Modern Palatant Strategies in Dry and Wet Pet Food: Formulation Technologies, Patent Innovations, and Market Evolution

Abstract

1. Introduction

2. Patent and Product Launch Trends in Palatability-Enhanced Pet Foods

3. Scientific Publications on Pet Food Palatability

| Palatant | Origin of Palatant | Pet | Food Types | Contents | How to Use | Protocol for Palatability Testing | Other Food Tests | Duration of Consumption | Other Major Findings | References |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. Natural olive extract | Olive extract provided by PhenoFarm (Scandriglia RI, Italy) | Cat | Kibble | Liquid palatants: 0, 15, 30, 50, 75, 150 ppm of olive extract Dry palatants: 0, 100, 200, 400, and 600 ppm of olive extract | Coating | Two-day, two-bowl test was conducted with a panel of 20 adult cats. Each cat received an experimental and a control bowl | Olive extract flavor was analyzed by HP-SPME coupled with GC/Q-TOF | 2 days |

| [19] |

| 2. Herbal mix: phosphatidylcholine | BioCholine®, Nuproxa México -Switzerland | Dog | Kibble | Unsupplemented diet (377 mg choline/kg) was compared with choline chloride (2000 mg/kg) and three levels of a phosphatidylcholine-rich herbal mix (200, 400, and 800 mg/kg) | Comparison between 0 vs. 200 g/kg and 0 vs. 400 mg/kg | Digestibility assay: feces were collectedtwice daily and stored at −20 °C before analysis (dry matter, crude protein, ether extract, ash, and neutral detergent fiber) | 30 min for two consecutive days |

| [20] | |

| 3. Chicken liver protein hydrolysates | Xinyuan Co., Ltd. (Shanghai, China) | Cat | Neutral cat food from corn flour | Food attractants CFA0 (control), CFA1, CFA2, CFA3, and CFA4 were prepared by spraying pet food with chicken liver protein hydrolysates (CLPHs) of varying degrees of hydrolysis (CLPH1, CLPH2, CLPH3, and CLPH4) | Spraying the cat food attractant into cat food | During the two-bowl test, we recorded the cat’s first choice and the amount of food left in each bowl. We then calculated the intake ratio by dividing the grams consumed by the grams provided | Volatile compound by GC-MS |

| [24] | |

| 4. Chicken liver, Lentinus edodes, and Tenebrio molitor | Chicken and mushroom species | Dog | Dog’s basic food | Control (dog’s basic food), control + chicken liver, control + L. edodes, and control + T. molitor | Spraying dog food attractant onto cat food | Two-bowl tests recorded ingestion rate (IR) and first preference (FP) as indices of palatability and pet food selection (PFS) | Volatile compound in attractant by HS-SPME-GC-MS and SDE-GC-MS | Two consecutive days, 2 meals per day. The control diet was given within 14 days |

| [25] |

| 5. Protein hydrolysate | Grass carp waste attractant prepared by Maillard reaction at pH 7 at 115 °C | Cat | Cat food (blank) | CK: Blank cat food A: Blank cat food + 3% of self-made attractant B: Blank cat food + 3% commercial attractant | Acceptance test: single-bowl feeding test. Palatability test: two-bowl feeding test. | Antioxidant activity (DPPH free radical scavenging ability, hydroxyl radical scavenging ability, Fe2+ chelation ability) Volatile compound analysis by GC-MS | Two consecutive days |

| [21] | |

| 6. Dog food palatability enhancer powder | Maillard reaction at pH of 6–9 at 100–140 °C | Dog | Basal dog food | Six different palatability enhancers DF1, DF2, DF3, DF4, DF5, and DF6 | Spray on basal dog food 1:20 | Two-bowl test | Volatile aroma compound (GC-MS, LLME–GC–MS) | Two consecutive days, 2 meals per day |

| [23] |

| 7. Dog food attractant (DFA) | Maillard reaction at pH of 6–9 at 100–140 °C | Dog | Basal dry dog food | Seven DFAs with different aroma compounds (DFA1, DFA2, DFA3, DFA4, DFA5, DFA6, and DFA7) | Spraying seven DFAs onto basal dog food | Eight adult beagle dogs: four males and four females with weight 7.5 to 15.7 kg An acceptance test (one-pan test) and preference tests (two-pan test and free-choice test) | Aroma compounds were analyzed using HS-SPME and GC-MS, and their relationship with palatability was modeled with PLSR | 500 g for 2–4 h daily for 5 days |

| [26] |

| 8. Commercial palatant | D’TECH 6 L obtained from SPF (Descalvado, São Paulo, Brazil) | Dog | Kibble | 2% of the ingredients | Coating in a tumble system | Two-pan method with two meals in 1 day for 38 individually kenneled dogs Remains weighed and consumption rate were calculated as relative consumption (%) of each diet | Descriptive sensory analysis: panelists chewed one kibble to evaluate flavor and texture | After a 12 h fast, dogs were offered two pans of experimental food and allowed to eat for 30 min |

| [27] |

| 9. Sodium pyrophosphate and/or yeast extract | Enzyme extraction from Saccharomyces cerevisiae | Cat | Kibbles | 0.2% yeast extract, 0.3% sodium pyrophosphate, and 0.5% blends (yeast extract plus sodium pyrophosphate at 40:60) | Faces | Two-bowl method with 20 cats and food relative consumption (%) | - | Two consecutive days and bowls were left with the cats for 24 h |

| [28] |

| Strain-specific yeast extract | Cellular extraction of the Saccharomyces cerevisiae yeast strain cultivated in sugarcane juice | Cat | Wet food | 2% of yeast extract | Mixed with wet food | Two-bowl method with 20 adult mixed-breed cats (male and female) and relative consumption (%) | Nutrient digestibility, energy utilization, nitrogen balance, and blood evaluation | Each cat was offered two dietary options once per day, with bowls left for 30 min or until completely consumed |

| [29] |

| 10. Spray-dried porcine plasma (SDP) | Porcine plasma | Dog | Extruded dog food | 0, 4, 8, and 12% spray-dried porcine plasma in diet | Added on top of pet food | Pair-wise diet comparison using 20 adult dogs and the intake ratio of the basal diet | Digestibility, facial characteristics, and blood evaluation | 30 min for two consecutive days |

| [30] |

| 11. Fermented turmeric, glasswort, and Ganghwa mugwort | Turmeric, glasswort, and Ganghwa mugwort | Dog | Pellet | Control, 1% fermented turmeric added to diet, 1% fermented glasswort added to diet, 1% fermented Ganghwa mugwort added to diet, and 1% fermented mixture added to diet | Sprayed uniformly prior to the last oil coating step of extrusion | Two-pan method | Four consecutive days |

| [33] |

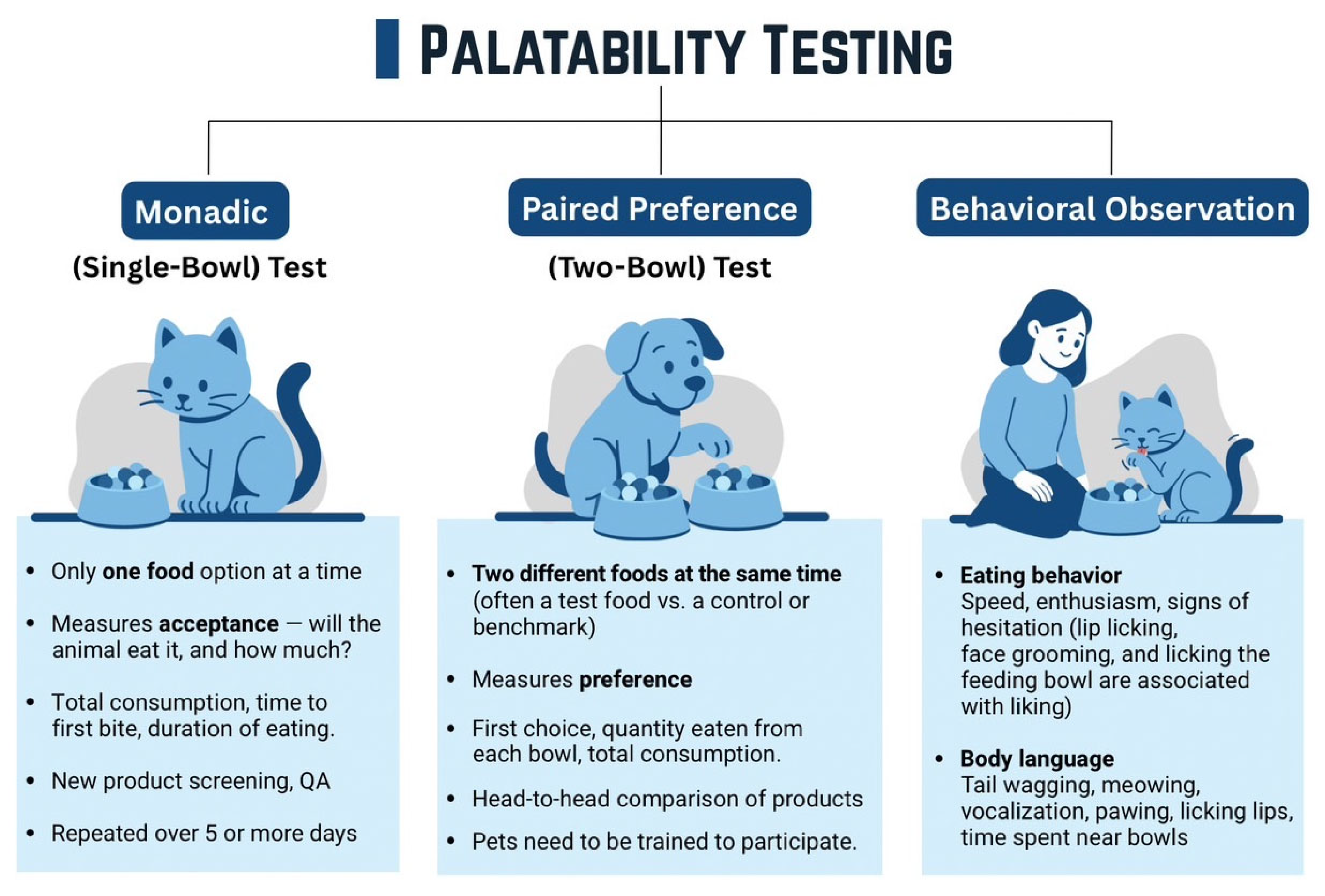

4. Palatability Testing

5. Palatability Influencers

6. Current Trends in Palatant Technology

7. Invention Patents of Palatants Used in Pet Food

8. Challenges and Future Opportunities

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aldrich, G.C.; Koppel, K. Pet food palatability evaluation: A review of standard assay techniques and interpretation of results with a primary focus on limitations. Animals 2015, 5, 43–55. [Google Scholar] [CrossRef]

- Kumar, R.; Goswami, M.; Pathak, V. Innovations in pet nutrition: Investigating diverse formulations and varieties of pet food: Mini review. MOJ Food Process Technols. 2024, 12, 86–89. [Google Scholar] [CrossRef]

- Tran, Q.D.; Hendriks, W.H.; van der Poel, A.F.B. Effects of extrusion processing on nutrients in dry pet food. Anim. Feed. Sci. Technol. 2008, 138, 298–311. [Google Scholar] [CrossRef]

- Murray, S.M.; Murray, S.M.; Patil, A.R.; Fahey, G.C., Jr.; Merchen, N.R.; Hughes, D.M. Raw and rendered animal by-products as ingredients in dog diets. J. Anim. Sci. 1997, 75, 2497–2505. [Google Scholar] [CrossRef]

- Katherine, P.; Lynnette Sue Gleadell, B.; Grey, R.M. Processed food, such as petfood, with improved palatability. WO Patent 2014089389A1, 12 June 2014. [Google Scholar]

- Martinez-Serna Villagran, M.D.; Alexander, J.; Silley, A.; Katherine, P.; Lee, A.H.B.; Lee, K.C.M. Attractive Fodder for Domestic Animals and Methods for Improving Attractiveness of Fodder for Domestic Animals. RU Patent 2598548C2, 27 September 2016. [Google Scholar]

- Goldy, G. Methods and Systems for Making Food. CA Patent 3067530A1, 8 November 2018. [Google Scholar]

- Mikami, T.; Kasamatsu, C.; Higuchi, E.; Fujieda, T. Method for Evaluating Food Preference of Pets. U.S. Patent 9810674B2, 7 November 2017. [Google Scholar]

- Samant, S.S.; Crandall, P.G.; Jarma Arroyo, S.E.; Seo, H.S. Dry Pet Food Flavor Enhancers and Their Impact on Palatability: A Review. Foods 2021, 10, 2599. [Google Scholar] [CrossRef]

- Calderón, N.; Calderón, N.; White, B.L.; Seo, H.S. Measuring palatability of pet food products: Sensory components, evaluations, challenges, and opportunities. J. Food Sci. 2024, 89, 8175–8196. [Google Scholar] [CrossRef] [PubMed]

- Watson, P.E.; Thomas, D.G.; Bermingham, E.N.; Schreurs, N.M.; Parker, M.E. Drivers of Palatability for Cats and Dogs-What It Means for Pet Food Development. Animals 2023, 13, 1134. [Google Scholar] [CrossRef] [PubMed]

- Bosch, G.; Swanson, K.S. Effect of using insects as feed on animals: Pet dogs and cats. J. Insects Food Feed. 2021, 7, 795–805. [Google Scholar] [CrossRef]

- Mota, C.S.; Cabrita, A.R.; Yergaliyev, T.; Camarinha-Silva, A.; Almeida, A.; Abreu, H.; Silva, J.; Fonseca, A.J.; Maia, M.R. Macroalgae and microalga blend in dogs’ food: Effects on palatability, digestibility, and fecal metabolites and microbiota. Algal Res. 2024, 84, 103775. [Google Scholar] [CrossRef]

- Rahman, C.F.; Kumar, R.R.; Chand, S.; Pattanaik, A.K.; Raypa, P.; Tarafdar, A.; Mendiratta, S.K.; Ajay, A. Keratin-based pet food produced through proteolytic hydrolysis of chicken feather: Characterisation and palatability study. Process Biochem. 2024, 146, 214–224. [Google Scholar] [CrossRef]

- Smith, S.C.; Aldrich, C.G. Evaluation of corn-fermented protein as a dietary ingredient in extruded dog and cat diets. Transl. Anim. Sci. 2023, 7, txad032. [Google Scholar] [CrossRef]

- Kim, H.S.; Kilburn, L.; Aldrich, C.G.; Dogan, H.; Li, Y.; Alavi, S. Alavi. Internal versus external fat in extrusion of dry expanded dog kibbles containing soy–Impact on process stability and product quality. Anim. Feed. Sci. Technol. 2025, 320, 116203. [Google Scholar] [CrossRef]

- Kazimierska, K.; Biel, W.; Iwański, R. Iwański. Palatability Testing of Spray-Dried Animal Plasma-Infused Dog Foods and Treats. Appl. Sci. 2024, 14, 7671. [Google Scholar] [CrossRef]

- Kilburn-Kappeler, L.R.; Aldrich, C.G. Evaluation of graded levels of corn fermented protein on extrusion processing and diet utilization in healthy adult dogs. Front. Anim. Sci. 2023, 4, 1202270. [Google Scholar] [CrossRef]

- Kokemuller, C.; Kokemuller, C.; Guldenpfennig, R.; Hsu, C.; Fries-Craft, K. Feline Responses to Increasing Inclusion of Natural Olive Extract in Liquid or Dry Palatant Formulations Applied to Kibble Diets. Pets 2025, 2, 13. [Google Scholar] [CrossRef]

- Mendoza Martínez, G.D.; López, M.Á.; Hernández García, P.A.; Ríos Hilario, J.J.; González, J.; Trujillo, A.G. Effect of the inclusion of herbal phosphatidylcholine on palatability, digestibility and metabolisable energy of the diet in dogs. Austral J. Vet. Sci. 2021, 53, 161–167. [Google Scholar] [CrossRef]

- Sun, K.; Sun, K.; Dai, Z.; Hong, W.; Zhao, J.; Zhao, H.; Luo, J.; Xie, G. Effects of maillard reaction on volatile compounds and antioxidant capacity of cat food attractant. Molecules 2022, 27, 7239. [Google Scholar] [CrossRef]

- El Hosry, L.; Elias, V.; Chamoun, V.; Halawi, M.; Cayot, P.; Nehme, A.; Bou-Maroun, E. Maillard Reaction: Mechanism, Influencing Parameters, Advantages, Disadvantages, and Food Industrial Applications: A Review. Foods 2025, 14, 1881. [Google Scholar] [CrossRef]

- Yin, M.; Yin, M.; Shao, S.; Zhou, Z.; Chen, M.; Zhong, F.; Li, Y. Characterization of the Key Aroma Compounds in Dog Foods by Gas Chromatography–Mass Spectrometry, Acceptance Test, and Preference Test. J. Agric. Food Chem. 2020, 68, 9195–9204. [Google Scholar] [CrossRef]

- Wei, Y.; Xie, L.; Muhoza, B.; Liu, Q.; Song, S. Generation of olfactory compounds in cat food attractants: Chicken liver-derived protein hydrolysates and their contribution to enhancing palatability. J. Agric. Food Chem. 2024, 72, 15906–15919. [Google Scholar] [CrossRef]

- Feng, T.; Hu, Z.; Tong, Y.; Yao, L.; Zhuang, H.; Zhu, X.; Song, S.; Lu, J. Preparation and evaluation of mushroom (Lentinus edodes) and mealworm (Tenebrio molitor) as dog food attractant. Heliyon 2020, 6, e05302. [Google Scholar] [CrossRef]

- Chen, M.; Chen, M.; Chen, X.; Nsor-Atindana, J.; Masamba, K.G.; Ma, J.; Zhong, F. Optimization of key aroma compounds for dog food attractant. Anim. Feed. Sci. Technol. 2017, 225, 173–181. [Google Scholar] [CrossRef]

- Koppel, K.; Monti, M.; Gibson, M.; Alavi, S.; Donfrancesco, B.D.; Carciofi, A.C. The effects of fiber inclusion on pet food sensory characteristics and palatability. Animals 2015, 5, 110–125. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, R.T.D.; Haese, D.; Kill, J.L.; Lima, A.; Malini, P.V.; Thompson, G.R. Palatability of cat food with sodium pyrophosphate and yeast extract. Ciência Rural 2016, 46, 2202–2205. [Google Scholar] [CrossRef]

- Lima, L.M.; Silva Jr, J.W.; Ogoshi, R.C.; dos Reis, J.S.; França, J.; Zangeronimo, M.G.; Saad, F.M. Evaluation of raw yeast extract (Saccharomyces cerevisiae) as an ingredient, additive or palatability agent in wet diet for cats. Int. J. Biol. 2016, 18, 1. [Google Scholar] [CrossRef]

- Andrade, T.; Lima, D.C.; Domingues, L.P.; Félix, A.P.; de Oliveira, S.G.; Maiorka, A. Spray-dried porcine plasma in dog foods: Implications on digestibility, palatability and haematology. Semin. Ciências Agrárias 2019, 40, 1287–1296. [Google Scholar] [CrossRef]

- Polo, J.; Polo, J.; Rodríguez, C.; Saborido, N.; Ródenas, J. Functional properties of spray-dried animal plasma in canned petfood. Anim. Feed. Sci. Technol. 2005, 122, 331–343. [Google Scholar] [CrossRef]

- Dust, J.M.; Grieshop, C.M.; Parsons, C.M.; Karr-Lilienthal, L.K.; Schasteen, C.S.; Quigley, J.D., III; Merchen, N.R.; Fahey, G.C., Jr. Chemical composition, protein quality, palatability, and digestibility of alternative protein sources for dogs. J. Anim. Sci. 2005, 83, 2414–2422. [Google Scholar] [CrossRef]

- Park, D.H.; Kothari, D.; Niu, K.M.; Han, S.G.; Yoon, J.E.; Lee, H.G.; Kim, S.K. Effect of Fermented Medicinal Plants as Dietary Additives on Food Preference and Fecal Microbial Quality in Dogs. Animals 2019, 9, 690. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, X.; Zheng, H.; Li, J.; Wu, X.; Xu, J.; Zhen, Z.; Du, C. The application of encapsulation technology in the food Industry: Classifications, recent Advances, and perspectives. Food Chem. X 2024, 21, 101240. [Google Scholar] [CrossRef]

- Schlanker, S. Paired vs. Monadic: What is the Difference? Global Pet Industry. 20 November 2017. Available online: https://globalpetindustry.com/article/paired-vs-monadic-what-difference/ (accessed on 4 April 2025).

- Principles of Pet Food Palatability. (n.d.). Scribd. Available online: https://www.scribd.com/document/319269253/Principles-of-Pet-Food-Palatability (accessed on 4 April 2025).

- Li, X.; Li, W.; Wang, H.; Bayley, D.L.; Cao, J.; Reed, D.R.; Bachmanov, A.A.; Huang, L.; Legrand-Defretin, V.; Beauchamp, G.K.; et al. Cats Lack a Sweet Taste Receptor1–3. J. Nutr. 2006, 136, 1932S–1934S. [Google Scholar] [CrossRef]

- Kokocińska-Kusiak, A.; Woszczyło, M.; Zybala, M.; Maciocha, J.; Barłowska, K.; Dzięcioł, M. Canine olfaction: Physiology, behavior, and possibilities for practical applications. Animals 2021, 11, 2463. [Google Scholar] [CrossRef]

- Alegría-Morán, R.A.; Guzmán-Pino, S.A.; Egaña, J.I.; Muñoz, C.; Figueroa, J. Food preferences in dogs: Effect of dietary composition and intrinsic variables on diet selection. Animals 2019, 9, 219. [Google Scholar] [CrossRef]

- Le Guillas, G.; Vanacker, P.; Salles, C.; Labouré, H. Insights to study, understand and manage extruded dry pet food palatability. Animals 2024, 14, 1095. [Google Scholar] [CrossRef] [PubMed]

- Rentas, M.F.; Rentas, M.F.; Pedreira, R.S.; Perini, M.P.; Risolia, L.W.; Zafalon, R.V.A.; Alvarenga, I.C.; Vendramini, T.H.A.; Balieiro, J.C.C.; Pontieri, C.F.F.; et al. Galactoligosaccharide and a prebiotic blend improve colonic health and immunity of adult dogs. PLoS ONE 2020, 15, e0238006. [Google Scholar] [CrossRef] [PubMed]

- González-Martínez, Á.; Muñiz de Miguel, S.; Graña, N.; Costas, X.; Diéguez, F.J. Serotonin and dopamine blood levels in ADHD-like dogs. Animals 2023, 13, 1037. [Google Scholar] [CrossRef] [PubMed]

- García-Luna, C.; Espitia-Bautista, E.; Alvarez-Salas, E.; Soberanes-Chávez, P.; de Gortari, P. Accumbal serotonin hypofunction and dopamine hyperfunction due to chronic stress and palatable food intake in rats. Nutr. Neurosci. 2024, 28, 773–787. [Google Scholar] [CrossRef]

- Shah, A.A.; Totakul, P.; Matra, M.; Cherdthong, A.; Hanboonsong, Y.; Wanapat, M. Nutritional composition of various insects and potential uses as alternative protein sources in animal diets. Anim. Biosci. 2022, 35, 317. [Google Scholar] [CrossRef]

- Halloran, A.; Hanboonsong, Y.; Roos, N.; Bruun, S. Life cycle assessment of cricket farming in north-eastern Thailand. J. Clean. Prod. 2017, 156, 83–94. [Google Scholar] [CrossRef]

- Corrigan, P.J. Process for Making a Pet Food in the Form of a Coated Kibble. U.S. Patent 9585412B2, 7 March 2017. [Google Scholar]

- Vanacker, P.; Glabasnia, A.; Zhang, J.; Pollien, P.; Vlaeminck, H. Methods and Composition for Palatable Pet Foods. WO Patent 2024231762A1, 14 November 2024. [Google Scholar]

- Callejon, L. Palatability Enhancers for Pet Food, Method of Preparation and Uses Thereof. KR Patent 20160103993A, 2 September 2016. [Google Scholar]

- Corrigan, P.J.; Sunvold, G.D. Pet Food in the Form of a Coated Kibble. AU Patent 2015200474B2, 11 September 2015. [Google Scholar]

- Cambou, S.; Nisolon, C. Preference Improver Containing Amino Reactant and Carbonyl Compound for Use in Cat Food. JP Patent 2017515860A, 15 June 2017. [Google Scholar]

- Foy, J.M.; Grey, R.M.; Reed, T.W.; Myrie, L.R.; Romanach, B.A.; Katherine, P.; Kristen, B.; Carnagey, M.; Westendorf, R.D. Compositions and Methods for a Life-Stage-Adapted Diet of an Animal. EP Patent 2750518B1, 20 May 2020. [Google Scholar]

- Corrigan, P.J. Process for Making Pet Food. WO Patent 2012099786A1, 26 July 2012. [Google Scholar]

- Nadeau, D.; Kappelman, D.; Montelongo, L. Process for preparing a pet food composition. U.S. Patent 10849349B2, 1 December 2020. [Google Scholar]

- Isabelle, G.; Bramoule, L.; Loiec, B.; de Latour, A.; Aurelie, B.R.; Clément, M.; Cremont, M. Specific Fat Fraction Containing Palatable Cat Kibble. JP Patent 2020114228A, 30 July 2020. [Google Scholar]

- Branville-Onno, M.; Lacotte, C.; de Latour, A. Taste Dry Cat Food and Method for Producing the Same. JP Patent 2017532978A, 9 November 2017. [Google Scholar]

- Reynes, P. Meat Emulsion Products, Methods of Making Such Products, and Pet Foods Containing Such Products. CA Patent 2974038A1, 4 August 2016. [Google Scholar]

| Types of Palatant | Origin of Palatant | Pet Type | Food Types | How to Use | Major Claim | Country of Patent Applicants | Patent Name | References |

|---|---|---|---|---|---|---|---|---|

| 1. Fat | Dogs | Dry pet food | Applied as external coating (post-extrusion), inner inclusion in granule | Improved palatability, softness, and texture through multilayered coating | Russia (RU) | Attractive fodder for domestic animals and methods for improving attractiveness of fodder for domestic animals | Mars Incorporated. (2016) [6] | |

| 2. Protein | Egg | Dogs and Cats | Dry pet food | Applied post-extrusion using fluidizing mixer | Enhanced palatability and nutritional value via protein–palatant–fat coating system with reduced thermal degradation | United States | Process for making a pet food in the form of a coated kibble | Corrigan (2017) [46] |

| 3. Protein | Dogs | Dry pet food | Palatants were sprayed on dry base food (DS-A) at 0.2% w/w for testing; preference measured via 2-pan test | Innovative method for evaluating pet food preference using mapped sensory analysis and preference data to optimize formulation without requiring humans to consume pet food | Japan | Method for evaluating food preference of pets | Mikami et al. (2017) [8] | |

| 4. Fatty acid Yeast Amino acid | Dogs and Cats | Dry pet food | Applied as topical coating Blended into food formulation | Improved palatability and acceptance by combining fatty acid esters, amino acids, and yeast-based flavor systems | International | Methods and Compositions for Palatable Pet Foods | Nestlé Purina PetCare Global Resources Inc. (2024) [47] | |

| 5. Protein digests Fats | Dogs and Cats | Dry pet food | Internal inclusions added before extrusion External coating post-extrusion Layering optimized using multistep application system | Enhanced sensory experience and palatability through spatially distinct placement of palatants (inside and outside the kibble); mimics meaty textures and flavors | Canada | Methods and Systems for Making Food | Nestlé Purina PetCare Centre (2019) [7] | |

| 6. Vitamin D3 Vitamin B1 Fat | Maillard precursors | Dogs and Cats | Dry, semi-moist, and wet pet foods | Added by coating or inclusion (before processing); optional heat-treatment to improve flavor development (e.g., Maillard reaction) | Improved palatability through vitamin-based enhancers in combination with carriers and flavor precursors; adaptable to various food forms and species | South Korea (KR) | Palatability Enhancers for Pet Food, Method of Preparation and Uses Thereof | Cayeux, L. (2016) [48] |

| 7. Protein Fat Probiotics Vitamins | Egg white Whey | Dogs and Cats | Dry pet food | Post-extrusion coating in fluidizing mixer | Enhanced palatability, nutrient delivery, and stability through sequential, multilayer coating with functional and flavor-enhancing components | Australia | Pet Food in the Form of a Coated Kibble | Sunvold and Corrigan (2016) [49] |

| 8. Amino acid | Cat | Dry, semi-moist, and wet cat foods | Applied as coating or internal inclusion; optionally heat-treated (80–200 °C for 10 s to 210 min) to generate Maillard-derived aroma and flavor compounds | Improved palatability in cat food using a fat-free system based on amino-carbonyl Maillard reaction products; adaptable to various moisture levels and food formats | Japan | Preference Improver Containing Amino Reactant and Carbonyl Compound for Use in Cat Food | Nestec S.A. (2017) [50] | |

| 9. Fat | Dogs and Cats | Dry pet food | Palatants added at various process stages Post-extrusion coating | Improved and consistent palatability by timing palatant addition at key production points; reduced loss of aroma compounds and improved consumer acceptance | International | Process for Making Pet Food | Corrigan, P. J. (2012) [52] | |

| 10. Meat analogues formed | Alginate–calcium gelation | Dogs and Cats | Wet pet food | Forms meat-like structures pre-retort Mixed with gravy containing palatants | Preparation of retort-stable, striated, restructured meat analogues using alginate–calcium gelation, suitable for canned/gravy-style pet foods | United States | Process for Preparing a Pet Food Composition | Hill’s Pet Nutrition, Inc. (2020) [53] |

| 11. Fat | Animal fats Plant fats | Cats | Dry pet food | Fat incorporated internally and coating post-extrusion | Enhanced palatability by controlling specific fat ratios from animal and plant sources; formulation shown to outperform standard kibbles | Japan | Specific Fat Fraction Containing Palatable Cat Kibble | Nestlé S.A. (2020) [54] |

| 12. Protein Fat | Poultry by-products Fish materials, dried whole egg, yeast | Cats | Dry pet food | Palatants included in formulation and also applied post-extrusion as coating | Enhanced palatability through optimized nutritional composition and targeted coating with attractant palatability agents | Japan | Taste Dry Cat Food and Method for Producing the Same | Nestlé S.A. (2017) [55] |

| 13. Protein hydrolysates Reducing sugars Fat | Wheat gluten Lactose Glucose | Dogs and Cats | Dry and wet pet foods | Mixture incorporated during production or applied post-processing | Improved palatability by generating desirable Maillard reaction products from plant-based protein, sugar, and lipid systems | International | Processed Food Such as Petfood with Improved Palatability | Nestlé S.A. (2014) [5] |

| 14. Emulsified meat-based matrix | Ground animal muscle Fat Plasma | Dogs and Cats | Wet pet foods | Meat emulsion prepared and cooked into stable chunks or paste and mixed with gravy containing palatants | Improved palatability, texture, and water retention in wet pet foods via emulsified meat matrices | Canada | Meat Emulsion Products, Methods of Making Such Products and Pet Foods Containing Such Products | Nestlé Purina PetCare Centre (2017) [56] |

| 15. Palatant concentration | Dogs and Cats | Dry and wet pet foods | Palatants integrated into each life-stage-specific formula or adjusted in level to drive voluntary intake | Life-stage-specific animal diets optimized in nutrient profile and optionally palatant concentration, enhancing selection and compliance through human–animal life stage visual cues | Netherlands | Compositions and Methods for Providing a Life-Stage Appropriate Animal Diet | Iams Europe B.V. (2020) [51] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klinmalai, P.; Kamonpatana, P.; Sodsai, J.; Promhuad, K.; Srisa, A.; Laorenza, Y.; Kovitvadhi, A.; Areerat, S.; Seubsai, A.; Harnkarnsujarit, N. Modern Palatant Strategies in Dry and Wet Pet Food: Formulation Technologies, Patent Innovations, and Market Evolution. Foods 2025, 14, 2824. https://doi.org/10.3390/foods14162824

Klinmalai P, Kamonpatana P, Sodsai J, Promhuad K, Srisa A, Laorenza Y, Kovitvadhi A, Areerat S, Seubsai A, Harnkarnsujarit N. Modern Palatant Strategies in Dry and Wet Pet Food: Formulation Technologies, Patent Innovations, and Market Evolution. Foods. 2025; 14(16):2824. https://doi.org/10.3390/foods14162824

Chicago/Turabian StyleKlinmalai, Phatthranit, Pitiya Kamonpatana, Janenutch Sodsai, Khwanchat Promhuad, Atcharawan Srisa, Yeyen Laorenza, Attawit Kovitvadhi, Sathita Areerat, Anusorn Seubsai, and Nathdanai Harnkarnsujarit. 2025. "Modern Palatant Strategies in Dry and Wet Pet Food: Formulation Technologies, Patent Innovations, and Market Evolution" Foods 14, no. 16: 2824. https://doi.org/10.3390/foods14162824

APA StyleKlinmalai, P., Kamonpatana, P., Sodsai, J., Promhuad, K., Srisa, A., Laorenza, Y., Kovitvadhi, A., Areerat, S., Seubsai, A., & Harnkarnsujarit, N. (2025). Modern Palatant Strategies in Dry and Wet Pet Food: Formulation Technologies, Patent Innovations, and Market Evolution. Foods, 14(16), 2824. https://doi.org/10.3390/foods14162824