Pre-Saturation of Bran as a Strategy for Developing Oat Bran-Enriched Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pre-Hydration Procedure of Oat Bran and Water Activity Measurement

2.3. Measurements of Flour and Dough Properties

2.3.1. Farinograph Tests

2.3.2. Dough Extensibility

2.4. Bread-Making Procedure

2.5. Bread Quality Evaluation

2.5.1. Specific Loaf Volume

2.5.2. Texture Profile Analysis

2.5.3. Microstructure Analysis

2.5.4. Porosity

2.5.5. Image Analysis for Crumb Grain Characteristics

2.6. Statistical Analysis

3. Results and Discussion

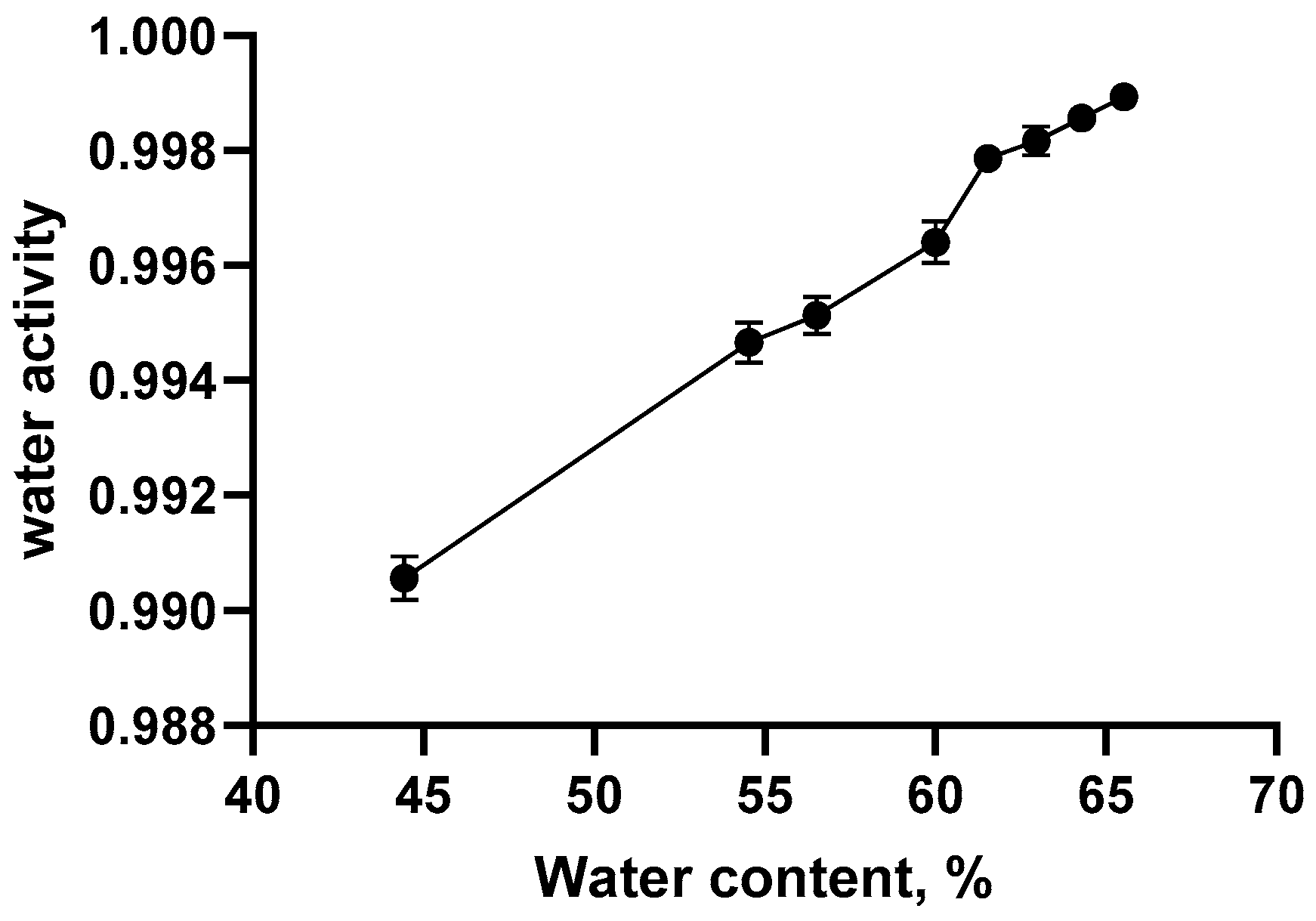

3.1. The Relationship Between Aw and Water Content in Pre-Hydrated Oat Bran

3.2. Impact of Oat Bran Pre-Hydration Levels on Flour and Dough Characteristics

3.2.1. Farinograph Analysis

3.2.2. Uniaxial Extensional Properties of Dough

3.3. Impact of Oat Bran Pre-Hydration Levels on Specific Loaf Volume

3.4. Impact of Oat Bran Pre-Hydration Levels on Textural Properties of Bread Crumb

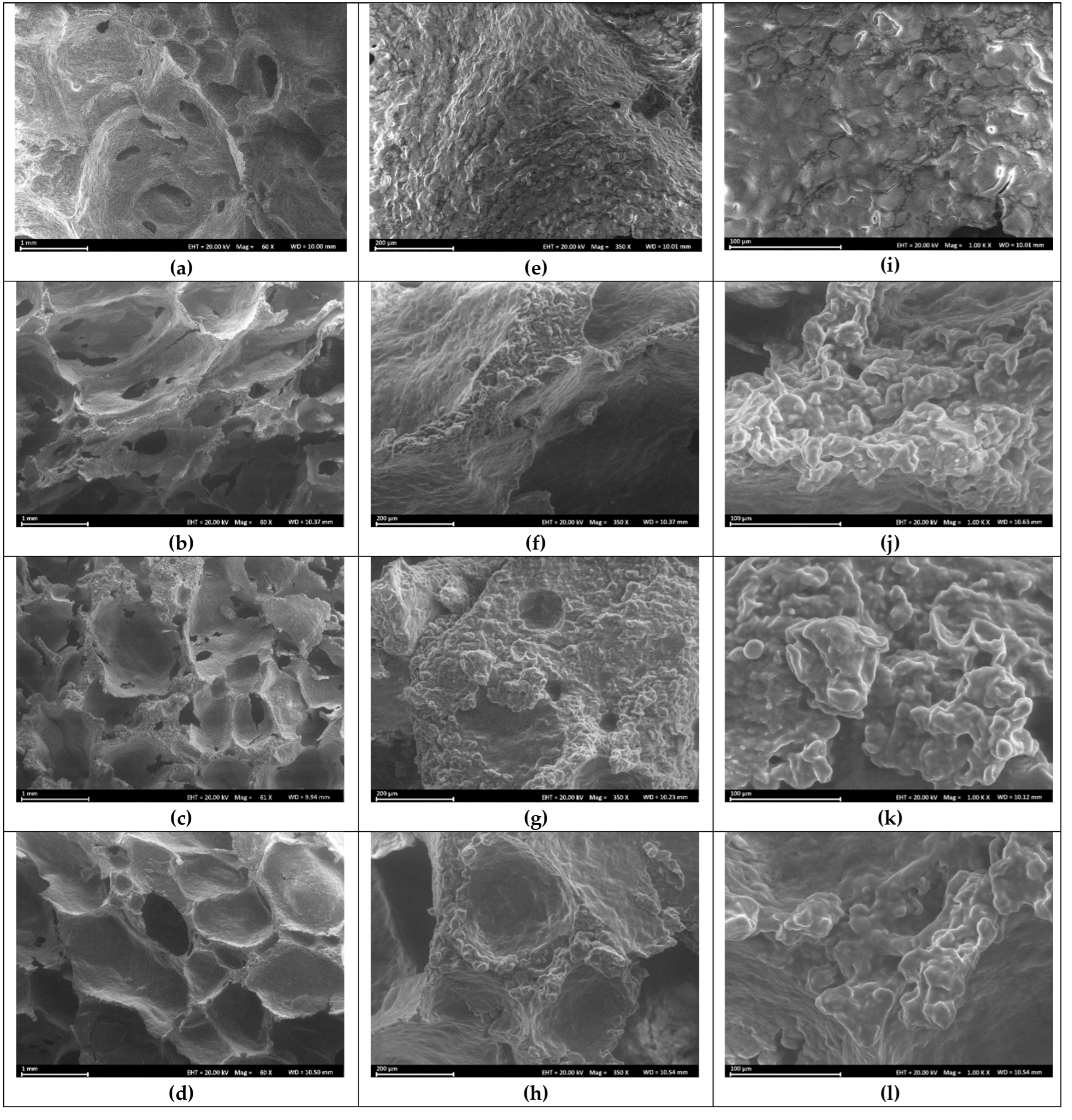

3.5. Impact of Oat Bran Pre-Hydration Levels on Bread Crumb Microstructure

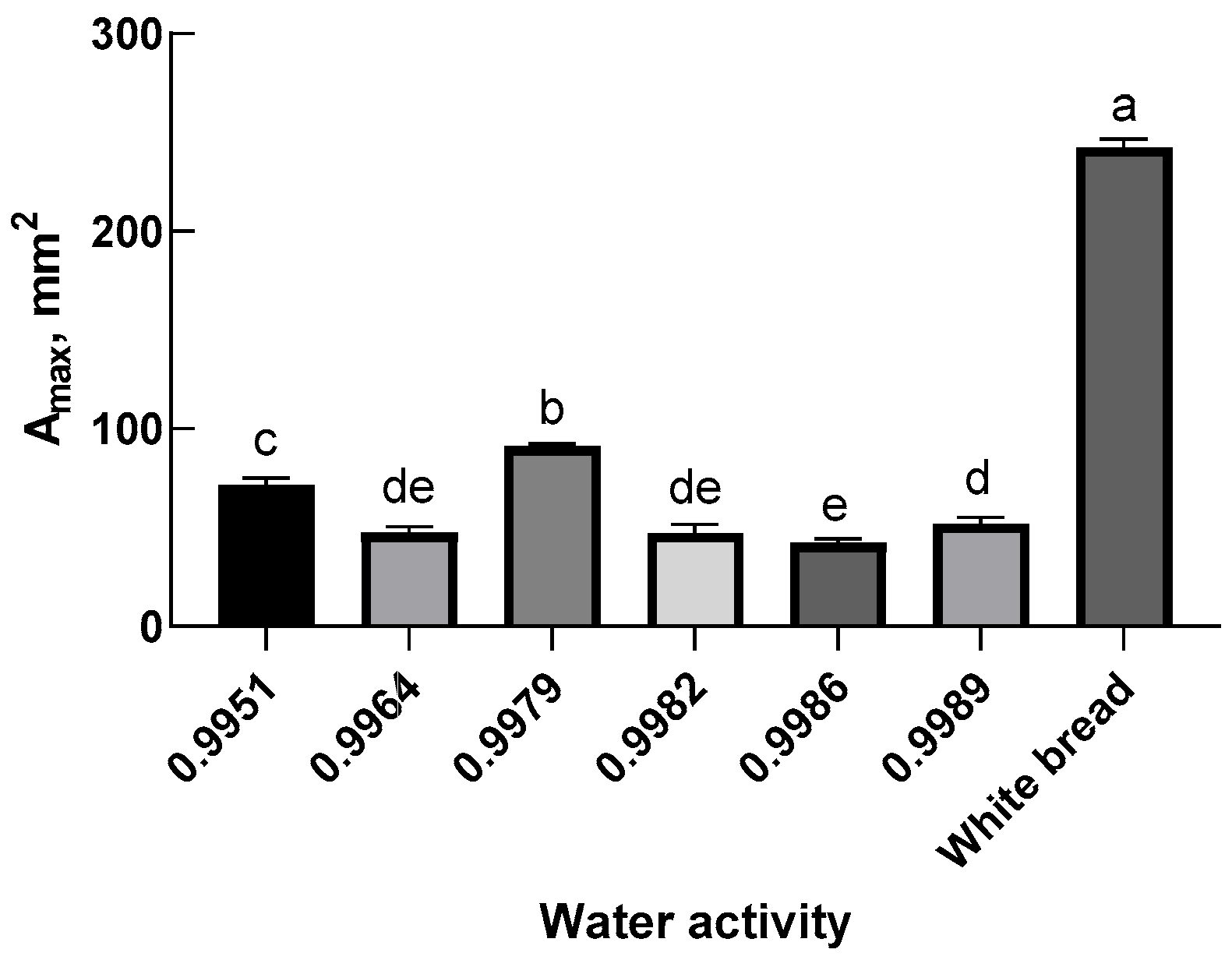

3.6. Grain Structure Characteristics of Bread Crumb and the Impact of Bran Pre-Hydration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leszczyńska, D.; Wirkijowska, A.; Gasiński, A.; Średnicka-Tober, D.; Trafiałek, J.; Kazimierczak, R. Oat and oat processed products—Technology, composition, nutritional value, and health. Appl. Sci. 2023, 13, 11267. [Google Scholar] [CrossRef]

- Tang, Y.; Li, S.; Yan, J.; Peng, Y.; Weng, W.; Yao, X.; Gao, A.; Cheng, J.; Ruan, J.; Xu, B. Bioactive components and health functions of oat. Food Rev. Int. 2023, 39, 4545–4564. [Google Scholar] [CrossRef]

- Mao, H.; Xu, M.; Ji, J.; Zhou, M.; Li, H.; Wen, Y.; Wang, J.; Sun, B. The utilization of oat for the production of wholegrain foods: Processing technology and products. Food Front. 2022, 3, 28–45. [Google Scholar] [CrossRef]

- Sang, S.; Chu, Y. Whole grain oats, more than just a fiber: Role of unique phytochemicals. Mol. Nutr. Food Res. 2017, 61, 1600715. [Google Scholar] [CrossRef]

- Kim, I.-S.; Hwang, C.-W.; Yang, W.-S.; Kim, C.-H. Multiple antioxidative and bioactive molecules of oats (Avena sativa L.) in human health. Antioxidants 2021, 10, 1454. [Google Scholar] [CrossRef]

- Liu, A.; Li, H.; Xu, W.; Zhu, L.; Ye, S.; Li, T.; Li, J.; Chang, S.; Xie, C. Modification of black wheat bran by superfine grinding and Neurospora crassa fermentation: Physicochemical properties, mixed flour quality, steamed bread quality, and flavor. LWT 2024, 213, 117049. [Google Scholar] [CrossRef]

- Saka, M.; Özkaya, B.; Saka, İ. The effect of bread-making methods on functional and quality characteristics of oat bran blended bread. Int. J. Gastron. Food Sci. 2021, 26, 100439. [Google Scholar] [CrossRef]

- Wenjun, L.; Margaret, B.; Luca, S.; Charles, B. The effect of oat bran on the dough rheology and quality of chinese steamed bread. Grain Oil Sci. Technol. 2018, 1, 126–130. [Google Scholar] [CrossRef]

- Zhou, Y.; Dhital, S.; Zhao, C.; Ye, F.; Chen, J.; Zhao, G. Dietary fiber-gluten protein interaction in wheat flour dough: Analysis, consequences and proposed mechanisms. Food Hydrocoll. 2021, 111, 106203. [Google Scholar] [CrossRef]

- Wang, C.-C.; Yang, Z.; Xing, J.-J.; Guo, X.-N.; Zhu, K.-X. Effects and underlying mechanisms of insoluble dietary fiber and ferulic acid on the crumb structure of steamed bread. Food Hydrocoll. 2022, 125, 107448. [Google Scholar] [CrossRef]

- Wang, C.-C.; Yang, Z.; Guo, X.-N.; Zhu, K.-X. Effects of insoluble dietary fiber and ferulic acid on the quality of steamed bread and gluten aggregation properties. Food Chem. 2021, 364, 130444. [Google Scholar] [CrossRef]

- Feng, Y.; Feng, X.; Liu, S.; Zhang, H.; Wang, J. Effects of dietary fiber and ferulic acid on dough characteristics and glutenin macropolymer (GMP) aggregation behavior during dough resting. LWT 2022, 166, 113782. [Google Scholar] [CrossRef]

- Djordjević, M.; Djordjević, M.; Šoronja-Simović, D.; Nikolić, I.; Šereš, Z. Delving into the role of dietary fiber in gluten-free bread formulations: Integrating fundamental rheological, technological, sensory, and nutritional aspects. Polysaccharides 2021, 3, 59–82. [Google Scholar] [CrossRef]

- Kłosok, K.; Welc, R.; Fornal, E.; Nawrocka, A. Effects of physical and chemical factors on the structure of gluten, gliadins and glutenins as studied with spectroscopic methods. Molecules 2021, 26, 508. [Google Scholar] [CrossRef]

- Li, R.; Wang, C.; Wang, Y.; Xie, X.; Sui, W.; Liu, R.; Wu, T.; Zhang, M. Extrusion Modification of Wheat Bran and Its Effects on Structural and Rheological Properties of Wheat Flour Dough. Foods 2023, 12, 1813. [Google Scholar] [CrossRef]

- Renzetti, S.; Theunissen, M.; Horrevorts, K. A systematic comparison of the intrinsic properties of wheat and oat bran fractions and their effects on dough and bread properties: Elucidation of chemical mechanisms, water binding, and steric hindrance. Foods 2021, 10, 2311. [Google Scholar] [CrossRef]

- Skendi, A.; Biliaderis, C.; Papageorgiou, M.; Izydorczyk, M. Effects of two barley β-glucan isolates on wheat flour dough and bread properties. Food Chem. 2010, 119, 1159–1167. [Google Scholar] [CrossRef]

- Hager, A.-S.; Ryan, L.A.; Schwab, C.; Gänzle, M.G.; O’Doherty, J.V.; Arendt, E.K. Influence of the soluble fibres inulin and oat β-glucan on quality of dough and bread. Eur. Food Res. Technol. 2011, 232, 405–413. [Google Scholar] [CrossRef]

- Li, Z.; Gao, W.; Liang, J.; Fan, H.; Yang, Y.; Suo, B.; Ai, Z. Mechanism underlying the weakening effect of β-glucan on the gluten system. Food Chem. 2023, 420, 136002. [Google Scholar] [CrossRef]

- Hemdane, S.; Jacobs, P.J.; Dornez, E.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Wheat (Triticum aestivum L.) bran in bread making: A critical review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 28–42. [Google Scholar] [CrossRef]

- Pietiäinen, S.; Moldin, A.; Ström, A.; Malmberg, C.; Langton, M. Effect of physicochemical properties, pre-processing, and extraction on the functionality of wheat bran arabinoxylans in breadmaking—A review. Food Chem. 2022, 383, 132584. [Google Scholar] [CrossRef]

- Salmenkallio-Marttila, M.; Katina, K.; Autio, K. Effects of bran fermentation on quality and microstructure of high-fiber wheat bread. Cereal Chem. 2001, 78, 429–435. [Google Scholar] [CrossRef]

- Gül, H.; Özer, M.S.; Dizlek, H. Improvement of the wheat and corn bran bread quality by using glucose oxidase and hexose oxidase. J. Food Qual. 2009, 32, 209–223. [Google Scholar] [CrossRef]

- de Erive, M.O.; Wang, T.; He, F.; Chen, G. Development of high-fiber wheat bread using microfluidized corn bran. Food Chem. 2020, 310, 125921. [Google Scholar] [CrossRef] [PubMed]

- Meerts, M.; Cardinaels, R.; Oosterlinck, F.; Courtin, C.M.; Moldenaers, P. The impact of water content and mixing time on the linear and non-linear rheology of wheat flour dough. Food Biophys. 2017, 12, 151–163. [Google Scholar] [CrossRef]

- Cauvain, S.P. Chapter 15—The contribution of water to dough formation and bread quality. In Breadmaking, 3rd ed.; Cauvain, S.P., Ed.; Woodhead Publishing: Cambridge, UK, 2020; pp. 441–464. [Google Scholar]

- Cai, L.; Choi, I.; Park, C.S.; Baik, B.-K. Bran Hydration and Physical Treatments Improve the Bread-Baking Quality of Whole Grain Wheat Flour. Cereal Chem. 2015, 92, 557–564. [Google Scholar] [CrossRef]

- Nelles, E.M.; Randall, P.G.; Taylor, J.R. Improvement of brown bread quality by prehydration treatment and cultivar selection of bran. Cereal Chem. 1998, 75, 536–540. [Google Scholar] [CrossRef]

- Hamada, S.; Aoki, N.; Suzuki, Y. Effects of water soaking on bread-making quality of brown rice flour. Food Sci. Technol. Res. 2012, 18, 25–30. [Google Scholar] [CrossRef]

- AACC. AACC Method 44-15A: Moisture-air-oven methods. In Approved Methods of the American Association of Cereal Chemists, 10th ed.; Cereals & Grains Association: St. Paul, MN, USA, 2000. [Google Scholar]

- AACC. AACC Method 54-21A: Farinograph method for flour. In Approved Methods of the American Association of Cereal Chemists, 10th ed.; Cereals & Grains Association: St. Paul, MN, USA, 2000. [Google Scholar]

- Wang, J.; Rosell, C.M.; de Barber, C.B. Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem. 2002, 79, 221–226. [Google Scholar] [CrossRef]

- Ozkoc, S.O.; Sumnu, G.; Sahin, S. The effects of gums on macro and micro-structure of breads baked in different ovens. Food Hydrocoll. 2009, 23, 2182–2189. [Google Scholar] [CrossRef]

- Skendi, A.; Mouselemidou, P.; Papageorgiou, M.; Papastergiadis, E. Effect of acorn meal-water combinations on technological properties and fine structure of gluten-free bread. Food Chem. 2018, 253, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Bhagwat, V.R. Safety of water used in food production. In Food Safety and Human Health; Elsevier: Amsterdam, The Netherlands, 2019; pp. 219–247. [Google Scholar]

- Itaya, Y.; Kobayashi, T.; Hayakawa, K.-I. Three-dimensional heat and moisture transfer with viscoelastic strain-stress formation in composite food during drying. Int. J. Heat. Mass. Transf. 1995, 38, 1173–1185. [Google Scholar] [CrossRef]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Singh, M.; Liu, S.X.; Vaughn, S.F. Effect of corn bran as dietary fiber addition on baking and sensory quality. Biocatal. Agric. Biotechnol. 2012, 1, 348–352. [Google Scholar] [CrossRef]

- Li, M.; Zheng, X.; Sun, B.; Li, L.; Wang, X.; Ma, S. Effects of the interaction of different particle size wheat bran dietary fiber with gluten protein and starch on dough structure and properties. Int. J. Biol. Macromol. 2025, 307, 142045. [Google Scholar] [CrossRef]

- Campbell, G.M.; Ross, M.; Motoi, L. Bran in bread: Effects of particle size and level of wheat and oat bran on mixing, proving and baking. In Bubbles in Food 2; Elsevier: Amsterdam, The Netherlands, 2008; pp. 337–354. [Google Scholar]

- Hooda, S.; Jood, S. Effect of fenugreek flour blending on physical, organoleptic and chemical characteristics of wheat bread. Nutr. Food Sci. 2005, 35, 229–242. [Google Scholar] [CrossRef]

- Stampfli, L.; Nersten, B.; Molteberg, E. Effects of emulsifiers on farinograph and extensograph measurements. Food Chem. 1996, 57, 523–530. [Google Scholar] [CrossRef]

- Ren, Y.; Linter, B.R.; Linforth, R.; Foster, T.J. A comprehensive investigation of gluten free bread dough rheology, proving and baking performance and bread qualities by response surface design and principal component analysis. Food Funct. 2020, 11, 5333–5345. [Google Scholar] [CrossRef]

- Waziiroh, E.; Schoenlechner, R.; Jaeger, H.; Brusadelli, G.; Bender, D. Understanding gluten-free bread ingredients during ohmic heating: Function, effect and potential application for breadmaking. Eur. Food Res. Technol. 2022, 248, 1021–1034. [Google Scholar] [CrossRef]

- Hemdane, S.; Langenaeken, N.; Jacobs, P.; Verspreet, J.; Delcour, J.; Courtin, C. Study of the role of bran water binding and the steric hindrance by bran in straight dough bread making. Food Chem. 2018, 253, 262–268. [Google Scholar] [CrossRef]

- Jacobs, P.J.; Bogaerts, S.; Hemdane, S.; Delcour, J.A.; Courtin, C.M. Impact of wheat bran hydration properties as affected by toasting and degree of milling on optimal dough development in bread making. J. Agric. Food Chem. 2016, 64, 3636–3644. [Google Scholar] [CrossRef]

- Ding, X.; Li, T.; Zhang, H.; Guan, C.; Qian, J.; Zhou, X. Effect of barley antifreeze protein on dough and bread during freezing and freeze-thaw cycles. Foods 2020, 9, 1698. [Google Scholar] [CrossRef] [PubMed]

- Park, E.Y.; Fuerst, E.P.; Baik, B.K. Effects of bran prehydration on functional characteristics and bread-baking quality of bran and flour blends. Cereal Chem. 2017, 94, 834–839. [Google Scholar] [CrossRef]

- Kollstrøm, M.O.; Böcker, U.; Uhlen, A.K.; Kristoffersen, A.Ø.; Dieseth, J.A.; Tengstrand, E.; Koga, S. The effect of weather conditions from heading to harvest on gluten quality of spring wheat–A study of historical data 2005–2022. J. Cereal Sci. 2025, 121, 104095. [Google Scholar] [CrossRef]

- Scherf, K.A.; Umseher, L.; Kieffer, R.; Koehler, P. Optimization of a micro-scale extension test for rehydrated vital wheat gluten. J. Cereal Sci. 2016, 68, 140–147. [Google Scholar] [CrossRef]

- Sroan, B.S.; Bean, S.R.; MacRitchie, F. Mechanism of gas cell stabilization in bread making. I. The primary gluten–starch matrix. J. Cereal Sci. 2009, 49, 32–40. [Google Scholar] [CrossRef]

- Liu, R.; Wu, L.; Zhang, Y.; Zhang, H.; Zhang, B.; Huang, B.; Wei, Y. Water state and distribution in noodle dough using low-field nuclear magnetic resonance and differential scanning calorimetric. Trans. Chin. Soc. Agric. Eng. 2015, 31, 288–294. [Google Scholar]

- Hayman, D.A.; Sipes, K.; Hoseney, R.; Faubion, J. Factors controlling gas cell failure in bread dough. Cereal Chem. 1998, 75, 585–589. [Google Scholar] [CrossRef]

- Janssen, F.; Wouters, A.G.; Delcour, J.A. Gas cell stabilization by aqueous-phase constituents during bread production from wheat and rye dough and oat batter: Dough or batter liquor as model system. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3881–3917. [Google Scholar] [CrossRef]

- Tebben, L.; Shen, Y.; Li, Y. Improvers and functional ingredients in whole wheat bread: A review of their effects on dough properties and bread quality. Trends Food Sci. Technol. 2018, 81, 10–24. [Google Scholar] [CrossRef]

- Hoseney, R.C. Principles of Cereal Science and Technology; American Association of Cereal Chemists: St. Paul, MN, USA, 1994. [Google Scholar]

- Mosharraf, L.; Kadivar, M.; Shahedi, M. Effect of hydrothermaled bran on physicochemical, rheological and microstructural characteristics of Sangak bread. J. Cereal Sci. 2009, 49, 398–404. [Google Scholar] [CrossRef]

- Sahi, S. Interfacial properties of the aqueous phases of wheat flour doughs. J. Cereal Sci. 1994, 20, 119–127. [Google Scholar] [CrossRef]

| Water Activity | Dough Moisture (%) | Consistency (BU) | Development Time (min) |

|---|---|---|---|

| 0.9951 | 56.52 | 526 ± 12 a | 5.9 ± 0.2 a |

| 0.9964 | 60.00 | 435 ± 10 b | 10.6 ± 0.3 b |

| 0.9979 | 61.54 | 366 ± 20 c | 11.8 ± 0.6 b |

| 0.9982 | 62.96 | 326 ± 11 cd | 14.9 ± 0.4 c |

| 0.9986 | 64.29 | 316 ± 8 d | 17.7 ± 1.2 d |

| 0.9989 | 65.52 | 237 ± 10 e | 22.4 ± 1.2 e |

| Water Activity | Specific Loaf Volume (cm3/g) | Hardness (N) | Springiness | Cohesiveness |

|---|---|---|---|---|

| 0.9951 | 3.53 ± 0.05 de | 554.499 ± 16.084 a | 0.945 ± 0.033 a | 0.532 ± 0.031 b |

| 0.9964 | 3.8 ± 0.08 cd | 525.748 ± 4.992 a | 0.952 ± 0.023 a | 0.582 ± 0.027 ab |

| 0.9979 | 4.21 ± 0.14 b | 346.039 ± 14.906 cd | 0.969 ± 0.022 a | 0.66 ± 0.035 a |

| 0.9982 | 3.85 ± 0.06 c | 443.633 ± 17.012 b | 0.963 ± 0.04 a | 0.621 ± 0.052 a |

| 0.9986 | 3.68 ± 0.11 cde | 409.825 ± 12.981 b | 0.964 ± 0.028 a | 0.611 ± 0.021 ab |

| 0.9989 | 3.47 ± 0.15 e | 360.43 ± 17.285 c | 0.951 ± 0.024 a | 0.59 ± 0.029 ab |

| White bread | 4.68 ± 0.06 a | 311.097 ± 10.653 d | 0.964 ± 0.007 a | 0.635 ± 0.01 a |

| Water Activity | Total Number of Cells | Porosity | Average Area of Cells, mm2 | Area Range of Cells, mm2 | Percentage of Number of Cells < 20 mm2, % |

|---|---|---|---|---|---|

| White | 1834 ± 102 a | 0.9021 ± 0.012 a | 51.1 ± 2.2 a | 2632.2 ± 142 a | 70.4 ± 3.2 a |

| 0.9951 | 1464 ± 70 b | 0.8122 ± 0.021 b | 73.2 ± 2.5 b | 3528 ± 151.8 b | 63.1 ± 2.2 b |

| 0.9979 | 1743 ± 72 a | 0.8603 ± 0.0275 ab | 66.7 ± 2.1 b | 2758.6 ± 134.8 a | 65.7 ± 3 ab |

| 0.9989 | 1153 ± 41 c | 0.8091 ± 0.0224 b | 103.4 ± 5.1 c | 3623.1 ± 130 b | 59.7 ± 2.7 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Wang, T.; de Erive, M.O.; Chen, G. Pre-Saturation of Bran as a Strategy for Developing Oat Bran-Enriched Bread. Foods 2025, 14, 2071. https://doi.org/10.3390/foods14122071

Wu Y, Wang T, de Erive MO, Chen G. Pre-Saturation of Bran as a Strategy for Developing Oat Bran-Enriched Bread. Foods. 2025; 14(12):2071. https://doi.org/10.3390/foods14122071

Chicago/Turabian StyleWu, Yun, Tao Wang, Maria Ortiz de Erive, and Guibing Chen. 2025. "Pre-Saturation of Bran as a Strategy for Developing Oat Bran-Enriched Bread" Foods 14, no. 12: 2071. https://doi.org/10.3390/foods14122071

APA StyleWu, Y., Wang, T., de Erive, M. O., & Chen, G. (2025). Pre-Saturation of Bran as a Strategy for Developing Oat Bran-Enriched Bread. Foods, 14(12), 2071. https://doi.org/10.3390/foods14122071