Flavouring Tunisian Extra Virgin Olive Oil (EVOO) with Cloves: Quality Indices, Stability, and Consumers’ Purchase Survey

Abstract

1. Introduction

2. Materials and Methods

2.1. Oil Flavouring

2.2. Oil Ageing Test

2.3. Determination of Oil Parameters

2.3.1. Density

2.3.2. Quality Indices

2.3.3. Pigments Quantification

2.3.4. Colour Determination

2.3.5. Total Phenols Determination

2.3.6. Fatty Acids Determination

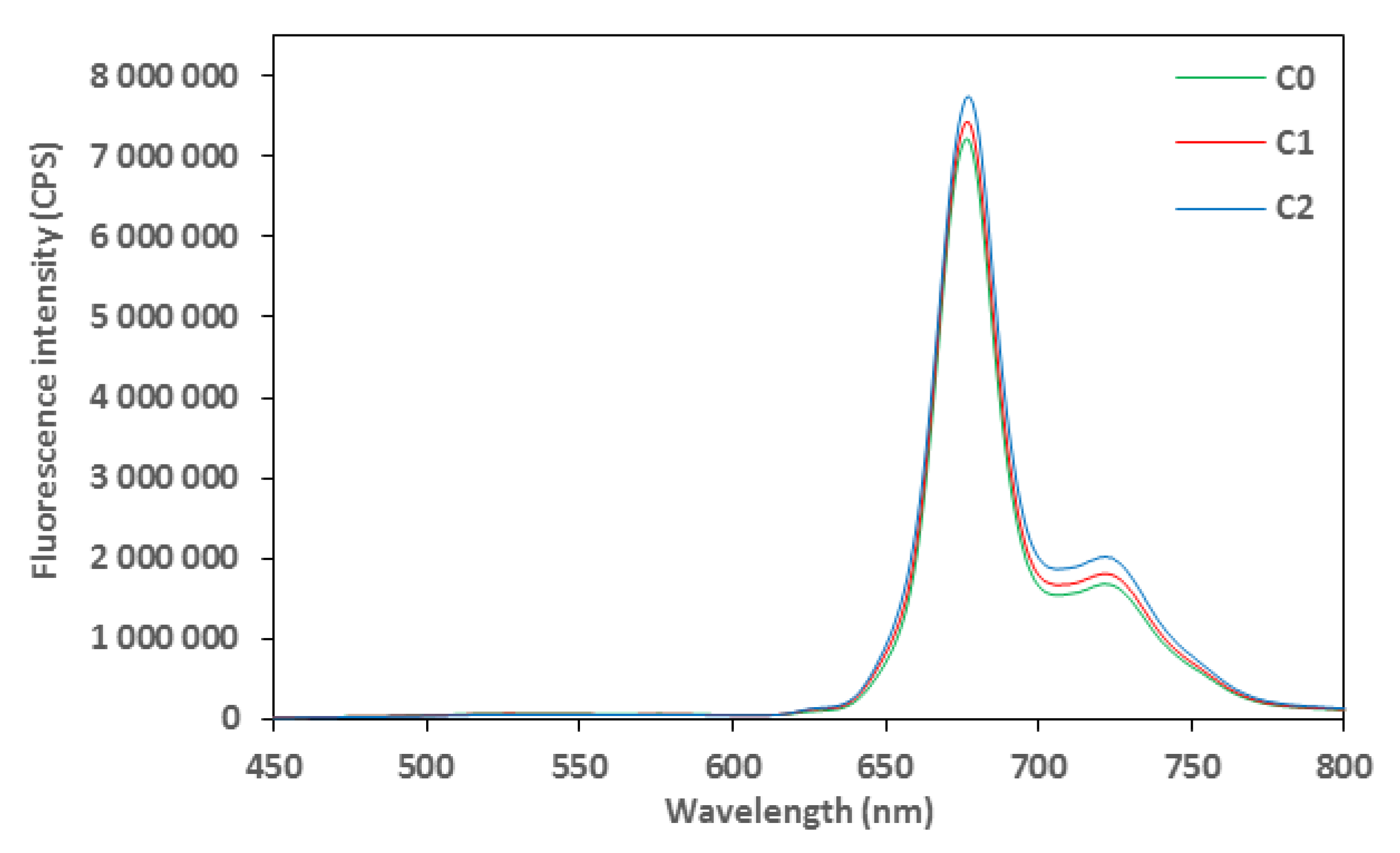

2.3.7. Fluorescence Spectroscopy

2.4. Consumer Survey

2.5. Statistical Analysis

3. Results and Discussion

3.1. Effect of Aromatization on the Physicochemical Characterisation of Flavoured EVOOs

3.2. Fatty Acid Analysis

3.3. Emission Fluorescence Spectra of Polyphenols and Chlorophylls for Aromatized Oils

3.4. Effect of Ageing on the Quality of Olive Oils

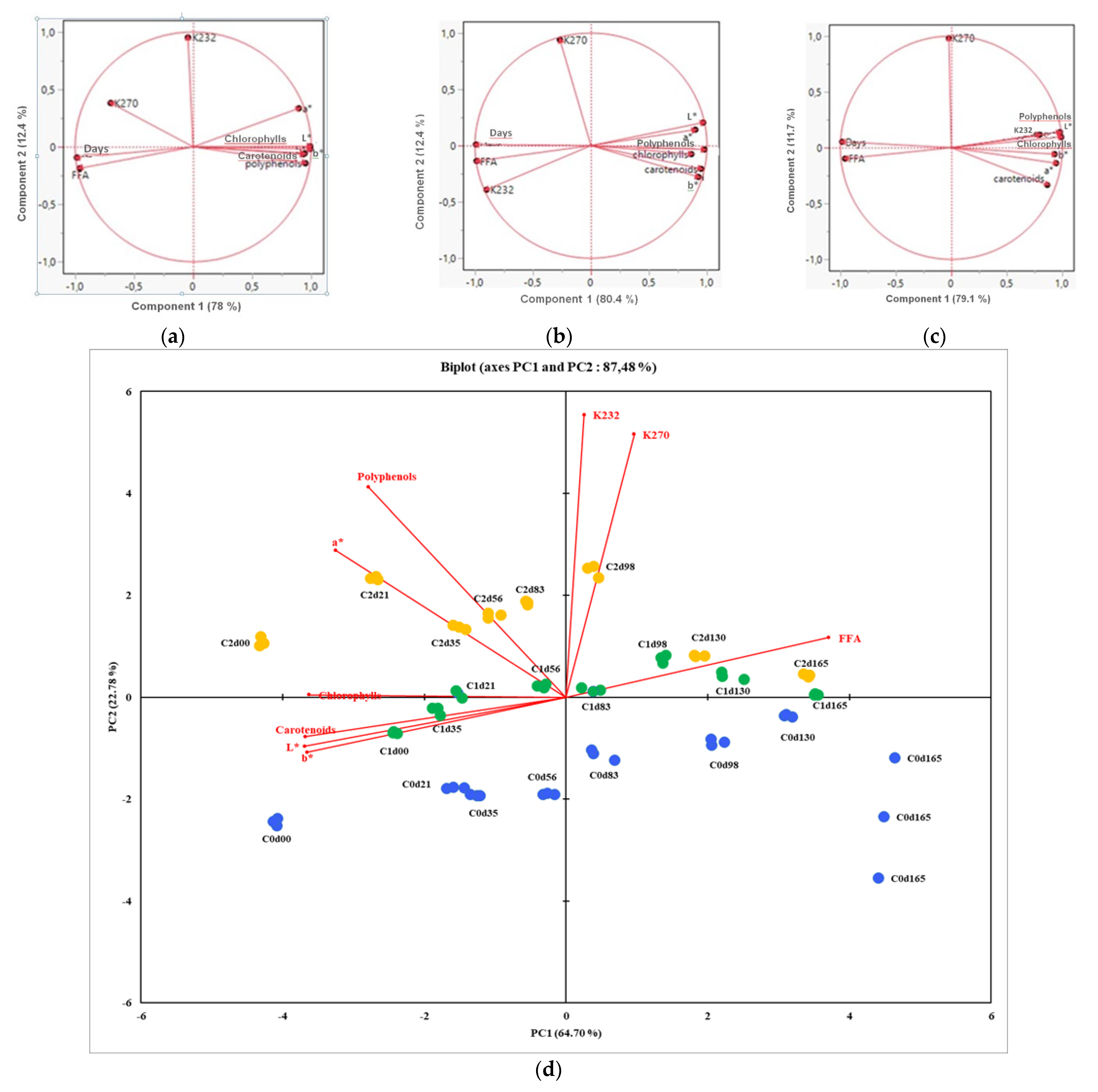

3.5. Principal Component Analysis

3.6. Consumer Survey

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dinu, M.; Pagliai, G.; Casini, A.; Sofi, F. Mediterranean diet and multiple health outcomes: An umbrella review of meta-analyses of observational studies and randomized trials. Eur. J. Clin. Nutr. 2018, 72, 30–43. [Google Scholar] [CrossRef] [PubMed]

- Frumuzachi, O.; Kieserling, H.; Rohn, S.; Mocan, A. The impact of oleuropein, hydroxytyrosol, and tyrosol on cardiometabolic risk factors: A meta-analysis of randomized controlled trials. Crit. Rev. Food Sci. Nutr. 2025, 1–21. [Google Scholar] [CrossRef]

- Memmola, R.; Petrillo, A.; Di Lorenzo, S.; Altuna, S.C.; Habeeb, B.S.; Soggiu, A.; Bonizzi, L.; Garrone, O.; Ghidini, M. Correlation between olive oil intake and gut microbiota in colorectal cancer prevention. Nutrients 2022, 14, 3749. [Google Scholar] [CrossRef] [PubMed]

- Fazlollahi, A.; Motlagh Asghari, K.; Aslan, C.; Noori, M.; Nejadghaderi, S.A.; Araj-Khodaei, M.; Sullman, M.J.M.; Karamzad, N.; Kolahi, A.A.; Safiri, S. The effects of olive oil consumption on cognitive performance: A systematic review. Front. Nutr. 2023, 10, 1218538. [Google Scholar] [CrossRef] [PubMed]

- Tzekaki, E.E.; Tsolaki, M.; Pantazaki, A.A.; Geromichalos, G.; Lazarou, E.; Kozori, M.; Sinakos, Z. The pleiotropic beneficial intervention of olive oil intake on the Alzheimer’s disease onset via fibrinolytic system. Exp. Gerontol. 2021, 150, 111344. [Google Scholar] [CrossRef]

- Kaddoumi, A.; Denney, T.S., Jr.; Deshpande, G.; Robinson, J.L.; Beyers, R.J.; Redden, D.T.; Praticò, D.; Kyriakides, T.C.; Lu, B.; Kirby, A.N.; et al. Extra-virgin olive oil enhances the blood–brain barrier function in mild cognitive impairment: A randomized controlled trial. Nutrients 2022, 14, 5102. [Google Scholar] [CrossRef]

- Rey-Giménez, R.; Sánchez-Gimeno, A.C. Effect of cultivar and environment on chemical composition and geographical traceability of Spanish olive oils. J. Am. Oil Chem. Soc. 2024, 101, 371–382. [Google Scholar] [CrossRef]

- Ellis, A.C.; Vieitez, I.; Gámbaro, A. Sensory and physicochemical characteristics of Uruguayan picual olive oil obtained from olives with different ripening indexes. Food Sci. Technol. 2024, 44, e00215. [Google Scholar] [CrossRef]

- Genovese, A.; Caporaso, N.; Sacchi, R. Flavour chemistry of virgin olive oil: An overview. Appl. Sci. 2021, 11, 1639. [Google Scholar] [CrossRef]

- Trade Standard Applying to Olive Oils and Olive Pomace Oils COI/T.15/NC No 3/Rev. 16 June 2021. Available online: https://www.internationaloliveoil.org/wp-content/uploads/2022/05/COI-T15-NC3-REV-16-2021-_ENG.pdf (accessed on 1 January 2025).

- Karacabey, E.; Özkan, G.; Dalgıç, L.; Sermet, S.O. Rosemary aromatization of extra virgin olive oil and process optimization including antioxidant potential and yield. TURJAF 2016, 4, 628–635. [Google Scholar] [CrossRef][Green Version]

- Barreca, S.; La Bella, S.; Maggio, A.; Licata, M.; Buscemi, S.; Leto, C.; Pace, A.; Tuttolomondo, T. Flavouring extra-virgin olive oil with aromatic and medicinal plants essential oils stabilizes oleic acid composition during photo-oxidative stress. Agriculture 2021, 11, 266. [Google Scholar] [CrossRef]

- Lamas, S.; Rodrigues, N.; Peres, A.M.; Pereira, J.A. Flavoured and fortified olive oils-pros and cons. Trends Food Sci. Technol. 2022, 124, 108–127. [Google Scholar] [CrossRef]

- Baiano, A.; Terracone, C.; Gambacorta, G.; La Notte, E. Changes in quality indices, phenolic content and antioxidant activity of flavoured olive oils during storage. J. Am. Oil Chem. Soc. 2010, 86, 1083. [Google Scholar] [CrossRef]

- Issaoui, M.; Flamini, G.; Souid, S.; Bendini, A.; Barbieri, S.; Gharbi, I.; Toschi, T.G.; Cioni, P.L.; Hammami, M. How the addition of spices and herbs to virgin olive oil to produce flavoured oils affects consumer acceptance. Nat. Prod. Commun. 2016, 11, 1934578X1601100619. [Google Scholar]

- Arslan, D.; Acar, A. Aromatization of olive oil with ginger and turmeric powder or extracts by the co-processing and maceration methods. Eur. J. Lipid Sci. Technol. 2024, 126, ex2300074. [Google Scholar] [CrossRef]

- Caponio, F.; Durante, V.; Varva, G.; Silletti, R.; Previtali, M.A.; Viggiani, I.; Squeo, G.; Summo, C.; Pasqualone, A.; Gomes, T.; et al. Effect of infusion of spices into the oil vs combined malaxation of olive paste and spices on quality of naturally flavoured virgin olive oils. Food Chem. 2016, 202, 221–228. [Google Scholar] [CrossRef]

- Habibi, M.; Abdallah, M.; Taamali, W.; Genovese, A.; Balivo, A.; Lorenzo, J.M.; Trabelsi, N. Enhancing olive oil quality through an advanced enrichment process utilizing ripe and fallen fruits. Eur. Food Res. Technol. 2024, 250, 2039–2051. [Google Scholar] [CrossRef]

- Hadidi, M.; Pouramin, S.; Adinepour, F.; Haghani, S.; Jafari, S.M. Chitosan nanoparticles loaded with clove essential oil: Characterization, antioxidant and antibacterial activities. Carbohydr. Polym. 2020, 236, 116075. [Google Scholar] [CrossRef]

- Silva, M.V.; De Lima, A.D.C.A.; Silva, M.G.; Caetano, V.F.; De Andrade, M.F.; Da Silva, R.G.C.; De Moraes Filho, L.E.P.T.; Lima Silva, I.D.D.; Vinhas, G.M. Clove essential oil and eugenol: A review of their significance and uses. Food Biosci. 2024, 62, 105112. [Google Scholar] [CrossRef]

- Bai, J.; Li, J.; Chen, Z.; Bai, X.; Yang, Z.; Wang, Z.; Yang, Y. Antibacterial activity and mechanism of clove essential oil against foodborne pathogens. LWT Food Sci. Technol. 2023, 173, 114249. [Google Scholar] [CrossRef]

- Kumar Pandey, V.; Shams, R.; Singh, R.; Dar, A.H.; Pandiselvam, R.; Rusu, A.V.; Trif, M. A comprehensive review on clove (Caryophyllus aromaticus L.) essential oil and its significance in the formulation of edible coatings for potential food applications. Front. Nutr. 2022, 9, 987674. [Google Scholar] [CrossRef] [PubMed]

- Indiarto, R.; Herwanto, J.A.; Filianty, F.; Lembong, E.; Subroto, E.; Muhammad, D.R.A. Total phenolic and flavonoid content, antioxidant activity and characteristics of a chocolate beverage incorporated with encapsulated clove bud extract. CyTA J. Food 2024, 22, 2329144. [Google Scholar] [CrossRef]

- Ricardo-Rodrigues, S.; Rouxinol, M.I.; Agulheiro-Santos, A.C.; Potes, M.E.; Laranjo, M.; Elias, M. The Antioxidant and Antibacterial Potential of Thyme and Clove Essential Oils for Meat Preservation—An Overview. Appl. Biosci. 2024, 3, 87–101. [Google Scholar] [CrossRef]

- Valente, M.T.; Orzali, L.; Manetti, G.; Magnanimi, F.; Matere, A.; Bergamaschi, V.; Grottoli, A.; Bechini, S.; Riccioni, L.; Aragona, M. Rapid molecular assay for the evaluation of clove essential oil antifungal activity against wheat common bunt. Front. Plant Sci. 2023, 14, 1130793. [Google Scholar] [CrossRef]

- Ben Akacha, B.; Švarc-Gajić, J.; Elhadef, K.; Ben Saad, R.; Brini, F.; Mnif, W.; Smaoui, S.; Ben Hsouna, A. The Essential Oil of Tunisian Halophyte Lobularia maritima: A Natural Food Preservative Agent of Ground Beef Meat. Life 2022, 12, 1571. [Google Scholar] [CrossRef]

- Idowu, S.; Adekoya, A.E.; Igiehon, O.O.; Idowu, A.T. Clove (Syzygium aromaticum) spices: A review on their bioactivities, current use, and potential application in dairy products. J. Food Meas. Charact. 2021, 15, 3419–3435. [Google Scholar] [CrossRef]

- Cortés-Rojas, D.F.; de Souza, C.R.; Oliveira, W.P. Clove (Syzygium aromaticum): A precious spice. Asian Pac. J. Trop. Biomed. 2014, 4, 90–96. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Trabelsi, N.; Marotta, S.M.; Giarratana, F.; Taamali, A.; Zarrouk, M.; Ziino, G.; Giuffrida, A. Use of Tunisian flavoured olive oil as anisakicidal agent in industrial anchovy marinating process. J. Sci. Food Agric. 2018, 98, 3446–3451. [Google Scholar] [CrossRef]

- Latino, M.E.; De Devitiis, B.; Corallo, A.; Viscecchia, R.; Bimbo, F. Consumer Acceptance and Preference for Olive Oil Attributes—A Review. Foods 2022, 11, 3805. [Google Scholar] [CrossRef]

- Wolff, J.P. Manuel D’analyse des Corps Gras; Tokyo University of Fisheries: Tokyo, Japan, 1968. [Google Scholar]

- International Olive Council (IOC). Determination Of free Fatty Acids, Cold Method, Code COI/T.20/Doc. No 34/Rev. 1 2017. Available online: https://www.internationaloliveoil.org/ (accessed on 1 January 2025).

- Determination of Peroxide Value. Code COI/T.20/Doc. No 35/Rev.1 2017 International Olive Council (IOC). Available online: https://www.internationaloliveoil.org/ (accessed on 1 January 2025).

- International Olive Council (IOC). Spectrophotometric Investigation in the Ultraviolet. Code COI/T.20/Doc. No 19/Rev. 5 2019. Available online: https://www.internationaloliveoil.org/ (accessed on 1 January 2025).

- Martakos, I.; Kostakis, M.; Dasenaki, M.; Pentogennis, M.; Thomaidis, N. Simultaneous determination of pigments, tocopherols, and squalene in Greek olive oils: A study of the influence of cultivation and oil-production parameters. Foods 2020, 9, 31–48. [Google Scholar] [CrossRef]

- Ammar, I.; BenAmira, A.; Khemakem, I.; Attia, H.; Ennouri, M. Effect of Opuntia ficus-indica flowers maceration on quality and on heat stability of olive oil. J. Food Sci. Technol. 2017, 54, 1502–1510. [Google Scholar] [CrossRef] [PubMed]

- Ameur, R.B.; Hadjkacem, B.; Ayadi, M.; Ikram, B.A.; Feki, A.; Gargouri, J.; Gargouri, A.; Allouche, N. Phytochemical profile of Tunisian Pistacia lentiscus fruits oil: Antioxidant, antiplatelet, and cytotoxic activities assessment. Eur. J. Lipid Sci. Technol. 2024, 126, 2300274. [Google Scholar] [CrossRef]

- Aljobair, M.O. Physicochemical, nutritional, and sensory quality and storage stability of cookies: Effect of clove powder. Int. J. Food Prop. 2022, 25, 1009–1020. [Google Scholar] [CrossRef]

- Díaz-Montaña, E.J.; Aparicio-Ruiz, R.; Morales, M.T. Effect of flavorization on virgin olive oil oxidation and volatile profile. Antioxidants 2023, 12, 242. [Google Scholar] [CrossRef]

- Revelou, P.K.; Konteles, S.J.; Batrinou, A.; Xagoraris, M.; Tarantilis, P.A.; Strati, I.F. Origanum majorana L. as Flavoring Agent: Impact on Quality Indices, Stability, and Volatile and Phenolic Profiles of Extra Virgin Olive Oil (EVOO). Foods 2024, 13, 3164. [Google Scholar] [CrossRef]

- Gambacorta, G.; Faccia, M.; Pati, S.; Lamacchia, C.; Baiano, A.; La Notte, E. Changes in the chemical and sensorial profile of extra virgin olive oils flavoured with herbs and spices during storage. J. Food Lipids 2006, 14, 202–215. [Google Scholar] [CrossRef]

- Sacchi, R.; Della, M.D.; Paduano, A.; Caporaso, N.; Genovese, A. Characterisation of lemon-flavoured olive oils. LWT Food Sci. Technol. 2017, 79, 326–332. [Google Scholar] [CrossRef]

- Ben Amar, F.; Guellaoui, I.; Ayadi, M.; Elloumi, O.; Triki, M.A.; Boubaker, M. ‘Zeitoun Ennour’: A new olive (Olea europaea L.) cultivar in Tunisia with high oil quality. Genet. Resour. 2021, 2, 1–6. [Google Scholar] [CrossRef]

- Pandey, V.K.; Srivastava, S.; Dash, K.K.; Singh, R.; Dar, A.H.; Singh, T.; Farooqui, A.; Shaikh, A.M.; Kovacs, B. Bioactive properties of clove (Syzygium aromaticum) essential oil nanoemulsion: A comprehensive review. Heliyon 2024, 10, e22437. [Google Scholar] [CrossRef]

- Lazzarini, C.; Tura, M.; Mandrioli, M.; Setti, M.; Mokhtari, N.; Ait Elkassia, A.; Barbieri, S.; Valli, E.; Bendini, A.; Gallina Toschi, T. Characterization of New Flavoured Oils Obtained Through the Co-Milling of Olives and Vegetable Food Products. Foods 2025, 14, 687. [Google Scholar] [CrossRef]

- Anvari, S.; Aguado, R.; Jurado, F.; Fendri, M.; Zaier, H.; Larbi, A.; Vera, D. Analysis of agricultural waste/byproduct biomass potential for bioenergy: The case of Tunisia. Energy Sustain. Dev. 2024, 78, 101367. [Google Scholar] [CrossRef]

- Chahdoura, H.; Mzoughi, Z.; Ziani, B.E.; Chakroun, Y.; Boujbiha, M.A.; Bok, S.E.; M’hadheb, M.B.; Majdoub, H.; Mnif, W.; Flamini, G.; et al. Effect of Flavouring with Rosemary, Lemon and Orange on the Quality, Composition and Biological Properties of Olive Oil: Comparative Study of Extraction Processes. Foods 2023, 12, 1301. [Google Scholar] [CrossRef]

| Parameters | CO | C1 | C2 | AOMC1 | AOMC2 | |

|---|---|---|---|---|---|---|

| Density | 0.908 ± 0.005 a | 0.915 ± 0.002 aA | 0.917 ± 0.002 aA | 0.914 ± 0.005 aA | 0.916 ± 0.002 aA | |

| Colour | L | 21.810 ± 0.043 a | 18.370 ± 0.036 bA | 20.223 ± 0.020 cC | 10.826 ± 0.005 dB | 10.245 ± 0.034 eD |

| a* | −0.843 ± 0.015 a | −0.843 ± 0.661 aA | −0.378 ± 0.021 bC | 0.226 ± 0.010 cB | 0.540 ± 0.122 dD | |

| b* | 13.503 ± 0.047 a | 11.393 ± 0.072 bA | 12.756 ± 0.083 cC | 2.483 ± 0.156 dB | 2.606 ± 0.176 dD | |

| FFA (%) | 0.175 ± 0.007 a | 0.185 ± 0.005 aA | 0.225 ± 0.001 bC | 0.380 ± 0.012 cB | 0.410 ± 0.014 dD | |

| PV (meq/kg) | 11.208 ± 0.325 a | 11.542 ± 0.477 aA | 12.458 ± 0.409 aC | 15.645 ± 0.161 bB | 17.865 ± 0.163 cD | |

| K232 | 1.651 ± 0.001 a | 1.928 ± 0.008 bA | 2.245 ± 0.001 cC | 2.135 ± 0.010 dB | 2.889 ± 0.014 eD | |

| K270 | 0.136 ± 0.006 a | 0.210 ± 0.003 bA | 0.249 ± 0.014 cC | 0.256 ± 0.002 cB | 0.262 ± 0.007 cC | |

| Chlorophylls (mg/kg) | 6.056 ± 0.010 a | 4.124 ± 0.040 bA | 4.371 ± 0.013 cC | 2.712 ± 0.029 dB | 1.984 ± 0.019 eD | |

| Carotenoïds (mg/kg) | 1.786 ± 0.028 a | 1.874 ± 0.010 aA | 1.960 ± 0.002 bC | 1.284 ± 0.040 cB | 1.048 ± 0.029 dD | |

| Total phenols (mg GAE/kg) | 385.703 ± 0.020 a | 517.880 ± 0.030 bA | 668.720 ± 0.040 cC | 451.620 ± 0.010 dB | 587.640 ± 0.010 eD | |

| Fatty Acids | C0 | C1 | C2 |

|---|---|---|---|

| Palmitic acid (C16:0) | 18.048 ± 0.314 a | 17.871 ± 0.055 a | 17.809 ± 0.037 a |

| Palmitoleic acid (C16:1) | 2.291 ± 0.040 a | 2.270 ± 0.064 a | 2.237 ± 0.019 a |

| Heptadecanoic acid (C17:0) | 0.0349 ± 0.001 a | 0.035 ± 0.001 a | 0.035 ± 0.007 a |

| Heptadecenoic acid (C17:1) | 0.274 ± 0.353 a | 0.066 ± 0.001 a | 0.066 ± 0.000 a |

| Stearic acid (C18:0) | 2.217 ± 0.028 a | 2.211 ± 0.045 a | 2.230 ± 0.005 a |

| Oleic acid (C18:1) | 60.434 ± 0.278 a | 60.512 ± 0.201 a | 60.576 ± 0.045 a |

| Linoleic acid (C18:2) | 15.821 ± 0.015 a | 15.939 ± 0.054 b | 15.946 ± 0.020 b |

| Linolenic acid (C18:3) | 0.564 ± 0.006 a | 0.553 ± 0.015 ac | 0.546 ± 0.002 bc |

| Arachidic acid (C20:0) | 0.360 ± 0.022 a | 0.377 ± 0.006 ac | 0.390 ± 0.006 bc |

| Eicosenoic acid (C20:1) | 0.147 ± 0.015 a | 0.151 ± 0.010 ab | 0.154 ± 0.010 ac |

| Saturated fatty acid (SFA) | 20.670 ± 0.266 a | 20.505 ± 0.082 a | 20.473 ± 0.046 a |

| Monounsaturated fatty acid | 63.148 ± 0.507 a | 63.002 ± 0.125 a | 63.034 ± 0.029 a |

| Polyunsaturated fatty acid | 16.386 ± 0.019 a | 16.493 ± 0.069 ab | 16.493 ± 0.022 b |

| Storage (days) | Olive Oil Samples | L | a* | b* |

|---|---|---|---|---|

| 0 | C0 | 21.81 ± 0.043 cA | −0.843 ± 0.015 bA | 13.503 ± 0.047 cA |

| C1 | 18.37 ± 0.036 aA | −0.842 ± 0.018 bA | 11.393 ± 0.072 aA | |

| C2 | 20.223 ± 0.02 bA | −0.378 ± 0.021 aA | 12.756 ± 0.083 bA | |

| 21 | C0 | 20.247 ± 0.05 cB | −0.833 ± 0.015 cA | 12.71 ± 0.026 bB |

| C1 | 18.310 ± 0.017 aA | −0.743 ± 0.05 bB | 10.176 ± 0.1 aB | |

| C2 | 19.793 ± 0.032 bB | −0.443 ± 0.02 aB | 12.703 ± 0.05 bA | |

| 35 | C0 | 18.417 ± 0.308 bC | −0.89 ± 0.026 cA | 11.66 ± 0.049 bC |

| C1 | 18.330 ± 0.01 bA | −0.740 ± 0.04 bB | 10.436 ± 0.04 aC | |

| C2 | 17.146 ± 0.09 aC | −0.483 ± 0.037 aB | 10.243 ± 0.096 aB | |

| 56 | C0 | 17.42 ± 0.073 aD | −0.96 ± 0.01 aB | 10.81 ± 0.04 bD |

| C1 | 17.646 ± 0.065 aB | −0.746 ± 0.030 bB | 9.726 ± 0.032 aD | |

| C2 | 17.873 ± 0.047 aD | −0.66 ± 0.036 cC | 10.256 ± 0.023 bB | |

| 83 | C0 | 16.556 ± 0.037 aE | −0.996 ± 0.077 cB | 9.870 ± 0.098 aE |

| C1 | 16.113 ± 0.156 aC | −0.849 ± 0.031 bA | 9.700 ± 0.01 aD | |

| C2 | 17.723 ± 0.085 bE | −0.76 ± 0.026 aD | 9.870 ± 0.05 aC | |

| 98 | C0 | 14.286 ± 0.031 aF | −1.253 ± 0.049 aC | 8.543 ± 0.04 aF |

| C1 | 15.653 ± 0.23 bD | −1.063 ± 0.015 bC | 9.2130.025 bE | |

| C2 | 15.986 ± 0.058 bF | −0.85 ± 0.045 cE | 9.193 ± 0.051 bC | |

| 130 | C0 | 12.903 ± 0.04 aG | −1.153 ± 0.02 aD | 7.826 ± 0.056 aG |

| C1 | 12.276 ± 0.066 aE | −1.09 ± 0.065 aC | 8.903 ± 0.055 bF | |

| C2 | 12.166 ± 0.065 aG | −0.93 ± 0.016 bF | 8.866 ± 0.071 bD | |

| 165 | C0 | 11.800 ± 0.05 aH | −1.568 ± 0.015 cE | 7.238 ± 0.034 aH |

| C1 | 11.230 ± 0.012 aF | −1.219 ± 0.011 bD | 8.842 ± 0.021 bF | |

| C2 | 11.010 ± 0.013 aH | −1.02 ± 0.026 aF | 8.012 ± 0.011 aE |

| Variables | Levels | N | % |

|---|---|---|---|

| Age | <25 | 102 | 45.5 |

| 25–40 | 76 | 33.9 | |

| 40–60 | 44 | 19.6 | |

| >60 | 2 | 1 | |

| Gender | F | 122 | 54.5 |

| M | 102 | 45.5 | |

| Other | 0 | 0 | |

| Educational level | Bachelor’s degree | 38 | 17 |

| High school diploma | 116 | 51.8 | |

| Lower secondary school certificate | 18 | 8 | |

| Master’s degree | 43 | 19.2 | |

| PhD or other | 9 | 4 |

| Question | Levels | % |

|---|---|---|

| How do you buy your olive oil? | Directly from the producer | 86.5 |

| From the supermarket | 4 | |

| From the grocer’s | 3.6 | |

| From the market | 5.9 | |

| On average, how often do you use olive oil in your personal diet? | 3 times/week | 70.2 |

| 1 to 2 times/week | 15.4 | |

| 1 time/15 days | 8.7 | |

| Less | 5.7 | |

| On average, what is your household’s monthly consumption of olive oil? | <½ L/month | 7.8 |

| 1 L/month | 27.2 | |

| 2 L/month | 23.3 | |

| >2 L/month | 41.7 | |

| Use of olive oil | Salad dressing | 51.5 |

| Cooking | 45.6 | |

| Frying | 2.9 | |

| Do you know about flavoured oils for food uses? | Yes | 30 |

| No | 70 | |

| What would be your reservations about buying ready-to-use flavoured oils in supermarkets? | Lack of advice | 22.3 |

| No specialised point of sale | 15.5 | |

| Doubts about the quality of the product | 46.6 | |

| The price is higher than that of an unflavoured oil | 15.5 | |

| Do you know the health benefits of cloves? | Yes | 52.7 |

| No | 47.3 | |

| If you find a clove-flavoured olive oil, would you be willing to buy it? | Yes | 83.9 |

| No | 14.3 | |

| Probably | 1.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ennouri, M.; Smaoui, S.; Varzakas, T. Flavouring Tunisian Extra Virgin Olive Oil (EVOO) with Cloves: Quality Indices, Stability, and Consumers’ Purchase Survey. Foods 2025, 14, 2114. https://doi.org/10.3390/foods14122114

Ennouri M, Smaoui S, Varzakas T. Flavouring Tunisian Extra Virgin Olive Oil (EVOO) with Cloves: Quality Indices, Stability, and Consumers’ Purchase Survey. Foods. 2025; 14(12):2114. https://doi.org/10.3390/foods14122114

Chicago/Turabian StyleEnnouri, Monia, Slim Smaoui, and Theodoros Varzakas. 2025. "Flavouring Tunisian Extra Virgin Olive Oil (EVOO) with Cloves: Quality Indices, Stability, and Consumers’ Purchase Survey" Foods 14, no. 12: 2114. https://doi.org/10.3390/foods14122114

APA StyleEnnouri, M., Smaoui, S., & Varzakas, T. (2025). Flavouring Tunisian Extra Virgin Olive Oil (EVOO) with Cloves: Quality Indices, Stability, and Consumers’ Purchase Survey. Foods, 14(12), 2114. https://doi.org/10.3390/foods14122114