Next-Generation Predictive Microbiology: A Software Platform Combining Two-Step, One-Step and Machine Learning Modelling

Abstract

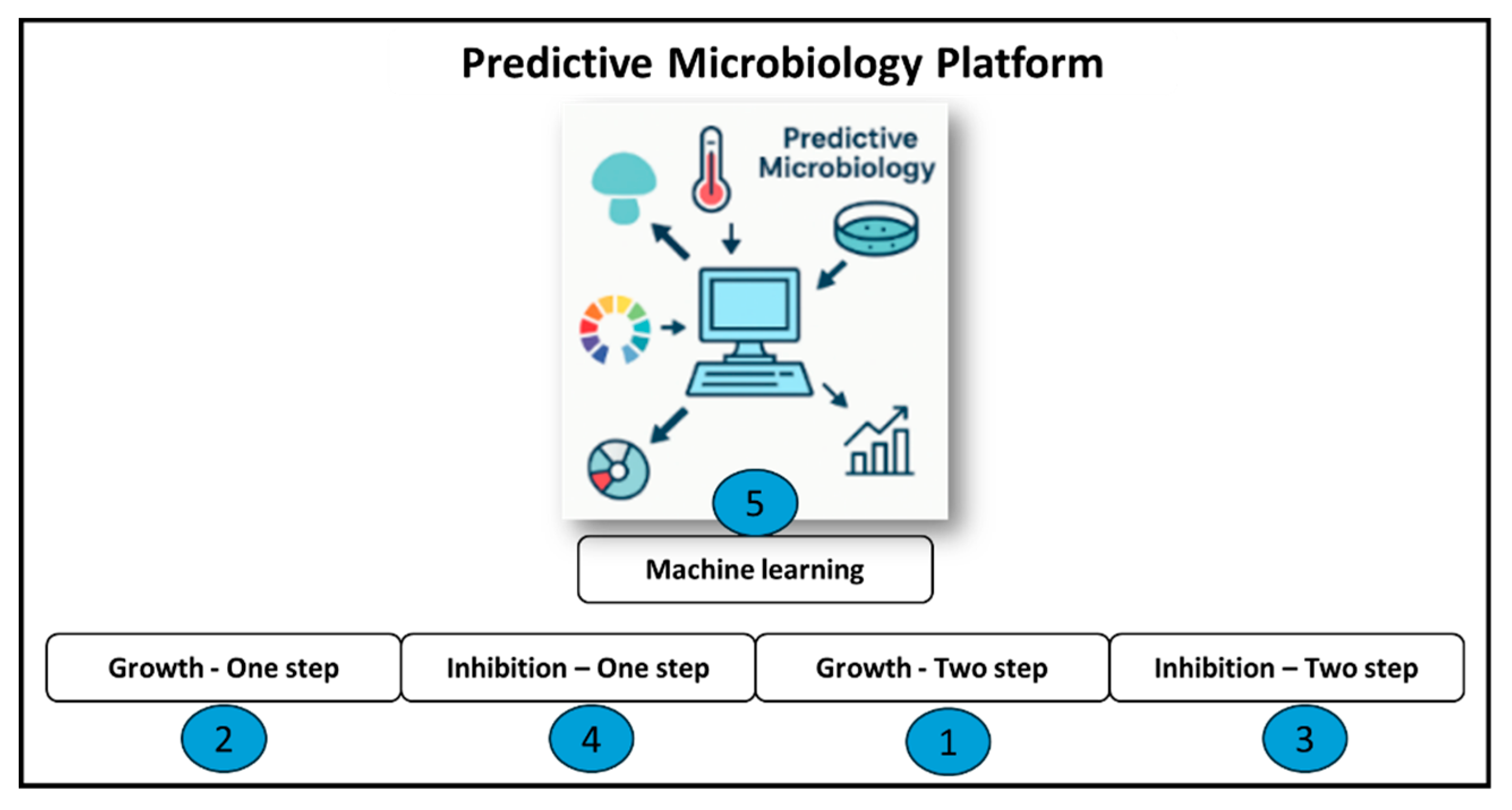

1. Introduction

2. Material and Methods

2.1. Classical (Traditional) Modelling

2.1.1. Growth Models

2.1.2. Inhibition Models

2.2. Machine Learning Models

2.3. Parameter Estimation and Uncertainty Quantification

2.4. Comparison of the Goodness of Fit

2.5. Statistical Analysis

2.6. Modelling Dataset and Preprocessing

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McMeekin, T.A.; Brown, J.; Krist, K.; Miles, D.; Neumeyer, K.; Nichols, D.S.; Olley, J.; Presser, K.; Ratkowsky, D.A.; Ross, T.; et al. Quantitative microbiology: A basis for food safety. Emerg. Infect. Dis. 1997, 3, 541–549. [Google Scholar] [CrossRef]

- den Besten, H.M.W.; Wells-Bennik, M.H.J.; Zwietering, M.H. Natural diversity in heat resistance of bacteria and bacterial spores: Impact on food safety and quality. Annu. Rev. Food Sci. Technol. 2018, 9, 383–410. [Google Scholar] [CrossRef]

- Pérez-Rodríguez, F.; Valero, A. Predictive Microbiology in Foods; Springer: New York, NY, USA, 2013. [Google Scholar]

- Ross, T.; Dalgaard, P. Secondary models. In Modeling Microbial Responses in Food; McKellar, R.C., Lu, X., Eds.; CRC Press: Boca Raton, FL, USA, 2004; pp. 63–150. [Google Scholar]

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; van’t Riet, K. Modeling of the bacterial growth curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [CrossRef] [PubMed]

- Baranyi, J.; Roberts, T.A. A dynamic approach to predicting bacterial growth in food. Int. J. Food Microbiol. 1994, 23, 277–294. [Google Scholar] [CrossRef]

- Huang, L. Optimization of a new mathematical model for bacterial growth. Food Control 2013, 32, 283–288. [Google Scholar] [CrossRef]

- Peleg, M. Advanced Quantitative Microbiology for Foods and Biosystems: Models for Predicting Growth and Inactivation; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Ratkowsky, D.A.; Olley, J.; McMeekin, T.A.; Ball, A. Relationship between temperature and growth rate of bacterial cultures. J. Bacteriol. 1982, 149, 1–5. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Rosso, L.; Robinson, T.P. A cardinal model to describe the effect of water activity on the growth of moulds. Int. J. Food Microbiol. 2001, 63, 265–273. [Google Scholar] [CrossRef] [PubMed]

- Pin, C.; Baranyi, J. Kinetics of single cells: Observation and modeling of a stochastic process. Appl. Environ. Microbiol. 2006, 72, 2163–2169. [Google Scholar] [CrossRef]

- Tarlak, F. Development and validation of one-step modelling approach for prediction of mushroom spoilage. J. Food Nutr. Res. 2020, 59, 281–289. [Google Scholar]

- Tarlak, F.; Pérez-Rodríguez, F. Development and validation of a one-step modelling approach for the determination of chicken meat shelf-life based on the growth kinetics of Pseudomonas spp. Food Sci. Technol. Int. 2022, 28, 672–682. [Google Scholar] [CrossRef]

- Geeraerd, A.H.; Herremans, C.H.; Van Impe, J.F. Structural model requirements to describe microbial inactivation during a mild heat treatment. Int. J. Food Microbiol. 2000, 59, 185–209. [Google Scholar] [CrossRef] [PubMed]

- Koyama, K.; Kubo, K.; Hiura, S.; Koseki, S. Is skipping the definition of primary and secondary models possible? Prediction of Escherichia coli O157 growth by machine learning. J. Microbiol. Methods 2022, 192, 106366. [Google Scholar] [CrossRef] [PubMed]

- Tarlak, F.; Yücel, Ö. Prediction of Pseudomonas spp. Population in Food Products and Culture Media Using Machine Learning-Based Regression Methods. Life 2023, 13, 1430. [Google Scholar] [CrossRef]

- Gospavic, R.; Kreyenschmidt, J.; Brückner, S.; Popov, V.; Haque, N. Mathematical modelling for predicting the growth of Pseudomonas spp. in poultry under variable temperature conditions. Int. J. Food Microbiol. 2008, 127, 290–297. [Google Scholar] [CrossRef]

- Lytou, A.; Panagou, E.Z.; Nychas, G.-J.E. Development of a predictive model for the growth kinetics of aerobic microbial population on pomegranate marinated chicken breast fillets under isothermal and dynamic temperature conditions. Food Microbiol. 2020, 86, 103326. [Google Scholar] [CrossRef]

- Possas, A.; Pérez-Rodríguez, F.; Tarlak, F.; García-Gimeno, R.M. Quantifying and modelling the inactivation of Listeria monocytogenes by electrolyzed water on food contact surfaces. J. Food Eng. 2021, 290, 110287. [Google Scholar] [CrossRef]

- Juneja, V.K.; Melendres, M.V.; Huang, L.; Gumudavelli, V.; Subbiah, J.; Thippareddi, H. Modeling the effect of temperature on growth of Salmonella in chicken. Food Microbiol. 2007, 24, 328–335. [Google Scholar] [CrossRef]

- Wijtzes, T.; Rombouts, F.M.; Kant-Muermans, M.L.T.; Van’t Riet, K.; Zwietering, M.H. Development and validation of a combined temperature, water activity, pH model for bacterial growth rate of Lactobacillus curvatus. Int. J. Food Microbiol. 2001, 63, 57–64. [Google Scholar] [CrossRef]

- Tarlak, F.; Johannessen, G.; Bascón Villegas, I.; Bolívar, A.; Posada-Izquierdo, G.D.; Pérez-Rodríguez, F. Modelling of the Behaviour of Salmonella enterica serovar Reading on Commercial Fresh-Cut Iceberg Lettuce Stored at Different Temperatures. Foods 2020, 9, 946. [Google Scholar] [CrossRef]

- Robinson, T.P.; Ocio, M.J.; Kaloti, A.; Mackey, B.M. The effect of the growth environment on the lag phase of Listeria monocytogenes. Int. J. Food Microbiol. 1998, 44, 83–92. [Google Scholar] [CrossRef] [PubMed]

- Peleg, M. Microbial inactivation kinetics models, survival curve shapes, and the temporal distributions of the individual germs’ deactivation. Food Eng. Rev. 2024, 16, 163–178. [Google Scholar] [CrossRef]

- Deringer, V.L.; Bartók, A.P.; Bernstein, N.; Wilkins, D.M.; Ceriotti, M.; Csányi, G. Gaussian process regression for materials and molecules. Chem. Rev. 2021, 121, 10073–10141. [Google Scholar] [CrossRef]

- Yücel, Ö.; Tarlak, F. An intelligent-based prediction of microbial behaviour in beef. Food Control 2023, 148, 109665. [Google Scholar] [CrossRef]

- Yildirim-Yalcin, M.; Yucel, Ö.; Tarlak, F. Development of prediction software to describe total mesophilic bacteria in spinach using a machine learning-based regression approach. Food Sci. Technol. Int. 2023, 31, 3–10. [Google Scholar] [CrossRef]

- Levenberg, K. A method for the solution of certain non-linear problems in least squares. Q. Appl. Math. 1944, 2, 164–168. [Google Scholar] [CrossRef]

- Marquardt, D.W. An algorithm for least-squares estimation of nonlinear parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Efron, B.; Tibshirani, R.J. An Introduction to the Bootstrap; Chapman Hall/CRC: Boca Raton, FL, USA, 1993. [Google Scholar]

- Draper, N.R.; Smith, H. Applied Regression Analysis, 3rd ed.; Wiley: Hoboken, NJ, USA, 1998. [Google Scholar]

- Tarlak, F.; Yücel, Ö. Assessment of robustness of machine learning-assisted modelling approach to describe growth kinetics of microorganisms using Monte Carlo simulation. J. Food Nutr. 2024, 63, 273–282. [Google Scholar]

- Skandamis, P.N. “Growth Predictor”: A new predictive modelling and quantitative microbial risk assessment tool. Food Res. Int. 2025, 209, 116329. [Google Scholar] [CrossRef]

- Cadavez, V.; Gonzales-Barron, U. CardinalFit: A Shiny App. To Fit Cardinal Models. 2020. Available online: https://ubarron.shinyapps.io/CardinalFit (accessed on 3 September 2025).

- Geeraerd, A.H.; Valdramidis, V.P.; Van Impe, J.F. GInaFiT, a freeware tool to assess non-log-linear microbial survivor curves. Int. J. Food Microbiol. 2005, 102, 95–105. [Google Scholar] [CrossRef] [PubMed]

| Source | Temperature (°C) | y0 (log CFU/g) | ymax (log CFU/g) | µmax (1/h) | RMSE | R2 |

|---|---|---|---|---|---|---|

| Gospavic et al. [17] | 2 | 3.97 ± 0.32 | 10.15 ± 0.46 | 0.026 ± 0.005 | 0.371 | 0.982 |

| 4 | 3.95 ± 0.30 | 9.73 ± 0.35 | 0.043 ± 0.008 | 0.338 | 0.986 | |

| 10 | 3.53 ± 0.33 | 10.14 ± 0.78 | 0.081 ± 0.015 | 0.395 | 0.980 | |

| 15 | 4.45 ± 0.26 | 9.51 ± 0.23 | 0.236 ± 0.042 | 0.329 | 0.986 | |

| 20 | 3.22 ± 0.15 | 8.40 ± 0.18 | 0.255 ± 0.028 | 0.153 | 0.996 | |

| Modelling platform | 2 | 3.71 ± 0.85 | 9.94 ± 0.29 | 0.024 ± 0.003 | 0.274 | 0.984 |

| 4 | 3.83 ± 0.70 | 9.61 ± 0.32 | 0.035 ± 0.005 | 0.285 | 0.982 | |

| 10 | 3.32 ± 2.33 | 9.87 ± 0.57 | 0.076 ± 0.010 | 0.333 | 0.974 | |

| 15 | 4.24 ± 0.58 | 9.46 ± 0.21 | 0.178 ± 0.022 | 0.220 | 0.987 | |

| 20 | 3.03 ± 0.94 | 8.19 ± 0.17 | 0.243 ± 0.028 | 0.168 | 0.991 |

| Source | Temperature (°C) | y0 (log CFU/g) | ymax (log CFU/g) | µmax (1/h) | RMSE | R2 |

|---|---|---|---|---|---|---|

| Lytou et al. [18] | 4 | 5.12 ± 0.20 | 9.84 ± 0.12 | 0.088 ± 0.011 | 0.320 | 0.967 |

| 10 | 5.26 ± 0.12 | 9.86 ± 0.16 | 0.155 ± 0.021 | 0.363 | 0.955 | |

| 15 | 5.67 ± 0.22 | 9.79 ± 0.17 | 0.233 ± 0.033 | 0.368 | 0.935 | |

| Modelling platform | 4 | 4.51 ± 0.29 | 9.59 ± 0.05 | 0.045 ± 0.002 | 0.090 | 0.997 |

| 10 | 4.78 ± 0.79 | 9.77 ± 0.11 | 0.062 ± 0.010 | 0.234 | 0.979 | |

| 15 | 4.75 ± 1.19 | 9.35 ± 0.13 | 0.085 ± 0.026 | 0.296 | 0.955 |

| Source | Primary Model | y0 (log CFU/g) | ymax (log CFU/g) | Tmin (°C) | b1 (1/h.°C2) | b2 (-) | RMSE | R2 |

|---|---|---|---|---|---|---|---|---|

| Tarlak and Pérez-Rodríguez [13] | Modified Gompertz | 3.97 ± 0.34 | 9.66 ± 0.13 | −9.10 ± 0.80 | 0.0014 ± 0.0002 | 1.30 ± 1.20 | 0.548 | 0.930 |

| Logistic | 3.42 ± 0.16 | 9.60 ± 0.11 | −9.10 ± 0.80 | 0.0014 ± 0.0001 | 0.00 ± 0.00 | 0.553 | 0.928 | |

| Baranyi | 4.13 ± 0.24 | 9.52 ± 0.11 | −9.10 ± 0.80 | 0.0011 ± 0.0001 | 0.60 ± 0.90 | 0.570 | 0.924 | |

| Huang | 4.24 ± 0.13 | 9.52 ± 0.11 | −9.10 ± 0.80 | 0.0011 ± 0.0001 | 0.80 ± 0.70 | 0.563 | 0.926 | |

| Modelling platform | Modified | 3.97 ± 0.34 | 9.66 ± 0.13 | −9.24 ± 0.84 | 0.0014 ± 0.0002 | 1.29 ± 1.20 | 0.530 | 0.933 |

| Logistic | 3.42 ± 0.54 | 9.60 ± 0.13 | −9.10 ± 0.81 | 0.0014 ± 0.0002 | 0.00 ± 1.79 | 0.535 | 0.932 | |

| Baranyi | 3.85 ± 0.60 | 9.52 ± 0.11 | −9.06 ± 0.77 | 0.0011 ± 0.0001 | 0.00 ± 1.81 | 0.551 | 0.928 | |

| Huang | 4.29 ± 0.14 | 9.56 ± 0.11 | −7.25 ± 0.85 | 0.0017 ± 0.0002 | 2.41 ± 0.58 | 0.533 | 0.933 |

| Source | Available Chlorine Concentration (mg/L) | δ (s) | p (-) | RMSE | R2 |

|---|---|---|---|---|---|

| Possas et al. [19] | 50 | 19.91 ± 4.50 | 0.33 ± 0.03 | 0.130 | 0.980 |

| 100 | 4.35 ± 2.93 | 0.27 ± 0.05 | 0.288 | 0.920 | |

| 150 | 4.32 ± 2.36 | 0.30 ± 0.04 | 0.284 | 0.930 | |

| 200 | 3.91 ± 1.66 | 0.37 ± 0.04 | 0.334 | 0.960 | |

| Modelling platform | 50 | 20.43 ± 9.70 | 0.33 ± 0.05 | 0.113 | 0.980 |

| 100 | 4.12 ± 4.93 | 0.27 ± 0.07 | 0.254 | 0.927 | |

| 150 | 5.02 ± 4.82 | 0.31 ± 0.06 | 0.254 | 0.942 | |

| 200 | 3.59 ± 2.87 | 0.37 ± 0.06 | 0.294 | 0.967 |

| Source | a (s) | b (s) | δ (s) | RMSE | R2 |

|---|---|---|---|---|---|

| Possas et al. [19] | 60.26 ± 11.73 | 25.16 ± 4.86 | 0.33 ± 0.02 | 0.286 | 0.950 |

| Modelling platform | 64.49 ± 25.02 | 26.92 ± 10.41 | 0.33 ± 0.03 | 0.274 | 0.954 |

| Microorganism Behaviour | Machine Learning Model c | Set | RMSE | R2 |

|---|---|---|---|---|

| Growth a | GPR | Train | 0.251 | 0.986 |

| Test | 0.326 | 0.974 | ||

| SVR | Train | 0.668 | 0.904 | |

| Test | 0.652 | 0.897 | ||

| RFR | Train | 0.252 | 0.986 | |

| Test | 0.328 | 0.974 | ||

| Inhibition b | GPR | Train | 0.105 | 0.993 |

| Test | 0.119 | 0.991 | ||

| SVR | Train | 0.385 | 0.912 | |

| Test | 0.368 | 0.912 | ||

| RFR | Train | 0.105 | 0.993 | |

| Test | 0.119 | 0.991 |

| Tool | Scope | Limitations |

|---|---|---|

| ComBase/DMFIT | Fits Baranyi growth model (primary only) | No secondary modelling; limited to a single model |

| Growth Predictor | Baranyi model with secondary modelling (two-step only) | Error propagation; limited flexibility |

| CardinalFit | Fits secondary models (cardinal parameter approach) | Cannot handle primary model fitting |

| GInaFiT | Fits inactivation models (e.g., log-linear, Weibull) under static conditions | Growth modelling not supported |

| Our Platform | Implemented Functions | Planned Functions |

| Comparative model fitting | Multiple primary models (growth & inactivation), one-step and two-step approaches | Integration with additional public microbial databases (e.g., ComBase) |

| Machine learning | SVR, RFR, GPR models for both growth and inactivation, with uncertainty quantification | Development of hybrid mechanistic–ML models for improved interpretability |

| Usability | Unified web interface and API, interactive diagnostics, exportable reports, reproducible workflows | Automated hyperparameter optimization, expanded visualization options |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarlak, F.; Şimşek, B.B.; Şahin, M.; Pérez-Rodríguez, F. Next-Generation Predictive Microbiology: A Software Platform Combining Two-Step, One-Step and Machine Learning Modelling. Foods 2025, 14, 3158. https://doi.org/10.3390/foods14183158

Tarlak F, Şimşek BB, Şahin M, Pérez-Rodríguez F. Next-Generation Predictive Microbiology: A Software Platform Combining Two-Step, One-Step and Machine Learning Modelling. Foods. 2025; 14(18):3158. https://doi.org/10.3390/foods14183158

Chicago/Turabian StyleTarlak, Fatih, Büşra Betül Şimşek, Melissa Şahin, and Fernando Pérez-Rodríguez. 2025. "Next-Generation Predictive Microbiology: A Software Platform Combining Two-Step, One-Step and Machine Learning Modelling" Foods 14, no. 18: 3158. https://doi.org/10.3390/foods14183158

APA StyleTarlak, F., Şimşek, B. B., Şahin, M., & Pérez-Rodríguez, F. (2025). Next-Generation Predictive Microbiology: A Software Platform Combining Two-Step, One-Step and Machine Learning Modelling. Foods, 14(18), 3158. https://doi.org/10.3390/foods14183158