Recent Advances and Future Perspectives on Heat and Mass Transfer Mechanisms Enhanced by Preformed Porous Media in Vacuum Freeze-Drying of Agricultural and Food Products

Abstract

1. Introduction

2. Spray-Based Techniques for Constructing Porous Structures: Methods and Applications

2.1. Types of Spray Freeze-Drying (SFD) Technologies

2.1.1. Spray Freezing into Vapor over Liquid (SFV/L)

2.1.2. Spray Freezing into Vapor (SFV)

2.1.3. Spray Freezing into Liquid (SFL)

2.1.4. Spray Freezing onto Cooling Surface (SFCS)

2.2. Process Parameters and Pore Structure Control

2.2.1. Droplet Size and Initial Concentration

2.2.2. Freezing Medium Temperature and Freezing Rate

2.2.3. Additives and Nucleation Control

2.3. Structural Design Strategies and Application Challenges

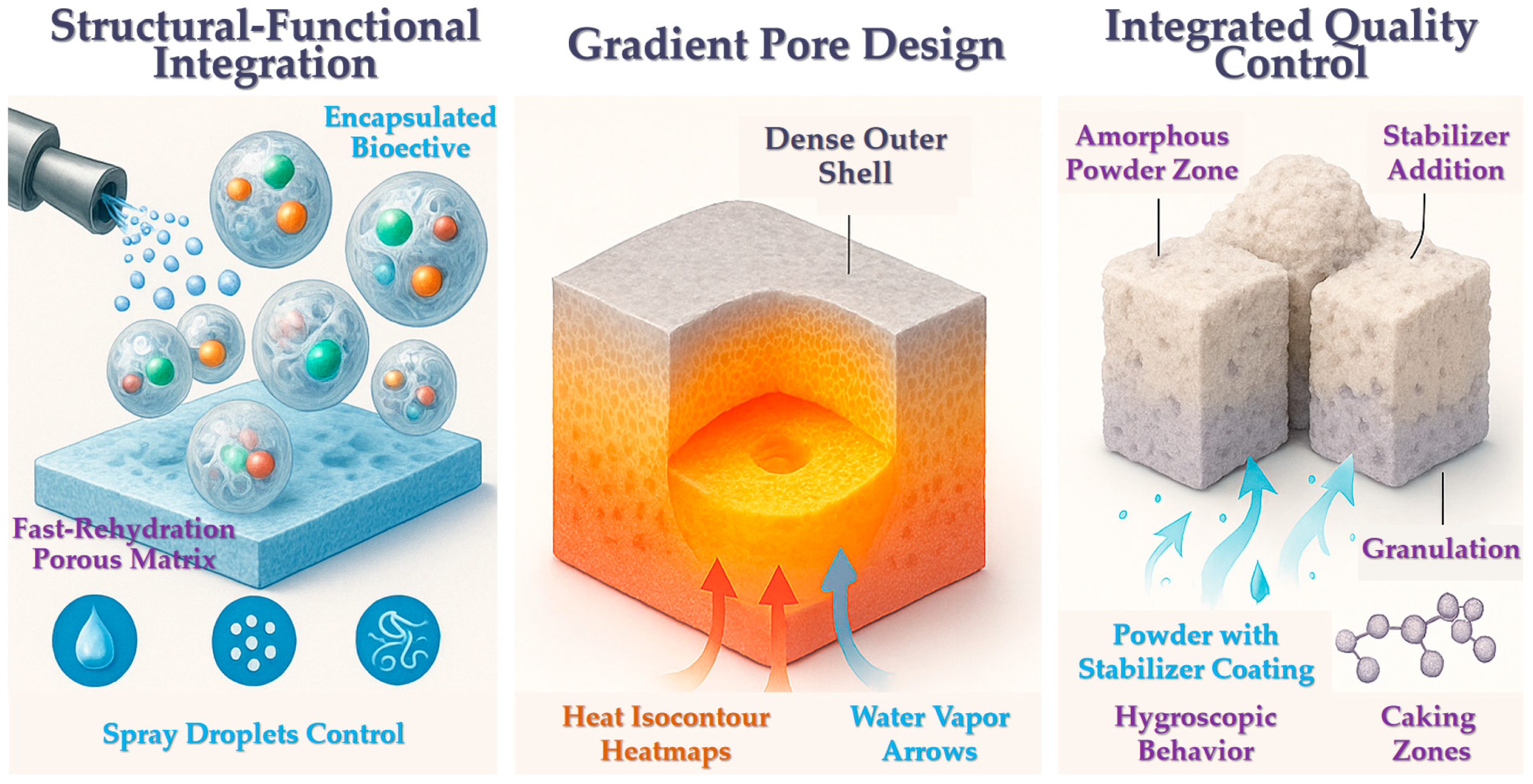

2.3.1. Structural–Functional Integration

2.3.2. Gradient Pore Structures

2.3.3. Integrated Quality Control

3. Mechanistic Analysis of Heat and Mass Transfer Enhancement by Porous Media

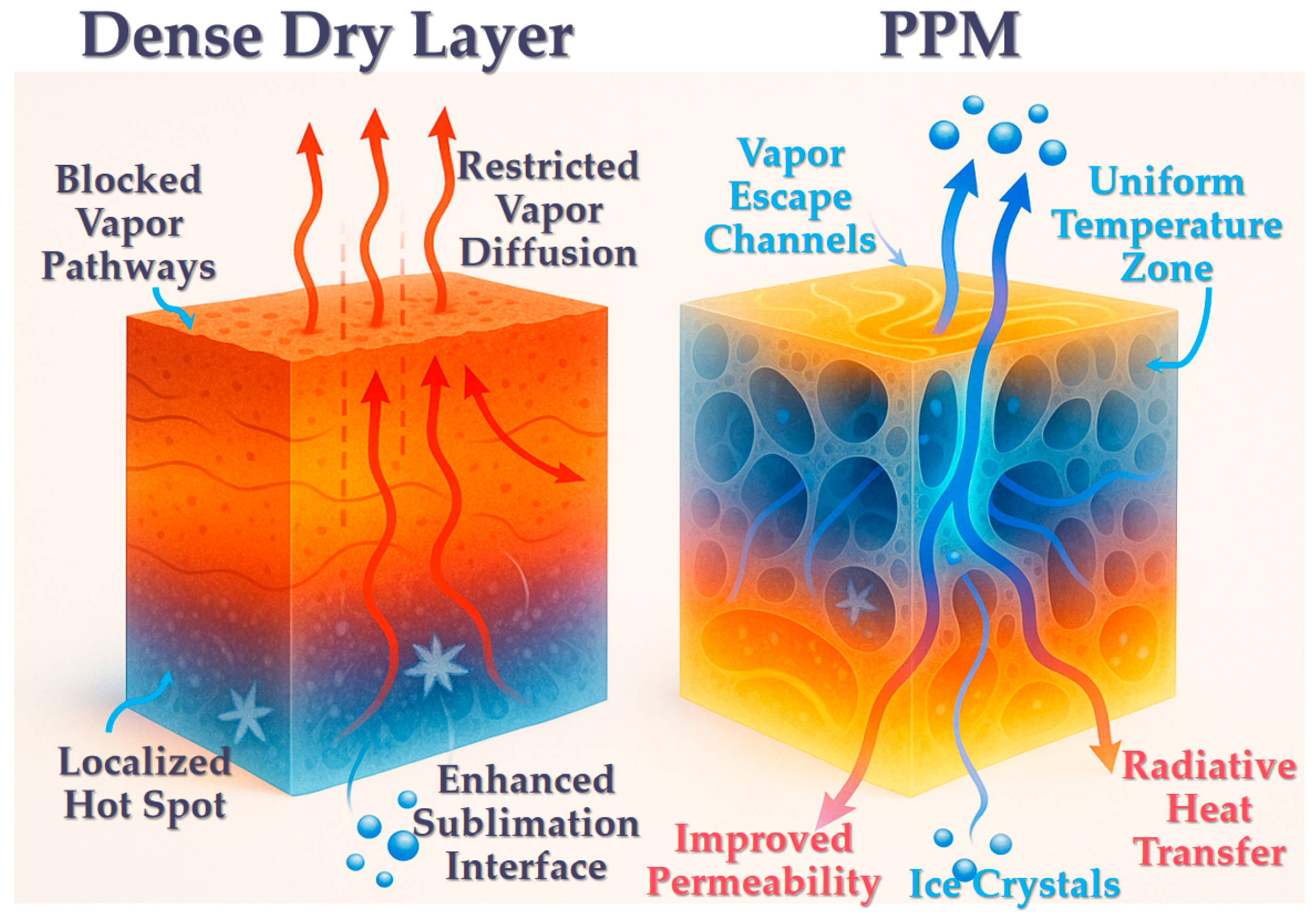

3.1. Reduction of Heat and Mass Transfer Resistance (Pore-Induced Resistance Mitigation)

3.1.1. Reduction of Water Vapor Diffusion Resistance

3.1.2. Thermal Conduction Dynamics in Porous Media: Resistance Mitigation vs. Gas Trapping Effects

3.1.3. Reduced Dry Layer Thickness Effect

3.2. Promotion of Convection and Uniform Heat Transfer (Internal Convection and Fluidization Effects)

3.2.1. Internal Gas Flow

3.2.2. Solid Particle Fluidization

3.2.3. Uniform Drying and Mitigation of Edge Effects

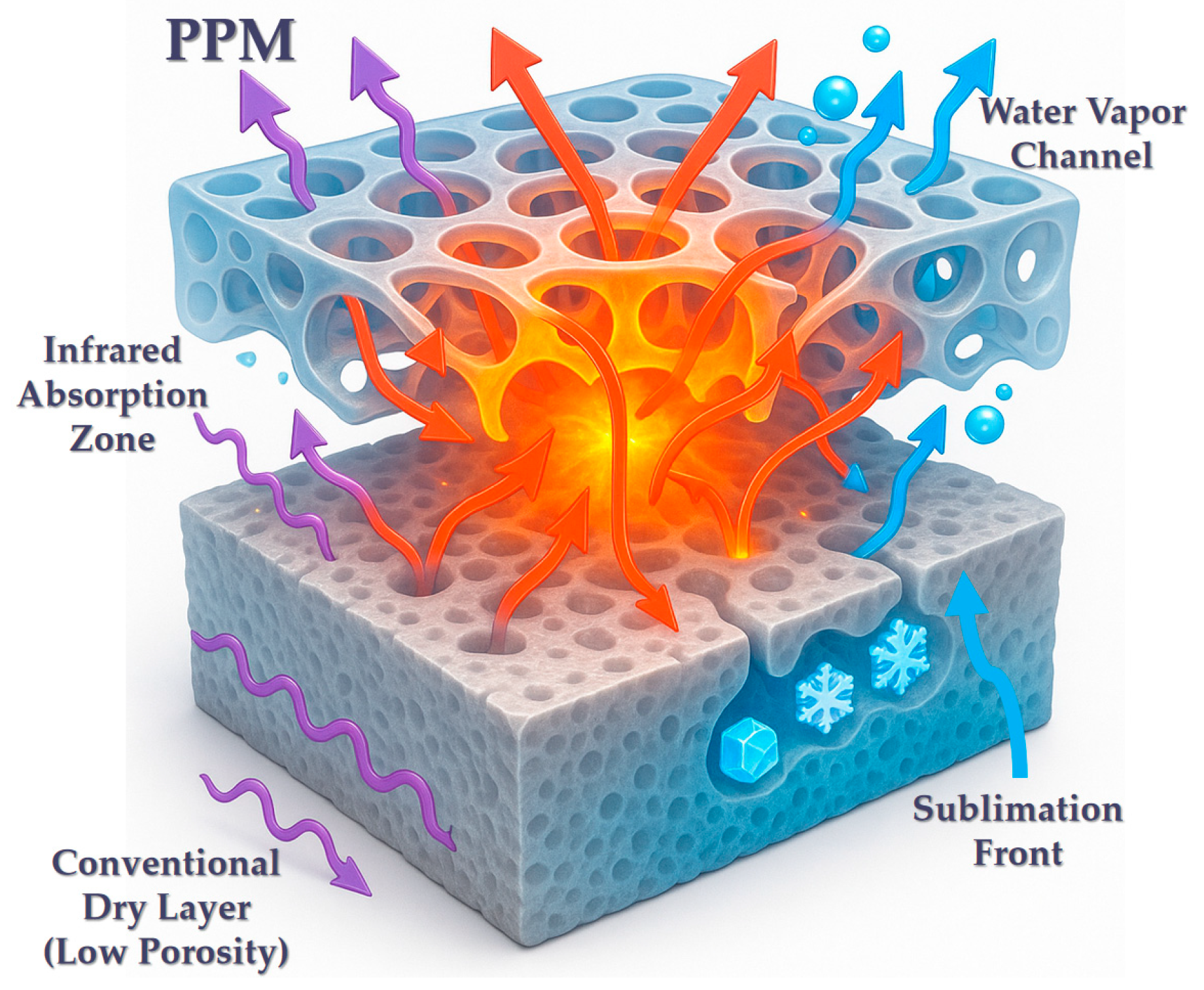

3.3. Enhancement of Radiative Heating (Porous Absorption and Transmission Effects)

3.3.1. Improving Radiative Absorptivity

3.3.2. Increasing Radiative Penetration Depth

4. Research Progress on Freeze-Drying Strengthening of Liquid Food and Solid Agricultural Products

4.1. Freeze-Drying Strengthening of High Value-Added Liquid Food

4.1.1. Dairy Products

4.1.2. Coffee, Tea, and Beverage Extract

4.1.3. Fermentation Broth and Bioactive Liquid

4.2. Freeze-Drying Strengthening of Solid Agricultural Products

4.2.1. Vegetable Fruits

4.2.2. Medicinal and Spice Plants

4.2.3. Aquatics and Meat

5. Discussion and Outlook

5.1. Comparative Discussion

5.2. Core Challenges

5.3. Engineering and Economic Implications

5.4. Future Outlook

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yao, J.; Chen, W.; Fan, K. Novel efficient physical technologies for enhancing freeze drying of fruits and vegetables: A review. Foods 2023, 12, 4321. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Hu, L. High efficient freeze-drying technology in food industry. Crit. Rev. Food Sci. Nutr. 2022, 62, 3370–3388. [Google Scholar] [CrossRef]

- Zhai, X.; Xue, Y.; Song, W.; Sun, Y.; Shen, T.; Zhang, X.; Li, Y.; Zhang, D.; Zhou, C.; Zhang, J.; et al. Rapid and facile synthesis of homoporous colorimetric films using leaf vein-mediated emulsion evaporation method for visual monitoring of food freshness. J. Agric. Food Chem. 2024, 72, 21854–21868. [Google Scholar] [CrossRef]

- Tchabo, W.; Ma, Y.; Kwaw, E.; Zhang, H.; Xiao, L.; Tahir, H.E. Aroma profile and sensory characteristics of a sulfur dioxide-free mulberry (Morus nigra) wine subjected to non-thermal accelerating aging techniques. Food Chem. 2017, 232, 89–97. [Google Scholar] [CrossRef] [PubMed]

- Osae, R.; Essilfie, G.; Alolga, R.N.; Akaba, S.; Song, X.; Owusu-Ansah, P.; Zhou, C. Application of non-thermal pretreatment techniques on agricultural products prior to drying: A review. J. Sci. Food Agric. 2020, 100, 2585–2599. [Google Scholar] [CrossRef]

- Ankeli, J.A.; Igbum, O.G.; Okibe, F.G. Comparative effects of drying methods on physicochemical properties of puree blends of some indigenous varieties of watermelon (Citrullus lanatus), orange (Citrus sinensis) and mango (Mangifera indica) fruits. J. Agric. Aquac. Anim. Sci. 2025, 2, 15–29. [Google Scholar] [CrossRef]

- Silva, N.C.; Santana, R.C.; Duarte, C.R.; Barrozo, M.A. Impact of freeze-drying on bioactive compounds of yellow passion fruit residues. J. Food Process Eng. 2017, 40, e12514. [Google Scholar] [CrossRef]

- Feng, Y.; Tan, C.P.; Zhou, C.; Yagoub, A.E.; Xu, B.; Sun, Y.; Ma, H.; Xu, X.; Yu, X. Effect of freeze-thaw cycles pretreatment on the vacuum freeze-drying process and physicochemical properties of the dried garlic slices. Food Chem. 2020, 324, 126883. [Google Scholar] [CrossRef] [PubMed]

- Ren, Z.; Yu, X.; Yagoub, A.E.; Fakayode, O.A.; Ma, H.; Sun, Y.; Zhou, C. Combinative effect of cutting orientation and drying techniques (hot air, vacuum, freeze and catalytic infrared drying) on the physicochemical properties of ginger (Zingiber officinale Roscoe). LWT 2021, 144, 111238. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, M.; Xu, B.; Chen, J. Improvement of the quality of solid ingredients of instant soups: A review. Food Rev. Int. 2023, 39, 1333–1358. [Google Scholar] [CrossRef]

- Saifullah, M.; Stanley, R.; Zare, D.; Juliano, P.; Hunt, W. Technology Options for Shelf-Stable Food Processing and Storage in Northern Australia; CSIRO: Canberra, Australia, 2023. [Google Scholar]

- Beesetti, L.; Srijaya, M. Novel technologies for shelf-life extension of food products as a competitive advantage: A review. In Food Production, Diversity, and Safety Under Climate Change; Springer: Berlin/Heidelberg, Germany, 2024; pp. 285–306. [Google Scholar]

- Jiang, M.; Sun, J.; Obadi, M.; Bai, X.; Zhu, W. Effects of ultrasonic vacuum drying on the drying kinetics, dynamic moisture distribution, and microstructure of honey drying process. Food Sci. Technol. Int. 2021, 27, 426–440. [Google Scholar] [CrossRef] [PubMed]

- Hameed, A.; Maan, A.A.; Khan, M.K.I.; Mahmood Khan, I.; Niazi, S.; Waheed Iqbal, M.; Riaz, T.; Abdalla, M.F.M. Evaporation kinetics and quality attributes of grape juice concentrate as affected by microwave and vacuum processing. Int. J. Food Prop. 2023, 26, 1596–1611. [Google Scholar] [CrossRef]

- Huang, Y.; Sun, Y.; Mehmood, A.; Lu, T.; Chen, X. Unraveling the temporal changes of Maillard reaction products and aroma profile in coffee leaves during hot-air drying. J. Food Compos. Anal. 2024, 128, 106055. [Google Scholar] [CrossRef]

- Boateng, I.D.; Soetanto, D.A.; Yang, X.M.; Zhou, C.; Saalia, F.K.; Li, F. Effect of pulsed-vacuum, hot-air, infrared, and freeze-drying on drying kinetics, energy efficiency, and physicochemical properties of Ginkgo biloba L. seed. J. Food Process Eng. 2021, 44, e13655. [Google Scholar] [CrossRef]

- Han, J.; Liang, J.; Li, Y.; Wahia, H.; Phyllis, O.; Zhou, C.; Zhang, L.; Chen, L.; Qiao, X.; Ma, H. Vacuum freeze drying combined with catalytic infrared drying to improve the aroma quality of chives: Potential mechanisms of their formation. Food Chem. 2024, 461, 140880. [Google Scholar] [CrossRef]

- Luo, S.; An, R.; Zhou, H.; Zhang, Y.; Ling, J.; Hu, H.; Li, P. The glucosinolate profiles of Brassicaceae vegetables responded differently to quick-freezing and drying methods. Food Chem. 2022, 383, 132624. [Google Scholar] [CrossRef]

- Naliyadhara, N.; Trujillo, F.J. Advancements in atmospheric freeze-drying: Innovations, technology integration, quality and sustainability implications for food preservation. J. Food Eng. 2024, 112, 112273. [Google Scholar] [CrossRef]

- Ratti, C. Hot air and freeze-drying of high-value foods: A review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Bhatta, S.; Stevanovic Janezic, T.; Ratti, C. Freeze-Drying of Plant-Based Foods. Foods 2020, 9, 87. [Google Scholar] [CrossRef] [PubMed]

- Liapis, A.I.; Bruttini, R. Freeze Drying. In Handbook of Industrial Drying; Mujumdar, A.S., Ed.; CRC Press: Boca Raton, FL, USA, 2020; pp. 309–343. [Google Scholar]

- Egbo, M. A Review of the Thermal Performance of Vapor Chambers and Heat Sinks: Critical Heat Flux, Thermal Resistances, and Surface Temperatures. Int. J. Heat Mass Transf. 2022, 183, 122108. [Google Scholar] [CrossRef]

- Zhao, J.-W.; Zhao, R.; Huo, Y.-K.; Cheng, W.-L. Effects of Surface Roughness, Temperature and Pressure on Interface Thermal Resistance of Thermal Interface Materials. Int. J. Heat Mass Transf. 2019, 140, 705–716. [Google Scholar] [CrossRef]

- Amit, S.K.; Uddin, M.M.; Rahman, R.; Islam, S.R.; Khan, M.S. A Review on Mechanisms and Commercial Aspects of Food Preservation and Processing. Agric. Food Secur. 2017, 6, 51. [Google Scholar] [CrossRef]

- Zhang, C.; Bu, X.; He, J.; Liu, C.; Lin, G.; Miao, J. Simulation of Evaporation and Sublimation Process in Porous Plate Water Sublimator Based on a Reduced CFD Model. Int. J. Heat Mass Transf. 2020, 154, 119787. [Google Scholar] [CrossRef]

- Thomik, M.; Gruber, S.; Kaestner, A.; Foerst, P.; Tsotsas, E.; Vorhauer-Huget, N. Experimental Study of the Impact of Pore Structure on Drying Kinetics and Sublimation Front Patterns. Pharmaceutics 2022, 14, 1538. [Google Scholar] [CrossRef]

- Stratta, L.; Capozzi, L.C.; Franzino, S.; Pisano, R. Economic Analysis of a Freeze-Drying Cycle. Processes 2020, 8, 1399. [Google Scholar] [CrossRef]

- Al-Ghamdi, S.; Alfaifi, B.; Elamin, W.; Lateef, M.A. Advancements in coffee manufacturing: From dehydration techniques to quality control. Food Eng. Rev. 2024, 16, 513–539. [Google Scholar] [CrossRef]

- El-Maghlany, W.M.; Bedir, A.E.R.; Elhelw, M.; Attia, A. Freeze-Drying Modeling via Multi-Phase Porous Media Transport Model. Int. J. Therm. Sci. 2019, 135, 509–522. [Google Scholar] [CrossRef]

- Michaud, V. A Review of Non-Saturated Resin Flow in Liquid Composite Moulding Processes. Transp. Porous Media 2016, 115, 581–601. [Google Scholar] [CrossRef]

- Dadmohammadi, Y.; Datta, A.K. Food as porous media: A review of the dynamics of porous properties during processing. Food Rev. Int. 2022, 38, 953–985. [Google Scholar] [CrossRef]

- Li, S.; Zhang, H.; Li, S.; Wang, J.; Wang, Q.; Cheng, Z. Advances in hierarchically porous materials: Fundamentals, preparation and applications. Renew. Sustain. Energy Rev. 2024, 202, 114641. [Google Scholar] [CrossRef]

- Xu, J.; Wang, B.; Wang, Y.; Zhang, M.; Chitrakar, B. Effect of applied voltage on the aggregation and conformational changes in peroxidase under electrospray. Food Bioprocess Technol. 2020, 13, 245–255. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold spray coating: Review of material systems and future perspectives. Surf. Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Ioannou Sartzi, M.; Drettas, D.; Stramarkou, M.; Krokida, M. A comprehensive review of the latest trends in spray freeze drying and comparative insights with conventional technologies. Pharmaceutics 2024, 16, 1533. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Li, H.; Wang, J.; Guo, X. Analysis of droplet characteristics and kinetic energy distribution for fixed spray plate sprinkler at low working pressure. Trans. ASABE 2021, 64, 447–460. [Google Scholar] [CrossRef]

- Wanning, S.; Süverkrüp, R.; Lamprecht, A. Pharmaceutical spray freeze drying. Int. J. Pharm. 2015, 488, 136–153. [Google Scholar] [CrossRef]

- Rostamnezhad, M.; Jafari, H.; Moradikhah, F.; Bahrainian, S.; Faghihi, H.; Khalvati, R.; Bafkary, R.; Vatanara, A. Spray freeze-drying for inhalation application: Process and formulation variables. Pharm. Dev. Technol. 2022, 27, 251–267. [Google Scholar] [CrossRef] [PubMed]

- Oyinbo, S.T.; Jen, T.C. A comparative review on cold gas dynamic spraying processes and technologies. Manuf. Rev. 2019, 6, 25. [Google Scholar] [CrossRef]

- Rogers, T.L.; Hu, J.; Yu, Z.; Johnston, K.P.; Williams, R.O. A novel particle engineering technology: Spray-freezing into liquid. Int. J. Pharm. 2002, 242, 93–100. [Google Scholar] [CrossRef]

- Mohit, M.; Xu, M.; Kurnia, J.C.; Mujumdar, A.S.; Sasmito, A.P. Spray freezing: An overview of applications and modeling. Dry. Technol. 2025, 43, 34–52. [Google Scholar] [CrossRef]

- Hindmarsh, J.P.; Russell, A.B.; Chen, X.D. Fundamentals of the spray freezing of foods—Microstructure of frozen droplets. J. Food Eng. 2007, 78, 136–150. [Google Scholar] [CrossRef]

- Al-Hakim, K. An Investigation of Spray-Freezing and Spray-Freeze-Dryings. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2004. [Google Scholar]

- Qian, L.; Zhang, H. Controlled freezing and freeze drying: A versatile route for porous and micro-/nano-structured materials. J. Chem. Technol. Biotechnol. 2011, 86, 172–184. [Google Scholar] [CrossRef]

- Mehta, A.; Vasudev, H.; Singh, S.; Prakash, C.; Saxena, K.K.; Linul, E.; Buddhi, D.; Xu, J. Processing and advancements in the development of thermal barrier coatings: A review. Coatings 2022, 12, 1318. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Xiang, Q.; Chen, C. Comparison of PIV experiment and numerical simulation on the velocity distribution of intermediate pressure jets with different nozzle parameters. Irrig. Drain. 2017, 66, 510–519. [Google Scholar] [CrossRef]

- Hua, L.; Li, H.; Jiang, Y. Axis-switching behavior of liquid jets issued from non-circular nozzles under low-intermediate pressure. Appl. Eng. Agric. 2021, 37, 367–378. [Google Scholar] [CrossRef]

- Joukhdar, H.; Seifert, A.; Jüngst, T.; Groll, J.; Lord, M.S.; Rnjak-Kovacina, J. Ice templating soft matter: Fundamental principles and fabrication approaches to tailor pore structure and morphology and their biomedical applications. Adv. Mater. 2021, 33, 2100091. [Google Scholar] [CrossRef]

- He, Z.; Liu, K.; Wang, J. Bioinspired materials for controlling ice nucleation, growth, and recrystallization. Acc. Chem. Res. 2018, 51, 1082–1091. [Google Scholar] [CrossRef]

- Niwa, T.; Shimabara, H.; Kondo, M.; Danjo, K. Design of porous microparticles with single-micron size by novel spray freeze-drying technique using four-fluid nozzle. Int. J. Pharm. 2009, 382, 88–97. [Google Scholar] [CrossRef]

- Thomas, T.; Zhang, C.; Feliciano Ruiz, K.M.; Ramos-Pagan, C.I.; Negron, D.M.; Boesl, B.; Agarwal, A. Engineering graphene-ceramic 3D composite foams by freeze drying. Adv. Eng. Mater. 2021, 23, 2001546. [Google Scholar] [CrossRef]

- D’Amico, V.; Cavaliere, M.; Ivone, M.; Lacassia, C.; Celano, G.; Vacca, M.; la Forgia, F.M.; Fontana, S.; De Angelis, M.; Denora, N.; et al. Microencapsulation of probiotics for enhanced stability and health benefits in dairy functional foods: A focus on pasta filata cheese. Pharmaceutics 2025, 17, 185. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.H.; Peng, H.; Ma, H.; Zeng, X.A. Effect of inlet air drying temperatures on the physicochemical properties and antioxidant activity of whey protein isolate–kale leaves chlorophyll (WPI–CH) microcapsules. J. Food Eng. 2019, 245, 149–156. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Peng, H.; Woo, M.W.; Zeng, X.A.; Brennan, M.; Brennan, C.S. Preparation and characterization of whey protein isolate–chlorophyll microcapsules by spray drying: Effect of WPI ratios on the physicochemical and antioxidant properties. J. Food Eng. 2020, 267, 109729. [Google Scholar] [CrossRef]

- Liu, C.J.; Xue, Y.L.; Guo, J.; Ren, H.C.; Jiang, S.; Li, D.J.; Song, J.F.; Zhang, Z.Y. Citric acid and sucrose pretreatment improves the crispness of puffed peach chips by regulating cell structure and mechanical properties. LWT 2021, 142, 111036. [Google Scholar] [CrossRef]

- Gugliuzza, A.; Jin, W. (Eds.) Porous Membranes: Breakthroughs in Manufacturing and Applications; Wiley: Hoboken, NJ, USA, 2025. [Google Scholar]

- Rakhmatulina, A.; Altybay, A.; Imanbayeva, N.; Bagitova, S.; Baikonys, A. Numerical simulation and experimental analysis of mare’s milk sublimation drying. Processes 2025, 13, 206. [Google Scholar] [CrossRef]

- Wang, W.; Yang, J.; Hu, D.; Pan, Y.; Wang, S.; Chen, G. Experimental and numerical investigations on freeze-drying of porous media with prebuilt porosity. Chem. Phys. Lett. 2018, 700, 80–87. [Google Scholar] [CrossRef]

- Berk, Z. Freeze drying (lyophilization) and freeze concentration. In Food Process Engineering and Technology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 567–581. [Google Scholar]

- Tung, H.Y.; Sun, T.P.; Sun, H.Y.; Guan, Z.Y.; Hu, S.K.; Chao, L.; Chen, H.Y. Construction and control of 3D porous structure based on vapor deposition on sublimation solids. Appl. Mater. Today 2017, 7, 77–81. [Google Scholar] [CrossRef]

- Vasheghani Farahani, M.; Hassanpouryouzband, A.; Yang, J.; Tohidi, B. Heat transfer in unfrozen and frozen porous media: Experimental measurement and pore-scale modeling. Water Resour. Res. 2020, 56, e2020WR027885. [Google Scholar] [CrossRef]

- Celzard, A.; Collas, F.; Marêché, J.F.; Furdin, G.; Rey, I. Porous electrodes-based double-layer supercapacitors: Pore structure versus series resistance. J. Power Sources 2002, 108, 153–162. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Mohanty, P.; Sahu, J.K.; Sahu, J.N. A critical review on drying of food materials: Recent progress and key challenges. Int. Commun. Heat Mass Transf. 2024, 158, 107863. [Google Scholar] [CrossRef]

- Fei, L.; Qin, F.; Zhao, J.; Derome, D.; Carmeliet, J. Pore-scale study on convective drying of porous media. Langmuir 2022, 38, 6023–6035. [Google Scholar] [CrossRef]

- Levin, P.; Buchholz, M.; Meunier, V.; Kessler, U.; Palzer, S.; Heinrich, S. Comparison of Knudsen diffusion and the dusty gas approach for the modeling of the freeze-drying process of bulk food products. Processes 2022, 10, 548. [Google Scholar] [CrossRef]

- Abdulmalek, S.H.; Assadi, M.K.; Al-Kayiem, H.H.; Gitan, A.A. A comparative analysis on the uniformity enhancement methods of solar thermal drying. Energy 2018, 148, 1103–1115. [Google Scholar] [CrossRef]

- Rong, L.; Xiao, J.; Wang, X.; Sun, J.; Jia, F.; Chu, M. Low-rank coal drying behaviors under negative pressure: Thermal fragmentation, volume shrinkage and changes in pore structure. J. Clean. Prod. 2020, 272, 122572. [Google Scholar] [CrossRef]

- Cheng, C.; Gao, M.; Miao, Z.; Wan, K.; He, Q. Structural changes mechanism of lignite during drying: Correlation between macroscopic and microscopic. Fuel 2023, 339, 126955. [Google Scholar] [CrossRef]

- Kumar, T.; Vineeth, H.; Sharma, P.; Dave, V. Modern evolution in drying, dehydration, and freeze-drying of food and biomanufacturing. In Nonthermal Food Processing, Safety, and Preservation; Wiley Online Library: Hoboken, NJ, USA, 2024; pp. 225–257. [Google Scholar]

- Pawar, S.B.; Pratape, V.M. Fundamentals of infrared heating and its application in drying of food materials: A review. J. Food Process Eng. 2017, 40, e12308. [Google Scholar] [CrossRef]

- Xie, T.; Xu, K.; Yang, B.; He, Y. Effect of pore size and porosity distribution on radiation absorption and thermal performance of porous solar energy absorber. Sci. China Technol. Sci. 2019, 62, 2213–2225. [Google Scholar] [CrossRef]

- Gan, Z.; Zhao, S.; Zhang, Z.; Li, X.; Zhang, P.; Song, Y.; Yang, Z. Highly ordered porous carbon aerogel via a novel strong confined effect freeze-casting strategy for efficient solar interfacial evaporation. Chem. Eng. J. 2025, 504, 158807. [Google Scholar] [CrossRef]

- Kostoglou, N.; Tzitzios, V.; Kontos, A.G.; Giannakopoulos, K.; Tampaxis, C.; Papavasiliou, A.; Rebholz, C. Synthesis of nanoporous graphene oxide adsorbents by freeze-drying or microwave radiation: Characterization and hydrogen storage properties. Int. J. Hydrogen Energy 2015, 40, 6844–6852. [Google Scholar] [CrossRef]

- Majcher, K.; Musiał, M.; Pakos, W.; Różański, A.; Sobótka, M.; Trapko, T. Methods of protecting buildings against HPM radiation—A review of materials absorbing the energy of electromagnetic waves. Materials 2020, 13, 5509. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhou, C.; Wang, B.; Zeng, S.; Mu, R.; Li, G.; Lv, W. Research progress and application of ultrasonic- and microwave-assisted food processing technology. Compr. Rev. Food Sci. Food Saf. 2023, 22, 3707–3731. [Google Scholar] [CrossRef]

- Gruber, S.; Vorhauer-Huget, N.; Foerst, P. In situ micro-computed tomography to study microstructure and sublimation front during freeze-drying. Food Struct. 2021, 29, 100213. [Google Scholar] [CrossRef]

- Kumi, F.; Mao, H.; Li, Q.; Luhua, H. Assessment of tomato seedling substrate-root quality using X-ray computed tomography and scanning electron microscopy. Appl. Eng. Agric. 2016, 32, 417–427. [Google Scholar]

- Wang, L.; Wu, T.; Zhang, Y.; Yang, K.; He, Y.; Deng, K.; Gu, Y. Comparative studies on the nutritional and physicochemical properties of yoghurts from cows’, goats’, and camels’ milk powder. Int. Dairy J. 2023, 138, 105542. [Google Scholar] [CrossRef]

- Wang, L.; Huang, T.; Cao, H.X.; Yuan, Q.X.; Liang, Z.P.; Liang, G.X. Application of air-assisted liquid-liquid microextraction for determination of some fluoroquinolones in milk powder and egg samples: Comparison with conventional dispersive liquid-liquid microextraction. Food Anal. Methods 2016, 9, 2223–2230. [Google Scholar] [CrossRef]

- Darniadi, S.; Ho, P.; Murray, B.S. Comparison of blueberry powder produced via foam-mat freeze-drying versus spray-drying: Evaluation of foam and powder properties. J. Sci. Food Agric. 2018, 98, 2002–2010. [Google Scholar] [CrossRef]

- Wu, S.; Cronin, K.; Fitzpatrick, J.; Miao, S. Updating insights into the rehydration of dairy-based powder and the achievement of functionality. Crit. Rev. Food Sci. Nutr. 2022, 62, 6664–6681. [Google Scholar] [CrossRef]

- Joardder, M.U.; Kumar, C.; Karim, M.A. Prediction of porosity of food materials during drying: Current challenges and directions. Crit. Rev. Food Sci. Nutr. 2018, 58, 2896–2907. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Pan, Y.; Wang, W.; Lin, R.; Zhang, S. Microwave freeze-drying of coffee solution frozen with initial pores assisted by wave-absorbing medium. Dry. Technol. 2023, 41, 419–433. [Google Scholar] [CrossRef]

- Gaikwad, N.N.; Kadam, A.A.; Giri, N.A.; Suryavanshi, S.K.; Marathe, R.A. Enhancing bioactive compounds retention in pomegranate juice powder through foam mat drying. J. Food Process Eng. 2024, 47, e14707. [Google Scholar] [CrossRef]

- Li, L.; Wang, B.; Wang, Y.; Liu, J. Effect of drying methods on the characterisation of pectin extracted from dried hawthorn fruit. J. Food Meas. Charact. 2022, 16, 3670–3681. [Google Scholar] [CrossRef]

- Wang, L.; He, M.; Wu, T.; Yang, K.; Wang, Y.; Zhang, Y.; Deng, K. Screening of the freeze-drying protective agent for high-quality milk beer yeast (Kluyveromyces marxianus) and optimization of freeze-drying process conditions. J. Food Process. Preserv. 2021, 45, e16016. [Google Scholar] [CrossRef]

- Miyamoto-Shinohara, Y.; Nozawa, F.; Sukenobe, J.; Imaizumi, T. Survival of yeasts stored after freeze-drying or liquid-drying. J. Gen. Appl. Microbiol. 2010, 56, 107–119. [Google Scholar] [CrossRef]

- Mour, M.; Das, D.; Winkler, T.; Hoenig, E.; Mielke, G.; Morlock, M.M.; Schilling, A.F. Advances in porous biomaterials for dental and orthopaedic applications. Materials 2010, 3, 2947–2974. [Google Scholar] [CrossRef]

- Valadez-Carmona, L.; Plazola-Jacinto, C.P.; Hernández-Ortega, M.; Hernández-Navarro, M.D.; Villarreal, F.; Necoechea-Mondragón, H.; Ortiz-Morene, A.; Ceballos-Reyes, G. Effects of microwaves, hot air and freeze-drying on the phenolic compounds, antioxidant capacity, enzyme activity and microstructure of cacao pod husks (Theobroma cacao L.). Innov. Food Sci. Emerg. Technol. 2017, 41, 378–386. [Google Scholar] [CrossRef]

- Roshan, K.; Keerthy, H.S. Orodispersible tablets: A compendious review. Asian J. Pharm. Res. Dev. 2021, 9, 66–75. [Google Scholar] [CrossRef]

- Feng, L.; Xu, Y.; Xiao, Y.; Song, J.; Li, D.; Zhang, Z.; Zhou, C. Effects of pre-drying treatments combined with explosion puffing drying on the physicochemical properties, antioxidant activities and flavor characteristics of apples. Food Chem. 2021, 338, 128015. [Google Scholar] [CrossRef] [PubMed]

- Solairaj, D.; Yang, Q.; Legrand, N.N.G.; Routledge, M.N.; Zhang, H. Molecular explication of grape berry-fungal infections and their potential application in recent postharvest infection control strategies. Trends Food Sci. Technol. 2021, 116, 903–917. [Google Scholar] [CrossRef]

- Yang, Z.; Zou, X.; Li, Z.; Huang, X.; Zhai, X.; Zhang, W.; Tahir, H.E. Improved postharvest quality of cold stored blueberry by edible coating based on composite gum arabic/roselle extract. Food Bioprocess Technol. 2019, 12, 1537–1547. [Google Scholar] [CrossRef]

- Ali, L.M.; Saleh, S.S.; Ahmed, A.E.R.; Hasan, H.E.S.; Suliman, A.E.R. Novel postharvest management using laser irradiation to maintain the quality of strawberry. J. Food Meas. Charact. 2020, 14, 3615–3624. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, C.; Guo, Y.; Zhang, C.; Li, D.; Gao, K.; Ma, J.; Ma, H. Comparative evaluation of physicochemical properties, microstructure, and antioxidant activity of jujube polysaccharides subjected to hot air, infrared, radio frequency, and freeze drying. Agriculture 2022, 12, 1606. [Google Scholar] [CrossRef]

- Sappati, P.K.; Nayak, B.; van Walsum, G.P. Effect of glass transition on the shrinkage of sugar kelp (Saccharina latissima) during hot air convective drying. J. Food Eng. 2017, 210, 50–61. [Google Scholar] [CrossRef]

- Amanor-Atiemoh, R.; Zhou, C.; Taiye, M.A.; Sarpong, F.; Wahia, H.; Amoa-Owusu, A.; Ma, H.; Chen, L. Effect of ultrasound-ethanol pretreatment on drying kinetics, quality parameters, functional group, and amino acid profile of apple slices using pulsed vacuum drying. J. Food Process Eng. 2020, 43, e13347. [Google Scholar] [CrossRef]

- Zhang, L.; Qiao, Y.; Wang, C.; Liao, L.; Shi, D.; An, K.; Hu, J.; Wang, J.; Shi, L. Influence of high hydrostatic pressure pretreatment on properties of vacuum-freeze dried strawberry slices. Food Chem. 2020, 331, 127203. [Google Scholar] [CrossRef]

- Oladejo, A.O.; Ma, H.; Qu, W.; Zhou, C.; Wu, B. Effects of ultrasound on mass transfer kinetics, structure, carotenoid and vitamin C content of osmodehydrated sweet potato (Ipomoea batatas). Food Bioprocess Technol. 2017, 10, 1162–1172. [Google Scholar] [CrossRef]

- Bogusz, R.; Nowacka, M.; Rybak, K.; Witrowa-Rajchert, D.; Gondek, E. Foam-mat freeze drying of kiwiberry (Actinidia arguta) pulp: Drying kinetics, main properties and microstructure. Appl. Sci. 2024, 14, 5629. [Google Scholar] [CrossRef]

- Zhou, C.; Feng, Y.; Zhang, L.; Yagoub, A.E.A.; Wahia, H.; Ma, H.; Sun, Y.; Yu, X. Rehydration characteristics of vacuum freeze-and hot air-dried garlic slices. LWT 2021, 143, 111158. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Ma, X.; Li, M.; Kong, D.; Phavady, P.; Abdelkader, T.K. Chinese medicinal materials’ drying technologies advancements–Principles, energy performance, and influence on the bioactive components. Dry. Technol. 2024, 42, 1815–1845. [Google Scholar] [CrossRef]

- Zhou, S.; Rahman, A.; Li, J.; Wei, C.; Chen, J.; Linhardt, R.J.; Ye, X.; Chen, S. Extraction methods affect the structure of Goji (Lycium barbarum) polysaccharides. Molecules 2020, 25, 936. [Google Scholar] [CrossRef]

- Okonkwo, C.E.; Onyeaka, H.; Olaniran, A.F.; Isaac-Bamgboye, F.J.; Nwaiwu, O.; Ukwuru, M.; Zhou, C. Changes in flavor profile of vegetable seasonings by innovative drying technologies: A review. J. Food Sci. 2024, 89, 6818–6838. [Google Scholar] [CrossRef]

- Feng, Y.; Xu, B.; Yagoub, A.E.A.; Ma, H.; Sun, Y.; Xu, X.; Yu, X.; Zhou, C. Role of drying techniques on physical, rehydration, flavor, bioactive compounds and antioxidant characteristics of garlic. Food Chem. 2021, 343, 128404. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.; Hussain, A.; Khan, S.; Korma, S.A.; Hussain, G.; Aadil, R.M.; Siddique, R.; Ali, A.; Shabbir, U.; Haq, A.U.; et al. Impact of thermal extrusion and microwave vacuum drying on fatty acids profile during fish powder preparation. Food Sci. Nutr. 2021, 9, 2743–2753. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhao, F.; Li, C.; Ban, X.; Gu, Z.; Li, Z. Acceleration mechanism of the rehydration process of dried rice noodles by the porous structure. Food Chem. 2024, 431, 137050. [Google Scholar] [CrossRef]

- Shi, H.; Zhou, T.; Wang, X.; Zou, Y.; Wang, D.; Xu, W. Effects of the structure and gel properties of myofibrillar protein on chicken breast quality treated with ultrasound-assisted potassium alginate. Food Chem. 2021, 358, 129873. [Google Scholar] [CrossRef]

- Wu, W.; Li, H.; Chen, Y.; Luo, Y.; Zeng, J.; Huang, J.; Gao, T. Recent advances in drying processing technologies for aquatic products. Processes 2024, 12, 942. [Google Scholar] [CrossRef]

- Dai, C.; Li, Z.; Zheng, K.; Zhang, J.H.; Dai, R.; Luo, D.; Gao, H.; Thabet, H.K.; El-Bahy, Z.M.; Pan, L.; et al. Strategic design of porous interfacial evaporators: A comprehensive review unveiling the significant role of pore engineering. Nano Energy 2024, 131, 110244. [Google Scholar] [CrossRef]

- Wahia, H.; Fakayode, O.A.; Mustapha, A.T.; Zhou, C.; Dabbour, M. Application and potential of multifrequency ultrasound in juice industry: Comprehensive analysis of inactivation and germination of Alicyclobacillus acidoterrestris spores. Crit. Rev. Food Sci. Nutr. 2024, 64, 4561–4586. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, X.; Yan, K.; Zhu, H.; Wang, B.; Zou, B. Laser micro/nano-structuring pushes forward smart sensing: Opportunities and challenges. Adv. Funct. Mater. 2023, 33, 2211272. [Google Scholar] [CrossRef]

- Huang, Z.; Shao, G.; Li, L. Micro/nano functional devices fabricated by additive manufacturing. Prog. Mater. Sci. 2023, 131, 101020. [Google Scholar] [CrossRef]

- Al Hagbani, T.; Alamoudi, J.A.; Bajaber, M.A.; Alsayed, H.I.; Al-Fanhrawi, H.J. Theoretical investigations on analysis and optimization of freeze drying of pharmaceutical powder using machine learning modeling of temperature distribution. Sci. Rep. 2025, 15, 948. [Google Scholar] [CrossRef]

- Miraei Ashtiani, S.H.; Martynenko, A. Toward intelligent food drying: Integrating artificial intelligence into drying systems. Dry. Technol. 2024, 42, 1240–1269. [Google Scholar] [CrossRef]

- El-Halwagi, M.M. Sustainable Design Through Process Integration: Fundamentals and Applications to Industrial Pollution Prevention, Resource Conservation, and Profitability Enhancement, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2025; pp. 1–650. [Google Scholar]

- Bains, A.; Sridhar, K.; Dhull, S.B.; Chawla, P.; Sharma, M.; Sarangi, P.K.; Gupta, V.K. Circular bioeconomy in carbon footprint components of nonthermal processing technologies towards sustainable food system: A review. Trends Food Sci. Technol. 2024, 149, 104520. [Google Scholar] [CrossRef]

| Spray Freezing Type | Freezing Medium | Freezing Mechanism | Product Morphology | Advantages | Limitations | Suitable Applications | Ref. |

|---|---|---|---|---|---|---|---|

| SFV/L | Vapor layer above cryogenic liquid (e.g., N2) | Droplets pre-cooled in cold vapor, then solidified upon contact with cryogenic liquid | Microparticles | Reduces droplet splashing; easier particle collection | Partial freezing before immersion; potential droplet coalescence; cryogen recovery needed | Powdered nutraceuticals, flavors | [39] |

| SFV | Cold gas (e.g., refrigerated N2, scCO2) | Droplets gradually freeze while suspended in cold vapor flow | Irregular particles or aggregates | Simplified equipment; avoids cryogenic liquid handling | Incomplete freezing; particle shape variation due to short vapor residence time | Sensitive compounds, volatile aroma ingredients | [40] |

| SFL | Liquid nitrogen or other cryogenic liquids | Droplets rapidly freeze upon direct contact with cryogen | Fine porous microspheres | Highest freezing rate; fine ice crystals and high porosity | Nozzle blockage risk; high-pressure required; safety and complexity concerns | Dairy powders, probiotic formulations, inhalable particles | [41] |

| SFCS | Pre-cooled metal plate (solid surface) | Droplets flatten, freeze into thin films on contact with cold plate | Porous flakes or sheets | Uniform film freezing; suitable for viscous or high-sugar formulations | Requires scraping and transfer step; limited particle control | Instant beverages, fruit juice sheets, sugar-rich food extracts | [43] |

| Process Parameter | Control Strategy | Effect on Pore Structure | Practical Considerations | Ref. |

|---|---|---|---|---|

| Droplet Size | Select nozzle type to adjust atomization (pressure, pneumatic, ultrasonic) | Small droplets (1–50 μm): 0.5–5 μm pores, 70–90% porosity Large droplets (200–1000 μm): 20–100 μm pores, 40–60% porosity | Align droplet size with desired pore size; avoid broad distribution | [47] |

| Initial Concentration | Adjust solid content in feed solution | Low conc. (5–10%): 50–200 μm pores, 80–95% porosity Medium conc. (10–30%): 20–50 μm pores, 60–80% porosity High conc. (>30%): <20 μm pores, 30–50% porosity | Balance porosity with mechanical strength | [48] |

| Freezing Medium Temperature | Use cryogens like liquid nitrogen vs cold gas | Liquid N2 (−196 °C): 0.1–5 μm pores, 85–95% porosity Cold gas (−40 °C): 10–100 μm pores, 50–70% porosity | Cryogen consumption and safety | [49] |

| Freezing Rate | Control cryogen flow rate and exposure time | Fast (>103 K/s): 0.1–1 μm pores, 85–95% porosity Slow (~101 K/s): 10–100 μm pores, 50–70% porosity | Avoid over-fast freezing that may reduce rehydration ability | [50] |

| Additives (e.g., Nucleating Agents) | Incorporate microparticles as ice nucleation sites | With agents (0.1–1.0 wt%): Pore size ↓30–50%, porosity ↑15–25% (e.g., 60% → 75–85%) | Ensure compatibility with feed material | [51] |

| Foaming Agents | Add foaming agents to introduce gas bubbles | Gas-derived pores: 50–500 μm, overall porosity 75–90% | Foam stability during freezing must be controlled | [52] |

| Thermal Gradient Control | Stepwise temperature reduction during spraying | Gradient pores: Surface (10–30 μm, 60–70% porosity) → Core (50–200 μm, 80–90% porosity) | Requires precise environmental control | [53] |

| Food Type | Method of PPM Formation | Enhancement Type/Effect | Ref. |

|---|---|---|---|

| Mare’s milk | Liquid atomized into ~50 μm droplets and frozen in cold air to form porous frozen granules | Drying time reduced by approximately 35% | [80] |

| Cow milk | Milk vigorously whipped with a small amount of emulsifier before freezing to form stable foam | Drying time reduced by 25%; improved powder looseness and rehydration | [81] |

| β-Carotene emulsion | Used cellular automata to simulate foam freeze-drying of carotenoid-loaded emulsions | Models incorporating preformed pores more accurately predicted drying kinetics, highlighting the necessity of structure-based modeling | [83] |

| Coffee | Vacuum foaming pretreatment induced bubble formation, followed by microwave-assisted freeze drying | Drying time reduced by over 40%; retained aroma and achieved excellent instant solubility | [29] |

| Coffee | Fe3O4 nanoparticles added to extract, then spray-frozen | Drying time reduced by nearly 50% | [84] |

| Juice | Concentrated juice pretreated into foam or gel beads with internal pores | Prevented crust formation and improved uniformity; foam orange powder had 15% higher porosity and better vitamin C retention | [85] |

| Lactic acid bacteria | Pore-forming protectants (e.g., sucrose, alginate) added, with stepwise freezing | Porous bacterial powder had over 20% higher survival rate and ~15% shorter drying time than control | [89] |

| Enzyme solution | Vacuum freeze-concentrated while stirring, forming porous ice network | Retained over 90% enzyme activity; non-porous sample lost activity due to prolonged heating | [90] |

| Blueberries | CO2 laser drilled ~50 micro-holes (~100 µm each) per fruit | Reduced total drying time from 30 h to 20 h; uniform dehydration without collapse | [95] |

| Grapes, red dates | Manually punctured or peeled | Significantly accelerated drying | [96] |

| Kelp | Stepwise freezing created large ice crystals and resultant macro-porous structure | Drying time reduced by ~15%; large pores promoted water release but required careful control to avoid tissue damage | [97] |

| Strawberries | High-pressure (HHP, 400 MPa) pretreatment increased tissue porosity | Drying time reduced by 18%; rehydration improved | [99] |

| Red bell pepper | Treated with 5 min high-power ultrasound to induce cracks and pores | Drying time reduced by 20%; improved vitamin C retention | [100] |

| Ginseng | Embedded fresh ginseng in alginate hydrogel, frozen into porous gel blocks before drying | Accelerated drying and increased ginsenoside retention by 15% | [103] |

| Goji berries | Freeze–thaw cycling caused microcracks from ice crystal expansion | Improved drying rate and increased polysaccharide yield | [104] |

| Mint, basil | Vacuum–microwave pre-drying induced micro-explosive pore formation in leaves | Accelerated drying while preserving volatile aroma compounds | [105,106] |

| Fish paste | Inert gas introduced to fish paste to form foam, then freeze-dried | Drying time reduced to ~20 min, several times faster than non-foamed samples; resulted in porous, fluffy texture with excellent rehydration | [108] |

| Chicken | Porous ceramic rods inserted for heat conduction, combined with microwave heating | Significantly reduced drying time | [109] |

| Kelp, shrimp | Fluidized bed freeze-drying | Used solid spherical media to enhance heat and mass transfer via mixed flow configuration | [110] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Zhang, B.; Du, X.; Zhang, H.; Zhu, T.; Zhang, S.; Yang, X.; Zhang, Z.; Yang, T.; Wang, X.; et al. Recent Advances and Future Perspectives on Heat and Mass Transfer Mechanisms Enhanced by Preformed Porous Media in Vacuum Freeze-Drying of Agricultural and Food Products. Foods 2025, 14, 2966. https://doi.org/10.3390/foods14172966

Hu X, Zhang B, Du X, Zhang H, Zhu T, Zhang S, Yang X, Zhang Z, Yang T, Wang X, et al. Recent Advances and Future Perspectives on Heat and Mass Transfer Mechanisms Enhanced by Preformed Porous Media in Vacuum Freeze-Drying of Agricultural and Food Products. Foods. 2025; 14(17):2966. https://doi.org/10.3390/foods14172966

Chicago/Turabian StyleHu, Xinkang, Bo Zhang, Xintong Du, Huanhuan Zhang, Tianwen Zhu, Shuang Zhang, Xinyi Yang, Zhenpeng Zhang, Tao Yang, Xu Wang, and et al. 2025. "Recent Advances and Future Perspectives on Heat and Mass Transfer Mechanisms Enhanced by Preformed Porous Media in Vacuum Freeze-Drying of Agricultural and Food Products" Foods 14, no. 17: 2966. https://doi.org/10.3390/foods14172966

APA StyleHu, X., Zhang, B., Du, X., Zhang, H., Zhu, T., Zhang, S., Yang, X., Zhang, Z., Yang, T., Wang, X., & Wu, C. (2025). Recent Advances and Future Perspectives on Heat and Mass Transfer Mechanisms Enhanced by Preformed Porous Media in Vacuum Freeze-Drying of Agricultural and Food Products. Foods, 14(17), 2966. https://doi.org/10.3390/foods14172966