Ultrasound in the Food Industry: Mechanisms and Applications for Non-Invasive Texture and Quality Analysis

Abstract

1. Introduction

2. Fundamentals of Ultrasound Technology

2.1. Principles of Ultrasound in Food Quality Enhancement

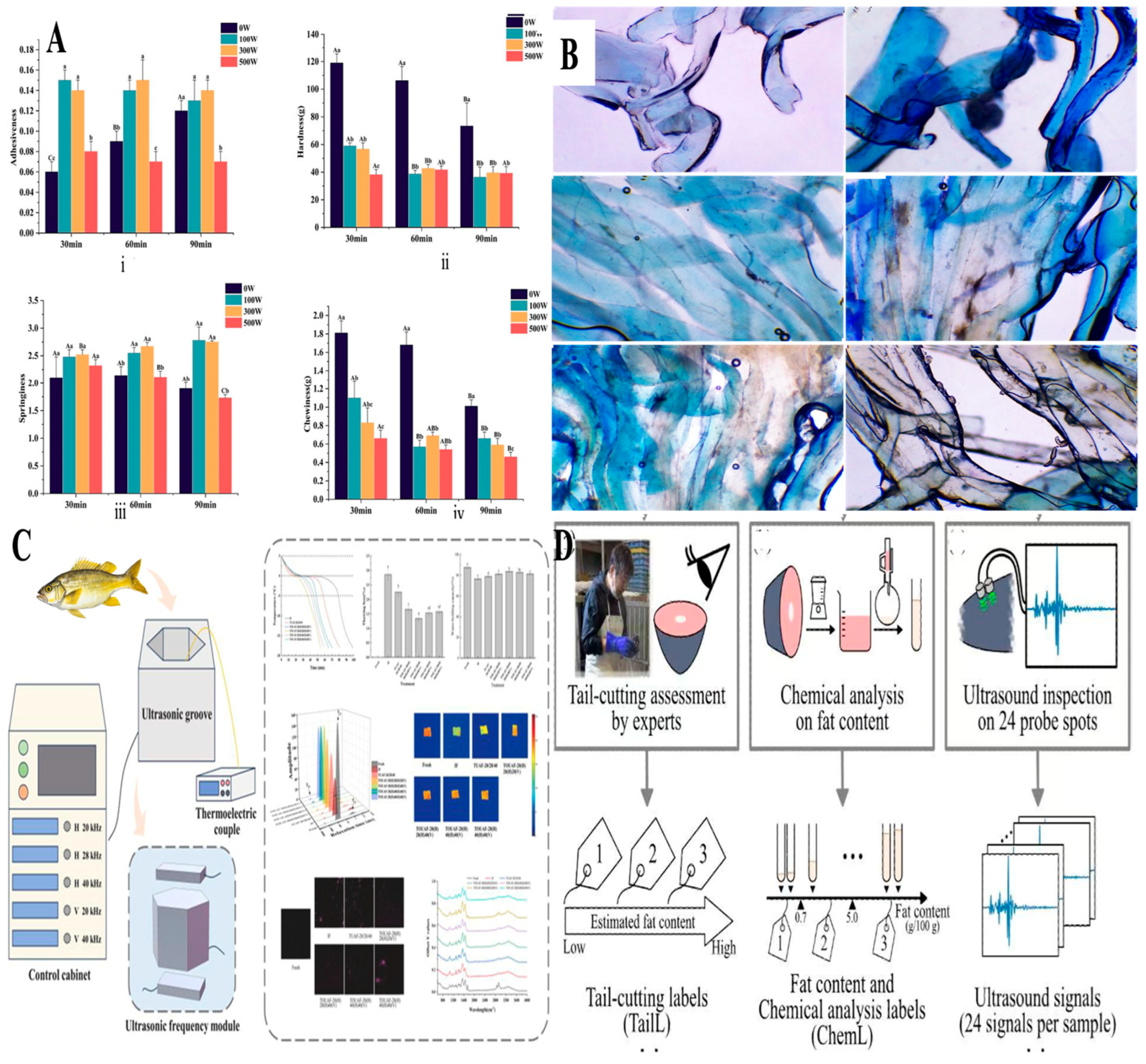

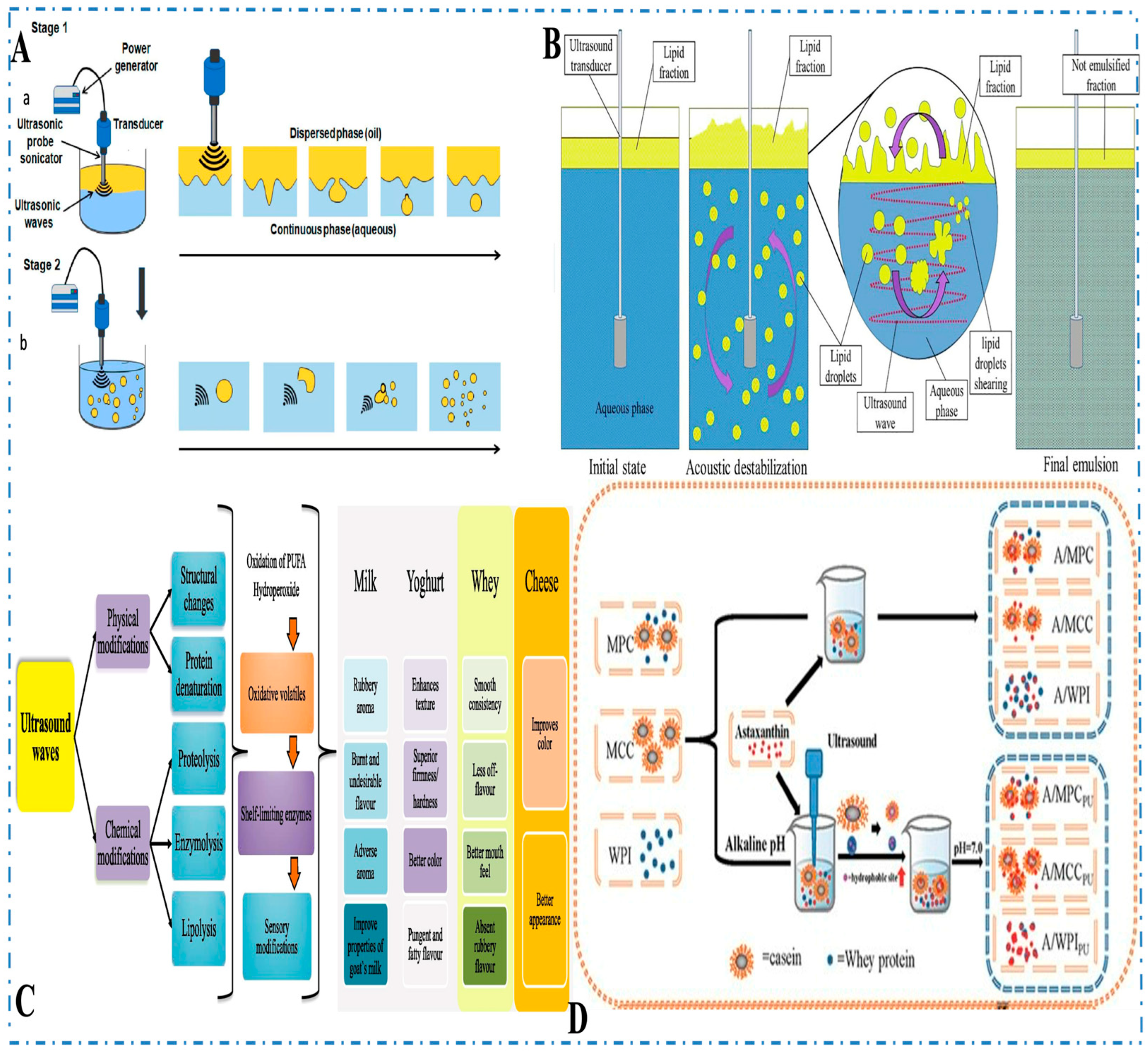

2.2. Ultrasound Application Techniques in Food Quality Enhancement

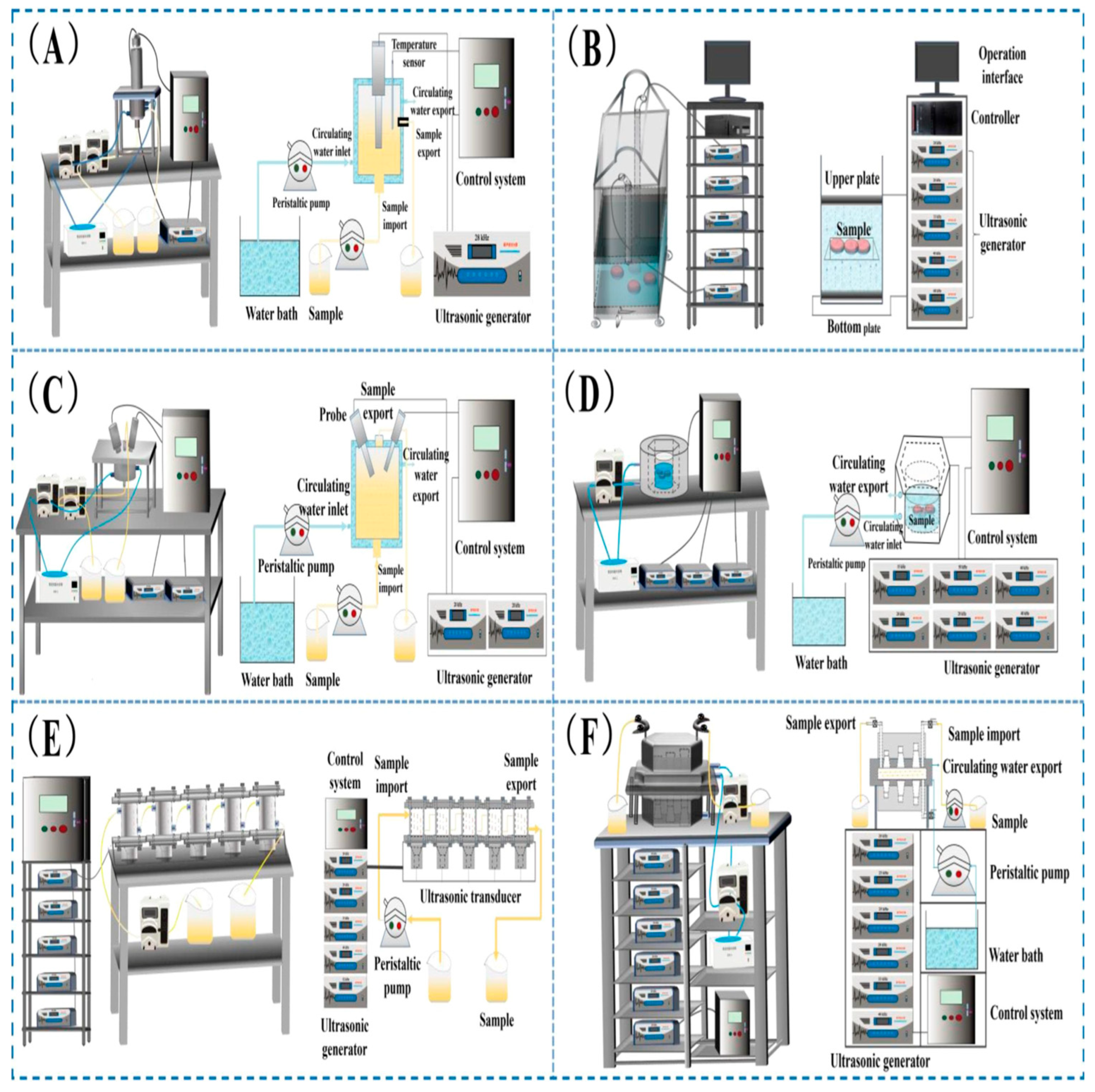

2.3. Instrumentation Design and Process Optimization

3. Mechanisms of Ultrasound Interaction with Food Matrices

3.1. Mechanical Effects of Ultrasound on Food Matrices

3.2. Acoustic and Thermal Effects

3.3. Correlation of Acoustic Properties with Texture

4. Ultrasound for Comprehensive Quality Assessments

4.1. Moisture Content and Water Distribution

4.2. Fat Content and Distribution

4.3. Structural and Microstructural Alterations

5. Applications of Ultrasound in Food Texture Evaluation

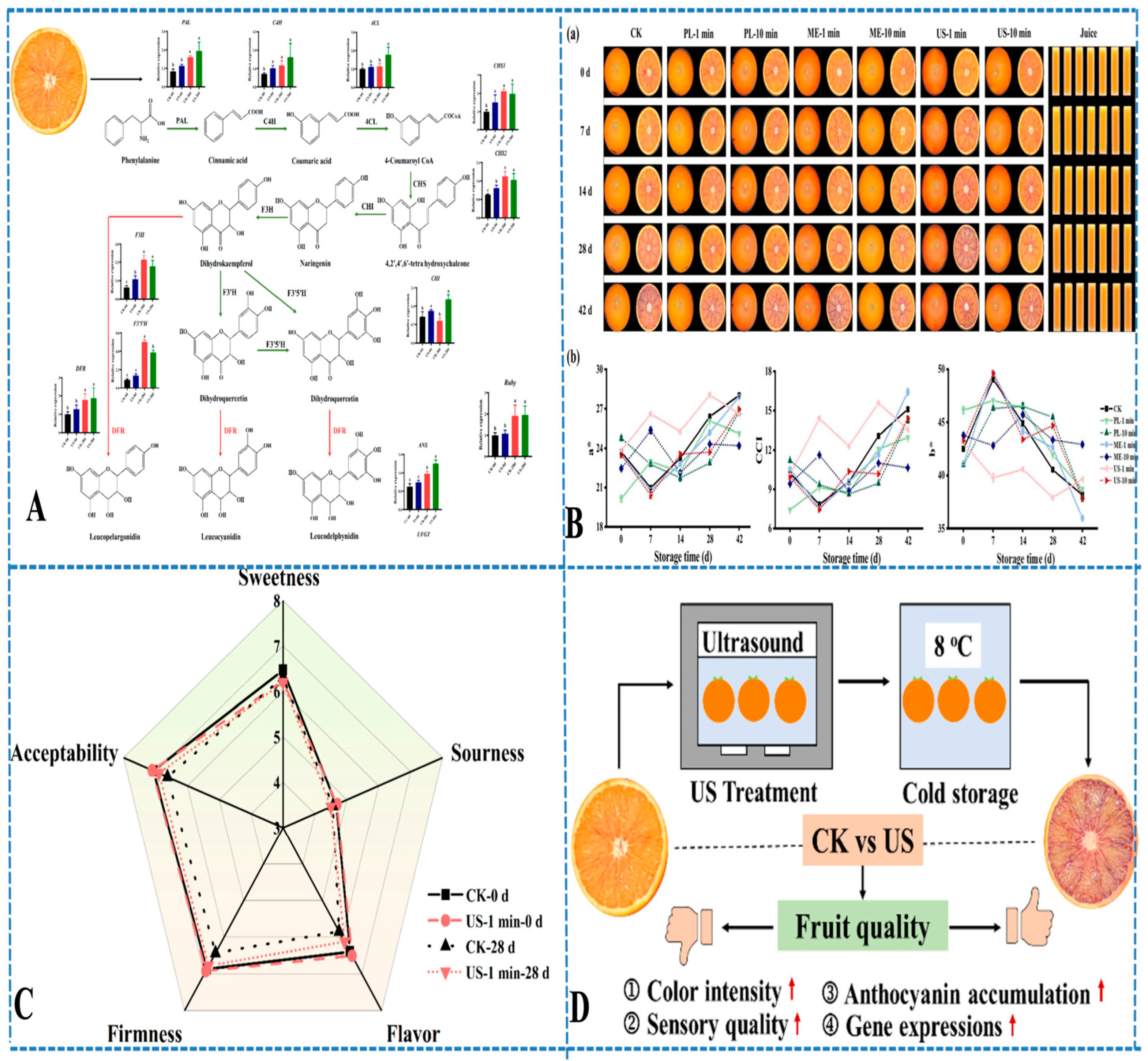

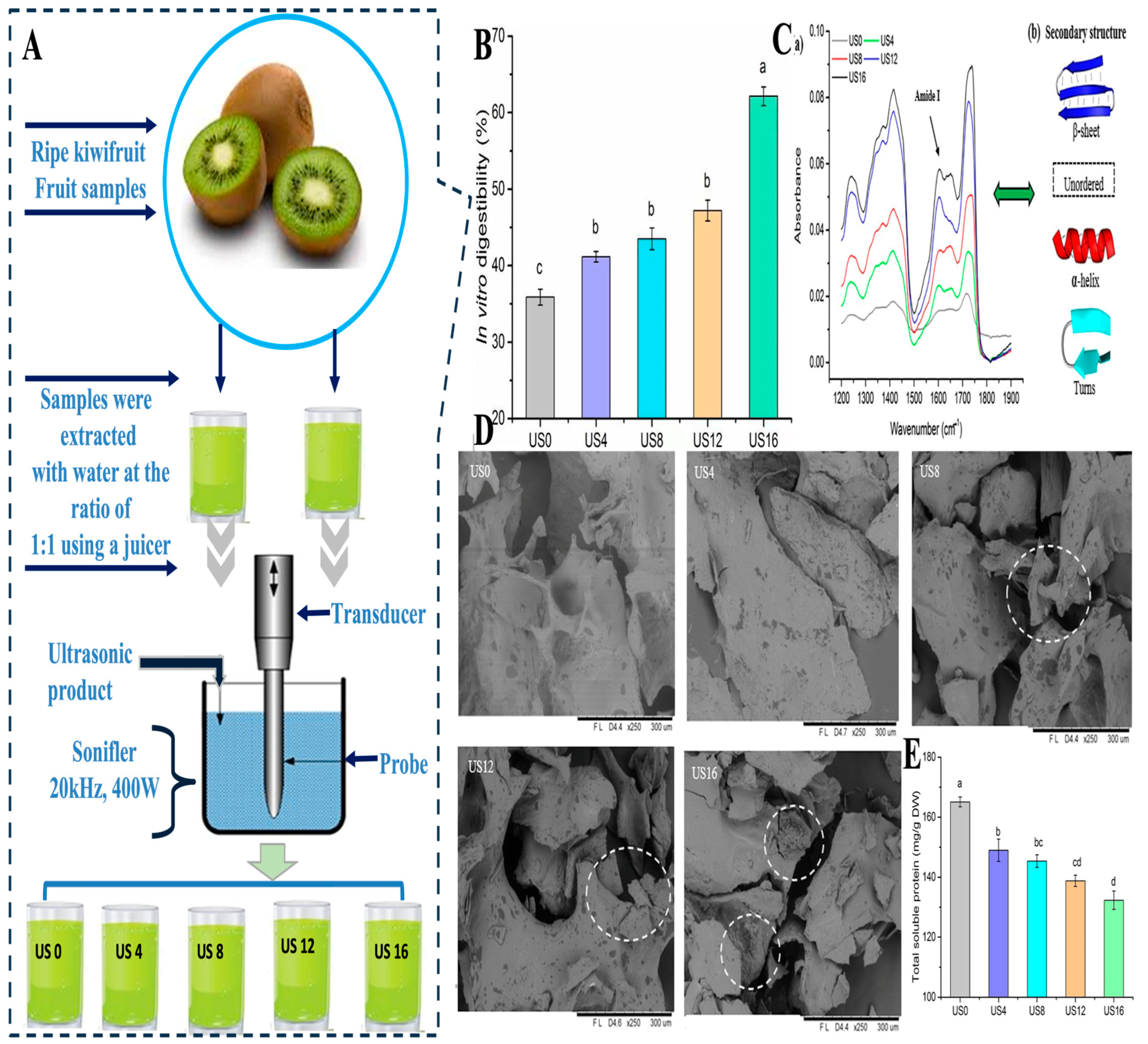

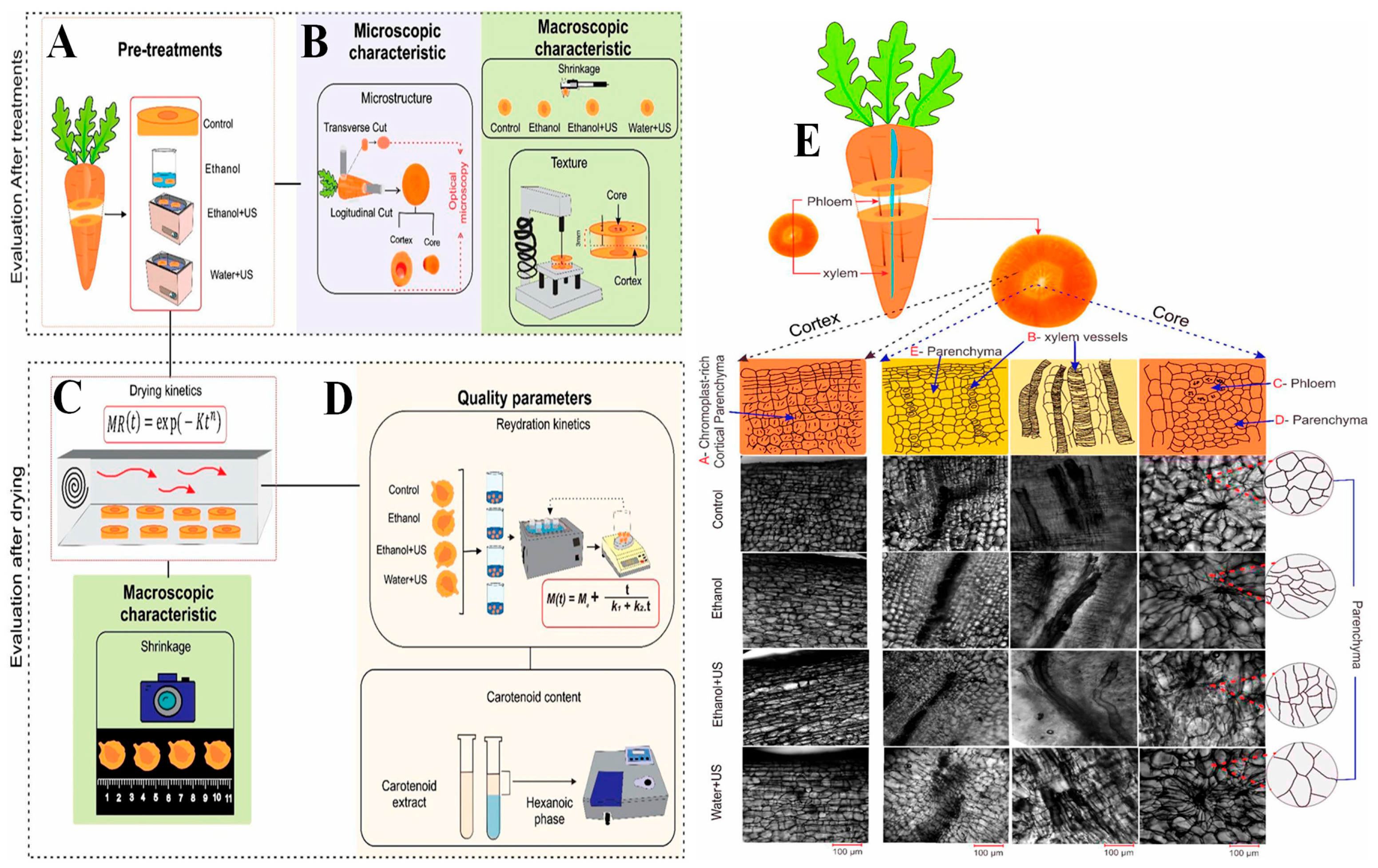

5.1. Applications in Fruits and Vegetables

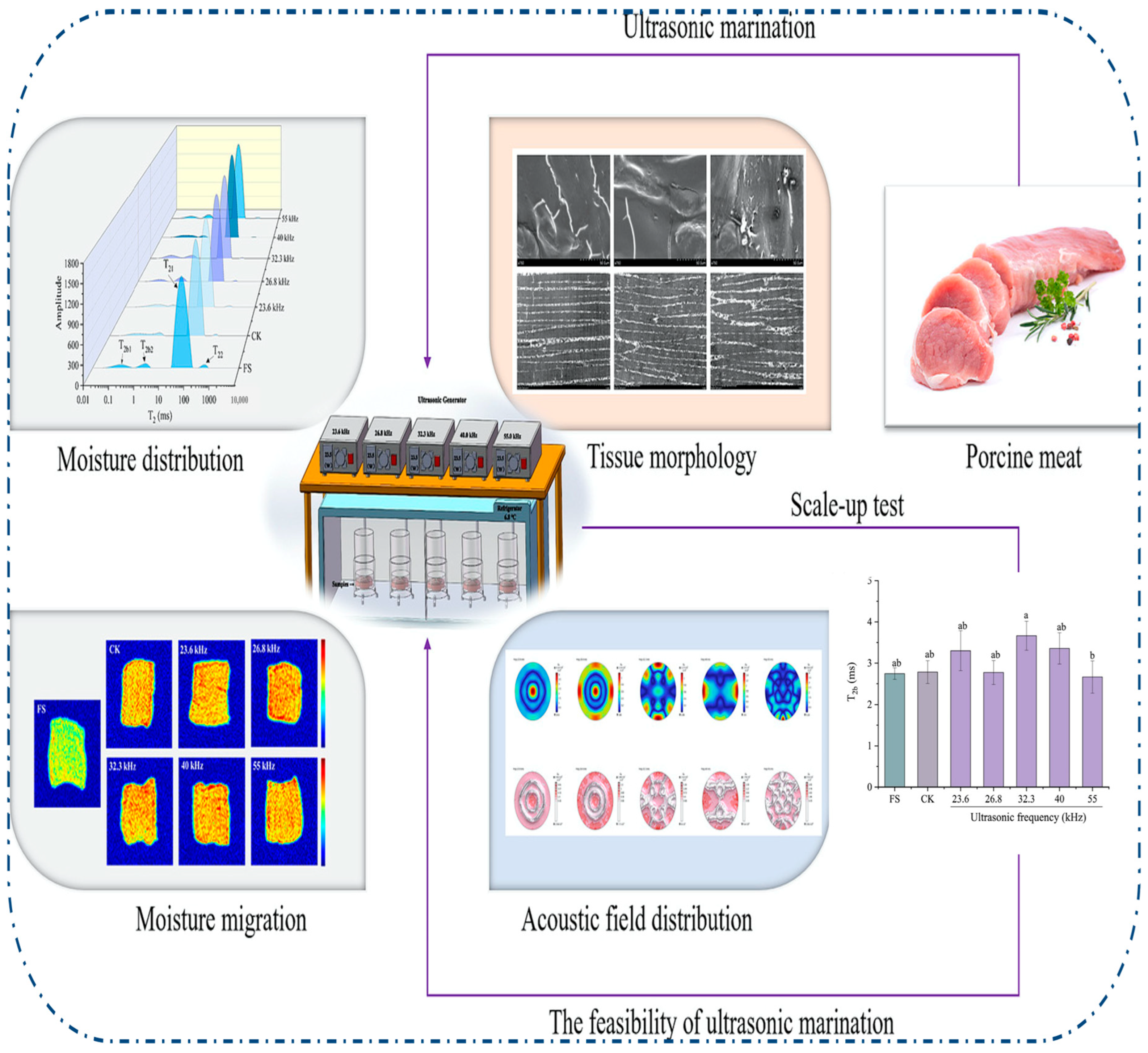

5.2. Meat and Seafood Products

| Meat/Fish | Ultrasound Parameters | Processing Method | Texture | Quality Attributes | Microbial Impact | Nutritional Changes | Observations | References |

|---|---|---|---|---|---|---|---|---|

| Chicken | 40 kHz, 300 W, 10–40 min | In brine | Improved at 10–20 min, reduced hardness at >40 min | Enhanced juiciness, improved marinade absorption | Reduced bacterial growth, extended shelf life | No major nutrient loss, protein structure preserved | Optimal texture at 10–20 min; longer durations reduced firmness | [121,122] |

| Beef | 20 kHz, 200–400 W, 10–30 min | Direct ultrasound | Increased tenderness | Improved water-holding capacity, better color stability | Significant microbial reduction | Slight increase in protein digestibility | Short treatments improved texture; prolonged exposure led to oversoftening | [123,124] |

| Pork | 22 kHz, 250 W, 5–25 min | Immersion in ultrasound bath | Tenderized, reduced chewiness | Enhanced water retention, better fat distribution | Reduced spoilage bacteria, slower lipid oxidation | Maintained fat integrity, minimal nutrient loss | Best results at 15 min; longer times led to excessive softening | [125] |

| Salmon | 25–40 kHz, 150–350 W, 5–20 min | Direct ultrasound | Improved firmness | Reduced lipid oxidation, extended shelf life | Inhibited bacterial growth, delayed spoilage | Retained omega-3 fatty acids | Low-frequency treatments preserved quality and texture | [126] |

| Cod | 30 kHz, 180 W, 10–15 min | In brine | More elastic, improved texture | Enhanced protein gelation, reduced cooking loss | Lower microbial counts, increased freshness duration | Maintained protein quality, slight fat breakdown | 10 min optimized texture without compromising firmness | [127] |

| Lamb | 35 kHz, 250 W, 15–30 min | Direct ultrasound | Increased tenderness, softer texture | Improved flavor absorption, reduced oxidation | Pathogen reduction, extended storage stability | Slight protein degradation at higher exposure | 15 min ideal for texture; longer treatments risked excessive softening | [128] |

| Shrimp | 40 kHz, 300 W, 10 min | In brine | Firm, crisp texture | Improved shell removal, better water retention | Lower microbial load, reduced spoilage | Maintained protein and mineral content | Short ultrasound treatments improved peeling efficiency and texture | [129] |

| Goose | 25 kHz, 300 W, 15 min | Direct ultrasound | Softer, juicier meat | Better fat distribution, improved marination | Reduced spoilage organisms | Maintained protein content, improved digestibility | 12 min treatment enhanced tenderness and flavor retention | [130] |

| Turkey | 25 kHz, 300 W, 15 min | In marinade | Enhanced tenderness | Improved flavorinfusion, juiciness | Decreased microbial load | Preserved protein content | 20 min treatment yielded optimal results | [131] |

| Duck | 25 kHz, 220 W, 10–15 min | Direct ultrasound | Softer texture | Better fat rendering, uniform cooking | Reduced spoilage organisms | Maintained nutritional profile | 15 min treatment improved tenderness without oversoftening | [132] |

| Tilapia | 40 kHz, 300 W, 5–15 min | In brine | Firmer texture | Enhanced water retention, improved flakiness | Lower bacterial counts | Omega-3 levels preserved | 10 min ultrasound-assisted brining improved texture | [133] |

| Trout | 35 kHz, 250 W, 12 min | Direct ultrasound | Improved firmness | Enhanced color retention, reduced lipid oxidation | Inhibited microbial growth | Nutrient content maintained | 12 min treatment optimized quality | [134] |

| Venison | 28 kHz, 275 W, 10–20 min | In marinade | Increased tenderness | Better marinade uptake, enhanced flavor | Decreased microbial load | Preserved protein integrity | 15 min ultrasound treatment improved texture and flavor | [135] |

| Goat | 30 kHz, 250 W, 15–25 min | Direct ultrasound | Softer texture | Improved juiciness, reduced cooking loss | Reduced spoilage bacteria | Maintained nutritional value | 20 min treatment yielded optimal tenderness | [136] |

| Mackerel | 32 kHz, 200 W, 5–15 min | In brine | Enhanced firmness | Improved protein solubility, better texture | Lower microbial counts | Increased essential amino acids | 10 min ultrasound treatment enhanced quality | [137] |

| Herring | 28 kHz, 180 W, 10–15 min | Direct ultrasound | Improved texture | Enhanced lipid stability, extended shelf life | Inhibited bacterial proliferation | Omega-3 content preserved | 15 min treatment optimized quality | [138] |

| Rabbit | 35 kHz, 240 W, 10–15 min | In marinade | Increased tenderness | Better flavor absorption, juiciness | Decreased microbial load | Preserved protein content | 12 min ultrasound-assisted marination improved texture | [139] |

| Crab | 25 kHz, 300 W, 10 min | Direct ultrasound | Improved tenderness | Enhanced flavor extraction | Reduced microbial load | Maintained protein content | Effective in reducing cooking time | [140] |

| Mussels | 22 kHz, 250 W, 5 min | Immersion in ultrasound bath | Firmer texture | Enhanced water retention | Lower microbial counts | Maintained mineral content | Improved shelf life | [141] |

| Squid | 25 kHz, 220 W, 10 min | Direct ultrasound | Softer texture | Improved moisture retention | Reduced spoilage organisms | Preserved protein integrity | Enhanced tenderness | [142] |

| Clams | 30 kHz, 180 W, 8 min | In brine | Improved firmness | Enhanced flavor retention | Decreased microbial load | Maintained nutrient content | Extended shelf life | [143] |

| Lobster | 28 kHz, 250 W, 12 min | Direct ultrasound | Increased tenderness | Better flavor absorption | Reduced spoilage bacteria | Preserved nutritional value | Improved texture and taste | [144] |

| Crawfish | 35 kHz, 200 W, 10 min | In marinade | Softer texture | Enhanced flavor infusion | Decreased microbial load | Maintained nutrient profile | Improved tenderness and flavor | [145] |

5.3. Processed Dairy Products

| Dairy Product | Ultrasound Parameters | Observed Effects | Quality Attributes | Sensory Impact | References |

|---|---|---|---|---|---|

| Milk | High-intensity ultrasound 20 kHz, 63 °C, 30 min | Reduction in fat globule size, improved homogenization, enhanced microbial inactivation | Improved stability and shelf life | Minimal impact on flavor and taste | [164,165] |

| Yogurt | High-intensity ultrasound 20 kHz, 31 W, 60 min | Improved rheological properties, enhanced texture, reduced syneresis | Increased viscosity and firmness | Enhanced mouthfeel and consumer acceptability | [166,167] |

| Cheese | High-intensity ultrasound 20 kHz, 400 W, 10 min | Accelerated ripening, improved texture, enhanced flavor development | Uniform texture and consistent quality | Potential enhancement of flavor profiles | [168] |

| Whey Protein | High-intensity ultrasound 20 kHz, 400 W, 15 min | Reduction in protein aggregate size, improved solubility, enhanced functional properties | Better emulsification and foaming properties | Neutral impact on sensory characteristics | [169,170] |

| Ice Cream | High-intensity ultrasound 20 kHz, 150 W, 5 min | Improved emulsification, smoother texture, reduced ice crystal size | Creamier consistency and enhanced overrun | Improved sensory properties, such as creaminess and smoothness | [171] |

| Butter | High-intensity ultrasound 20 kHz, 200 W, 10 min | Enhanced fat crystallization, improved spreadability, better texture | Softer texture and easier spreadability | Positive consumer perception due to improved spreadability | [172] |

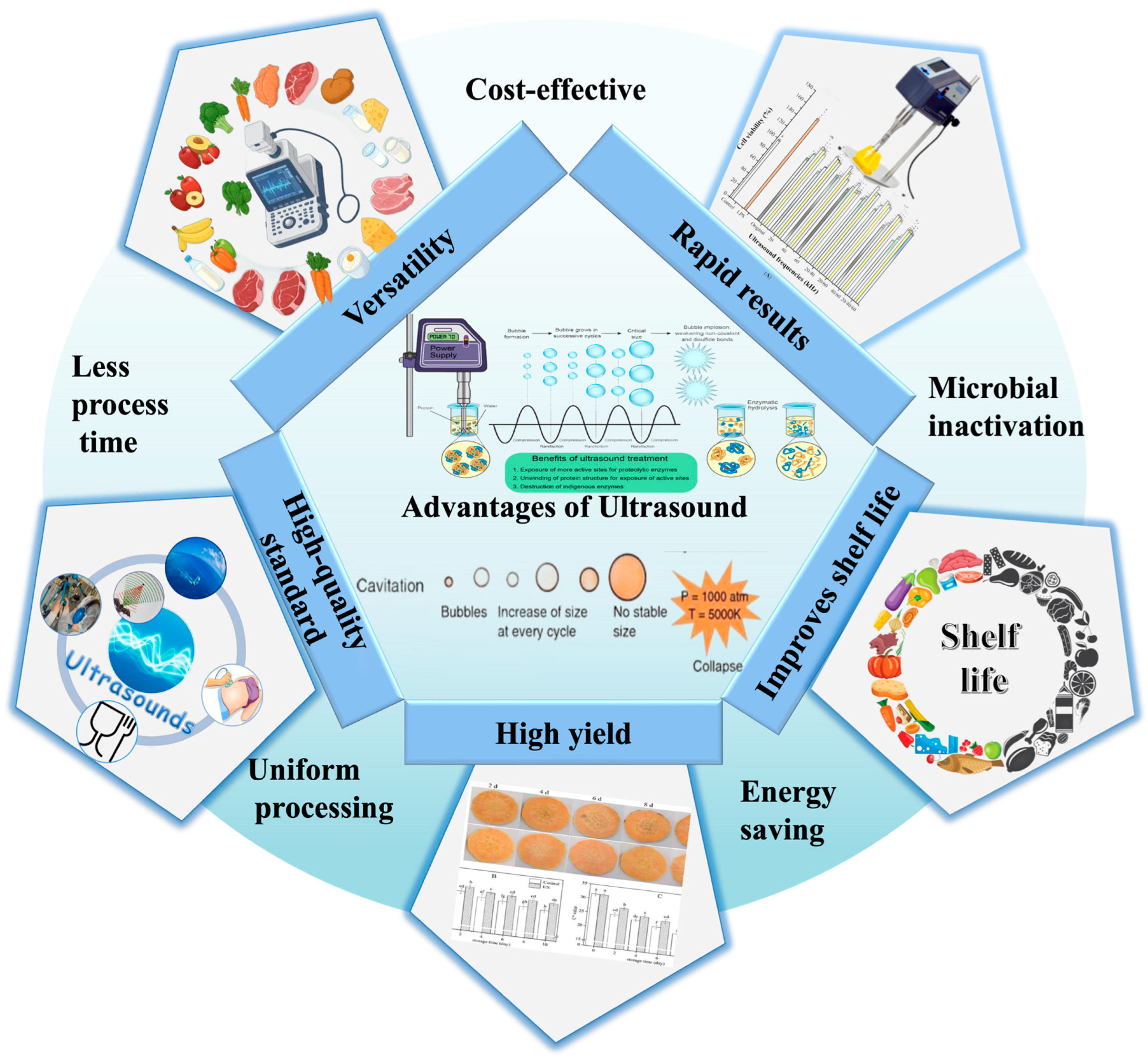

6. Advantages of Ultrasound Technology

6.1. Non-Destructive, Real-Time Quality Monitoring

6.2. Versatility Across Diverse Food Sectors

6.3. Minimization of Sample Loss and Waste Reduction

7. Challenges and Limitations

7.1. Technical Constraints in Ultrasound Analysis

7.2. Economic and Scalability Issues

7.3. Standardization and Protocol Development

8. Innovations and Future Directions

8.1. Integration with Advanced Technologies

8.2. Portable and Handheld Ultrasound Devices

8.3. Expanding Applications in Novel Foods

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kohyama, K. Food Texture–Sensory Evaluation and Instrumental Measurement. In Textural Characteristics of World Foods; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2020; pp. 1–13. [Google Scholar] [CrossRef]

- Xu, B.; Azam, S.M.R.; Feng, M.; Wu, B.; Yan, W.; Zhou, C.; Ma, H. Application of multi-frequency power ultrasound in selected food processing using large-scale reactors: A review. Ultrason. Sonochem. 2021, 81, 105855. [Google Scholar] [CrossRef] [PubMed]

- Rustagi, S. Food Texture and Its Perception, Acceptance and Evaluation. Biosci. Biotechnol. Res. Asia 2020, 17, 651–658. [Google Scholar] [CrossRef]

- Mustapha, A.T.; Zhou, C.; Sun, Y.; Wahia, H.; Sarpong, F.; Owusu-Ansah, P.; Osae, R.; Otu, P.; Ma, H. Simultaneous multifrequency: A possible alternative to improve the efficacy of ultrasound treatment on cherry tomato during storage. J. Food Process. Preserv. 2019, 43, e14083. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, X.; Liang, Q.; Hou, T.; Zhou, H. Effects of Different Working Modes of Ultrasound on Structural Characteristics of Zein and ACE Inhibitory Activity of Hydrolysates. J. Food Qual. 2017, 2017, 7896037. [Google Scholar] [CrossRef]

- Ojha, K.S.; Tiwari, B.K.; O’Donnell, C.P. Chapter Six-Effect of Ultrasound Technology on Food and Nutritional Quality. In Advances in Food and Nutrition Research; Academic Press: Cambridge, MA, USA, 2018; Volume 84, pp. 207–240. [Google Scholar] [CrossRef]

- Anjali; Jena, A.; Bamola, A.; Mishra, S.; Jain, I.; Pathak, N.; Sharma, N.; Joshi, N.; Pandey, R.; Kaparwal, S.; et al. State-of-the-art non-destructive approaches for maturity index determination in fruits and vegetables: Principles, applications, and future directions. Food Prod. Process. Nutr. 2024, 6, 56. [Google Scholar] [CrossRef]

- Qayum, A.; Rashid, A.; Liang, Q.; Wu, Y.; Cheng, Y.; Kang, L.; Liu, Y.; Zhou, C.; Hussain, M.; Ren, X.; et al. Ultrasonic and homogenization: An overview of the preparation of an edible protein-polysaccharide complex emulsion. Compr. Rev. Food Sci. Food Saf. 2023, 22, 4242–4281. [Google Scholar] [CrossRef] [PubMed]

- Cichoski, A.J.; Silva, M.S.; Leães, Y.S.V.; Brasil, C.C.B.; de Menezes, C.R.; Barin, J.S.; Wagner, R.; Campagnol, P.C.B. Ultrasound: A promising technology to improve the technological quality of meat emulsions. Meat Sci. 2019, 148, 150–155. [Google Scholar] [CrossRef]

- Guo, L.; Hong, C.; Wang, W.; Zhang, X.; Chen, J.; Chen, Z.; Ashokkumar, M.; Ma, H. Evaluation of low-temperature ultrasonic marination of pork meat at various frequencies on physicochemical properties, myoglobin levels, and volatile compounds. Meat Sci. 2024, 217, 109606. [Google Scholar] [CrossRef]

- Yeung, C.; Huang, S. Effects of Ultrasound Pretreatment and Ageing Processing on Quality and Tenderness of Pork Loin. J. Food Nutr. Res. 2017, 5, 809. [Google Scholar] [CrossRef]

- Luo, D.; Wu, R.; Zhang, J.; Zhang, K.; Xu, B.; Li, P.; Yuan, Y.; Li, X. Effects of ultrasound assisted dough fermentation on the quality of steamed bread. J. Cereal Sci. 2018, 83, 147–152. [Google Scholar] [CrossRef]

- Amaral, R.D.A.; Benedetti, B.C.; Pujola, M.; Achaerandio, I.; Bachelli, M.L.B. Effect of Ultrasound on Quality of Fresh-Cut Potatoes During Refrigerated Storage. Food Eng. Rev. 2015, 7, 176–184. [Google Scholar] [CrossRef]

- Salehi, F.; Amiri, M.; Ghazvineh, S. Effect of ultrasound combined with edible coating based on guar gum on the physicochemical quality and texture of fried zucchini slices. J. Food Sci. 2025, 90, e17608. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Su, Y.; Zhang, Y.; Zhu, P.; Mei, Z.; Zhou, X.; Yu, H. Potential use of ultrasound to promote fermentation, maturation, and properties of fermented foods: A review. Food Chem. 2021, 357, 129805. [Google Scholar] [CrossRef]

- Johnson, N.A.N.; Adade, S.Y.-S.S.; Ekumah, J.-N.; Li, Y.; Betchem, G.; Issaka, E.; Ma, Y. Efficacy of Ultrasound-Assisted Lactic Acid Fermentation and Its Effect on the Nutritional and Sensory Quality of Novel Chickpea-Based Beverage. Fermentation 2023, 9, 495. [Google Scholar] [CrossRef]

- Shi, H.; Zhou, T.; Wang, X.; Zou, Y.; Wang, D.; Xu, W. Effects of the structure and gel properties of myofibrillar protein on chicken breast quality treated with ultrasound-assisted potassium alginate. Food Chem. 2021, 358, 129873. [Google Scholar] [CrossRef] [PubMed]

- Aslam, R.; Alam, M.S.; Kaur, J.; Panayampadan, A.S.; Dar, O.I.; Kothakota, A.; Pandiselvam, R. Understanding the effects of ultrasound processng on texture and rheological properties of food. J. Texture Stud. 2022, 53, 775–799. [Google Scholar] [CrossRef]

- Amal Sudaraka Samarasinghe, H.G.; Dharmaprema, S.; Manodya, U.; Kariyawasam, K.P.; Samaranayake, U.C. Exploring Impact of the Ultrasound and Combined Treatments on Food Quality: A Comprehensive Review. Turk. J. Agric.-Food Sci. Technol. 2024, 12, 349–365. [Google Scholar] [CrossRef]

- Chen, T.-T.; Zhang, Z.-H.; Wang, Z.-W.; Chen, Z.-L.; Ma, H.; Yan, J.-K. Effects of ultrasound modification at different frequency modes on physicochemical, structural, functional, and biological properties of citrus pectin. Food Hydrocoll. 2021, 113, 106484. [Google Scholar] [CrossRef]

- Alshehhi, M.; Wu, G.; Kit Wayne, C.; Show, P.-L. Ultrasound-Assisted Food Processing: A Mini Review of Mechanisms, Applications, and Challenges. E3S Web Conf. 2023, 428, 02011. [Google Scholar] [CrossRef]

- Chang, H.-J.; Wang, Q.; Tang, C.-H.; Zhou, G.-H. Effects of Ultrasound Treatment on Connective Tissue Collagen and Meat Quality of Beef Semitendinosus Muscle. J. Food Qual. 2015, 38, 256–267. [Google Scholar] [CrossRef]

- Zhou, S.; Chen, W.; Fan, K. Recent advances in combined ultrasound and microwave treatment for improving food processing efficiency and quality: A review. Food Biosci. 2024, 58, 103683. [Google Scholar] [CrossRef]

- Rathnayake, P.Y.; Yu, R.; Yeo, S.E.; Choi, Y.S.; Hwangbo, S.; Yong, H.I. Application of Ultrasound to Animal-Based Food to Improve Microbial Safety and Processing Efficiency. Food Sci. Anim. Resour. 2025, 45, 199–222. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Zhang, X.; Hong, C.; Liu, N.; Ouyang, N.; Chen, J.; Ashokkumar, M.; Ma, H. Application of ultrasound treatment in pork marination: Effects on moisture migration and microstructure. Food Chem. 2024, 447, 138950. [Google Scholar] [CrossRef]

- Bhargava, N.; Mor, R.S.; Kumar, K.; Sharanagat, V.S. Advances in application of ultrasound in food processing: A review. Ultrason. Sonochem. 2021, 70, 105293. [Google Scholar] [CrossRef]

- Dong, T.; Norisuye, T.; Nakanishi, H.; Tran-Cong-Miyata, Q. Particle size distribution analysis of oil-in-water emulsions using static and dynamic ultrasound scattering techniques. Ultrasonics 2020, 108, 106117. [Google Scholar] [CrossRef]

- Dourado, T.C.; Alvarenga, A.V.; Peters, F.C.; Mansur, W.J.; Costa-Félix, R.P.B. Simultaneous use of pulse-echo and through-transmission methods in determining a combined reflection coefficient. Appl. Acoust. 2022, 192, 108700. [Google Scholar] [CrossRef]

- Mustapha, A.T.; Wahia, H.; Ji, Q.; Fakayode, O.A.; Zhang, L.; Zhou, C. Multiple-frequency ultrasound for the inactivation of microorganisms on food: A review. J. Food Process Eng. 2024, 47, e14587. [Google Scholar] [CrossRef]

- Zhang, K.; Gao, G.; Ma, W.; Li, R.; Xiang, D.; Ma, J. A thermo-mechanical coupling load model for high-frequency piezoelectric ultrasonic transducer. Ultrason. Sonochem. 2024, 111, 107148. [Google Scholar] [CrossRef]

- Görgülü, A. Real-time quality analysis of baked goods using advanced technologies. J. Food Eng. 2025, 388, 112359. [Google Scholar] [CrossRef]

- Zhou, W.; Sarpong, F.; Zhou, C. Use of Ultrasonic Cleaning Technology in the Whole Process of Fruit and Vegetable Processing. Foods 2022, 11, 2874. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Zhou, G.; Xu, X. Ultrasound: A reliable method for regulating food component interactions in protein-based food matrices. Trends Food Sci. Technol. 2022, 128, 316–330. [Google Scholar] [CrossRef]

- Nguyen, V.-T.; Sagar, H.J.; Moctar, O.e.; Park, W.-G. Understanding cavitation bubble collapse and rebound near a solid wall. Int. J. Mech. Sci. 2024, 278, 109473. [Google Scholar] [CrossRef]

- Bernardo, Y.A.d.A.; do Rosario, D.K.A.; Conte-Junior, C.A. Principles, Application, and Gaps of High-Intensity Ultrasound and High-Pressure Processing to Improve Meat Texture. Foods 2023, 12, 476. [Google Scholar] [CrossRef]

- Umair, M.; Jabbar, S.; Nasiru, M.M.; Lu, Z.; Zhang, J.; Abid, M.; Murtaza, M.A.; Kieliszek, M.; Zhao, L. Ultrasound-Assisted Extraction of Carotenoids from Carrot Pomace and Their Optimization through Response Surface Methodology. Molecules 2021, 26, 6763. [Google Scholar] [CrossRef]

- Qian, J.; Chen, D.; Zhang, Y.; Gao, X.; Xu, L.; Guan, G.; Wang, F. Ultrasound-Assisted Enzymatic Protein Hydrolysis in Food Processing: Mechanism and Parameters. Foods 2023, 12, 4027. [Google Scholar] [CrossRef]

- Suchintita Das, R.; Tiwari, B.K.; Chemat, F.; Garcia-Vaquero, M. Impact of ultrasound processing on alternative protein systems: Protein extraction, nutritional effects and associated challenges. Ultrason. Sonochem. 2022, 91, 106234. [Google Scholar] [CrossRef]

- Qayum, A.; Rashid, A.; Khan, A.A.; Zhong, M.; Liu, Y.; Hussain, M.; Virk, M.S.; Ahmed, Z.; Rehman, A.; Hussain, A.; et al. Exploring the interface dynamics of emulsion gel via a novel non-destructive technique provides insights into the underlying mechanism of gel formation, water mobility, functionality and structural variations. Food Biosci. 2024, 61, 104721. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; He, R.; Liu, D.; Kumah Mintah, B.; Dabbour, M.; Ma, H. Improvement in enzymolysis efficiency and changes in conformational attributes of corn gluten meal by dual-frequency slit ultrasonication action. Ultrason. Sonochem. 2020, 64, 105038. [Google Scholar] [CrossRef]

- Cheng, Y.; Donkor, P.O.; Ren, X.; Wu, J.; Agyemang, K.; Ayim, I.; Ma, H. Effect of ultrasound pretreatment with mono-frequency and simultaneous dual frequency on the mechanical properties and microstructure of whey protein emulsion gels. Food Hydrocoll. 2019, 89, 434–442. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Y.; Xu, L.; Ma, H. An efficient ultrasound-assisted extraction method of pea protein and its effect on protein functional properties and biological activities. LWT 2020, 127, 109348. [Google Scholar] [CrossRef]

- Juliano, P.; Kutter, A.; Cheng, L.J.; Swiergon, P.; Mawson, R.; Augustin, M.A. Enhanced creaming of milk fat globules in milk emulsions by the application of ultrasound and detection by means of optical methods. Ultrason. Sonochem. 2011, 18, 963–973. [Google Scholar] [CrossRef]

- Yang, X.; Li, Y.; Li, S.; Ren, X.; Olayemi Oladejo, A.; Lu, F.; Ma, H. Effects and mechanism of ultrasound pretreatment of protein on the Maillard reaction of protein-hydrolysate from grass carp (Ctenopharyngodon idella). Ultrason. Sonochem. 2020, 64, 104964. [Google Scholar] [CrossRef] [PubMed]

- Chandrapala, J.; Oliver, C.; Kentish, S.; Ashokkumar, M. Ultrasonics in food processing–Food quality assurance and food safety. Trends Food Sci. Technol. 2012, 26, 88–98. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, Y.; Ren, Z.; Zhang, X.; Duan, H.; Liu, Z.; Wang, X. Food-Grade Pickering Emulsions Stabilized by Ultrasound-Treated Foxtail Millet Prolamin: Characterization and In Vitro Release Behavior of Curcumin. Foods 2025, 14, 417. [Google Scholar] [CrossRef]

- Guillermic, R.M.; Franczyk, A.J.; Kerhervé, S.O.; House, J.D.; Page, J.H.; Koksel, F. Characterization of the mechanical properties of high-moisture meat analogues using low-intensity ultrasound: Linking mechanical properties to textural and nutritional quality attributes. Food Res. Int. 2023, 173, 113193. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, B.; Zhou, C.; Atungulu, G.G.; Xu, K.; Ma, H.; Ye, X.; Abdualrahman, M.A.Y. Surface topography, nano-mechanics and secondary structure of wheat gluten pretreated by alternate dual-frequency ultrasound and the correlation to enzymolysis. Ultrason. Sonochem. 2016, 31, 267–275. [Google Scholar] [CrossRef]

- Khan, A.A.; Ullah, M.W.; Qayum, A.; Khalifa, I.; Ul-Islam, M.; Bacha, S.A.S.; Zeb, U.; Yao, F.-J.; Alharbi, S.A.; Shrahili, M.; et al. Structure-property relationship of ultrasound-assisted nanoemulsion-impregnated bioactive polysaccharide films for enhanced shelf life of mushrooms. Food Packag. Shelf Life 2024, 46, 101372. [Google Scholar] [CrossRef]

- Xu, B.-g.; Zhang, M.; Bhandari, B.; Sun, J.; Gao, Z. Infusion of CO2 in a solid food: A novel method to enhance the low-frequency ultrasound effect on immersion freezing process. Innov. Food Sci. Emerg. Technol. 2016, 35, 194–203. [Google Scholar] [CrossRef]

- Wu, Z.; Ma, W.; Xue, S.J.; Zhou, A.; Liu, Q.; Hui, A.; Shen, Y.; Zhang, W.; Shi, J. Ultrasound-assisted immersion thawing of prepared ground pork: Effects on thawing time, product quality, water distribution and microstructure. LWT 2022, 163, 113599. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, M.; Xu, B. Application of ultrasonic technology in postharvested fruits and vegetables storage: A review. Ultrason. Sonochem. 2020, 69, 105261. [Google Scholar] [CrossRef]

- Wang, H.; Gao, Z.; Guo, X.; Gao, S.; Wu, D.; Liu, Z.; Wu, P.; Xu, Z.; Zou, X.; Meng, X. Changes in Textural Quality and Water Retention of Spiced Beef under Ultrasound-Assisted Sous-Vide Cooking and Its Possible Mechanisms. Foods 2022, 11, 2251. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.-g.; Zhang, M.; Bhandari, B.; Cheng, X.-f.; Sun, J. Effect of Ultrasound Immersion Freezing on the Quality Attributes and Water Distributions of Wrapped Red Radish. Food Bioprocess Technol. 2015, 8, 1366–1376. [Google Scholar] [CrossRef]

- Carrillo-Lopez, L.M.; Garcia-Galicia, I.A.; Tirado-Gallegos, J.M.; Sanchez-Vega, R.; Huerta-Jimenez, M.; Ashokkumar, M.; Alarcon-Rojo, A.D. Recent advances in the application of ultrasound in dairy products: Effect on functional, physical, chemical, microbiological and sensory properties. Ultrason. Sonochem. 2021, 73, 105467. [Google Scholar] [CrossRef] [PubMed]

- Fabbri, G.; Gianesella, M.; Gallo, L.; Morgante, M.; Contiero, B.; Muraro, M.; Boso, M.; Fiore, E. Application of Ultrasound Images Texture Analysis for the Estimation of Intramuscular Fat Content in the Longissimus Thoracis Muscle of Beef Cattle after Slaughter: A Methodological Study. Animals 2021, 11, 1117. [Google Scholar] [CrossRef]

- Li, K.; Ma, H.; Li, S.; Zhang, C.; Dai, C. Effect of Ultrasound on Alkali Extraction Protein from Rice Dreg Flour. J. Food Process Eng. 2017, 40, e12377. [Google Scholar] [CrossRef]

- Huang, L.; Ding, X.; Dai, C.; Ma, H. Changes in the structure and dissociation of soybean protein isolate induced by ultrasound-assisted acid pretreatment. Food Chem. 2017, 232, 727–732. [Google Scholar] [CrossRef]

- Wang, Q.; Gu, C.; Wei, R.; Luan, Y.; Liu, R.; Ge, Q.; Yu, H.; Wu, M. Enhanced gelling properties of myofibrillar protein by ultrasound-assisted thermal-induced gelation process: Give an insight into the mechanism. Ultrason. Sonochem. 2023, 94, 106349. [Google Scholar] [CrossRef]

- Yan, Y.; Huang, L.; Shen, J.; Chen, Y.; He, R. The impact of ultrasound synergized with salt on the structure and loading characteristics of whey protein isolate-chitosan complexes. Int. J. Biol. Macromol. 2025, 307, 141769. [Google Scholar] [CrossRef]

- Chávez-Martínez, A.; Reyes-Villagrana, R.A.; Rentería-Monterrubio, A.L.; Sánchez-Vega, R.; Tirado-Gallegos, J.M.; Bolivar-Jacobo, N.A. Low and High-Intensity Ultrasound in Dairy Products: Applications and Effects on Physicochemical and Microbiological Quality. Foods 2020, 9, 1688. [Google Scholar] [CrossRef]

- Cheng, Y.; Shi, X.; Yeboah, G.B.; Chen, L.; Wu, J. Effect of Multi-Mode Divergent Ultrasound Pretreatment on Hardness, Microstructure and Digestion of Acid-Induced Whey Protein Gels. Foods 2024, 13, 1926. [Google Scholar] [CrossRef]

- Song, Y.; Xiao, J.; Li, L.; Wan, L.; Li, B.; Zhang, X. Ultrasound treatment of crystalline oil-in-water emulsions stabilized by sodium caseinate: Impact on emulsion stability through altered crystallization behavior in the oil globules. Ultrason. Sonochem. 2024, 106, 106897. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Fu, L.; Zhao, Y.-Y.; Xue, S.-W.; Wang, P.; Xu, X.-L.; Bai, Y.-H. Use of high-intensity ultrasound to improve emulsifying properties of chicken myofibrillar protein and enhance the rheological properties and stability of the emulsion. Food Hydrocoll. 2020, 98, 105275. [Google Scholar] [CrossRef]

- Akdeniz, V.; Akalın, A.S. New approach for yoghurt and ice cream production: High-intensity ultrasound. Trends Food Sci. Technol. 2019, 86, 392–398. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, C.; Liu, Z.; Xu, H.; Wei, B.; Wang, B.; Sun, Q.; Zhou, C.; Ma, H. Starches modification with rose polyphenols under multi-frequency power ultrasonic fields: Effect on physicochemical properties and digestion behavior. Ultrason. Sonochem. 2023, 98, 106515. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Chen, J.; Chitrakar, B.; Li, H.; Wang, J.; Wei, B.; Zhou, C.; Ma, H. Effects of flat sweep frequency and pulsed ultrasound on the activity, conformation and microstructure of mushroom polyphenol oxidase. Ultrason. Sonochem. 2022, 82, 105908. [Google Scholar] [CrossRef]

- Alenyorege, E.A.; Ma, H.; Ayim, I.; Zhou, C.; Wu, P.; Hong, C.; Osae, R. Effect of multi-frequency ultrasound surface washing treatments on Escherichia coli inactivation and some quality characteristics of non-heading Chinese cabbage. J. Food Process. Preserv. 2018, 42, e13747. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Y.; Okonkwo, C.E.; Chen, L.; Zhou, C. Multimode ultrasonic-assisted decontamination of fruits and vegetables: A review. Food Chem. 2024, 450, 139356. [Google Scholar] [CrossRef]

- Khuriyati, N.; Kasih, A.N.; Perdana, M.R.A.; Izdihar, F.Y.; Falah, M.A.F.; Wagiman. A comparative study of acoustic and ultrasonic nondestructive testing for evaluating melon quality. IOP Conf. Ser. Earth Environ. Sci. 2024, 1377, 012006. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, Y.; Liu, F.; Chen, J.; Sun, Y.; Ye, X.; Liu, D.; Cheng, H. Ultrasound Treatment Improves Fruit Quality of Postharvest Blood Oranges (Citrus sinensis L. Osbeck): Anthocyanin Enrichment and Its Biosynthesis. J. Agric. Food Chem. 2023, 71, 14013–14026. [Google Scholar] [CrossRef]

- Amanor-Atiemoh, R.; Zhou, C.; Wahia, H.; Mustapha, A.T.; Rashid, M.T.; Sampson, G.; Amoa-Owusu, A.; Ma, H.; Zhou, R. Acoustically-aided osmo-dehydration pretreatments under pulsed vacuum dryer for apple slices: Drying kinetics, thermodynamics, and quality attributes. J. Food. Sci. 2020, 85, 3909–3919. [Google Scholar] [CrossRef]

- Xu, B.; Chen, J.; Sylvain Tiliwa, E.; Yan, W.; Roknul Azam, S.M.; Yuan, J.; Wei, B.; Zhou, C.; Ma, H. Effect of multi-mode dual-frequency ultrasound pretreatment on the vacuum freeze-drying process and quality attributes of the strawberry slices. Ultrason. Sonochem. 2021, 78, 105714. [Google Scholar] [CrossRef]

- Xu, B.; Sylvain Tiliwa, E.; Wei, B.; Wang, B.; Hu, Y.; Zhang, L.; Mujumdar, A.S.; Zhou, C.; Ma, H. Multi-frequency power ultrasound as a novel approach improves intermediate-wave infrared drying process and quality attributes of pineapple slices. Ultrason. Sonochem. 2022, 88, 106083. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wu, B.; Lu, D.; Pan, Z.; Ma, H. Tri-frequency ultrasound as pretreatment to infrared drying of carrots: Impact on enzyme inactivation, color changes, nutrition quality parameters and microstructures. Int. J. Food Eng. 2021, 17, 275–284. [Google Scholar] [CrossRef]

- Gao, K.; Liu, B.; Wu, B.; Guo, Y.; Song, C.; Nan, S.; Dai, J.; Shen, Y.; Ma, H. A Study on the Effect Mechanism of Pectin Modification on the Carrot Cell Wall’s Texture Formation under Ultrasonic and Infrared Drying. Agriculture 2024, 14, 803. [Google Scholar] [CrossRef]

- Garcia-Noguera, J.; Oliveira, F.; Gallao, M.; Weller, C.; Rodrigues, S.; Fernandes, F. Ultrasound-Assisted Osmotic Dehydration of Strawberries: Effect of Pretreatment Time and Ultrasonic Frequency. Dry. Technol. 2010, 28, 294–303. [Google Scholar] [CrossRef]

- Rashid, A.; Qayum, A.; Liang, Q.; Kang, L.; Raza, H.; Chi, Z.; Chi, R.; Ren, X.; Ma, H. Preparation and characterization of ultrasound-assisted essential oil-loaded nanoemulsions stimulated pullulan-based bioactive film for strawberry fruit preservation. Food Chem. 2023, 422, 136254. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, M.; Devahastin, S.; Yu, D. Effect of ultrasound-assisted osmotic dehydration pretreatments on drying and quality characteristics of pulsed fluidized bed microwave freeze-dried strawberries. LWT 2021, 145, 111300. [Google Scholar] [CrossRef]

- Allahdad, Z.; Nasiri, M.; Varidi, M.; Varidi, M.J. Effect of sonication on osmotic dehydration and subsequent air-drying of pomegranate arils. J. Food Eng. 2019, 244, 202–211. [Google Scholar] [CrossRef]

- Ricce, C.; Rojas, M.L.; Miano, A.C.; Siche, R.; Augusto, P.E.D. Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef]

- Guo, Y.; Wu, B.; Guo, X.; Ding, F.; Pan, Z.; Ma, H. Effects of power ultrasound enhancement on infrared drying of carrot slices: Moisture migration and quality characterizations. LWT 2020, 126, 109312. [Google Scholar] [CrossRef]

- Corrêa, J.L.G.; Rasia, M.C.; Mulet, A.; Cárcel, J.A. Influence of ultrasound application on both the osmotic pretreatment and subsequent convective drying of pineapple (Ananas comosus). Innov. Food Sci. Emerg. Technol. 2017, 41, 284–291. [Google Scholar] [CrossRef]

- La Fuente, C.I.A.; Zabalaga, R.F.; Tadini, C.C. Combined effects of ultrasound and pulsed-vacuum on air-drying to obtain unripe banana flour. Innov. Food Sci. Emerg. Technol. 2017, 44, 123–130. [Google Scholar] [CrossRef]

- Sun, M.; Su, Y.; Chen, Y.; Li, J.; Ren, A.; Xu, B. Reducing the oil absorption and tailoring starch properties in banana slices by integrated ultrasound in infrared frying. Innov. Food Sci. Emerg. Technol. 2024, 95, 103695. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Q.-S.; Wang, X.-D.; Hong, Z.-d.; Zhao, B. Pretreatment of ultrasound combined vacuum enhances the convective drying efficiency and physicochemical properties of okra (Abelmoschus esculentus). LWT 2019, 112, 108201. [Google Scholar] [CrossRef]

- Chen, Z.-L.; Wang, C.; Ma, H.; Ma, Y.; Yan, J.-K. Physicochemical and functional characteristics of polysaccharides from okra extracted by using ultrasound at different frequencies. Food Chem. 2021, 361, 130138. [Google Scholar] [CrossRef]

- Bozkir, H.; Rayman Ergün, A.; Serdar, E.; Metin, G.; Baysal, T. Influence of ultrasound and osmotic dehydration pretreatments on drying and quality properties of persimmon fruit. Ultrason. Sonochem. 2019, 54, 135–141. [Google Scholar] [CrossRef]

- Ren, F.; Perussello, C.A.; Zhang, Z.; Kerry, J.P.; Tiwari, B.K. Impact of ultrasound and blanching on functional properties of hot-air dried and freeze dried onions. LWT 2018, 87, 102–111. [Google Scholar] [CrossRef]

- Tao, Y.; Li, D.; Siong Chai, W.; Show, P.L.; Yang, X.; Manickam, S.; Xie, G.; Han, Y. Comparison between airborne ultrasound and contact ultrasound to intensify air drying of blackberry: Heat and mass transfer simulation, energy consumption and quality evaluation. Ultrason. Sonochem. 2021, 72, 105410. [Google Scholar] [CrossRef]

- Tao, Y.; Han, M.; Gao, X.; Han, Y.; Show, P.-L.; Liu, C.; Ye, X.; Xie, G. Applications of water blanching, surface contacting ultrasound-assisted air drying, and their combination for dehydration of white cabbage: Drying mechanism, bioactive profile, color and rehydration property. Ultrason. Sonochem. 2019, 53, 192–201. [Google Scholar] [CrossRef]

- Jahanbakhshi, A.; Yeganeh, R.; Momeny, M. Influence of ultrasound pre-treatment and temperature on the quality and thermodynamic properties in the drying process of nectarine slices in a hot air dryer. J. Food Process. Preserv. 2020, 44, e14818. [Google Scholar] [CrossRef]

- Ren, M.; Ren, Z.; Chen, L.; Zhou, C.; Okonkwo, C.E.; Mujumdar, A.S. Comparison of ultrasound and ethanol pretreatments before catalytic infrared drying on physicochemical properties, drying, and contamination of Chinese ginger (Zingiber officinale Roscoe). Food Chem. 2022, 386, 132759. [Google Scholar] [CrossRef] [PubMed]

- Zhu, R.; Shen, J.; Law, C.L.; Ma, X.; Li, D.; Han, Y.; Kiani, H.; Manickam, S.; Tao, Y. Combined calcium pretreatment and ultrasonic/microwave drying to dehydrate black chokeberry: Novel mass transfer modeling and metabolic pathways of polyphenols. Innov. Food Sci. Emerg. Technol. 2023, 83, 103215. [Google Scholar] [CrossRef]

- Tekin, Z.H.; Baslar, M. The effect of ultrasound-assisted vacuum drying on the drying rate and quality of red peppers. J. Therm. Anal. Calorim. 2018, 132, 1131–1143. [Google Scholar] [CrossRef]

- Salehi, F.; Inanloodoghouz, M. Effects of gum-based coatings combined with ultrasonic pretreatment before drying on quality of sour cherries. Ultrason. Sonochem. 2023, 100, 106633. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Yu, X.; Yagoub, A.E.A.; Owusu-Ansah, P.; Wahia, H.; Ma, H.; Zhou, C. Effects of low frequency multi-mode ultrasound and it’s washing solution’s interface properties on freshly cut cauliflower. Food Chem. 2022, 366, 130683. [Google Scholar] [CrossRef]

- Zhang, Q.; Wan, F.; Zang, Z.; Jiang, C.; Xu, Y.; Huang, X. Effect of ultrasonic far-infrared synergistic drying on the characteristics and qualities of wolfberry (Lycium barbarum L.). Ultrason. Sonochem. 2022, 89, 106134. [Google Scholar] [CrossRef] [PubMed]

- Lu, F.; Zhai, R.; Ruan, S.; Yang, X.; Alenyorege, E.A.; Wang, Y.; Ding, Y.; Ma, H. Enhancement of ultrasound on the dynamic decolorization of wolfberry (Lycium barbarum) polysaccharides. LWT 2021, 145, 111384. [Google Scholar] [CrossRef]

- Vivek, K.; Subbarao, K.V.; Srivastava, B. Optimization of postharvest ultrasonic treatment of kiwifruit using RSM. Ultrason. Sonochem. 2016, 32, 328–335. [Google Scholar] [CrossRef]

- Forghani, F.; Oh, D.-H. Hurdle enhancement of slightly acidic electrolyzed water antimicrobial efficacy on Chinese cabbage, lettuce, sesame leaf and spinach using ultrasonication and water wash. Food Microbiol. 2013, 36, 40–45. [Google Scholar] [CrossRef]

- Azam, S.M.R.; Ma, H.; Xu, B.; Devi, S.; Stanley, S.L.; Siddique, M.A.B.; Mujumdar, A.S.; Zhu, J. Multi-frequency multi-mode ultrasound treatment for removing pesticides from lettuce (Lactuca sativa L.) and effects on product quality. LWT 2021, 143, 111147. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, C. Combined effects of aqueous chlorine dioxide and ultrasonic treatments on postharvest storage quality of plum fruit (Prunus salicina L.). Postharvest Biol. Technol. 2011, 61, 117–123. [Google Scholar] [CrossRef]

- Zhang, X.-t.; Zhang, M.; Devahastin, S.; Guo, Z. Effect of Combined Ultrasonication and Modified Atmosphere Packaging on Storage Quality of Pakchoi (Brassica chinensis L.). Food Bioprocess Technol. 2019, 12, 1573–1583. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, Z.; Lin, X.; Zhang, Y. A meta-analysis of the effects of ultrasonic pretreatment on the characteristics of dried fruits and vegetables. J. Food Process Eng. 2024, 47, e14689. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Kranthi Vanga, S.; Raghavan, V. Influence of high-intensity ultrasound on the IgE binding capacity of Act d 2 allergen, secondary structure, and In-vitro digestibility of kiwifruit proteins. Ultrason. Sonochem. 2021, 71, 105409. [Google Scholar] [CrossRef]

- Hong, C.; Zhou, H.-C.; Zhao, Y.-M.; Ma, H. Ultrasonic washing as an abiotic elicitor to induce the accumulation of phenolics of fresh-cut red cabbages: Effects on storage quality and microbial safety. Front. Nutr. 2022, 9, 1006440. [Google Scholar] [CrossRef] [PubMed]

- Santos, K.C.; Guedes, J.S.; Rojas, M.L.; Carvalho, G.R.; Augusto, P.E.D. Enhancing carrot convective drying by combining ethanol and ultrasound as pre-treatments: Effect on product structure, quality, energy consumption, drying and rehydration kinetics. Ultrason. Sonochem. 2021, 70, 105304. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Feng, M.; Chitrakar, B.; Cheng, J.; Wei, B.; Wang, B.; Zhou, C.; Ma, H. Multi-frequency power thermosonication treatments of clear strawberry juice: Impact on color, bioactive compounds, flavor volatiles, microbial and polyphenol oxidase inactivation. Innov. Food Sci. Emerg. Technol. 2023, 84, 103295. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Chen, L.; Wang, Y.; Okonkwo, C.E.; Yagoub, A.E.A.; Wahia, H.; Zhou, C. Application of ultrasound and its real-time monitoring of the acoustic field during processing of tofu: Parameter optimization, protein modification, and potential mechanism. Compr. Rev. Food Sci. Food Saf. 2023, 22, 2747–2772. [Google Scholar] [CrossRef]

- Caraveo-Suarez, R.O.; Garcia-Galicia, I.A.; Santellano-Estrada, E.; Carrillo-Lopez, L.M.; Huerta-Jimenez, M.; Vargas-Bello-Pérez, E.; Alarcon-Rojo, A.D. High-Frequency Focused Ultrasound on Quality Traits of Bovine Triceps brachii Muscle. Foods 2021, 10, 2074. [Google Scholar] [CrossRef]

- Caraveo-Suarez, R.O.; Garcia-Galicia, I.A.; Santellano-Estrada, E.; Carrillo-Lopez, L.M.; Huerta-Jimenez, M.; Morales-Rodriguez, S.; Vargas-Bello-Pérez, E.; Alarcon-Rojo, A.D. Ultrasound as a Potential Technology to Improve the Quality of Meat Produced from a Mexican Autochthonous Bovine Breed. Sustainability 2022, 14, 3886. [Google Scholar] [CrossRef]

- Mengdi, W.; Haile, M.; Huimin, L. Effects of different modes of ultrasonic assisted low-temperature curing on beef quality. Food Mach. 2023, 39, 177–182, 233. [Google Scholar]

- Guo, L.; Xu, X.; Zhang, X.; Chen, Z.; He, R.; Ma, H. Application of simultaneous ultrasonic curing on pork (Longissimus dorsi): Mass transport of NaCl, physical characteristics, and microstructure. Ultrason. Sonochem. 2023, 92, 106267. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-Y.; Yan, J.-K.; Ding, Y.; Ma, H. Effects of ultrasound on the thawing of quick-frozen small yellow croaker (Larimichthys polyactis) based on TMT-labeled quantitative proteomic. Food Chem. 2022, 366, 130600. [Google Scholar] [CrossRef]

- Bai, H.; Li, L.; Wu, Y.; Chen, S.; Zhao, Y.; Cai, Q.; Wang, Y. Ultrasound improves the low-sodium salt curing of sea bass: Insights into the effects of ultrasound on texture, microstructure, and flavor characteristics. Ultrason. Sonochem. 2023, 100, 106597. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Raghavan, V. High-intensity ultrasound treatment of Atlantic cod: Impact on nutrients, structure, sensory quality, bioactivity, and in-vitro digestibility. Food Res. Int. 2024, 186, 114363. [Google Scholar] [CrossRef]

- Yang, W.; Xu, Z.; Mei, J.; Xie, J. Effects of triple-frequency orthogonal ultrasound-assisted freezing on the quality properties of large yellow croaker (Larimichthys crocea). LWT 2025, 217, 117429. [Google Scholar] [CrossRef]

- Yagi, M.; Sakai, A.; Yasutomi, S.; Suzuki, K.; Kashikura, H.; Goto, K. Assessment of Tail-Cutting in Frozen Albacore (Thunnus alalunga) Through Ultrasound Inspection and Chemical Analysis. Foods 2024, 13, 3860. [Google Scholar] [CrossRef]

- Li, P.; Sun, L.; Wang, J.; Wang, Y.; Zou, Y.; Yan, Z.; Zhang, M.; Wang, D.; Xu, W. Effects of combined ultrasound and low-temperature short-time heating pretreatment on proteases inactivation and textural quality of meat of yellow-feathered chickens. Food Chem. 2021, 355, 129645. [Google Scholar] [CrossRef]

- Cao, C.; Xiao, Z.; Tong, H.; Tao, X.; Gu, D.; Wu, Y.; Xu, Z.; Ge, C. Effect of ultrasound-assisted enzyme treatment on the quality of chicken breast meat. Food Bioprod. Process. 2021, 125, 193–203. [Google Scholar] [CrossRef]

- Chen, X.; Zou, Y.; Wang, D.; Xiong, G.; Xu, W. Effects of ultrasound pretreatment on the extent of Maillard reaction and the structure, taste and volatile compounds of chicken liver protein. Food Chem. 2020, 331, 127369. [Google Scholar] [CrossRef]

- Soltani Firouz, M.; Sardari, H.; Alikhani Chamgordani, P.; Behjati, M. Power ultrasound in the meat industry (freezing, cooking and fermentation): Mechanisms, advances and challenges. Ultrason. Sonochem. 2022, 86, 106027. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Li, C.; Liu, X.; He, L.; Zhang, M.; Huang, S.; Huang, S.; Liu, Y.; Zhang, Y.; Jin, G. A multivariate insight into the organoleptic properties of porcine muscle by ultrasound-assisted brining: Protein oxidation, water state and microstructure. LWT 2022, 159, 113136. [Google Scholar] [CrossRef]

- Inguglia, E.S.; Granato, D.; Kerry, J.P.; Tiwari, B.K.; Burgess, C.M. Ultrasound for Meat Processing: Effects of Salt Reduction and Storage on Meat Quality Parameters. Appl. Sci. 2021, 11, 117. [Google Scholar] [CrossRef]

- Nilsuwan, K.; Thongnoi, S.; Prodpran, T.; Benjakul, S. Properties and Characteristics of Film from Salmon Skin Acid-Soluble Collagen Solution as Influenced by Ultrasonication Process. Foods 2025, 14, 1088. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, X.; Luan, J.; Zhu, W.; Xu, Y.; Yi, S.; Li, J.; Wang, J.; Li, X. Effects of ultrasound pretreatment at different powers on flavor characteristics of enzymatic hydrolysates of cod (Gadus macrocephalus) head. Food Res. Int. 2022, 159, 111612. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Zang, M.; Qiao, X.; Wang, S.; Zhao, B.; Shi, Y.; Bai, J.; Wu, J. Effects of ultrasound-assisted thawing on lamb meat quality and oxidative stability during refrigerated storage using non-targeted metabolomics. Ultrason. Sonochem. 2022, 90, 106211. [Google Scholar] [CrossRef]

- Marques, L.P.; Bernardo, Y.A.A.; Conte-Junior, C.A. Applications of high-intensity ultrasound on shrimp: Potential, constraints, and prospects in the extraction and retrieval of bioactive compounds, safety, and quality. J. Food Sci. 2024, 89, 3148–3166. [Google Scholar] [CrossRef]

- Shi, W.; Wang, Y.; Chen, X.; Hu, H.; Chen, X.; Mintah, B.K.; Dabbour, M.; Meng, X.; Zhang, Z.; He, R.; et al. Thawing of goose meat by simultaneous dual frequency ultrasound for process efficiency: Thawing rate, quality attributes, structural characteristics. Innov. Food Sci. Emerg. Technol. 2024, 92, 103588. [Google Scholar] [CrossRef]

- Nalbant Tepeoğlu, H.; Karakaya, S. Effect of ultrasound and marination on functional and sensory properties, protein profiles and bioaccessibility of amino acids in turkey meat. Int. J. Food Sci. Technol. 2024, 59, 6558–6570. [Google Scholar] [CrossRef]

- Sun, H.; Zhao, Y.; Zhao, J.; Sun, J. Ultrasound thawing for improving the eating quality and off-flavor of frozen duck meat and its possible mechanisms. LWT 2023, 187, 115314. [Google Scholar] [CrossRef]

- Cuevas-Acuña, D.A.; Arias-Moscoso, J.L.; Torres-Arreola, W.; Cadena-Cadena, F.; Valdez-Melchor, R.G.; Chaparro-Hernandez, S.; Santacruz-Ortega, H.d.C.; Ruiz-Cruz, S. High-Intensity Ultrasound Pulses Effect on Physicochemical and Antioxidant Properties of Tilapia (Oreochromis niloticus) Skin Gelatin. Appl. Sci. 2020, 10, 1004. [Google Scholar] [CrossRef]

- Torres Neto, L.; Monteiro, M.L.G.; da Silva, B.D.; Machado, M.A.M.; Mutz, Y.d.S.; Conte-Junior, C.A. Ultrasound-Assisted Nanoemulsion Loaded with Optimized Antibacterial Essential Oil Blend: A New Approach against Escherichia coli, Staphylococcus aureus, and Salmonella Enteritidis in Trout (Oncorhynchus mykiss) Fillets. Foods 2024, 13, 1569. [Google Scholar] [CrossRef] [PubMed]

- Abril, B.; Bou, R.; García-Pérez, J.V.; Benedito, J. Role of Enzymatic Reactions in Meat Processing and Use of Emerging Technologies for Process Intensification. Foods 2023, 12, 1940. [Google Scholar] [CrossRef]

- Kumar, P.; Ahmed, M.A.; Hayat, M.N.; Abubakar, A.A.; Rahman, M.M.; Ismail-Fitry, M.R.; Kaka, U.; Sazili, A.Q. Ultrasound application and its effect on quality attributes of marinated goat meat. Indian J. Small Rumin. 2024, 30, 293–298. [Google Scholar] [CrossRef]

- Cropotova, J.; Kvangarsnes, K.; Rustad, T.; Stangeland, J.; Roda, G.; Fanzaga, M.; Bartolomei, M.; Lammi, C. Effect of ultrasound treatment on quality parameters and health promoting activity of fish protein hydrolysates extracted from side streams of Atlantic mackerel (Scomber scombrus). Front. Nutr. 2024, 11, 1446485. [Google Scholar] [CrossRef]

- Santschi, M.V.; Undeland, I.; Abdollahi, M. Ultrasound-aided pH-shift processing for resource-smart valorization of salmon and herring side streams. Ultrason. Sonochem. 2023, 99, 106539. [Google Scholar] [CrossRef] [PubMed]

- Carrillo-Lopez, L.M.; Robledo, D.; Martínez, V.; Huerta-Jimenez, M.; Titulaer, M.; Alarcon-Rojo, A.D.; Chavez-Martinez, A.; Luna-Rodriguez, L.; Garcia-Flores, L.R. Post-mortem ultrasound and freezing of rabbit meat: Effects on the physicochemical quality and weight loss. Ultrason. Sonochem. 2021, 79, 105766. [Google Scholar] [CrossRef]

- Condón-Abanto, S.; Arroyo, C.; Álvarez, I.; Brunton, N.; Whyte, P.; Lyng, J.G. An assessment of the application of ultrasound in the processing of ready-to-eat whole brown crab (Cancer pagurus). Ultrason. Sonochem. 2018, 40, 497–504. [Google Scholar] [CrossRef]

- Yu, C.; Wu, F.; Cha, Y.; Qin, Y.; Du, M. Effects of ultrasound on structure and functional properties of mussel (Mytilus edulis) protein isolates. J. Food Process. Preserv. 2018, 42, e13690. [Google Scholar] [CrossRef]

- Valdez-Hurtado, S.; López-Bermúdez, L.S.; Higuera-Barraza, O.A.; Del Toro-Sanchez, C.L.; Ruiz-Cruz, S.; Suárez-Jiménez, M.G.; Marquez-Rios, E. Effect of ultrasonication time on the functional properties of giant squid (Dosidicus gigas) mantle protein concentrate. Food Biosci. 2019, 27, 1–5. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Wang, Y.; Wang, J.; Xu, Y.; Yi, S.; Zhu, W.; Mi, H.; Li, T.; Li, J. Combined ultrasound and heat pretreatment improve the enzymatic hydrolysis of clam (Aloididae aloidi) and the flavor of hydrolysates. Innov. Food Sci. Emerg. Technol. 2021, 67, 102596. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Luo, X.; Su, P.; Balakrishnan, B.; Zhang, W. Highly efficient recovery of nutritional proteins from Australian Rock Lobster heads (Jasus edwardsii) by integrating ultrasonic extraction and chitosan co-precipitation. Innov. Food Sci. Emerg. Technol. 2020, 60, 102308. [Google Scholar] [CrossRef]

- Sun, R.; Xu, W.; Xiong, L.; Jiang, N.; Xia, J.; Zhu, Y.; Wang, C.; Liu, Q.; Ma, Y.; Luo, H. The combined effects of ultrasound and plasma-activated water on microbial inactivation and quality attributes of crayfish during refrigerated storage. Ultrason. Sonochem. 2023, 98, 106517. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, S.; Zhang, A.; Zhang, H.; Wang, R.; Wang, X.; Hu, Y.; Ma, H.; Zhou, C. Green efficient preparation and on-line monitoring: Hybrid effect of okra pectin and controlled-temperature ultrasound on physicochemical properties of low-fat yogurt. J. Food Eng. 2024, 370, 111963. [Google Scholar] [CrossRef]

- Su, J.; Cavaco-Paulo, A. Effect of ultrasound on protein functionality. Ultrason. Sonochem. 2021, 76, 105653. [Google Scholar] [CrossRef]

- Soltani Firouz, M.; Sardari, H.; Soofiabadi, M.; Hosseinpour, S. Ultrasound assisted processing of milk: Advances and challenges. J. Food Process Eng. 2023, 46, e14173. [Google Scholar] [CrossRef]

- Mu, Q.; Su, H.; Zhou, Q.; Xiao, S.; Zhu, L.; Xu, X.; Pan, S.; Hu, H. Effect of ultrasound on functional properties, flavor characteristics, and storage stability of soybean milk. Food Chem. 2022, 381, 132158. [Google Scholar] [CrossRef] [PubMed]

- Bermudez-Aguirre, D.; Niemira, B.A. Pasteurization of Foods with Ultrasound: The Present and the Future. Appl. Sci. 2022, 12, 10416. [Google Scholar] [CrossRef]

- Sun, Y.; Roos, Y.H.; Miao, S. Modifying physicochemical properties, rheology, and creaming stability of milk fat globule and membrane through ultrasound treatment. Ultrason. Sonochem. 2024, 111, 107058. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L.; Fu, X.; Li, X.; Liu, L.; Wang, X.; Zhang, J.; Zhou, W. Addition of Phospholipids Improved the Physical Stability and Fat Globule Structure of Processed Milk. Foods 2025, 14, 375. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, Q.; Zhou, T.; Liu, L.; Wang, Y.; Li, X.; Zhang, X.; Dang, X.; Jean Eric-Parfait Kouame, K. Ultrasound-induced structural changes of different milk fat globule membrane protein-phospholipids complexes and their effects on physicochemical and functional properties of emulsions. Ultrason. Sonochem. 2024, 103, 106799. [Google Scholar] [CrossRef] [PubMed]

- Vargas, S.A.; Ruiz-López, I.I.; Amador-Espejo, G.G.; Ruiz-Espinosa, H. Use of high-intensity ultrasound and micellar casein concentrate addition for improving whey Ricotta cheese production. Int. J. Dairy Technol. 2024, 77, 518–531. [Google Scholar] [CrossRef]

- Huang, G.; Chen, S.; Tang, Y.; Dai, C.; Sun, L.; Ma, H.; He, R. Stimulation of low intensity ultrasound on fermentation of skim milk medium for yield of yoghurt peptides by Lactobacillus paracasei. Ultrason. Sonochem. 2019, 51, 315–324. [Google Scholar] [CrossRef]

- Stepišnik Perdih, T.; Zupanc, M.; Dular, M. Revision of the mechanisms behind oil-water (O/W) emulsion preparation by ultrasound and cavitation. Ultrason. Sonochem. 2019, 51, 298–304. [Google Scholar] [CrossRef]

- Plüisch, C.S.; Wittemann, A. Assembly of Nanoparticles into “Colloidal Molecules”: Toward Complex and yet Defined Colloids with Exiting Perspectives. In Advances in Colloid Science; IntechOpen: London, UK, 2016. [Google Scholar]

- Kaci, M.; Meziani, S.; Arab-Tehrany, E.; Gillet, G.; Desjardins-Lavisse, I.; Desobry, S. Emulsification by high frequency ultrasound using piezoelectric transducer: Formation and stability of emulsifier free emulsion. Ultrason. Sonochem. 2014, 21, 1010–1017. [Google Scholar] [CrossRef] [PubMed]

- Chouliara, E.; Georgogianni, K.G.; Kanellopoulou, N.; Kontominas, M.G. Effect of ultrasonication on microbiological, chemical and sensory properties of raw, thermized and pasteurized milk. Int. Dairy J. 2010, 20, 307–313. [Google Scholar] [CrossRef]

- Wang, X.P.; Wang, C.F.; Zhao, X.Q.; Ma, M.J.; Li, Z.H.; Jiang, H.; Zhang, X.N.; Yuan, C.Z. Comparison of milk protein concentrate, micellar casein, and whey protein isolate in loading astaxanthin after the treatment of ultrasound-assisted pH shifting. J. Dairy Sci. 2024, 107, 141–154. [Google Scholar] [CrossRef]

- Pegu, K.; Arya, S.S. Non-thermal processing of milk: Principles, mechanisms and effect on milk components. J. Agric. Food Res. 2023, 14, 100730. [Google Scholar] [CrossRef]

- Ren, X.; Liang, Q.; Zhang, X.; Hou, T.; Li, S.; Ma, H. Stability and antioxidant activities of corn protein hydrolysates under simulated gastrointestinal digestion. Cereal Chem. 2018, 95, 760–769. [Google Scholar] [CrossRef]

- D’Incecco, P.; Limbo, S.; Hogenboom, J.A.; Pellegrino, L. Novel technologies for extending the shelf life of drinking milk: Concepts, research trends and current applications. LWT 2021, 148, 111746. [Google Scholar] [CrossRef]

- Astráin-Redín, L.; Skipnes, D.; Cebrián, G.; Álvarez-Lanzarote, I.; Rode, T.M. Effect of the Application of Ultrasound to Homogenize Milk and the Subsequent Pasteurization by Pulsed Electric Field, High Hydrostatic Pressure, and Microwaves. Foods 2023, 12, 1457. [Google Scholar] [CrossRef] [PubMed]

- Hussain, M.; Zhong, H.; Hussain, K.; Manzoor, M.F.; Qayum, A.; Liu, X.; Xu, J.; Hussain, A.; Ahsan, H.M.; Guan, R. Emerging high intensity ultrasound for soymilk in boosting bioactivity, amino acids release, reducing anti-nutritional factors and allergenicity. Food Biosci. 2024, 59, 104138. [Google Scholar] [CrossRef]

- Rathnakumar, K.; Surangna, J.; Nancy, A.; Pranav, V.; Priyamvada, T.; Bharathi, R.; Gayathri, B.; Karthik, S.B.; Seema, R.; Sarvesh, R.; et al. Ultrasonic processing: Effects on the physicochemical and microbiological aspects of dairy products. Crit. Rev. Biotechnol. 2024, 44, 1638–1652. [Google Scholar] [CrossRef]

- Umego, E.C.; He, R.; Huang, G.; Dai, C.; Ma, H. Ultrasound-assisted fermentation: Mechanisms, technologies, and challenges. J. Food Process. Preserv. 2021, 45, e15559. [Google Scholar] [CrossRef]

- Scudino, H.; Guimarães, J.T.; Ramos, G.L.P.A.; Santillo, A.; Pimentel, T.C.; Cruz, A.G.; Albenzio, M. High-intensity ultrasound in cheese processing. Curr. Opin. Food Sci. 2023, 50, 101004. [Google Scholar] [CrossRef]

- Vargas, S.A.; Delgado-Macuil, R.J.; Ruiz-Espinosa, H.; Rojas-López, M.; Amador-Espejo, G.G. High-intensity ultrasound pretreatment influence on whey protein isolate and its use on complex coacervation with kappa carrageenan: Evaluation of selected functional properties. Ultrason. Sonochem. 2021, 70, 105340. [Google Scholar] [CrossRef]

- Cheng, Y.; Ofori Donkor, P.; Yeboah, G.B.; Ayim, I.; Wu, J.; Ma, H. Modulating the in vitro digestion of heat-set whey protein emulsion gels via gelling properties modification with sequential ultrasound pretreatment. LWT 2021, 149, 111856. [Google Scholar] [CrossRef]

- Nazarewicz, S.; Kozłowicz, K.; Gładyszewska, B.; Rząd, K.; Matwijczuk, A.; Kobus, Z.; Ivanišová, E.; Harangozo, L.; Skrzypek, T. Effects of Ultrasound Treatment on the Physical and Chemical Properties of Ice Cream with a Strawberry Seed Oil Oleogel. Sustainability 2023, 15, 8975. [Google Scholar] [CrossRef]

- Lee, J.; Martini, S. Modifying the physical properties of butter using high-intensity ultrasound. J. Dairy Sci. 2019, 102, 1918–1926. [Google Scholar] [CrossRef]

- Astráin-Redín, L.; Alejandre, M.; Raso, J.; Cebrián, G.; Álvarez, I. Direct Contact Ultrasound in Food Processing: Impact on Food Quality. Front. Nutr. 2021, 8, 633070. [Google Scholar] [CrossRef]

- Lin, Y.; Ji, M.; Qijun, W.; and Sun, D.-W. Applications of machine learning techniques for enhancing nondestructive food quality and safety detection. Crit. Rev. Food Sci. Nutr. 2023, 63, 1649–1669. [Google Scholar] [CrossRef] [PubMed]

- Bowler, A.; Ozturk, S.; di Bari, V.; Glover, Z.J.; Watson, N.J. Machine learning and domain adaptation to monitor yoghurt fermentation using ultrasonic measurements. Food Control 2023, 147, 109622. [Google Scholar] [CrossRef]

- Meškinytė, E.; Jukna, V.; Zigmantaitė, V.; Ilina, O.; Kučinskas, A. The Effectiveness of the Use of Ultrasound Methodology (Applied to Live Animals) to Assess the Quality of Meat. Animals 2025, 15, 872. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Wang, X.; Hu, Y.; Abiola Fakayode, O.; Ma, H.; Zhou, C.; Hu, Z.; Xia, A.; Li, Q. Dual-frequency multi-angle ultrasonic processing technology and its real-time monitoring on physicochemical properties of raw soymilk and soybean protein. Ultrason. Sonochem. 2021, 80, 105803. [Google Scholar] [CrossRef]

- Guo, Z.; Jayan, H. Fast Nondestructive Detection Technology and Equipment for Food Quality and Safety. Foods 2023, 12, 3744. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Li, S.; Zhang, H.; Ma, H. In Situ Monitoring of the Effect of Ultrasound on the Sulfhydryl Groups and Disulfide Bonds of Wheat Gluten. Molecules 2018, 23, 1376. [Google Scholar] [CrossRef]

- Charoux, C.M.G.; O’Donnell, C.P.; Tiwari, B.K. Chapter 9-Ultrasound Processing and Food Quality. In Ultrasound: Advances for Food Processing and Preservation; Bermudez-Aguirre, D., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 215–235. [Google Scholar]

- Mahmoud, M.Z.; Davidson, R.; Abdelbasset, W.K.; Fagiry, M.A. The new achievements in ultrasonic processing of milk and dairy products. J. Radiat. Res. Appl. Sci. 2022, 15, 199–205. [Google Scholar] [CrossRef]

- Dabbour, M.; He, R.; Mintah, B.; Tang, Y.; Ma, H. Ultrasound assisted enzymolysis of sunflower meal protein: Kinetics and thermodynamics modeling. J. Food Process Eng. 2018, 41, e12865. [Google Scholar] [CrossRef]

- Xing, Z.; Xiaoshan, H.; Tang, Y.; He, R.; Mintah, B.; Dabbour, M.; Ma, H. Monitoring of polypeptide content in the solid-state fermentation process of rapeseed meal using NIRS and chemometrics. J. Food Process Eng. 2018, 41, e12853. [Google Scholar] [CrossRef]

- Ma, H.; Jia, J.; Ge, Y.-Q.; He, R.; Zhou, C.; Wei, X.; Qu, W.; Wang, B.; Wu, B.; Sun, L.; et al. The Basic Concept and Research Progress of Food Physical Processing. In Advances in Food Processing Technology; Springer: Singapore, 2019. [Google Scholar] [CrossRef]

- Yildiz, F.; Özdemir, A.T.; Uluışık, S. Evaluation Performance of Ultrasonic Testing on Fruit Quality Determination. J. Food Qual. 2019, 2019, 6810865. [Google Scholar] [CrossRef]

- Nunes, J.L.; Piquerez, M.; Pujadas, L.; Armstrong, E.; Fernández, A.; Lecumberry, F. Beef quality parameters estimation using ultrasound and color images. BMC Bioinform. 2015, 16, S6. [Google Scholar] [CrossRef] [PubMed]

- Yıldırım, A.; Yilmaz, M. Ultrasound technology and applications in food industry. In Some Innovative and Sustainable Approaches in Food Production Chain; Efe Academy: Madrid, Spain, 2024; pp. 195–225. [Google Scholar] [CrossRef]

- Chandrapala, J.; Zisu, B. Ultrasound Technology in Dairy Processing; Chandrapala, J., Zisu, B., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–40. [Google Scholar] [CrossRef]

- Ekow, A.E.; Haile, M.; John, O.; Narku, E.F. Microwave-vacuum drying effect on drying kinetics, lycopene and ascorbic acid content of tomato slices. J. Stored Prod. Postharvest Res. 2013, 4, 11–22. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Kotsanopoulos, K.V.; Savva, A.G. Use of ultrasounds in the food industry-Methods and effects on quality, safety, and organoleptic characteristics of foods: A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 109–128. [Google Scholar] [CrossRef] [PubMed]

- Schiller, D.; Mertes, S.; Achzet, M.; Hellmann, F.; Schlagowski, R.; André, E. More Than Noise: Assessing the Viscosity of Food Products Based on Sound Emission. In Deep Learning Theory and Applications; Fred, A., Hadjali, A., Gusikhin, O., Sansone, C., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 210–218. [Google Scholar] [CrossRef]

- Yolandani; Ma, H.; Liu, D.; Cheng, Y.; Raynaldo, F.A.; Dabbour, M.; Chao, J.; Ali, A.; Yang, S. Ultrasound viscous reduction effects on the proteolysis of soy protein isolate at a limited degree of hydrolysis: Changes in the functional characteristics and protein structure. Ultrason. Sonochem. 2024, 104, 106847. [Google Scholar] [CrossRef]

- Poggi, C.; Palavecino, M. Ultrasound principles and instrumentation. Surg. Open Sci. 2024, 18, 123–128. [Google Scholar] [CrossRef]

- Gallo, M.; Ferrara, L.; Naviglio, D. Application of Ultrasound in Food Science and Technology: A Perspective. Foods 2018, 7, 164. [Google Scholar] [CrossRef]

- Hong, C.; Zhao, Y.-M.; Zhou, C.; Guo, Y.; Ma, H. Ultrasonic washing as an abiotic elicitor to increase the phenolic content in fruits and vegetables: A review. Compr. Rev. Food Sci. Food Saf. 2023, 22, 785–808. [Google Scholar] [CrossRef]

- Grazhdani, H.; David, E.; Ventura Spagnolo, O.; Buemi, F.; Perri, A.; Orsogna, N.; Gigli, S.; Chimenz, R. Quality assurance of ultrasound systems: Current status and review of literature. J. Ultrasound 2018, 21, 173–182. [Google Scholar] [CrossRef]

- Stewart, K.A.; Navarro, S.M.; Kambala, S.; Tan, G.; Poondla, R.; Lederman, S.; Barbour, K.; Lavy, C. Trends in Ultrasound Use in Low and Middle Income Countries: A Systematic Review. Int. J. MCH AIDS 2020, 9, 103–120. [Google Scholar] [CrossRef]

- Wu, X.; Worthington, A.E.; Gertner, M.R.; Hunt, J.W.; Sherar, M.D. Characterization of changes in therapeutic ultrasound transducer performance over time using the angular spectrum method. IEEE Trans. Ultrason Ferroelectr. Freq. Control 2007, 54, 1028–1035. [Google Scholar] [CrossRef]

- Li, W.; Ma, H.; He, R.; Ren, X.; Zhou, C. Prospects and application of ultrasound and magnetic fields in the fermentation of rare edible fungi. Ultrason. Sonochem. 2021, 76, 105613. [Google Scholar] [CrossRef] [PubMed]

- Arruda, T.R.; Vieira, P.; Silva, B.M.; Freitas, T.D.; do Amaral, A.J.B.; Vieira, E.N.R.; Leite Júnior, B.R.d.C. What are the prospects for ultrasound technology in food processing? An update on the main effects on different food matrices, drawbacks, and applications. J. Food Process Eng. 2021, 44, e13872. [Google Scholar] [CrossRef]

- Hashempour-Baltork, F.; Mirza Alizadeh, A.; Taghizadeh, M.; Hosseini, H. Cold plasma technology: A cutting-edge approach for enhancing shrimp preservation. Heliyon 2024, 10, e40460. [Google Scholar] [CrossRef]

- Xia, Q.; Du, M.; Li, B.; Hou, L.; Chen, Z. Interdisciplinary Collaboration Opportunities, Challenges, and Solutions for Artificial Intelligence in Ultrasound. Curr. Med. Imaging 2022, 18, 1046–1051. [Google Scholar] [CrossRef]

- Sicaire, A.-G.; Fine, F.; Vian, M.; Chemat, F. HACCP and HAZOP in Ultrasound Food Processing. In Handbook of Ultrasonics and Sonochemistry; Springer: Singapore, 2016; pp. 1335–1353. [Google Scholar] [CrossRef]

- Bayati, M.; Manzari Tavakoli, M.; Nejad Ebrahimi, S.; Aliahmadi, A.; Rezadoost, H. Optimization of effective parameters in cold pasteurization of pomegranate juice by response surface methodology and evaluation of physicochemical characteristics. LWT 2021, 147, 111679. [Google Scholar] [CrossRef]

- Maruvada, S.; Harris, G.R. Challenges in the characterization of high intensity therapeutic ultrasound devices and fields and regulatory guidance development. J. Acoust. Soc. Am. 2013, 134, 4152. [Google Scholar] [CrossRef]

- Pallavi, B.; Komal, D.; Rahul, M.; Alamjot, S.; Vivek, A. A Green Technology for the Extraction of Essential Oil Using Microwave and Ultrasound-assisted Techniques. Curr. Anal. Chem. 2025, 21, 79–105. [Google Scholar] [CrossRef]

- Tong, X.; Yang, J.; Zhao, Y.; Wan, H.; He, Y.; Zhang, L.; Wan, H.; Li, C. Greener extraction process and enhanced in vivo bioavailability of bioactive components from Carthamus tinctorius L. by natural deep eutectic solvents. Food Chem. 2021, 348, 129090. [Google Scholar] [CrossRef]

- Li, Y.; Xiang, D. Stability of oil-in-water emulsions performed by ultrasound power or high-pressure homogenization. PLoS ONE 2019, 14, e0213189. [Google Scholar] [CrossRef]

- Xu, G.; Tobin, J.T.; Amani, H.; Subhir, S.; O’Donnell, C.P.; O’Shea, N. Potential of acoustic sensors for real-time monitoring of physicochemical properties of milk protein concentrate during ultrafiltration. J. Food Eng. 2025, 387, 112314. [Google Scholar] [CrossRef]

- Lee, I.-H.; Ma, L. Integrating machine learning, optical sensors, and robotics for advanced food quality assessment and food processing. Food Innov. Adv. 2025, 4, 65–72. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, M.; Jiang, Q.; Mujumdar, A.S. Intelligent System/Equipment for Quality Deterioration Detection of Fresh Food: Recent Advances and Application. Foods 2024, 13, 1662. [Google Scholar] [CrossRef] [PubMed]

- Fatima, K.; Imran, M.; Ahmad, M.H.; Khan, M.K.; Khalid, W.; AL-Farga, A.; Alansari, W.S.; Shamlan, G.; Eskandrani, A.A. Ultrasound-Assisted Extraction of Protein from Moringa oleifera Seeds and Its Impact on Techno-Functional Properties. Molecules 2023, 28, 2554. [Google Scholar] [CrossRef] [PubMed]

- Silva, M.; Kadam, M.R.; Munasinghe, D.; Shanmugam, A.; Chandrapala, J. Encapsulation of Nutraceuticals in Yoghurt and Beverage Products Using the Ultrasound and High-Pressure Processing Technologies. Foods 2022, 11, 2999. [Google Scholar] [CrossRef]

- Pallarés, N.; Berrada, H.; Ferrer, E.; Zhou, J.; Wang, M.; Barba, F.J.; Brnčić, M. Chapter 10-Ultrasound Processing: A Sustainable Alternative. In Sustainable Production Technology in Food; Lorenzo, J.M., Munekata, P.E.S., Barba, F.J., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 155–164. [Google Scholar] [CrossRef]

- Khan, A.A.; Cui, F.-J.; Ullah, M.W.; Qayum, A.; Khalifa, I.; Bacha, S.A.S.; Ying, Z.-Z.; Khan, I.; Zeb, U.; Alarfaj, A.A.; et al. Fabrication and characterization of bioactive curdlan and sodium alginate films for enhancing the shelf life of Volvariella volvacea. Food Biosci. 2024, 62, 105137. [Google Scholar] [CrossRef]

| Fruits/Vegetables | Objective | Ultrasound Conditions | Findings and Quality Effects | References |

|---|---|---|---|---|

| Strawberry | Explore the efficacy of ultrasound-assisted osmotic dehydration in enhancing water diffusivity and reducing drying time in strawberries, using varied sucrose solution concentrations and treatment times to assess impacts on drying dynamics and fruit structure. | Treatment duration: 10, 20, 30, 45 min; Frequency: 25 kHz; Temperature: 30 °C; Power: 60 W. | Quality potentially enhanced due to improved texture and reduced microbial load, though effects on taste not specified. | [77,78] |

| Evaluate the effectiveness of ultrasonic-assisted osmotic dehydration (UAOD) in enhancing strawberry drying rates and quality by varying ultrasonic power and osmotic solutes. The aim is to optimize ultrasound use to improve drying efficiency and outcomes. | Ultrasonic Power: 180 W, 240 W, 300 W; Osmotic solutes: Sucrose, trehalose, sucrose and maltodextrin combination. | UAOD improved texture and nutritional quality; low-hygroscopicity sugars improved drying outcomes. | [79] | |

| Pomegranate | Enhance the efficiency of osmotic dehydration in arils through ultrasound pretreatment, evaluating the effects on moisture removal rates and solute gain. | Frequencies: 25 kHz, 40 kHz; Treatment intervals: Varying. | Ultrasound increased water loss (2-fold at 25 kHz, 2.7-fold at 40 kHz) and solute gain during osmotic dehydration. | [80] |

| Carrot | Describe the mechanisms by which ultrasound pretreatment enhances the drying and rehydration processes of carrot slices, correlating the effects with structural changes and drying temperatures. | Treatment duration: 30 and 60 min; Frequency: 25 kHz; Power: 41 W/L. | Ultrasound-enhanced drying led to faster rehydration rates and improved process efficiency. | [81,82] |

| Pineapple | Explore the effects of ultrasound application during both osmotic dehydration and convective drying on the drying kinetics of pineapple, examining the impact on mass transfer and drying rate. | Pretreatment: 20 or 40 min, 55.5 kW/m3, 40 kHz; Drying: 21.8 kHz, 31 kW/m3. | Enhanced drying rates through ultrasound application suggest improved process efficiency, though specific quality impacts need further study. | [83] |

| Unripe Banana | Investigate the effects of ultrasound and pulsed-vacuum pretreatments on drying kinetics, diffusivity, and energy efficiency in producing unripe banana flour. | Ultrasound: 20 and 25 min, 35 kHz; combined with pulsed vacuum and air drying at 50 °C and 60 °C. | Ultrasound application preserved resistant starch content, improving the functional quality of unripe banana flour and reducing energy costs compared to conventional processes. | [84,85] |

| Okra | Examine the impact of ultrasonic combined vacuum pretreatment (UVP) on the drying efficiency and physicochemical properties of okra, optimizing conditions via response surface methodology. | Ultrasound Power: 250 W; Sample thickness: 0.5 cm; Duration: 15 min. | UVP-treated okra showed improved color, bioactive substances, antioxidant activity, and rehydration potential, outperforming control samples. | [86,87] |

| Persimmon | Assess the impact of ultrasound-assisted osmotic dehydration prior to convective drying on drying behavior and quality properties of persimmon. | Frequency: 35 kHz; Duration: 10, 20, 30 min; 30 °C, 45° Brix and 70° Brix sucrose solutions. | Ultrasound treatment maintained phenolic content and caused minimal color change, preserving quality while enhancing drying efficiency. | [88] |

| Onions | Investigate the effects of ultrasound and blanching pretreatments on the retention of bioactive compounds and antioxidant activity in onions during drying. | Frequency: 20 kHz; Amplitude levels: 24.4–61 mm; Duration: 1, 3, 5 min. | Ultrasound-treated onions showed higher retention of bioactive compounds and similar color change compared to blanched samples, suggesting it as an alternative to blanching. | [89] |

| Blackberries | Investigate the effects of airborne and contact ultrasound on the air-drying performances of blackberries, focusing on energy consumption and retention of bioactive compounds. | 20 kHz ultrasound probe; Airborne and contact ultrasound methods. | Contact ultrasound yielded blackberries with higher anthocyanin and organic acid content, suggesting superior quality compared to airborne ultrasound. | [90] |

| White Cabbage | Study the influences of surface contacting ultrasound on the drying kinetics and quality of white cabbage. | Surface contacting ultrasound: 492.3 and 1131.1 W/m2; Temperature: 60 °C. | While blanching led to higher vitamin C retention, contacting ultrasound did not alleviate the losses of other phenolics and glucosinolates despite shorter drying times. | [91] |

| Nectarine Slices | Investigate the effect of ultrasound pretreatment and temperature on the quality and thermodynamic properties of drying nectarine slices in a hot air dryer. | Duration: 0, 10, 20, 40 min; Temperature levels: 50, 60, 75 °C. | The highest shrinkage and color change occurred at 75 °C in control samples. Ultrasound resulted in greater retention of quality attributes at varying temperatures. | [92] |

| Ginger Slices | Examine the effects of various pretreatment methods, including ethanol and ultrasound, on the drying process and quality of catalytic-infrared-dried ginger slices. | Ultrasound: 40 kHz, 300 W; Volumetric power: 60 W/L; Duration: 15 min; Ethanol: 75% (v/v). | Ethanol + US-pretreated ginger retained higher amounts of bioactive compounds, although rehydration ratio and gingerol content slightly decreased. | [93] |

| Black Chokeberries | Explore the mechanisms of water transport and metabolic pathways of polyphenols in black chokeberries dried by sequential calcium pretreatment and ultrasonic/microwave drying. | Ultrasound: 20 kHz, 300 W; Diameter: 5.5 cm; Inserted into a convective dryer. | Enhanced retention of phenolic content; the modified diffusional model provided insights into cellular water dynamics and polyphenol metabolism under hybrid drying technologies. | [94] |

| Red Peppers | Examine the effects of ultrasound-assisted vacuum (USV) drying on the drying rate and quality parameters of red peppers at various temperatures. | Ultrasound-assisted vacuum drying at temperatures of 45, 55, 65, and 75 °C. | USV drying resulted in significant reductions in yeast and mold counts, suggesting enhanced microbial safety without compromising bioactive compound stability. | [95] |

| Sour Cherries | Measure the impacts of gum-based coatings and sonication before drying on various quality parameters of sour cherries. | Ultrasound: 40 kHz, 150 W; at 25 °C for 12 min. | Coatings significantly enhanced bioactive compound retention and reduced color changes and shrinkage, with basil seed gum showing the best results. | [96] |

| Cauliflower | Investigate the effects of single- and dual-frequency ultrasound washing, combined with additives, on the microbial reduction and shelf life of freshly cut cauliflower. | Hexagonal ultrasonic washing tank: 20, 28, 40 kHz; Power densities: 30, 40, 50 W/L; Modes: Pulsed, sweep; Additives: ZA, TS, ET. | Use of zinc acetate as a washing solution particularly benefited the quality maintenance of cauliflower during storage, enhancing bioactive compound content and reducing microbial load. | [97] |

| Wolfberry | Investigate the effects of ultrasonic frequency, power, irradiation height, and temperature on the drying characteristics and quality of wolfberry by ultrasonic-assisted far-infrared drying. | Frequencies: 40 kHz; Power: 24 W; Temperature and irradiation height varied. | Highest antioxidantactivity and total flavonoid content observed in optimized conditions, enhancing quality preservation and accelerating the drying process. | [98,99] |

| Kiwifruit | Optimize ultrasonic treatment combined with sodium hypochlorite on kiwifruit to enhance microbial control and maintain textural quality. | Ultrasonic intensity: 184–368 W/cm2; Temperature: 25–40 °C; Treatment time: 8–15 min; Solvent concentration: 30–60 ppm. | Enhanced textural quality and extended shelf life of whole and fresh cut kiwifruits, showing potential for chitosan-coated fresh cut fruits. | [100] |

| Fresh Vegetables | Enhance the antimicrobial efficiency of slightly acidic electrolyzed water (SAEW) through ultrasonication and water wash treatments for sanitizing fresh vegetables. | SAEW parameters: pH 5.2–5.5, oxidation reduction potential 500–600 mV, available chlorine concentration 21–22 mg/L; Ultrasonication: 3 min; Water wash: 150 rpm, 1 min. | The optimized treatment effectively reduced yeast, mold, and bacterial counts on fresh vegetables, suggesting a potential for improving produce safety. | [101,102] |

| Plum Fruit | Investigate the individual and combined effects of aqueous chlorine dioxide and ultrasonic treatments on the postharvest storage quality of plum fruit. | Aqueous chlorine dioxide: 40 mg/L for 10 min; Ultrasound: 100 W for 10 min; Modes: Simultaneous (one-step), sequential (two-step). | No detectable chemical residues were found in treated samples using the one-step mode, ensuring safety for consumers. The treatment maintained content of total flavonoids, ascorbic acid, reducing sugars, and titratable acids. | [103] |

| Pakchoi | Evaluate the use of ultrasonic treatment in combination with modified atmosphere packaging to preserve pakchoi. | Frequency: 30 kHz; Duration: 5, 10, 15 min; MAP: 5% O2 + 10% CO2 + 85% N2. | This method effectively reduced peroxidase and polyphenol oxidase activities, indicating enhanced preservation of pakchoi during storage. | [104] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prempeh, N.Y.A.; Nunekpeku, X.; Murugesan, A.; Li, H. Ultrasound in the Food Industry: Mechanisms and Applications for Non-Invasive Texture and Quality Analysis. Foods 2025, 14, 2057. https://doi.org/10.3390/foods14122057

Prempeh NYA, Nunekpeku X, Murugesan A, Li H. Ultrasound in the Food Industry: Mechanisms and Applications for Non-Invasive Texture and Quality Analysis. Foods. 2025; 14(12):2057. https://doi.org/10.3390/foods14122057

Chicago/Turabian StylePrempeh, Nama Yaa Akyea, Xorlali Nunekpeku, Arul Murugesan, and Huanhuan Li. 2025. "Ultrasound in the Food Industry: Mechanisms and Applications for Non-Invasive Texture and Quality Analysis" Foods 14, no. 12: 2057. https://doi.org/10.3390/foods14122057

APA StylePrempeh, N. Y. A., Nunekpeku, X., Murugesan, A., & Li, H. (2025). Ultrasound in the Food Industry: Mechanisms and Applications for Non-Invasive Texture and Quality Analysis. Foods, 14(12), 2057. https://doi.org/10.3390/foods14122057