Comparative Analysis of Chemical Composition and Food Safety of Commercial Fish Sauces from Four Asian Countries

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Determination of Physical and Chemical Properties of Fish Sauce

2.3. Determination of Salt Concentration

2.4. Determination of Nitrogenous Compounds

2.4.1. Total Volatile Basic Nitrogen (TVBN), Trimethylamine Oxide (TMAO), and Trimethylamine (TMA) Determination

2.4.2. Determination of Total Nitrogen (TN), and Amino Nitrogen (AN)

2.5. Determination of Biogenic Amine (BA) Content

2.6. 1H NMR Spectroscopy and Spectral Analysis

2.7. Statistical Analyses

3. Results and Discussion

3.1. Chemical Properties

3.2. Nitrogenous Compounds of Fish Sauces

3.3. Total Nitrogen (TN) and Amino Nitrogen (AN)

3.4. Biogenic Amine (Bas)

3.5. Preservatives

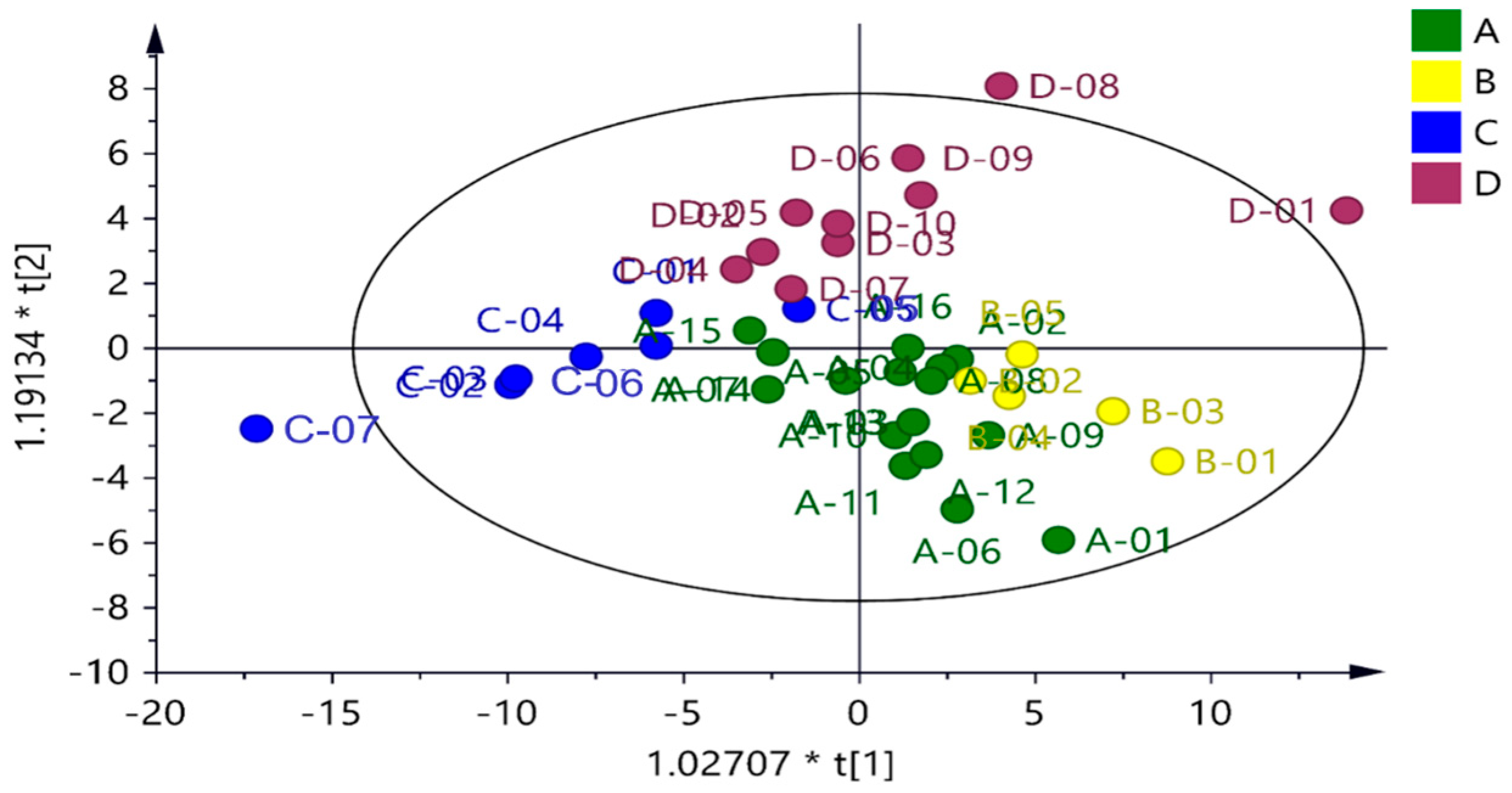

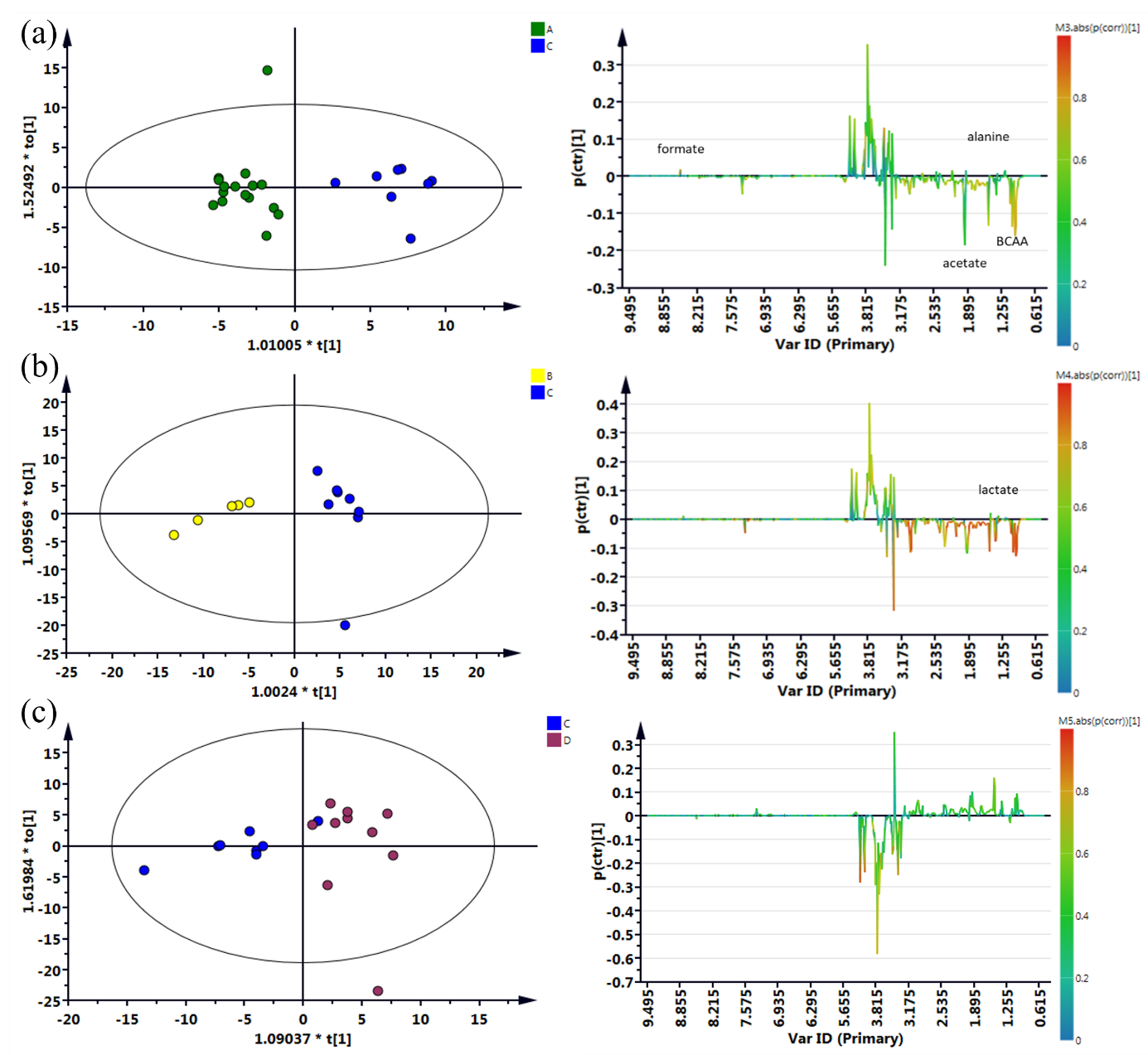

3.6. Metabolomic Analysis of Fish Sauce via 1H-NMR Spectroscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sample | Origin | Price TWD/100 mL | Raw Materials | Remark |

|---|---|---|---|---|

| A1 | Thailand | 50 | Anchovies, salt, sucrose, syrup, licorrhizin | |

| A2 | Thailand | 45 | Anchovies, salt, sugar, syrup | |

| A3 | Thailand | 25 | Anchovies, sugar, salt | |

| A4 | Thailand | 25 | Anchovies, salt, sugar | |

| A5 | Thailand | 80 | Anchovies, salt, sugar | |

| A6 | Thailand | 11 | Anchovies, salt, sugar | |

| A7 | Thailand | 20 | Anchovies, salt, sugar | |

| A8 | Thailand | 25 | Anchovies, salt, sugar | |

| A9 | Thailand | 22 | Anchovies, salt, sugar | |

| A10 | Thailand | 24 | Anchovies, salt, sugar | |

| A11 | Thailand | 11 | Anchovies, salt, sugar | |

| A12 | Thailand | 9 | Anchovies, iodized salt, sugar | |

| A13 | Thailand | 11 | Anchovies, salt, sugar | |

| A14 | Thailand | 38 | Anchovies, salt, sugar, monosodium glutamate (MSG) | |

| A15 | Thailand | 10 | Gourami, Anabas testudineus, minnow, salt, sugar, sucralose, monosodium L-glutamate | |

| A16 | Thailand | 20 | Anchovies, salt, sugar | |

| B1 | Korea | 18 | Sand lance, salt | |

| B2 | Korea | 36 | Sand lance, salt, shrimp, sugar, monosodium L-glutamate, sodium 5’-inosinate (IMP), sodium 5’-guanylate (GMP), maltodextrin, yeast extract, fructose, vitamin B1 | |

| B3 | Korea | 24 | Anchovies, salt, glucose, lactic acid, alcohol, IMP, GMP, glycine | |

| B4 | Korea | 24 | Sand lance, shrimp, salt | |

| B5 | Korea | 24 | Anchovies, salt, monosodium L-glutamate | |

| C1 | Taiwan | 7 | Fish sauce, hydrolyzate of soybean protein, salt, sugar, disodium succinate, potassium sorbate | |

| C2 | Taiwan | 40 | Mackerel fish sauce, salt, sucrose, potassium sorbate | |

| C3 | Taiwan | 20 | Mackerel fish sauce, salt, sucrose | |

| C4 | Taiwan | 12 | Mackerel fish sauce, salt, sucrose, potassium sorbate | |

| C5 | Taiwan | 7 | Soybean hydrolyzate, fish sauce, salt, sucralose, acesulfame potassium, benzoic acid, silicon dioxide | |

| C6 | Taiwan | 8 | Salt, anchovies, hydrolyzate of soybean protein, sugar | |

| C7 | Taiwan | 33 | Milkfish, non-GMO soybeans, wheat, sugar, salt, rice vinegar, shiitake seasoning, IMP, sodium erythorbate | |

| D1 | Vietnam | 23 | Salanxchinensis, salt, acesulfame potassium | |

| D2 | Vietnam | 7 | Anchovies, salt, sugar, monosodium L-glutamate, GMP, IMP, acetic acid, citric acid, salmon flavor, potassium sorbate, sodium benzoate, xanthan gum, caramel color, carmine | |

| D3 | Vietnam | 10 | Anchovies, salt, sugar, monosodium L-glutamate, DL-alanine, glycine, acetic acid, citric acid, salmon flavor, potassium sorbate, sodium benzoate, xanthan gum, aspartame, gardenia yellow, caramel color, carmine | TN > 10 g/L |

| D4 | Vietnam | 14 | Anchovies, salt, sugar, monosodium L-glutamate, GMP, IMP, acetic acid, citric acid, flavor, potassium sorbate, sodium benzoate, xanthan gum, caramel color, carmine | |

| D5 | Vietnam | 14 | Anchovies, salt, sugar, DL-alanine, monosodium L-glutamate, IMP, GMP, L-glutamic acid, glycine, acetic acid, citric acid, salmon flavor, sodium benzoate, xanthan gum, beta vulgaris color, caramel color, gardenia yellow, aspartame | |

| D6 | Vietnam | 16 | Anchovies, iodized salt, L-glutamic acid, monosodium L-glutamate, IMP, GMP, DL-alanine, glycine, citric acid, sodium citrate, glucono-δ-lactone, fish sauce flavor, gardenia yellow | |

| D7 | Vietnam | 6 | Salt, anchovies, monosodium L-glutamate, IMP, GMP, acetic acid, citric acid, sodium benzoate, potassium sorbate, acesulfame potassium, xanthan gum, caramel color | |

| D8 | Vietnam | 128 | Anchovies, salt, E631(disodium inosinate), E950 (acesulfame potassium) | |

| D9 | Vietnam | 70 | Anchovies, sugar, iodized salt, E330 (citric acid), D-xylitol, natural flavor, E950 (acesulfame potassium), caramel | TN = 35 g/L |

| D10 | Vietnam | 6 | Anchovies, salt, monosodium L-glutamate, glycine, L-alanine, GMP, IMP, sodium citrate, DL-malic acid, soybean hydrolyzate, fish sauce flavor, salmon flavor, sodium benzoate, potassium sorbate, acesulfame potassium, aspartame, xanthan gum, caramel color, carmine, gardenia yellow |

References

- Sanceda, N.G.; Kurata, T.; Arakawa, N. Accelerated fermentation process for the manufacture of fish sauce using histidine. J. Food Sci. 1996, 61, 220–222. [Google Scholar] [CrossRef]

- Gao, P.; Xia, W.; Li, X.; Liu, S.Q. Use of wine and dairy yeasts as single starter cultures for flavor compound modification in fish sauce fermentation. Front. Microbiol. 2019, 10, 2300. [Google Scholar] [CrossRef]

- Grand View Research. Fish Sauce Market Size, Share & Trends Analysis Report by Product, by Application, by Distribution Channel, by Region, and Segment Forecasts, 2024–2030; Grand View Research: San Francisco, CA, USA, 2024; Available online: https://www.grandviewresearch.com/industry-analysis/fish-sauce-market (accessed on 14 August 2025).

- Tsai, Y.H.; Lin, C.Y.; Chien, L.T.; Lee, T.M.; Wei, C.I.; Hwang, D.F. Histamine contents of fermented fish products in Taiwan and isolation of histamine-forming bacteria. Food Chem. 2006, 98, 64–70. [Google Scholar] [CrossRef]

- Zarei, M.; Najafzadeh, H.; Eskandari, M.H.; Pashmforoush, M.; Enayati, A.; Gharibi, D.; Fazlara, A. Chemical and microbial properties of mahyaveh, a traditional Iranian fish sauce. Food Control 2012, 23, 511–514. [Google Scholar] [CrossRef]

- Jiang, W.; Xu, Y.; Li, C.; Dong, X.; Wang, D. Biogenic amines in commercially produced Yulu, a Chinese fermented fish sauce. Food Addit. Contam. Part B 2014, 7, 25–29. [Google Scholar] [CrossRef]

- Colombo, F.M.; Cattaneo, P.; Confalonieri, E.; Bernardi, C. Histamine Food Poisonings: A Systematic Review and Meta-Analysis. Crit. Rev. Food Sci. Nutr. 2018, 58, 1131–1151. [Google Scholar] [CrossRef] [PubMed]

- MOHW Food No. 1031901169 (MOHWH0014.03); General Method of Test for Heavy Metals. Ministry of Health and Welfare: Taiwan, China, 2014.

- Konosu, S.; Watanabe, K.; Shimizu, T. Distribution of nitrogenous components in the muscle extracts of eight species of fish. Nippon. Suisan Gakkaishi 1974, 40, 909–914. [Google Scholar] [CrossRef][Green Version]

- Cobb, B.; Alaniz, I.; Thompson, C. Biochemical and microbial studies on shrimp: Volatile nitrogen and amino nitrogen analysis. J. Food Sci. 1973, 38, 431–436. [Google Scholar] [CrossRef]

- Huang, Y.R.; Liu, K.J.; Hsieh, H.S.; Hsieh, C.H.; Hwang, D.F.; Tsai, Y.H. Histamine level and histamine-forming bacteria in dried fish products sold in Penghu Island of Taiwan. Food Control 2010, 21, 1234–1239. [Google Scholar] [CrossRef]

- AOAC. Official Method of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2000. [Google Scholar]

- TISI. Standard for Local Fish Sauce; Thai Industrial Standards Institute, Ministry of Industry: Bangkok, Thailand, 1983. [Google Scholar]

- Chen, H.C.; Huang, Y.R.; Hsu, H.H.; Lin, C.S.; Chen, W.C.; Lin, C.M.; Tsai, Y.H. Determination of histamine and biogenic amines in fish cubes (Tetrapturus angustirostris) implicated in a food-borne poisoning. Food Control 2010, 21, 13–18. [Google Scholar] [CrossRef]

- Cho, Y.J.; Im, S.Y.; Lee, K.W.; Kim, G.B.; Choi, Y.J. Quality investigation of commercial northern sand lance, Ammodytes personatus sauces. Korean J. Fish. Aquat. Sci. 1999, 32, 612–617. [Google Scholar]

- Um, I.S.; Park, K.S. Biogenic amine contents of commercial salted and fermented sand lance Ammodytes personatus sauces. Korean J. Fish. Aquat. Sci. 2015, 48, 883–887. [Google Scholar] [CrossRef][Green Version]

- Park, J.N.; Fukumoto, Y.; Fujita, E.; Tanaka, T.; Washio, T.; Otsuka, S.; Shimizu, T.; Watanabe, K.; Abe, H. Chemical composition of fish sauces produced in Southeast and East Asian countries. J. Food Compos. Anal. 2001, 14, 113–125. [Google Scholar] [CrossRef]

- Nakano, M.; Sagane, Y.; Koizumi, R.; Nakazawa, Y.; Yamazaki, M.; Watanabe, T.; Takano, K.; Sato, H. Data on the chemical properties of commercial fish sauce products. Data Brief 2017, 15, 658–664. [Google Scholar] [CrossRef] [PubMed]

- Lopetcharat, K.; Park, J.W. Characteristics of fish sauce made from Pacific whiting and surimi by-products during fermentation stage. J. Food Sci. 2002, 67, 511–516. [Google Scholar] [CrossRef]

- Yimdee, T.; Wang, X.C. Comparison of odor and taste of commercial brand fish sauces from East and Southeast Asian countries. Int. J. Food Prop. 2016, 19, 873–896. [Google Scholar] [CrossRef]

- Order No. 1101300478; Regulations on the Compliance of Nutritional Labeling on Packaged Foods. Ministry of Health and Welfare: Taipei, Taiwan, 2022.

- Zhu, W.; Luan, H.; Bu, Y.; Li, J.; Li, X.; Zhang, Y. Changes in taste substances during fermentation of fish sauce and the correlation with protease activity. Food Res. Int. 2021, 144, 110349. [Google Scholar] [CrossRef]

- Bulushi, I.A.; Poole, S.; Deeth, H.C.; Dykes, G.A. Biogenic amines in fish: Roles in intoxication, spoilage, and nitrosamine formation—A review. Crit. Rev. Food Sci. Nutr. 2009, 49, 369–377. [Google Scholar] [CrossRef]

- International Agency for Research on Cancer. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; IARC Scientific Publications: Lyon, France, 2012; Volume 100, p. 385. [Google Scholar]

- Bekhit, A.E.D.A.; Holman, B.W.; Giteru, S.G.; Hopkins, D.L. Total volatile basic nitrogen (TVB-N) and its role in meat spoilage: A review. Trends Food Sci. Technol. 2021, 109, 280–302. [Google Scholar] [CrossRef]

- Park, S.; Sung, J.; Choi, H.Y.; Jeong, J.; Jeong, H.G.; Kim, J.C.; Jang, M. Changes in the physicochemical properties and metabolites of Myeolchi-jeot (salted-fermented anchovy) based on fermentation time. LWT 2023, 177, 114456. [Google Scholar] [CrossRef]

- Jiang, J.J.; Zeng, Q.X.; Zhu, Z.W.; Zhang, L.Y. Chemical and sensory changes associated Yu-lu fermentation process—A traditional Chinese fish sauce. Food Chem. 2007, 104, 1629–1634. [Google Scholar] [CrossRef]

- KSH 6022; Korean Industrial Standards: Fermented Anchovy Sauce. Korean Agency for Technology and Standards (KATS): Eumsung, Republic of Korea, 2016.

- Cho, Y.J.; Lee, H.H.; Kim, B.K.; Gye, H.J.; Jung, W.Y.; Shim, K.B. Quality evaluation to determine the grading of commercial salt-fermented fish sauce in Korea. J. Fish. Mar. Sci. Educ. 2014, 26, 823–830. [Google Scholar][Green Version]

- Joung, B.C.; Min, J.G. Changes in postfermentation quality during the distribution process of anchovy (Engraulis japonicus) fish sauce. J. Food Prot. 2018, 81, 969–976. [Google Scholar] [CrossRef]

- Moon, J.S.; Kim, Y.; Jang, K.I.; Cho, K.J.; Yang, S.J.; Yoon, G.M.; Kim, S.Y.; Han, N.S. Analysis of biogenic amines in fermented fish products consumed in Korea. Food Sci. Biotechnol. 2010, 19, 1689–1692. [Google Scholar] [CrossRef]

- Kim, B.K.; Kim, Y.H.; Lee, H.H.; Cho, Y.J.; Kim, D.S.; Oh, S.M.; Shim, K.B. Comparison of the chemical compositions and biogenic amine contents of salt-fermented fish sauces produced in Korea to evaluate the quality characteristics. J. Fish. Mar. Educ. 2011, 23, 607–614. [Google Scholar]

- Kimura, B.; Konagaya, Y.; Fujii, T. Histamine Formation by Tetragenococcus muriaticus, a Halophilic Lactic Acid Bacterium Isolated from Fish Sauce. Int. J. Food Microbiol. 2001, 70, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.W. Characteristics of kimchi added with anchovy sauce from heat and non-heat treatments. Culin. Sci. Hosp. Res. 2013, 19, 49–58. [Google Scholar]

- Tran, Q.H.; Nguyen, T.T.; Pham, K.P. Development of the high sensitivity and selectivity method for the determination of histamine in fish and fish sauce from Vietnam by UPLC-MS/MS. Int. J. Anal. Chem. 2020, 2020, 2187646. [Google Scholar] [CrossRef] [PubMed]

- U.S. Food and Drug Administration (FDA). Fish and Fishery Products Hazards and Controls Guidance, 2022th ed.; U.S. Department of Health and Human Services: Washington, DC, USA, 2022; Chapter 7: Scombrotoxin (Histamine) Formation.

- European Commission. Commission Regulation (EU) No 1019/2013 of 23 October 2013 amending Annex I to Regulation (EC) No 2073/2005 as regards histamine in fishery products. Off. J. Eur. Union 2013, L282, 46–47. [Google Scholar]

- Wu, T.; Wang, M.; Wang, P.; Tian, H.; Zhan, P. Advances in the formation and control methods of undesirable flavors in fish. Foods 2022, 11, 2504. [Google Scholar] [CrossRef]

- Devos, M.F.J.P. Standardized human olfactory thresholds. J. Odor Res. Eng. 1995, 26, 27–47. [Google Scholar]

- Van Gemert, L.J. Compilations of Odour Threshold Values in Air, Water and Other Media; Oliemans Punter & Partners BV: Utrecht, The Netherlands, 2003. [Google Scholar]

- Udomsil, N.; Rodtong, S.; Choi, Y.J.; Hua, Y.; Yongsawatdigul, J. Use of Tetragenococcus halophilus as a Starter Culture for Flavor Improvement in Fish Sauce Fermentation. J. Agric. Food Chem. 2011, 59, 8401–8408. [Google Scholar] [CrossRef]

- Bai, J.; Baker, S.M.; Goodrich-Schneider, R.M.; Montazeri, N.; Sarnoski, P.J. Aroma profile characterization of mahi-mahi and tuna for determining spoilage using purge and trap gas chromatography-mass spectrometry. J. Food Sci. 2019, 84, 481–489. [Google Scholar] [CrossRef]

- Lapsongphon, N.; Yongsawatdigul, J.; Cadwallader, K.R. Identification and characterization of the aroma-impact components of Thai fish sauce. J. Agric. Food Chem. 2015, 63, 2628–2638. [Google Scholar] [CrossRef]

- Liu, C.; Meng, F.; Tang, X.; Shi, Y.; Wang, A.; Gu, Z.; Pan, Z. Comparison of nonvolatile taste active compounds of wild and cultured mud crab Scylla paramamosain. Fish. Sci. 2018, 84, 897–907. [Google Scholar]

- Wang, Y.; Li, C.; Li, L.; Yang, X.; Chen, S.; Wu, Y.; Zhao, Y.; Wang, J.; Wei, Y.; Yang, D. Application of UHPLC-Q/TOF-MS-based metabolomics in the evaluation of metabolites and taste quality of Chinese fish sauce (Yu-lu) during fermentation. Food Chem. 2019, 296, 132–141. [Google Scholar] [CrossRef] [PubMed]

- McKelvie, J.R.; Yuk, J.; Xu, Y.; Simpson, A.J.; Simpson, M.J. 1H NMR and GC/MS metabolomics of earthworm responses to sub-lethal DDT and endosulfan exposure. Metabolomics 2009, 5, 84–94. [Google Scholar] [CrossRef]

- Ciampa, A.; Laghi, L.; Picone, G. Validation of a 1H-NMR spectroscopy quantitative method to quantify trimethylamine content and K-index value in different species of fish. J. Food Qual. 2022, 1, 3612095. [Google Scholar] [CrossRef]

- Picone, G. The 1H HR-NMR Methods for the Evaluation of the Stability, Quality, Authenticity, and Shelf Life of Foods. Encyclopedia 2024, 4, 1617–1628. [Google Scholar] [CrossRef]

| No. of Sample | pH | Aw | Na (mg/100 mL) | TVBN 1 (mg/100 g) | TMA 2 (mg/100 g) | TMAO 3 (mg/100 g) | |

|---|---|---|---|---|---|---|---|

| Thailand | 16 | 4.79–5.62 4 (5.26 ± 0.28) b,5 | 0.701–0.841 (0.731 ± 0.033) b | 8621.96–12,637.12 (11,018.18 ± 909.09) a | 13.85–457.03 (199.16 ± 106.93) ab | 7.80–49.28 (23.78 ± 10.96) b | ND 6–61.64 (33.37 ± 16.64) a |

| Korea | 5 | 5.60–6.13 (5.80 ± 0.29) a | 0.735–0.767 (0.747 ± 0.012) b | 10,323.69–12,308.68 (11,546.30 ± 535.00) a | 147.49–236.29 (186.66 ± 38.87) ab | 12.73–72.14 (42.93 ± 21.94) a | ND–41.89 (18.15 ± 15.30) |

| Taiwan | 7 | 4.51–6.04 (5.50 ± 0.59 ) ab | 0.745–0.870 (0.813 ± 0.050) a | 5037.55–11,417.20 (7968.11 ± 2319.58) b | 38.95–117.39 (66.45 ± 29.80) b | 19.03–32.17 (27.44 ± 4.78) ab | 1.64–47.64 ab (20.85 ± 14.49) |

| Vietnam | 10 | 4.63–5.99 (5.11 ± 0.42) b | 0.674–0.822 (0.754 ± 0.056) b | 8621.96–11,334.49 (9512.79 ± 1158.52) c | 26.65–689.29 (253.71 ± 205.53) a | 2.05–66.66 (31.57 ± 20.29) ab | ND–69.80 (13.55 ± 21.79) b |

| Code 1 | Label Values (mg/100 mL) | Laboratory Values (mg/100 mL) | Tolerance Limit (%) 2 |

|---|---|---|---|

| A5 | 7400 | 10,791.60 | 146 |

| A6 | 7400 | 11,542.32 | 156 |

| A11 | 7990 | 11,041.84 | 138 |

| A12 | 6900 | 12,167.92 | 176 |

| A13 | 8850 | 11,135.68 | 126 |

| A14 | 7300 | 10,134.72 | 139 |

| B1 | 6821 | 12,308.68 | 180 |

| B2 | 6344 | 11,334.49 | 179 |

| B3 | 8955 | 11,158.07 | 125 |

| B4 | 6821 | 11,886.40 | 174 |

| B5 | 7579 | 11,043.86 | 146 |

| C7 | 3950 | 5037.55 | 128 |

| D1 | 8100 | 11,229.52 | 139 |

| D8 | 6064 | 10,365.73 | 171 |

| D10 | 6800 | 8621.96 | 127 |

| Country | TN 1 | AN 2 |

|---|---|---|

| Thailand | 5.93–20.09 3 (13.32 ± 4.70) ab,4 | 3.50–12.46 (7.62 ± 2.67) b |

| Korea | 9.01–13.02 (10.70 ± 2.03) b | 2.15–8.32 (5.97 ± 2.48) b |

| Taiwan | 1.80–8.19 (4.77 ± 2.54) b | 0.97–8.41 (3.28 ± 2.57) b |

| Vietnam | 2.45–56.40 (22.00 ± 16.46) a | 0.74–32.56 (13.97 ± 10.70) a |

| Country | No. of Sample | Trp 1 | Pea 2 | Put 3 | Cad 4 | Him 5 | Tyr 6 | Spd 7 | Spe 8 |

|---|---|---|---|---|---|---|---|---|---|

| Contents of Biogenic Amine (ppm) | |||||||||

| Thailand | 16 | 5.04–63.65 9 (18.96 ± 14.89) b,10 | 1.52–25.57 (8.03 ± 6.34) b | 9.75–161.67 (44.63 ± 44.12) a | 28.24–360.06 (94.95 ± 84.26) a | 26.09–514.54 (150.16 ± 136.97) b | 6.21–86.32 (32.57 ± 20.04) a | ND–11.68 (1.01 ± 3.00) a | ND–0.36 (0.05 ± 0.12) b |

| Korea | 5 | 88.59–219.29 (127.46 ± 55.72) a | 17.37–37.72 (26.54 ± 8.28) a | 19.50–53.42 (33.55 ± 13.98) a | 20.60–64.85 (44.34 ± 15.73) ab | 192.11–1046.05 (539.85 ± 318.88) a | 14.02–55.00 (35.25 ± 15.06) a | ND (ND) a,11 | ND (ND) b |

| Taiwan | 7 | 1.88–11.82 (5.21 ± 3.70) c | 0.11–32.37 (6.63 ± 11.56) b | ND–52.87 (15.91 ± 19.73) a | ND–97.00 (23.53 ± 40.38) b | 2.72–132.71 (60.40 ± 55.68) b | 6.53–116.96 (41.26 ± 41.97) a | ND (ND) a | ND–7.16 (2.76 ± 3.09) a |

| Vietnam | 10 | 0.53–137.95 (42.58 ± 37.14) b | ND–99.56 (18.03 ± 29.04) ab | ND–91.56 (24.35 ± 26.94) a | 1.68–116.22 (53.77 ± 35.20) ab | ND–511.39 (194.08 ± 137.49) b | 2.74–34.86 (15.68 ± 9.57) a | ND–88.16 (12.89 ± 27.99) a | ND (ND) b |

| Sample | Product Label | Benzoic Acid (g/kg) | Sorbic Acid (g/kg) |

|---|---|---|---|

| C1 | Sorbic acid | ND 1 | 3.07 a |

| C2 | Sorbic acid | ND | 1.69 a |

| C4 | Sorbic acid | ND | ND b |

| C5 | Benzoic acid | 0.53 | ND |

| C6 | None | ND | 3.22 ac |

| D2 | Benzoic and sorbic acids | 0.54 | ND b |

| D3 | Benzoic and sorbic acids | 0.58 | 0.11 |

| D4 | Benzoic and sorbic acids | 0.50 | ND |

| D5 | Benzoic acid | 0.59 | ND |

| D7 | Benzoic and sorbic acids | 0.46 | 0.87 |

| D10 | Benzoic and sorbic acids | 0.39 | 1.12 a |

| Thailand | Korea | Taiwan | Vietnam | |

|---|---|---|---|---|

| Glucose | 425.50 ± 241.06 ab,4 (49.82–932.22) 5 | 34.80 ± 27.49 b (3.35–64.10) | 762.98 ± 479.83 a (3.14–1580.92) | 389.40 ± 906.02 ab (2.12–2940.64) |

| Betaine | 4.16 ± 2.14 ab (0.79–10.62) | 5.41 ± 2.87 a (1.78–9.78) | 1.82 ± 1.13 b (0.49–4.19) | 4.50 ± 4.33 ab (0.13–12.16) |

| TMA 1 | 1.14 ± 0.54 bc (0.35–2.66) | 2.57 ± 0.83 a (1.49–3.70) | 0.22 ± 0.16 c (0.03–0.48) | 1.49 ± 1.90 b (0.04–6.18) |

| DMA 2 | 0.56 ± 0.39 a (0.11–1.68) | 0.30 ± 0.14 ab (0.10–0.45) | 0.12 ± 0.07 b (0.03–0.25) | 0.32 ± 0.46 ab (0.02–1.50) |

| Acetate | 37.89 ± 18.81 a (6.03–94.22) | 39.92 ± 17.50 a (17.81–60.01) | 6.87 ± 2.92 b (3.05–11.83) | 29.96 ± 33.38 a (4.22–98.34) |

| Alanine | 28.68 ± 14.90 ab (4.43–73.63) | 29.04 ± 12.19 ab (15.93–48.70) | 10.61 ± 6.52 b (1.84–20.53) | 44.04 ± 31.76 a (0.81–96.96) |

| Valine | 38.03 ± 18.74 a (6.13–93.53) | 37.78 ± 13.08 a (28.44–60.08) | 9.08 ± 5.58 b (2.90–19.36) | 37.72 ± 39.17 a (0.79–115.13) |

| Lactate | 20.26 ± 9.95 ab (4.20–48.22) | 15.23 ± 8.70 ab (7.31–29.19) | 6.70 ± 4.20 b (2.42–16.39) | 24.03 ± 23.40 a (1.17–66.28) |

| Glycine | 63.78 ± 67.83 a (10.15–284.64) | 28.35 ± 20.41 a (12.47–63.18) | 42.61 ± 35.33 a (10.68–125.68) | 68.55 ± 60.39 a (9.39–181.29) |

| DMS 3 | 3.44 ± 1.57 a (1.74–8.49) | 4.15 ± 1.44 a (2.99–6.37) | 0.99 ± 0.61 b (0.43–2.33) | 3.80 ± 3.63 a (0.33–10.52) |

| Glucose | Betaine | Lactate | Gly | Val | Ala | Glucose | Betaine | Lactate | Gly | Val | Ala | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Threshold 1 | 860 2 | 250 2 | 126 2 | 130 3 | 60 3 | 40 3 | Threshold | 860 2 | 250 2 | 126 2 | 130 3 | 60 3 | 40 3 |

| Code | TAV | Code | TAV | ||||||||||

| A1 | 1.08 * | 0.04 | 0.38 | 2.19 | 1.56 | 1.84 | B4 | 0.00 | 0.02 | 0.14 | 0.17 | 0.53 | 0.66 |

| A2 | 0.34 | 0.02 | 0.20 | 1.03 | 0.80 | 0.94 | B5 | 0.07 | 0.01 | 0.06 | 0.10 | 0.47 | 0.40 |

| A3 | 0.68 | 0.02 | 0.19 | 0.31 | 0.66 | 0.79 | C1 | 0.61 | 0.01 | 0.05 | 0.29 | 0.17 | 0.38 |

| A4 | 0.28 | 0.02 | 0.16 | 0.62 | 0.65 | 0.71 | C2 | 1.33 | 0.01 | 0.04 | 0.26 | 0.09 | 0.08 |

| A5 | 0.57 | 0.02 | 0.21 | 0.61 | 0.67 | 0.85 | C3 | 1.20 | 0.01 | 0.04 | 0.25 | 0.11 | 0.16 |

| A6 | 0.60 | 0.02 | 0.21 | 0.26 | 0.79 | 0.83 | C4 | 0.73 | 0.00 | 0.02 | 0.17 | 0.05 | 0.05 |

| A7 | 0.78 | 0.01 | 0.13 | 0.24 | 0.42 | 0.53 | C5 | 0.00 | 0.00 | 0.03 | 0.08 | 0.07 | 0.23 |

| A8 | 0.06 | 0.01 | 0.08 | 0.10 | 0.52 | 0.46 | C6 | 0.80 | 0.01 | 0.06 | 0.37 | 0.24 | 0.51 |

| A9 | 0.07 | 0.01 | 0.11 | 0.13 | 0.72 | 0.63 | C7 | 0.58 | 0.01 | 0.04 | 0.24 | 0.17 | 0.37 |

| A10 | 0.61 | 0.02 | 0.18 | 0.23 | 0.61 | 0.74 | D1 | 1.84 | 0.02 | 0.13 | 0.97 | 0.32 | 0.35 |

| A11 | 0.85 | 0.02 | 0.21 | 0.36 | 0.77 | 0.90 | D2 | 0.02 | 0.04 | 0.49 | 0.53 | 1.92 | 2.42 |

| A12 | 0.54 | 0.02 | 0.16 | 0.49 | 0.67 | 0.75 | D3 | 3.42 | 0.05 | 0.53 | 1.39 | 1.62 | 2.19 |

| A13 | 0.30 | 0.01 | 0.11 | 0.35 | 0.44 | 0.46 | D4 | 0.18 | 0.01 | 0.08 | 0.24 | 0.26 | 1.08 |

| A14 | 0.48 | 0.01 | 0.09 | 0.15 | 0.28 | 0.34 | D5 | 0.47 | 0.01 | 0.08 | 0.16 | 0.26 | 0.37 |

| A15 | 0.48 | 0.00 | 0.03 | 0.08 | 0.10 | 0.11 | D6 | 0.27 | 0.01 | 0.09 | 0.21 | 0.29 | 0.93 |

| A16 | 0.21 | 0.01 | 0.12 | 0.71 | 0.48 | 0.58 | D7 | 0.02 | 0.01 | 0.10 | 1.31 | 0.33 | 0.97 |

| B1 | 0.06 | 0.04 | 0.23 | 0.49 | 1.00 | 1.22 | D8 | 0.00 | 0.00 | 0.01 | 0.07 | 0.01 | 0.02 |

| B2 | 0.05 | 0.02 | 0.08 | 0.12 | 0.49 | 0.59 | D9 | 0.01 | 0.03 | 0.30 | 0.31 | 0.90 | 1.42 |

| B3 | 0.01 | 0.02 | 0.10 | 0.22 | 0.65 | 0.76 | D10 | 0.14 | 0.02 | 0.18 | 0.57 | 0.59 | 1.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.-R.; Wu, P.-C.; Lo, C.-J.; Lee, Y.-C.; Tsai, Y.-H. Comparative Analysis of Chemical Composition and Food Safety of Commercial Fish Sauces from Four Asian Countries. Foods 2025, 14, 3134. https://doi.org/10.3390/foods14173134

Huang Y-R, Wu P-C, Lo C-J, Lee Y-C, Tsai Y-H. Comparative Analysis of Chemical Composition and Food Safety of Commercial Fish Sauces from Four Asian Countries. Foods. 2025; 14(17):3134. https://doi.org/10.3390/foods14173134

Chicago/Turabian StyleHuang, Yu-Ru, Pei-Chuan Wu, Chi-Jen Lo, Yi-Chen Lee, and Yung-Hsiang Tsai. 2025. "Comparative Analysis of Chemical Composition and Food Safety of Commercial Fish Sauces from Four Asian Countries" Foods 14, no. 17: 3134. https://doi.org/10.3390/foods14173134

APA StyleHuang, Y.-R., Wu, P.-C., Lo, C.-J., Lee, Y.-C., & Tsai, Y.-H. (2025). Comparative Analysis of Chemical Composition and Food Safety of Commercial Fish Sauces from Four Asian Countries. Foods, 14(17), 3134. https://doi.org/10.3390/foods14173134