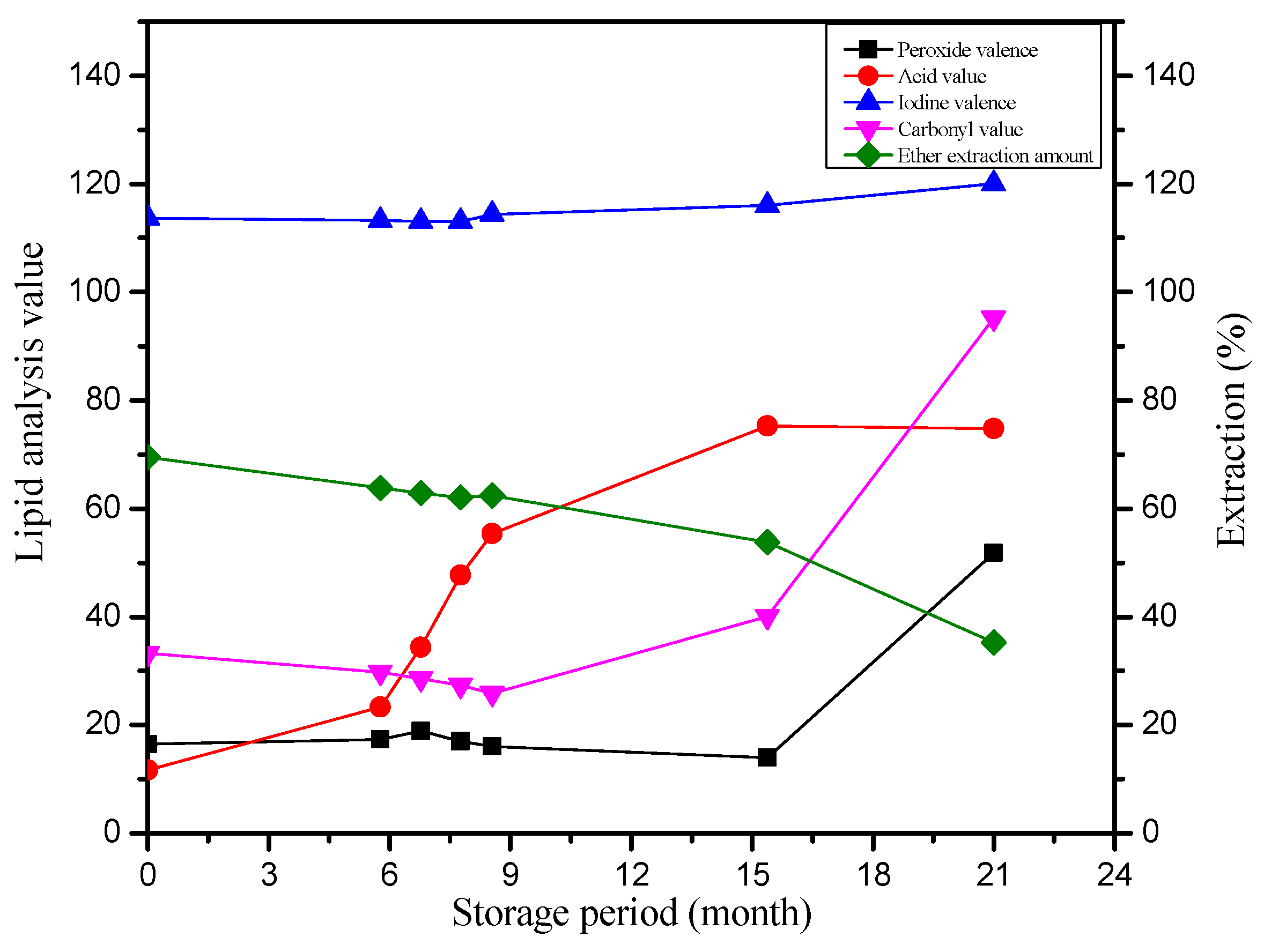

4.1. Lipids

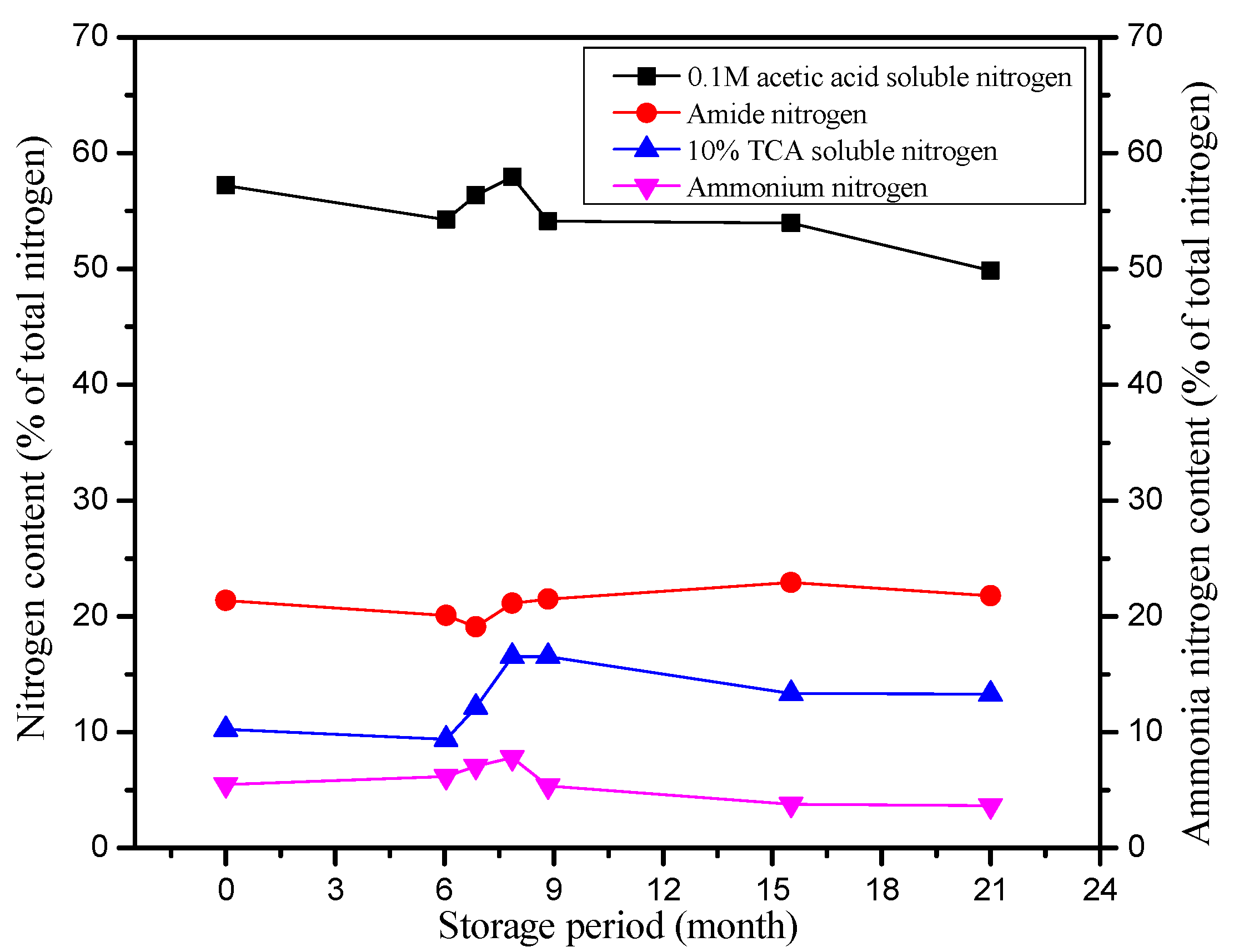

4.2. Proteins

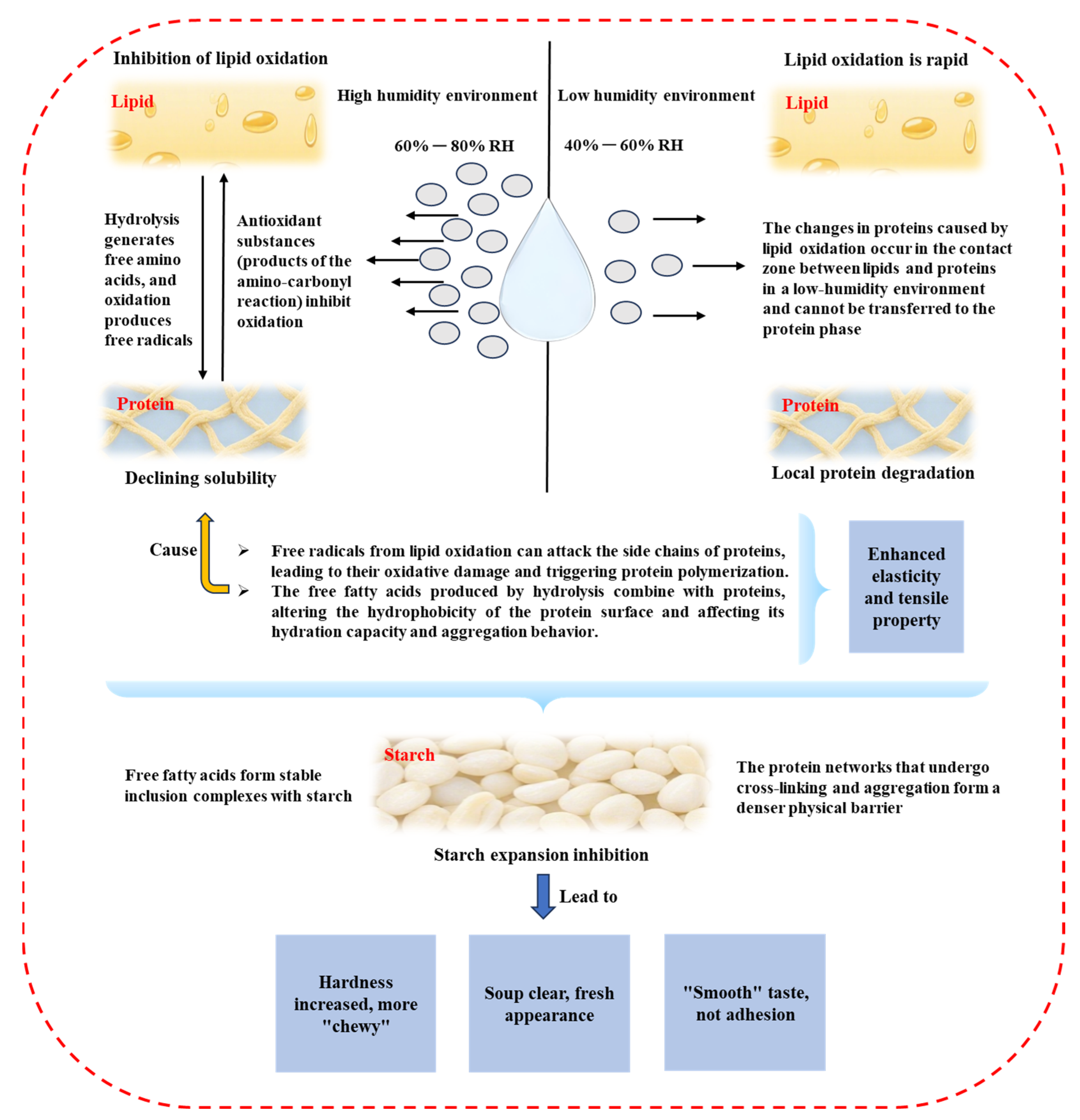

4.3. Starch Granule Swelling

5. Molecular Interactions Under Maturation Conditions in a Simulated System

5.1. Lipid Stability and Moisture

5.2. Protein Changes and Moisture in the Gluten–Lipid System

5.3. The Impact of Sugar Reduction on Tenobe Somen Noodles

6. Conclusions and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Katagiri, M.; Kitabatake, N. Rheological Properties of Somen Noodles—A Traditional Japanese Wheat Product. J. Food Sci. 2010, 75, E51–E58. [Google Scholar] [CrossRef] [PubMed]

- Gengo, O. Tenobe somen noodles. Sci. Cook. 1985, 18, 11–16. [Google Scholar] [CrossRef]

- Wang, J.R.; Guo, X.N.; Yang, Z.; Xing, J.J.; Zhu, K.X. Insight into the Relationship Between Quality Characteristics and Major Chemical Components of Chinese Traditional Hand-Stretched Dried Noodles: A Comparative Study. Food Bioprocess Technol. 2021, 14, 945–955. [Google Scholar] [CrossRef]

- Zhang, N.; Ma, G. Noodles, traditionally and today. J. Ethn. Foods 2016, 3, 209–212. [Google Scholar] [CrossRef]

- Lu, S. Qingdao Haikejia made a strong appearance at the 23rd China Convenience Food Conference. In Proceedings of the 23rd China Convenience Food Conference, Beijing, China, 4–6 September 2023. [Google Scholar]

- Qi, X.; Hong, T.; Nie, A.; Xu, D.; Jin, Y.; Xu, X.; Wu, F. Impacts of surfactin on the qualities and gluten network structure of fresh noodles during storage. Food Hydrocoll. 2023, 138, 108417. [Google Scholar] [CrossRef]

- Xu, N.; Shanbhag, A.G.; Li, B.; Angkuratipakorn, T.; Decker, E.A. Impact of Phospholipid–Tocopherol Combinations and Enzyme-Modified Lecithin on the Oxidative Stability of Bulk Oil. J. Agric. Food Chem. 2019, 67, 7954–7960. [Google Scholar] [CrossRef] [PubMed]

- Redondo-Cuevas, L.; Castellano, G.; Torrens, F.; Raikos, V. Revealing the relationship between vegetable oil composition and oxidative stability: A multifactorial approach. J. Food Compos. Anal. 2018, 66, 221–229. [Google Scholar] [CrossRef]

- Niihara, R.; Yonezawa, D. Change in Lipid Composition during “yaku” and its Effect on Texture of Cooked “Somen”. Nippon. Shokuhin Kagaku Kogaku Kaishi 1990, 37, 779–785. [Google Scholar] [CrossRef][Green Version]

- Qi, J.; Wang, X.; Wang, X.; Akoh, C.C.; Jin, Q. Effect of Oil Type and Emulsifier on Oil Absorption of Steam-and-fried Instant Noodles. J. Oleo Sci. 2019, 68, 559–566. [Google Scholar] [CrossRef]

- Niihara, R.; Nishida, Y.; Yonezawa, D. Changes of Gluten during Storage of Gluten-Lipid Mixture in Presence and Absence of Moisture. Nippon. Nōgeikagaku Kaishi 1973, 47, 825–832. [Google Scholar] [CrossRef][Green Version]

- Shimada, A.; Yazawa, E.; Yoshimatsu, F.; Kato, H.; Fujimaki, M. Rheological and Chemical Changes of Tenobe Somen (Handmade Fine Noodle) during Storage in the Warm Rainy Season. Nippon. Nōgeikagaku Kaishi 1979, 53, 5–11. [Google Scholar] [CrossRef]

- Niihara, R.; Yonezawa, D. Change of Amylase Activity by Yaku of Tenobe-somen and Its Influence on Heat-swelling of Wheat Starch. Nippon. Shokuhin Kogyo Gakkaishi 1983, 30, 624–628. [Google Scholar] [CrossRef]

- Nobuko, N.; Yoshito, S. On the Expansion and Softening Mechanisms of Freeze-Dried Tofu. Sci. Cook. 1971, 4, 150–155. [Google Scholar] [CrossRef]

- Ritsuko, N.; Daizo, Y. The Yaku of Tenobe Somen Noodles. Sci. Cook. 1974, 7, 134–140. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Obadi, M.; Jiang, Y.; Chen, Z.; Jiang, S.; Xu, B. Effect of steaming and defatting treatments of oats on the processing and eating quality of noodles with a high oat flour content. J. Cereal Sci. 2019, 89, 102794. [Google Scholar] [CrossRef]

- Rahimi, J.; Ngadi, M.O. Structure and irregularities of surface of fried batters studied by fractal dimension and lacunarity analysis. Food Struct. 2016, 9, 13–21. [Google Scholar] [CrossRef]

- Low, Y.K.; Effarizah, M.E.; Cheng, L.H. Factors Influencing Rice Noodles Qualities. Food Rev. Int. 2020, 36, 781–794. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, M.; Zhang, X.; Qu, Z.; Gao, Y.; Li, Q.; Yu, X. Mechanism, indexes, methods, challenges, and perspectives of edible oil oxidation analysis. Crit. Rev. Food Sci. Nutr. 2023, 63, 4901–4915. [Google Scholar] [CrossRef]

- Cao, H.; Xue, B.; Jiang, Y.; Han, X.; Shi, H.; Cao, W. Application of triacylglycerol polymer determination in the quality evaluation of vegetable oil. LWT-Food Sci. Technol. 2017, 82, 243–247. [Google Scholar] [CrossRef]

- Sui, X.; Wang, K.; Gluchowski, N.L.; Elliott, S.D.; Liao, M.; Walther, T.C.; Farese, R.V. Structure and catalytic mechanism of a human triacylglycerol-synthesis enzyme. Nature 2020, 581, 323–328. [Google Scholar] [CrossRef]

- Ghazali, H.M.; Tan, A.; Abdulkarim, S.M.; Dzulkifly, M.H. Oxidative stability of virgin coconut oil compared with RBD palm olein in deep-fat frying of fish crackers. J. Food Agric. Environ. 2009, 7, 23–27. [Google Scholar] [CrossRef]

- Mishra, S.K.; Belur, P.D.; Iyyaswami, R. Use of antioxidants for enhancing oxidative stability of bulk edible oils: A review. Int. J. Food Sci. Technol. 2021, 56, 1–12. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, Y.-L.; Zhao, F.; Xin, R.; Huang, X.-H.; Zhang, Y.-Y.; Zhou, D.; Qin, L. Unraveling the Thermal Oxidation Products and Peroxidation Mechanisms of Different Chemical Structures of Lipids: An Example of Molecules Containing Oleic Acid. J. Agric. Food Chem. 2022, 70, 16410–16423. [Google Scholar] [CrossRef]

- Nagy, K.; Iacob, B.-C.; Bodoki, E.; Oprean, R. Investigating the Thermal Stability of Omega Fatty Acid-Enriched Vegetable Oils. Foods 2024, 13, 2961. [Google Scholar] [CrossRef] [PubMed]

- Bao, Y.; Pignitter, M. Mechanisms of lipid oxidation in water-in-oil emulsions and oxidomics-guided discovery of targeted protective approaches. Compr. Rev. Food Sci. Food Saf. 2023, 22, 2678–2705. [Google Scholar] [CrossRef] [PubMed]

- Das, P.P.; Gul, M.Z.; Weber, A.M.; Srivastava, R.K.; Marathi, B.; Ryan, E.P.; Ghazi, I.A. Rice Bran Extraction and Stabilization Methods for Nutrient and Phytochemical Biofortification, Nutraceutical Development, and Dietary Supplementation. Nutr. Rev. 2025, 83, 692–712. [Google Scholar] [CrossRef]

- Mezouari, S.; Eichner, K. Comparative study on the stability of crude and refined rice bran oil during long-term storage at room temperature. Eur. J. Lipid Sci. Technol. 2007, 109, 198–205. [Google Scholar] [CrossRef]

- Edem, D.O. Palm oil: Biochemical, physiological, nutritional, hematological, and toxicological aspects: A review. Plant Foods Hum. Nutr. 2002, 57, 319–341. [Google Scholar] [CrossRef]

- Berrios, M.; Siles, J.; Martín, M.A.; Martín, A. A kinetic study of the esterification of free fatty acids (FFA) in sunflower oil. Fuel 2007, 86, 2383–2388. [Google Scholar] [CrossRef]

- Naz, S.; Siddiqi, R.; Sheikh, H.; Sayeed, S.A. Deterioration of olive, corn and soybean oils due to air, light, heat and deep-frying. Food Res. Int. 2005, 38, 127–134. [Google Scholar] [CrossRef]

- Miyazaki, R.; Kato, S.; Otoki, Y.; Rahmania, H.; Sakaino, M.; Takeuchi, S.; Sato, T.; Imagi, J.; Nakagawa, K. Elucidation of decomposition pathways of linoleic acid hydroperoxide isomers by GC-MS and LC-MS/MS. Biosci. Biotechnol. Biochem. 2023, 87, 179–190. [Google Scholar] [CrossRef] [PubMed]

- Nishida, Y.; Niihara, R.; Yonezawa, D. On the Contribution of Starch to the Change in Swelling of Cooked Somen Caused by the Storage Process of Tenobe-somen Called Yaku. Nippon. Shokuhin Kogyo Gakkaishi 1980, 27, 323–326. [Google Scholar] [CrossRef]

- Xu, D.; Hao, J.; Wang, Z.; Liang, D.; Wang, J.; Ma, Y.; Zhang, M. Physicochemical properties, fatty acid compositions, bioactive compounds, antioxidant activity and thermal behavior of rice bran oil obtained with aqueous enzymatic extraction. LWT 2021, 149, 111817. [Google Scholar] [CrossRef]

- Imam, M.; Murtaja Alam Khan, A.; Suyal, M.; Zahiruddin, S.; Jain, V.; Ahmad, S.; Chandra, K. Characterization of Amino Acid Composition, Nutritional Value, and Glycemic Index Study of Eleusine coracana Grains: A Functional Food for Diabetes Management. J. Food Qual. 2025, 2025, 7758886. [Google Scholar] [CrossRef]

- Lim, S.Y.; Abdul Mutalib, M.S.; Khaza’ai, H.; Chang, S.K. Detection of fresh palm oil adulteration with recycled cooking oil using fatty acid composition and FTIR spectral analysis. Int. J. Food Prop. 2018, 21, 2428–2451. [Google Scholar] [CrossRef]

- Camp, A.; Marshall, J. Abstract 2027 Fatty Acid Composition of Peanuts With Different Solvents and Methods Of Extraction. J. Biol. Chem. 2024, 300, 106805. [Google Scholar] [CrossRef]

- Lish, M.P.; Ashjari, M.; Yousefi, M.; Mohammadi, M.; Ramazani, A. Immobilized Candida antarctica lipase B (CALB) for biodiesel production from rapeseed oil; evaluation of the effect of immobilization protocol. Int. J. Biol. Macromol. 2025, 297, 139814. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Wang, S.; Chen, H.; Sun, J.; Zhang, N.; Zhang, H. Fatty acid composition and key aroma components of two different cold pressed sesame oils. J. Food Compos. Anal. 2025, 139, 107143. [Google Scholar] [CrossRef]

- Zhang, B.; Li, K.; Cheng, H.; Hu, J.; Qi, X.; Guo, X. Effect of thermal treatments on volatile profiles and fatty acid composition in sweet corn (Zea mays L.). Food Chem. X 2023, 18, 100743. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Kuai, Y.; Guo, X.; Bu, G.; Yang, C.; Chen, F. Effect of Dietary Oils with Different Fatty Acid Compositions on Serum Lipid and Gut Microbiota of Rats. Foods 2025, 14, 61. [Google Scholar] [CrossRef]

- Miri Nargesi, M.; Sedaghathoor, S.; Hashemabadi, D. Effect of foliar application of amino acid, humic acid and fulvic acid on the oil content and quality of olive. Saudi J. Biol. Sci. 2022, 29, 3473–3481. [Google Scholar] [CrossRef]

- Talebi, S.M.; Darbandi, N.; Naziri, F.; Matsyura, A. Seed morphometry and fatty acid profile in oilseed and non-oilseed sunflower cultivars. Biochem. Syst. Ecol. 2024, 113, 104805. [Google Scholar] [CrossRef]

- Ustra, M.K.; Silva, J.R.F.; Ansolin, M.; Balen, M.; Cantelli, K.; Alkimim, I.P.; Mazutti, M.A.; Voll, F.A.P.; Cabral, V.F.; Cardozo-Filho, L.; et al. Effect of temperature and composition on density, viscosity and thermal conductivity of fatty acid methyl esters from soybean, castor and Jatropha curcas oils. J. Chem. Thermodyn. 2013, 58, 460–466. [Google Scholar] [CrossRef]

- Fasina, O.O.; Colley, Z. Viscosity and Specific Heat of Vegetable Oils as a Function of Temperature: 35 °C to 180 °C. Int. J. Food Prop. 2008, 11, 738–746. [Google Scholar] [CrossRef]

- Fasina, O.O.; Hallman, H.; Craig-Schmidt, M.; Clements, C. Predicting temperature-dependence viscosity of vegetable oils from fatty acid composition. J. Am. Oil Chem. Soc. 2006, 83, 899–903. [Google Scholar] [CrossRef]

- Nduka, J.K.C.; Omozuwa, P.O.; Imanah, O.E. Effect of heating time on the physicochemical properties of selected vegetable oils. Arab. J. Chem. 2021, 14, 103063. [Google Scholar] [CrossRef]

- Yang, D.; Wu, G.; Li, P.; Qi, X.; Zhang, H.; Wang, X.; Jin, Q. The effect of fatty acid composition on the oil absorption behavior and surface morphology of fried potato sticks via LF-NMR, MRI, and SEM. Food Chem. X 2020, 7, 100095. [Google Scholar] [CrossRef]

- Bonnet, J.-P.; Devesvre, L.; Artaud, J.; Moulin, P. Dynamic viscosity of olive oil as a function of composition and temperature: A first approach. Eur. J. Lipid Sci. Technol. 2011, 113, 1019–1025. [Google Scholar] [CrossRef]

- Camacho, S.; van Riel, V.; de Graaf, C.; van de Velde, F.; Stieger, M. Physical and Sensory Characterizations of Oral Coatings of Oil/Water Emulsions. J. Agric. Food Chem. 2014, 62, 5789–5795. [Google Scholar] [CrossRef]

- Hur, S.J.; Lee, S.J.; Lee, S.Y.; Bahk, Y.Y.; Kim, C.G. Effect of emulsifiers on microstructural changes and digestion of lipids in instant noodle during in vitro human digestion. LWT-Food Sci. Technol. 2015, 60, 630–636. [Google Scholar] [CrossRef]

- Fuhrmann, P.L.; Kalisvaart, L.C.M.; Sala, G.; Scholten, E.; Stieger, M. Clustering of oil droplets in o/w emulsions enhances perception of oil-related sensory attributes. Food Hydrocoll. 2019, 97, 105215. [Google Scholar] [CrossRef]

- Oh, I.; Lee, S. Rheological, microstructural, and tomographical studies on the rehydration improvement of hot air-dried noodles with oleogel. J. Food Eng. 2020, 268, 109750. [Google Scholar] [CrossRef]

- Pinto, F.S.T.; Fogliatto, F.S.; Qannari, E.M. A method for panelists’ consistency assessment in sensory evaluations based on the Cronbach’s alpha coefficient. Food Qual. Prefer. 2014, 32, 41–47. [Google Scholar] [CrossRef]

- Yeoh, S.-Y.; Lubowa, M.; Tan, T.-C.; Murad, M.; Mat Easa, A. The use of salt-coating to improve textural, mechanical, cooking and sensory properties of air-dried yellow alkaline noodles. Food Chem. 2020, 333, 127425. [Google Scholar] [CrossRef]

- Nurhayati, N.; Maria, B.; Jay, J.; Infidzah, S.V. Increasing of Wet Noodles Quality Using Vegetables Oil Coating. In Proceedings of the 6th International Conference of Food, Agriculture, and Natural Resource (IC-FANRES 2021), Bandung, Indonesia, 4–5 August 2022; pp. 242–246. [Google Scholar]

- Lyu, K.; Guo, X.-N.; Zhu, K.-X. Changes in rheology and components during the processing of Chinese traditional handmade hollow dried noodle. Food Res. Int. 2024, 189, 114526. [Google Scholar] [CrossRef]

- Shi, Y.; Li, X.; Qi, Y.; Manzoor, M.F.; Cui, S.; Xu, B. Investigating the positive effects of wrap-around resting on the qualities of semi-dried noodles through the quantitative analysis of gluten network. J. Texture Stud. 2023, 54, 105–114. [Google Scholar] [CrossRef]

- Niihara, R.; Nishida, Y.; Yonezawa, D.; Sakurai, Y. Changes of Lipids and Proteins in Noodle and Its Physical Properties during Manufacture of “Tenobe-somen&rdquo. Nippon. Nōgeikagaku Kaishi 1973, 47, 423–433. [Google Scholar] [CrossRef]

- Liu, J.; Qi, Y.; Hassane Hamadou, A.; Tufail, T.; Guo, Q.; Zhang, J.; Xu, B. Effects of dough sheets resting on textural properties of long-life noodles via moisture migration and gluten network development. Int. J. Food Sci. Technol. 2024, 59, 3167–3175. [Google Scholar] [CrossRef]

- Ma, M.; Sun, Q.-J.; Li, M.; Zhu, K.-X. Deterioration mechanisms of high-moisture wheat-based food–A review from physicochemical, structural, and molecular perspectives. Food Chem. 2020, 318, 126495. [Google Scholar] [CrossRef] [PubMed]

- Yanfei, G.; Zhang, Y.; Zhang, B.; Boli, G.; Yimin, W. The moisture migration behavior of wheat starch/gluten blended powders and extrudates. Dry. Technol. 2021, 39, 1401–1411. [Google Scholar] [CrossRef]

- Liu, S.; Jiang, Y.; Xu, B.; Jiang, S. Analysis of the effect of rolling speed on the texture properties of noodle dough from water-solid interaction, development of gluten network, and bubble distribution. Food Chem. 2023, 404, 134359. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, X.; Zhang, Y.; Zhang, B.; Zhang, M.; Wei, Y. Effects of gluten and moisture content on water mobility during the drying process for Chinese dried noodles. Dry. Technol. 2019, 37, 759–769. [Google Scholar] [CrossRef]

- Inazu, T.; Iwasaki, K.-i.; Furuta, T. Stress and crack prediction during drying of Japanese noodle (udon). Int. J. Food Sci. Technol. 2005, 40, 621–630. [Google Scholar] [CrossRef]

- Niihara, R.; Yonezawa, D. Inhibitory Effect of Fatty Acids and Proteins on Gelatinization of Starch in Tenobe-somen. Nippon. Shokuhin Kogyo Gakkaishi 1981, 28, 522–527. [Google Scholar] [CrossRef]

- Shao, L.-F.; Guo, X.-N.; Li, M.; Zhu, K.-X. Effect of different mixing and kneading process on the quality characteristics of frozen cooked noodle. LWT 2019, 101, 583–589. [Google Scholar] [CrossRef]

- Du, J.; Li, Q.; Obadi, M.; Qi, Y.; Liu, S.; An, D.; Zhou, X.; Zhang, D.; Xu, B. Quality Evaluation Systems and Methods of the Whole Making Process of Asian Noodles: A Review. Food Rev. Int. 2023, 39, 3830–3857. [Google Scholar] [CrossRef]

- Kojima, M.; Murase, M.; Totani, S.; Sugimoto, M. Scanning Electron Microscopy of Hand-Streched Noodles (Tenobe-men) and Machine-Made Noodles (Kikai-men). Nippon. Shokuhin Kogyo Gakkaishi 1992, 39, 471–476. [Google Scholar] [CrossRef][Green Version]

- Katagiri, M.; Masuda, T.; Tani, F.; Kitabatake, N. Changes in Textural Properties of Japanese Tenobe Somen Noodles during Storage. J. Food Sci. 2011, 76, S500–S507. [Google Scholar] [CrossRef]

- Buzera, A.; Gikundi, E.; Kajunju, N.; Ishara, J.; Orina, I.; Sila, D. Investigating potato flour processing methods and ratios for noodle production. Food Sci. Nutr. 2024, 12, 4005–4018. [Google Scholar] [CrossRef]

- Chen, Y.-F.; Singh, J.; Midgley, J.; Archer, R. Influence of time-temperature cycles on potato starch retrogradation in tuber and starch digestion in vitro. Food Hydrocoll. 2020, 98, 105240. [Google Scholar] [CrossRef]

- Nawaz, A.; Li, E.; Khalifa, I.; Walayat, N.; Liu, J.; Irshad, S.; Zahra, A.; Ahmed, S.; Simirgiotis, M.J.; Pateiro, M.; et al. Effect of Different Processing Methods on Quality, Structure, Oxidative Properties and Water Distribution Properties of Fish Meat-Based Snacks. Foods 2021, 10, 2467. [Google Scholar] [CrossRef]

- Zang, P.; Gao, Y.; Chen, P.; Lv, C.; Zhao, G. Recent Advances in the Study of Wheat Protein and Other Food Components Affecting the Gluten Network and the Properties of Noodles. Foods 2022, 11, 3824. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, X.; Xu, X.; Feng, X.; Wang, Z.; Meng, L.; Wu, D.; Tang, X. Effects of soaking conditions on the quality and in vitro starch digestibility of extruded whole buckwheat noodles. J. Cereal Sci. 2022, 108, 103584. [Google Scholar] [CrossRef]

- Xiong, X.; Liu, C.; Song, M.; Zheng, X. Effect of characteristics of different wheat flours on the quality of fermented hollow noodles. Food Sci. Nutr. 2021, 9, 4927–4937. [Google Scholar] [CrossRef] [PubMed]

- Hatcher, D.W.; Kruger, J.E.; Anderson, M.J. Influence of Water Absorption on the Processing and Quality of Oriental Noodles. Cereal Chem. 1999, 76, 566–572. [Google Scholar] [CrossRef]

- Yao, M.; Li, M.; Dhital, S.; Tian, Y.; Guo, B. Texture and digestion of noodles with varied gluten contents and cooking time: The view from protein matrix and inner structure. Food Chem. 2020, 315, 126230. [Google Scholar] [CrossRef]

- Li, J.; Qi, Y.; Ahmed, Z.; Xu, B. A methodological study of the hardness of cooked Chinese noodles based on the texture analyzer. Int. J. Food Eng. 2024, 20, 551–560. [Google Scholar] [CrossRef]

- Snyder, H. The Proteins of the Wheat Kernel. By Thos. B. Osborne. Published by the Carnegie Institution of Washington, D.C. 1907. Pp. 119. Science 1907, 26, 865. [Google Scholar] [CrossRef][Green Version]

- Delcour, J.A.; Joye, I.J.; Pareyt, B.; Wilderjans, E.; Brijs, K.; Lagrain, B. Wheat Gluten Functionality as a Quality Determinant in Cereal-Based Food Products. Annu. Rev. Food Sci. Technol. 2012, 3, 469–492. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, J.F.; Lewkowicz, P. Gliadin and Glutenin: The Unique Balance of Wheat Quality. Int. J. Biol. Macromol. 2008, 42, 81. [Google Scholar] [CrossRef]

- An, D.; Li, H.; Li, D.; Zhang, D.; Huang, Y.; Obada, M.; Xu, B. The relation between wheat starch properties and noodle springiness: From the view of microstructure quantitative analysis of gluten-based network. Food Chem. 2022, 393, 133396. [Google Scholar] [CrossRef]

- Kamali Rousta, L.; Pouya Ghandehari Yazdi, A.; Khorasani, S.; Tavakoli, M.; Ahmadi, Z.; Amini, M. Optimization of novel multigrain pasta and evaluation of physicochemical properties: Using D-optimal mixture design. Food Sci. Nutr. 2021, 9, 5546–5556. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Shen, J.; Yang, Y.; Wang, H.; Xu, B. Intact aleurone cells limit the hydrolysis of endogenous lipids in wheat bran during storage. Food Res. Int. 2022, 161, 111799. [Google Scholar] [CrossRef]

- Imami, T.; Kasuya, T.; Takasima, S. The “Yaku” treatment of Tenobe Somen Noodles. J. Util. Agric. Prod. 1957, 4, 118–122. [Google Scholar] [CrossRef]

- Chaitanya, P.K.; Prabhu, N.P. Stability and Activity of Porcine Lipase Against Temperature and Chemical Denaturants. Appl. Biochem. Biotechnol. 2014, 174, 2711–2724. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lei, J.; Wen, T.; Qian, Y.; Meng, C.; Sun, L.; Sun, W.-J.; Cui, F. Selective production of functional sn-1,3-diacylglycerol by microbial lipases: A comprehensive review. Food Chem. 2025, 481, 144017. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Ye, P.-P.; Cui, F.-J.; Tan, M.; Zhang, H.-B.; Zhou, T.-L.; Shi, J.-C.; Shu, X.-Q.; Chen, Z.-W. Overall quality changes and deterioration mechanism of fragrant rapeseed oils during 6-Month storage. Food Chem. 2024, 439, 138116. [Google Scholar] [CrossRef]

- Xu, B.; Han, J.; Zhou, S.; Wu, Q.; Ding, F. Quality Characteristics of Wheat Germ Oil Obtained by Innovative Subcritical Butane Experimental Equipment. J. Food Process Eng. 2016, 39, 79–87. [Google Scholar] [CrossRef]

- Qi, Y.; Yang, Y.; Hassane Hamadou, A.; Shen, Q.; Xu, B. Tempering–preservation treatment inactivated lipase in wheat bran and retained phenolic compounds. Int. J. Food Sci. Technol. 2022, 57, 2104–2112. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, J.; Zhang, H.; Duan, Y.; Ma, H. Plant protein-derived antioxidant peptides: Isolation, identification, mechanism of action and application in food systems: A review. Trends Food Sci. Technol. 2020, 105, 308–322. [Google Scholar] [CrossRef]

- Obadi, M.; Li, Y.; Xu, B. Recent advances in extending the shelf life of fresh wet noodles: Influencing factors and preservation technologies. J. Food Sci. 2023, 88, 3626–3648. [Google Scholar] [CrossRef]

- Bao, Y.; Ertbjerg, P.; Estévez, M.; Yuan, L.; Gao, R. Freezing of meat and aquatic food: Underlying mechanisms and implications on protein oxidation. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5548–5569. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Cheng, Y.; Dong, Y. Antioxidant Activity of Lactobacillus plantarum DY-1 Fermented Wheat Germ Extract and Its Influence on Lipid Oxidation and Texture Properties of Emulsified Sausages. J. Food Qual. 2020, 2020, 8885886. [Google Scholar] [CrossRef]

- Shi, T.; Xiong, Z.; Jin, W.; Yuan, L.; Sun, Q.; Zhang, Y.; Li, X.; Gao, R. Suppression mechanism of l-arginine in the heat-induced aggregation of bighead carp (Aristichthys nobilis) myosin: The significance of ionic linkage effects and hydrogen bond effects. Food Hydrocoll. 2020, 102, 105596. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, Q.; Xia, Q.; Zha, B.; Sun, J.; Xu, B.; Shi, Y.-C. Intact endosperm cells in buckwheat flour limit starch gelatinization and digestibility in vitro. Food Chem. 2020, 330, 127318. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Li, C.; Li, E.; Gilbert, R.G.; Xu, B. A molecular explanation of wheat starch physicochemical properties related to noodle eating quality. Food Hydrocoll. 2020, 108, 106035. [Google Scholar] [CrossRef]

- Zhang, Q.; Jin, M.; An, D.; Ahmed, Z.; Qi, Y.; Xu, B. Modelling dried noodle quality: Contribution of starch and protein physicochemical properties of 32 wheat cultivars. Food Res. Int. 2023, 174, 113501. [Google Scholar] [CrossRef]

- Chen, Z.; Xia, Q.; Zha, B.; Sun, J.; Xu, B.; Chen, Z. Triboelectric separation of wheat bran tissues: Influence of tribo-material, water content, and particle size. J. Food Process Eng. 2020, 43, e13346. [Google Scholar] [CrossRef]

- Gumus, C.E.; Decker, E.A. Oxidation in Low Moisture Foods as a Function of Surface Lipids and Fat Content. Foods 2021, 10, 860. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, C.; Guo, Y.; Zhang, C.; Li, D.; Gao, K.; Ma, Y.; Ma, H. Comparative Evaluation of Physicochemical Properties, Microstructure, and Antioxidant Activity of Jujube Polysaccharides Subjected to Hot Air, Infrared, Radio Frequency, and Freeze Drying. Agriculture 2022, 12, 1606. [Google Scholar] [CrossRef]

- Gao, R.; Wang, Y.; Mu, J.; Shi, T.; Yuan, L. Effect of l-histidine on the heat-induced aggregation of bighead carp (Aristichthys nobilis) myosin in low/high ionic strength solution. Food Hydrocoll. 2018, 75, 174–181. [Google Scholar] [CrossRef]

- Zhong, M.; Sun, Y.; Qayum, A.; Liang, Q.; Rehman, A.; Gan, R.; Ma, H.; Ren, X. Research progress in soybean lipophilic protein (LP): Extraction, structural, techno-functional properties, and high-performance food applications. Trends Food Sci. Technol. 2024, 147, 104440. [Google Scholar] [CrossRef]

- Kang, L.; Liang, Q.; Chen, H.; Zhou, Q.; Chi, Z.; Rashid, A.; Ma, H.; Ren, X. Insights into ultrasonic treatment on the properties of pullulan/oat protein/nisin composite film:mechanical, structural and physicochemical properties. Food Chem. 2023, 402, 134237. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Qi, Y.; Hassane Hamadou, A.; Ahmed, Z.; Guo, Q.; Zhang, J.; Xu, B. Effect of high-temperature drying at different moisture levels on texture of dried noodles: Insights into gluten aggregation and pore distribution. J. Cereal Sci. 2024, 115, 103817. [Google Scholar] [CrossRef]

- Wu, B.; Ma, Y.; Guo, X.; Guo, Y.; Qiu, C.; Gao, K.; Ma, H.; Pan, Z. Catalytic infrared blanching and drying of carrot slices with different thicknesses: Effects on surface dynamic crusting and quality characterization. Innov. Food Sci. Emerg. Technol. 2023, 88, 103444. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, C.; Guo, Y.; Zhang, C.; Guo, X.; Bouhile, Y.; Ma, H. Ultrasonic-assisted flowing water thawing of frozen beef with different frequency modes: Effects on thawing efficiency, quality characteristics and microstructure. Food Res. Int. 2022, 157, 111484. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wu, B.; Guo, X.; Liu, D.; Qiu, C.; Ma, H. Thermosonication inactivation of horseradish peroxidase with different frequency modes: Effect on activity, structure, morphology and mechanisms. Food Chem. 2022, 384, 132537. [Google Scholar] [CrossRef]

- Vhangani, L.N.; Van Wyk, J. Antioxidant activity of Maillard reaction products (MRPs) in a lipid-rich model system. Food Chem. 2016, 208, 301–308. [Google Scholar] [CrossRef] [PubMed]

| Types of Oil | 5 °C | 10 °C | 20 °C | 30 °C | 40 °C |

|---|---|---|---|---|---|

| Cottonseed oil grade 1 | 122 ± 1.25 c | 103 ± 0.35 c | 75.4 ± 0.35 e | 54.4 ± 0.92 d | 39.4 ± 0.35 c |

| Cottonseed oil grade 2 | 120.4 ± 0.72 c | 101.7 ± 0.31 cd | 74.3 ± 0.12 ef | 53.5 ± 0.12 e | 37.7 ± 0.12 d |

| Cottonseed oil grade 3 | 117.7 ± 0.42 d | 99.6 ± 0.6 d | 73.6 ± 0.35 f | 52.2 ± 0.6 f | 35.4 ± 0.2 e |

| Compound oil | 132.5 ± 1.5 b | 113.6 ± 3.0 b | 78.4 ± 0.35 d | 58 ± 0.35 c | 39.2 ± 0.35 c |

| Rice bran oil | 152 ± 0.7 a | 121.8 ± 0.87 a | 83.3 ± 0.58 c | 65 ± 0.35 a | 43.2 ± 0.6 a |

| Soybean oil | 99.6 ± 0.6 e | 86.8 ± 0.35 e | 62 ± 0.35 g | 47.6 ± 0.35 g | 32.4 ± 0.2 f |

| Palm oil (PO-A) | / | / | 132 ± 1.2 a | 62 ± 0.35 b | 41.8 ± 0.35 b |

| Palm oil (PO-B) | / | / | 114.4 ± 0.92 b | 64.8 ± 0.2 a | 41.4 ± 0.6 b |

| Ingredients | Biochemical Indicators (Units) | After the First “Yaku” (Stored for 6 to 8 Months) | After the Second “Yaku” (Stored for 18 to 20 Months) | Product Texture | References |

|---|---|---|---|---|---|

| Lipids | Acid value (mg KOH/g) | Significant increase (Increase from 10 meq/kg to 25–30 meq/kg) | Basically remain stable | Free fatty acids generated from hydrolysis form insoluble complexes with amylose, significantly inhibiting the gelatinization degree and swelling power of starch granules. This directly leads to increased hardness and reduced stickiness of the cooked noodles, resulting in a smoother mouthfeel. | [12] |

| Peroxide value (meq/kg) | Remain unchanged (16–17 meq/kg) | Significant increase (25–30 meq/kg) | Volatile substances such as carbonyl compounds generated by lipid oxidation participate in the Maillard reaction, creating a unique umami flavor. | [13] | |

| Ether extract (%) | Slow reduction | Significant reduction (down to initial 50%) | Lipids become inextractable due to hydrolysis and oxidation reactions, resulting in a dry appearance. | [70] | |

| Proteins | Solubility in 0.1 M acetic acid (%) | No significant difference (maintained at 58–60%) | Significantly reduced | Proteins undergo intermolecular cross-linking and polymerization, forming a more compact and robust three-dimensional network structure, which enhances the hardness and elastic modulus of noodles, and provides excellent chewiness and tensile strength. | [59] |

| Wet gluten yield | Hard to group, loss of liquidity | Almost impossible to extract | The protein undergoes irreversible changes and its water absorption rate decreases. | [66] | |

| Starch | Swelling power after cooking | Starch granule swelling inhibition | Further swelling suppression | The expansion of starch particles is restricted, making the noodles more chewy. | [33] |

| Solubility after cooking (%) | Slightly down(from 17.6% to 15.0%) | Further decline | The dissolution of amylose is reduced, the cooking loss is decreased, and the noodle soup is clearer. | [66] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Q.; Li, W.; Qi, Y.; Liu, S.; Chen, Z.; Xu, B. Investigation of Quality Enhancement Mechanisms in Tenobe Somen Noodles During Storage and Maturation. Foods 2025, 14, 3204. https://doi.org/10.3390/foods14183204

Wu Q, Li W, Qi Y, Liu S, Chen Z, Xu B. Investigation of Quality Enhancement Mechanisms in Tenobe Somen Noodles During Storage and Maturation. Foods. 2025; 14(18):3204. https://doi.org/10.3390/foods14183204

Chicago/Turabian StyleWu, Qifei, Wei Li, Yajing Qi, Shuyi Liu, Zhongwei Chen, and Bin Xu. 2025. "Investigation of Quality Enhancement Mechanisms in Tenobe Somen Noodles During Storage and Maturation" Foods 14, no. 18: 3204. https://doi.org/10.3390/foods14183204

APA StyleWu, Q., Li, W., Qi, Y., Liu, S., Chen, Z., & Xu, B. (2025). Investigation of Quality Enhancement Mechanisms in Tenobe Somen Noodles During Storage and Maturation. Foods, 14(18), 3204. https://doi.org/10.3390/foods14183204