Food 3D Printing Equipment and Innovation: Precision Meets Edibility

Abstract

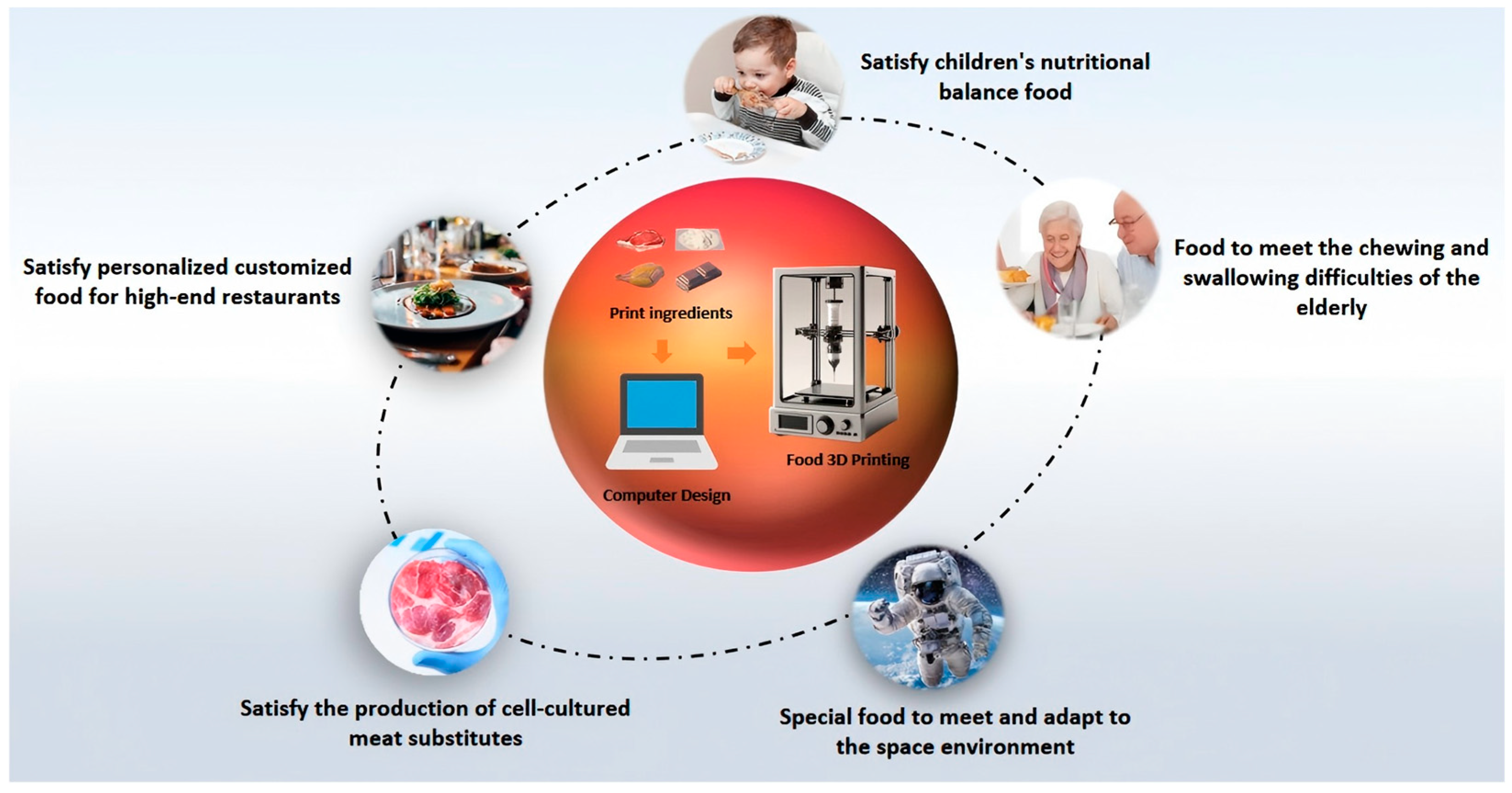

1. Introduction

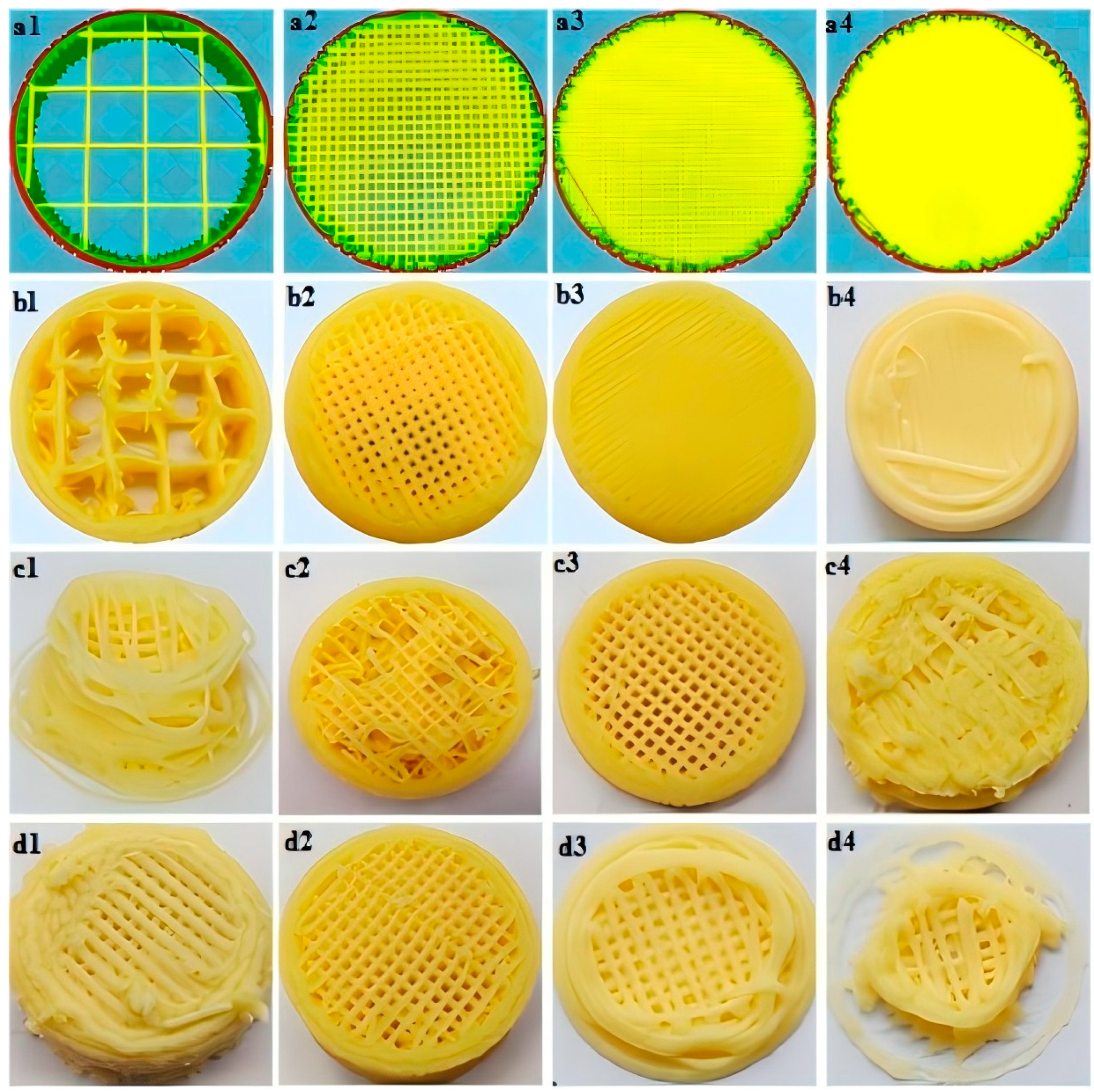

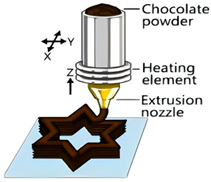

2. Traditional Food 3D Printing Technology Types

3. Emerging Food 3D Printing Technology Applications

3.1. Multi-Axis 3D Printing

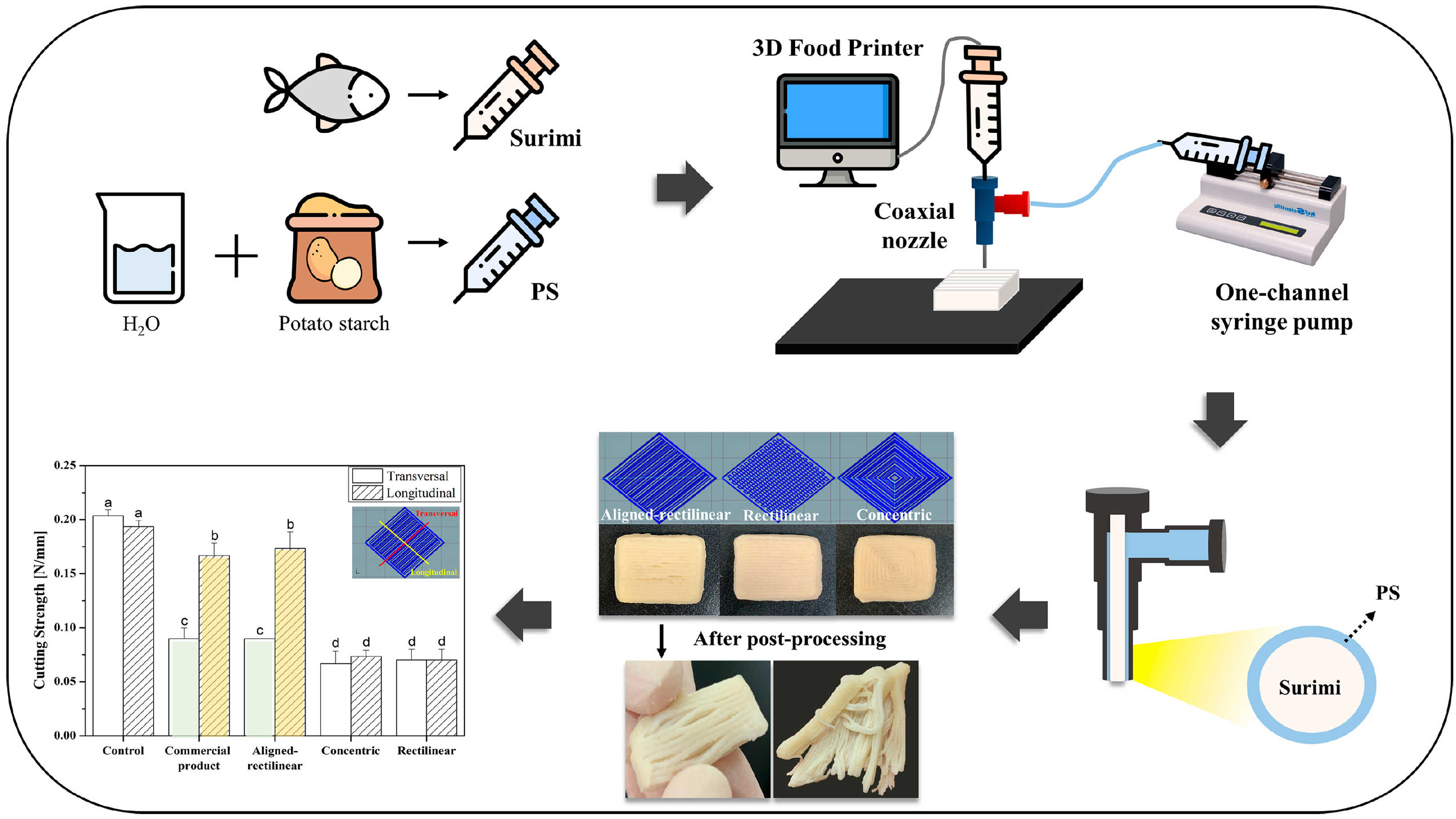

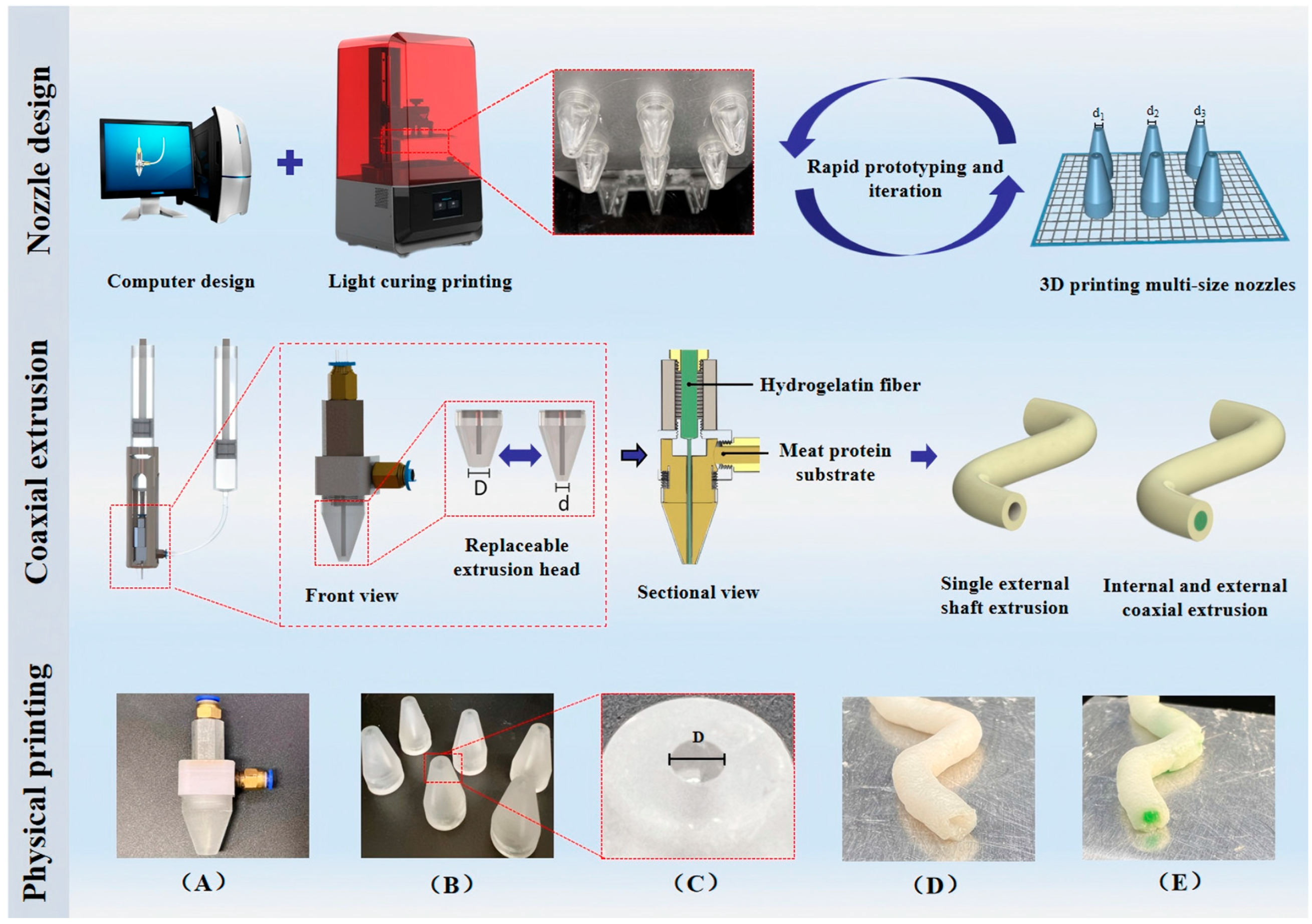

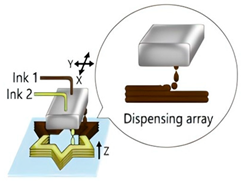

3.2. Coaxial 3D Printing

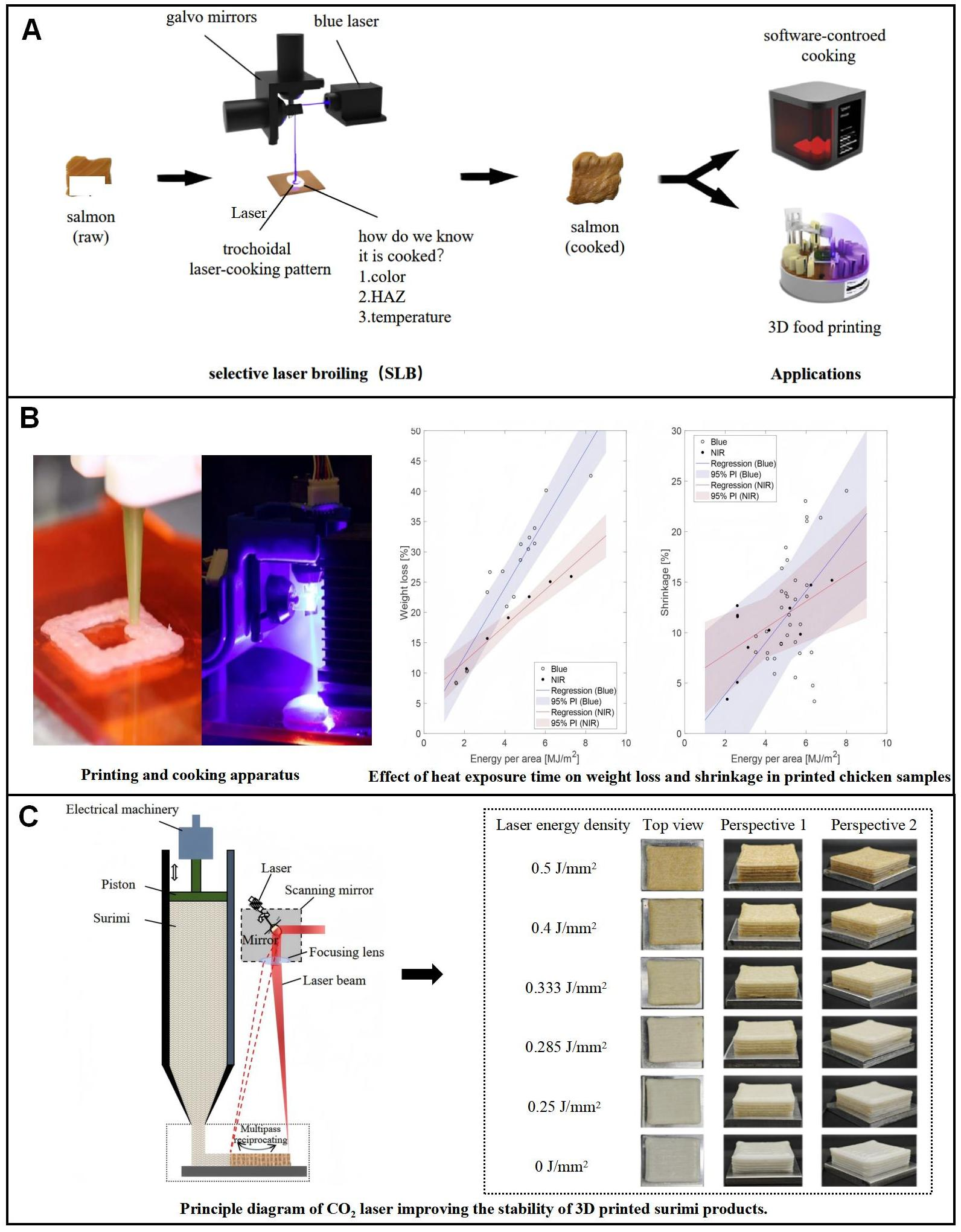

3.3. Laser-Assisted 3D Printing

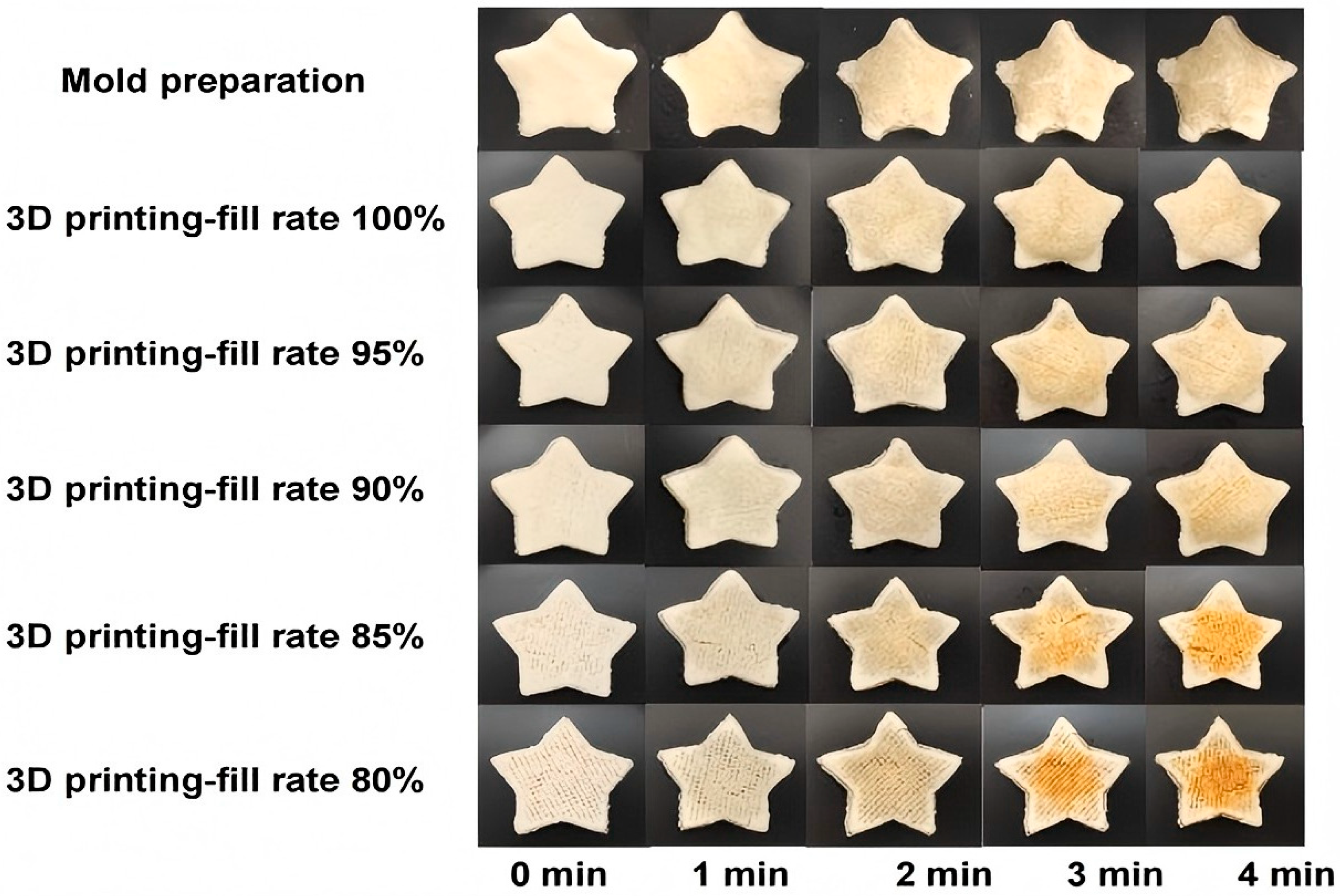

3.4. Microwave-Assisted 3D Printing

3.5. Ultrasonic-Assisted 3D Printing

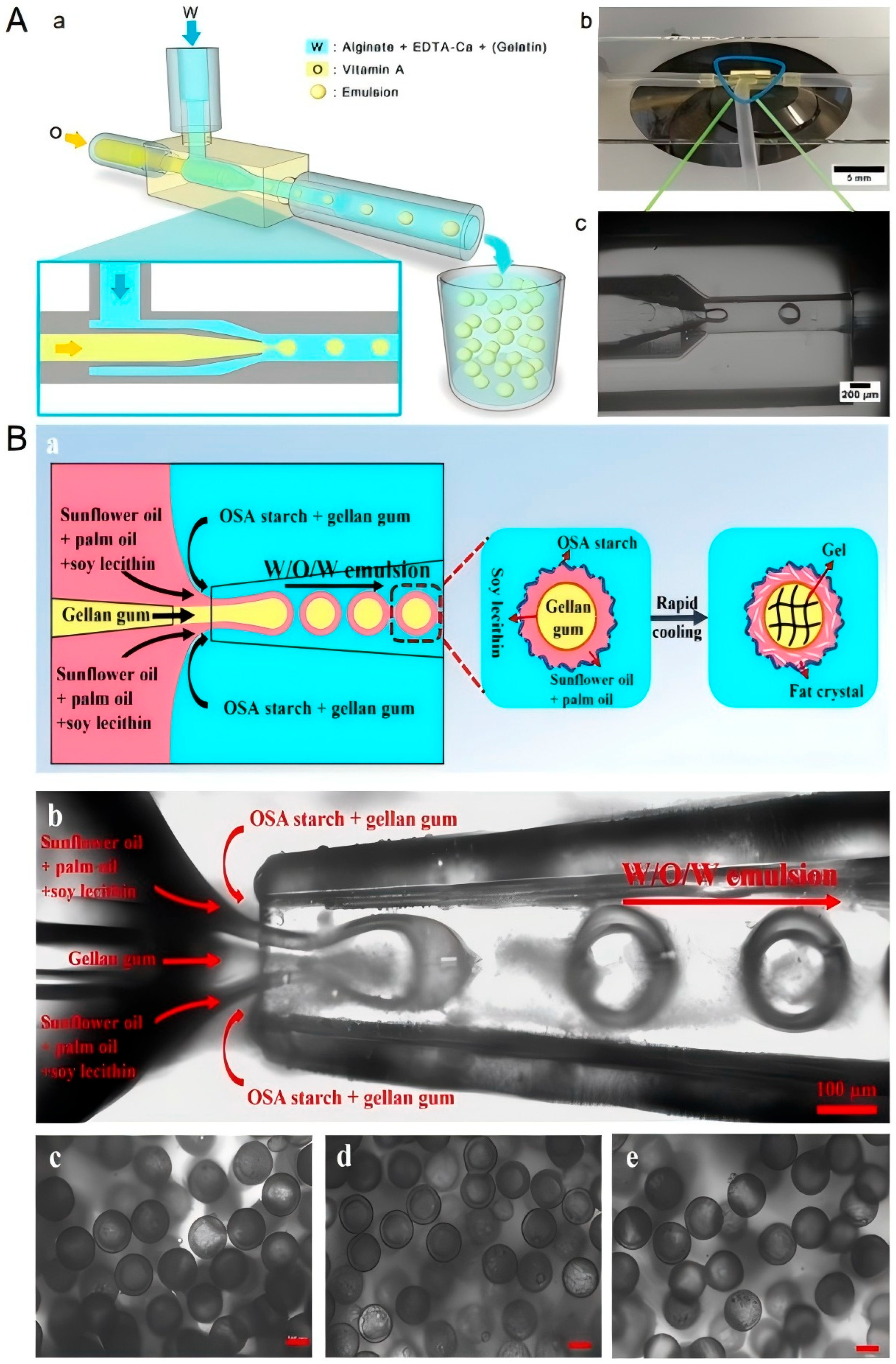

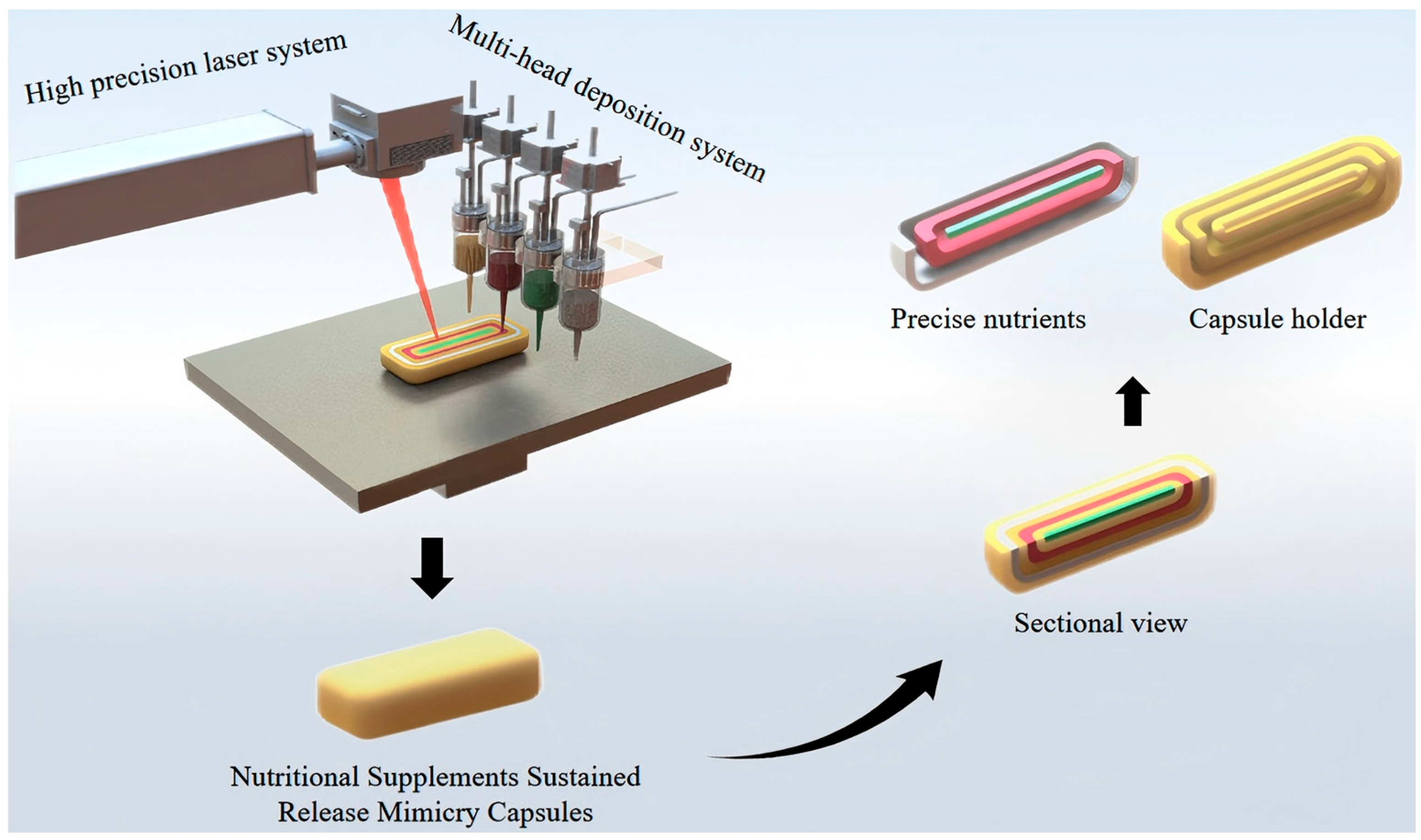

3.6. Microfluidic 3D Printing

4. Potential Challenges of 3D Printing Food

4.1. Food Safety

4.2. Consumer Acceptance

4.3. Relevant Regulations and Standard Systems

5. Future Challenges and Opportunities

- (1)

- The safety control system for 3D-printed foods still requires further improvement. Potential safety risks exist throughout the entire production process, from raw material pre-treatment to final product storage, necessitating the establishment of a comprehensive HACCP system. In particular, areas such as equipment sterilization, printing environment control, and shelf-life prediction demand in-depth research and enhancement.

- (2)

- Consumer acceptance of 3D-printed foods remains relatively low, primarily due to concerns about product safety, nutritional value, and taste. Future efforts should focus on technological innovation to improve product quality, alongside strengthening public education to enhance consumer understanding and trust. Additionally, more application scenarios that meet consumer needs should be developed.

- (3)

- The regulatory and standard systems need further refinement, especially in terms of raw material evaluation, equipment standards, process specifications, and product quality. A comprehensive standard system covering the entire industry chain should be established to provide normative guidance for industrial development. Simultaneously, international mutual recognition and harmonization of standards should be strengthened to promote global standardization.

- (4)

- Future development directions will focus on new material development, technological innovation, and health applications, particularly in the fields of functional ingredient utilization, intelligent manufacturing technology integration, and personalized nutritional intervention. Additionally, implementing sustainable development strategies, including raw material recycling, energy conservation, emission reduction, and localized production, will become critical topics for industrial growth.

- (5)

- The emergence of new 3D printing technologies presents fresh opportunities for 3D-printed foods. However, challenges remain in terms of equipment costs, operational complexity, and process standardization. Future efforts should strengthen industry–academia research collaboration to drive technological breakthroughs and promote the in-depth development of industrial applications.

- (6)

- The transition from 3D printing to 4D printing transforms products from being entirely passive to becoming “smart foods” capable of actively sensing and adapting to environmental changes. In the future, research should focus on intelligent response mechanisms based on pH-responsive or temperature-sensitive materials, exploring how these materials can enable foods to undergo shape changes or structural transformations under specific conditions, thereby enhancing functionality and nutrient retention. Additionally, effectively preserving nutritional value and ensuring food safety will remain critical issues for further investigation.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. United. States Patent Appl. No. 638905, 8 August 1984. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2015; ISBN 978-1-4939-2112-6. [Google Scholar]

- Rayna, T.; Striukova, L. From Rapid Prototyping to Home Fabrication: How 3D Printing Is Changing Business Model Innovation. Technol. Forecast. Soc. Change 2016, 102, 214–224. [Google Scholar] [CrossRef]

- Elhadad, A.A.; Rosa-Sainz, A.; Canete, R. Applications and Multidisciplinary Perspective on 3D Printing Techniques: Recent Developments and Future Trends. Mater. Sci. Eng. R: Rep. 2023, 156, 100760. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K. (Kelvin) 3D Printing of Polymer Composites: Materials, Processes, and Applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- Song, Y.; Ghafari, Y.; Asefnejad, A.; Toghraie, D. An Overview of Selective Laser Sintering 3D Printing Technology for Biomedical and Sports Device Applications: Processes, Materials, and Applications. Opt. Laser Technol. 2024, 171, 110459. [Google Scholar] [CrossRef]

- Lodhi, S.K.; Gill, A.Y.; Hussain, I. 3D Printing Techniques: Transforming Manufacturing with Precision and Sustainability. Int. J. Multidiscip. Sci. Arts 2024, 3, 129–138. Available online: https://www.jurnal.itscience.org/index.php/ijmdsa/article/view/4568 (accessed on 6 January 2025). [CrossRef]

- Tong, Q.; Xiao, S.; Li, Y.; Jiang, Y.; Dong, X. Research Progress of 3D Printing Technology in the Field of Space Food Processing. Food Sci. 2024, 45, 299–306. [Google Scholar] [CrossRef]

- Alberts, M.; Nachtigall, T.R.; Doubrovski, Z.; Saakes, D. From Dribbling Honey to Non-Planar 3D-Printing: Coiling Becomes Craft. In Proceedings of the Companion Publication of the 2024 ACM Designing Interactive Systems Conference; Association for Computing Machinery, New York, NY, USA, 1 July 2024; pp. 328–332. [Google Scholar]

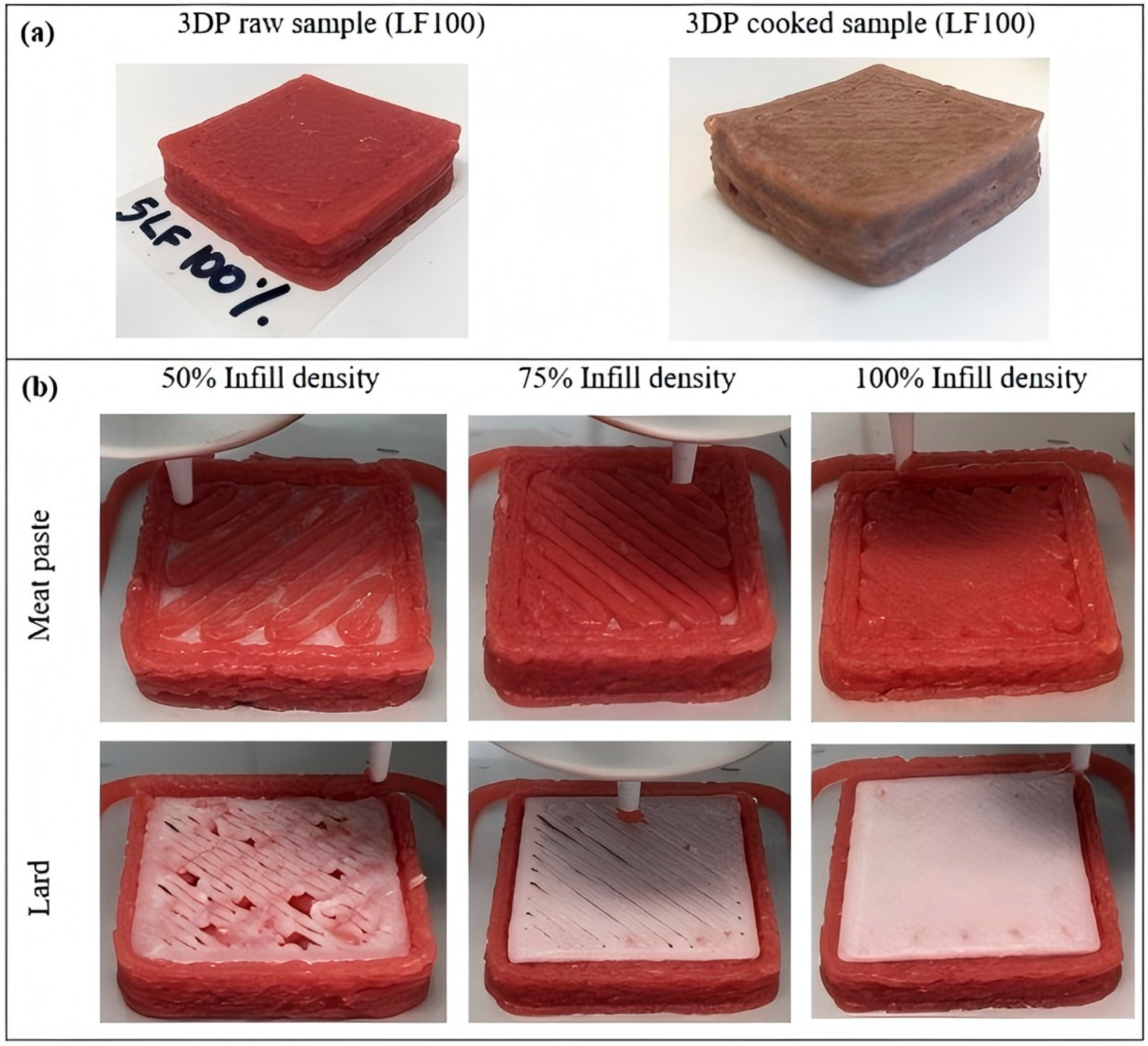

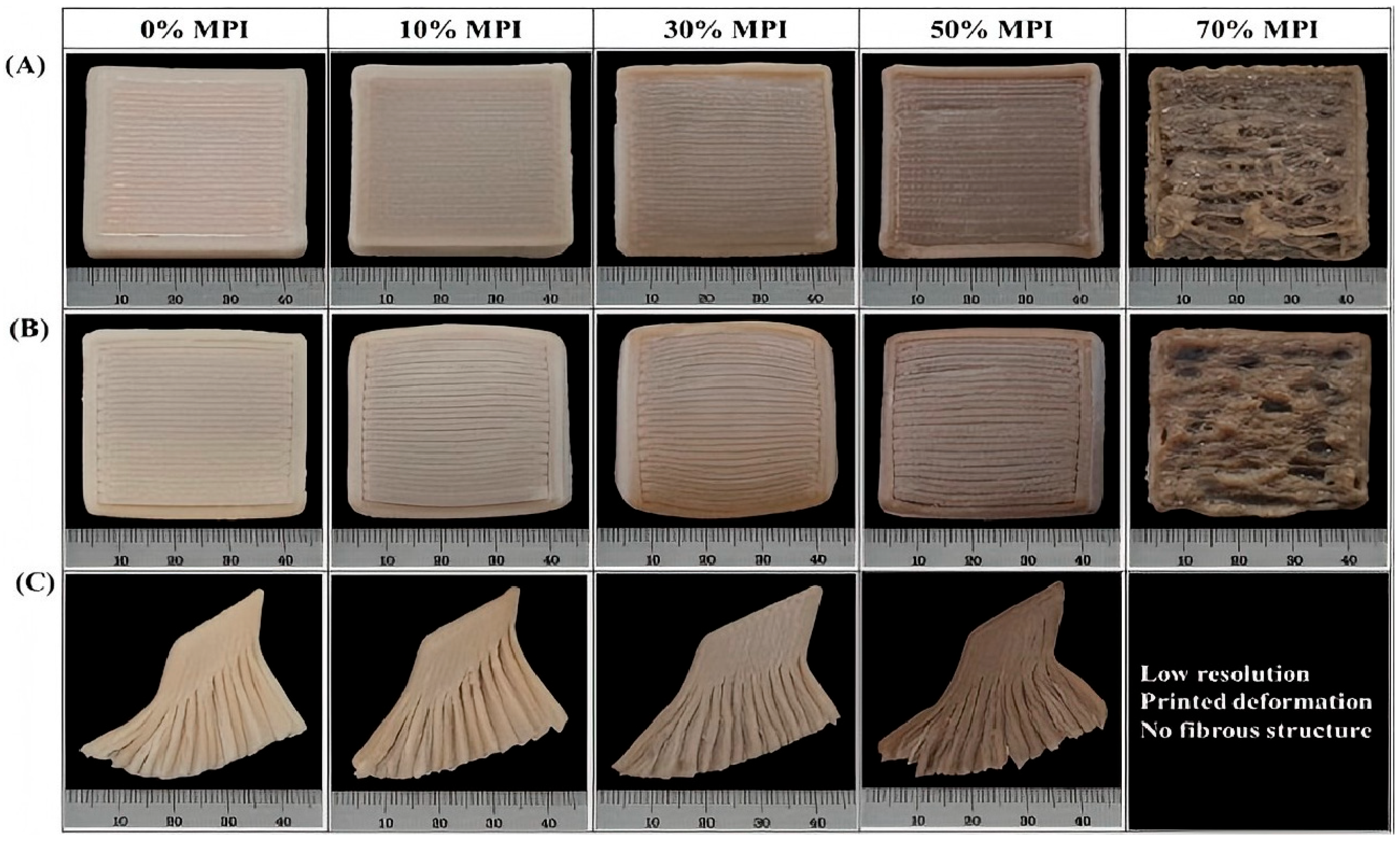

- Dong, H.; Wang, P.; Yang, Z.; Xu, X. 3D Printing Based on Meat Materials: Challenges and Opportunities. Curr. Res. Food Sci. 2023, 6, 100423. [Google Scholar] [CrossRef]

- Ricci, I.; Antonio, D.; Carla, S. 3D Printed Food From Fruits and Vegetables—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/B9780128145647000055 (accessed on 6 January 2025).

- Le Tohic, C.; O’Sullivan, J.J.; Drapala, K.P.; Chartrin, V.; Chan, T.; Morrison, A.P.; Kerry, J.P.; Kelly, A.L. Effect of 3D Printing on the Structure and Textural Properties of Processed Cheese. J. Food Eng. 2018, 220, 56–64. [Google Scholar] [CrossRef]

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Optimization of Chocolate 3D Printing by Correlating Thermal and Flow Properties with 3D Structure Modeling. Innov. Food Sci. Emerg. Technol. 2017, 44, 21–29. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A. Grain Structure Control during Metal 3D Printing by High-Intensity Ultrasound. Nat. Commun. 2020, 11, 142. Available online: https://www.nature.com/articles/s41467-019-13874-z (accessed on 6 January 2025). [CrossRef]

- Hassan, I.; Rasheed, N.; Gani, A.; Gani, A. Rice Starch, Millet Flour Supplemented with Algal Biomass for 3D Food Printing. Int. J. Biol. Macromol. 2025, 303, 140604. [Google Scholar] [CrossRef] [PubMed]

- Mittal, S.; Bhuiyan, M.H.R.; Ngadi, M.O. Challenges and Prospects of Plant-Protein-Based 3D Printing. Foods 2023, 12, 4490. Available online: https://www.mdpi.com/2304-8158/12/24/4490 (accessed on 21 February 2025). [CrossRef] [PubMed]

- Motoki, K.; Park, J.; Spence, C.; Velasco, C. Contextual Acceptance of Novel and Unfamiliar Foods: Insects, Cultured Meat, Plant-Based Meat Alternatives, and 3D Printed Foods. Food Qual. Prefer. 2022, 96, 104368. [Google Scholar] [CrossRef]

- Donn, P.; Prieto, M.A.; Mejuto, J.C.; Cao, H.; Simal-Gandara, J. Functional Foods Based on the Recovery of Bioactive Ingredients from Food and Algae By-Products by Emerging Extraction Technologies and 3D Printing. Food Biosci. 2022, 49, 101853. Available online: https://www.sciencedirect.com/science/article/pii/S2212429222003121 (accessed on 21 February 2025). [CrossRef]

- Xiao, S.; Jang, Y.; Tong, Q. Meat Products 3D Printing Technology and Application Progress. Food Ind. Technol. 2025, 46, 435–443. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Huang, D. 3D Food Printing: Perspectives. Polym. Food Appl. 2018, 725–755. [Google Scholar] [CrossRef]

- Tong, Q.; Jiang, Y.; Xiao, S.; Meng, Y.; Dong, X. Research on Improving the Structural Stability of Surimi 3D Printing through Laser Cooking Techniques. J. Food Eng. 2024, 375, 112075. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d Printing Technologies Applied for Food Design: Status and Prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef]

- Tong, Q.; Zhao, W.T.; Guo, T.R. A Study of the Gelatin Low-Temperature Deposition Manufacturing Forming Process Based on Fluid Numerical Simulation. Foods 2023, 12, 2687. Available online: https://www.mdpi.com/2304-8158/12/14/2687 (accessed on 21 February 2025). [CrossRef]

- Sarbu, I.; Fitaac, A.C.; Popovici, V. Innovative Methods for the Characterization of a Novel Pharmaceutical Adhesive for 3D Printing Drugs. Farmacia 2022, 70, 1140–1147. [Google Scholar] [CrossRef]

- Jonkers, N.; van Dommelen, J.A.W.; Geers, M.G.D. An Anisotropic Elasto-Viscoplastic-Damage Model for Selective Laser Sintered Food. Eng. Fract. Mech. 2022, 266, 108368. [Google Scholar] [CrossRef]

- Tong, Q.; Xiao, S.; Jang, Y.; Dong, X.; Pang, G. Application and Development Trend of Laser Technology in Food 3D Printing. Food Sci. 2025, 46, 315–324. [Google Scholar] [CrossRef]

- Tan, C.; Toh, W.Y.; Wong, G.; Li, L. Extrusion-Based 3D Food Printing—Materials and Machines. Int. J. Bioprint. 2018, 4, 143. [Google Scholar] [CrossRef]

- Tang, P.; Zhao, X.; Shi, H.; Hu, B.; Ding, J.; Yang, B.; Xu, W. A Review of Multi-Axis Additive Manufacturing: Potential, Opportunity and Challenge. Addit. Manuf. 2024, 83, 104075. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Yan, L. Extrusion-Based Food Printing for Digitalized Food Design and Nutrition Control. J. Food Eng. 2018, 220, 1–11. [Google Scholar] [CrossRef]

- Sun, J.; Zhuo, D.P. Extrusion-Based Multiple Material Mixer Design in Food Printing. Int. J. Food Eng. 2019, 121–126. [Google Scholar] [CrossRef]

- Yao, Y.; Cheng, L.; Li, Z. A Comparative Review of Multi-Axis 3D Printing. J. Manuf. Process. 2024, 120, 1002–1022. [Google Scholar] [CrossRef]

- Yang, G.; Tao, Y.; Wang, P. Optimizing 3D Printing of Chicken Meat by Response Surface Methodology and Genetic Algorithm: Feasibility Study of 3D Printed Chicken Product. LWT 2022, 154, 112693. [Google Scholar] [CrossRef]

- Leelapunnawut, S.; Ngamwonglumlert, L.; Devahastin, S. Effects of Texture Modifiers on Physicochemical Properties of 3D-Printed Meat Mimics from Pea Protein Isolate-Alginate Gel Mixture. Foods 2022, 11, 3947. [Google Scholar] [CrossRef]

- Liu, P.; Dang, X.; Woo, M.W.; Chattha, S.A.; An, J.; Shan, Z. Feasibility Study of Starch-Based Biomass Incorporated 3D Printed Beef. Starch Stärke 2022, 74, 2200030. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Prakash, S. Post-Processing Feasibility of Composite-Layer 3D Printed Beef. Meat Sci. 2019, 153, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Park, J.W.; Lee, S.H.; Kim, H.W.; Park, H.J. Application of Extrusion-Based 3D Food Printing to Regulate Marbling Patterns of Restructured Beef Steak. Meat Sci. 2023, 202, 109203. [Google Scholar] [CrossRef]

- Lanaro, M.; Forrestal, D.P.; Scheurer, S. 3D Printing Complex Chocolate Objects: Platform Design, Optimization and Evaluation. J. Food Eng. 2017, 215, 13–22. [Google Scholar] [CrossRef]

- Lee, C.P.; Karyappa, R. 3D Printing of Milk-Based Product. RSC Adv. 2020, 10, 29821–29828. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, Q.; Zhang, W. Advances in the Potential Application of 3D Food Printing to Enhance Elderly Nutritional Dietary Intake. Foods 2023, 12, 1842. [Google Scholar] [CrossRef]

- Ortega, O.; Martín, A.; Clavé, P. Diagnosis and Management of Oropharyngeal Dysphagia Among Older Persons, State of the Art. J. Am. Med. Dir. Assoc. 2017, 18, 576–582. [Google Scholar] [CrossRef]

- Chao, C.; Hwang, J.S.; Kim, I.W.; Choi, R.Y.; Kim, H.W.; Park, H.J. Coaxial 3D Printing of Chicken Surimi Incorporated with Mealworm Protein Isolate as Texture-Modified Food for the Elderly. J. Food Eng. 2022, 333, 111151. [Google Scholar] [CrossRef]

- Kim, S.M.; Kim, H.W.; Park, H.J. Preparation and Characterization of Surimi-Based Imitation Crab Meat Using Coaxial Extrusion Three-Dimensional Food Printing. Innov. Food Sci. Emerg. Technol. 2021, 71, 102711. [Google Scholar] [CrossRef]

- Niu, R.; Zhao, R.; Hu, H.; Yu, X.; Huang, Z.; Cheng, H.; Yin, J.; Zhou, J.; Xu, E.; Liu, D. Co-Encapsulation of Hydrophilic and Hydrophobic Bioactives Stabilized in Nanostarch-Assisted Emulsion for Inner Core Gel of Coaxial 3D Printing. Carbohydr. Polym. 2024, 343, 122499. [Google Scholar] [CrossRef]

- Blutinger, J.D.; Meijers, Y.; Lipson, H. Selective Laser Broiling of Atlantic Salmon. Food Res. Int. 2019, 120, 196–208. [Google Scholar] [CrossRef] [PubMed]

- Blutinger, J.D.; Tsai, A.; Storvick, E. Precision Cooking for Printed Foods via Multiwavelength Lasers. npj Sci. Food 2021, 5, 24. [Google Scholar] [CrossRef]

- Fan, H.; Zhang, M.; Liu, Z.; Ye, Y. Effect of Microwave-Salt Synergetic Pre-Treatment on the 3D Printing Performance of SPI-Strawberry Ink System. LWT 2020, 122, 109004. [Google Scholar] [CrossRef]

- Li, M.; Zhou, C.; Wang, B.; Zeng, S. Research Progress and Application of Ultrasonic-and Microwave-assisted Food Processing Technology. Compr. Rev. Food Sci. Food Saf. 2023, 22, 3707–3731. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Liu, Z.; Zhang, X.; He, C.; Zhang, X. Microwave-Triggered 4D Automatic Color Change in 3D-Printed Food Materials Incorporating Natural Pigments. Foods 2023, 12, 2055. [Google Scholar] [CrossRef]

- Li, N.; Li, H.B.; Liu, Z.B.; Lv, S. Preparation and Product Characterization of Microwaveable Food Using Lentinus Edodes Protein through 3D Printing. Polymers 2023, 15, 3736. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Q.; Yan, B.; Gao, W.; Jiao, X.; Huang, J.; Zhao, J.; Zhang, H.; Chen, W.; Fan, D. Synergistic Effect of Microwave 3D Print and Transglutaminase on the Self-Gelation of Surimi during Printing. Innov. Food Sci. Emerg. Technol. 2021, 67, 102546. [Google Scholar] [CrossRef]

- Brudzynski, S.M.; Bihari, F.; Ociepa, D.; Fu, X.-W. Analysis of 22 kHz Ultrasonic Vocalization in Laboratory Rats: Long and Short Calls. Physiol. Behav. 1993, 54, 215–221. [Google Scholar] [CrossRef]

- Mayer, H. Recent Developments in Ultrasonic Fatigue. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 3–29. [Google Scholar] [CrossRef]

- He, C.; Zhang, M.; Fang, Z. 3D Printing of Food: Pretreatment and Post-Treatment of Materials. Crit. Rev. Food Sci. Nutr. 2020, 60, 2379–2392. [Google Scholar] [CrossRef]

- Liu, Y.; Yi, S.; Ye, T.; Leng, Y.; Alomgir Hossen, M.; Sameen, D.E.; Dai, J.; Li, S.; Qin, W. Effects of Ultrasonic Treatment and Homogenization on Physicochemical Properties of Okara Dietary Fibers for 3D Printing Cookies. Ultrason. Sonochem. 2021, 77, 105693. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Bai, M.; Li, C.; Cui, H.; Lin, L. Advances in the Mechanism of Different Antibacterial Strategies Based on Ultrasound Technique for Controlling Bacterial Contamination in Food Industry. Trends Food Sci. Technol. 2020, 105, 211–222. [Google Scholar] [CrossRef]

- Xu, K.; Zhang, M.; Bhandari, B. Effect of Novel Ultrasonic- Microwave Combined Pretreatment on the Quality of 3D Printed Wheat Starch-Papaya System. Food Biophys. 2020, 15, 249–260. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, M.; Rao, Z. Effect of Ultrasound-Assisted Thawing on Gelling and 3D Printing Properties of Silver Carp Surimi. Food Res. Int. 2021, 145, 110405. [Google Scholar] [CrossRef] [PubMed]

- Habuš, M.; Golubić, P.; Vukušić Pavičić, T.; Čukelj Mustač, N.; Voučko, B.; Herceg, Z.; Ćurić, D.; Novotni, D. Influence of Flour Type, Dough Acidity, Printing Temperature and Bran Pre-Processing on Browning and 3D Printing Performance of Snacks. Food Bioprocess Technol. 2021, 14, 2365–2379. [Google Scholar] [CrossRef]

- Gu, M.; Gu, H.; Raghavan, V.; Wang, J. Ultrasound Treatment Improved the Physicochemical Properties of Pea Protein with Pectin Ink Used for 3D Printing. Future Foods 2024, 9, 100377. [Google Scholar] [CrossRef]

- Li, Z.; He, W.; Huang, X.; Hu, X.; Chen, H.; Zhang, Y.; Shi, J.; Zou, X. Contactless Printing of Food Micro-Particles Controlled by Ultrasound. J. Food Eng. 2025, 388, 112375. [Google Scholar] [CrossRef]

- Yazdi, A.A.; Popma, A.; Wong, W.; Nguyen, T.; Pan, Y.; Xu, J. 3D Printing: An Emerging Tool for Novel Microfluidics and Lab-on-a-Chip Applications. Microfluid. Nanofluid. 2016, 20, 50. [Google Scholar] [CrossRef]

- Racaniello, G.F.; Silvestri, T.; Pistone, M.; D’Amico, V.; Arduino, I.; Denora, N.; Lopedota, A.A. Innovative Pharmaceutical Techniques for Paediatric Dosage Forms: A Systematic Review on 3D Printing, Prilling/Vibration and Microfluidic Platform. J. Pharm. Sci. 2024, 113, 1726–1748. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, R.; Zhang, Y.; Pan, Y.; Shum, H.C.; Jiang, Z. Alginate-Gelatin Emulsion Droplets for Encapsulation of Vitamin A by 3D Printed Microfluidics. Particuology 2022, 64, 164–170. [Google Scholar] [CrossRef]

- Balakrishnan, H.K.; Badar, F.; Doeven, E.H.; Novak, J.I.; Merenda, A.; Dumée, L.F.; Loy, J.; Guijt, R.M. 3D Printing: An Alternative Microfabrication Approach with Unprecedented Opportunities in Design. Anal. Chem. 2021, 93, 350–366. [Google Scholar] [CrossRef] [PubMed]

- Hwang, Y.-H.; Um, T.; Ahn, G.-N.; Kim, D.-P.; Lee, H. Robust and Scalable Production of Emulsion-Templated Microparticles in 3D-Printed Milli-Fluidic Device. Chem. Eng. J. 2022, 431, 133998. [Google Scholar] [CrossRef]

- Guo, L.; Cao, M.; Chen, X.; Zhang, L.; Zhang, X.; Zou, L.; Liu, W. One-Step Fabrication of Microfluidic W/O/W Droplets as Fat-Reduced High Internal Phase Emulsions: Microstructure, Stability and 3D Printing Performance. Food Hydrocoll. 2024, 150, 109742. [Google Scholar] [CrossRef]

- Li, X.; You, B.; Shum, H.C.; Chen, C.-H. Future Foods: Design, Fabrication and Production through Microfluidics. Biomaterials 2022, 287, 121631. [Google Scholar] [CrossRef]

- Shen, D.; Zhang, M.; Mujumdar, A.S. Advances and Application of Efficient Physical Fields in Extrusion Based 3D Food Printing Technology. Trends Food Sci. Technol. 2023, 131, 104–117. [Google Scholar] [CrossRef]

- Severini, C.; Derossi, A.; Ricci, I.; Caporizzi, R.; Fiore, A. Printing a Blend of Fruit and Vegetables. New Advances on Critical Variables and Shelf Life of 3D Edible Objects. J. Food Eng. 2018, 220, 89–100. [Google Scholar] [CrossRef]

- Jayaprakash, S.; Paasi, J.; Pennanen, K.; Flores Ituarte, I.; Lille, M.; Partanen, J.; Sozer, N. Techno-Economic Prospects and Desirability of 3D Food Printing: Perspectives of Industrial Experts, Researchers and Consumers. Foods 2020, 9, 1725. [Google Scholar] [CrossRef]

- Brunner, T.A.; Delley, M.; Denkel, C. Consumers’ Attitudes and Change of Attitude toward 3D-Printed Food. Food Qual. Prefer. 2018, 68, 389–396. [Google Scholar] [CrossRef]

- Manstan, T.; McSweeney, M.B. Consumers’ Attitudes towards and Acceptance of 3D Printed Foods in Comparison with Conventional Food Products. Int. J. Food Sci. Technol. 2020, 55, 323–331. [Google Scholar] [CrossRef]

- Lupton, D.; Turner, B. Food of the Future? Consumer Responses to the Idea of 3D-Printed Meat and Insect-Based Foods. Food Foodways 2018, 26, 269–289. [Google Scholar] [CrossRef]

- McDonald, J. Regulatory Considerations for Devices Manufactured Using Additive Manufacturing Technologies. In Polymer-Based Additive Manufacturing: Biomedical Applications; Devine, D.M., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 243–254. ISBN 978-3-030-24532-0. [Google Scholar]

- de Boer, A.; Bast, A. Demanding Safe Foods—Safety Testing under the Novel Food Regulation (2015/2283). Trends Food Sci. Technol. 2018, 72, 125–133. [Google Scholar] [CrossRef]

- Baiano, A. 3D Printed Foods: A Comprehensive Review on Technologies, Nutritional Value, Safety, Consumer Attitude, Regulatory Framework, and Economic and Sustainability Issues. Food Rev. Int. 2022, 38, 986–1016. [Google Scholar] [CrossRef]

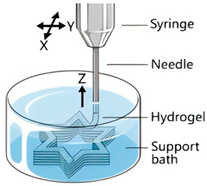

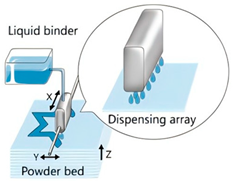

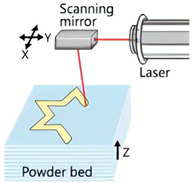

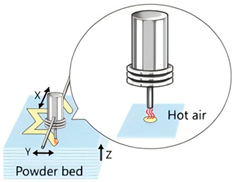

| Extrusion 3D Printing | Inkjet 3D Printing | Hydrogel Molding Extrusion Printing | Adhesive Spray Molding Technology Printing | Selective Laser Sintering | Selective Hot Air Sintering | |

|---|---|---|---|---|---|---|

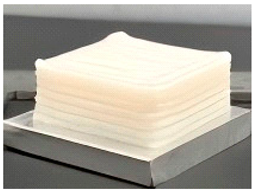

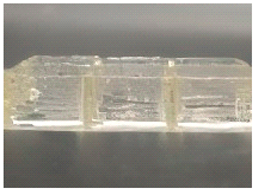

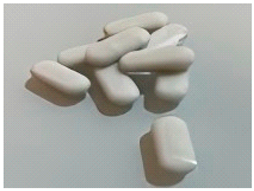

| Schematic diagram |  |  |  |  |  |  |

| Advantages | Applicable to a variety of materials, simple equipment. | High resolution for fine patterns and colorful food decorations. | Capable of printing complex hydrogel structures. | No heating required, fast printing speed. | High precision, suitable for complex geometries. | No laser source required, low equipment cost. |

| Available materials | Chocolate, cheese, fruit puree, meat puree, etc. | Syrups, sauces, etc. | Hydrogel, trehalose, pectin, etc. | Starch, powdered sugar, flour, and other food powders. | Sugar powder, chocolate, fat, and other food powders | Flour, powdered sugar, and other food powders. |

| Application scope | Personalized food customization, catering creativity, etc. | Food surface decoration, personalized patterns, customized cakes, etc. | Soft foods (jelly, gummies, etc.) | Food powder molding, biscuits, bread, etc. | High-precision creative food, exquisite candies, personalized food, etc. | Low-sugar and low-fat customized food. |

| Printing limitations | Slow printing speed; cannot handle low-liquid ingredients. | Slow printing speed; Only suitable for liquid or colloidal state materials. | Slow printing speed; high temperature control requirements, limited applicability | High requirements for glue spray control; high requirements for powder fluidity, particle size, etc. | High powder quality and particle size requirements; high equipment costs. | Strict temperature control requirements; accuracy is not as good as laser sintering, but suitable for simple food structures. |

| Print products |  |  |  |  |  |  |

| References | [20,21] | [20,22] | [20,23] | [20,24] | [20,25] | [20,26] |

| Printing Materials | Print Parameters | Conditions | Ultrasonic Application Mode | Significant Findings | Reference |

|---|---|---|---|---|---|

| Wheat Starch-Papaya | Temperature: 25 °C, nozzle diameter: 1.0 mm, layer height: 1.0 mm, printing speed: 15 mm/s. | Ultrasonic: 80 W; 30 min, microwave: 80 W; 4 min. | Indirect (pre-treatment) | Improve the stability and accuracy of 3D printed samples. | [56] |

| Silver carp surimi | Temperature: 25 °C, nozzle diameter: 1.5 mm, layer height: 1.5 mm, printing speed: 15 mm/s. | Frequency: 45, 80, and 100 kHz. | Indirect (pre-treatment) | Reduce damage to the myogenic protein structure; improve the printing accuracy of surimi gel; improve the hardness, elasticity, and chewiness of printed products. | [57] |

| Wheat bran | Temperature: 20 °C, nozzle diameter: 1.0 mm, layer height: 0.4 mm, printing speed: 25 mm/s. | Power: 400 W, time: 2 min. | Indirect (pre-treatment) | Reduce polyphenol oxidase activity and effectively stop the browning process; increase the viscosity of dough and enhance the accuracy of printed snack shapes. | [58] |

| Pectin and pea protein | Temperature: 25 °C, nozzle diameter: 0.84 mm, layer height: 0.84 mm, printing speed: 15 mm/s, filling density 60%. | Power: 390 W, frequency: 29 kHz, time: 10 min. | Indirect (pre-treatment) | Incorporating pectin after ultrasonic treatment can improve the texture and rheological properties of the pea protein matrix; improve the mechanical strength and stability of the printed product. | [59] |

| Popcorn | Voltage: 5–16 V, printing accuracy: 0.16 mm, vertical speed: 25 cm/s, horizontal speed: 12.5 cm/s. | Ultrasonic phased array: A phased array composed of 16 × 16 40 kHz ultrasonic transducers (model MA40S4S). | Indirect (pre-treatment) | Developed a non-contact 3D printing method based on ultrasonic phased array. It is highly precise, sensitive, non-contact, and has a wide range of applications; it enables rapid movement of suspension points. | [60] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, S.; Yang, J.; Bi, Y.; Li, Y.; Cao, Y.; Zhou, M.; Pang, G.; Dong, X.; Tong, Q. Food 3D Printing Equipment and Innovation: Precision Meets Edibility. Foods 2025, 14, 2066. https://doi.org/10.3390/foods14122066

Xiao S, Yang J, Bi Y, Li Y, Cao Y, Zhou M, Pang G, Dong X, Tong Q. Food 3D Printing Equipment and Innovation: Precision Meets Edibility. Foods. 2025; 14(12):2066. https://doi.org/10.3390/foods14122066

Chicago/Turabian StyleXiao, Shuailei, Junhao Yang, Ye Bi, Yi Li, Yanwu Cao, Mengdi Zhou, Guibing Pang, Xiuping Dong, and Qiang Tong. 2025. "Food 3D Printing Equipment and Innovation: Precision Meets Edibility" Foods 14, no. 12: 2066. https://doi.org/10.3390/foods14122066

APA StyleXiao, S., Yang, J., Bi, Y., Li, Y., Cao, Y., Zhou, M., Pang, G., Dong, X., & Tong, Q. (2025). Food 3D Printing Equipment and Innovation: Precision Meets Edibility. Foods, 14(12), 2066. https://doi.org/10.3390/foods14122066