1. Introduction

Plain boiled beef, as a high-protein and low-fat meat product, is favored by consumers, according to Bhat et al. [

1]. However, during the processing of plain boiled beef, issues such as meat texture hardening, juice loss, and flavor deterioration often occur, especially under low-sodium conditions. The development of low-sodium foods represents a crucial strategy to address health problems caused by modern high-sodium diets, such as hypertension and cardiovascular diseases. Nevertheless, the reduction in sodium salts typically leads to the deterioration of water-holding capacity (WHC), texture, and flavor in meat products, as described by Inguglia et al. [

2].

The reduction in sodium in traditional high-salt processing methods could lead to decreased protein solubility, increased moisture loss, disruption of myofibrillar structure, and dull coloration of the product, as reported by Zhang et al. [

3]. These issues severely restrict the quality and market competitiveness of the products. Currently, the primary sodium chloride substitution technologies involve utilizing other metal salts with properties similar to those of NaCl to replace sodium chloride, thereby reducing sodium intake. Among them, the main substitutes for NaCl include KCl, MgCl

2, CaCl

2, phosphates, etc. [

4,

5]. However, the substitution of NaCl with other metal salts is not without drawbacks. When the replacement ratio of NaCl reaches a certain level, the products tend to develop metallic and bitter flavors, while the intensity of saltiness diminishes. These changes could severely compromise the flavor profile of meat products [

6]. In the low-sodium substitution of meat products, phosphates are the most widely applied by Thangavelu et al. [

7], in the marination solution for chicken breast meat, the addition of sodium tripolyphosphate significantly reduced the usage of sodium NaCl. However, excessive intake of phosphorus also poses safety risks to human health, disrupting the elemental balance within the body, particularly imposing a significant burden on kidney function [

8,

9]. Nowadays, the application of ultra-high pressure (UHP) and ultrasonic technologies in the food sector has become increasingly mature. However, advanced techniques, such as UHP treatment or vacuum packaging, entail high costs and pose significant challenges for industrial-scale implementation, as reported by Li et al. [

10].

In recent years, the application of exogenous L-lysine (L-Lys) in food processing garnered increasing attention [

11]. Numerous scholars successively suggested that basic amino acids could significantly increase the solubility of myosin under low ionic strength. Specifically, the solubility of myosin in environments with low ionic strength was capable of being enhanced by histidine (His) and L-Lys [

12]. Among them, exogenous L-Lys, as an essential amino acid for humans and a multifunctional regulator, was widely recognized as the “first essential amino acid”, as reported by Guo et al. [

13]. Owing to its ability to promote protein solubility, enhance hydration, and exhibit antioxidant properties, it emerged as a potential agent for improving the quality of low-sodium meat products [

14,

15]. Zhang et al. [

3] observed that whether used individually or in combination, L-Lys and arginine (Arg) have been shown to enhance the tenderness and WHC of cooked chicken breast meat. Moreover, while L-Lys itself exhibits a certain degree of saltiness, its combination with salt substitutes in a specific proportion could neutralize the bitter and astringent tastes of other metal salts, simultaneously enhancing the saltiness of the mixed salts. Da Silva et al. [

16] found that when the substitution ratio of KCl for NaCl reaches 60%, it impairs the emulsion stability, texture structure, and sensory quality of sausage products. Thus, they combined His and Arg, which share similar properties with L-Lys, with the KCl substitution technology. The results indicate that both individual and combined additions of Arg and His effectively mitigated the sensory defects caused by the addition of KCl and enhanced the overall quality of the products [

16]. However, current research on L-Lys has not clearly defined its optimal addition level or storage stability, and there is a lack of integrated analysis of the multidimensional effects of L-Lys. It is hypothesized that there exists an appropriate concentration which can enhance the quality, appearance, and microstructure of low-sodium plain boiled beef, and meanwhile moderately improve the edible quality of low-sodium marinated braised beef without affecting the product shelf life. This study aimed to reveal the effects of exogenous L-Lys on the quality indices, distribution of water content, microstructure, and sensory evaluation of plain boiled beef, screen for the optimal addition dosage, further explore the quality and storage stability of marinated braised beef after sauce-braising processing, and integrate the findings from both plain boiled beef and marinated braised beef to provide a theoretical basis and new directions for the development of low-sodium meat products.

2. Materials and Methods

2.1. Raw Material Preparation

The raw meat used in this experiment was obtained from the beef shank of Simmental × Luxi hybrid cattle provided by a halal meat food company in Heze, Shandong Province. Six cattle with a similar feeding environment and carcass weight of about 350 kg were selected and slaughtered using Islamic slaughtering methods. After slaughter, the carcasses were aged at 4 °C for 24 h, followed by primary segmentation. The segmented meat was transported back to the laboratory at 4 °C for further trimming and then frozen and stored at −20 °C. The pH of the aged beef was measured using a portable pH meter to ensure that the pH values of the selected meat samples ranged between 5.4 and 5.8.

2.2. Experimental Design

The beef shanks from the left and right carcasses were trimmed and divided into beef blocks weighing approximately 150 g each, which were then stored at −20 °C. For the experiment, 20 beef blocks were randomly selected and thawed. Then, they were injected with different L-Lys-containing marinades. The injection amount was 20% of the meat weight, and the marinades had a salt concentration of 7.5%, a 60% KCl substitution ratio, 10 h of marination time, and 2 h of cooking time, with the L-Lys addition level serving as the variable. After marination, the beef samples were vacuum-packaged (specifications: 320 mm × 200 mm multilayer heat-shrinkable packaging with high barrier to oxygen (35 cm3/m2/d at 23 °C) and water vapor (9 gH2O/m2/d at 38 °C, 90% RH), thickness: 55 μm) and cooked using a water bath method to ensure even heat distribution, then the beef samples were cooled to room temperature and stored overnight at 4 °C. The effects of the different concentrations of L-Lys addition on the quality of low-sodium plain boiled beef were subsequently analyzed.

The remaining beef shanks were divided into beef blocks weighing approximately 150 g each and stored at −20 °C. During the experiment, they were taken out and thawed. The meat pieces obtained from each biceped femoris muscle were randomly grouped. They were, respectively, injected with a brine solution containing 0% (control, C) treatment and a brine solution containing 0.6% (L-Lys, L) treatment of L-Lys for marinating. After the marinating was completed, the marinated samples were braised in a double-jacketed pot for 2 h. The ratio of the braising liquid components was water accounting for 300% of the meat mass, including NaCl 1.2%, KCl 1.8%, broad bean paste 0.7%, monosodium glutamate 0.3%, cooking wine 1%, sucrose 1%, soy sauce 1.7%, bay leaves 0.1%, Angelica dahurica 0.1%, tsaoko fruit 0.1%, fennel 0.1%, cassia bark 0.2%, star anise 0.2%, clove 0.05%, scallions 1.4%, and ginger 1.4%. Then, it was cooled to room temperature. Ten groups were selected and exposed to air for contamination. After that, they were packaged in trays and stored at 4 °C. The storage indexes were determined on day 0, 3, 6, 9, and 12, and the meat color and tenderness were measured. Each piece of meat was measured three times.

2.3. Determination of Quality Indicators of Low-Sodium Plain Boiled Beef

2.3.1. pH Value

The pH measurement method was adapted from that reported by Zuo et al. [

17]. The pH value was determined using a portable solid-state pH meter (SenVengo, Mettler Toledo, Zurich, Switzerland). The pH meter was calibrated using a two-point method with pH buffers of 4.00 and 7.00, ensuring a slope correction of over 95%. After the low-sodium plain boiled beef was prepared, it was cut in half against the fiber direction using a dissection knife. Six points were randomly and evenly selected from the center of the beef. A small hole was punctured at each selected point using the dissection knife, and the probe was inserted into the hole for measurement. The mean value of the 6 measurements was taken as the final pH value.

2.3.2. Cooking Loss

The method for determining the cooking loss was adapted from that described by Liu et al. [

18], with minor modifications. Before cooking, beef samples were dried by blotting surface juices with absorbent paper and weighed as W

1. The experimental samples were then treated with different marinades, each injected at 20% of the meat weight. After the low-sodium plain boiled beef was prepared, the juices from the cooking bags were drained and the samples were left to cool at room temperature. Once the samples cooled to room temperature, they were further chilled at 4 °C for 12 h. After chilling, the surface juices and any residual blood were blotted dry with filter paper, and the samples were weighed again, with the final weight recorded as W

2.

Equation (1) is as follows:

2.3.3. Shear Force

The method for determining shear force was adapted from that reported by Hou et al. [

19], with minor modifications. After cooking, low-sodium plain boiled beef samples were cooled to room temperature and stored at 4 °C for at least 12 h. Using a 1.27 cm-diameter hollow corer, cylindrical meat cores longer than 3 cm were cored along the muscle fiber direction, with at least 6 cores collected (at least 2 cores per meat piece), avoiding tendons and fat. Shear force measurements were performed on these cores using a TA-XT2i texture analyzer (TA-XT 2i Stable Micro Systems, London, UK). The average shear force value of the 6 cores was taken as the shear force for that group. For the texture analyzer, specific operation parameters were established. The speed before the test started was 2.0 mm/s. During the testing process, the speed was 1.0 mm/s, and after the test, the speed reached 5.0 mm/s. The force for detection was maintained at less than 1 N. A trigger force of 0.098 N was set to initiate the measurement. The probe was set to penetrate the sample to a distance of 23.0 mm. Additionally, the HDP/BSW type of probe was chosen for conducting the texture analysis.

2.3.4. Meat Color

The method for color measurement was adapted from that described by Zuo et al. [

17], with minor modifications. The low-sodium plain boiled beef was cut in half against the fiber direction. The spectrophotometer was calibrated with a white ceramic plate adjusted to Y-93.7, x = 0.3160, and y = 0.3323. A colorimeter (SP62, X-rite, Co., Ltd., Grand Rapids, MI, USA) with a measurement aperture of 8 mm, light source A, and a standard viewing angle of 10° was used to measure the lightness

(L*), redness

(a*), yellowness (

b*), chroma (

C*), and hue (

H*) values of the beef. The calculation formulas are as follows:

C* = (

a*2 +

b*2)

1/2,

H* = [arctangent (

b*/

a*)]. Six random and evenly distributed points were selected on each sample for measurement. The mean value of these 6 points was taken as the final value for each color parameter.

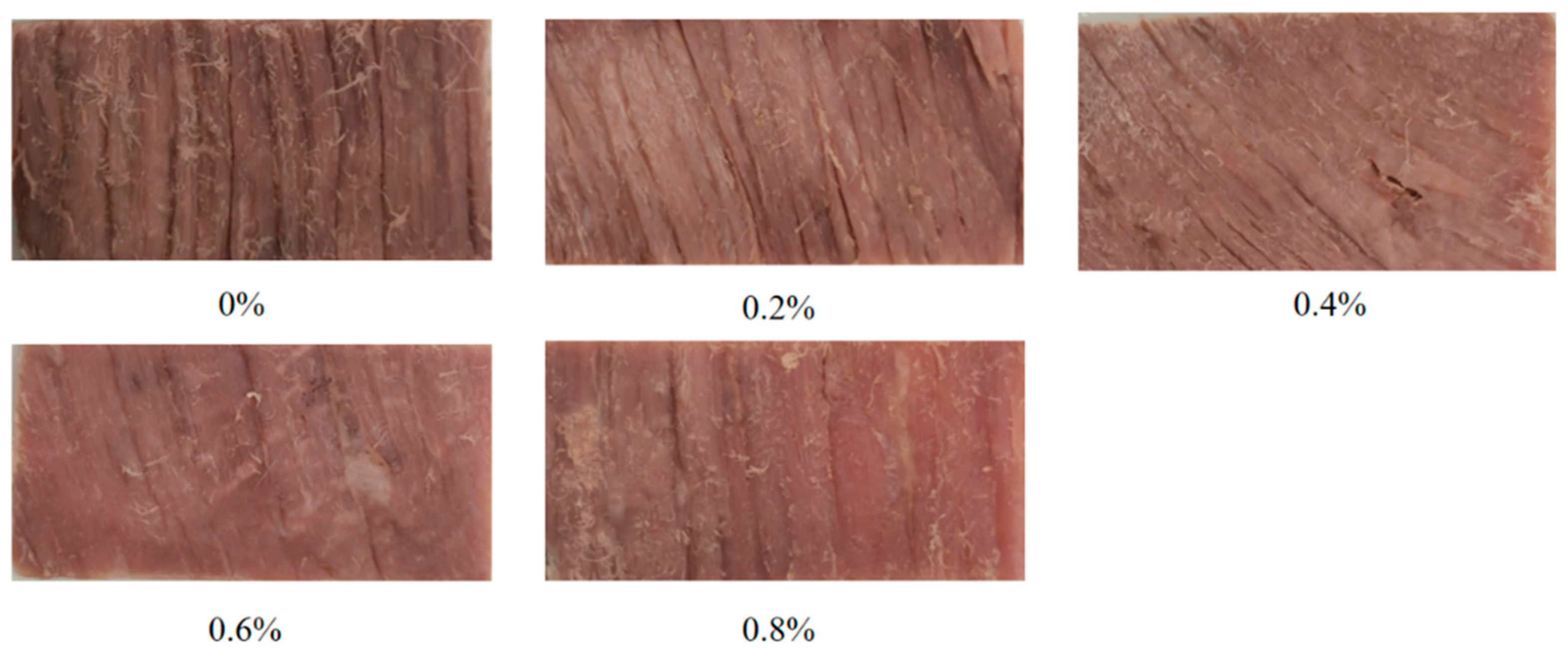

2.3.5. Appearance

After the low-sodium plain boiled beef was prepared, it was cooled to room temperature and then stored at 4 °C for more than 12 h. Suitable samples were selected, and slices approximately 3 mm thick were cut from the middle section of the samples. These slices were placed on a white porcelain plate and illuminated with a white light source at an appropriate brightness level for photography.

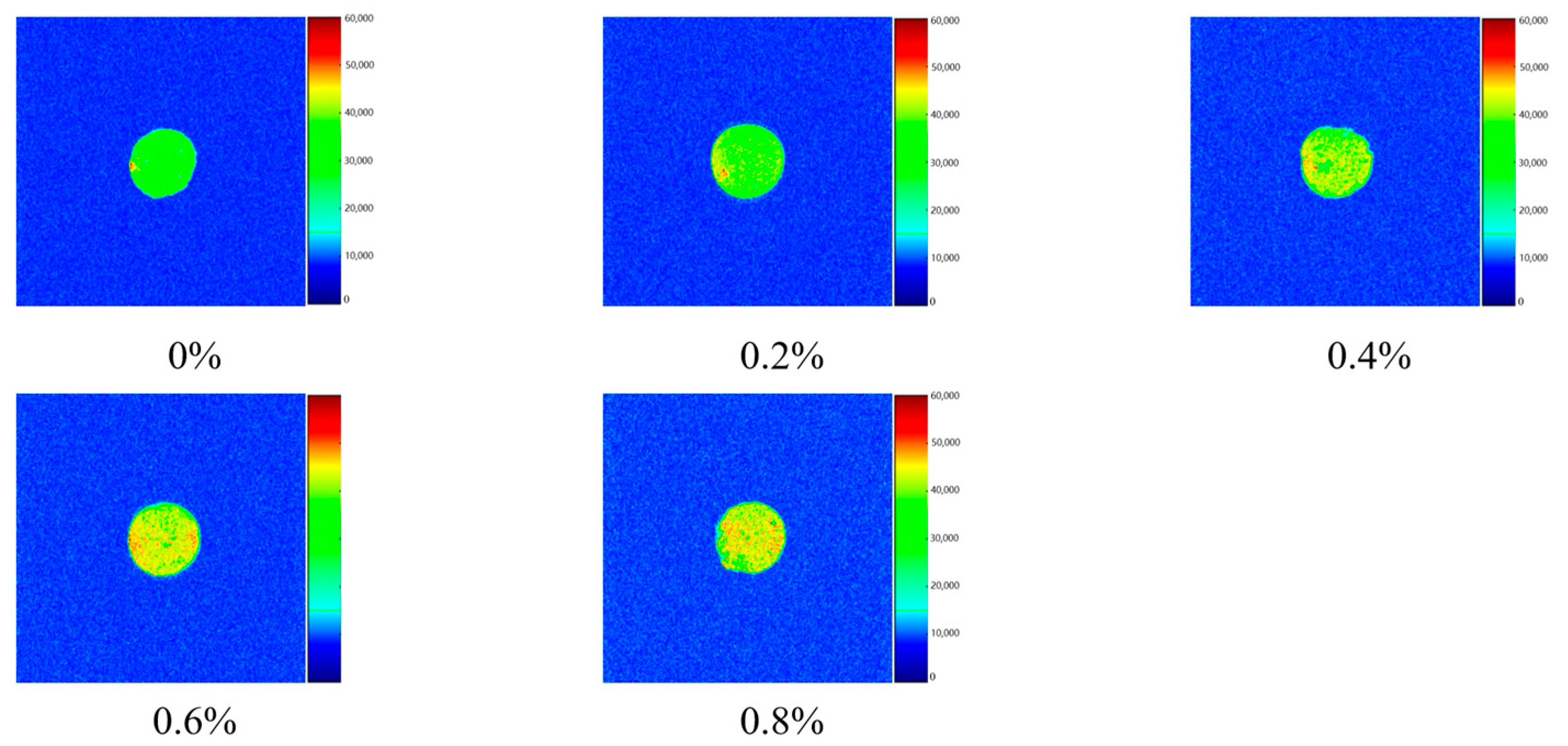

2.3.6. Low-Field Nuclear Magnetic Resonance (LF-NMR) and Magnetic Resonance Imaging (MRI)

From the central portion of low-sodium plain boiled beef, 1 cm-thick meat blocks were cut, avoiding tendons and adipose tissues, and further trimmed into 1 cm × 1 cm × 2 cm cylindrical cores along the muscle fiber direction, with at least 3 cores prepared per group. The meat cylinders were gently placed into NMR tubes without compression and sealed with parafilm to prevent moisture evaporation. The LF-NMR spectrometer (NMRI20-015V-I, Niumag Co., Ltd., Shanghai, China) was preheated for 30 min at a test temperature of 32 °C. Prior to testing, the instrument was calibrated using a standard oil sample with a free induction decay (FID) sequence. The samples were measured using the Carr–Purcell–Meiboom–Gill (CPMG) sequence. For MRI testing at 32 °C, the instrument was calibrated with a standard oil sample after preheating, and appropriate images were selected and saved following a pre-imaging process.

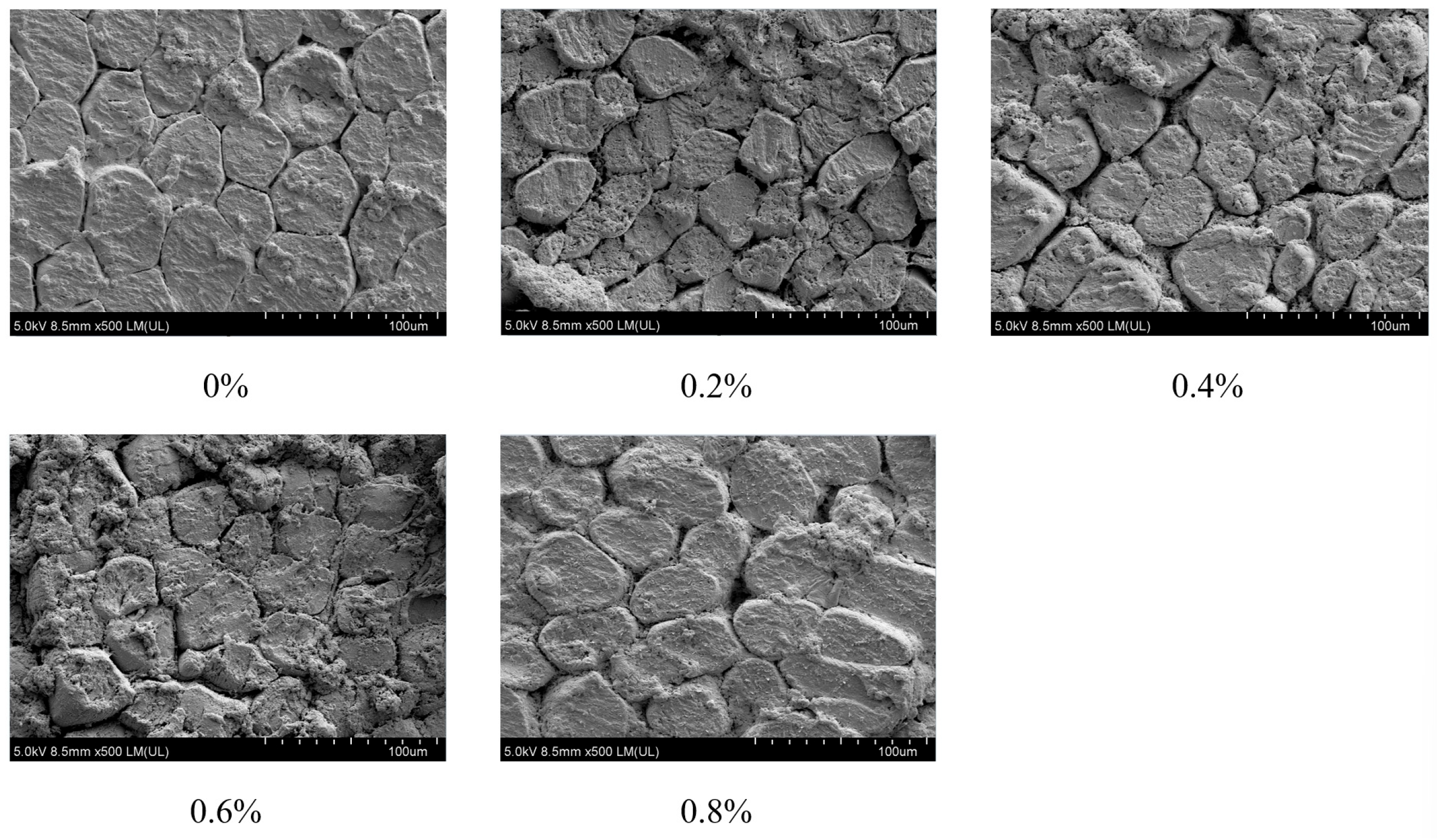

2.3.7. Microstructure

The method for determining the microstructure was adapted from that described by Zhang et al. [

20], with minor modifications. The microstructure was observed using the scanning electron microscope (SEM). After cooking, low-sodium plain boiled beef samples were cooled to room temperature and stored at 4 °C for over 12 h. From the central portion of each group of low-sodium plain boiled beef, 1 cm × 1 cm × 1 cm meat cubes were excised using a dissecting knife. The samples were subjected to critical point drying followed by gold sputtering. Scanning was performed from 2 orientations, with 4 scans conducted for each orientation. After scanning, appropriate magnifications were selected for analysis. Electron microscopy parameters: accelerating voltage of 3 kV or 5 kV, resolution of 50 nm.

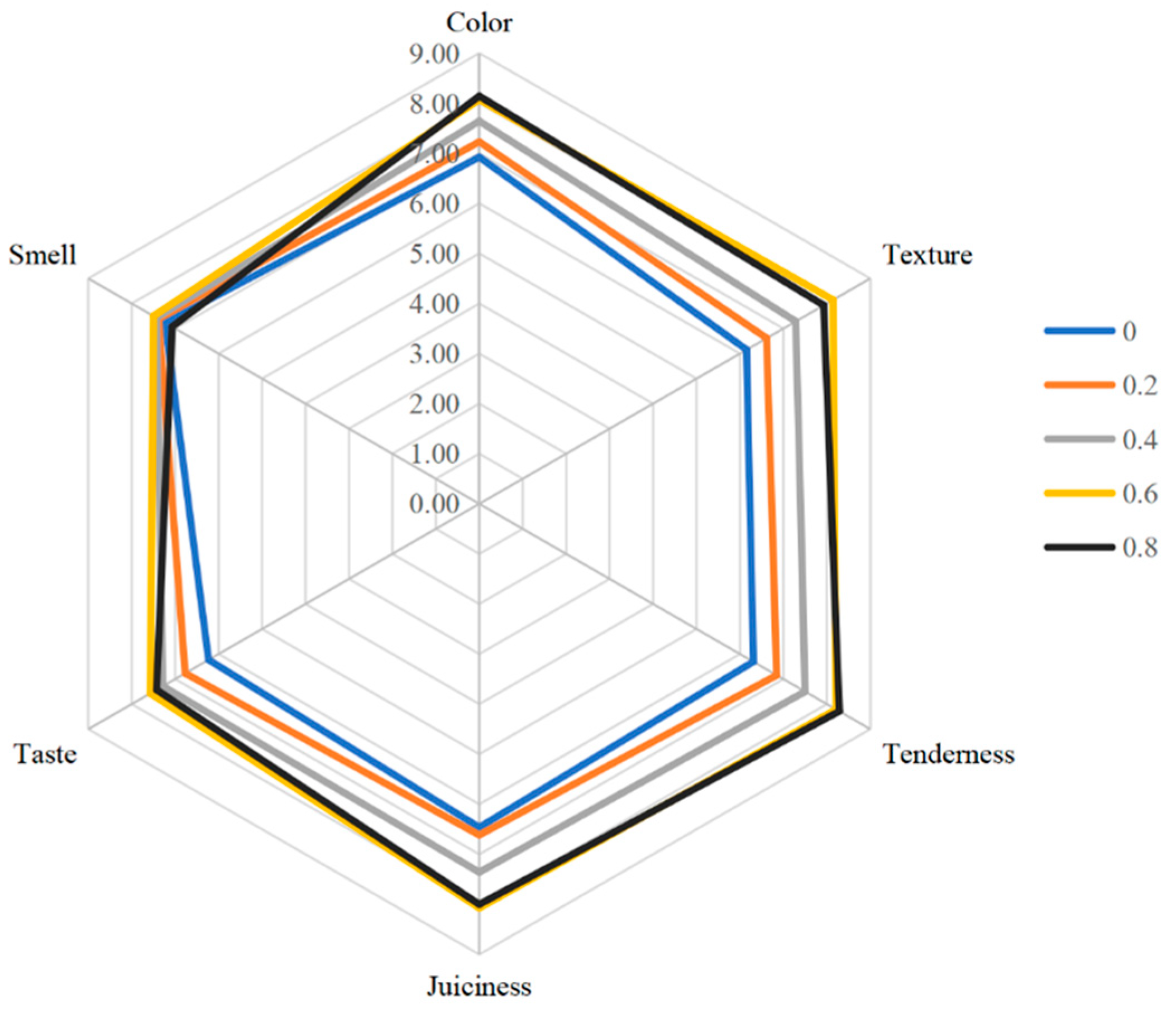

2.3.8. Quantitative Descriptive Analysis (QDA) Evaluation

This study recruited 15 beef quality researchers aged 20–30 years with experience in sensory evaluation. The QDA method was employed to assess the effects of different L-Lys addition levels on the eating quality of plain boiled beef. Samples were thinly sliced into 2–3 mm thickness, randomly coded with 3 slices per person per group, and presented to evaluators under blind testing conditions. Evaluators scored 6 attributes, including color, texture, and tenderness, on a 10-point scale. The entire testing process was conducted in a standardized environment, with taste interference controlled by soda water and soda biscuits. Samples from each treatment group were presented 3 times in a cross-randomized manner to ensure data reliability.

2.4. Determination of Storage Indices for Low-Sodium Marinated Braised Beef

2.4.1. Shear Force During Storage

After cooking the 2 groups of low-sodium marinated braised beef, each piece was measured at least 3 times on day 0, 3, 6, 9, and 12 with the specific methods described in

Section 2.3.3.

2.4.2. Meat Color During Storage

After cooking the 2 groups of low-sodium marinated braised beef, each piece was measured at least 3 times on day 0, 3, 6, 9, and 12 with the specific methods described in

Section 2.3.4.

2.4.3. Thiobarbituric Acid Reactive Substances (TBARS)

A 0.06 mol/L 2-thiobarbituric acid (TBA) solution and a 10% trichloroacetic acid (TCA) solution were prepared in advance, and a standard curve was constructed. The 2 groups of low-sodium marinated braised beef were sampled on day 0, 3, 6, 9, and 12 with 5 replicates per group, respectively. For each replicate, 1 g of sample was collected. Samples were placed into 5 mL grinding tubes, followed by the addition of 4 mL of pure water and steel beads. The mixtures were ground using a freeze grinder at 50 Hz for 45 s, with 3 grinding cycles performed to ensure uniform disruption. Following the grinding process, the samples were transferred into centrifuge tubes with a capacity of 10 mL. Subsequently, 4 mL of the TCA solution was added and the mixture was thoroughly mixed by vigorous shaking. After the shaking was completed, the mixture was filtered using a funnel and filter paper. In total, 1 milliliter of the filtrate was then transferred into a 1.5 mL centrifuge tube, and 0.25 mL of the TBA solution was added. The mixture was subjected to a metal bath at 80 °C for 90 min. After the reaction was completed, 250 μL of the resulting solution was transferred into a microplate, and this procedure was repeated 3 times. The absorbance was measured at 532 nm using a microplate reader. For the blank group, the mixture consisted of 0.5 mL of water, 0.5 mL of TCA, and 0.25 mL of TBA. A standard curve was constructed using solutions of 1,1,3,3-tetraethoxypropane (TEP) at concentrations of 0, 0.05, 0.1, 0.15, 0.2, 0.3, 0.4, 0.6, 0.8, and 1 μmol/L, and the content of malondialdehyde (MDA) was calculated based on this standard curve.

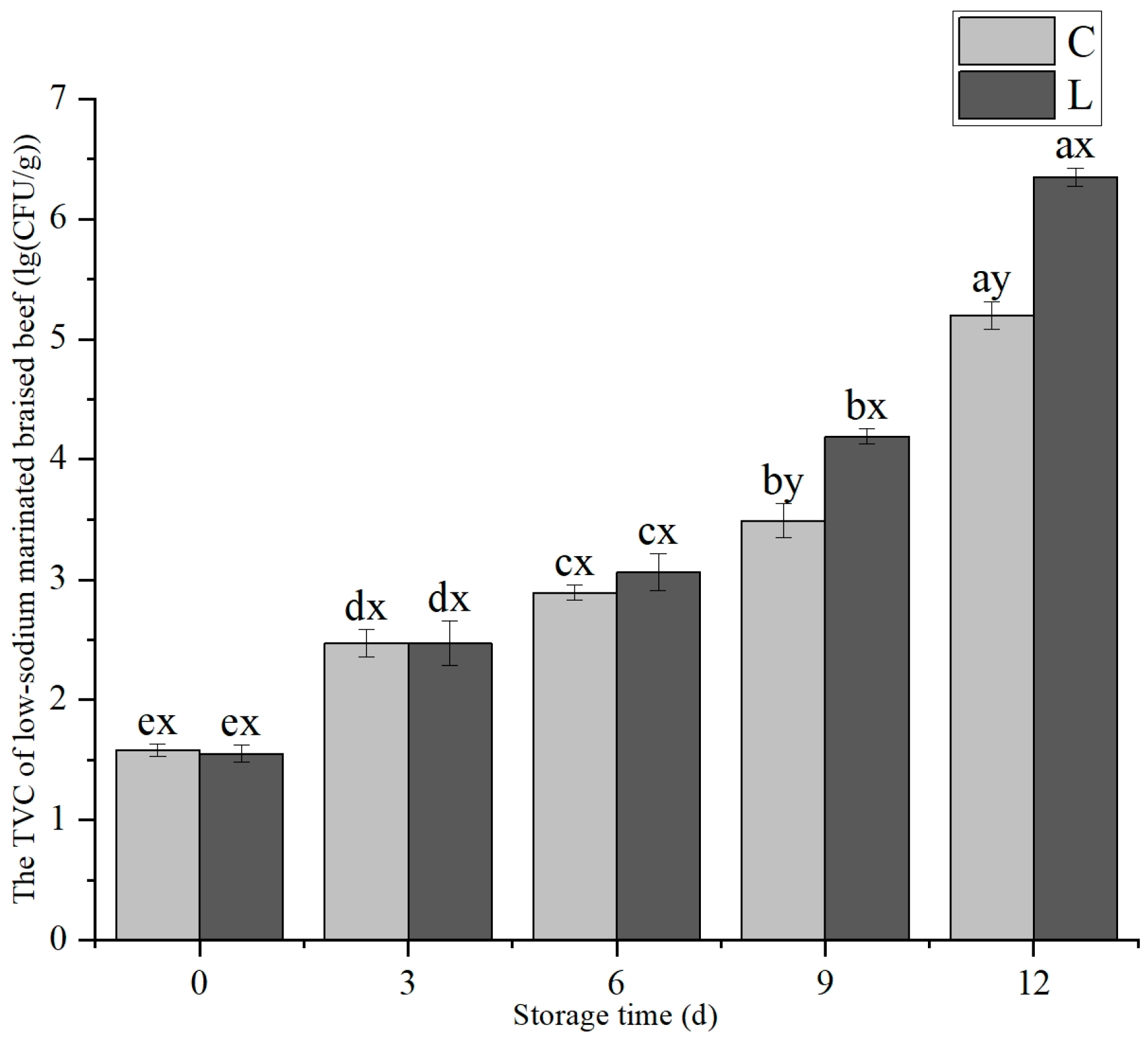

2.4.4. Total Viable Count (TVC)

After the 2 groups of low-sodium marinated braised beef were prepared, on days 0, 3, 6, 9, and 12, 10 g of beef samples were aseptically taken from the surface of the marinated braised beef and placed into stomacher bags. Subsequently, 90 mL of physiological saline containing 0.85% NaCl and 0.1% peptone was added to each bag. The bags were then inserted into a stomacher machine and subjected to mechanical stomaching for 2 min. After stomaching, 1 mL of the original bacterial suspension was successively added to test tubes containing 9 mL of sterile saline (0.85% NaCl, 0.1% peptone) for serial dilution, with vigorous mixing after each addition. One milliliter of the appropriately diluted bacterial suspension was then inoculated onto Petri dishes, to which an adequate amount of plate count agar medium was added and spread evenly using a rotating motion. After the medium was evenly distributed, the Petri dishes were closed and incubated. Three replicates were prepared for each dilution. After 48 h of incubation, the TVC was determined by counting the colonies.

2.5. Statistical Analysis of Data

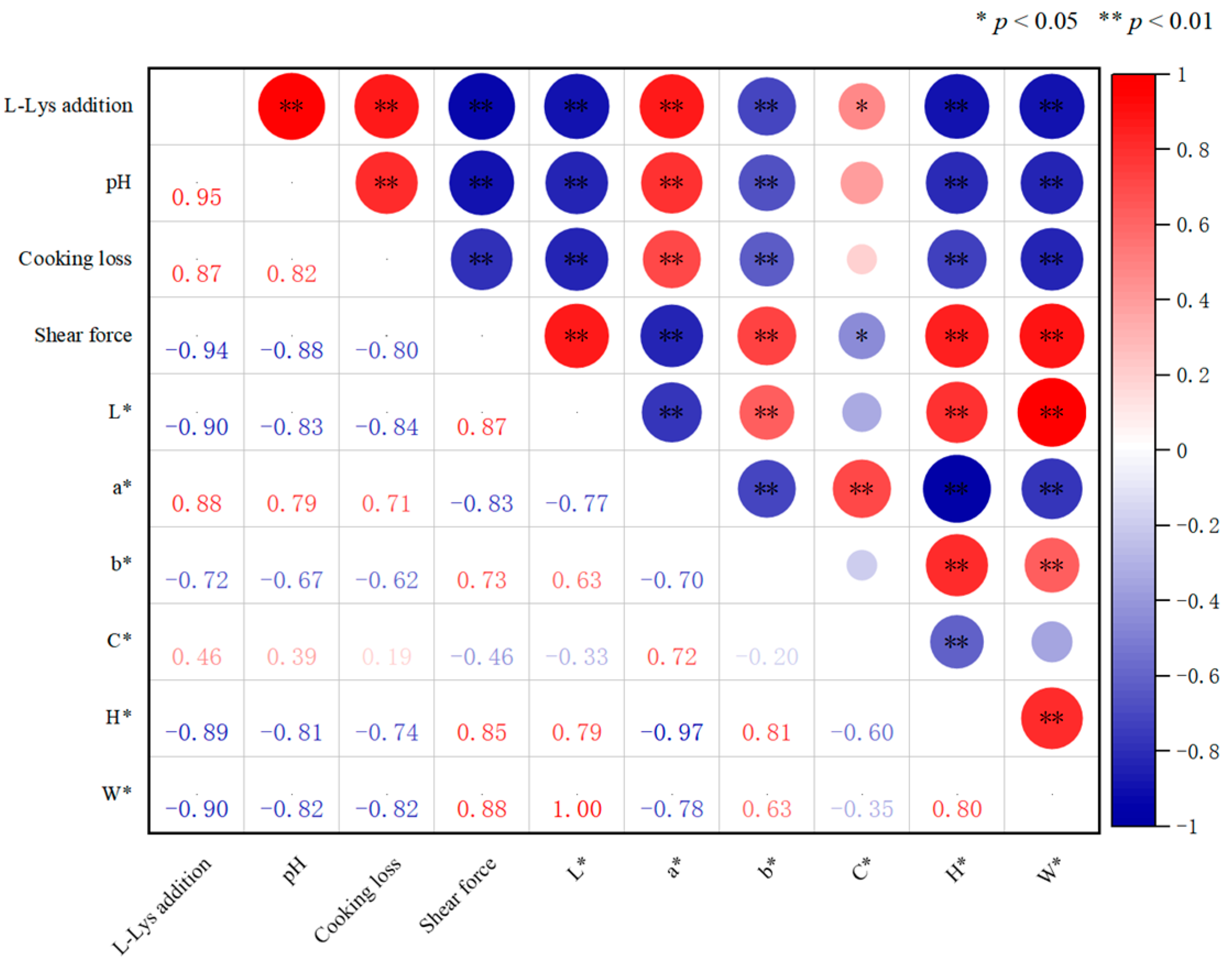

In this study, the data were subjected to significance analysis using SAS 9.0 software. In the single-factor experiment of L-Lys addition, only the level of L-Lys addition was varied. Six cattle were used for biological replication as the random factor, and a single-factor significance analysis was conducted. An appropriate level of L-Lys addition was selected based on the results, which was then used as the data group for the subsequent two-factor experiment. In the two-factor experiment, the addition of L-Lys and storage days were treated as fixed factors, while biological replication was used as the random factor. Analysis of variance (ANOVA) for each indicator was conducted using the mixed model in SAS, with a significance level set at (p < 0.05). Graphical analysis was then performed using Origin2024 software based on the significance results.

4. Discussion

The addition of exogenous L-lysine, an alkaline amino acid, caused an increase in pH, as the pH of 0.2–0.8% L-lysine was above 9. Moreover, the side-chain amino group (-NH

2) of L-lysine neutralized acidic metabolites, such as lactic acid in muscle tissues, thereby increasing the pH value of the intracellular environment by Zhang et al. [

3]. An increase in pH might enhance protein electrostatic repulsion and hydration; specifically, L-Lys could bind to myosin, enhancing its surface charge density and reducing the release of acidic substances caused by muscle tissue autolysis, thereby improving WHC and tenderness by Li et al. [

23]. The addition of exogenous L-Lys effectively reduced the cooking loss of plain boiled beef by Wachirasiri et al. [

24]. This might be attributed to the amino group (-NH

2) of L-Lys facilitating the cross-linking of collagen and myosin through the formation of ε-lysine bonds, thereby constructing a more stable gel network and reducing the amount of moisture released during the cooking process by Nils et al. [

25]. Furthermore, L-Lys could also enhance hydration by forming hydrogen bonds with water molecules through its hydrophilic groups, and it could alter the conformation of proteins to expose more hydrophilic sites [

14,

26]. Overall, the results presented here show that exogenous L-Lys addition can modify the structure of plain boiled beef via two separate mechanisms. One is through its direct, inherent actions, and the other is by changing the meat’s pH. These combined effects lead to an enhancement in the water holding capacity (WHC).

The addition of exogenous L-lysine also reduced the shear force of low-sodium plain boiled beef. Zhang et al. [

3] found that the effects of L-arginine and L-Lys on the tenderness of chicken breast indicated that such alkaline regulatory effects not only influenced protein electrostatic repulsion, but also promoted hydration. Beef tenderness is regulated by factors such as salt-soluble protein solubility and myofibrillar protein phosphorylation. L-Lys has been shown to alter the secondary structure of myosin and enhance protein solubility; this process promotes the degradation of troponin-T and the breakdown of actomyosin, while inhibiting myosin aggregation, ultimately improving meat tenderness by Zhang et al. [

3]. L-Lys achieved significant tenderization in low-sodium plain boiled beef by enhancing proteolytic enzyme activity, stabilizing cell membranes, and regulating osmotic pressure [

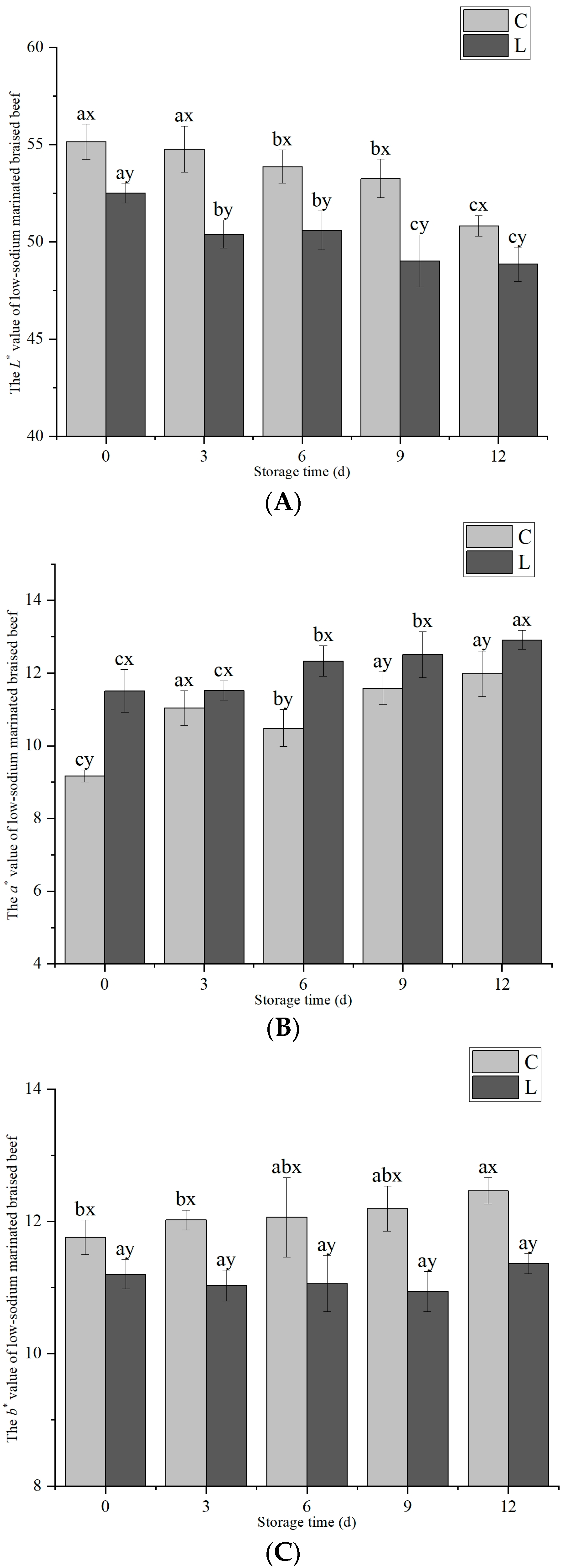

27]. The addition of L-Lys significantly reduced the shear force of low-sodium plain boiled beef, improving its texture and palatability. The supplementation of exogenous L-lysine improved the meat color and appearance of low-sodium plain boiled beef. This might be attributed to the ability of L-Lys to chelate ferrous ions, thereby altering the protein structure of plain boiled beef by Ning et al. [

28]. Concurrently, L-Lys promoted the solubility of salt-soluble proteins and enhanced WHC, thereby reducing the migration of moisture to the surface, which would otherwise lead to a decrease in the

L* value of meat products. Moreover, L-Lys could inhibit lipid oxidation, thereby reducing the

b* value [

29,

30]. Therefore, the addition of L-Lys could improve the color characteristics of low-sodium plain boiled beef, resulting in a more vivid red color and a more natural appearance.

Zhang et al. [

3] found that L-Lys enhanced the electrostatic repulsion of proteins by increasing pH and promoted the dissociation of actomyosin, facilitating the transformation of free water into bound water and less mobile water. Additionally, L-Lys might also bind to myofibrillar proteins through its amino groups and promote collagen cross-linking, forming a stable three-dimensional network structure, thereby reducing water loss during cooking and storage by Wang et al. [

31], significantly improved the WHC of low-sodium plain boiled beef (

p < 0.05) and reduced cooking loss. Therefore, it was speculated that L-Lys might maintain the good quality of low-sodium plain boiled beef under low-salt conditions by optimizing the WHC and gel network structure of proteins and improving the distribution and state of water. Additionally, L-Lys could enhance the electrostatic repulsion of proteins by increasing the pH value, promote the precipitation of salt-soluble proteins, activate calcium-dependent proteases, promote the degradation of muscle proteins, release small molecular peptide chains, as described by Zhou et al. [

23], form a stable gel network, and improve the microstructure of meat products, as described by Wang et al. [

31]. Moreover, the amino group in L-Lys could form ionic bonds or hydrogen bonds with the carboxyl group of collagen, myosin, or other functional proteins, thereby softening the meat texture. However, if the concentration of L-Lys was too high, it might have led to excessive degradation of proteins, loss of elasticity, and even produced an undesirable texture, affecting the quality of meat products [

21]. The addition of L-Lys causes an increase in the gap between muscle fibers, and this effect continuously enhanced with the increase in the addition amount. This result indicates that the addition of exogenous L-Lys might improve the tenderness and WHC of plain boiled beef by influencing its microstructure.

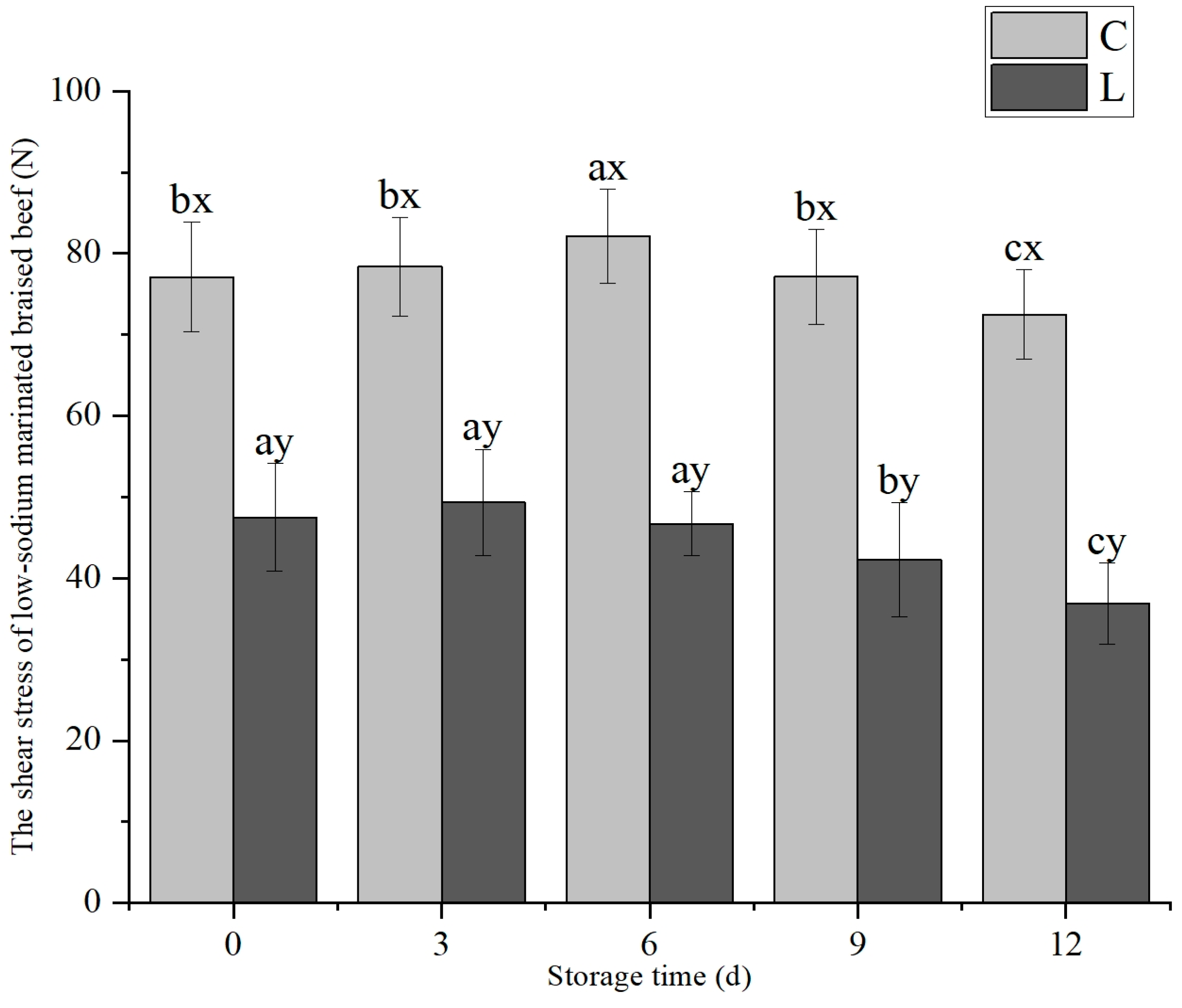

The addition of exogenous L-lysine effectively reduced the shear force of low-sodium marinated braised beef throughout the entire storage period because L-Lys has the function of delaying protein decomposition and water loss [

23,

32]. The addition of exogenous L-Lys reduced the shear force of low-sodium marinated braised beef and improved its tenderness. Moreover, L-Lys degrades troponin-T by maintaining the activity of calpain, thereby reducing the shear force and increasing the tenderness of the meat. Meanwhile, the addition of L-Lys could also increase the pH value of the meat, which also contributes to the improvement of the meat’s tenderness [

3]. Exogenous L-Lys delayed the color deterioration of low-sodium marinated braised beef during storage by improving the WHC and antioxidant capacity. The addition of L-Lys could scavenge DPPH radicals and hydroxyl radicals [

33], enhance the antioxidant property of low-sodium marinated braised beef, and retard the oxidation of myoglobin and lipids [

23]. As a result, the color of the low-sodium marinated braised beef in the L group was more stable during the shelf life, enabling the product to exhibit a more vivid and natural red characteristic.

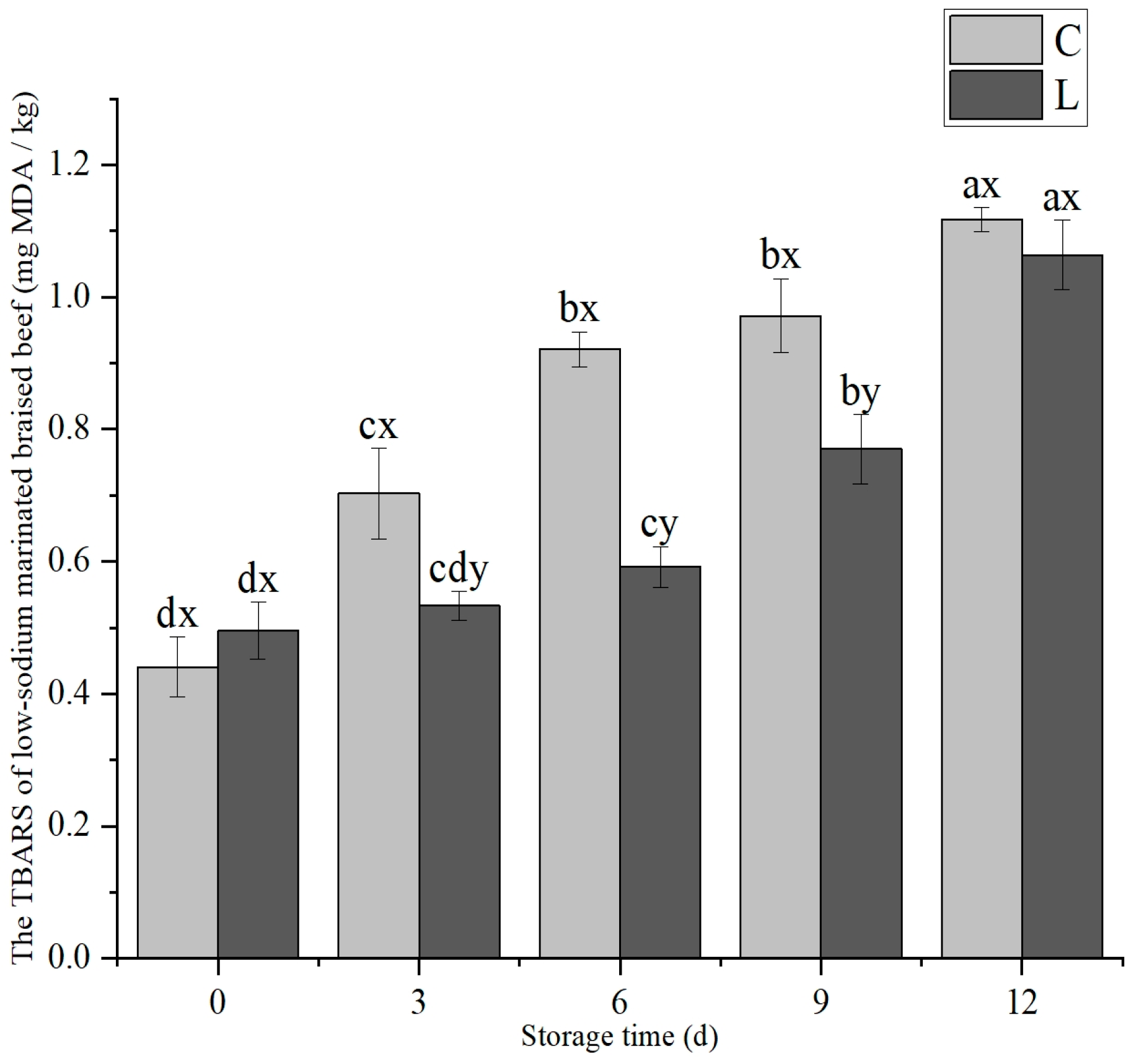

With the increase in storage time, the degree of fat oxidation in low-sodium marinated braised beef continuously increased. The addition of exogenous L-Lys was helpful to alleviate the rate of fat oxidation in meat products in the early stage of storage. However, when the storage time reached day 12, this effect became ineffective. Moreover, as the storage time extended, the total number of colonies in the beef gradually increased. This suggested that it might be because the increase in bacteria decomposed the fat, which not only caused the pH value to rise, but also promoted the fat oxidation of the beef, as reported by Krochmal-Marczak et al. [

34]. The study and analysis of the total number of colonies in low-sodium marinated braised beef showed that the effects of exogenous L-Lys on meat products are not entirely beneficial. The lower salt content in meat is more conducive to bacterial growth. During the shelf life, the pH values of meat and meat products might change because of microbial activity [

35]. This change has the potential to affect the product storage performance. The total viable count (TVC) exhibited exponential growth in the late storage period, and both groups showed spoilage at 12 days of storage; thus, the addition of exogenous L-Lys had no effect on the shelf life of low-sodium marinated braised beef. This experiment investigated the effects of exogenous L-lysine on improving the quality characteristics of low-sodium plain boiled beef and low-sodium marinated braised beef. However, it failed to conduct detailed studies on the action mechanism of L-lysine on beef, protein structural changes, and color variations during shelf life, which need to be verified by follow-up research.

5. Conclusions

This experiment confirmed the hypothesis proposed in the introduction that L-lysine exerted improving effects on the quality, appearance, and microstructure of low-sodium plain boiled beef. Moreover, it enhanced the edible quality of low-sodium marinated braised beef without compromising its shelf life. When the KCL substitution rate is 60%, the quality of low-sodium plain boiled beef and low-sodium marinated braised beef can be improved by adding 0.6% exogenous L-Lys. In low-sodium plain boiled beef, L-Lys effectively mitigated the deterioration of meat quality induced by low-sodium processing through increasing pH, reducing cooking loss, elevating a* value, and decreasing shear force (p < 0.05). Additionally, the optimal addition level of 0.6% was determined by combining sensory evaluation. The marinated braised beef was prepared from plain boiled beef treated with 0.6% L-Lys. During the 0–12 d storage period, the a* value of the marinated braised beef was progressively increased, resulting in a more vivid red color. Moreover, its tenderness and fat oxidation stability were improved. Although the TVC from 9 to 12 d was higher in the low-sodium group with L-Lys addition compared to the low-sodium group without L-Lys, both groups had spoiled by 12 d; thus, the L-Lys addition did not affect the product shelf life. The addition of L-Lys primarily optimizes beef quality by enhancing hydration, improving muscle structural properties, and exerting antioxidant synergistic effects. Thus, the addition of exogenous L-Lys provided critical theoretical support and technical guidance to produce low-sodium plain boiled beef and its further-processed derivatives. Future research could investigate the synergistic interactions between L-Lys and other amino acids to achieve a holistic improvement in product quality.